Preliminary Datasheet SGP40

Indoor Air Quality Sensor for VOC Measurements

MOx based gas sensor for indoor air quality applications

Outstanding long-term stability and lifetime

I2C interface with digital output signal

Very small 6-pin DFN package: 2.44 x 2.44 x 0.85 mm3

Low power consumption: 2.6 mA at 3.3 V

Tape and reel packaged, reflow solderable

VOC Algorithm feature an unmatched robustness

against contaminating gases present in real-world

applications enabling a unique long-term stability as

well as low drift and device-to-device variation. The very

small 2.44 x 2.44 x 0.85 mm3 DFN package enables

applications

Sensirion’s

state-of-the-art production process guarantees high

reproducibility and reliability. Tape and reel packaging

together with suitability for standard SMD assembly

processes make the SGP40 predestined for high-

volume applications.

spaces.

in

limited

Product Summary

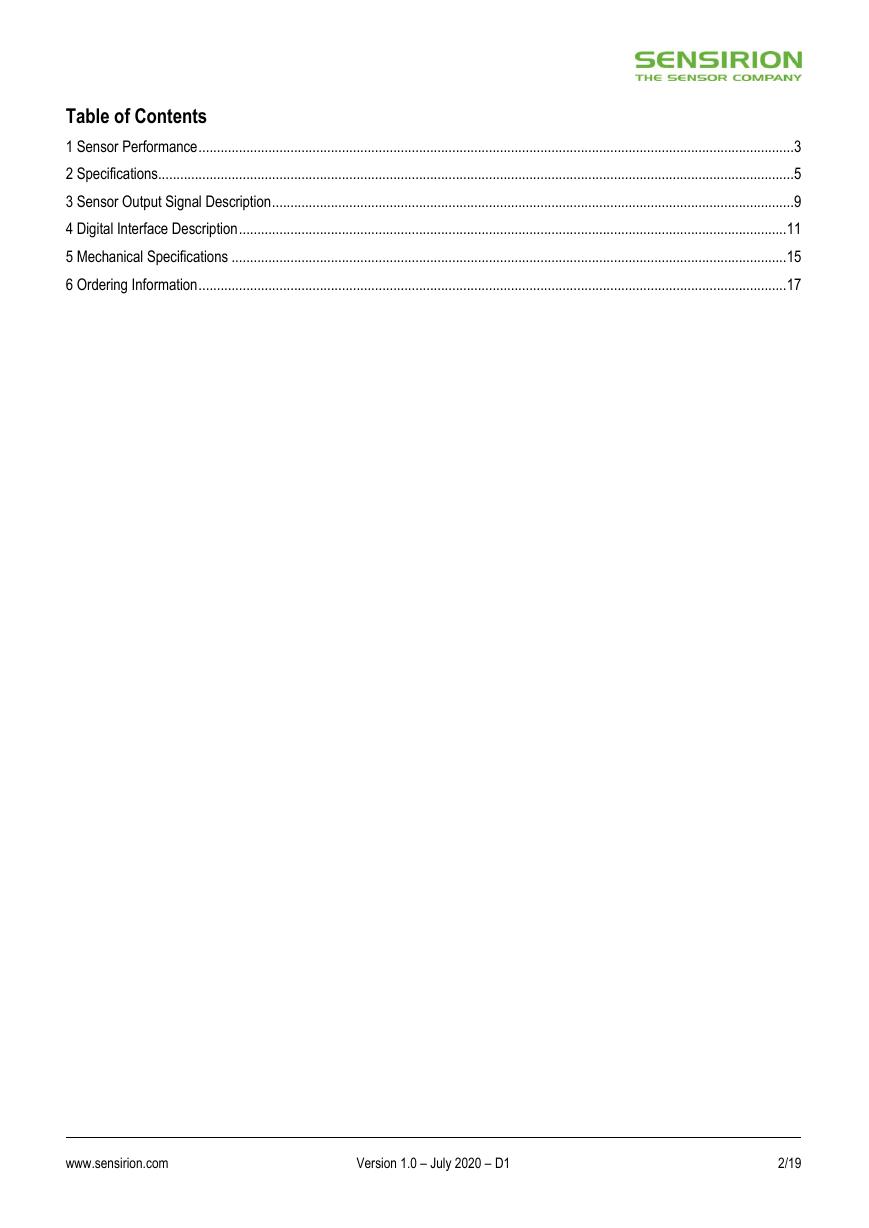

The SGP40 is a digital gas sensor designed for easy

integration

into air purifiers or demand-controlled

ventilation systems. Sensirion’s CMOSens® technology

offers a complete, easy-to-use sensor system on a single

chip featuring a digital I2C interface and a temperature-

controlled micro hotplate, providing a humidity-

compensated VOC based indoor air quality signal. The

output signal can be directly processed by Sensirion’s

powerful VOC Algorithm to translate the raw signal into a

VOC Index as a robust measure for indoor air quality. The

VOC Algorithm automatically adapts to the environment

the sensor is exposed to. Both sensing element and

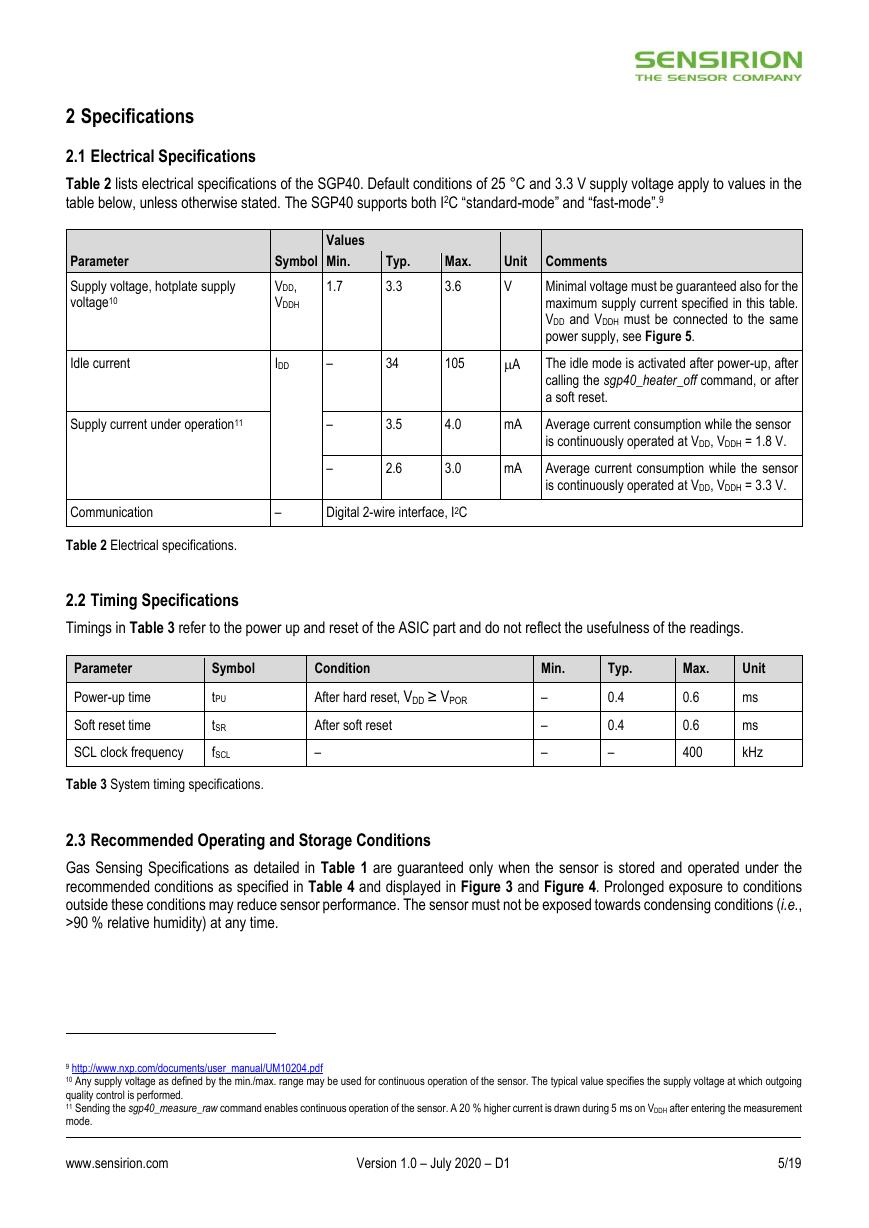

Figure 1 Functional block diagram of the SGP40.

www.sensirion.com

Version 1.0 – July 2020 – D1

1/19

�

Table of Contents

1 Sensor Performance .................................................................................................................................................................. 3

2 Specifications............................................................................................................................................................................. 5

3 Sensor Output Signal Description .............................................................................................................................................. 9

4 Digital Interface Description ..................................................................................................................................................... 11

5 Mechanical Specifications ....................................................................................................................................................... 15

6 Ordering Information ................................................................................................................................................................ 17

www.sensirion.com

Version 1.0 – July 2020 – D1

2/19

�

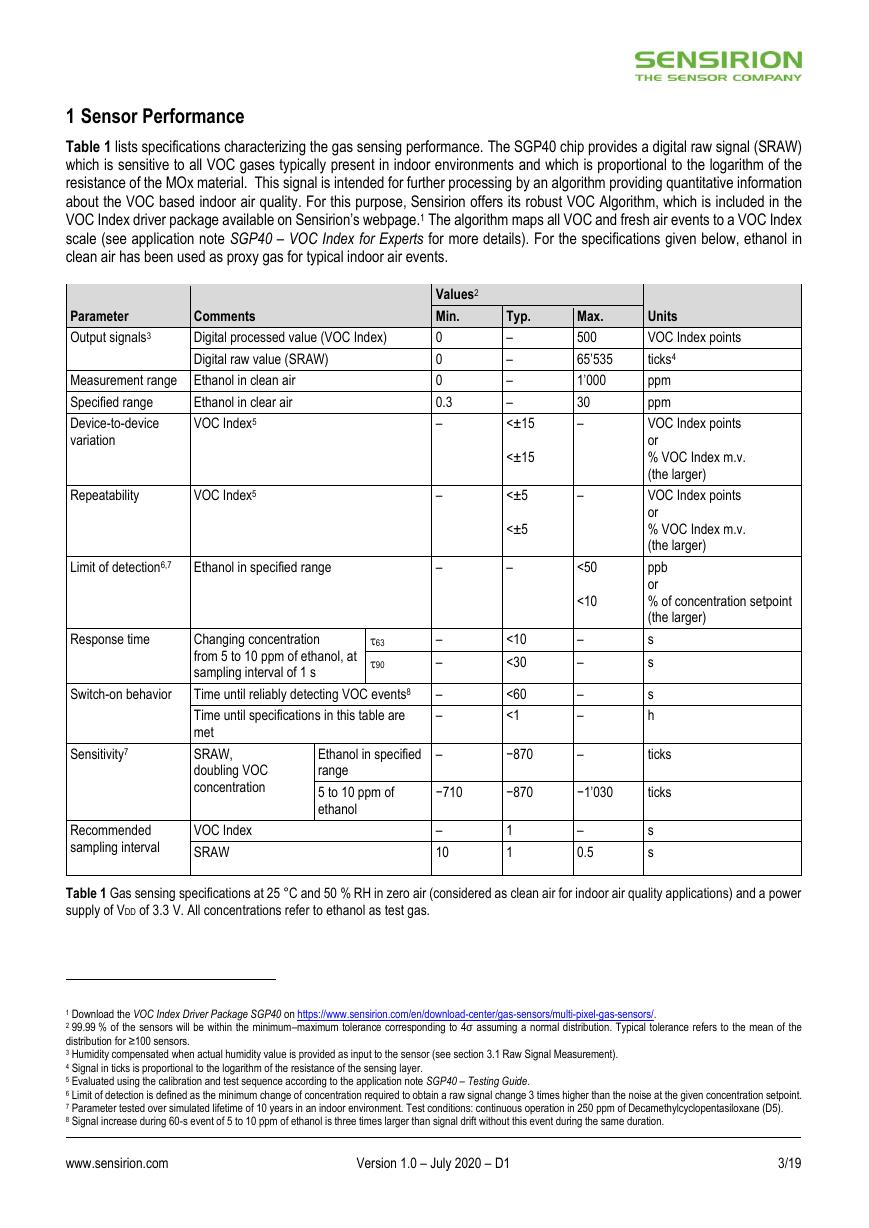

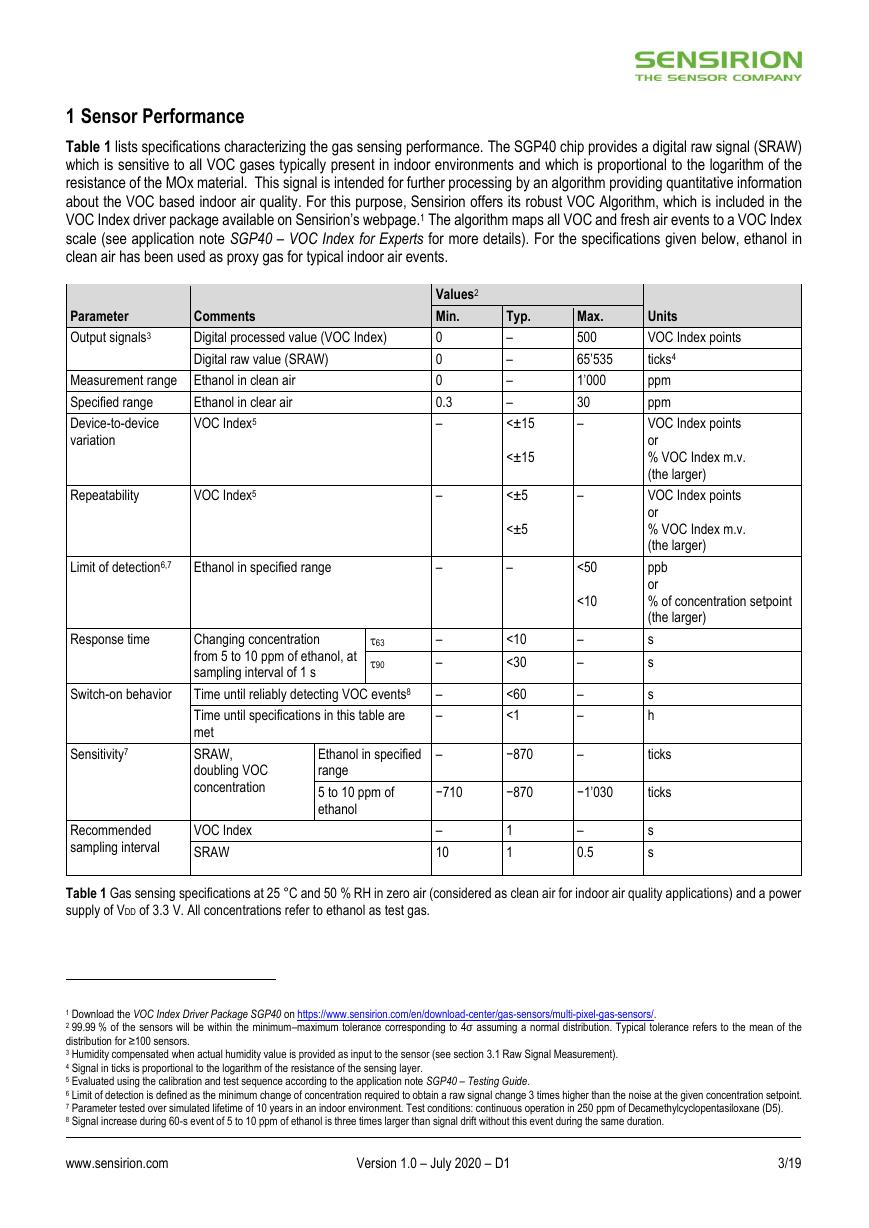

1 Sensor Performance

Table 1 lists specifications characterizing the gas sensing performance. The SGP40 chip provides a digital raw signal (SRAW)

which is sensitive to all VOC gases typically present in indoor environments and which is proportional to the logarithm of the

resistance of the MOx material. This signal is intended for further processing by an algorithm providing quantitative information

about the VOC based indoor air quality. For this purpose, Sensirion offers its robust VOC Algorithm, which is included in the

VOC Index driver package available on Sensirion’s webpage.1 The algorithm maps all VOC and fresh air events to a VOC Index

scale (see application note SGP40 – VOC Index for Experts for more details). For the specifications given below, ethanol in

clean air has been used as proxy gas for typical indoor air events.

Parameter

Comments

Output signals3

Digital processed value (VOC Index)

Digital raw value (SRAW)

Measurement range Ethanol in clean air

Specified range

Ethanol in clear air

Device-to-device

variation

VOC Index5

Repeatability

VOC Index5

Limit of detection6,7

Ethanol in specified range

Response time

Changing concentration

from 5 to 10 ppm of ethanol, at

sampling interval of 1 s

63

90

Switch-on behavior

Time until reliably detecting VOC events8

Sensitivity7

Time until specifications in this table are

met

SRAW,

doubling VOC

concentration

Ethanol in specified

range

5 to 10 ppm of

ethanol

Recommended

sampling interval

VOC Index

SRAW

Values2

Min.

Typ.

0

0

0

0.3

–

–

–

–

–

–

–

–

–

–

–

–

<±15

<±15

<±5

<±5

–

<10

<30

<60

<1

−870

Max.

500

65’535

1’000

30

–

–

<50

<10

–

–

–

–

–

Units

VOC Index points

ticks4

ppm

ppm

VOC Index points

or

% VOC Index m.v.

(the larger)

VOC Index points

or

% VOC Index m.v.

(the larger)

ppb

or

% of concentration setpoint

(the larger)

s

s

s

h

ticks

−710

−870

−1’030

ticks

–

10

1

1

–

0.5

s

s

Table 1 Gas sensing specifications at 25 °C and 50 % RH in zero air (considered as clean air for indoor air quality applications) and a power

supply of VDD of 3.3 V. All concentrations refer to ethanol as test gas.

1 Download the VOC Index Driver Package SGP40 on https://www.sensirion.com/en/download-center/gas-sensors/multi-pixel-gas-sensors/.

2 99.99 % of the sensors will be within the minimum–maximum tolerance corresponding to 4σ assuming a normal distribution. Typical tolerance refers to the mean of the

distribution for ≥100 sensors.

3 Humidity compensated when actual humidity value is provided as input to the sensor (see section 3.1 Raw Signal Measurement).

4 Signal in ticks is proportional to the logarithm of the resistance of the sensing layer.

5 Evaluated using the calibration and test sequence according to the application note SGP40 – Testing Guide.

6 Limit of detection is defined as the minimum change of concentration required to obtain a raw signal change 3 times higher than the noise at the given concentration setpoint.

7 Parameter tested over simulated lifetime of 10 years in an indoor environment. Test conditions: continuous operation in 250 ppm of Decamethylcyclopentasiloxane (D5).

8 Signal increase during 60-s event of 5 to 10 ppm of ethanol is three times larger than signal drift without this event during the same duration.

www.sensirion.com

Version 1.0 – July 2020 – D1

3/19

�

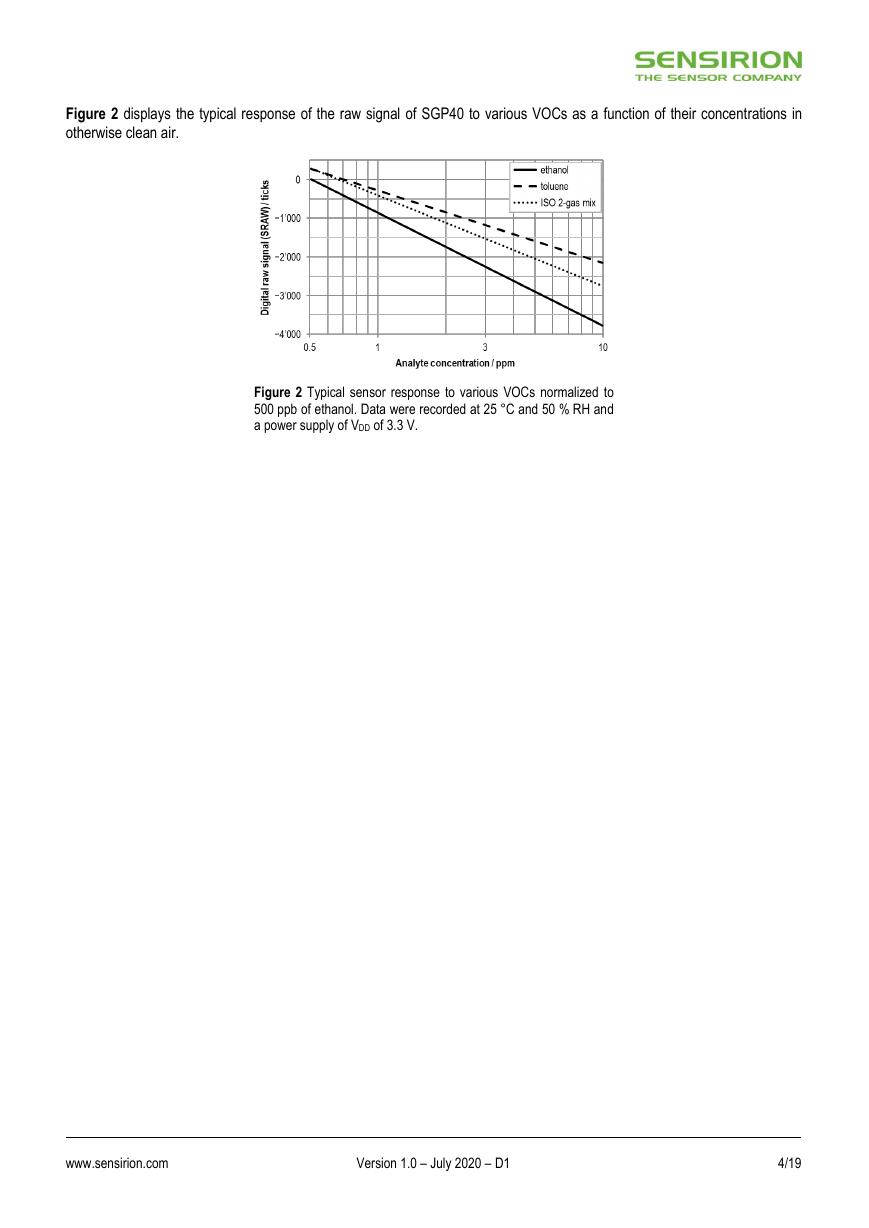

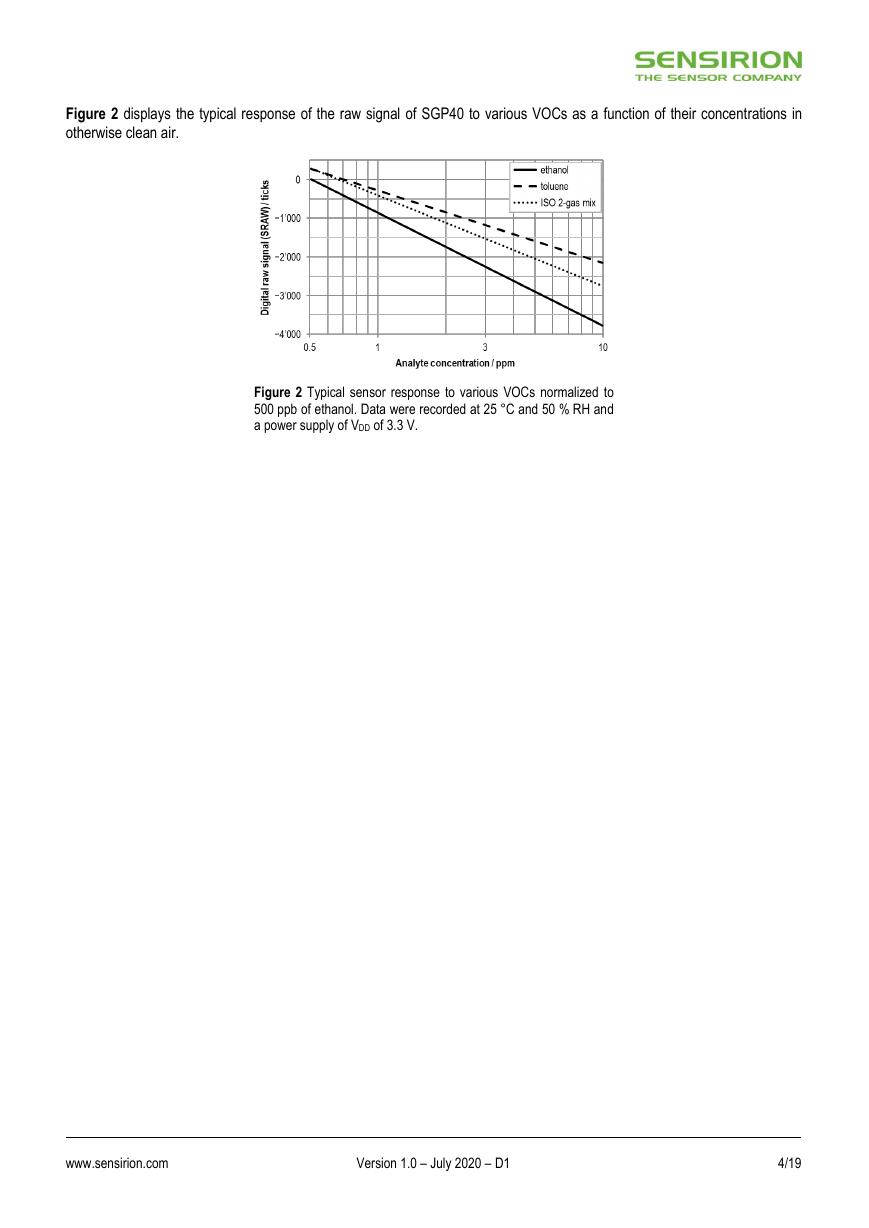

Figure 2 displays the typical response of the raw signal of SGP40 to various VOCs as a function of their concentrations in

otherwise clean air.

Figure 2 Typical sensor response to various VOCs normalized to

500 ppb of ethanol. Data were recorded at 25 °C and 50 % RH and

a power supply of VDD of 3.3 V.

www.sensirion.com

Version 1.0 – July 2020 – D1

4/19

�

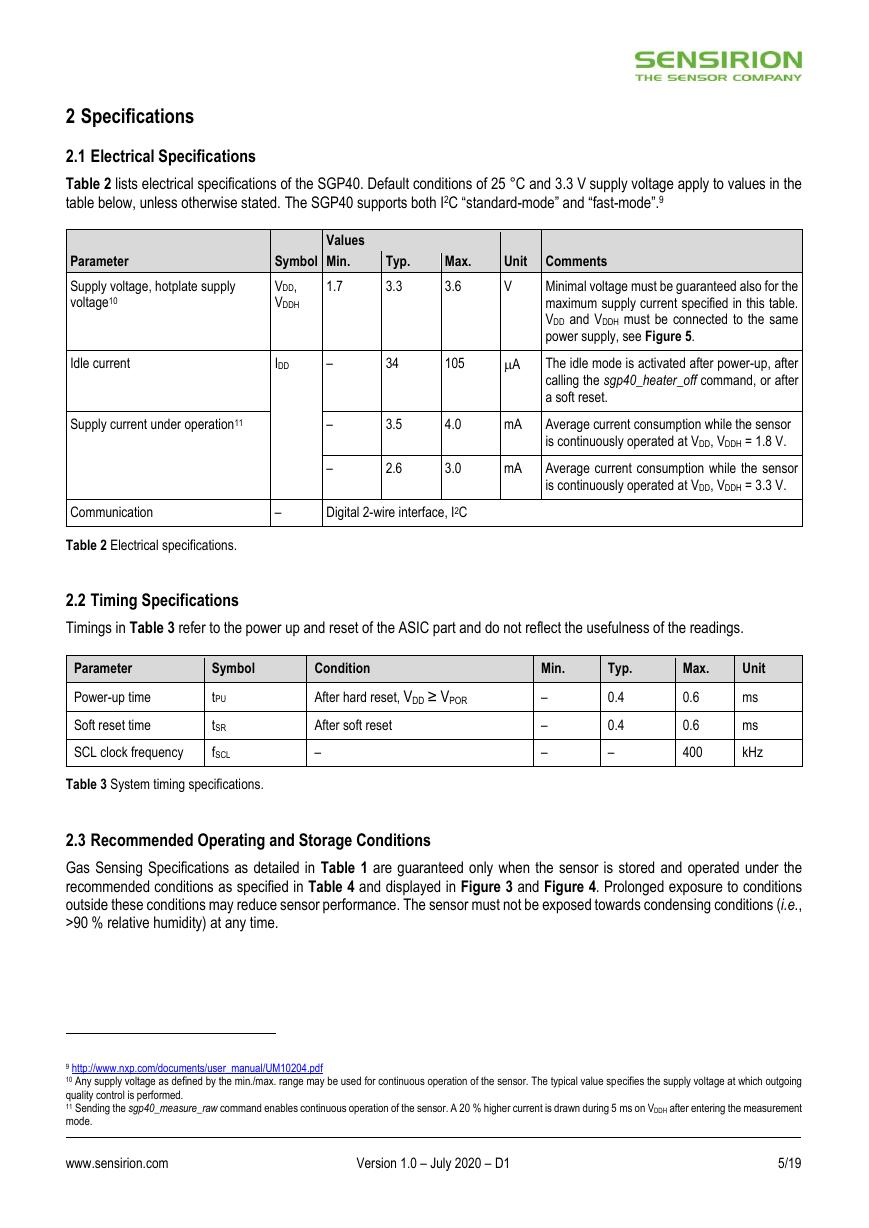

2 Specifications

2.1 Electrical Specifications

Table 2 lists electrical specifications of the SGP40. Default conditions of 25 °C and 3.3 V supply voltage apply to values in the

table below, unless otherwise stated. The SGP40 supports both I2C “standard-mode” and “fast-mode”.9

Parameter

Supply voltage, hotplate supply

voltage10

Values

Symbol

Min.

VDD,

VDDH

1.7

Typ.

3.3

Idle current

IDD

–

34

105

A

Max.

Unit Comments

3.6

V

Minimal voltage must be guaranteed also for the

maximum supply current specified in this table.

VDD and VDDH must be connected to the same

power supply, see Figure 5.

The idle mode is activated after power-up, after

calling the sgp40_heater_off command, or after

a soft reset.

Supply current under operation11

–

–

3.5

4.0

mA

Average current consumption while the sensor

is continuously operated at VDD, VDDH = 1.8 V.

2.6

3.0

mA

Average current consumption while the sensor

is continuously operated at VDD, VDDH = 3.3 V.

Communication

–

Digital 2-wire interface, I2C

Table 2 Electrical specifications.

2.2 Timing Specifications

Timings in Table 3 refer to the power up and reset of the ASIC part and do not reflect the usefulness of the readings.

Parameter

Symbol

Condition

Min.

Typ.

Max.

Unit

Power-up time

Soft reset time

tPU

tSR

After hard reset, VDD ≥ VPOR

After soft reset

SCL clock frequency

fSCL

–

Table 3 System timing specifications.

–

–

–

0.4

0.4

–

0.6

0.6

400

ms

ms

kHz

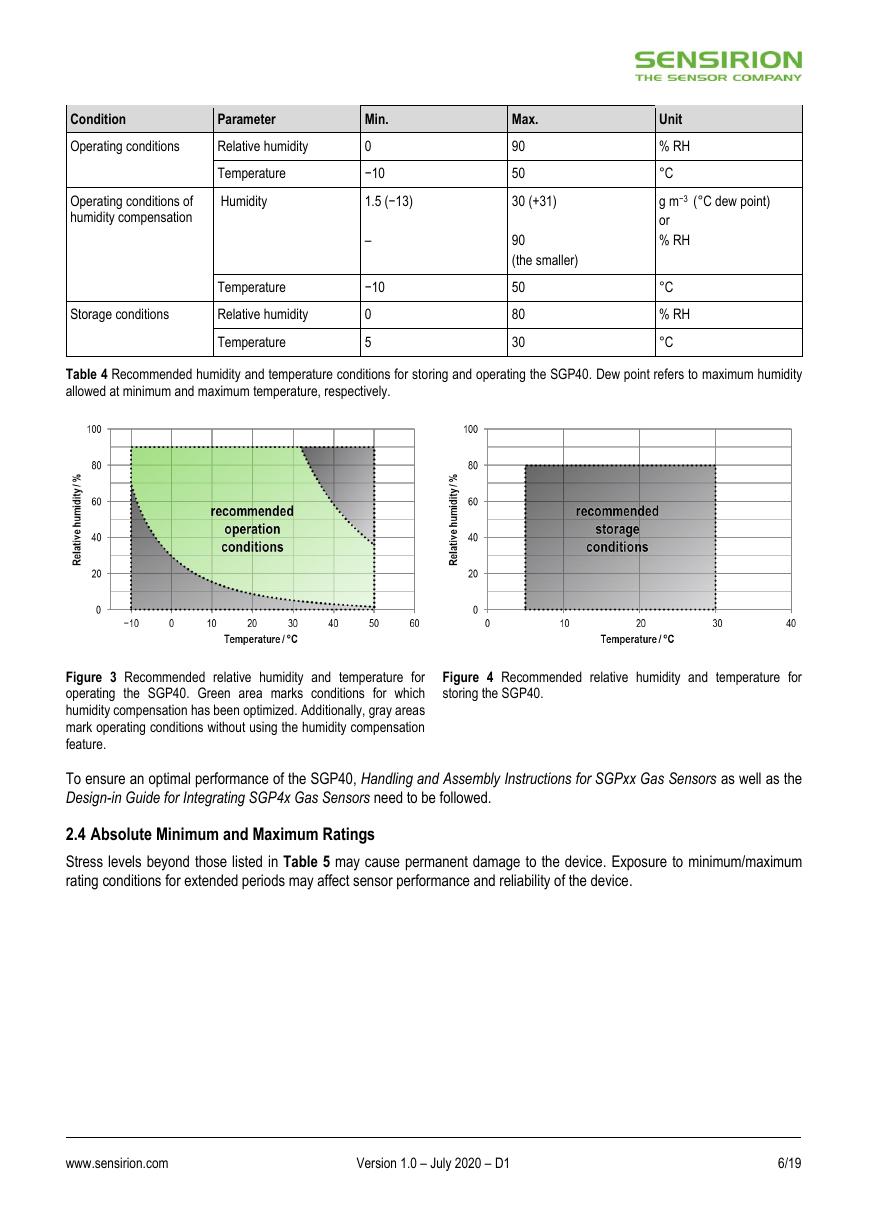

2.3 Recommended Operating and Storage Conditions

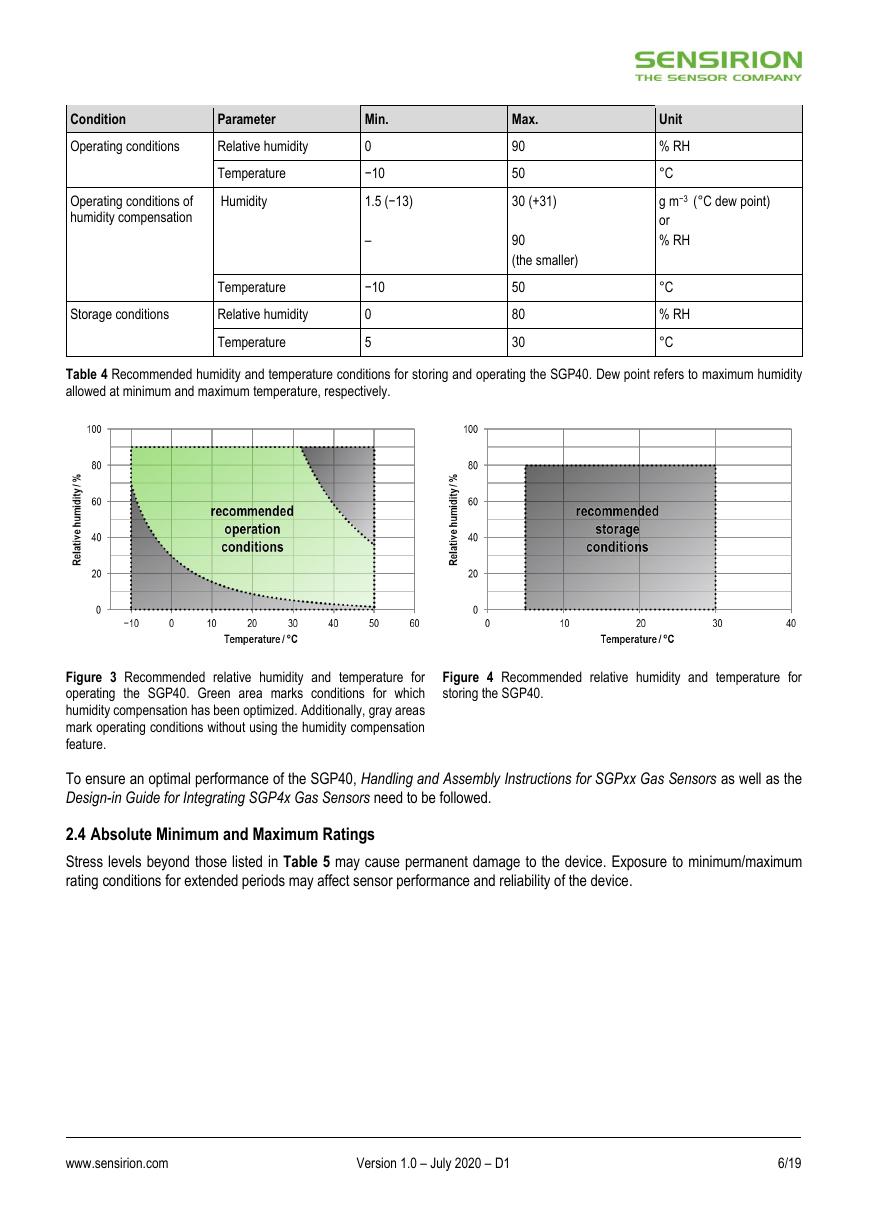

Gas Sensing Specifications as detailed in Table 1 are guaranteed only when the sensor is stored and operated under the

recommended conditions as specified in Table 4 and displayed in Figure 3 and Figure 4. Prolonged exposure to conditions

outside these conditions may reduce sensor performance. The sensor must not be exposed towards condensing conditions (i.e.,

>90 % relative humidity) at any time.

9 http://www.nxp.com/documents/user_manual/UM10204.pdf

10 Any supply voltage as defined by the min./max. range may be used for continuous operation of the sensor. The typical value specifies the supply voltage at which outgoing

quality control is performed.

11 Sending the sgp40_measure_raw command enables continuous operation of the sensor. A 20 % higher current is drawn during 5 ms on VDDH after entering the measurement

mode.

www.sensirion.com

Version 1.0 – July 2020 – D1

5/19

�

Condition

Parameter

Operating conditions

Relative humidity

Operating conditions of

humidity compensation

Temperature

Humidity

Temperature

Storage conditions

Relative humidity

Temperature

Min.

0

−10

1.5 (−13)

–

−10

0

5

Max.

90

50

30 (+31)

90

(the smaller)

50

80

30

Unit

% RH

°C

g m−3 (°C dew point)

or

% RH

°C

% RH

°C

Table 4 Recommended humidity and temperature conditions for storing and operating the SGP40. Dew point refers to maximum humidity

allowed at minimum and maximum temperature, respectively.

Figure 3 Recommended relative humidity and temperature for

operating the SGP40. Green area marks conditions for which

humidity compensation has been optimized. Additionally, gray areas

mark operating conditions without using the humidity compensation

feature.

Figure 4 Recommended relative humidity and temperature for

storing the SGP40.

To ensure an optimal performance of the SGP40, Handling and Assembly Instructions for SGPxx Gas Sensors as well as the

Design-in Guide for Integrating SGP4x Gas Sensors need to be followed.

2.4 Absolute Minimum and Maximum Ratings

Stress levels beyond those listed in Table 5 may cause permanent damage to the device. Exposure to minimum/maximum

rating conditions for extended periods may affect sensor performance and reliability of the device.

www.sensirion.com

Version 1.0 – July 2020 – D1

6/19

�

Parameter

Supply voltage VDD

Supply voltage VDDH

Short-term storage temperature range12

Operating temperature range

Rating

−0.3 to +3.6 V

−0.3 to +3.6 V

−40 to +70 °C

−20 to +55 °C

Short-term storage humidity range12

0 to 80 % (non-condensing)

Operating humidity range

0 to 90 % (non-condensing)

ESD HBM

ESD CDM

Latch up, JESD78 Class II, 125 °C

Table 5 Absolute minimum and maximum ratings.

2.5 Interface Specifications

2 kV

500 V

100 mA

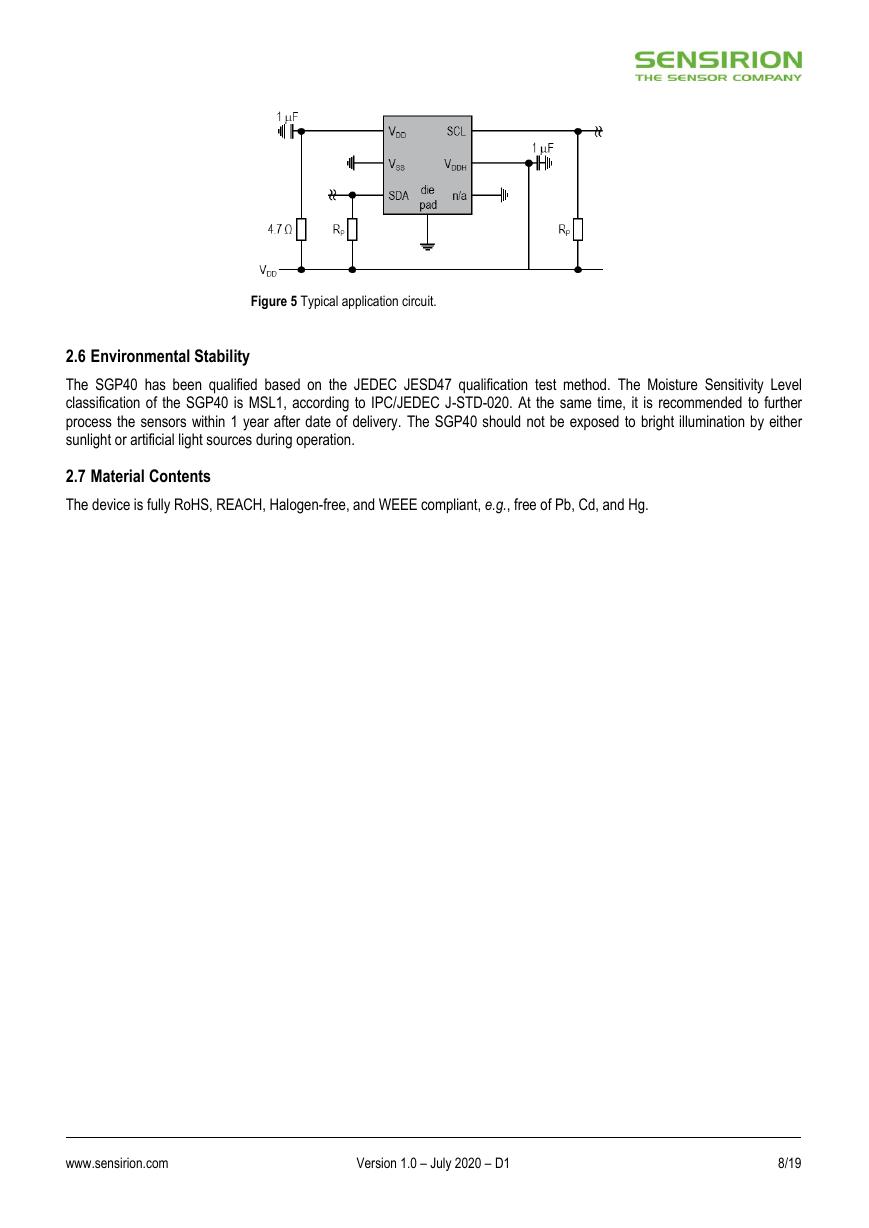

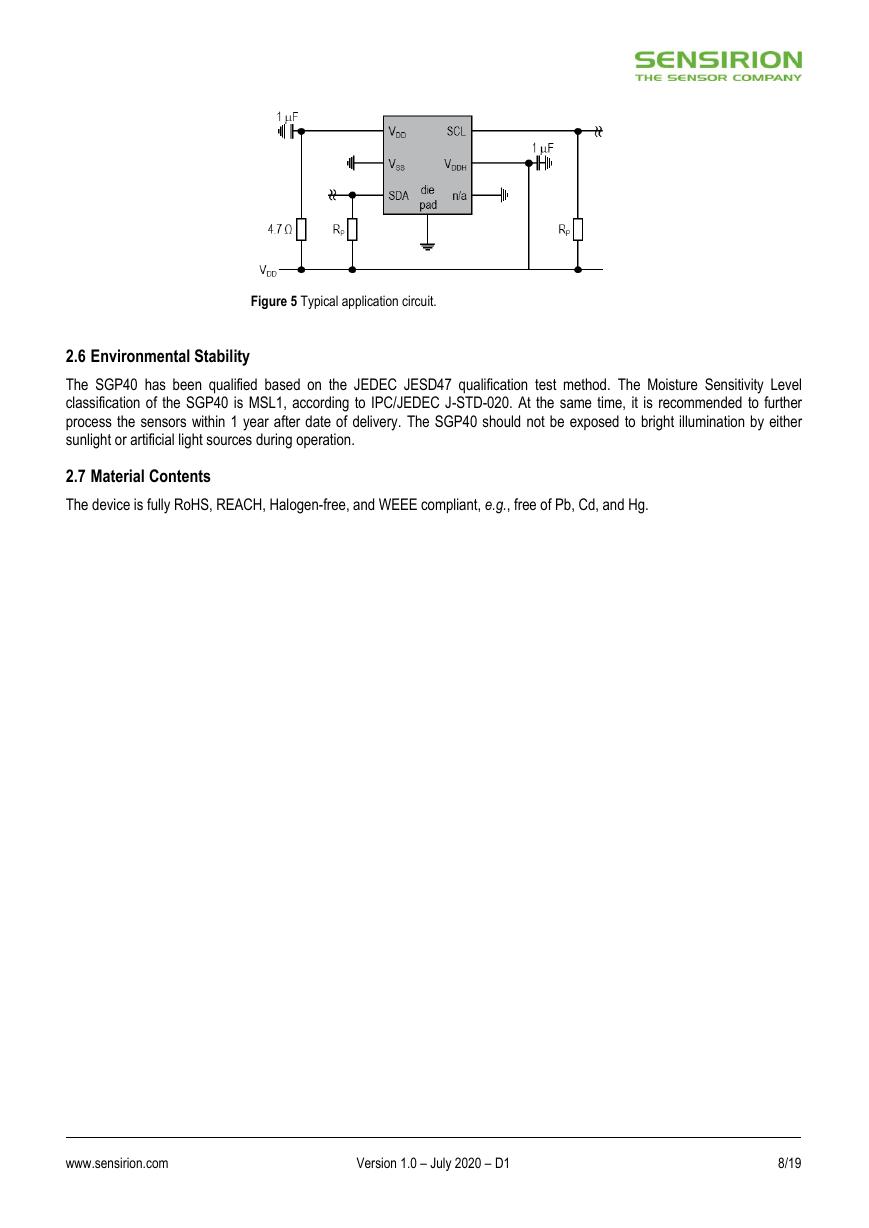

The SGP40 comes in a 6-pin DFN package, see Table 6. Figure 5 shows a typical application circuit. The VDD pin must be

decoupled with an RC element. The required decoupling for VDDH depends on the power supply network connected to the sensor,

a capacitor of 1 F is recommended. VDD and VDDH must be connected to one single supply VDD. The external pull-up resistors

(e.g., Rp = 10 k) are required to pull the SDA and SCL signal lines high. For dimensioning resistor sizes please take bus

capacity and communication frequency into account (see section 7.1 of NXPs I2C Manual for more details, see footnote 9 on

page 5). It should be noted that pull-up resistors may be included in I/O circuits of microcontrollers. The die pad or center pad is

electrically connected to GND. Hence, electrical considerations do not impose constraints on the wiring of the die pad. However,

for mechanical stability it is recommended to solder the die pad to the PCB.

Pin

Name

Comments

1

2

3

4

5

6

VDD

VSS

SDA

n/a

VDDH

SCL

Supply voltage

Ground

Serial data, bidirectional

Connect to ground (no electrical function)

Supply voltage, hotplate

Serial clock, bidirectional

Table 6 Pin assignment (transparent top view). Dashed lines are only visible from the bottom.

12 Short-term storage refers to temporary conditions during, e.g., transport.

www.sensirion.com

Version 1.0 – July 2020 – D1

7/19

�

Figure 5 Typical application circuit.

2.6 Environmental Stability

The SGP40 has been qualified based on the JEDEC JESD47 qualification test method. The Moisture Sensitivity Level

classification of the SGP40 is MSL1, according to IPC/JEDEC J-STD-020. At the same time, it is recommended to further

process the sensors within 1 year after date of delivery. The SGP40 should not be exposed to bright illumination by either

sunlight or artificial light sources during operation.

2.7 Material Contents

The device is fully RoHS, REACH, Halogen-free, and WEEE compliant, e.g., free of Pb, Cd, and Hg.

www.sensirion.com

Version 1.0 – July 2020 – D1

8/19

�

V2版本原理图(Capacitive-Fingerprint-Reader-Schematic_V2).pdf

V2版本原理图(Capacitive-Fingerprint-Reader-Schematic_V2).pdf 摄像头工作原理.doc

摄像头工作原理.doc VL53L0X简要说明(En.FLVL53L00216).pdf

VL53L0X简要说明(En.FLVL53L00216).pdf 原理图(DVK720-Schematic).pdf

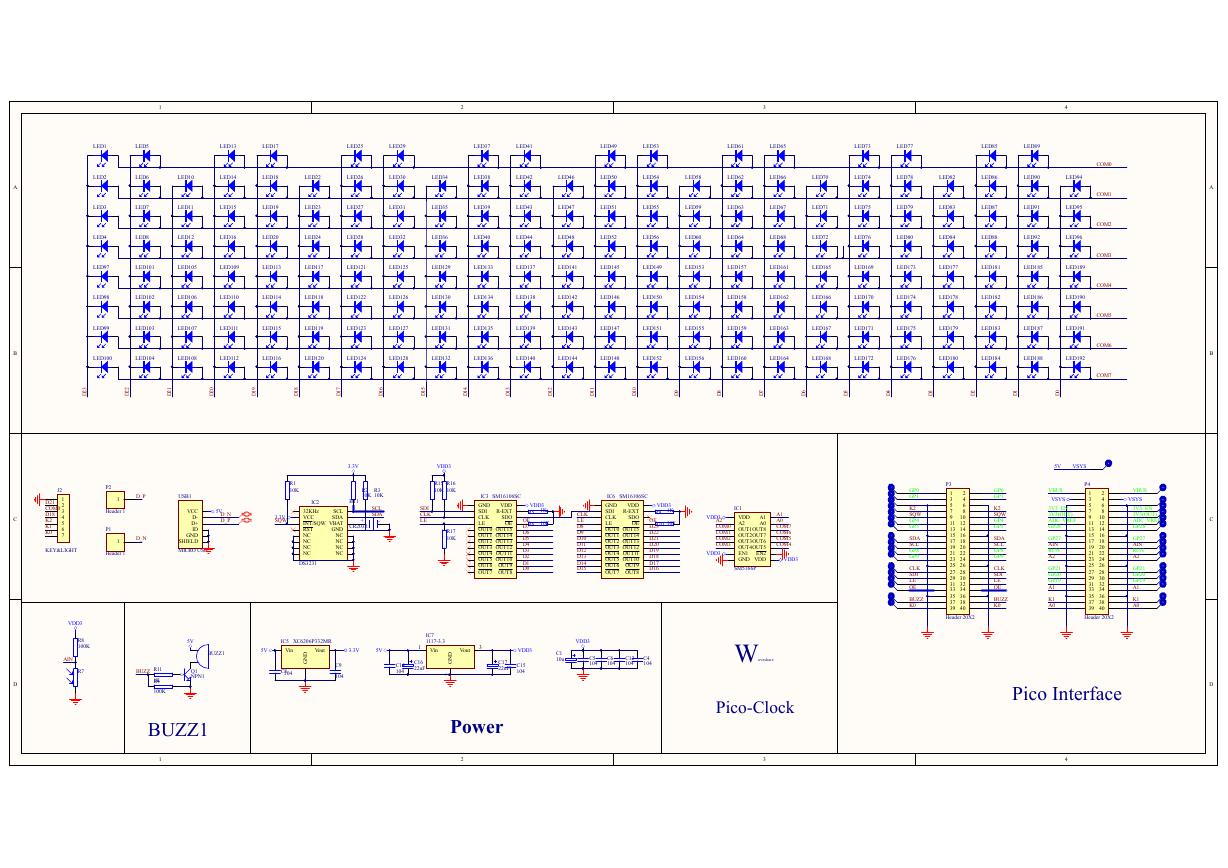

原理图(DVK720-Schematic).pdf 原理图(Pico-Clock-Green-Schdoc).pdf

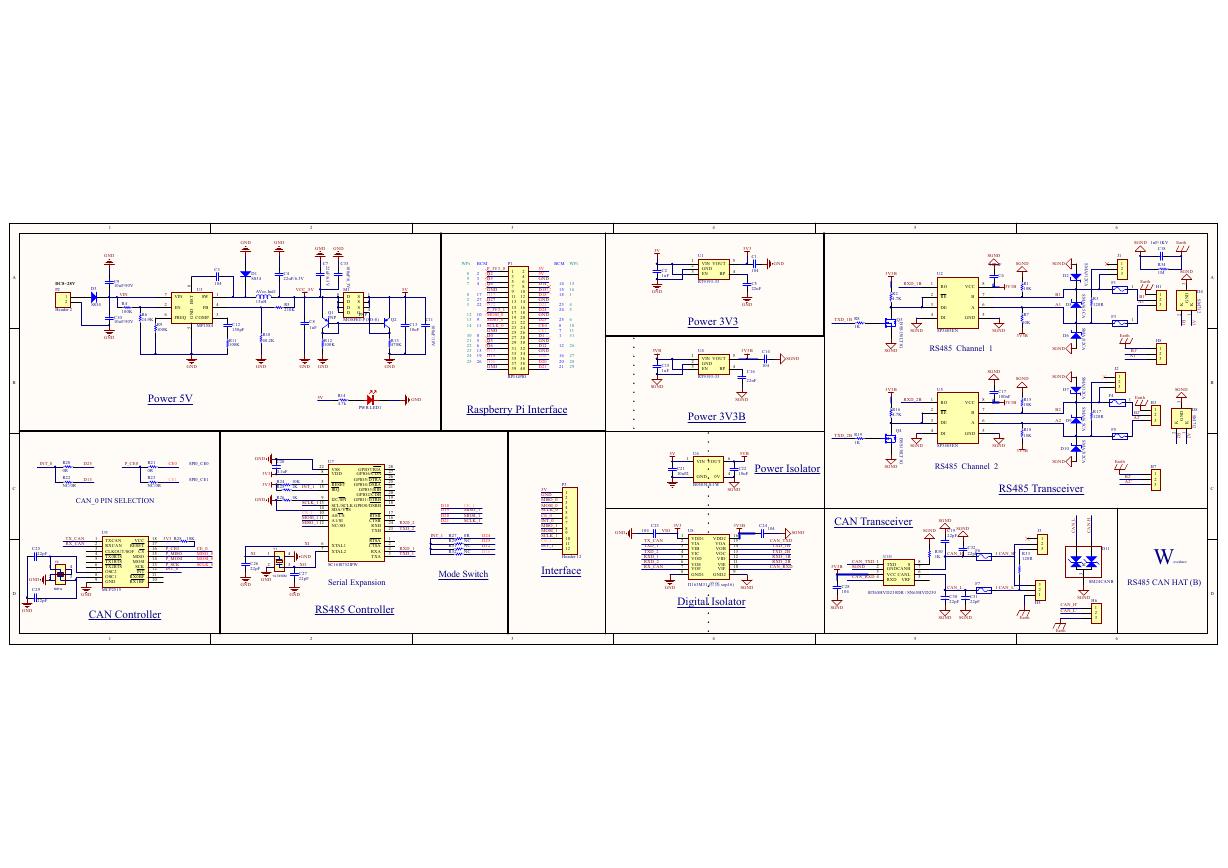

原理图(Pico-Clock-Green-Schdoc).pdf 原理图(RS485-CAN-HAT-B-schematic).pdf

原理图(RS485-CAN-HAT-B-schematic).pdf File:SIM7500_SIM7600_SIM7800 Series_SSL_Application Note_V2.00.pdf

File:SIM7500_SIM7600_SIM7800 Series_SSL_Application Note_V2.00.pdf ADS1263(Ads1262).pdf

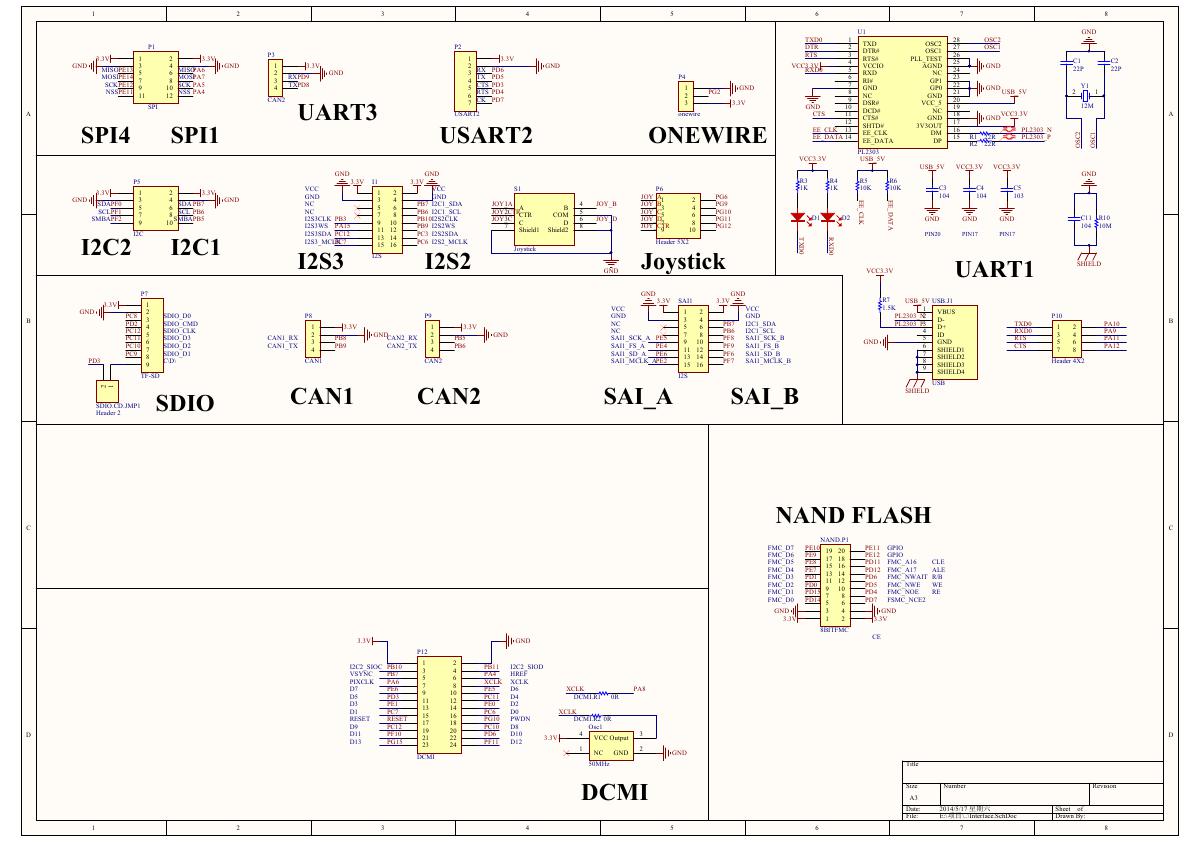

ADS1263(Ads1262).pdf 原理图(Open429Z-D-Schematic).pdf

原理图(Open429Z-D-Schematic).pdf 用户手册(Capacitive_Fingerprint_Reader_User_Manual_CN).pdf

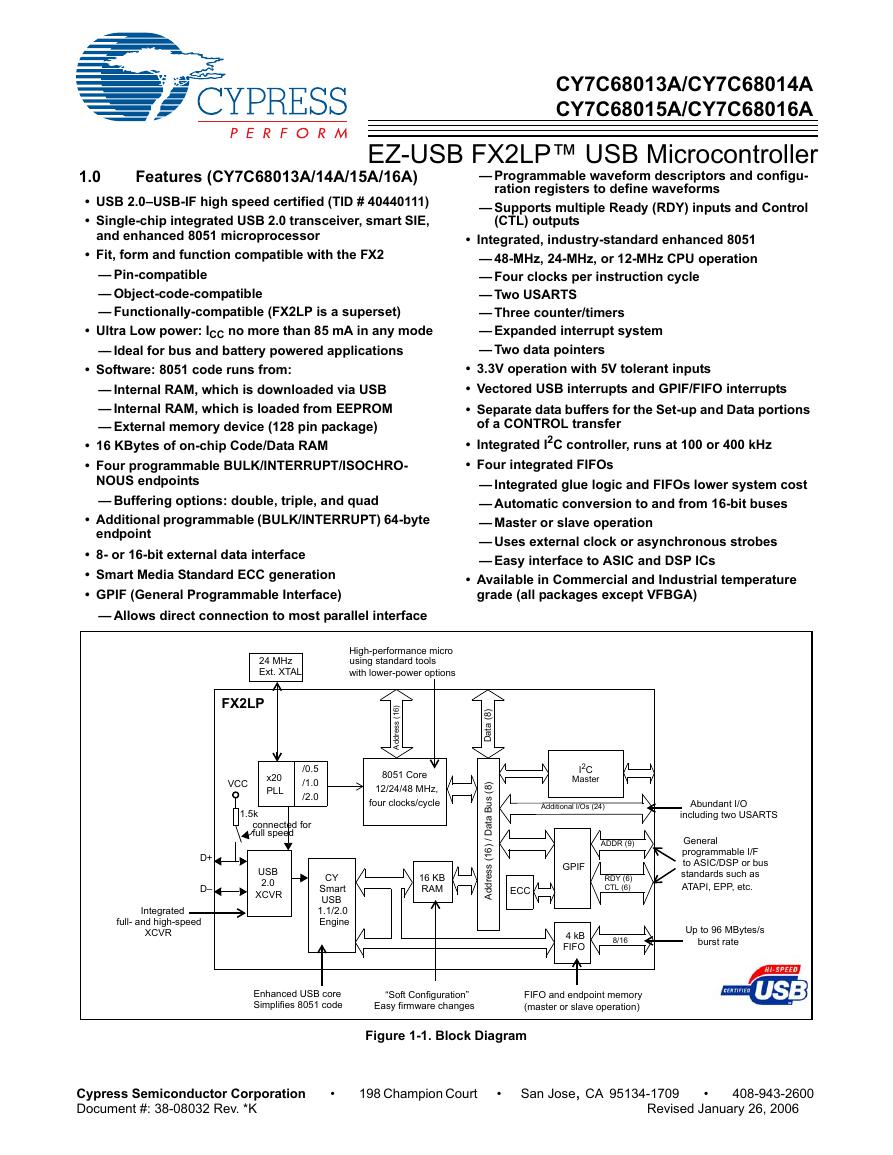

用户手册(Capacitive_Fingerprint_Reader_User_Manual_CN).pdf CY7C68013A(英文版)(CY7C68013A).pdf

CY7C68013A(英文版)(CY7C68013A).pdf TechnicalReference_Dem.pdf

TechnicalReference_Dem.pdf