Freescale Semiconductor

Application Note

Document Number: AN4247

Rev. 2, 07/2011

Layout Recommendations for PCBs

Using a Magnetometer Sensor

by: Talat Ozyagcilar

Applications Engineer

Introduction

1

This application note is intended to guide engineers in

the successful design of Printed Circuit Boards (PCBs)

incorporating magnetometer sensors. For convenience,

the application discussed is an electronic compass

(or eCompass) designed into a smartphone but the

guidelines are equally applicable to other products using

a magnetometer.

This note covers:

• Characteristics of the geomagnetic field

•

Sensing range and resolution required in the

magnetometer

Contents

1

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.1 Key Words . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1.2 Summary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

The Geomagnetic Field . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Magnetic Interference within the Smartphone . . . . . . . . . 3

Hard Iron Interference . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Soft Iron Interference. . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Fields from PCB Currents . . . . . . . . . . . . . . . . . . . . . . . . 6

Other Sources of PCB Interference. . . . . . . . . . . . . . . . . 7

Component and Material Selection . . . . . . . . . . . . . . . . . 8

Experimental Determination of the Magnetometer

Measurement Locus . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

10 Mathematical Annex . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

2

3

4

5

6

7

8

9

• Level of accuracy needed from the calibration

software

Physics of magnetic interference from hard and

soft iron effects and PCB currents

•

• Guidelines for component selection

• Experimental approach to visualize field

distortions prior to layout and fabrication of the

PCB

© Freescale Semiconductor, Inc., 2011. All rights reserved.

�

Introduction

The mathematical formalism of hard and soft iron interference is provided in the Mathematical Annex for

engineers wishing to understand the theoretical derivation of ellipsoidal measurement loci.

Additional information on the mathematics of a tilt-compensated eCompass can be found in the Freescale

Application Note AN4248 “Implementing a Tilt-Compensated eCompass using Accelerometer and

Magnetometer Sensors”. This and other application notes can be downloaded from

http://www.freescale.com.

Key Words

1.1

eCompass, Geomagnetic, Magnetometer, Hard Iron, Soft Iron, Layout, Calibration, Ferromagnetic.

1.2

Summary

• A smartphone magnetometer measures the sum of the geomagnetic field plus magnetic

interference generated by ferromagnetic components on the smartphone PCB. This interference is

classified into permanent hard iron and induced soft iron components.

• The magnitude of hard iron and soft iron interference can exceed 1000 μT and saturate the

magnetometer if care is not taken to minimize the use of ferromagnetic components, such as

speakers, and to optimize the PCB layout by placing the magnetometer away from sources of

magnetic interference.

Software calibration algorithms are required to calculate the characteristics of, and mathematically

remove, both hard iron and soft iron interference from the magnetometer readings allowing the

geomagnetic field component to be measured with an error below 0.5 μT.

•

• An experimental approach is described which uses a Freescale RD4247MAG3110 eCompass

evaluation board to measure and visualize the level of hard iron and soft iron interference prior to

PCB fabrication.

Layout Recommendations for PCBs Using a Magnetometer Sensor, Rev. 2

2

Freescale Semiconductor

�

The Geomagnetic Field

The Geomagnetic Field

2

The magnitude of the earth's magnetic field (the geomagnetic field) varies over the surface of the earth

from a minimum of 22 μT over South America to a maximum of 67 μT south of Australia. The heading

of an eCompass is determined from the relative strengths of the two horizontal geomagnetic field

components and these vary from zero at the magnetic poles to a maximum of 42 μT over East Asia.

Detailed geomagnetic field maps are available from the World Data Center for Geomagnetism at

http://wdc.kugi.kyoto-u.ac.jp/igrf/.

A rough and ready estimate of the error in an eCompass heading is given in radians by the ratio of the error

in geomagnetic field estimation to the horizontal geomagnetic field strength. For example, the lowest value

of the horizontal field strength likely to be experienced by a smartphone user is 10 μT in northern Canada

and Russia. A compass heading accuracy of 0.05 radians or 3 degrees therefore requires that the error in

estimating the geomagnetic field be no more than 0.5 μT.

Magnetic Interference within the Smartphone

3

Unlike accelerometer, pressure, and gyroscope MEMS sensors, which use mechanical sensing elements

unaffected by electromagnetic components on the PCB, magnetometers are sensitive to the magnetic fields

generated by other circuit components.

The most common magnetic field sources are:

•

•

•

permanent ferromagnets (as found in speakers or buzzers).

induced fields within any ferromagnetic material lacking a permanent field (such as sheet steel).

fields generated by current flows (ranging from strong currents in power supply tracks to smaller

currents within coils).

Even in a well-designed smartphone, these sources create extraneous fields with magnitudes approaching

1000 μT in the vicinity of the magnetometer placing severe constraints on the performance of both the

magnetometer and the calibration software running within the smartphone eCompass application. The

magnetometer must have an operating range of ±1000 μT to accommodate the sum of the geomagnetic

and interfering fields and the calibration software must identify and remove this interference to accuracy

better than 0.5 μT or one part in two thousand for 1000 μT interference.

Designers should not assume that the calibration software will always correct for a poor layout.

Component selection and layout should therefore be optimized to reduce the interfering fields as much as

is realistically feasible. Smaller interference fields ease the job of the calibration software and result in

more accurate compass headings.

Layout Recommendations for PCBs Using a Magnetometer Sensor, Rev. 2

Freescale Semiconductor

3

�

Hard Iron Interference

Hard Iron Interference

4

'Hard iron' magnetic fields are those which are generated by permanently magnetized ferromagnetic

components on the PCB, such as an audio speaker or buzzer. Permanently magnetized components also

create induced magnetic fields in normally unmagnetized ferromagnetic materials in their vicinity. Since

the magnetometer and all components on the PCB are in fixed positions with respect to each other, the hard

iron interference manifests as an additive magnetic field vector when measured in the magnetometer

reference frame.

It makes little sense for manufacturers to supply carefully calibrated zero field offset magnetometers into

the smartphone market since the magnetometer will be exposed to an unknown additive hard iron field.

The manufacturer will typically specify only the limits between which the zero field offset will lie. The

magnetometer zero field offset is also independent of the smartphone orientation and therefore simply adds

to the hard iron field. The calibration algorithm then adds the magnetometer zero field offset to the PCB

hard iron interference and removes both.

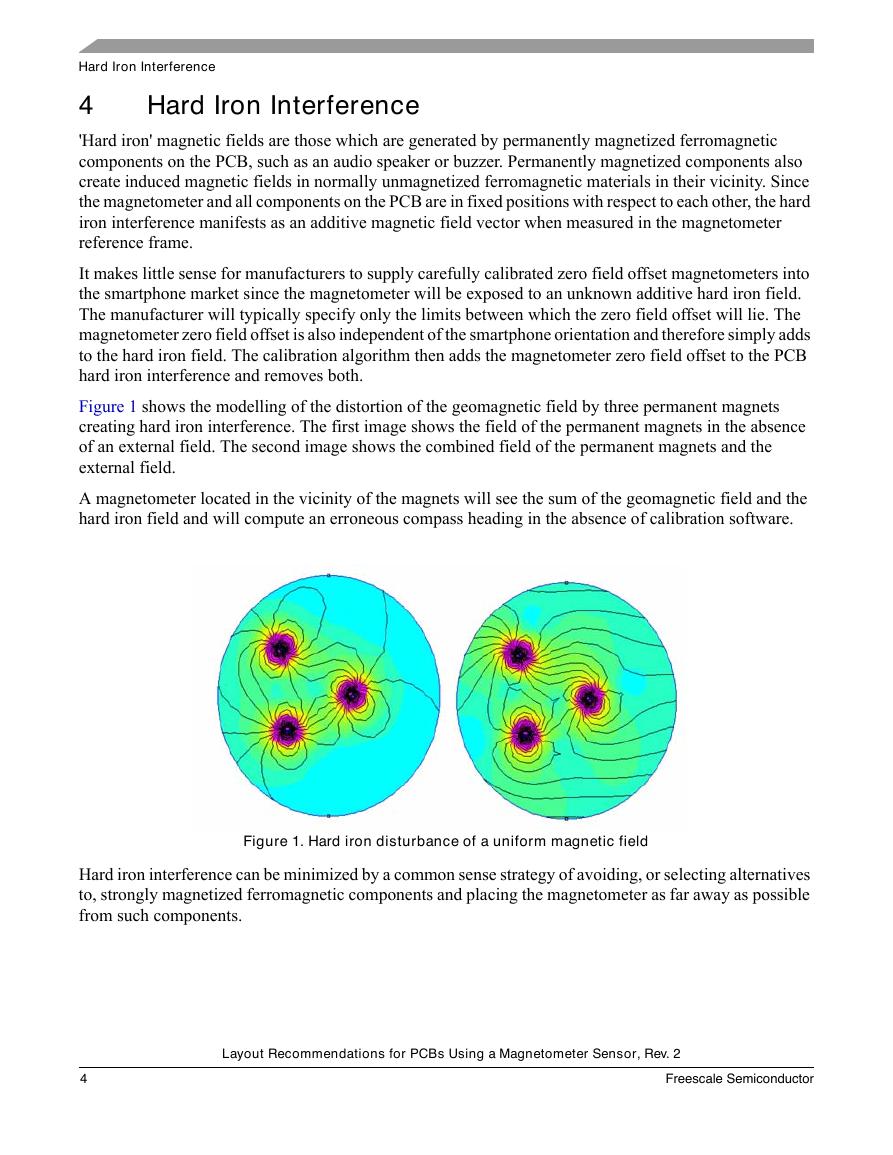

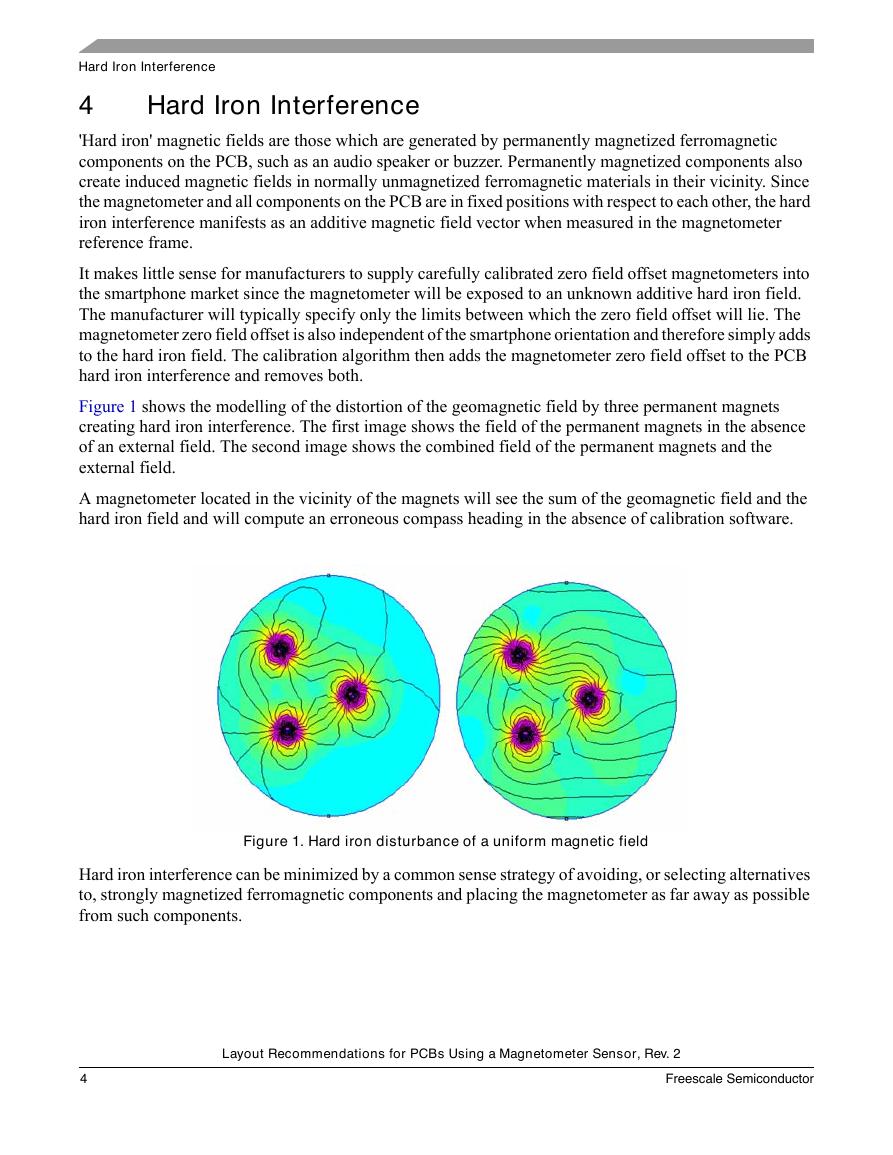

Figure 1 shows the modelling of the distortion of the geomagnetic field by three permanent magnets

creating hard iron interference. The first image shows the field of the permanent magnets in the absence

of an external field. The second image shows the combined field of the permanent magnets and the

external field.

A magnetometer located in the vicinity of the magnets will see the sum of the geomagnetic field and the

hard iron field and will compute an erroneous compass heading in the absence of calibration software.

Figure 1. Hard iron disturbance of a uniform magnetic field

Hard iron interference can be minimized by a common sense strategy of avoiding, or selecting alternatives

to, strongly magnetized ferromagnetic components and placing the magnetometer as far away as possible

from such components.

Layout Recommendations for PCBs Using a Magnetometer Sensor, Rev. 2

4

Freescale Semiconductor

�

Soft Iron Interference

Soft Iron Interference

5

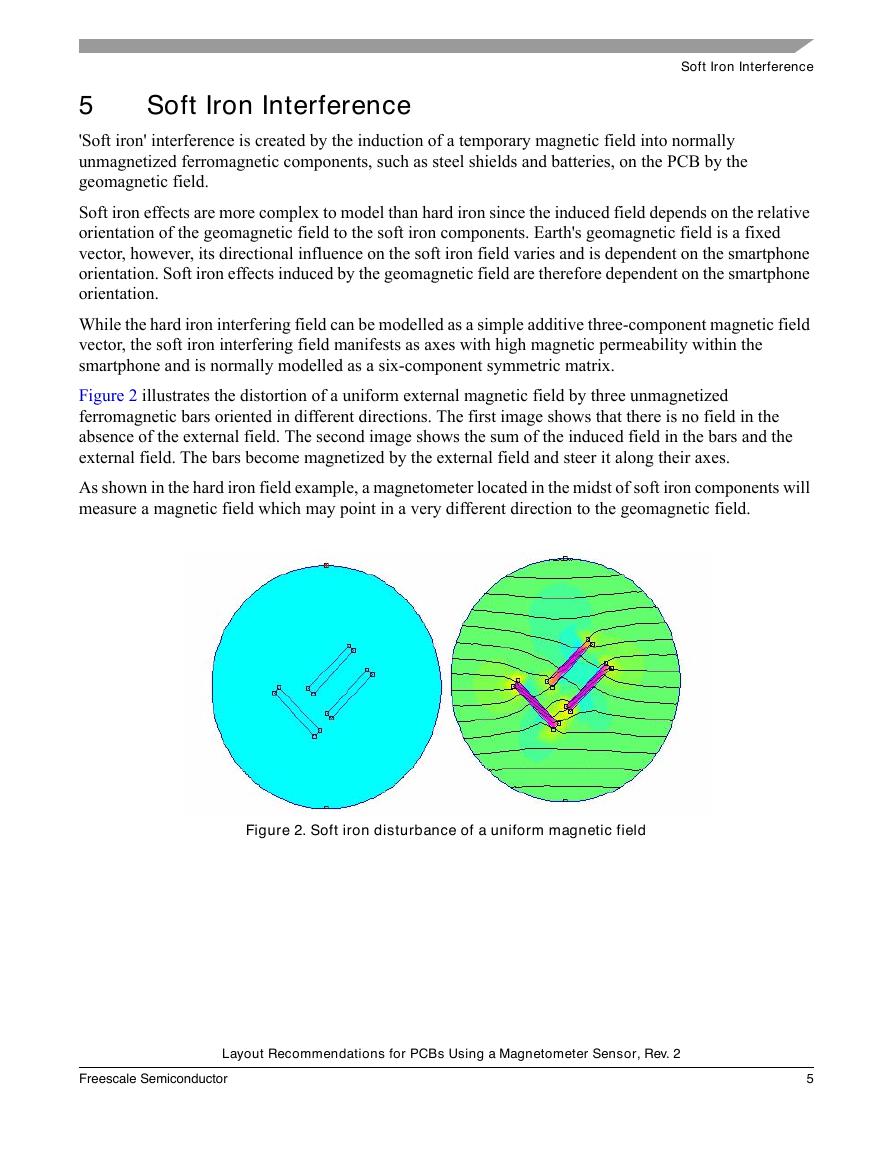

'Soft iron' interference is created by the induction of a temporary magnetic field into normally

unmagnetized ferromagnetic components, such as steel shields and batteries, on the PCB by the

geomagnetic field.

Soft iron effects are more complex to model than hard iron since the induced field depends on the relative

orientation of the geomagnetic field to the soft iron components. Earth's geomagnetic field is a fixed

vector, however, its directional influence on the soft iron field varies and is dependent on the smartphone

orientation. Soft iron effects induced by the geomagnetic field are therefore dependent on the smartphone

orientation.

While the hard iron interfering field can be modelled as a simple additive three-component magnetic field

vector, the soft iron interfering field manifests as axes with high magnetic permeability within the

smartphone and is normally modelled as a six-component symmetric matrix.

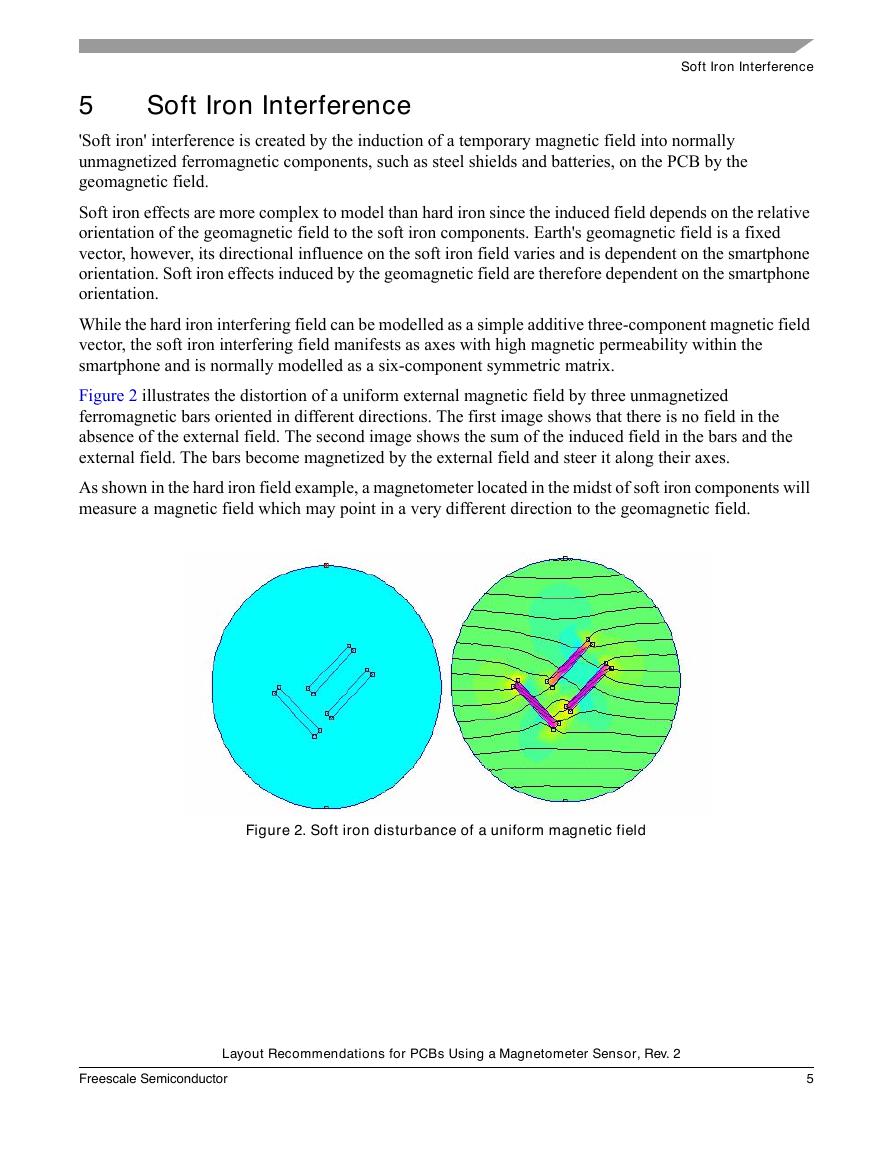

Figure 2 illustrates the distortion of a uniform external magnetic field by three unmagnetized

ferromagnetic bars oriented in different directions. The first image shows that there is no field in the

absence of the external field. The second image shows the sum of the induced field in the bars and the

external field. The bars become magnetized by the external field and steer it along their axes.

As shown in the hard iron field example, a magnetometer located in the midst of soft iron components will

measure a magnetic field which may point in a very different direction to the geomagnetic field.

Figure 2. Soft iron disturbance of a uniform magnetic field

Layout Recommendations for PCBs Using a Magnetometer Sensor, Rev. 2

Freescale Semiconductor

5

�

Fields from PCB Currents

Fields from PCB Currents

6

Fixed currents, whether in PCB tracks or within coils, will generate fixed magnetic fields which add to the

hard iron component. Calibration software will attempt to calibrate these fields and remove them, but it is

good practice to minimize these fields. The strength of the resulting field measured at the magnetometer

follows the standard rules of electromagnetism: the generated field is proportional to the current, is

multiplied by coherent addition of the same current in a coil, and reduces with distance from the current

source.

Designers should therefore place high current tracks and coils as far away as possible from the

magnetometer. Ferromagnetic cores within coils become magnetized by both the coil current and the

geomagnetic field creating additional soft iron interference.

An estimate of the magnetic field sourced by a PCB power supply track can be obtained from MAG3110's

equation relating the curl of the magnetic field B to the local current density j and the time derivative of

the local electric field E:

×

∇ B μ0j

=

ε0+

μ0

∂E

-------

∂t

μ0 is the permeability of free space and is defined to have value:

μ0

=

4π 10 7–

×

NA 2–

Eqn. 1

Eqn. 2

If the PCB trace is straight with extent in both directions greater than the separation of the magnetometer

from the trace, then edge effects can be ignored and the magnetic field will be rotationally symmetrical.

With the additional constraint that the electric and magnetic fields are constant, Equation 1 can be

rewritten using Stokes' theorem in terms of line and surface integrals for a closed circular path at normal

distance r0 from the trace:

∫°

B.dr

r

=

2πr0B r0(

)

∇ B×(

).dS

∫∫=

s

μ0 j.dS

∫∫=

s

Eqn. 3

The current density j includes both free currents in the trace and bound currents in ferromagnetic materials.

If there are no ferromagnetic materials in the vicinity of the magnetometer and PCB trace then the surface

integral of the current density j simply equals the PCB trace current I. The return current flow through the

ground plane is assumed to be spatially diffused and is ignored.

Layout Recommendations for PCBs Using a Magnetometer Sensor, Rev. 2

6

Freescale Semiconductor

�

Other Sources of PCB Interference

If, in addition, the less than one part in 106 difference in the magnetic permeability of air and vacuum is

ignored in Equation 3, then the magnetic field B(r0) at distance r0 from the PCB trace is given in Teslas by:

B r0(

)

=

μ0I

-----------

2πr0

=

10 6– I

×

0.2

--------------------------

r0

Eqn. 4

Modern smartphone power traces can easily source 1A in current. At 10-3m separation, the magnetic field

from a 1A current trace will be 200 μT reducing to 20 μT at 10-2m separation. This field will in turn induce

a soft iron field in local ferromagnetic components on the PCB which may amplify the prediction of

Equation 4 several times over.

The effects of time varying currents depend on their frequency. The highest sampling rate of a consumer

magnetometer is approximately 100 Hz so currents at significantly higher frequencies will not be

detectable by the magnetometer. Signals at lower frequencies may be detectable as modulation of the

magnetic output and the compass heading. Incremental changes in current will create corresponding

changes in the magnetic field and compass error.

The most difficult situation for the calibration software is the placement too close to the magnetometer of

a power supply trace supplying a varying current depending on the smartphone processor load, the state

of the LCD backlight and whether the RF power amplifier is active.

Other Sources of PCB Interference

7

PCB designers should also make industrial designers and mechanical engineers aware of the consequences

of including magnetic materials into the smartphone housing. These should generally be avoided since

they add to the overall hard and soft iron field. Industrial designers should be aware that different phone

configurations (such as a clamshell phone being open or closed) also create different magnetic interference

which further complicates the task of the calibration software.

NOTE:

Engineers should not attempt to shield the magnetometer from PCB hard

iron or soft iron interference by placing the magnetometer or the interfering

magnetic materials under shielding. Aluminum shielding is transparent to

magnetic fields and has no effect. Steel shielding acts as an additional source

of soft iron interference distorting both the direction and magnitude of the

geomagnetic field and amplifying the effects of permanently magnetized

components on the PCB.

Layout Recommendations for PCBs Using a Magnetometer Sensor, Rev. 2

Freescale Semiconductor

7

�

Component and Material Selection

Component and Material Selection

8

Components using iron, cobalt, nickel and their alloys (generally referred to as ferromagnets) can maintain

a permanent magnetic field and are the predominant source of hard iron interference. Typical components

with permanent magnetization include speaker magnets, vibrator and camera modules.

The same ferromagnetic materials when normally unmagnetized are responsible for the soft iron magnetic

interference. Any external field, whether the hard iron or the geomagnetic field, induces a temporary

magnetic field in these materials. Common sources of soft iron distortion include the smartphone battery

and steel shields in the RF module.

Materials that are safe for use in the proximity of the magnetometer include brass, aluminum, copper, gold,

silver and titanium.

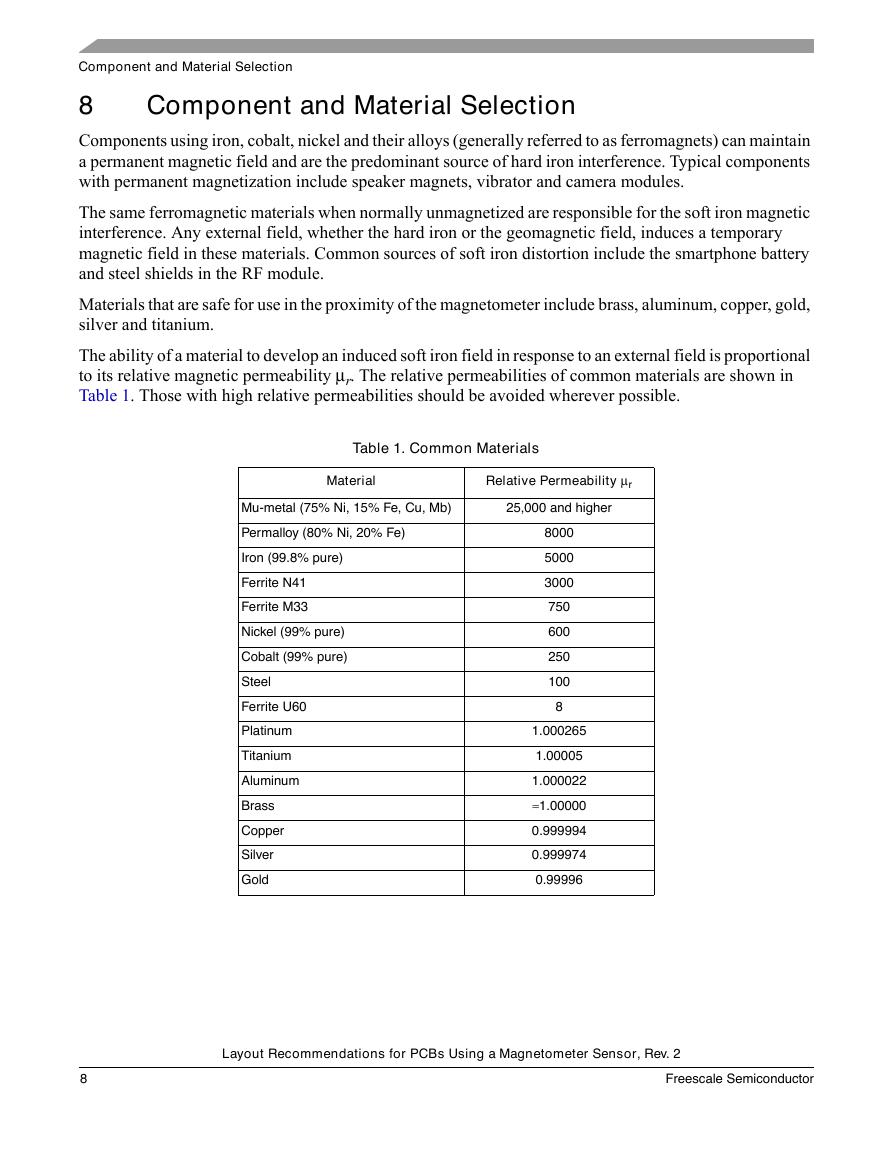

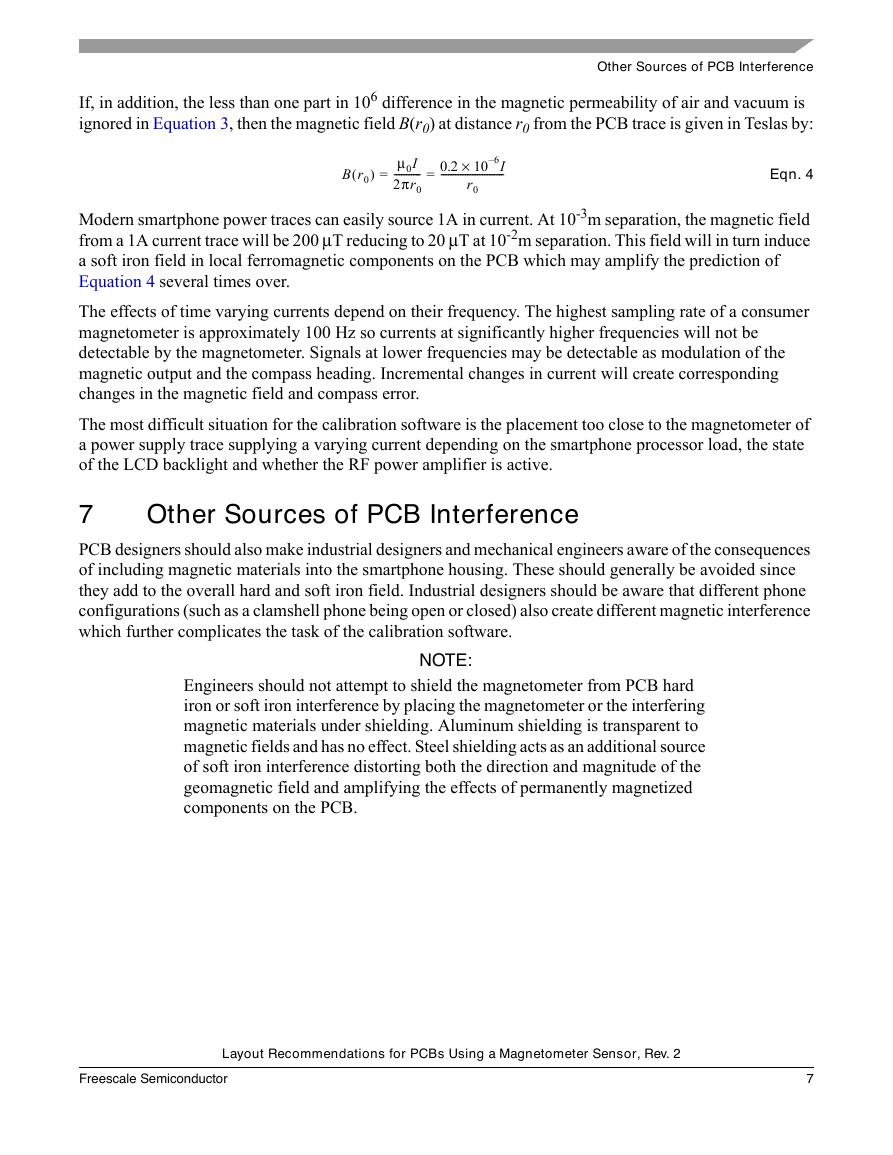

The ability of a material to develop an induced soft iron field in response to an external field is proportional

to its relative magnetic permeability μr. The relative permeabilities of common materials are shown in

Table 1. Those with high relative permeabilities should be avoided wherever possible.

Table 1. Common Materials

Material

Relative Permeability μr

Mu-metal (75% Ni, 15% Fe, Cu, Mb)

25,000 and higher

Permalloy (80% Ni, 20% Fe)

Iron (99.8% pure)

Ferrite N41

Ferrite M33

Nickel (99% pure)

Cobalt (99% pure)

Steel

Ferrite U60

Platinum

Titanium

Aluminum

Brass

Copper

Silver

Gold

8000

5000

3000

750

600

250

100

8

1.000265

1.00005

1.000022

≈1.00000

0.999994

0.999974

0.99996

Layout Recommendations for PCBs Using a Magnetometer Sensor, Rev. 2

8

Freescale Semiconductor

�

V2版本原理图(Capacitive-Fingerprint-Reader-Schematic_V2).pdf

V2版本原理图(Capacitive-Fingerprint-Reader-Schematic_V2).pdf 摄像头工作原理.doc

摄像头工作原理.doc VL53L0X简要说明(En.FLVL53L00216).pdf

VL53L0X简要说明(En.FLVL53L00216).pdf 原理图(DVK720-Schematic).pdf

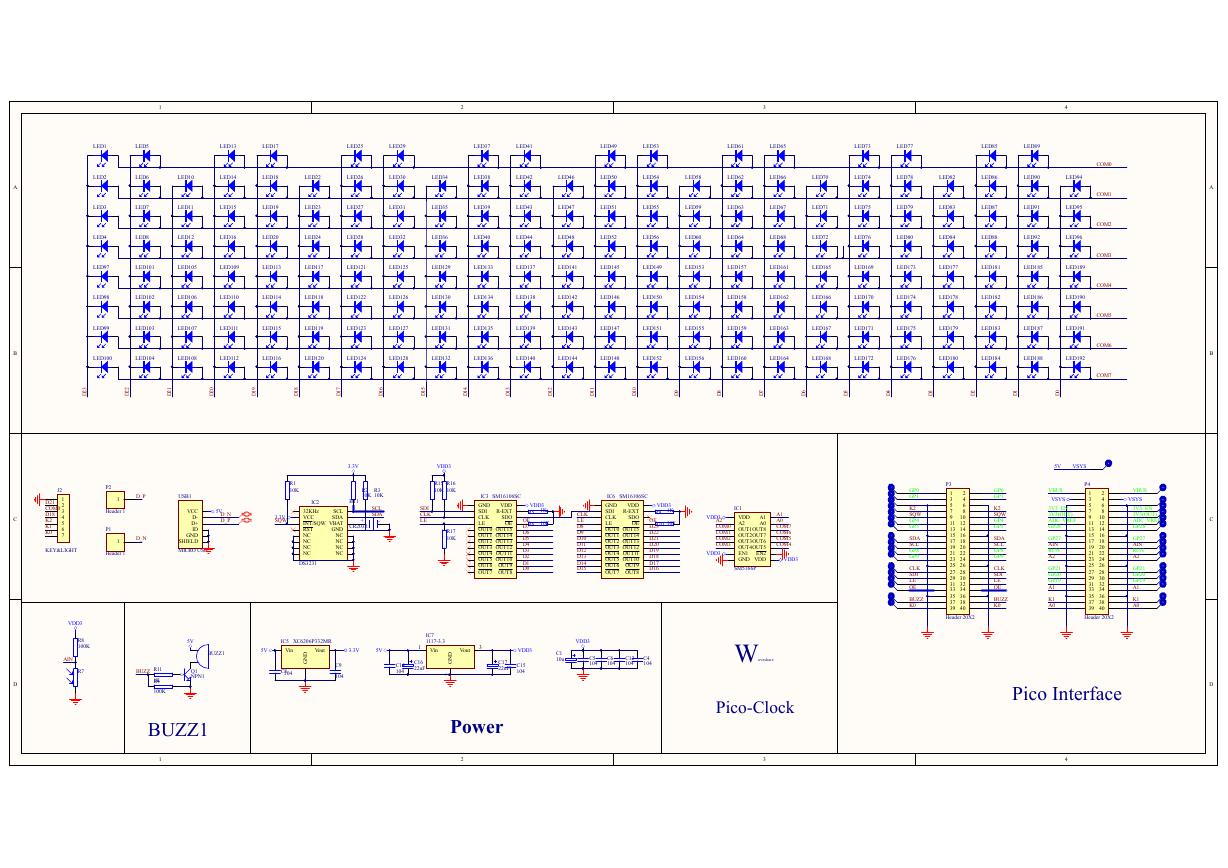

原理图(DVK720-Schematic).pdf 原理图(Pico-Clock-Green-Schdoc).pdf

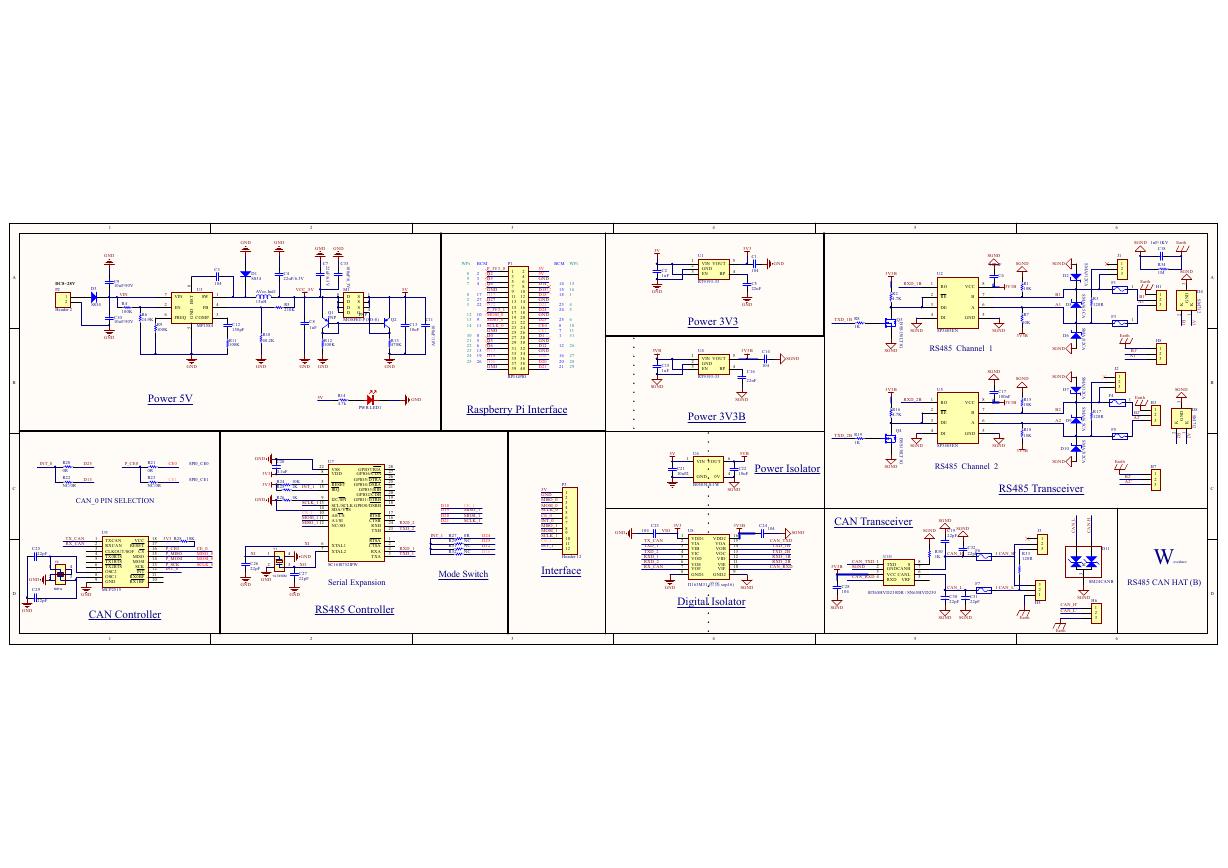

原理图(Pico-Clock-Green-Schdoc).pdf 原理图(RS485-CAN-HAT-B-schematic).pdf

原理图(RS485-CAN-HAT-B-schematic).pdf File:SIM7500_SIM7600_SIM7800 Series_SSL_Application Note_V2.00.pdf

File:SIM7500_SIM7600_SIM7800 Series_SSL_Application Note_V2.00.pdf ADS1263(Ads1262).pdf

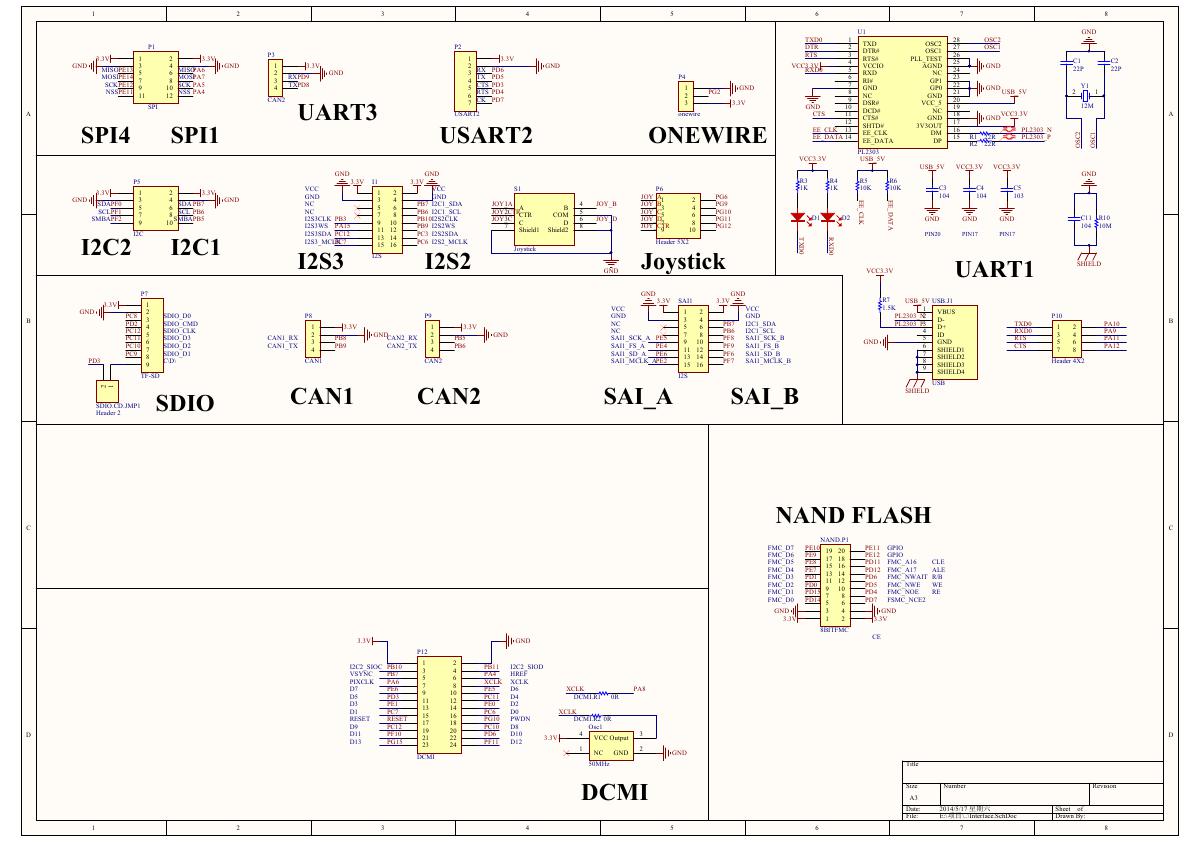

ADS1263(Ads1262).pdf 原理图(Open429Z-D-Schematic).pdf

原理图(Open429Z-D-Schematic).pdf 用户手册(Capacitive_Fingerprint_Reader_User_Manual_CN).pdf

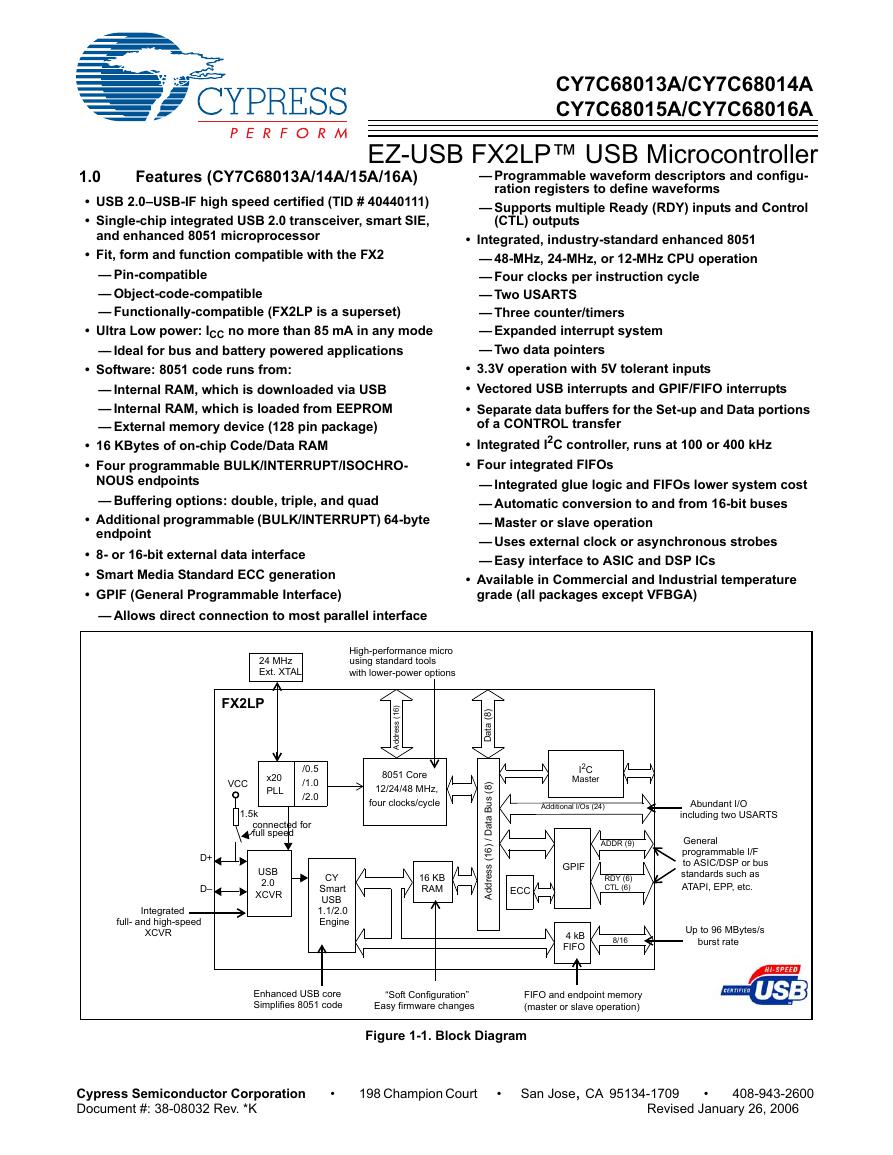

用户手册(Capacitive_Fingerprint_Reader_User_Manual_CN).pdf CY7C68013A(英文版)(CY7C68013A).pdf

CY7C68013A(英文版)(CY7C68013A).pdf TechnicalReference_Dem.pdf

TechnicalReference_Dem.pdf