Freescale Semiconductor

Advance Information

3-Axis, Digital Magnetometer

Freescale’s MAG3110 is a small, low-power, digital 3-axis magnetometer.

The device can be used in conjunction with a 3-axis accelerometer to produce

orientation independent accurate compass heading information. It features a

standard I2C serial interface output and smart embedded functions.

The MAG3110 is capable of measuring magnetic fields with an Output Data

Rate (ODR) up to 80 Hz; these output data rates correspond to sample intervals

from 12 ms to several seconds.

The MAG3110 is available in a plastic DFN package and it is guaranteed to

Full Scale Range ±1000 μT

1.95V to 3.6V Supply Voltage (VDD)

1.65V to VDD IO Voltage (VDDIO)

operate over the extended temperature range of -40°C to +85°C.

Features

•

•

• Ultra Small 2 mm x 2 mm x 0.85 mm, 0.4 mm Pitch, 10 Pin Package

•

• Sensitivity of 0.10 μT

• Noise down to 0.05 μT rms

• Output Data Rates (ODR) up to 80 Hz

•

•

• Sampled Low Power Mode

• RoHS compliant

Applications

• Electronic Compass

• Dead-reckoning assistance for GPS backup

•

I2C digital output interface (operates up to 400 kHz Fast Mode)

7-bit I2C address = 0x0E

Document Number: MAG3110

Rev 2.0, 02/2011

MAG3110

MAG3110: 3-AXIS DIGITAL

MAGNETOMETER

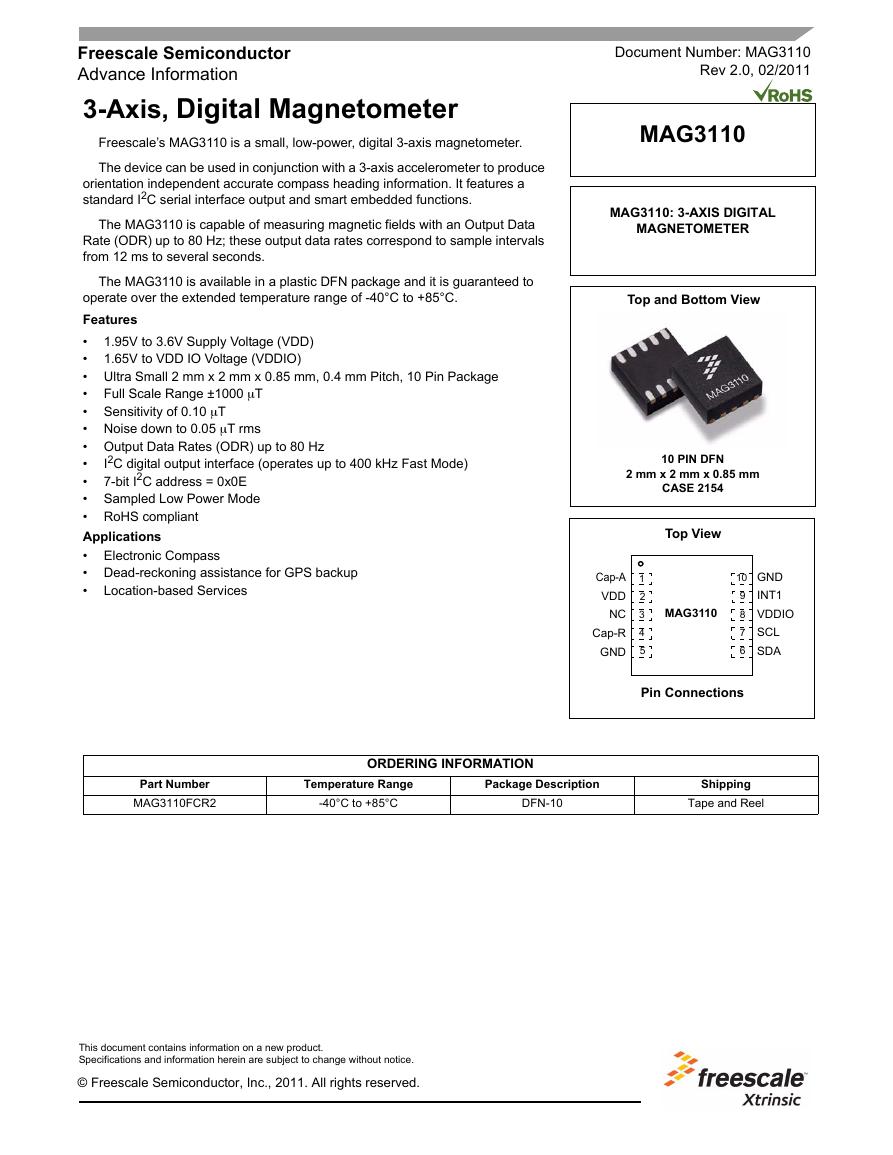

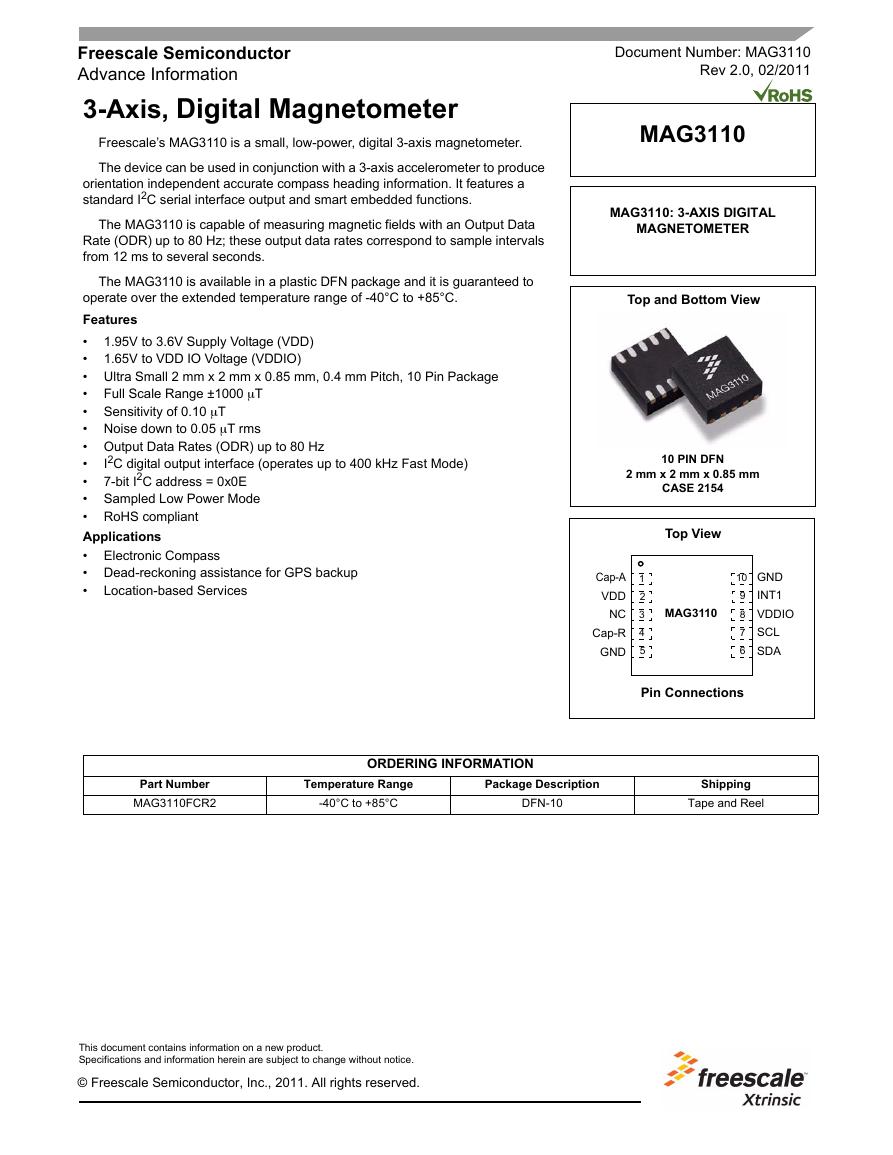

Top and Bottom View

2 mm x 2 mm x 0.85 mm

10 PIN DFN

CASE 2154

Top View

MAG3110

10

9

8

7

6

GND

INT1

VDDIO

SCL

SDA

Cap-A

VDD

NC

Cap-R

GND

1

2

3

4

5

Pin Connections

Location-based Services

Part Number

MAG3110FCR2

Temperature Range

-40°C to +85°C

Package Description

DFN-10

Shipping

Tape and Reel

ORDERING INFORMATION

This document contains information on a new product.

Specifications and information herein are subject to change without notice.

© Freescale Semiconductor, Inc., 2011. All rights reserved.

�

Application Notes for Reference

The following is a list of Freescale Application Notes written for the MAG3110:

• AN4246, Calibrating for Soft Iron and Hard Iron Distortions

• AN4247, PCB Layout Guidelines and Recommendations

• AN4248, Using the MAG3110 Magnetometer for an eCompass Application

• AN4249, Using the MAG3110 Magnetometer to Implement a 3-D Pointer

1

1.1

Block Diagram and Pin Description

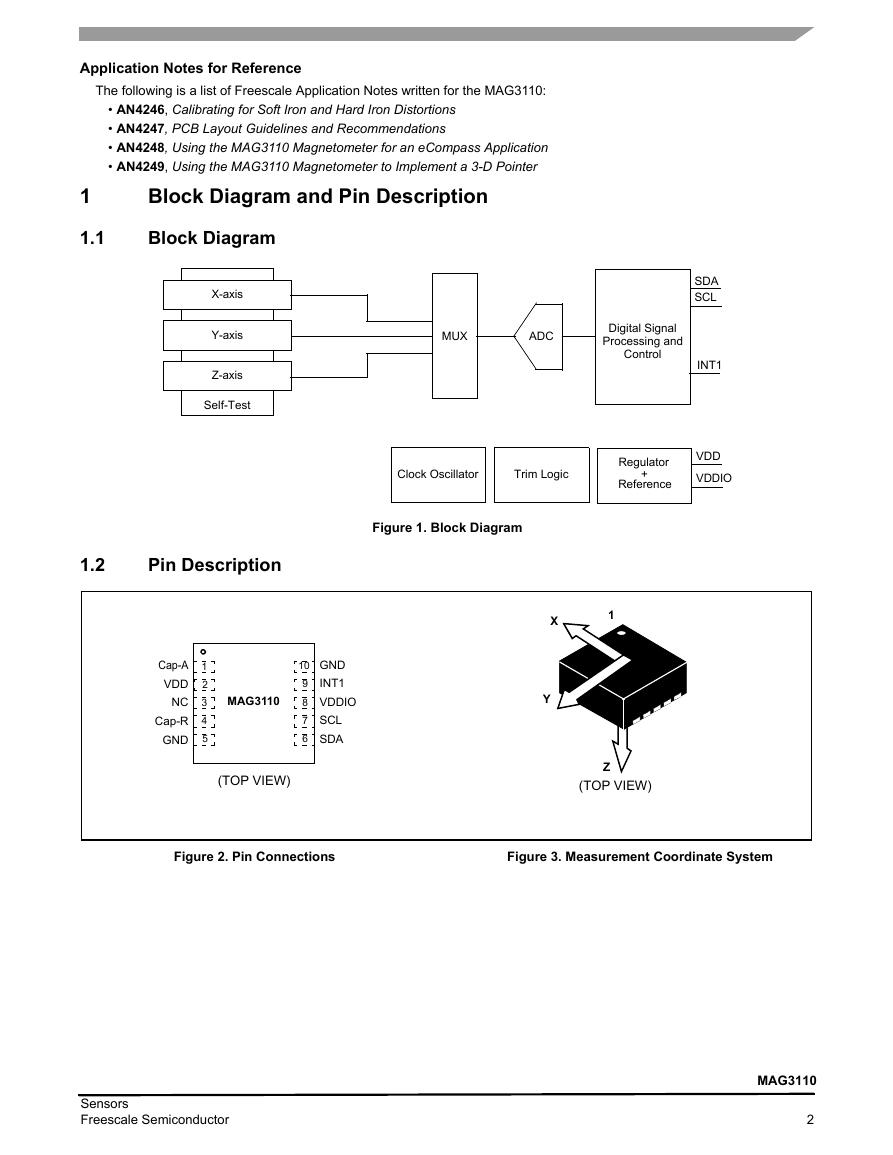

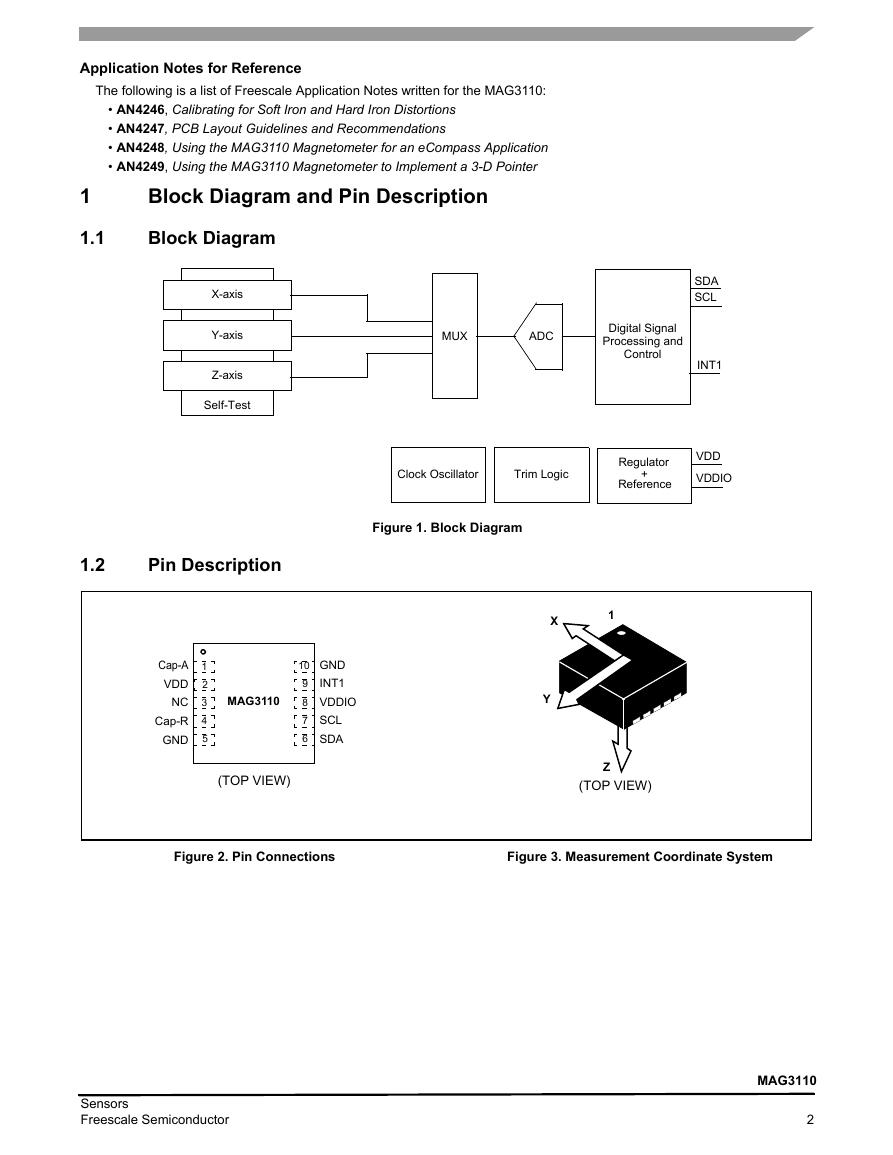

Block Diagram

X-axis

Y-axis

Z-axis

Self-Test

MUX

ADC

Digital Signal

Processing and

Control

SDA

SCL

INT1

Clock Oscillator

Trim Logic

Regulator

Reference

+

VDD

VDDIO

Figure 1. Block Diagram

1.2

Pin Description

Cap-A

VDD

NC

Cap-R

GND

1

2

3

4

5

MAG3110

(TOP VIEW)

10

9

8

7

6

GND

INT1

VDDIO

SCL

SDA

X

1

Y

Z

(TOP VIEW)

Figure 2. Pin Connections

Figure 3. Measurement Coordinate System

Sensors

Freescale Semiconductor

MAG3110

2

�

Table 1. Pin Description

Pin

1

2

3

4

5

6

7

8

9

10

Name

Cap-A

VDD

NC

Bypass Cap for Internal Regulator

Power Supply, 1.95V – 3.6V

No Connect – do not connect

Function

Cap-R

Cap for Reset Pulse

GND

SDA

SCL

GND

I2C Serial Data (Write = 0x1C; Read = 0x1D)

I2C Serial Clock

VDDIO

Power for I/O Buffers, 1.65V - VDD

INT1

GND

Interrupt - Active High Output

GND

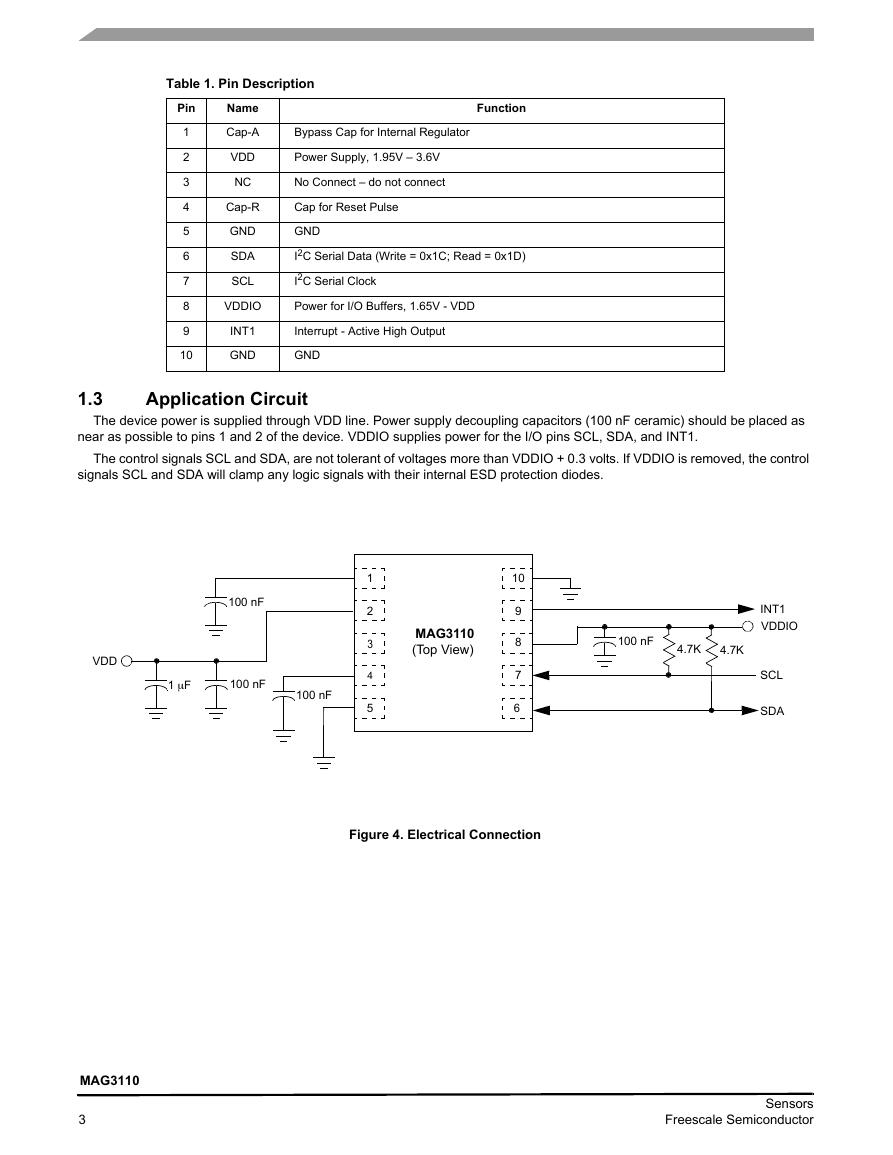

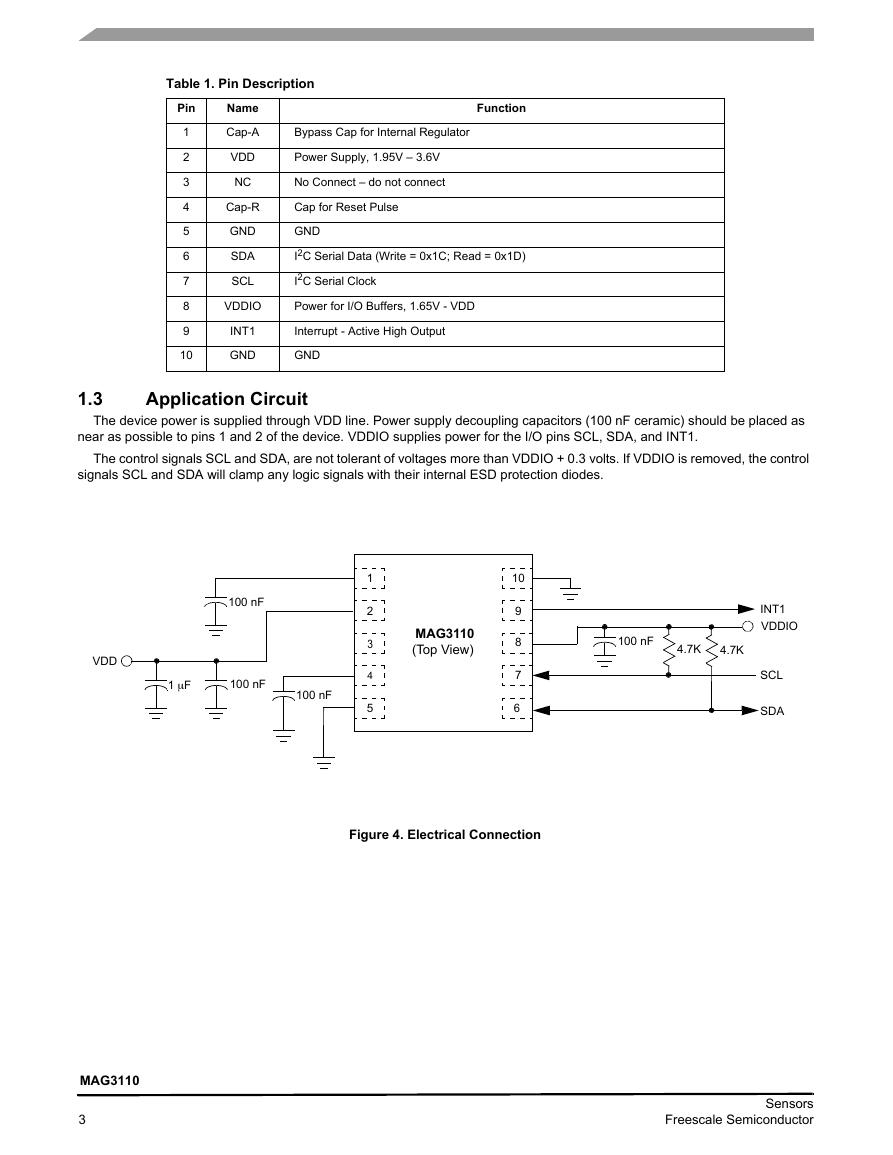

1.3

Application Circuit

The device power is supplied through VDD line. Power supply decoupling capacitors (100 nF ceramic) should be placed as

near as possible to pins 1 and 2 of the device. VDDIO supplies power for the I/O pins SCL, SDA, and INT1.

The control signals SCL and SDA, are not tolerant of voltages more than VDDIO + 0.3 volts. If VDDIO is removed, the control

signals SCL and SDA will clamp any logic signals with their internal ESD protection diodes.

100 nF

VDD

1 μF

100 nF

100 nF

1

2

3

4

5

MAG3110

(Top View)

10

9

8

7

6

100 nF

4.7K

4.7K

INT1

VDDIO

SCL

SDA

Figure 4. Electrical Connection

MAG3110

3

Sensors

Freescale Semiconductor

�

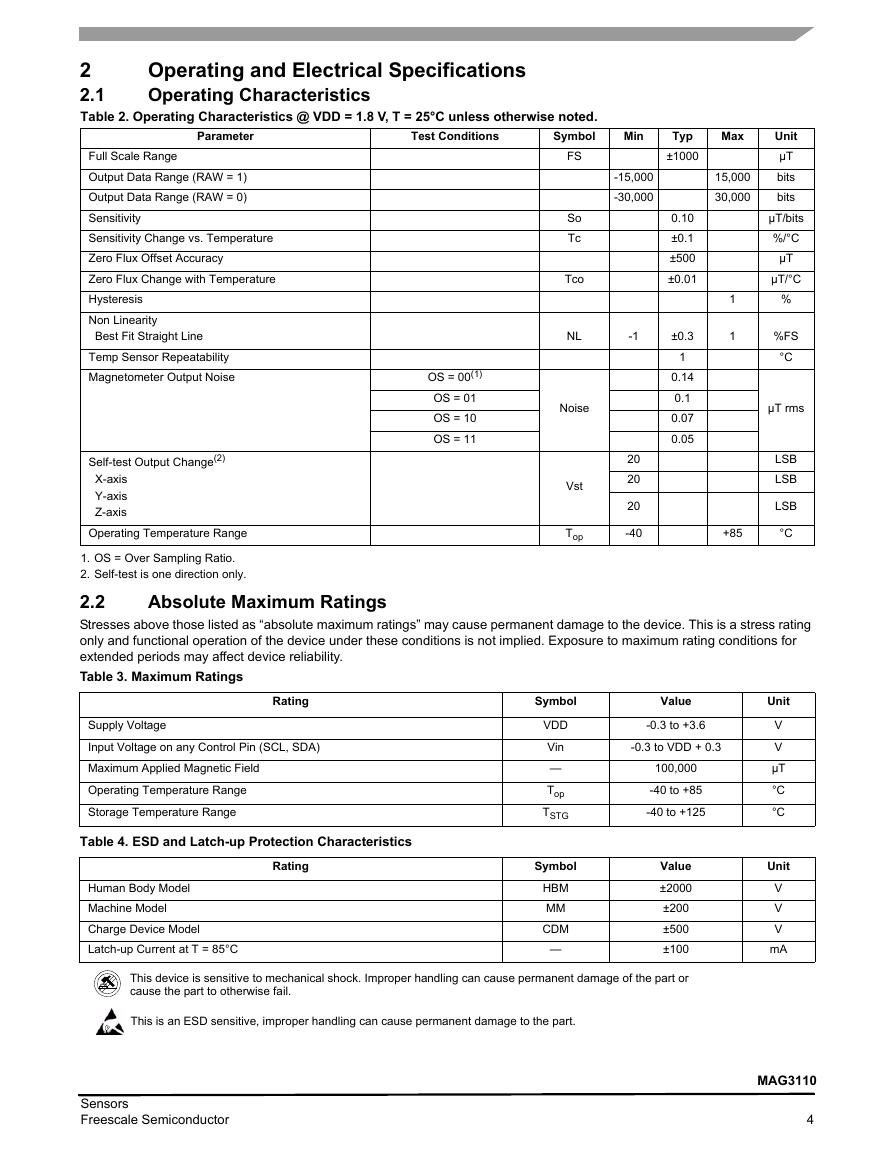

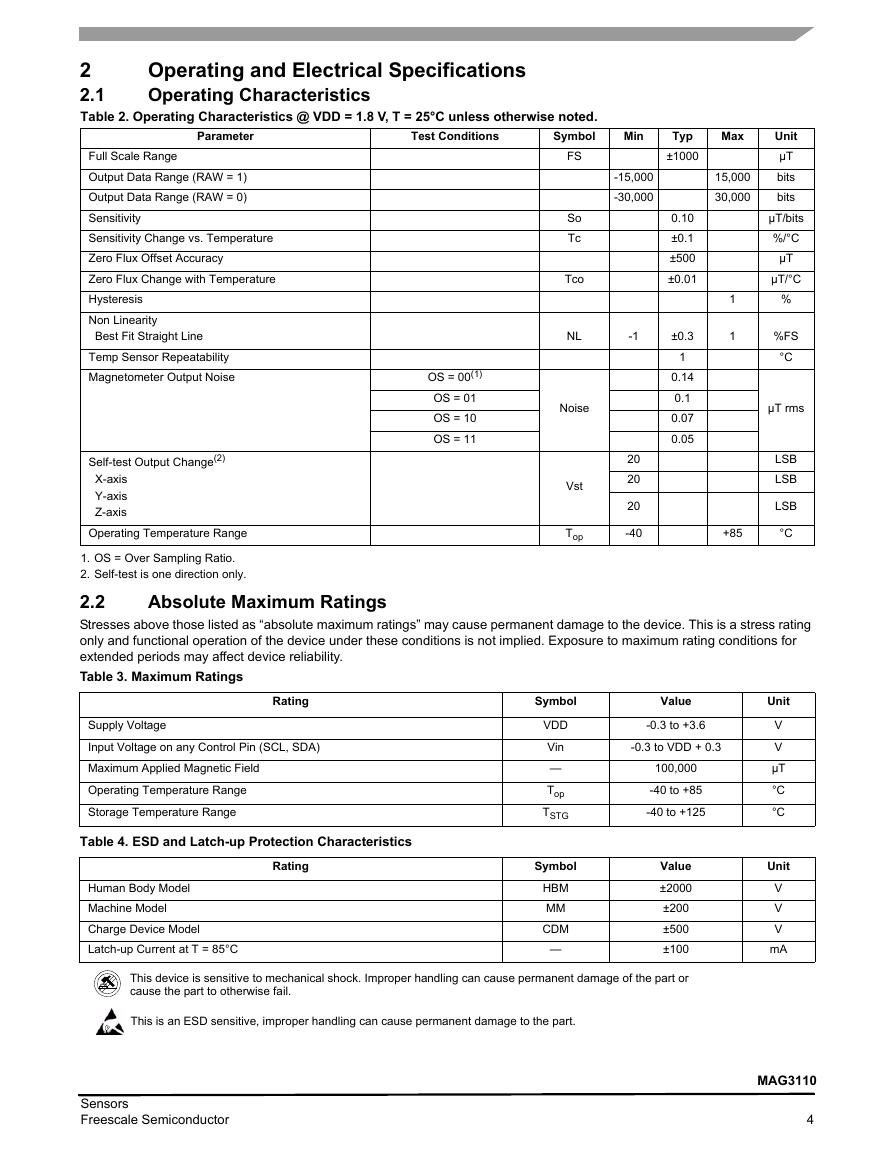

Operating and Electrical Specifications

Operating Characteristics

2

2.1

Table 2. Operating Characteristics @ VDD = 1.8 V, T = 25°C unless otherwise noted.

Symbol

Parameter

Test Conditions

Full Scale Range

Output Data Range (RAW = 1)

Output Data Range (RAW = 0)

Sensitivity

Sensitivity Change vs. Temperature

Zero Flux Offset Accuracy

Zero Flux Change with Temperature

Hysteresis

Non Linearity

Best Fit Straight Line

Temp Sensor Repeatability

Magnetometer Output Noise

Self-test Output Change(2)

X-axis

Y-axis

Z-axis

Operating Temperature Range

Min

Typ

±1000

-15,000

-30,000

Max

15,000

30,000

FS

So

Tc

Tco

OS = 00(1)

OS = 01

OS = 10

OS = 11

NL

-1

Noise

Vst

Top

20

20

20

-40

Unit

µT

bits

bits

µT/bits

%/°C

µT

µT/°C

%

%FS

°C

µT rms

LSB

LSB

LSB

°C

0.10

±0.1

±500

±0.01

±0.3

1

0.14

0.1

0.07

0.05

1

1

+85

Absolute Maximum Ratings

1. OS = Over Sampling Ratio.

2. Self-test is one direction only.

2.2

Stresses above those listed as “absolute maximum ratings” may cause permanent damage to the device. This is a stress rating

only and functional operation of the device under these conditions is not implied. Exposure to maximum rating conditions for

extended periods may affect device reliability.

Table 3. Maximum Ratings

Rating

Supply Voltage

Input Voltage on any Control Pin (SCL, SDA)

Maximum Applied Magnetic Field

Operating Temperature Range

Storage Temperature Range

Table 4. ESD and Latch-up Protection Characteristics

Rating

Human Body Model

Machine Model

Charge Device Model

Latch-up Current at T = 85°C

Symbol

VDD

Vin

—

Top

TSTG

Symbol

HBM

MM

CDM

—

Value

-0.3 to +3.6

-0.3 to VDD + 0.3

100,000

-40 to +85

-40 to +125

Value

±2000

±200

±500

±100

Unit

V

V

µT

°C

°C

Unit

V

V

V

mA

This device is sensitive to mechanical shock. Improper handling can cause permanent damage of the part or

cause the part to otherwise fail.

This is an ESD sensitive, improper handling can cause permanent damage to the part.

Sensors

Freescale Semiconductor

MAG3110

4

�

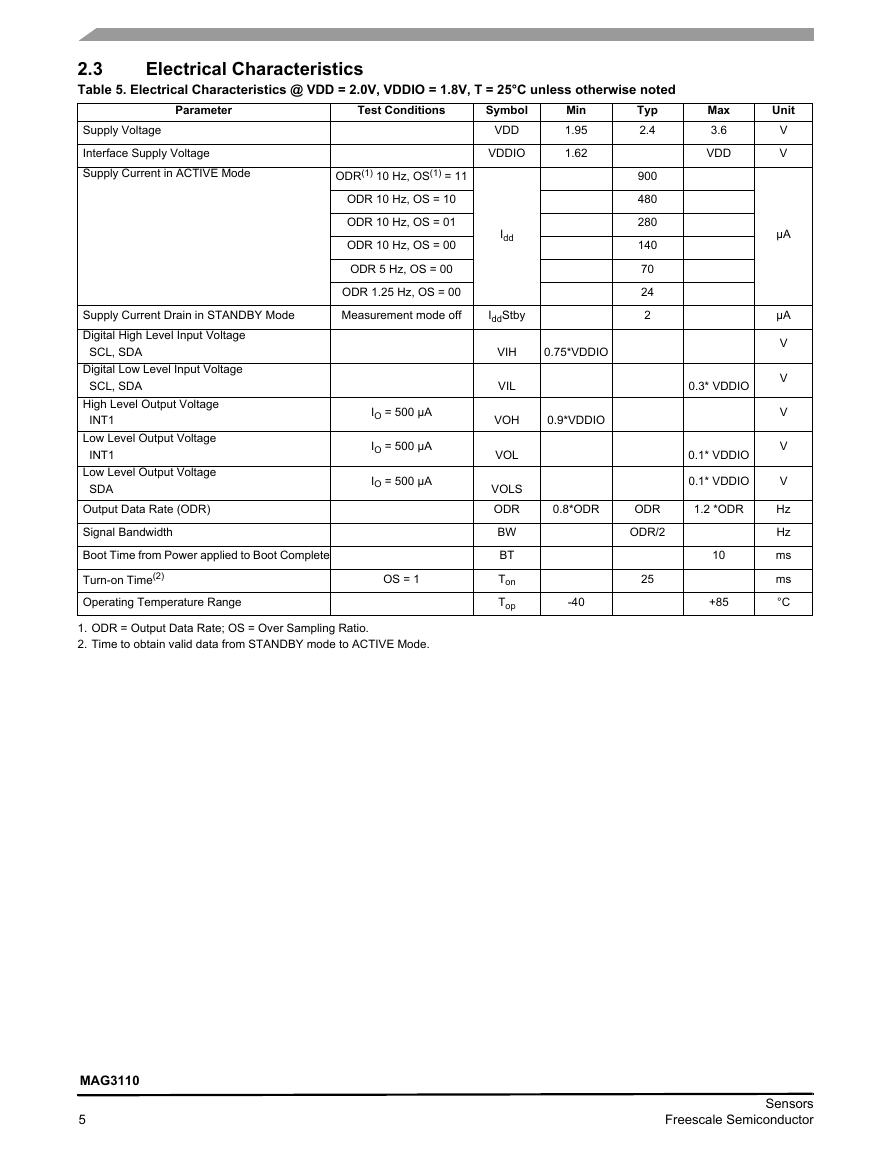

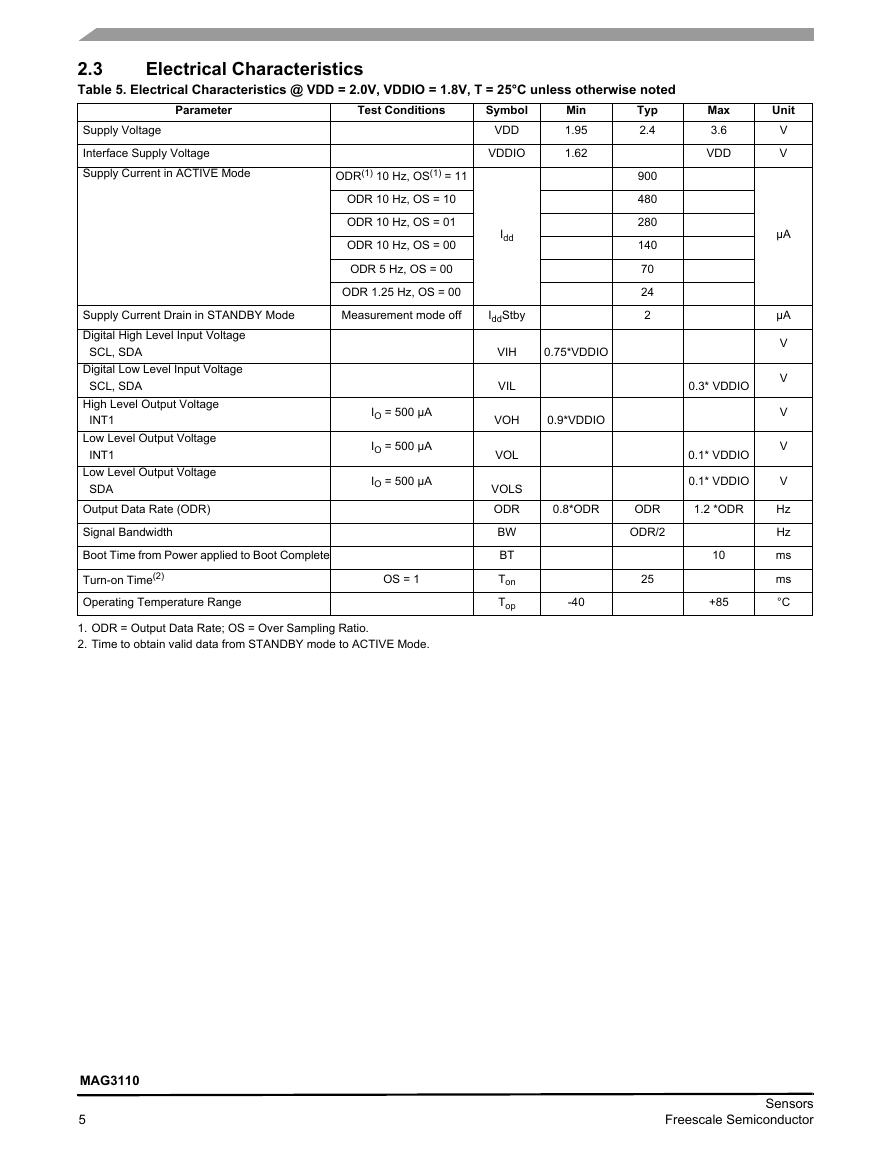

2.3

Table 5. Electrical Characteristics @ VDD = 2.0V, VDDIO = 1.8V, T = 25°C unless otherwise noted

Electrical Characteristics

Parameter

Test Conditions

Supply Voltage

Interface Supply Voltage

Supply Current in ACTIVE Mode

Supply Current Drain in STANDBY Mode

Digital High Level Input Voltage

SCL, SDA

Digital Low Level Input Voltage

SCL, SDA

High Level Output Voltage

INT1

Low Level Output Voltage

INT1

Low Level Output Voltage

SDA

Output Data Rate (ODR)

Signal Bandwidth

Boot Time from Power applied to Boot Complete

Turn-on Time(2)

Operating Temperature Range

ODR(1) 10 Hz, OS(1) = 11

ODR 10 Hz, OS = 10

ODR 10 Hz, OS = 01

ODR 10 Hz, OS = 00

ODR 5 Hz, OS = 00

ODR 1.25 Hz, OS = 00

Measurement mode off

IO = 500 µA

IO = 500 µA

IO = 500 µA

OS = 1

1. ODR = Output Data Rate; OS = Over Sampling Ratio.

2. Time to obtain valid data from STANDBY mode to ACTIVE Mode.

Typ

2.4

900

480

280

140

70

24

2

Symbol

VDD

VDDIO

Min

1.95

1.62

Idd

IddStby

VIH

VIL

0.75*VDDIO

VOH

0.9*VDDIO

VOL

VOLS

ODR

BW

BT

Ton

Top

0.8*ODR

-40

ODR

ODR/2

25

Max

3.6

VDD

Unit

V

V

µA

µA

V

V

V

V

V

Hz

Hz

ms

ms

°C

0.3* VDDIO

0.1* VDDIO

0.1* VDDIO

1.2 *ODR

10

+85

MAG3110

5

Sensors

Freescale Semiconductor

�

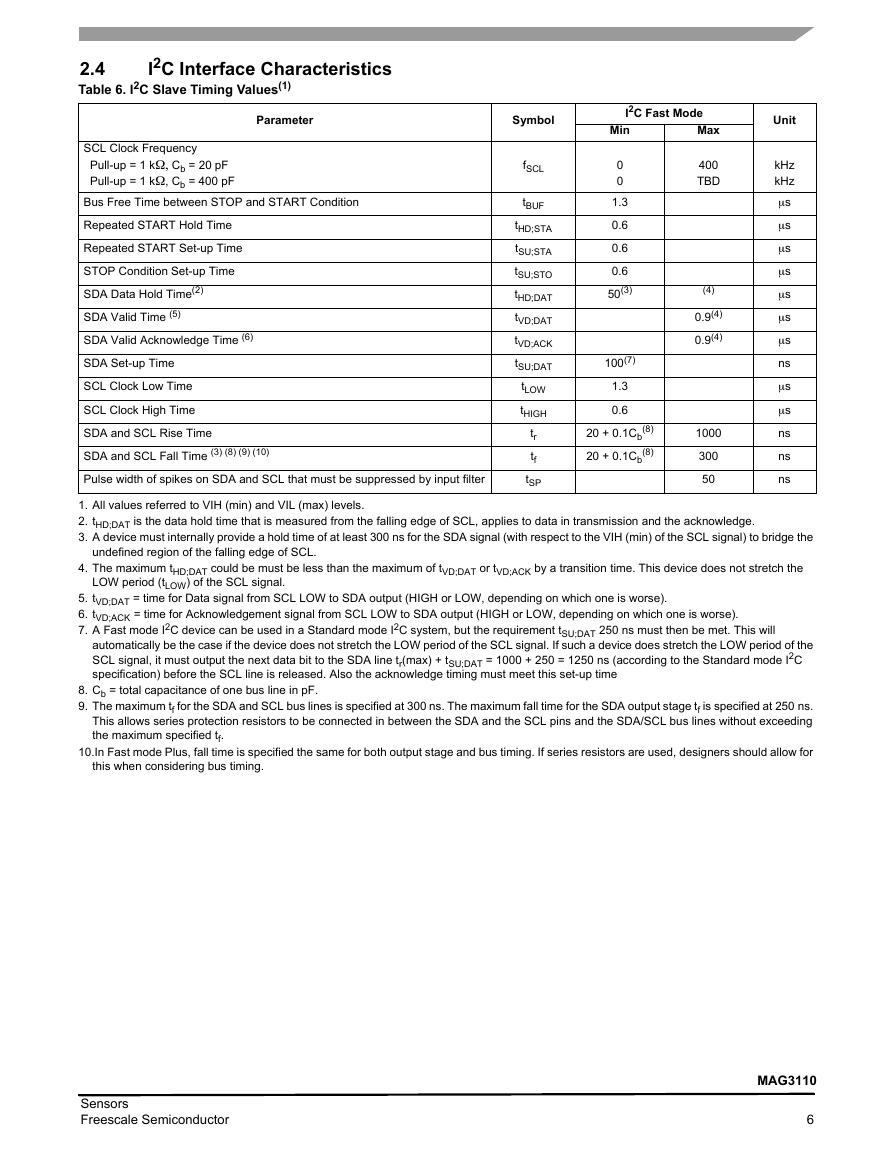

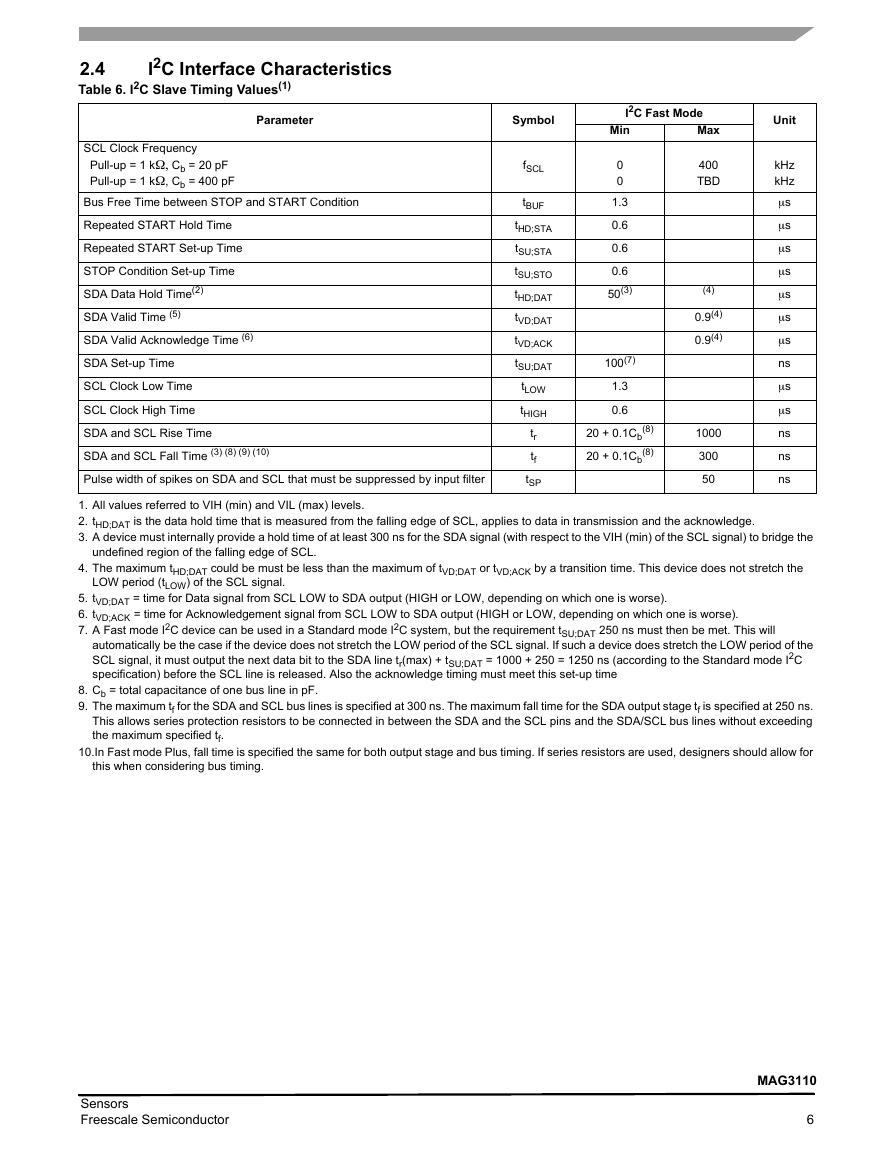

2.4

Table 6. I2C Slave Timing Values(1)

I2C Interface Characteristics

Parameter

SCL Clock Frequency

Pull-up = 1 kΩ, Cb = 20 pF

Pull-up = 1 kΩ, Cb = 400 pF

Bus Free Time between STOP and START Condition

Repeated START Hold Time

Repeated START Set-up Time

STOP Condition Set-up Time

SDA Data Hold Time(2)

SDA Valid Time (5)

SDA Valid Acknowledge Time (6)

SDA Set-up Time

SCL Clock Low Time

SCL Clock High Time

SDA and SCL Rise Time

SDA and SCL Fall Time (3) (8) (9) (10)

Pulse width of spikes on SDA and SCL that must be suppressed by input filter

Symbol

fSCL

tBUF

tHD;STA

tSU;STA

tSU;STO

tHD;DAT

tVD;DAT

tVD;ACK

tSU;DAT

tLOW

tHIGH

tr

tf

tSP

I2C Fast Mode

Min

0

0

1.3

0.6

0.6

0.6

50(3)

100(7)

1.3

0.6

20 + 0.1Cb

20 + 0.1Cb

(8)

(8)

Max

400

TBD

(4)

0.9(4)

0.9(4)

1000

300

50

Unit

kHz

kHz

μs

μs

μs

μs

μs

μs

μs

ns

μs

μs

ns

ns

ns

1. All values referred to VIH (min) and VIL (max) levels.

2. tHD;DAT is the data hold time that is measured from the falling edge of SCL, applies to data in transmission and the acknowledge.

3. A device must internally provide a hold time of at least 300 ns for the SDA signal (with respect to the VIH (min) of the SCL signal) to bridge the

undefined region of the falling edge of SCL.

4. The maximum tHD;DAT could be must be less than the maximum of tVD;DAT or tVD;ACK by a transition time. This device does not stretch the

LOW period (tLOW) of the SCL signal.

5. tVD;DAT = time for Data signal from SCL LOW to SDA output (HIGH or LOW, depending on which one is worse).

6. tVD;ACK = time for Acknowledgement signal from SCL LOW to SDA output (HIGH or LOW, depending on which one is worse).

7. A Fast mode I2C device can be used in a Standard mode I2C system, but the requirement tSU;DAT 250 ns must then be met. This will

automatically be the case if the device does not stretch the LOW period of the SCL signal. If such a device does stretch the LOW period of the

SCL signal, it must output the next data bit to the SDA line tr(max) + tSU;DAT = 1000 + 250 = 1250 ns (according to the Standard mode I2C

specification) before the SCL line is released. Also the acknowledge timing must meet this set-up time

8. Cb = total capacitance of one bus line in pF.

9. The maximum tf for the SDA and SCL bus lines is specified at 300 ns. The maximum fall time for the SDA output stage tf is specified at 250 ns.

This allows series protection resistors to be connected in between the SDA and the SCL pins and the SDA/SCL bus lines without exceeding

the maximum specified tf.

10.In Fast mode Plus, fall time is specified the same for both output stage and bus timing. If series resistors are used, designers should allow for

this when considering bus timing.

Sensors

Freescale Semiconductor

MAG3110

6

�

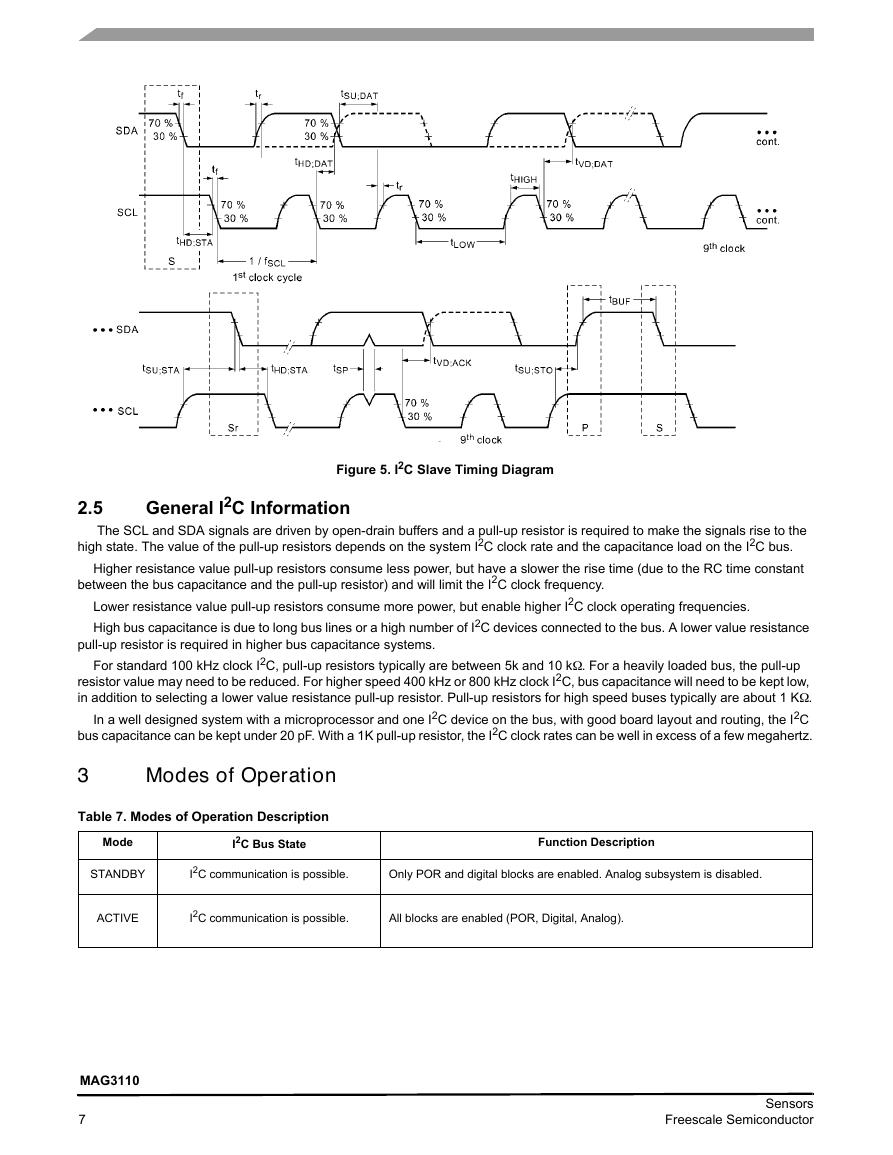

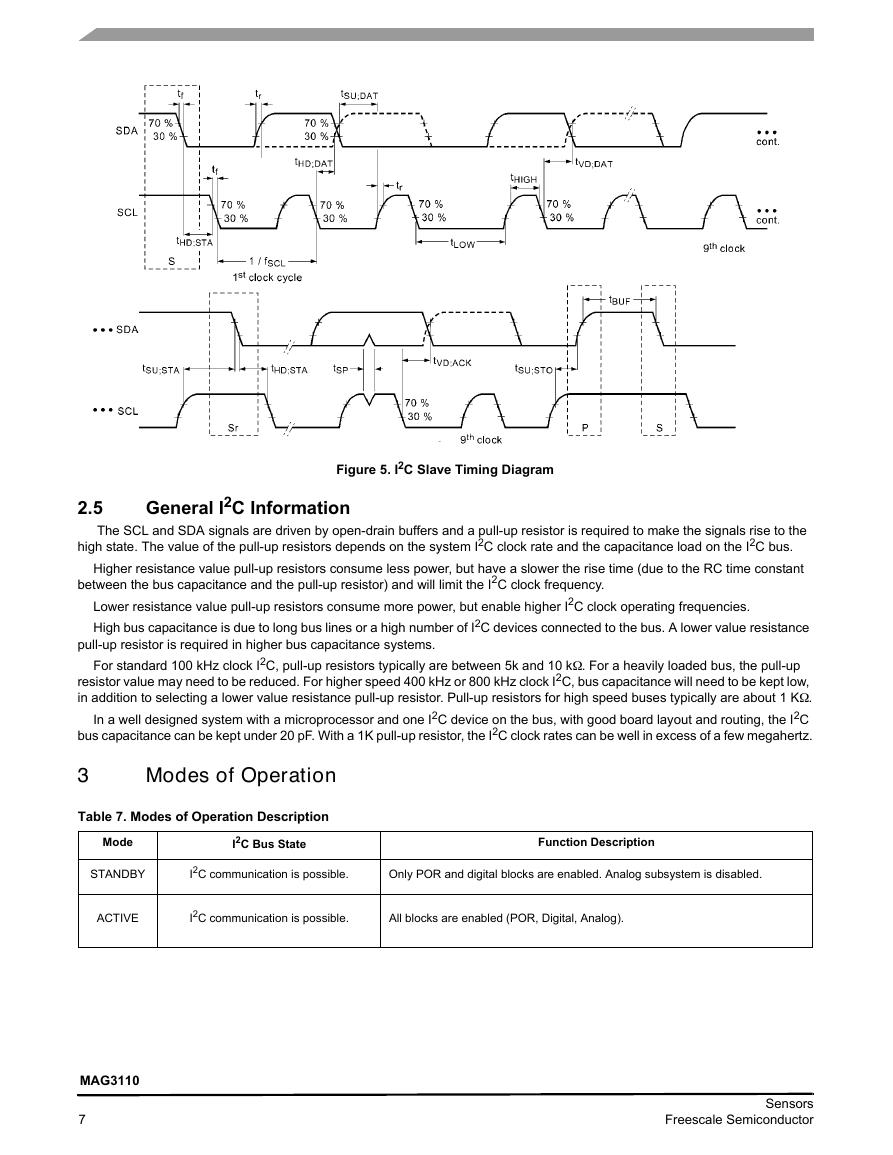

Figure 5. I2C Slave Timing Diagram

2.5

General I2C Information

The SCL and SDA signals are driven by open-drain buffers and a pull-up resistor is required to make the signals rise to the

high state. The value of the pull-up resistors depends on the system I2C clock rate and the capacitance load on the I2C bus.

Higher resistance value pull-up resistors consume less power, but have a slower the rise time (due to the RC time constant

between the bus capacitance and the pull-up resistor) and will limit the I2C clock frequency.

Lower resistance value pull-up resistors consume more power, but enable higher I2C clock operating frequencies.

High bus capacitance is due to long bus lines or a high number of I2C devices connected to the bus. A lower value resistance

pull-up resistor is required in higher bus capacitance systems.

For standard 100 kHz clock I2C, pull-up resistors typically are between 5k and 10 kΩ. For a heavily loaded bus, the pull-up

resistor value may need to be reduced. For higher speed 400 kHz or 800 kHz clock I2C, bus capacitance will need to be kept low,

in addition to selecting a lower value resistance pull-up resistor. Pull-up resistors for high speed buses typically are about 1 KΩ.

In a well designed system with a microprocessor and one I2C device on the bus, with good board layout and routing, the I2C

bus capacitance can be kept under 20 pF. With a 1K pull-up resistor, the I2C clock rates can be well in excess of a few megahertz.

3

Modes of Operation

Table 7. Modes of Operation Description

Mode

I2C Bus State

Function Description

STANDBY

I2C communication is possible.

Only POR and digital blocks are enabled. Analog subsystem is disabled.

ACTIVE

I2C communication is possible.

All blocks are enabled (POR, Digital, Analog).

MAG3110

7

Sensors

Freescale Semiconductor

�

4

Functionality

MAG3110 is a small low-power, digital output, 3-axis linear magnetometer packaged in a 10 pin DFN. The device contains a

magnetic transducer for sensing and an ASIC for control and digital I2C communications.

4.1

I2C Serial Interface

Communication with the MAG3110 takes place over an I2C bus. The MAG3110 also has an interrupt signal indicating that new

magnetic data readings are available. Interrupt driven sampling allows operation without the overhead of software polling.

4.2

Factory Calibration

MAG3110 is factory calibrated for sensitivity, offset and temperature coefficient. All factory calibration coefficients are applied

automatically by the MAG3110 ASIC before the magnetic field readings are written to registers 0x01 to 0x06 (see section 5).

There is no need for the user to apply the calibration correction in the software and the calibration coefficients are not therefore

accessible to the user.

The offset registers in the addresses 0x09 to 0x0E are not a factory calibration offset but allow the user to define a hard iron

offset which can be automatically subtracted from the magnetic field readings (see section 4.3.3).

4.3

Digital Interface

Table 8. Serial Interface Pin Description

Pin Name

Pin Description

VDDIO

IO voltage

SCL

SDA

INT

I2C Serial Clock

I2C Serial Data

Data ready interrupt pin

There are two signals associated with the I2C bus: the Serial Clock Line (SCL) and the Serial Data line (SDA). External pull-

up resistors (connected to VDDIO) are needed for SDA and SCL. When the bus is free, both lines are high. The I2C interface is

compliant with Fast mode (400 kHz), and Normal mode (100 kHz) I2C standards.

4.3.1

General I2C Operation

I2C is an asynchronous, open collector driven, addressed and packetized serial bus interface. It is capable of supporting

multiple masters and multiple slave devices on the same bus. I2C uses two bi-directional lines, the serial clock line or SCL and

the serial data line or SDA. Pull-up resistors are required on both lines.

An I2C transaction starts with a start condition (START) and ends with a stop condition (STOP). A START condition is defined

as a HIGH to LOW transition on the data line while the clock line is held HIGH. A STOP condition is defined as a LOW to HIGH

transition on the data line while the clock line is held HIGH. At all other times, the data line can only change state when the clock

line is low. If the data line changes state when the clock is high, the I2C transaction is aborted and the new start or stop condition

is recognized.

After START has been transmitted by the master, the bus is considered busy. The next byte of data transmitted after START

condition is the slave address in the first 7 bits, and the eighth bit is the Read/Write (R/W) bit (read = 1, write = 0). The R/W bit

determines whether the I2C master intends on receiving data from the slave – Read mode or intends to transmit data to the slave

– Write mode. When an address is sent, each device on the I2C bus compares the first 7 bits after a start condition with its own

internal address. If the address matches, the device considers itself addressed by the Master and continues to respond. If the

address does not match, the device ignores further bus activity until the next start condition happens.

The ninth bit (clock pulse), following each I2C byte is for the acknowledge (ACK) bit. The master releases the SDA line during

the ACK period. Because of the pull-up resistor, the data line will tend to float high. To signal ACK back to the master, the slave

must then pull the data line low during this clock period.

The number of bytes per transfer can be unlimited. If a receiving device can't accept another complete byte of data until it has

performed some other function, it can hold the clock line, SCL, low to force the transmitter into a wait state. Data transfer only

continues when the receiver is ready for another byte and releases the data line. This delay action is called clock stretching. The

MAG3110 device does clock stretching.

A data transfer is always terminated by a STOP.

The MAG3110 I2C 7-bit device address is 0x0E. In I2C practice, the device address is shifted left by one bit field and a read/

write bit is set in the lowest bit position. The I2C 8-bit write address is 0x1C and the read address is 0x1D.

The I2C 8-bit write address is 0x3A and the read address is 0x3B. Please consult the factory for alternate addresses.

Sensors

Freescale Semiconductor

MAG3110

8

�

V2版本原理图(Capacitive-Fingerprint-Reader-Schematic_V2).pdf

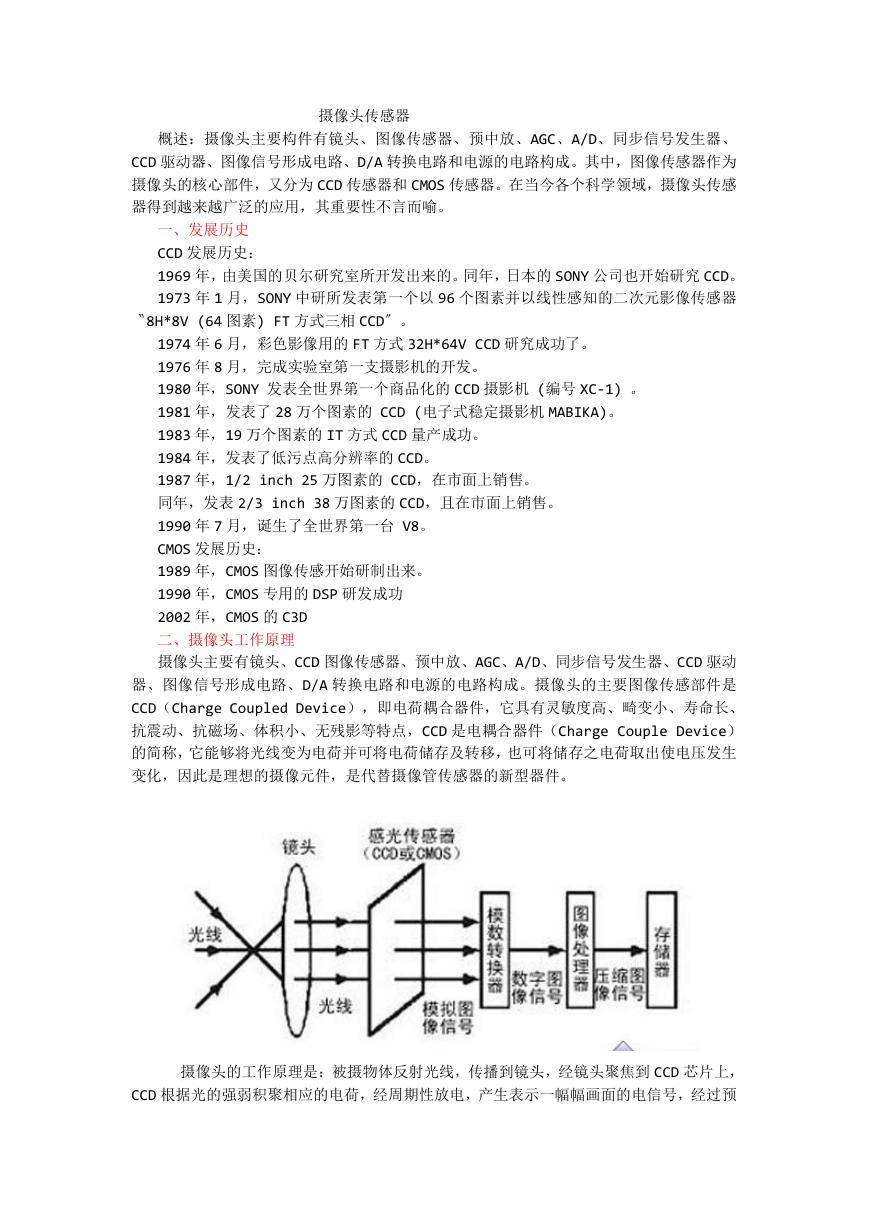

V2版本原理图(Capacitive-Fingerprint-Reader-Schematic_V2).pdf 摄像头工作原理.doc

摄像头工作原理.doc VL53L0X简要说明(En.FLVL53L00216).pdf

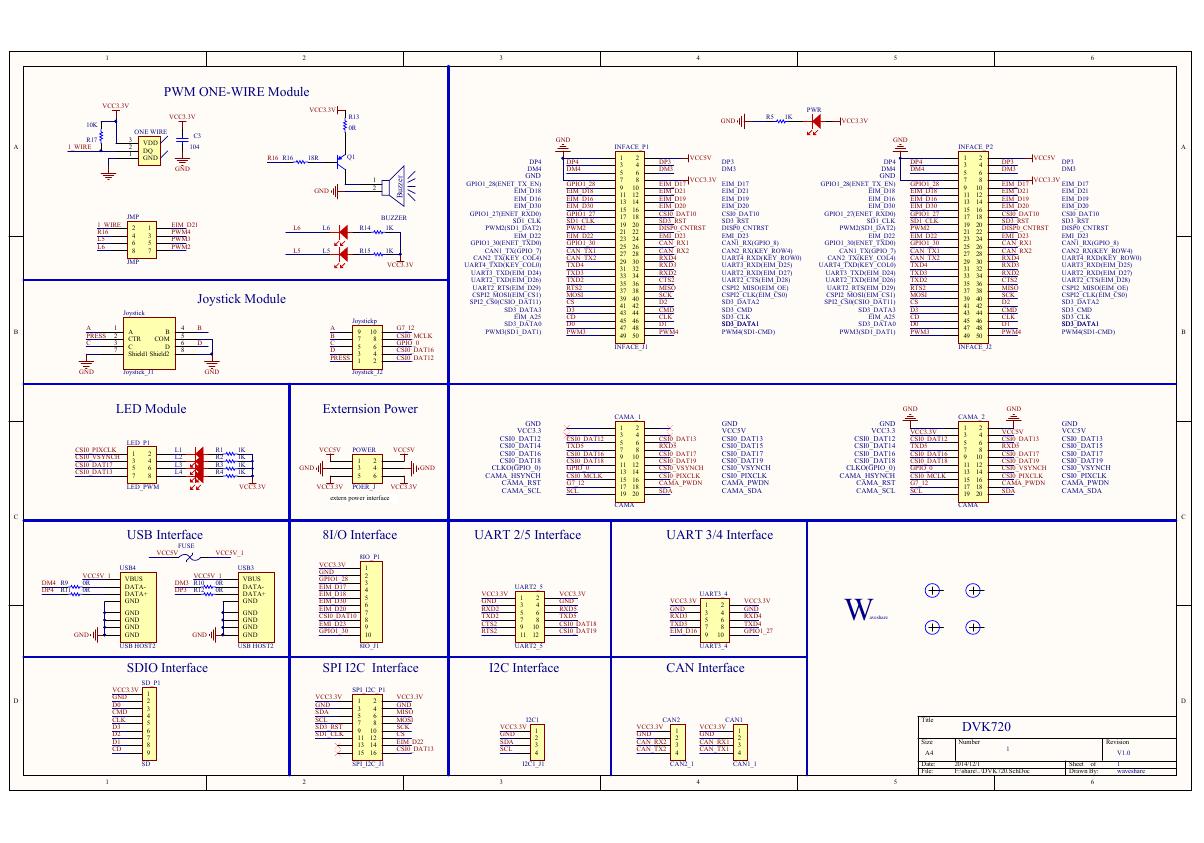

VL53L0X简要说明(En.FLVL53L00216).pdf 原理图(DVK720-Schematic).pdf

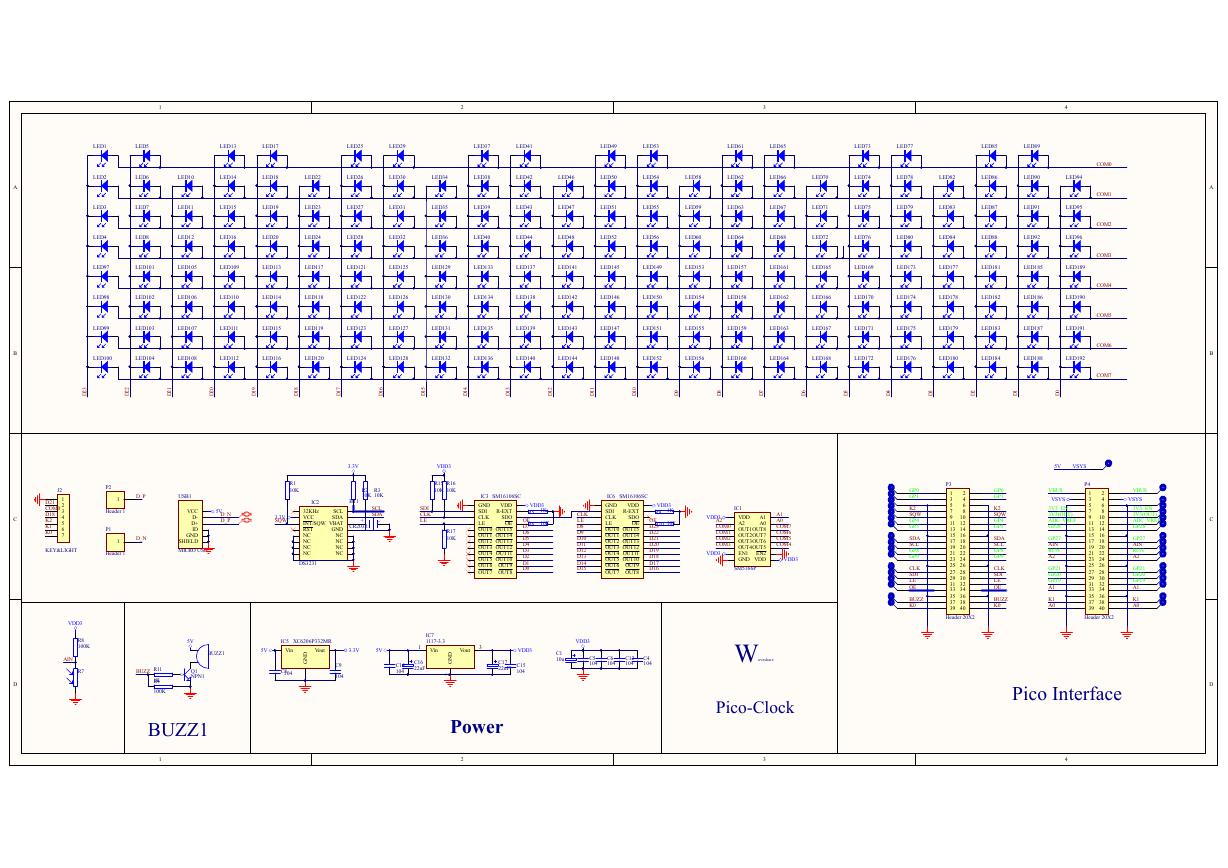

原理图(DVK720-Schematic).pdf 原理图(Pico-Clock-Green-Schdoc).pdf

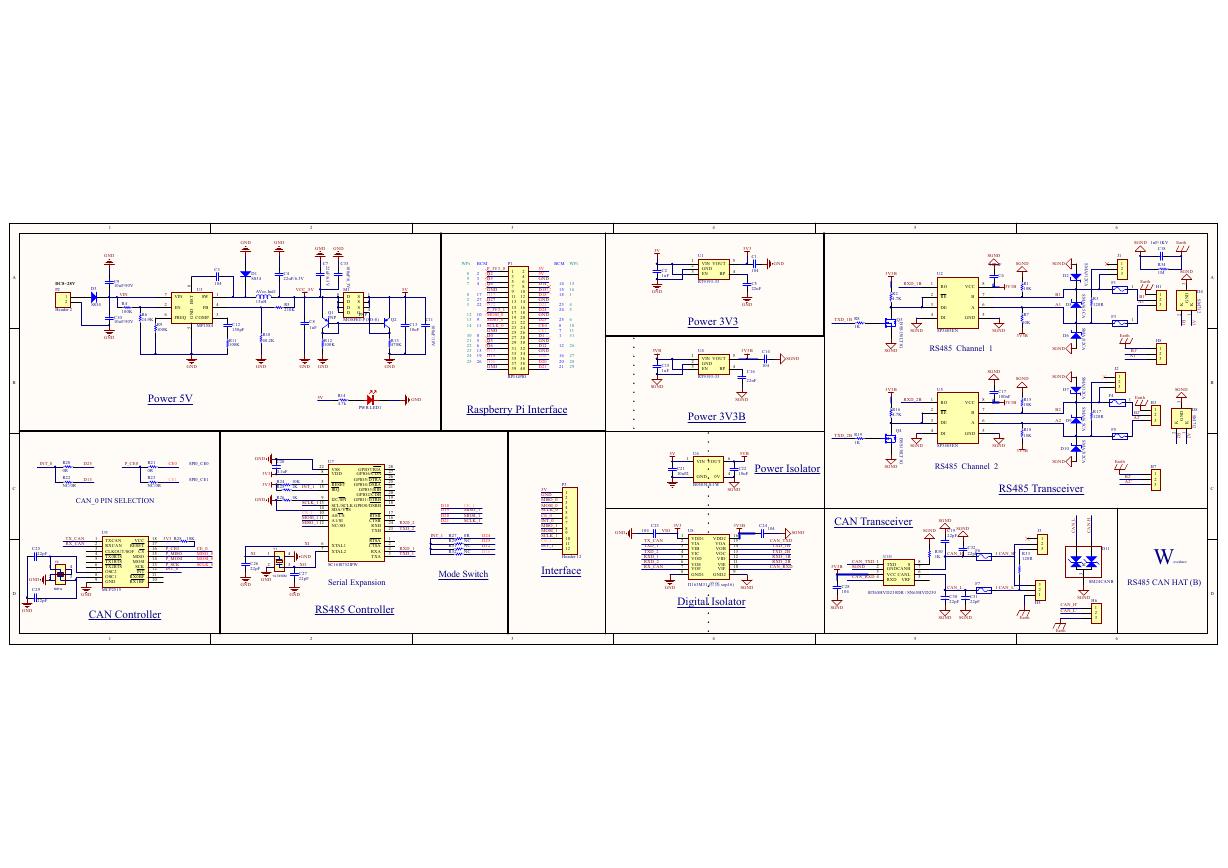

原理图(Pico-Clock-Green-Schdoc).pdf 原理图(RS485-CAN-HAT-B-schematic).pdf

原理图(RS485-CAN-HAT-B-schematic).pdf File:SIM7500_SIM7600_SIM7800 Series_SSL_Application Note_V2.00.pdf

File:SIM7500_SIM7600_SIM7800 Series_SSL_Application Note_V2.00.pdf ADS1263(Ads1262).pdf

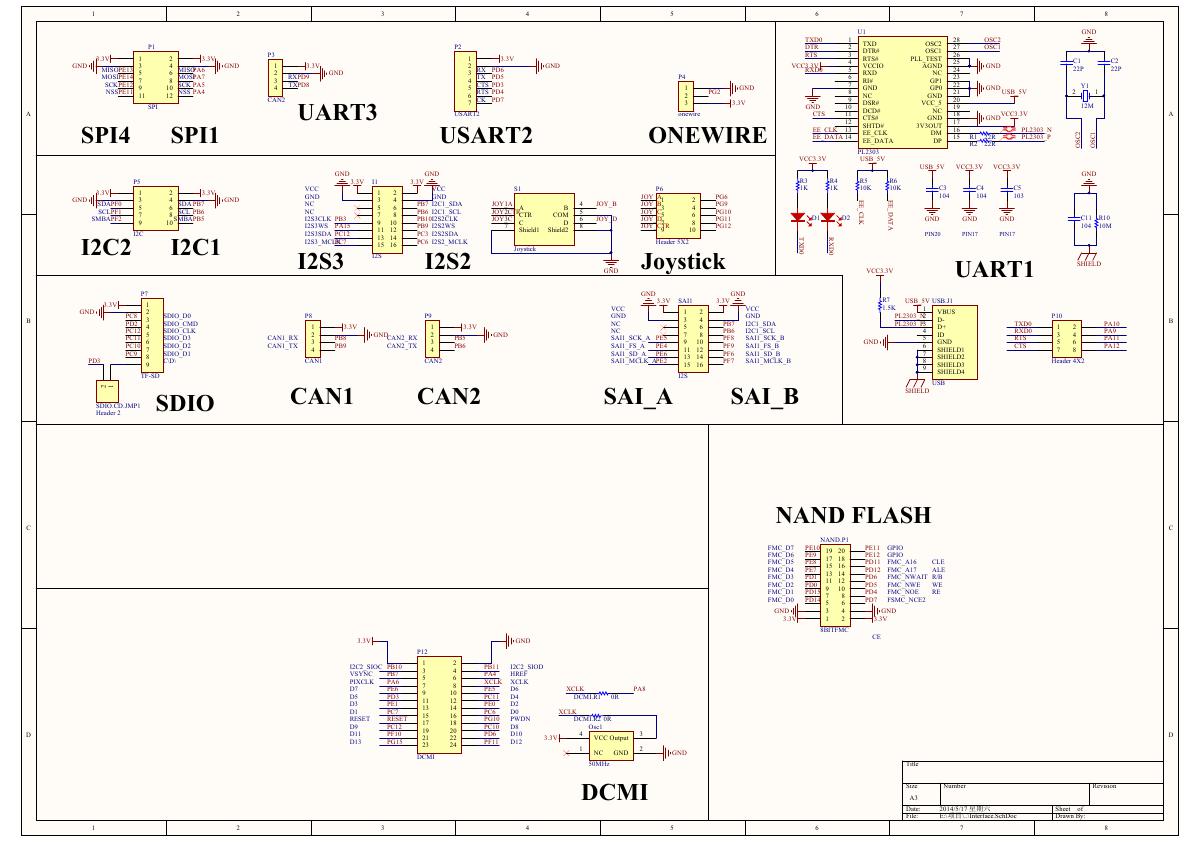

ADS1263(Ads1262).pdf 原理图(Open429Z-D-Schematic).pdf

原理图(Open429Z-D-Schematic).pdf 用户手册(Capacitive_Fingerprint_Reader_User_Manual_CN).pdf

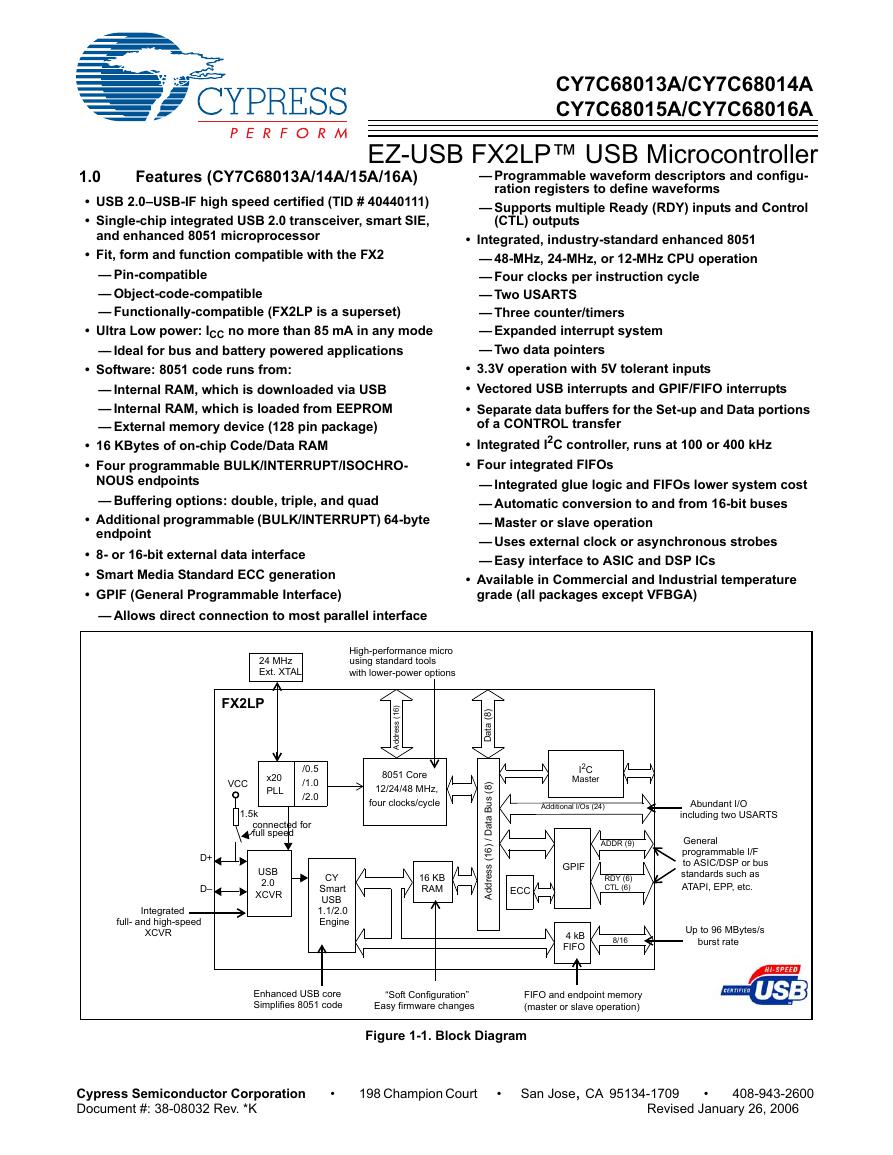

用户手册(Capacitive_Fingerprint_Reader_User_Manual_CN).pdf CY7C68013A(英文版)(CY7C68013A).pdf

CY7C68013A(英文版)(CY7C68013A).pdf TechnicalReference_Dem.pdf

TechnicalReference_Dem.pdf