WS2812B LED

Intelligent control LED integrated light source

WORLDSEMI CO.,LIMITED

WS2812B Datasheet and Specifications

Intelligent control LED integrated light source

Jan,2016

V1.0

1/9

�

WS2812B LED

Intelligent control LED integrated light source

Features and Benefits

Intelligent reverse connect protection, the power supply reverse connection does not damage the IC.

The control circuit and the LED share the only power source.

Control circuit and RGB chip are integrated in a package of 5050 components, form a complete control of pixel

point.

Built-in signal reshaping circuit, after wave reshaping to the next driver, ensure wave-form distortion not

accumulate.

Built-in electric reset circuit and power lost reset circuit.

Each pixel of the three primary color can achieve 256 brightness display, completed 16777216 color full color

display, and scan frequency not less than 400Hz/s.

Cascading port transmission signal by single line.

Any two point the distance more than 5m transmission signal without any increase circuit.

When the refresh rate is 30fps, cascade number are not less than1024 points.

Send data at speeds of 800Kbps.

The color of the light were highly consistent, cost-effective..

Applications

Full-color module, Full color soft lights a lamp strip.

LED decorative lighting, Indoor/outdoor LED video irregular screen.

General description

WS2812B is a intelligent control LED light source that the control circuit and RGB chip are integrated in

a package of 5050 components. It internal include intelligent digital port data latch and signal reshaping ampli

fication drive circuit. Also include a precision internal oscillator and a 12V voltage programmable constant curr

e-nt control part, effectively ensuring the pixel point light color height consistent.

The data transfer protocol use single NZR communication mode. After the pixel power-on reset, the DIN

port receive data from controller, the first pixel collect initial 24bit data then sent to the internal data latch,

the other data which reshaping by the internal signal reshaping amplification circuit sent to the next cascade

pixel through the DO port. After transmission for each pixel,the signal to reduce 24bit. pixel adopt auto resha

-ping transmit technology, making the pixel cascade number is not limited the signal transmission, only depend

on the speed of signal transmission.

LED with low driving voltage, environmental protection and energy saving, high brightness, scattering angl

e is large, good consistency, low power, long life and other advantages. The control chip integrated in LED

above becoming more simple circuit, small volume, convenient installation.

2/9

�

WS2812B LED

Intelligent control LED integrated light source

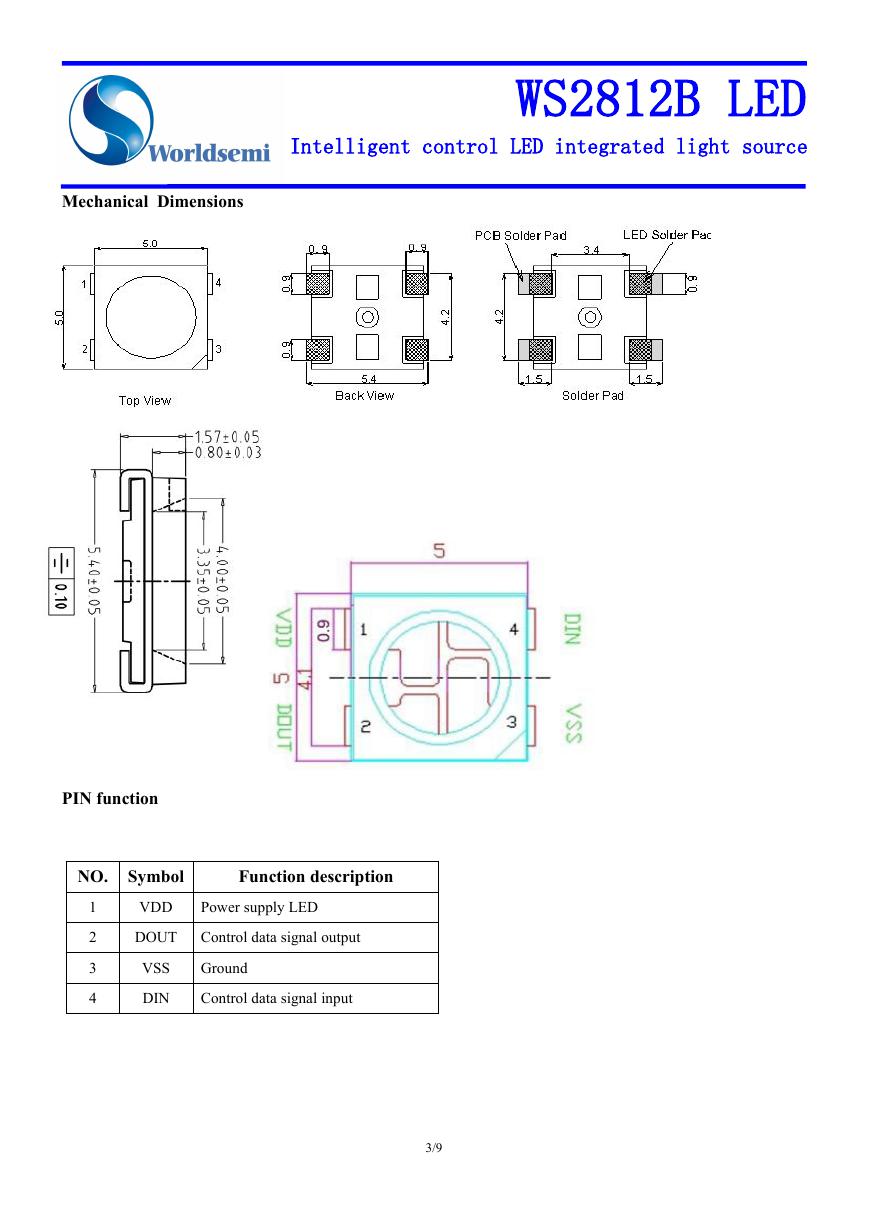

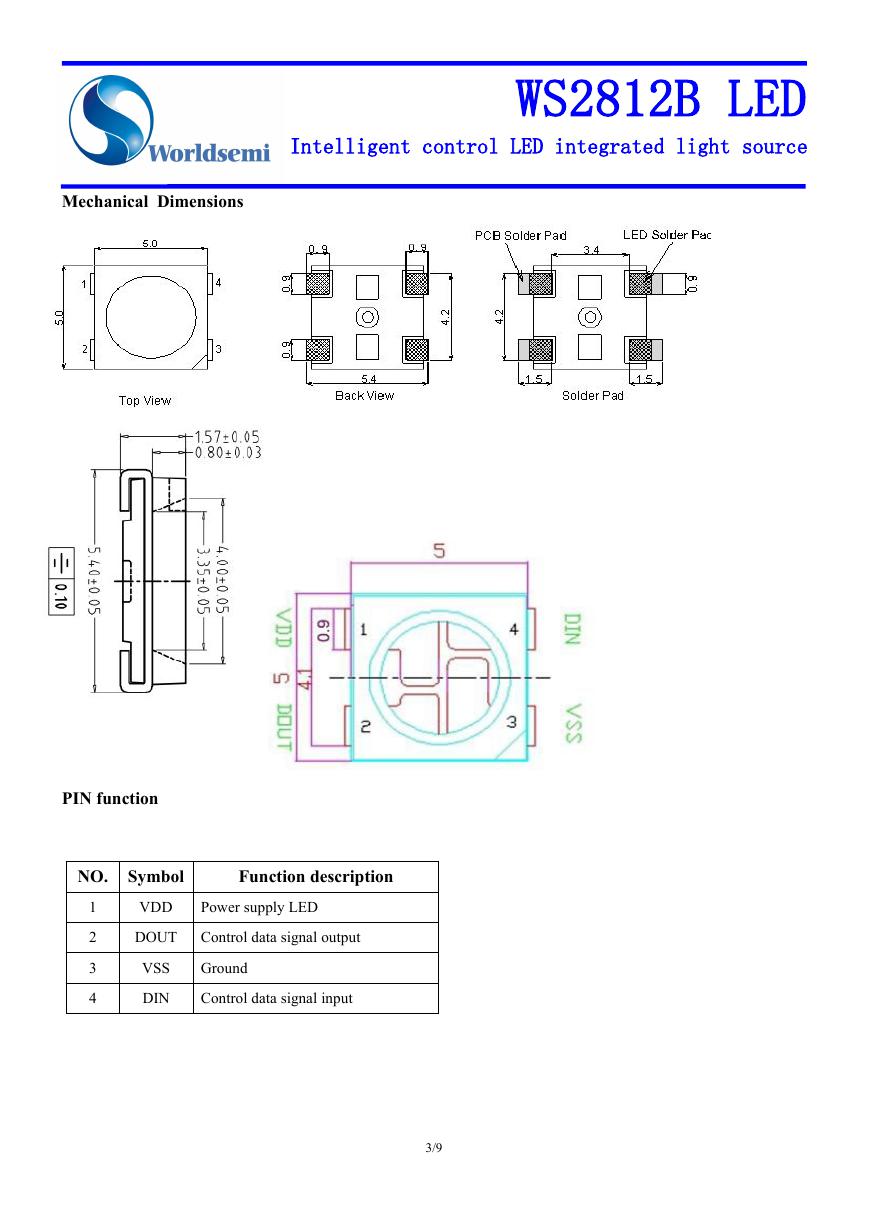

Mechanical Dimensions

PIN configuration

PIN function

NO.

1

Symbol

VDD

Function description

Power supply LED

2

3

4

DOUT

Control data signal output

VSS

DIN

Ground

Control data signal input

3/9

�

WS2812B LED

Intelligent control LED integrated light source

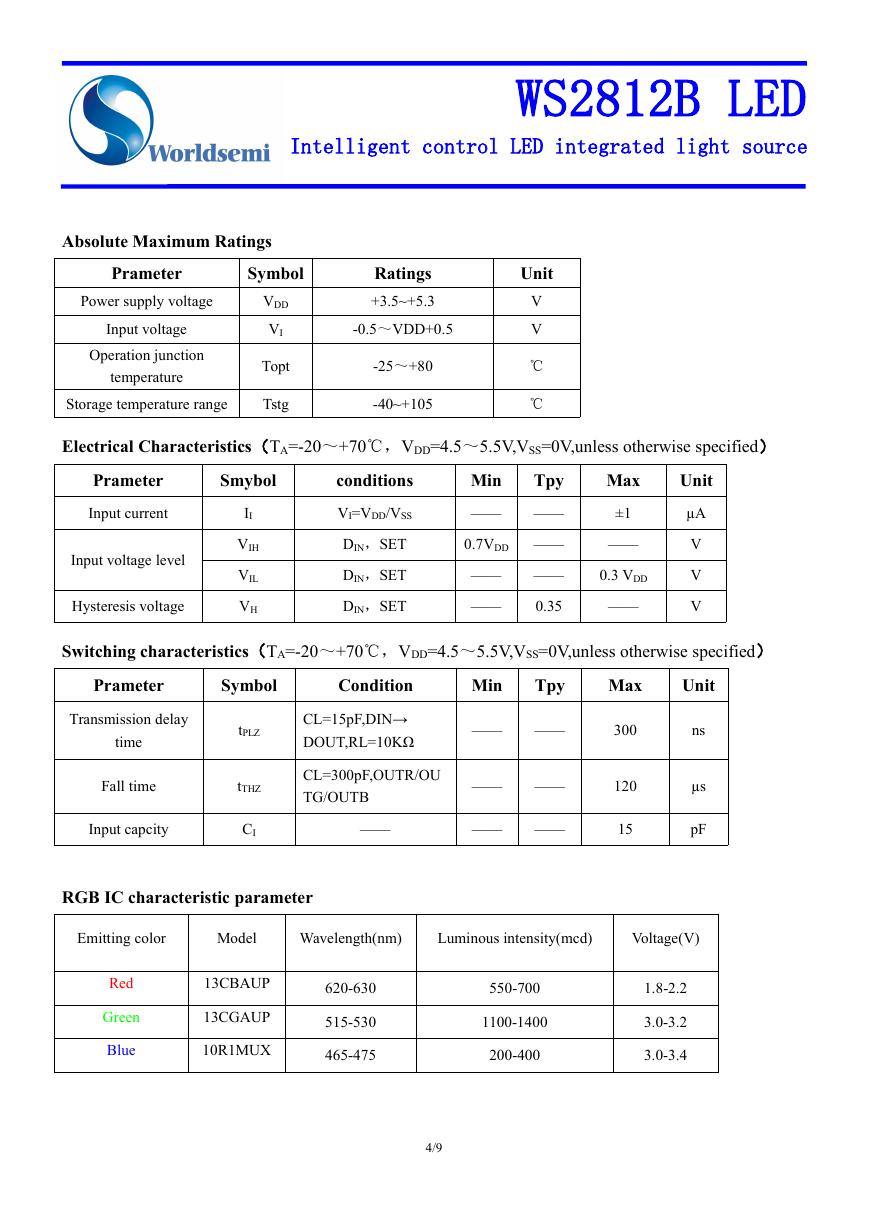

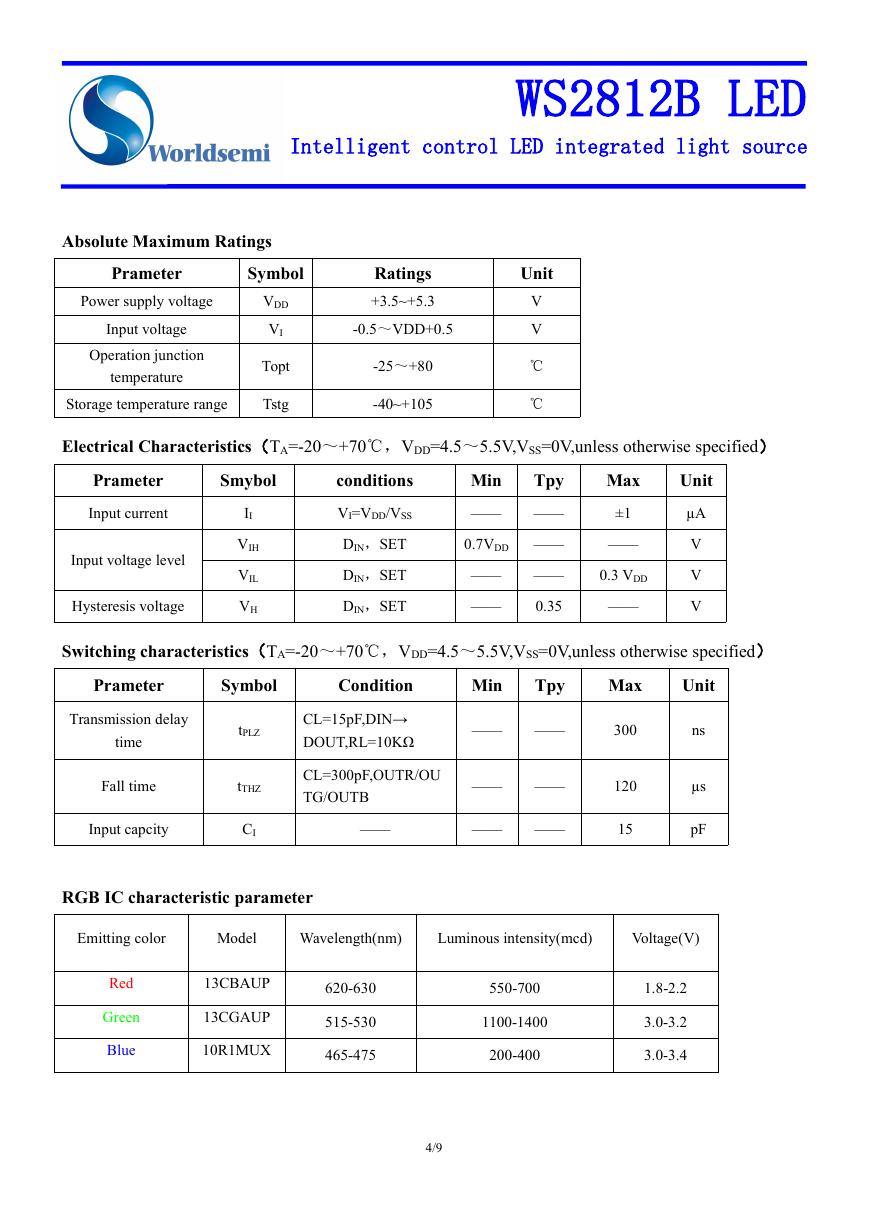

Absolute Maximum Ratings

Prameter

Symbol

Power supply voltage

Input voltage

Operation junction

temperature

Storage temperature range

VDD

VI

Topt

Tstg

Ratings

+3.5~+5.3

-0.5~VDD+0.5

-25~+80

-40~+105

Unit

V

V

℃

℃

Electrical Characteristics(TA=-20~+70℃,VDD=4.5~5.5V,VSS=0V,unless otherwise specified)

Prameter

Input current

Input voltage level

Hysteresis voltage

Smybol

II

VIH

VIL

VH

conditions

VI=VDD/VSS

DIN,SET

DIN,SET

DIN,SET

Min

——

Tpy

——

0.7VDD ——

——

——

——

0.35

Max

±1

——

0.3 VDD

——

Unit

µA

V

V

V

Switching characteristics(TA=-20~+70℃,VDD=4.5~5.5V,VSS=0V,unless otherwise specified)

Prameter

Symbol

Condition

Min

Tpy

Max

Unit

Transmission delay

time

Fall time

Input capcity

tPLZ

tTHZ

CI

CL=15pF,DIN→

DOUT,RL=10KΩ

CL=300pF,OUTR/OU

TG/OUTB

——

——

——

——

——

——

——

300

120

15

ns

µs

pF

RGB IC characteristic parameter

Emitting color

Model

Wavelength(nm)

Luminous intensity(mcd)

Voltage(V)

Red

Green

Blue

13CBAUP

13CGAUP

10R1MUX

620-630

515-530

465-475

550-700

1100-1400

200-400

1.8-2.2

3.0-3.2

3.0-3.4

4/9

�

WS2812B LED

Intelligent control LED integrated light source

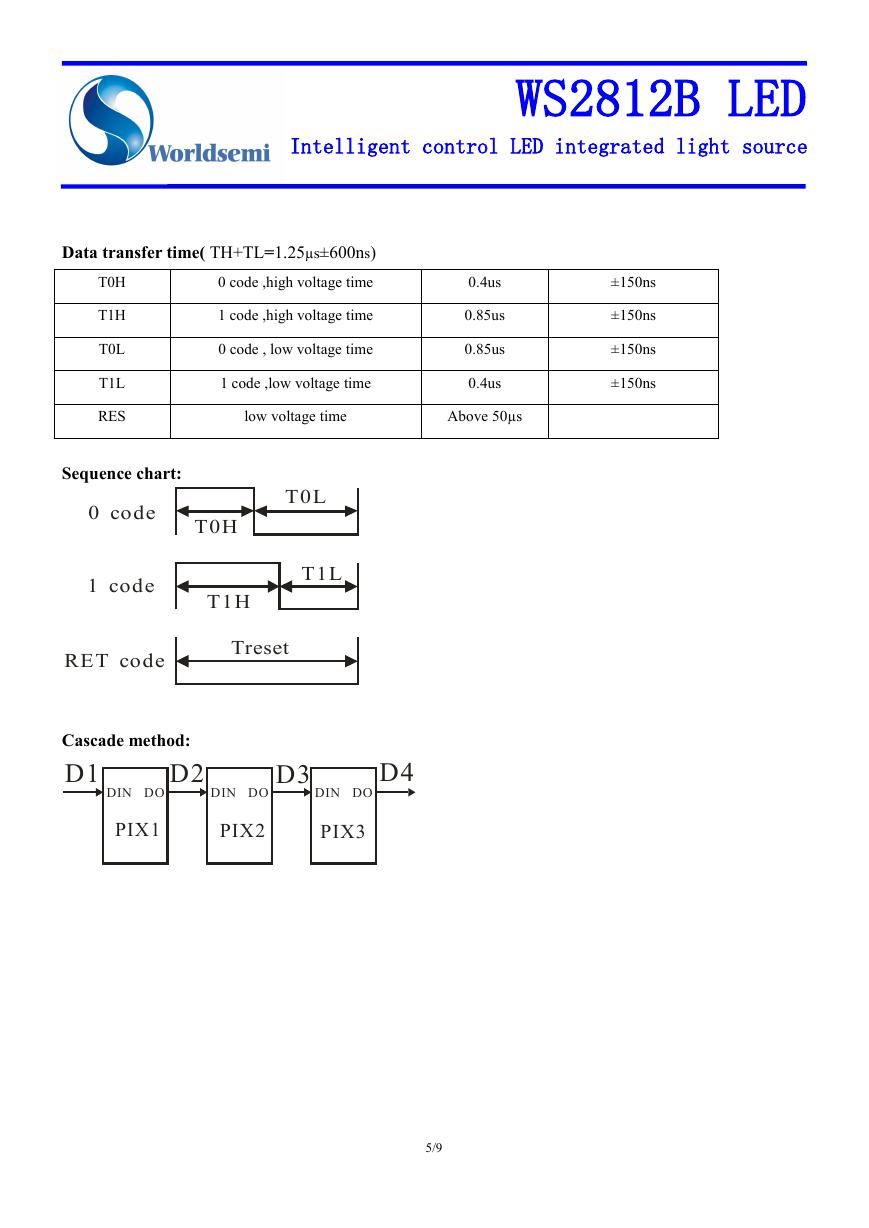

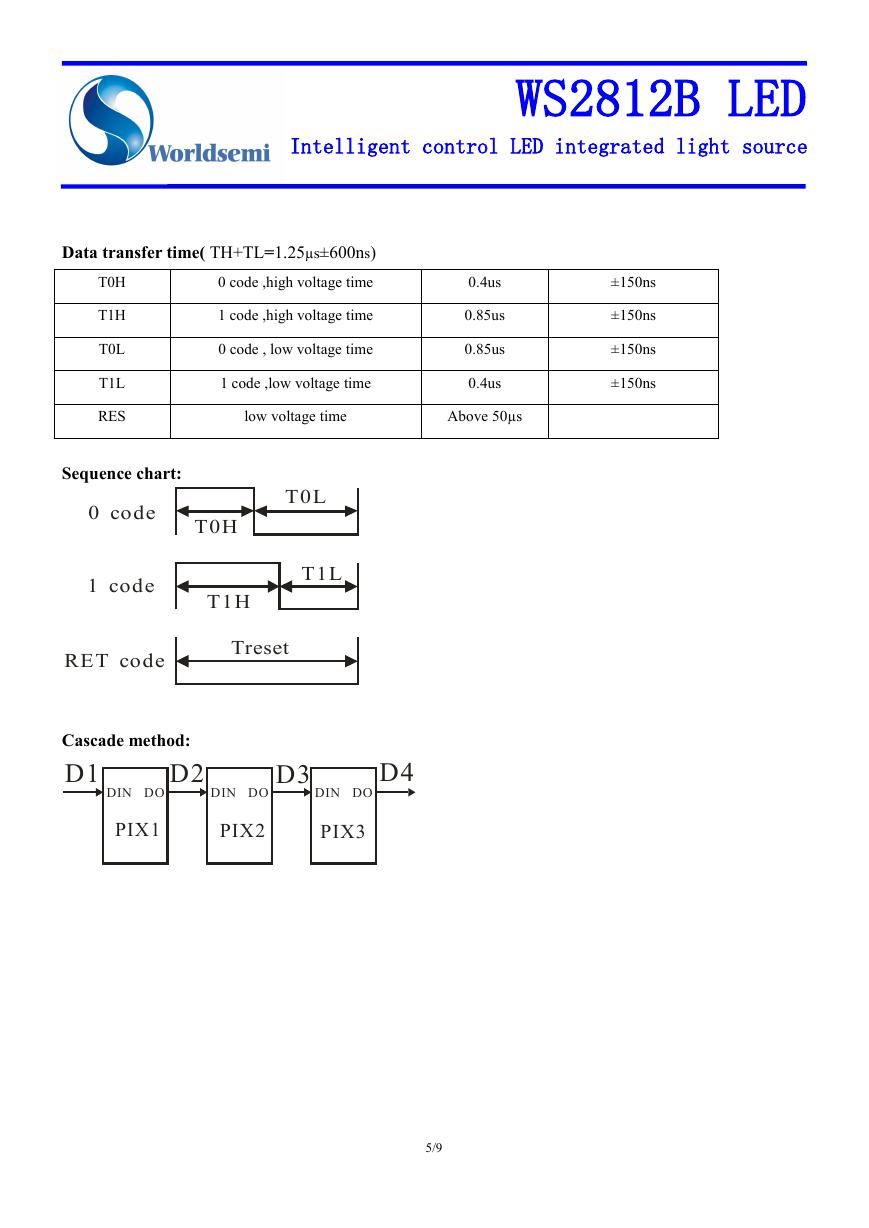

Data transfer time( TH+TL=1.25µs±600ns)

0 code ,high voltage time

T0H

1 code ,high voltage time

0 code , low voltage time

1 code ,low voltage time

0.4us

0.85us

0.85us

0.4us

±150ns

±150ns

±150ns

±150ns

T1H

T0L

T1L

RES

Sequence chart:

0 code

T0H

1 code

RET code

Cascade method:

D1

D2

DIN

DO

PIX1

low voltage time

Above 50µs

T0L

T1L

T1H

Treset

D4

D3

DIN

DO

PIX3

DIN

DO

PIX2

5/9

�

WS2812B LED

Intelligent control LED integrated light source

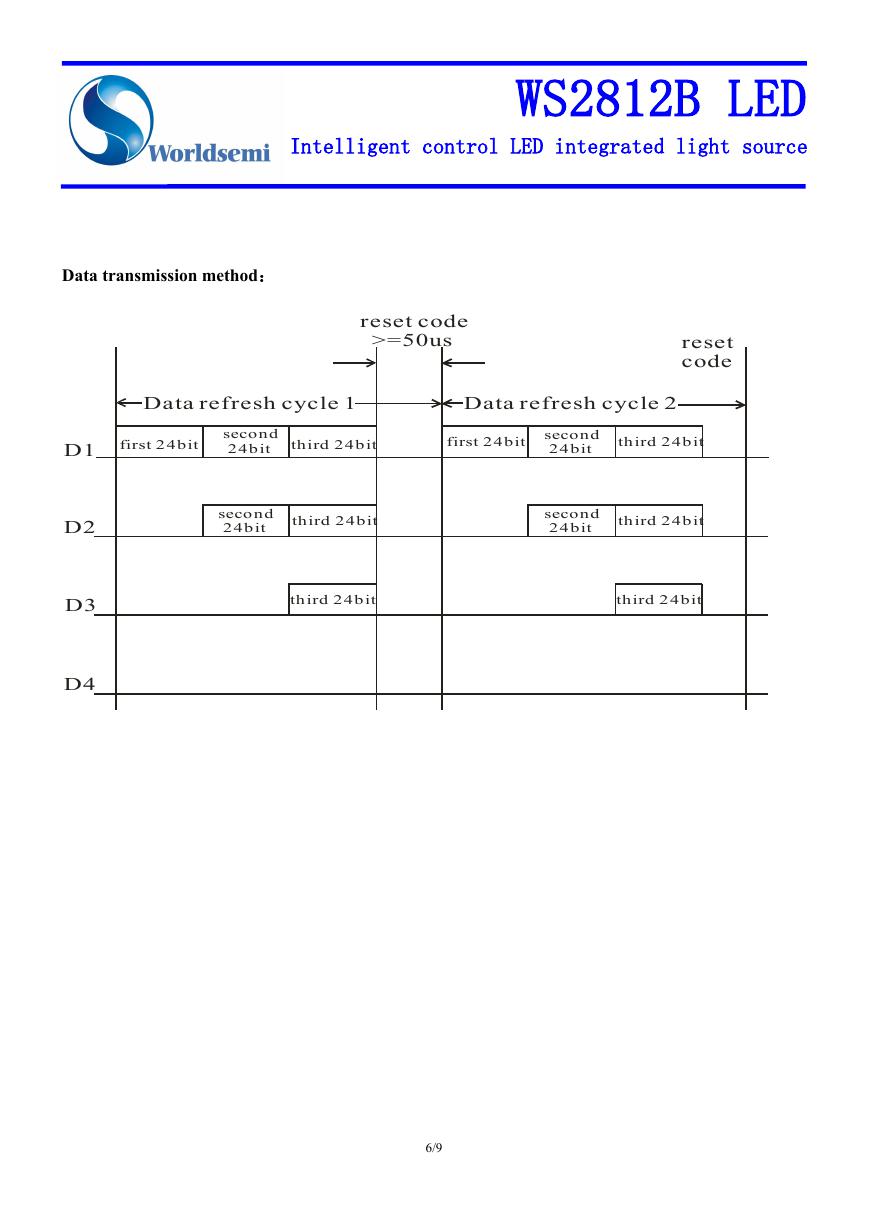

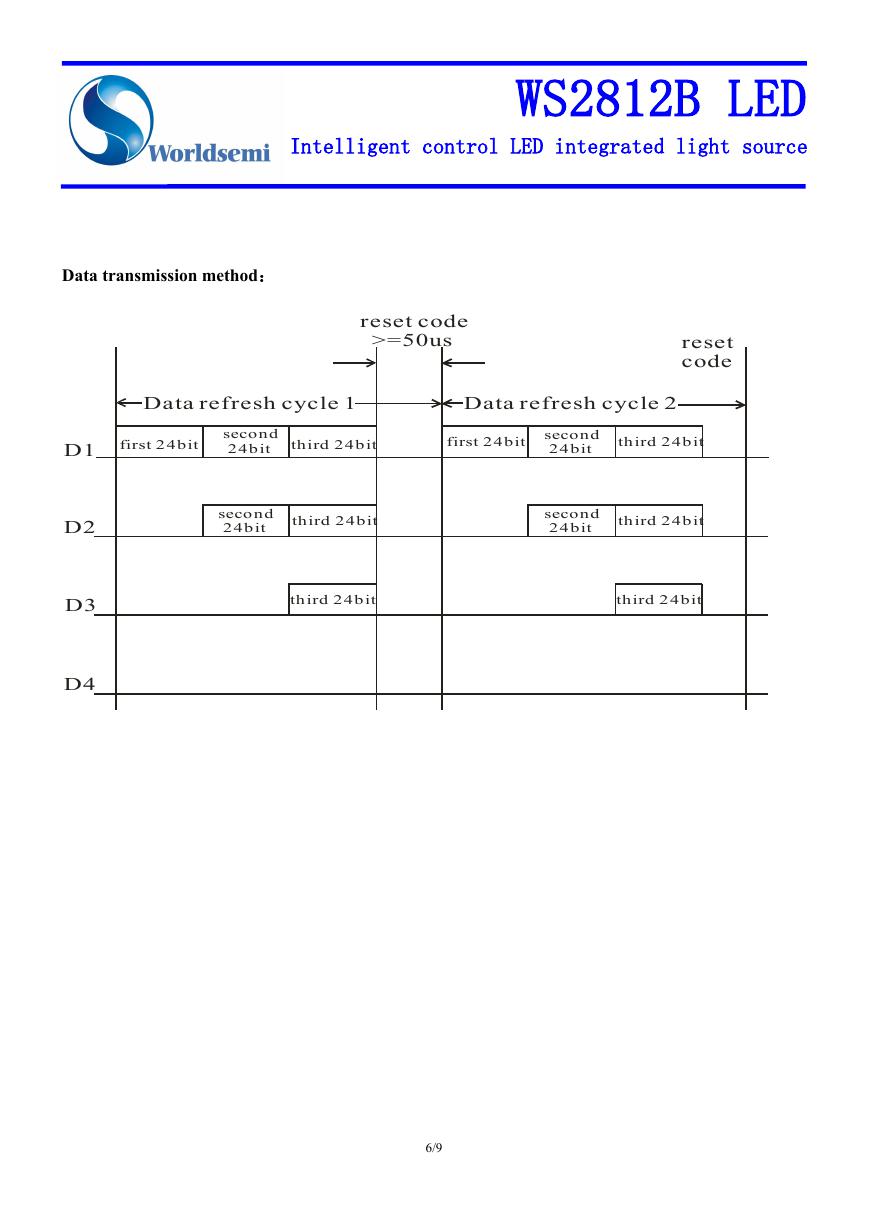

Data transmission method:

reset code

>=50us

reset

code

Data refresh cycle 1

Data refresh cycle 2

D1

first 24bit

second

24bit

third 24bit

first 24bit

second

24bit

third 24bit

second

24bit

third 24bit

second

24bit

third 24bit

third 24bit

third 24bit

D2

D3

D4

6/9

�

WS2812B LED

Intelligent control LED integrated light source

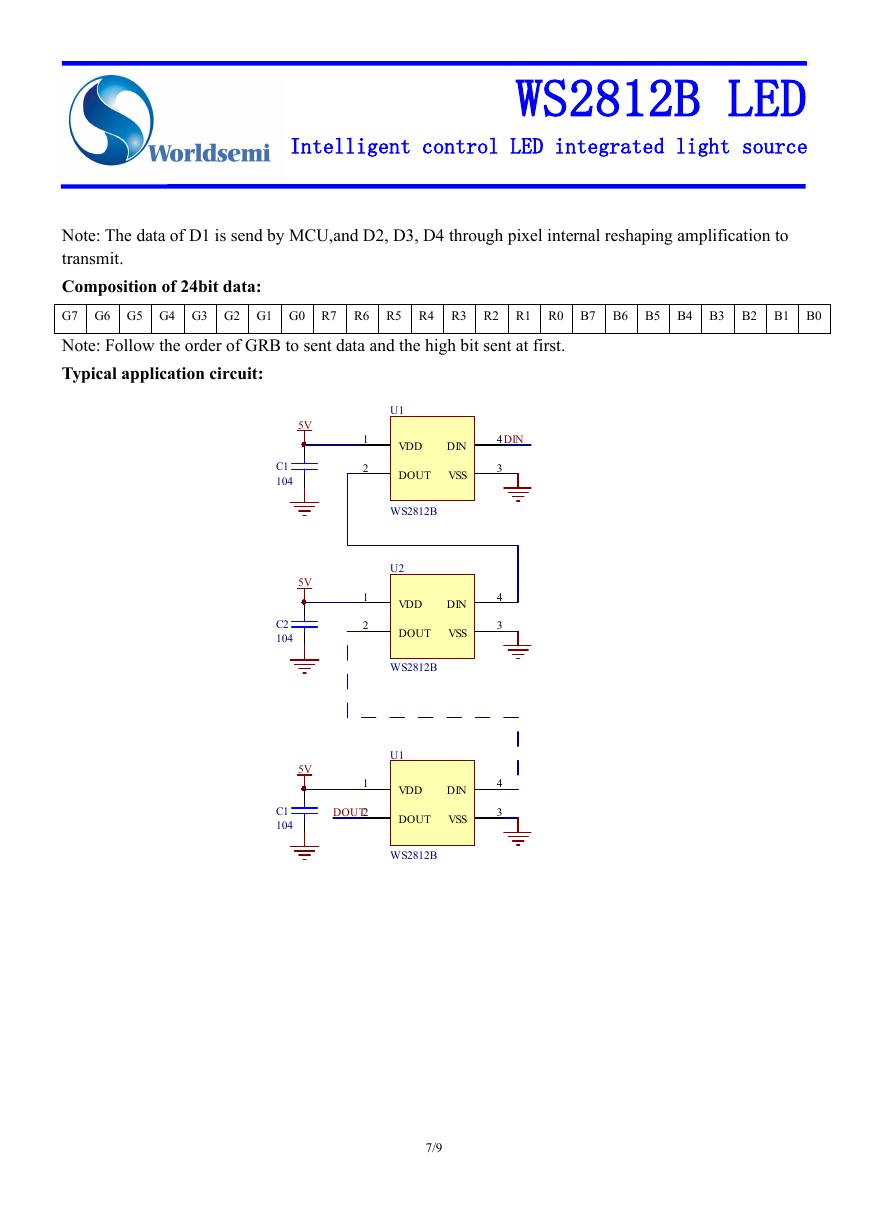

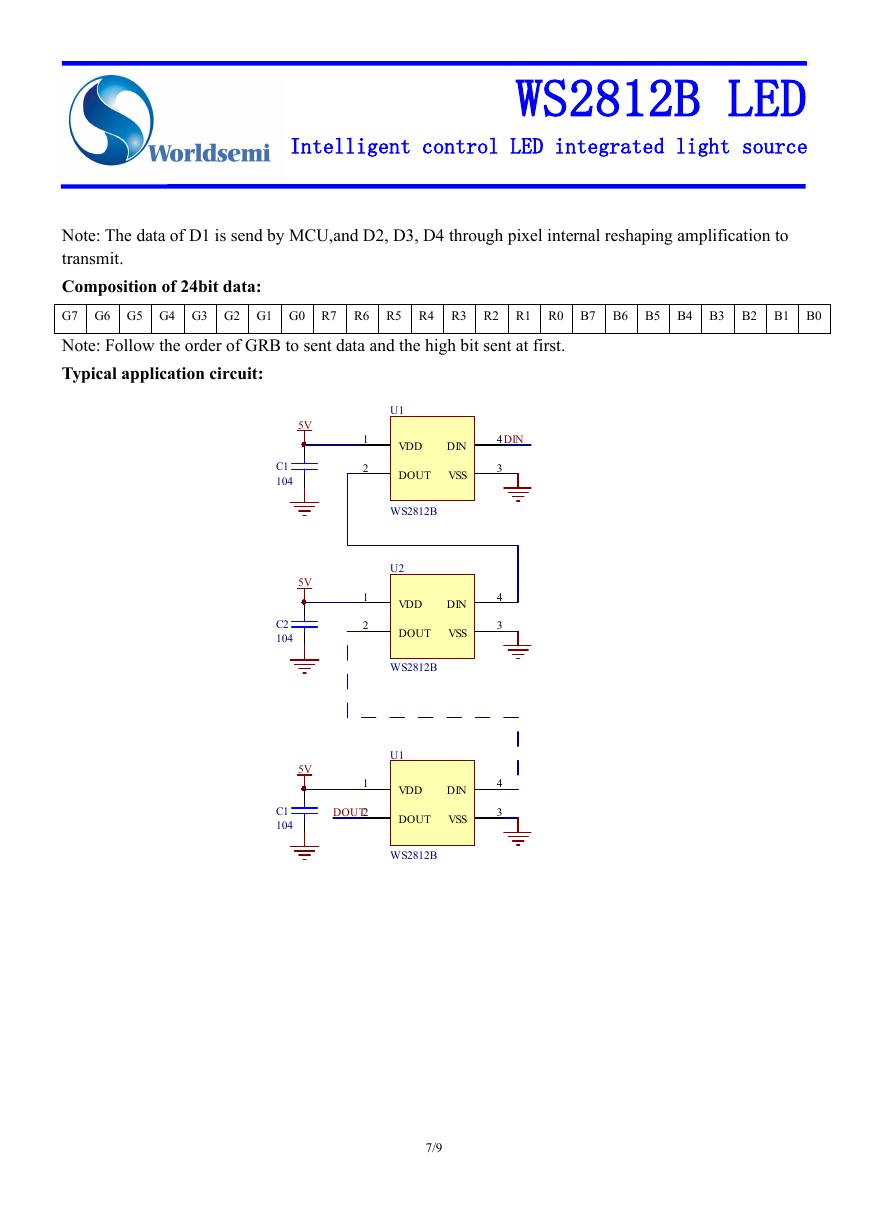

Note: The data of D1 is send by MCU,and D2, D3, D4 through pixel internal reshaping amplification to

transmit.

Composition of 24bit data:

G7 G6 G5 G4 G3 G2 G1 G0 R7 R6 R5 R4 R3 R2 R1 R0 B7 B6 B5 B4 B3 B2 B1 B0

Note: Follow the order of GRB to sent data and the high bit sent at first.

Typical application circuit:

5V

C1

104

5V

C2

104

5V

1

2

1

2

1

C1

104

2

DOUT

U1

VDD

DIN

DOUT

VSS

WS2812B

U2

VDD

DIN

DOUT

VSS

WS2812B

U1

VDD

DIN

DOUT

VSS

WS2812B

4

DIN

3

4

3

4

3

7/9

2

3

�

WS2812B LED

Intelligent control LED integrated light source

WS2812B Products Using Instructions

MSL=5A Level

1. Purpose:

WS2812B-Mini LED lamp’s surface use the high hardness silicone resin,can ensure that no

matter customers use PU glue or epoxy resin to do the silicone drop rubber

processing,won’t lead the LED to die;also has a very good anti sulfide capacity. Good

compatibility with bracket, but the silicon resin has a higher requirements on the humidity

and dehumidification process, especially pay attention during wet season,ensure the

production safety.

2. Transport and application area:

All WS2812S/B products during the transportation process, need to maintain a positive

upward, moisture-proof, during the transport process,shall avoid the extrusion, collision

and vibration.

3. Product storage and deadline:

Sealed storage at room temperature: 20 ℃ ~ 30 ℃, 40% ~ 60%RH, the product is valid

for 3 months;

Moisture seal storage: 20 ℃ ~ 30 ℃, 25% ~ 60%RH, the product is valid for 6 months;

After opening the product packaging , suggest using them within 1 hours,(environmental

conditions of temperature <30 ℃, humidity <60%).

4. Dehumidification process:

LED products which is beyond the prescribed time limit,or for getting damp for some other

reasons,we recommend the customer first do the dehumidification process,then use

them.Dehumidification method:under 75 ℃ / 22 ±2 hours.

5. Electrostatic protection:

LED is the electrostatic sensitive devices, although the LED product has excellent

anti-static ability, but after each ESD impact, will cause a certain degree of damage to LED.

Thus in using process of LED products, must do the electrostatic protection measures, such

as anti-static gloves, anti-static Bracelet etc..

6. Manual welding operation instruction

Suggest using the Electric soldering iron whose power is less than 30W, then control the

8/9

�

V2版本原理图(Capacitive-Fingerprint-Reader-Schematic_V2).pdf

V2版本原理图(Capacitive-Fingerprint-Reader-Schematic_V2).pdf 摄像头工作原理.doc

摄像头工作原理.doc VL53L0X简要说明(En.FLVL53L00216).pdf

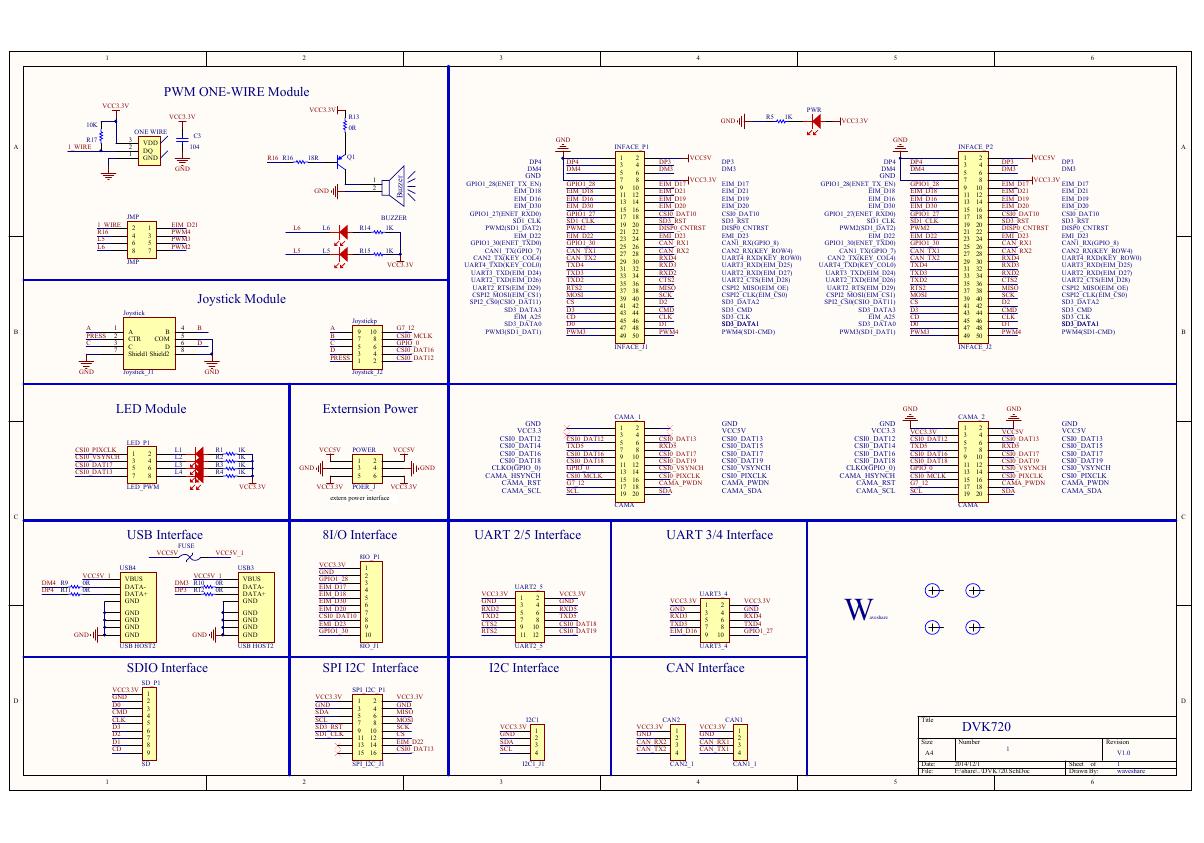

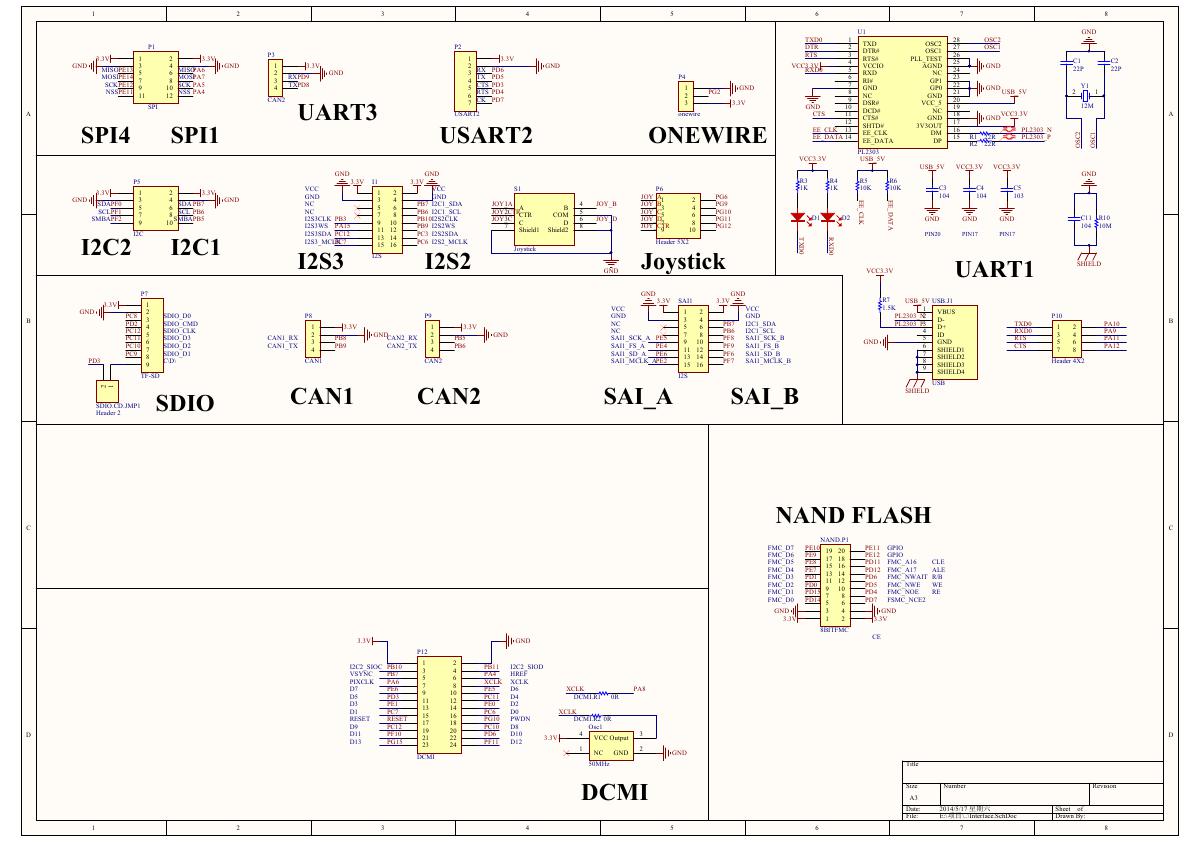

VL53L0X简要说明(En.FLVL53L00216).pdf 原理图(DVK720-Schematic).pdf

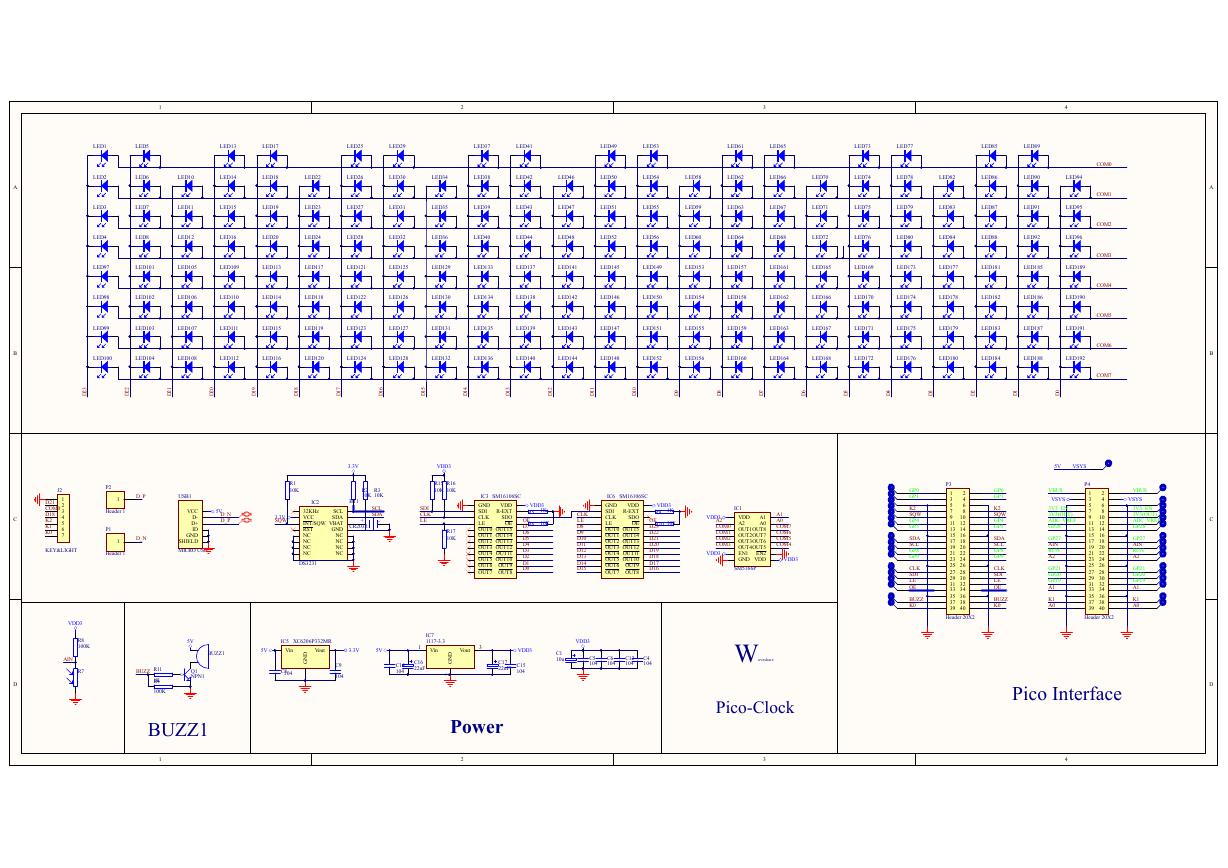

原理图(DVK720-Schematic).pdf 原理图(Pico-Clock-Green-Schdoc).pdf

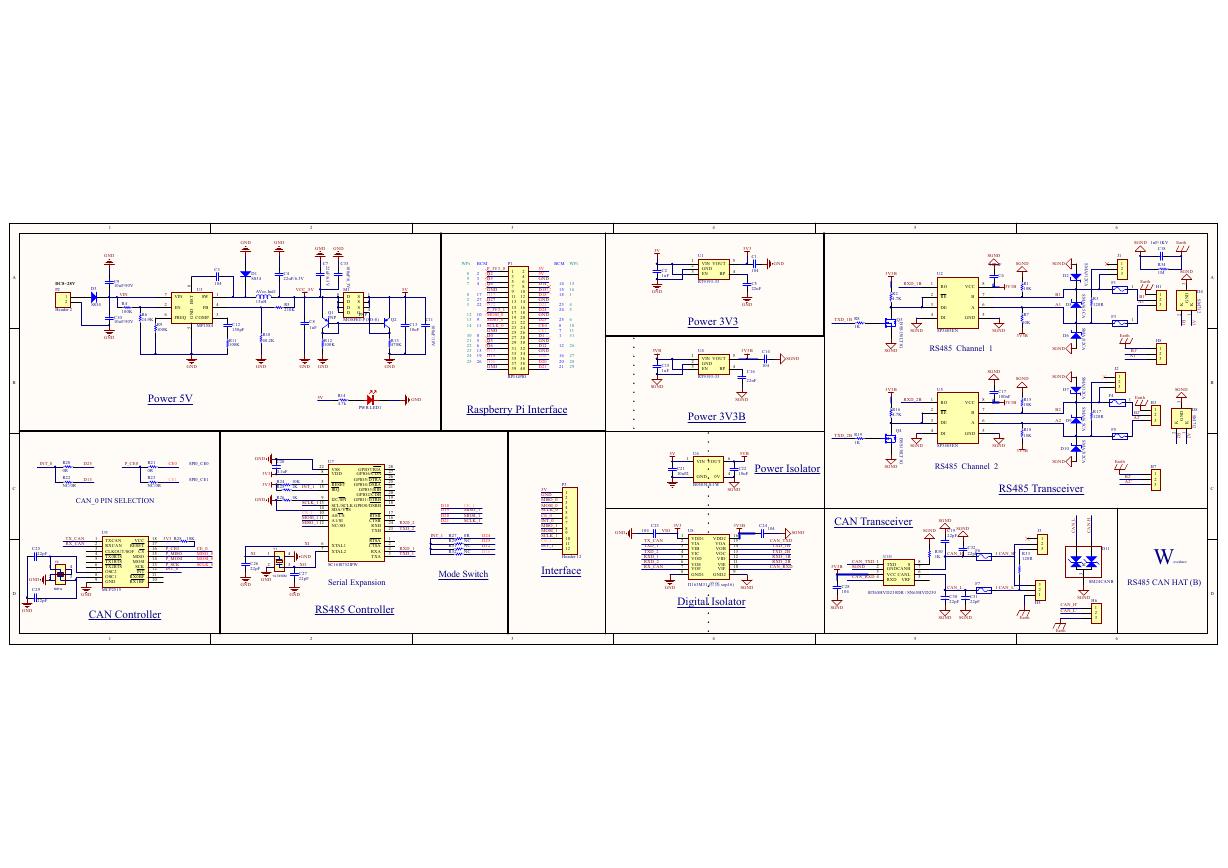

原理图(Pico-Clock-Green-Schdoc).pdf 原理图(RS485-CAN-HAT-B-schematic).pdf

原理图(RS485-CAN-HAT-B-schematic).pdf File:SIM7500_SIM7600_SIM7800 Series_SSL_Application Note_V2.00.pdf

File:SIM7500_SIM7600_SIM7800 Series_SSL_Application Note_V2.00.pdf ADS1263(Ads1262).pdf

ADS1263(Ads1262).pdf 原理图(Open429Z-D-Schematic).pdf

原理图(Open429Z-D-Schematic).pdf 用户手册(Capacitive_Fingerprint_Reader_User_Manual_CN).pdf

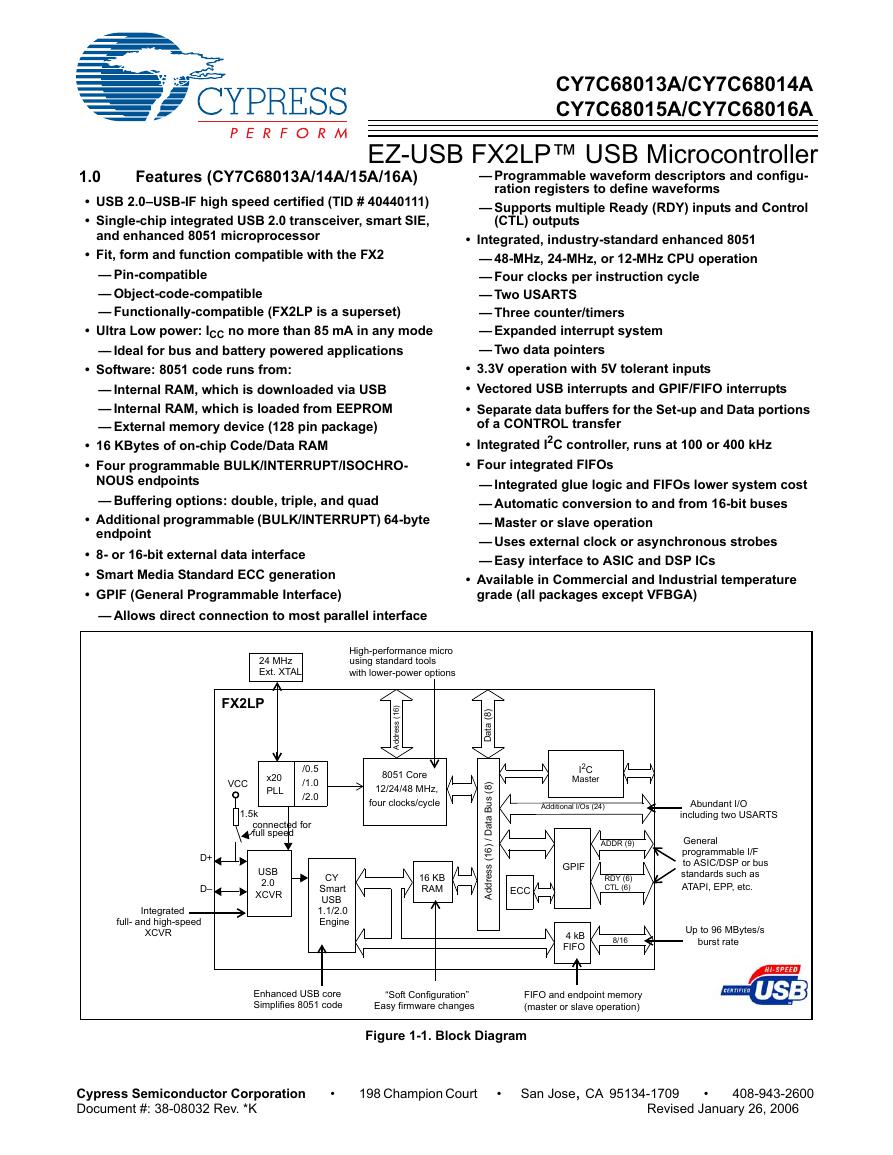

用户手册(Capacitive_Fingerprint_Reader_User_Manual_CN).pdf CY7C68013A(英文版)(CY7C68013A).pdf

CY7C68013A(英文版)(CY7C68013A).pdf TechnicalReference_Dem.pdf

TechnicalReference_Dem.pdf