Desktop 3 Microfilmer

A-61036

Part No. 4C2063 User’s Guide

Safety Information for the Kodak Desktop 3 Microfilmer

IMPORTANT: Equipment shall be installed by qualified

personnel.

WARNING: Dangerous voltage. Disconnect the main

power before installation.

CAUTION: Moving parts, avoid contact

ATTENTION: Eviter le contact, pieces en mouvement

VORSICHT: Bewegliche teile, berüehrung vermeiden

CAUTION: Hot surface, avoid contact

ATTENTION: Eviter le contact, pieces brulantes

VORSICHT: Heisse oberfläeche, berüehrung vermeiden

CAUTION: Risk of explosion if battery is replaced by an

incorrect type.

ATTENTION: une explosion peut se produire si la pile est

remplacée par un modèle incorrect.

VORSICHT: Bei Verwendung eines falschen Batterietyps

besteht Explosionsgefahr.

Acoustic Emission

Maschinenläerminformations verordnung – 3, GSGV

Der arbeitsplatzbezogene Emissionswert betraegt <70 dB(A).

[ Machine Noise Information Ordinance – 3, GSGV

– The operator-position noise emission value is <70 dB(A) ].

This equipment was designed for connection to IT Power Systems.

Safety and Regulatory Following is some additional safety and regulatory

Information information.

Warning: To prevent fire or shock hazard, do not

expose unit to rain or moisture. To prevent

possibility of injury or damage to the unit, do

not operate with any covers or panels

removed.

• Read and Follow Instructions — Read and follow all the

safety and operating instructions before operating the unit.

• Heed Warnings — Heed all warnings on the equipment and

in the operating instructions.

• Power Sources — The unit should be operated only from the

type of power source indicated on the dataplate label. If you

are not sure of the type of power supply that will be used,

consult a dealer or local power company.

• Power Cord Damage — Avoid damage to the power cord. If

damage should occur, replace it with the specific cord for this

unit.

• Power Cord Protection — Power supply cords should be

routed so they are not likely to be walked on or pinched by

items placed upon or against them; pay particular attention to

cords at plugs, convenience receptacles, and the point where

they leave the units.

NOTE: The power cord must have appropriate Safety Agency

approval for the country where the unit is installed.

• Grounding — The unit is equipped with a 3-wire grounding-

type plug, a plug having a third (grounding) pin. The 3-wire

grounding-type plug will fit into a grounding-type power outlet.

This is a safety feature. If you are unable to insert the plug into

the outlet, contact an electrician to replace the obsolete outlet.

Do not defeat the safety purpose of the grounding-type plug.

Regulatory Information The Kodak Imagelink Desktop 3 Microfilmer (including the

Image Mark and Endorser accessories) has been tested

and complies with the following standard.

Product Safety

• CSA NRTL/C marked and certified by Canadian Standards

Association to CSA 22.2 No. 950 and UL 1950.

• TUV GS marked and licensed to EN 60950 by Techniscer

Uberwachungs - Verein Rheinland of North America, Inc.

• The standards and specifications are in accordance with the

73/23 EEC directive and amendments.

Electromagnetic Compatibility (EMC)

• The equipment has been found to comply with the EN

55014/1987 and EN 50082-1/1992 standards for Information

Technology Equipment.

• The standards and specifications are in accordance with the

89/336 EEC directive and amendments.

Introduction

The Kodak Desktop 3 Microfilmer is intended for medium-to low-volume

operations that require rapid, high-reduction microfilming. Documents up

to 9.00 inches (22.9 cm) wide and 11.7 inches (29.7 cm) long can be

microfilmed, with images captured on 16 mm film at a 40:1 reduction

ratio.

Thick-base (5 mil) film cassettes accept 100 ft. (30.5 m) lengths of

microfilm. Thin-base (2.5 mil) film cassettes accept 215 ft. (65.5 m)

lengths. A choice of duplex or duo modes provide flexibility in

microfilming.

Documents to be microfilmed are placed in the automatic feeder in the

front of the unit, photographed as they pass between two clear document

guides, and exit into an adjustable receiving area at the upper front of the

microfilmer.

No special skills or knowledge are required to operate the Desktop 3

Microfilmer.

A-61036 July 2000 1

1 Overview

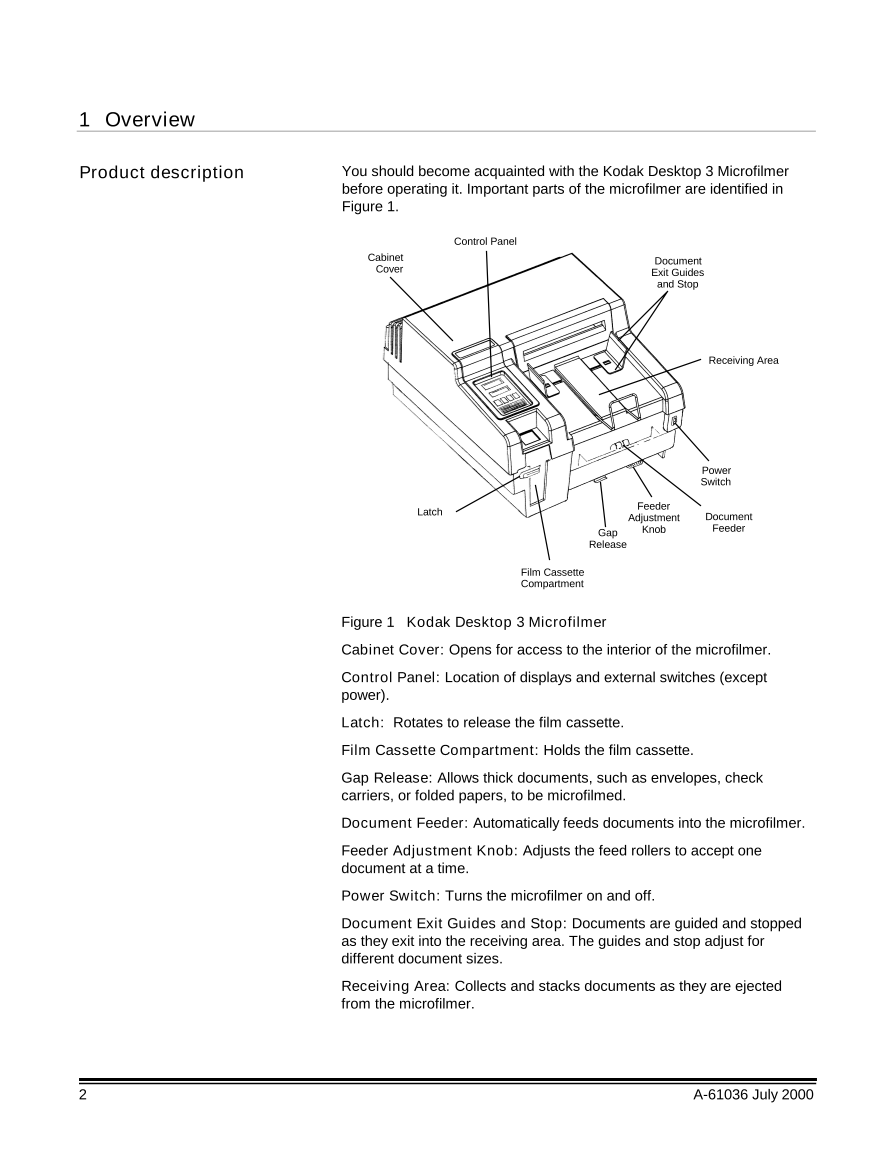

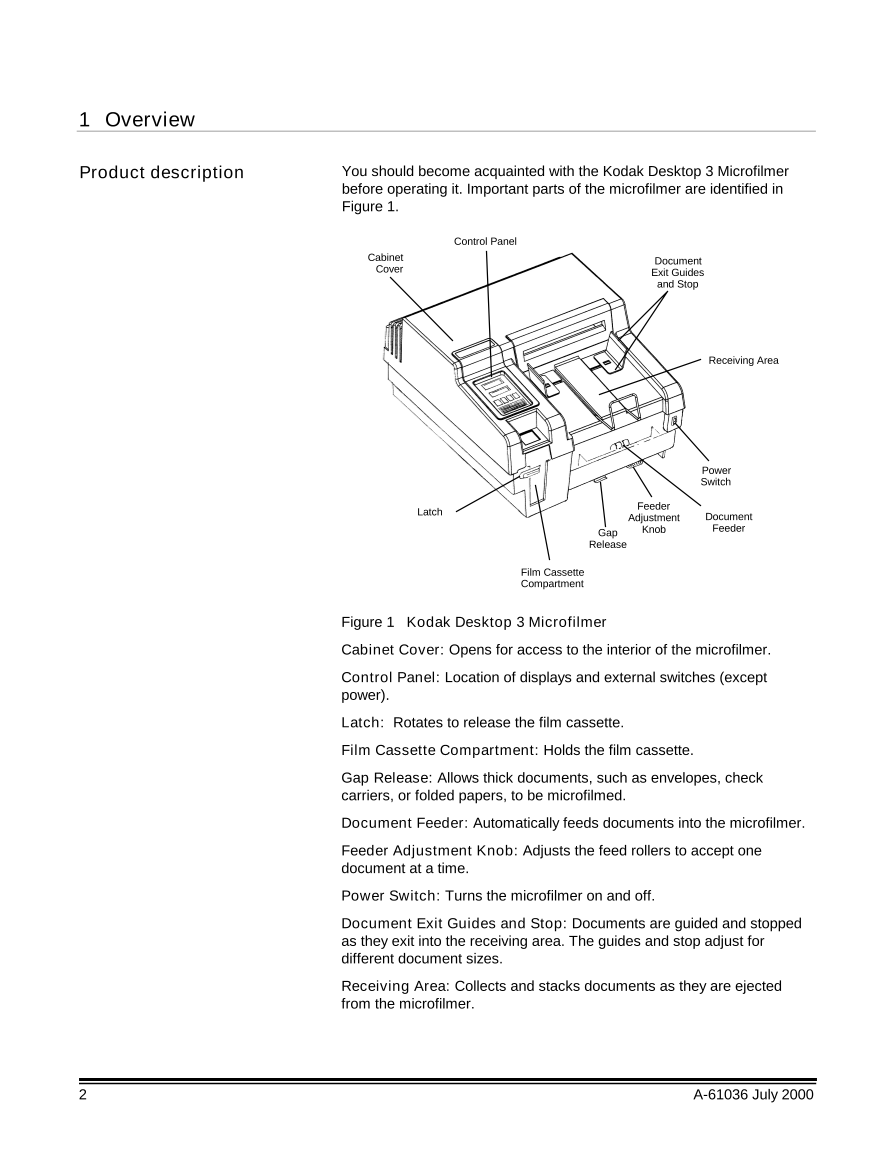

Product description You should become acquainted with the Kodak Desktop 3 Microfilmer

before operating it. Important parts of the microfilmer are identified in

Figure 1.

Control Panel

Cabinet Document

Cover Exit Guides

and Stop

Receiving Area

Power

Switch

Latch Feeder

Adjustment Document

Gap Knob Feeder

Release

Film Cassette

Compartment

Figure 1 Kodak Desktop 3 Microfilmer

Cabinet Cover: Opens for access to the interior of the microfilmer.

Control Panel: Location of displays and external switches (except

power).

Latch: Rotates to release the film cassette.

Film Cassette Compartment: Holds the film cassette.

Gap Release: Allows thick documents, such as envelopes, check

carriers, or folded papers, to be microfilmed.

Document Feeder: Automatically feeds documents into the microfilmer.

Feeder Adjustment Knob: Adjusts the feed rollers to accept one

document at a time.

Power Switch: Turns the microfilmer on and off.

Document Exit Guides and Stop: Documents are guided and stopped

as they exit into the receiving area. The guides and stop adjust for

different document sizes.

Receiving Area: Collects and stacks documents as they are ejected

from the microfilmer.

2 A-61036 July 2000

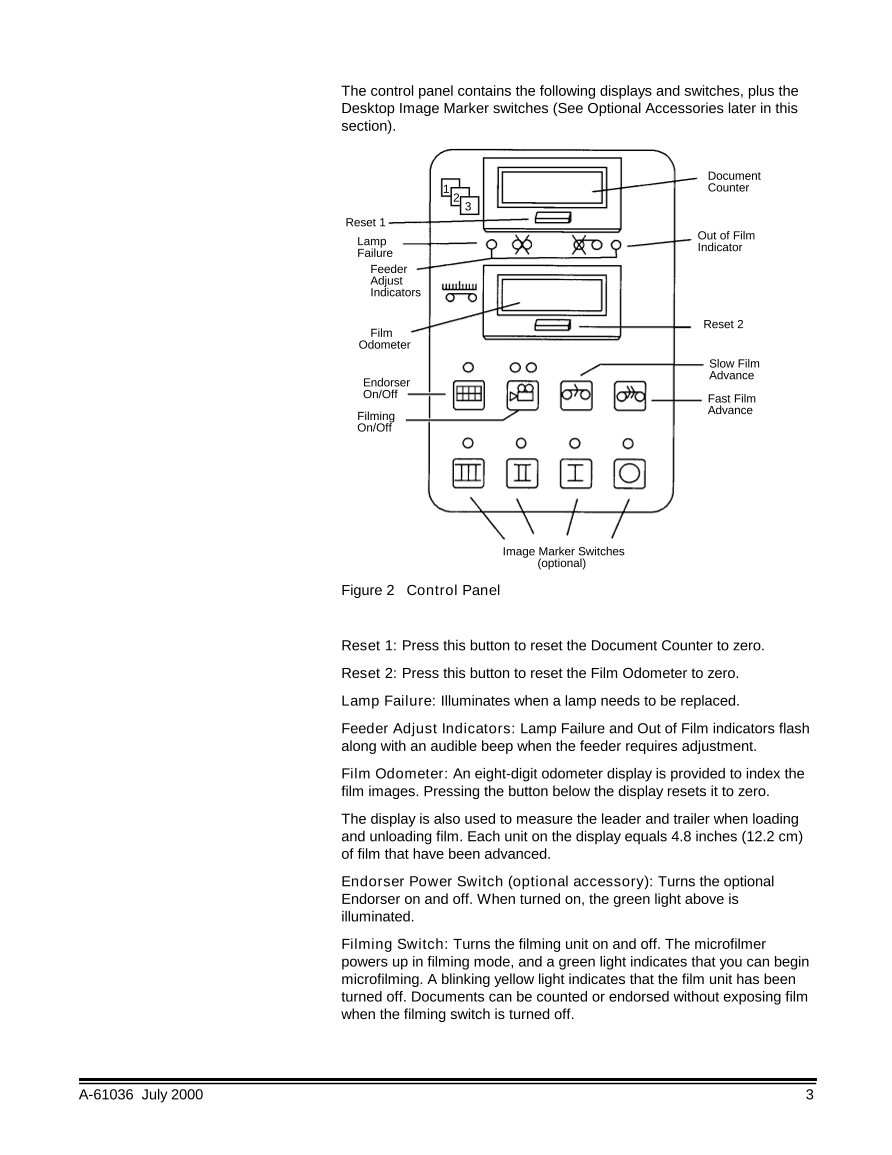

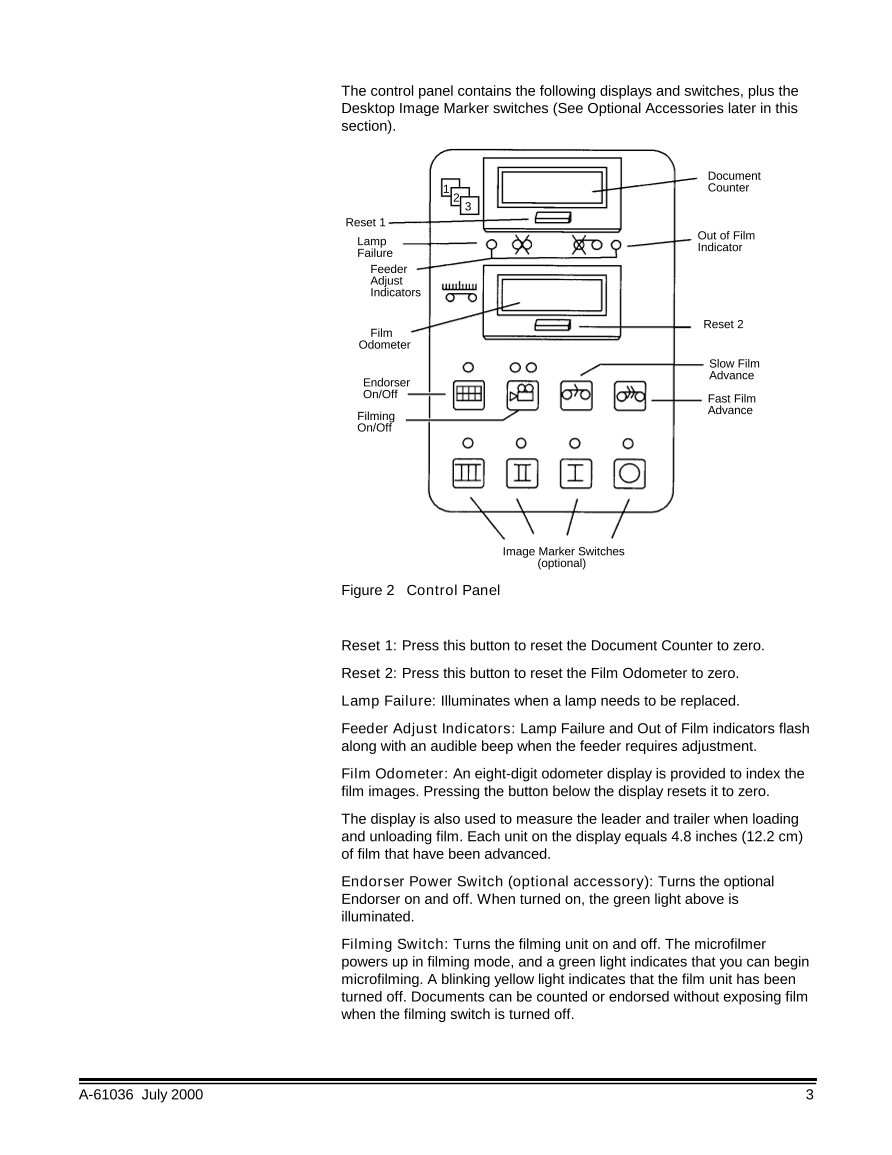

The control panel contains the following displays and switches, plus the

Desktop Image Marker switches (See Optional Accessories later in this

section).

Document

1 Counter

2

3

Reset 1

Lamp Out of Film

Failure Indicator

Feeder

Adjust

Indicators

Reset 2

Film

Odometer

Slow Film

Endorser Advance

On/Off Fast Film

Filming Advance

On/Off

Image Marker Switches

(optional)

Figure 2 Control Panel

Reset 1: Press this button to reset the Document Counter to zero.

Reset 2: Press this button to reset the Film Odometer to zero.

Lamp Failure: Illuminates when a lamp needs to be replaced.

Feeder Adjust Indicators: Lamp Failure and Out of Film indicators flash

along with an audible beep when the feeder requires adjustment.

Film Odometer: An eight-digit odometer display is provided to index the

film images. Pressing the button below the display resets it to zero.

The display is also used to measure the leader and trailer when loading

and unloading film. Each unit on the display equals 4.8 inches (12.2 cm)

of film that have been advanced.

Endorser Power Switch (optional accessory): Turns the optional

Endorser on and off. When turned on, the green light above is

illuminated.

Filming Switch: Turns the filming unit on and off. The microfilmer

powers up in filming mode, and a green light indicates that you can begin

microfilming. A blinking yellow light indicates that the film unit has been

turned off. Documents can be counted or endorsed without exposing film

when the filming switch is turned off.

A-61036 July 2000 3

Document Counter: An eight-digit counter that shows how many

documents have been processed by the microfilmer. Pressing the button

below the display resets the counter to zero. It is possible to count

documents without microfilming them (See Filming Switch on the

previous page).

Out of Film Indicator: Illuminates when the film supply is almost empty.

Slow Film Advance: Advances film at approximately 7 inches (17.8 cm)

per second when this switch is pressed. Film is automatically advanced

1.5 to 2.0 inches (3.8 cm to 5.1 cm) when the microfilmer is turned on or

when a different film cassette is installed.

Fast Film Advance Switch: Advances film approximately 48 inches

(121.9 cm) when pressed. Used when the operator loads and unloads

film.

Image Marker Switches: By pressing one of these optional switches,

you can determine the size of the image mark placed adjacent to each

film image. III = large; II - medium; I = small; 0 = none.

Alarm and interlocks Built-in alarms and interlocks provide safe and reliable operation and

contribute to high-quality microfilm images.

• An alarm sounds and a light is illuminated when the filming switch is on

and the film supply is low or empty.

• A blinking light above the filming switch indicates that filming is shut off.

• An alarm sounds, a light is illuminated, and the microfilmer transport

shuts off automatically if either of the exposure lamps fail.

• The microfilmer transport shuts off automatically if a document

becomes lodged in the document conveyor system.

• The microfilmer will not operate when the cabinet cover is open.

• Operator-replaceable fuses, mounted in the rear of the microfilmer,

shut off the microfilmer in the event of an electrical overload.

• An alarm sounds and the top two lights on the control panel flash if the

document spacing becomes too close, and the feeder needs

adjustment.

4 A-61036 July 2000

V2版本原理图(Capacitive-Fingerprint-Reader-Schematic_V2).pdf

V2版本原理图(Capacitive-Fingerprint-Reader-Schematic_V2).pdf 摄像头工作原理.doc

摄像头工作原理.doc VL53L0X简要说明(En.FLVL53L00216).pdf

VL53L0X简要说明(En.FLVL53L00216).pdf 原理图(DVK720-Schematic).pdf

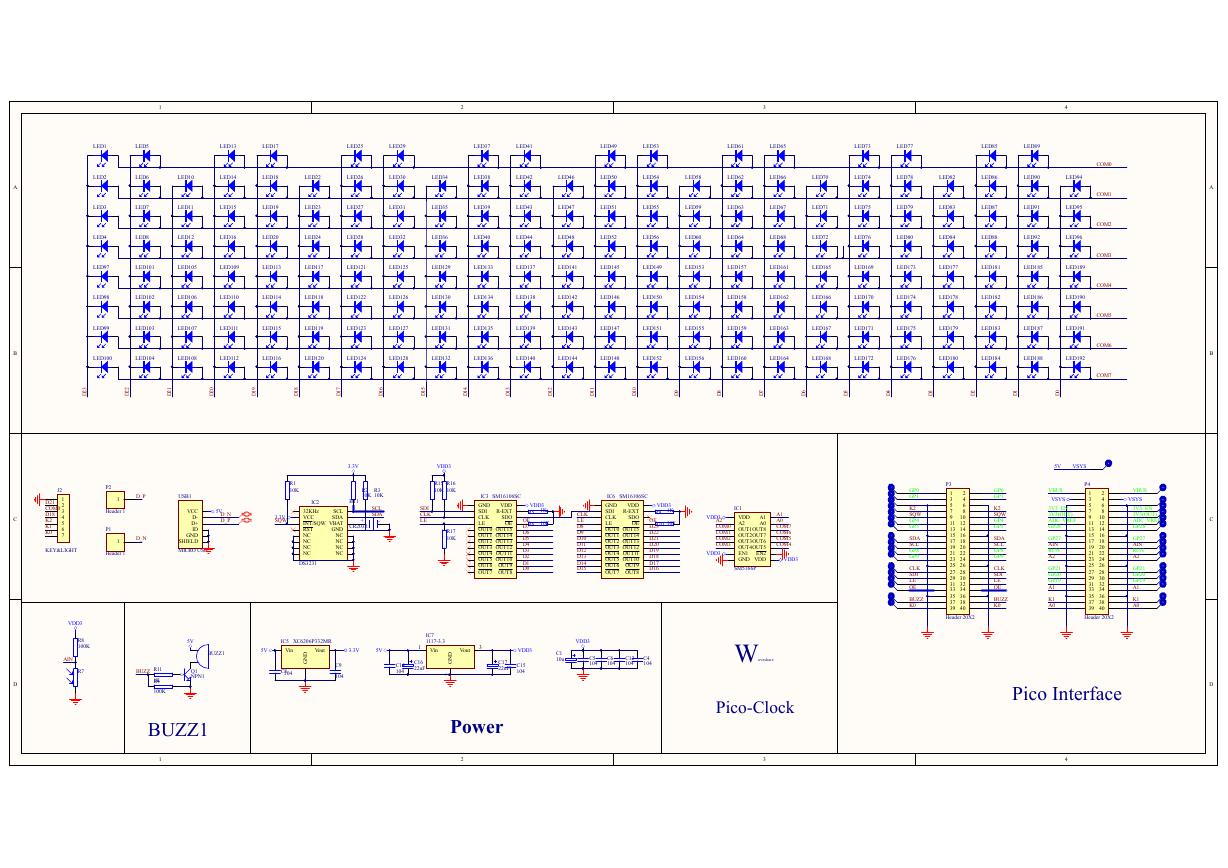

原理图(DVK720-Schematic).pdf 原理图(Pico-Clock-Green-Schdoc).pdf

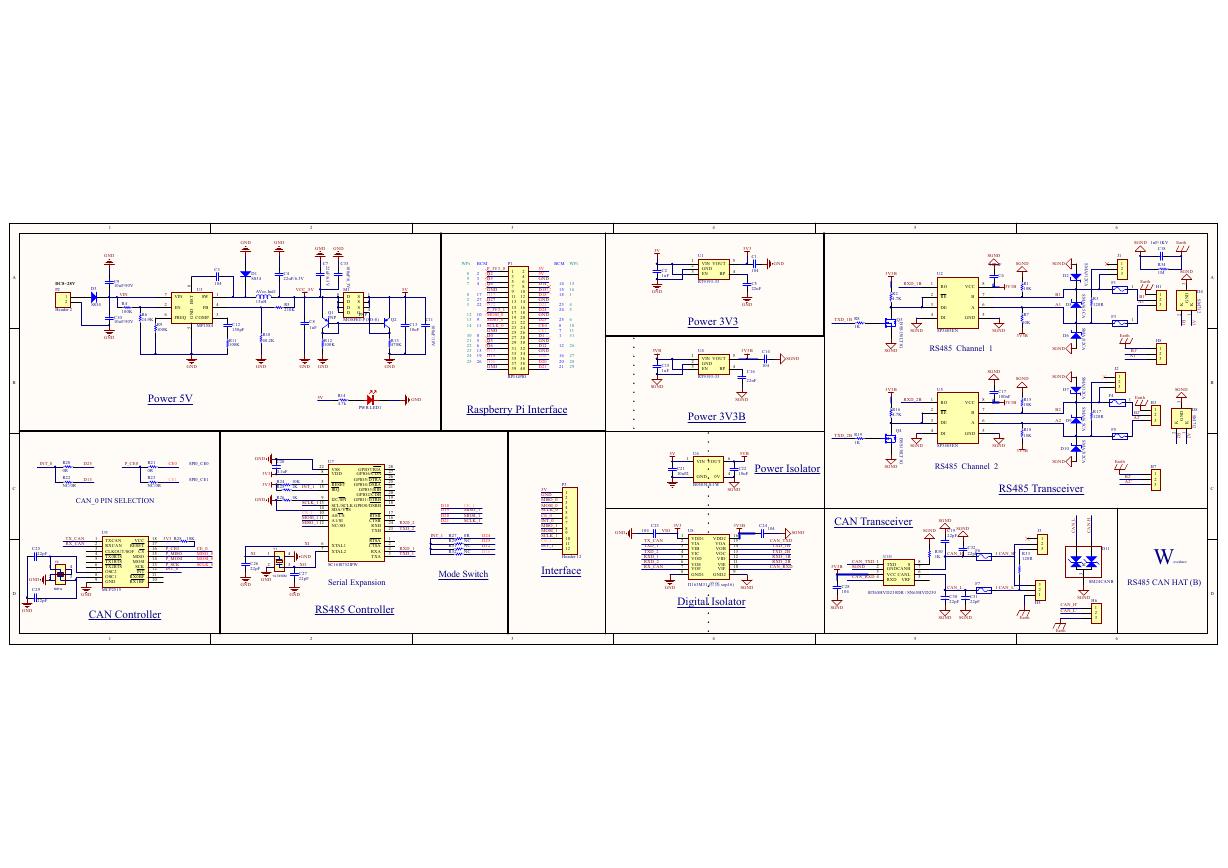

原理图(Pico-Clock-Green-Schdoc).pdf 原理图(RS485-CAN-HAT-B-schematic).pdf

原理图(RS485-CAN-HAT-B-schematic).pdf File:SIM7500_SIM7600_SIM7800 Series_SSL_Application Note_V2.00.pdf

File:SIM7500_SIM7600_SIM7800 Series_SSL_Application Note_V2.00.pdf ADS1263(Ads1262).pdf

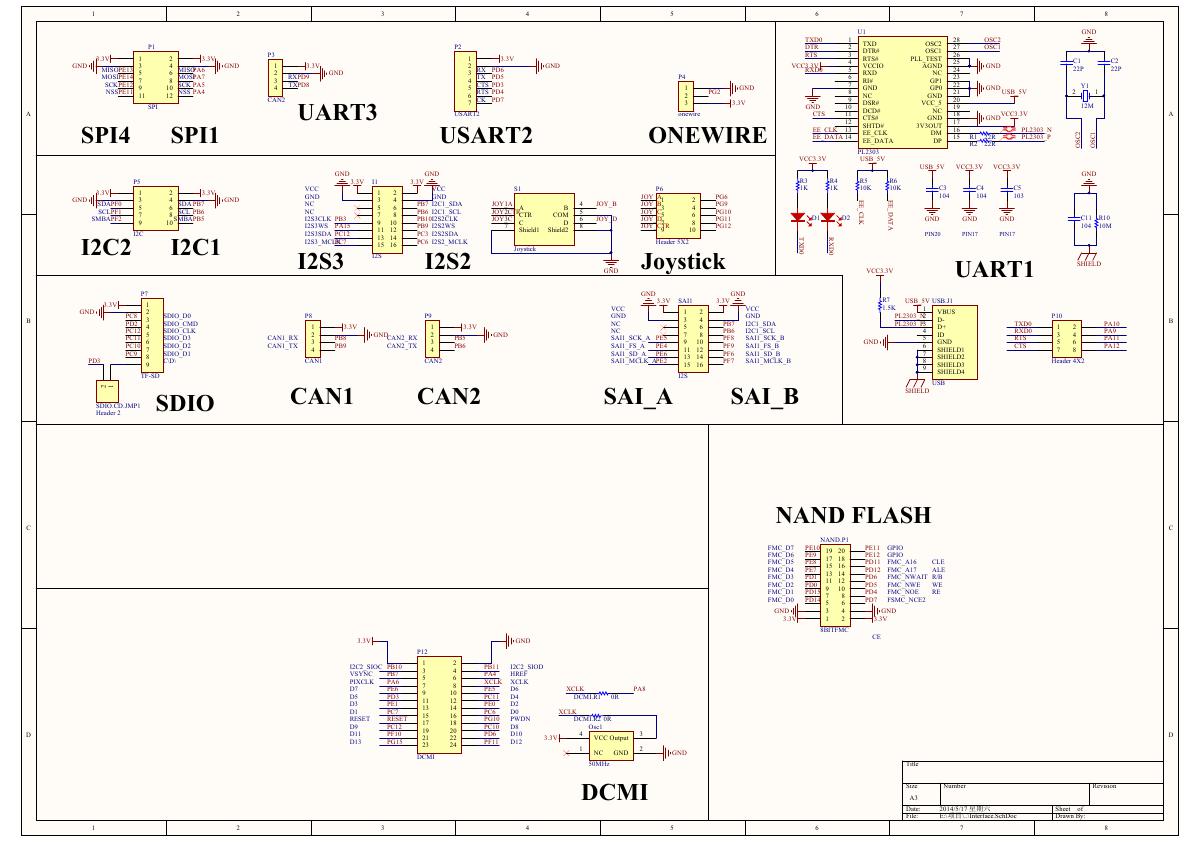

ADS1263(Ads1262).pdf 原理图(Open429Z-D-Schematic).pdf

原理图(Open429Z-D-Schematic).pdf 用户手册(Capacitive_Fingerprint_Reader_User_Manual_CN).pdf

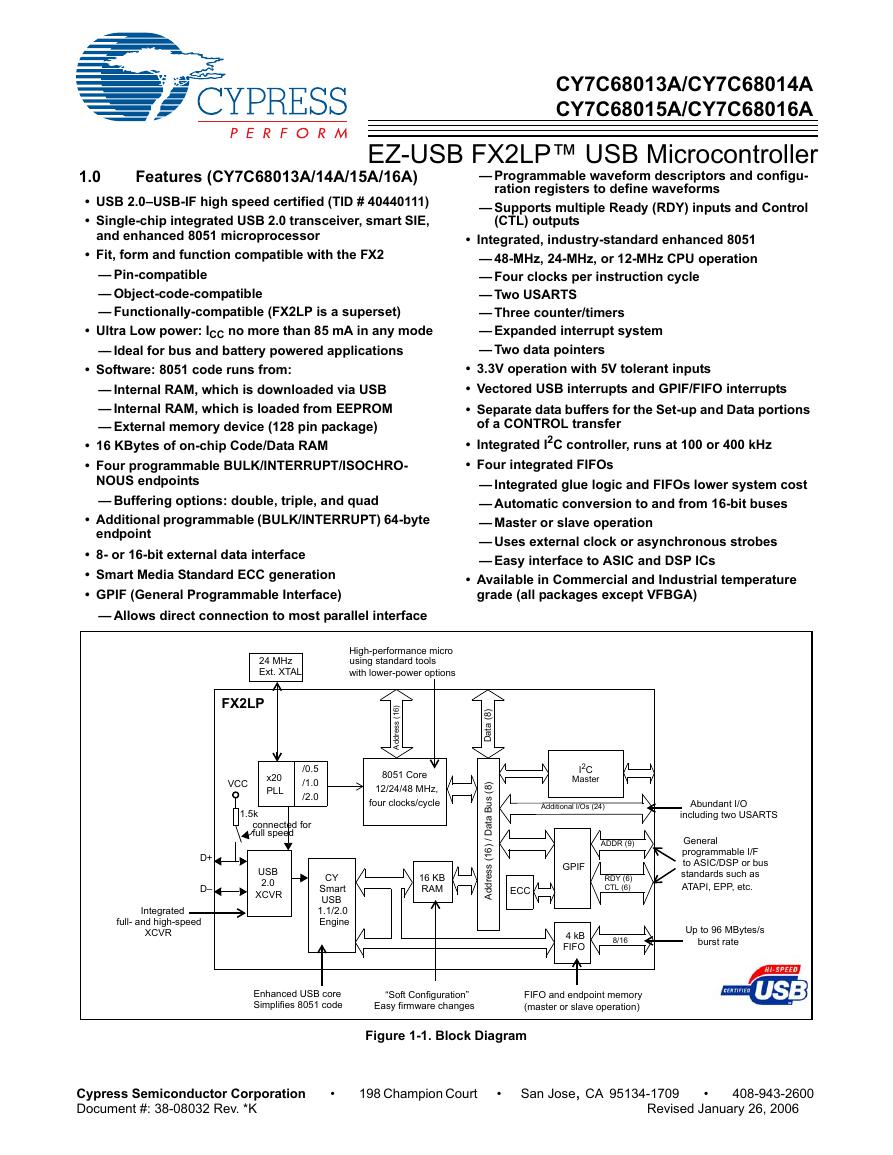

用户手册(Capacitive_Fingerprint_Reader_User_Manual_CN).pdf CY7C68013A(英文版)(CY7C68013A).pdf

CY7C68013A(英文版)(CY7C68013A).pdf TechnicalReference_Dem.pdf

TechnicalReference_Dem.pdf