�

RECORDS OF REVISION

Model No. : LS013B7DH05

SPEC No.

DATE

REVISED

No

PAGE

SUMMARY

NOTE

LCP-1113019A

2014/7/4

LD-26912A

2014/9/10

A

A

First edition

First edition (Because of the division in charge

change)

<

>

SPEC No.

MODEL No.

PAGE

LD-26912A

LS013B7DH05

1

NOTICE

○ This technical literature is the proprietary product of SHARP CORPORATION ("SHARP") and include

materials protected under copyright of SHARP. Do not reproduce or cause any third party to reproduce them

in any form or by any means, electronic or mechanical, for any purpose, in whole or in part, without the

express written permission of SHARP.

○ The application examples in this technical literature is provided to explain the representative applications of

the device and are not intended to guarantee any industrial property right or other rights or license you to use

them. SHARP assumes no responsibility for any problems related to any industrial property right of a third

party resulting from the use of the device.

○ SHARP reserves the right to make changes in the specifications, characteristics, data, materials, structures

and other contents described herein at any time without notice in order to improve design or reliability. Contact

SHARP in order to obtain the latest technical literature before using any SHARP's device. Manufacturing

locations are also subject to change without notice.

Observe the following points when in using any device in this publication. SHARP takes no responsibility

for damage caused by improper use of the devices.

The devices in this publication are designed for use in general electronic equipment designs, such as:

・Personal computers ・Office automation ・Telecommunication equipment

・Test and measurement equipment ・Industrial control

・Audio visual and multimedia equipment ・Consumer electronics

The appropriate design measures should be taken to ensure reliability and safety when SHARP's devices are

used for equipment such as:

・Transportation control and safety equipment(i.e.,aircraft,trains,automobiles,etc.)

・Traffic signals ・Gas leakage sensor breakers

・Alarm equipment ・Various safety devices etc.

○ SHARP's devices shall not be used for equipment that requires extremely high level of reliability, such as:

・Military and space applications ・Nuclear power control equipment

・Medical equipment for life support

○ SHARP assumes no responsibility for any damage resulting from the use of the device which does not

comply with the instructions and the precautions specified in this technical literature.

○ Contact and consult with a SHARP sales representative for any questions about this device.

�

SPEC No.

MODEL No.

PAGE

LD-26912A

LS013B7DH05

2

(1) Handle with care as glass is used in this LCD panel. Dropping or contact against hard object may cause

[For handling and system design]

cracks or chips.

(2) Be careful to handle this LCD panel in order to avoid injury yourself by panel`s edge as this panel is made of

glass and might be a sharp edge.

(3) Do not scratch the surface of the polarizer as it is easily damaged.

(4) Water droplets on the polarizer must be wiped off immediately as they may cause color changes, or other

defects if remained for a long time.

(5)Do not leave the LCD panel in direct sun or under ultraviolet ray.

(6) To clean LCD panel surface, wipe clean with absorbent cotton or soft cloth. If further cleaning is needed,

use IPA (isopropyl alcohol) and wipe clean lightly on surface only. Do not use organic solvents as it may

damage the LCD panel terminal area which uses organic material. Also, do not directly touch with finger.

When the terminals cleaning are needed, those should be wiped by a soft cloth or a cotton swab without

directly touching by hand.

(7) Do not expose gate driver, etc. on the panel (circuit area outside panel display area) to light as it may not

operate properly. Design that shields gate driver, etc. from light is required when mounting the LCD module.

(8) To avoid circuit failure, do not touch panel terminal area.

(9) Support for the LCD panel should be carefully designed to avoid stress that exceeds specification on glass

surface.

(10) When handling LCD module and assembling them into cabinets, be noted that storage in the environment

of oxidization or deoxidization gas and the use of such materials as reagent, solvent, adhesive, resin, and etc.

which generate these gasses, may cause corrosion and discoloration of LCD modules.

(11)To avoid picture uniformity failure, do not put a seal or an adhesive material on the panel surface.

(12) Do not use chloroprene rubber as it generates chlorine gas and affects reliability in LCD panel

connective area.

(13) Protective film is attached to the surface of polarizer on LCD panel to prevent scratches or other

damages. Remove this protective film before use. In addition, do not attach the protective film which is

removed from LCD module again. When the LCD panel which has the reattached protective film is needed

to storage for a long time, the polarizer might have a damage with picture quality failure.

(14) Panel is susceptible to mechanical stress and such stress may affect the display. Place the panel on flat

surface to avoid stress caused by twist, bend, etc.

(15) When transporting LCD panels, secure them in LCD panel tray to avoid mechanical stress. The tray

should be conductive to protect LCD panels from static charge.

Material used in set or epoxy resin (amine type hardening agent) from packaging, and silicon adhesive

(dealcoholized or oxime) all release gas which may affect quality of polarizer. Do confirm compatibility

with user materials.

�

SPEC No.

MODEL No.

PAGE

LD-26912A

LS013B7DH05

3

(16) As this LCD module is composed electronic circuits, it is sensitive to electrostatic discharge of 200V or

more. Handle with care using cautions for the followings:

Operators

Operators must wear anti-static wears to prevent electrostatic charge up to and discharge from

human body.

Equipment and containers

Process equipment such as conveyer, soldering iron, working bench and containers may possibly

generate electrostatic charge up and discharge. Equipment must be grounded through 100Mohms

resistance. Use ion blower.

Floor

Floor plays an important role in leaking static electricity generated in human body or equipment. If

the floor is made of insulated material (such as polymer or rubber material), such static electricity

may charge. Proper measure should be taken to avoid static electricity charge (electrostatic earth:

100Mohms).There is a possibility that the static electricity is charged to them without leakage in case

of insulating floor, so the electrostatic earth:1×108Ω should be made.

Humidity

Humidity in work area relates to surface resistance of the persons or objects that

generate electrostatics, and it can be manipulated to prevent electrostatic charge.

Humidity of 40% or lower increases electrostatic earth resistance and promotes

electrostatic charging. Therefore, the humidity in the work area should be kept above

40%. Specifically for film peeling process or processes that require human hands,

humidity should be kept above 50% and use electricity removal blower.

Transportation/Storage

Containers and styroform used in transporation and storage may charge electrostatic (from friction

and peeling) or electrostatic charge from human body, etc. may cause containers and styroform to

have induced charge. Proper electrostatic measure should be taken for containers and storage

material.

�

SPEC No.

MODEL No.

PAGE

LD-26912A

LS013B7DH05

4

(1) Do not operate the LCD panel under outside of electrical specification. Otherwise LCD panel may be

[For operating LCD module]

damaged.

(2) Do not use the LCD panel under outside of specified driving timing chart. Otherwise LCD panel may not

have proper picture quality.

(3) A still image should be displayed less than two hours, if it is necessary to display still image longer than

two hour, display image data must be refreshed in order to avoid sticking image on LCD panel.

(4) If LCD module takes a static electricity, as the display image which is written into pixel memory might not

be displayed, Data update should be executed frequently.

(5) It is neither a breakdown nor a defective indication though very slight change in black level might be

periodically seen in a black part on the black display image according to the source of light (angle of the

luminance and the source of light).

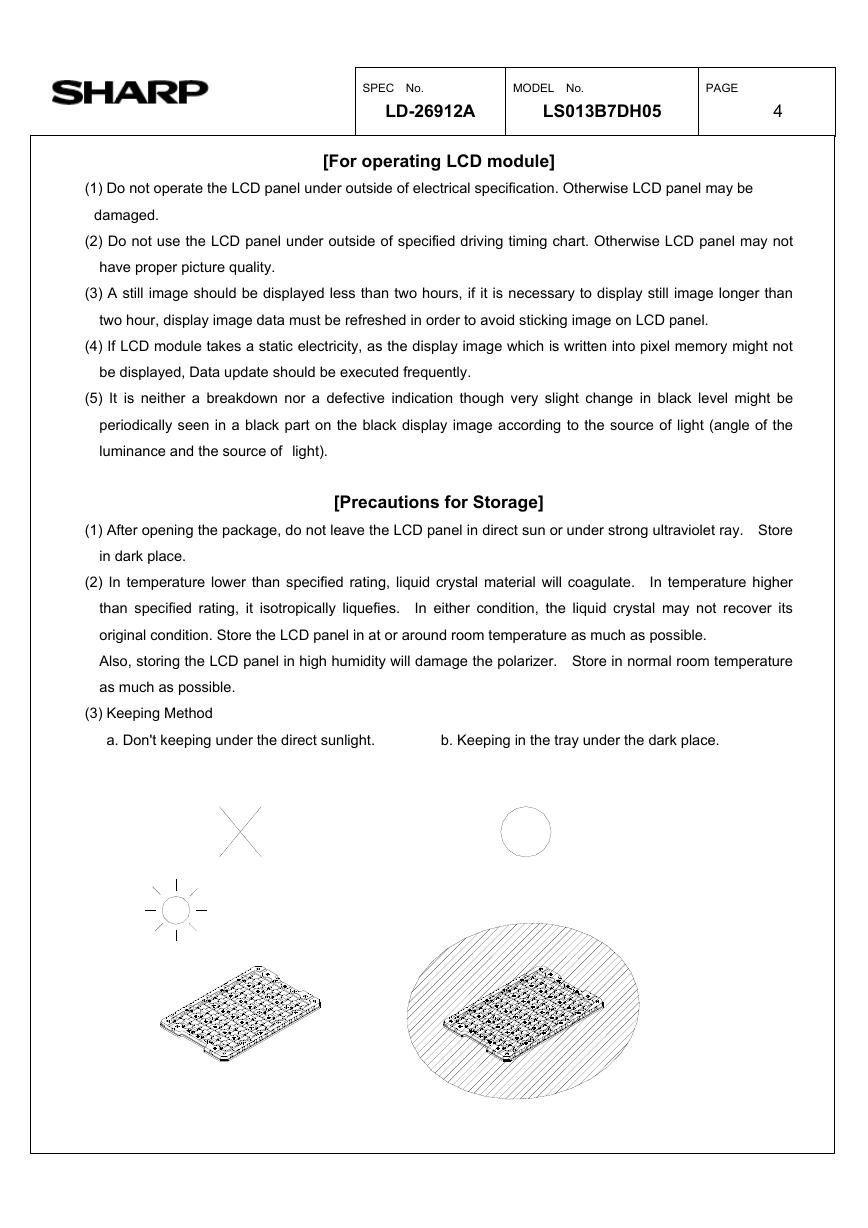

[Precautions for Storage]

(1) After opening the package, do not leave the LCD panel in direct sun or under strong ultraviolet ray. Store

in dark place.

(2) In temperature lower than specified rating, liquid crystal material will coagulate. In temperature higher

than specified rating, it isotropically liquefies. In either condition, the liquid crystal may not recover its

original condition. Store the LCD panel in at or around room temperature as much as possible.

Also, storing the LCD panel in high humidity will damage the polarizer. Store in normal room temperature

as much as possible.

(3) Keeping Method

a. Don't keeping under the direct sunlight. b. Keeping in the tray under the dark place.

�

SPEC No.

MODEL No.

PAGE

LD-26912A

LS013B7DH05

5

[Other Notice]

(1) Operation outside specified environmental conditions cannot be guaranteed.

(2) As power supply (VDD-GND、VDDA-GND) impedance is lowered during use, bus controller should be

inserted near LCD module as much as possible.

(3) Polarizer is applied over LCD panel surface. Liquid crystal inside LCD panel deteriorates with ultraviolet

ray. The panel should not be left in direct sun or under strong ultraviolet ray for prolonged period of time

even with the polarizer.

(4) Disassembling the LCD module will cause permanent damage to the module. Do not disassemble the

module.

(5) If LCD panel is broken, do not ingest the liquid crystal from the broken panel. If hand, leg, or clothes

come in contact with liquid crystal, wash off immediately with soap.

(6) ODS (specific chlorofuorocarbon, specific halon, 1-1-1 trichloroethane, carbon tetrachloride) are not used

or contained in material or all production processes of this product.

(7) Observe all other precautionary requirements in handling general electronic components.

LCD Panel:

Discarding liquid crystal modules

Dispose of as glass waste. This LCD module contains no harmful substances.

The liquid crystal panel contains no dangerous or harmful substances.

This liquid crystal panel contains only an extremely small amount of

liquid crystal (approximately 100mg) and therefore it will not leak

even if the panel should break.

Its median lethal dose (LD50) is greater than 2,000 mg/kg and a mutagenetic

(Aims test: negative) material is used.

�

SPEC No.

MODEL No.

PAGE

LD-26912A

LS013B7DH05

6

Contents

1. Outline .............................................................................................................................................................. 7

2. Characteristics ................................................................................................................................................ 7

3. Mechanical Specification ................................................................................................................................ 7

4. Input terminal names and functions ............................................................................................................. 8

6. Electrical characteristics .............................................................................................................................. 10

7. Optical characteristics .................................................................................................................................. 21

8. Module outline ............................................................................................................................................... 23

9. External capacitors ....................................................................................................................................... 24

10. Marking ......................................................................................................................................................... 24

12. Packaging .................................................................................................................................................... 25

13. Reliability Test Conditions ......................................................................................................................... 27

�

V2版本原理图(Capacitive-Fingerprint-Reader-Schematic_V2).pdf

V2版本原理图(Capacitive-Fingerprint-Reader-Schematic_V2).pdf 摄像头工作原理.doc

摄像头工作原理.doc VL53L0X简要说明(En.FLVL53L00216).pdf

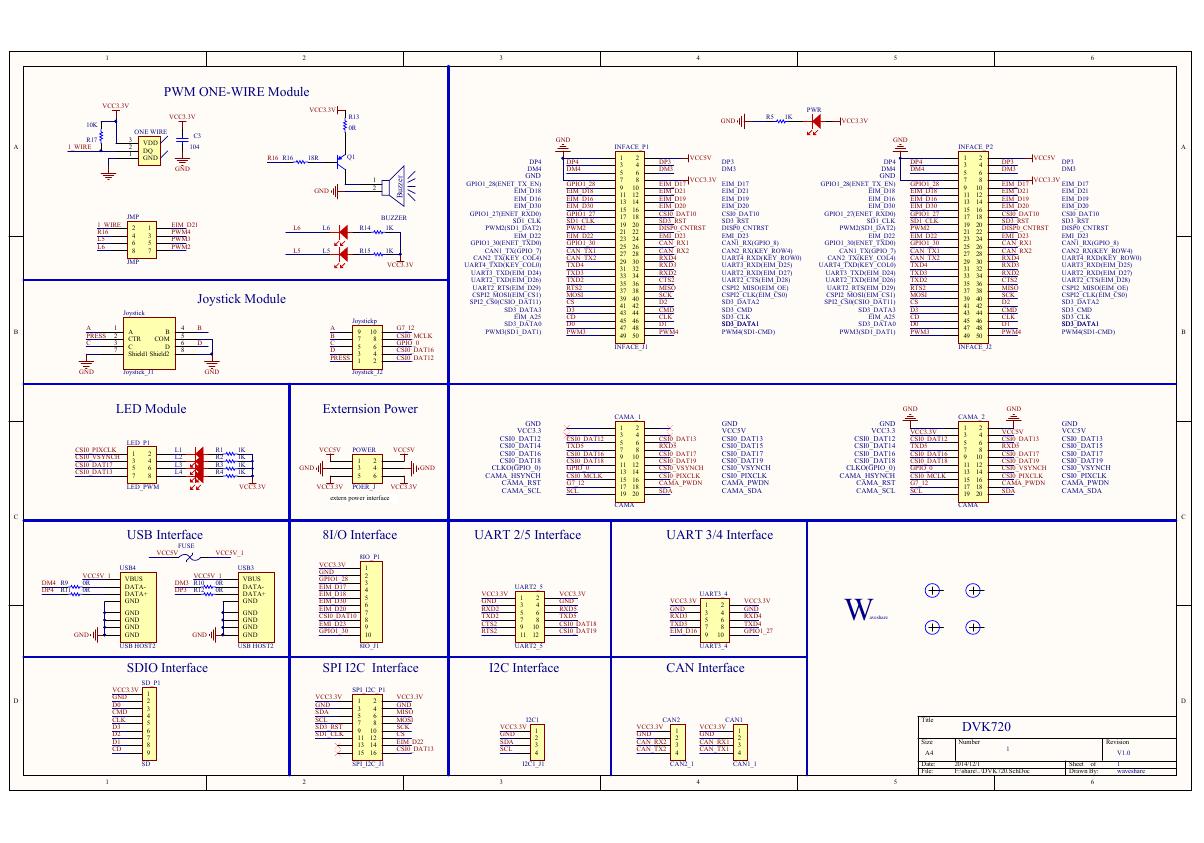

VL53L0X简要说明(En.FLVL53L00216).pdf 原理图(DVK720-Schematic).pdf

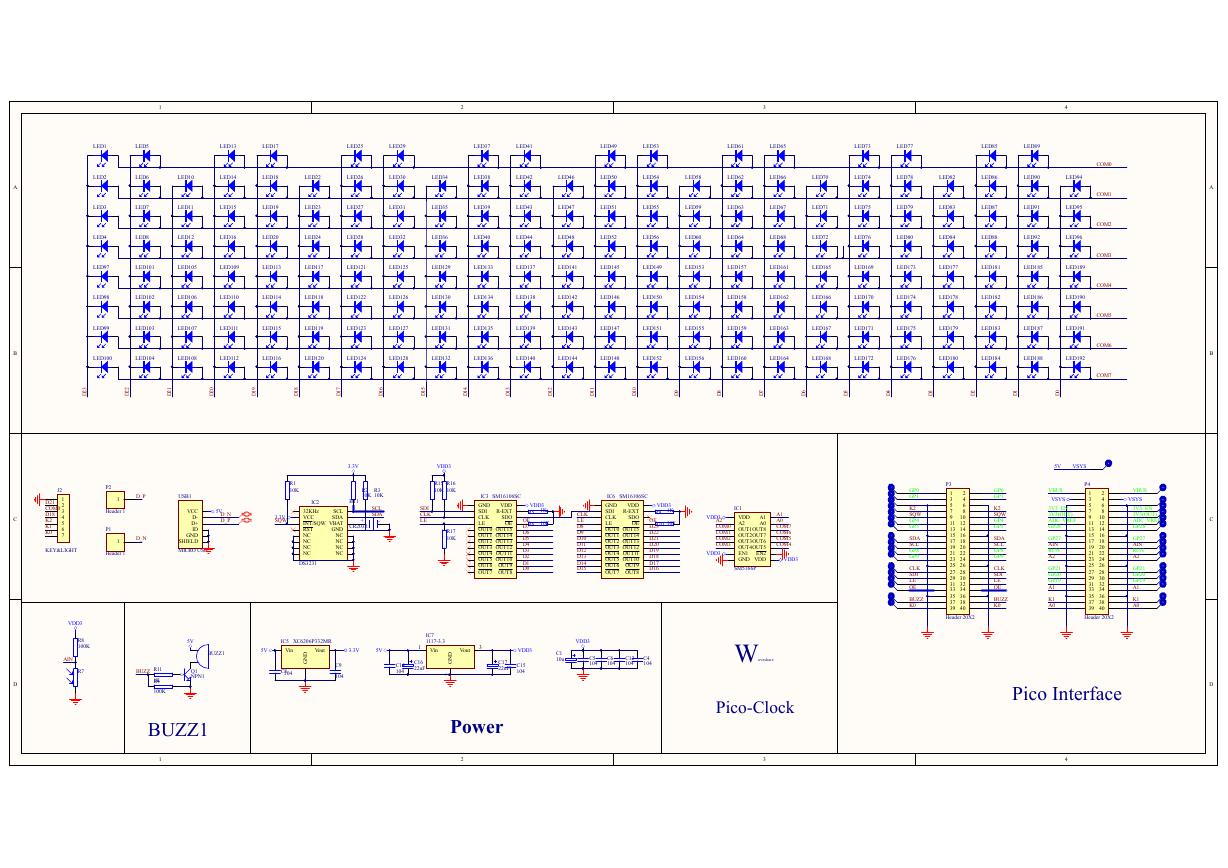

原理图(DVK720-Schematic).pdf 原理图(Pico-Clock-Green-Schdoc).pdf

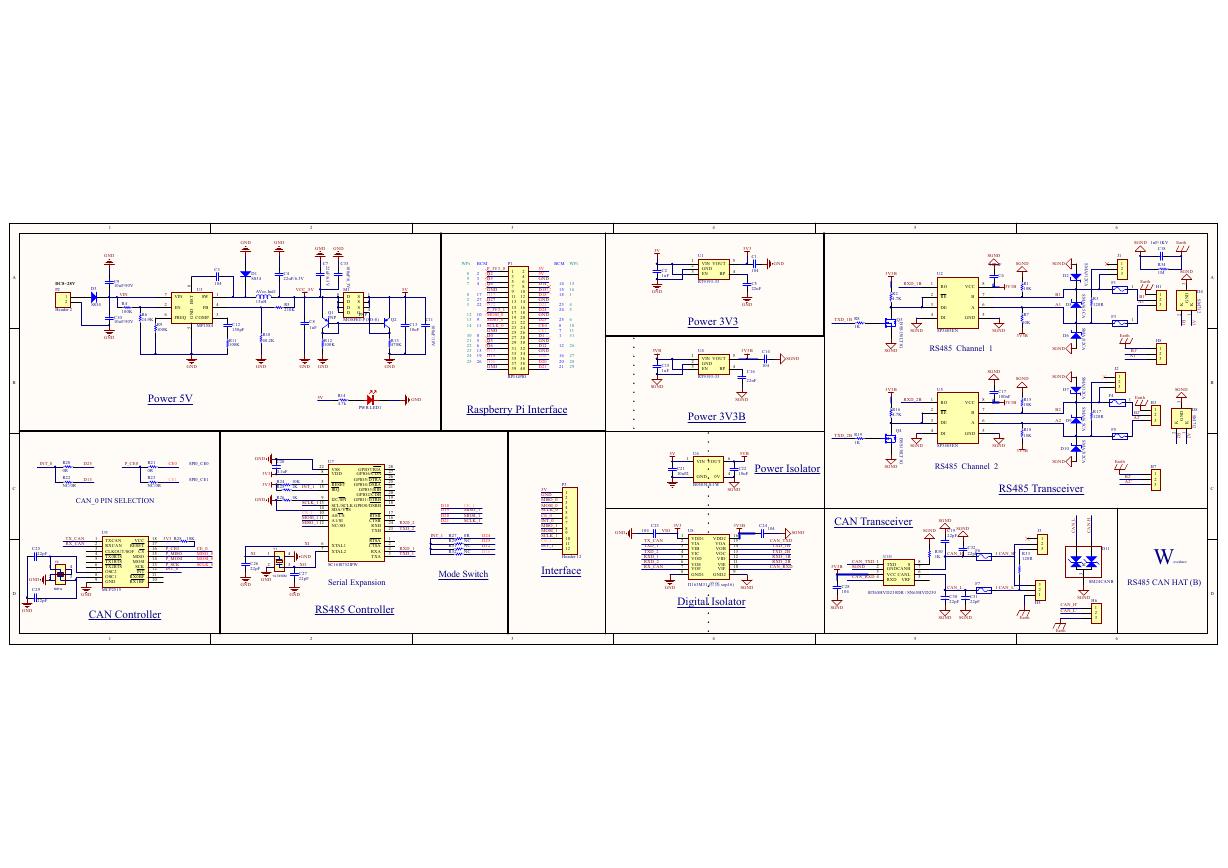

原理图(Pico-Clock-Green-Schdoc).pdf 原理图(RS485-CAN-HAT-B-schematic).pdf

原理图(RS485-CAN-HAT-B-schematic).pdf File:SIM7500_SIM7600_SIM7800 Series_SSL_Application Note_V2.00.pdf

File:SIM7500_SIM7600_SIM7800 Series_SSL_Application Note_V2.00.pdf ADS1263(Ads1262).pdf

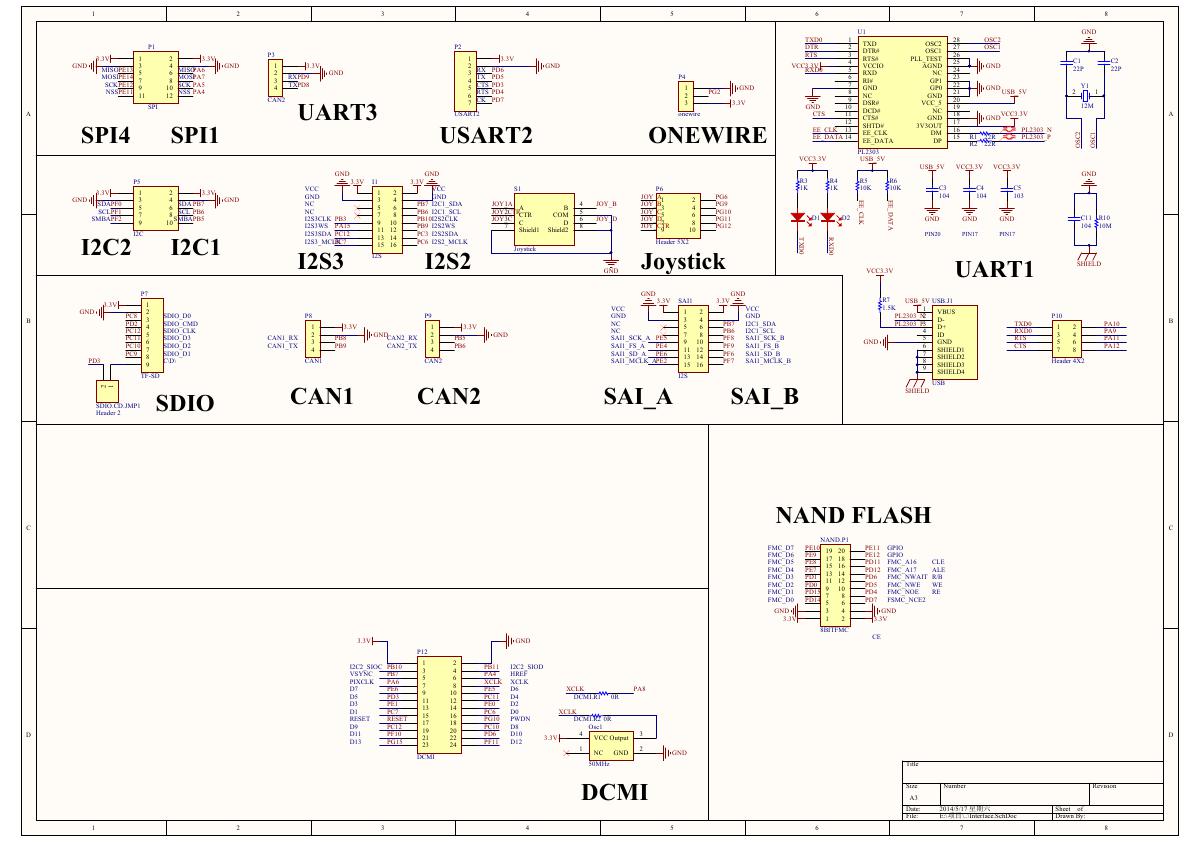

ADS1263(Ads1262).pdf 原理图(Open429Z-D-Schematic).pdf

原理图(Open429Z-D-Schematic).pdf 用户手册(Capacitive_Fingerprint_Reader_User_Manual_CN).pdf

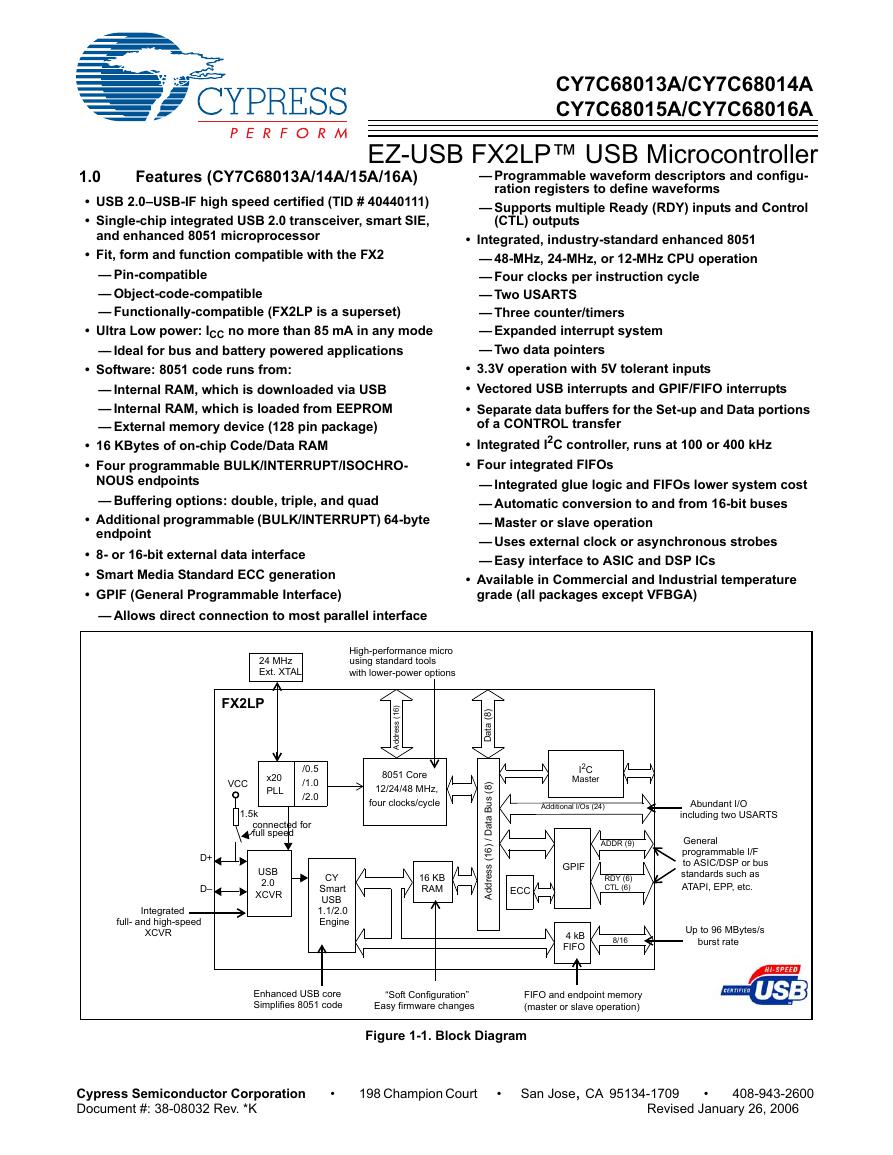

用户手册(Capacitive_Fingerprint_Reader_User_Manual_CN).pdf CY7C68013A(英文版)(CY7C68013A).pdf

CY7C68013A(英文版)(CY7C68013A).pdf TechnicalReference_Dem.pdf

TechnicalReference_Dem.pdf