UM1857

User manual

Stepper motor driver expansion board based on L6474 for

STM32 Nucleo

Introduction

The X-NUCLEO-IHM01A1 is a stepper motor driving board based on the L6474.

It provides an affordable and easy-to-use solution for driving stepper motors in your STM32 Nucleo

project.

The advanced current control of the L6474 and the complete set of protections guarantee high

performance and robustness.

The X-NUCLEO-IHM01A1 is compatible with the Arduino UNO R3 connector on the ST Morpho

connector.

More boards of the same type can be stacked easily to drive up to three stepper motors with a single

STM32 Nucleo board.

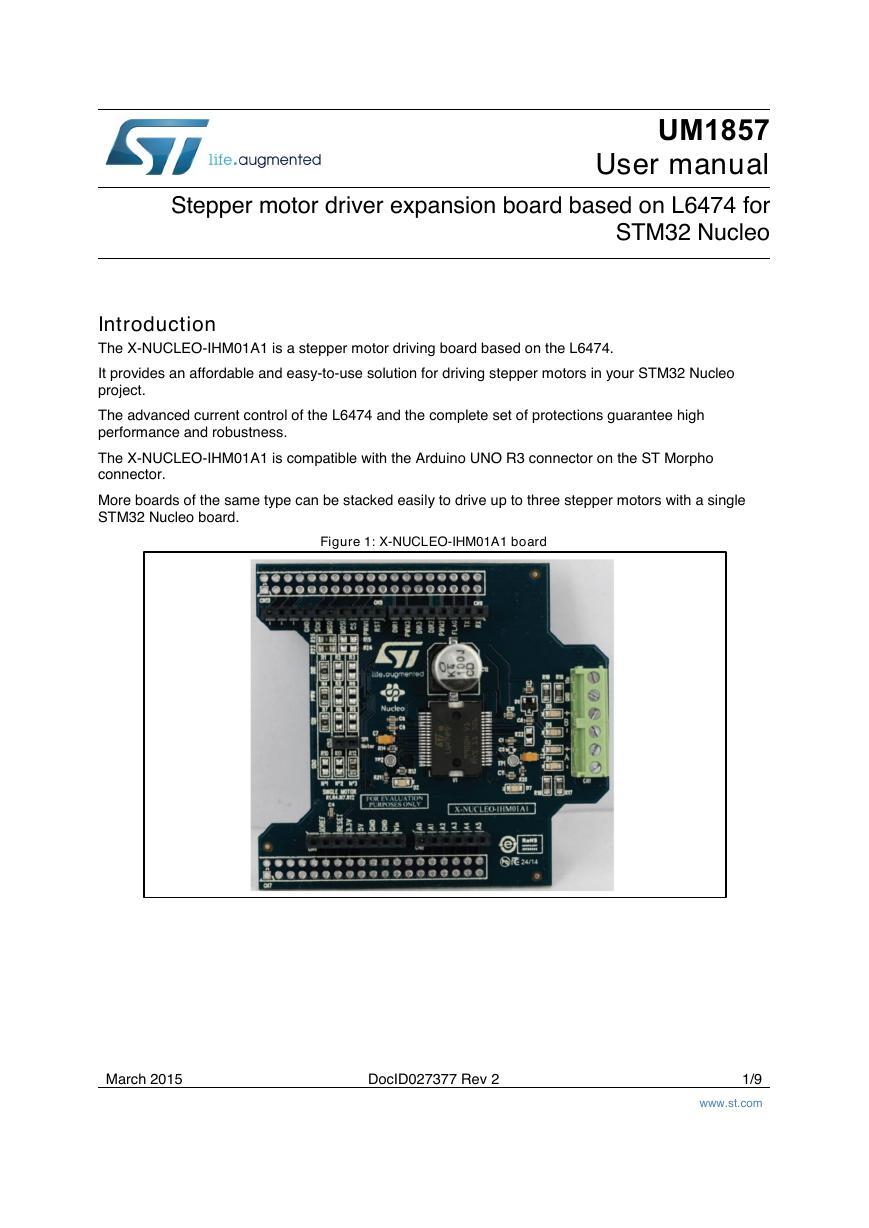

Figure 1: X-NUCLEO-IHM01A1 board

March 2015

DocID027377 Rev 2

1/9

www.st.com

�

Contents

Contents

UM1857

Getting started ................................................................................ 3

Hardware description and configuration ...................................... 4

2.1

2.2

Selecting the chip select and clock lines of the SPI ......................... 6

Multi motor configuration .................................................................. 6

Revision history ............................................................................. 8

1

2

3

2/9

DocID027377 Rev 2

�

UM1857

Getting started

1

Getting started

The X-NUCLEO-IHM01A1 expansion board is a stepper motor driver covering a wide

range of applications.

The maximum ratings are:

Power stage supply voltage (VS) from 8 V to 45 V

Motor phase current up to 3 A rms

To start your project with the board:

1. Check the jumper position in accordance with your configuration (see Section 2:

"Hardware description and configuration" ).

2. Connect the board to the STM32 Nucleo board with the connector:

a. Arduino UNO R3 for the X-NUCLEO-IHM01A1.

b. ST Morpho for the X-NUCLEO-IHM01A.

Up to three expansion boards can be stacked on the same STM32 Nucleo board, as

described in Section 2.2: "Multi motor configuration".

1. Supply the board through input 1 (VS) and 2 (ground) of the connector CN1.

2. The power OK (green) and fault (red) LEDs turn on.

3. Develop your application using the examples provided with the firmware library.

Further support material is available on the L6474 and STM32 Nucleo web pages

(www.st.com/stm32nucleo).

DocID027377 Rev 2

3/9

�

Hardware description and configuration

2

Hardware description and configuration

UM1857

The Figure 2: "Jumpers and connectors position" shows the position of the connectors and

the configuration jumpers of the board.

Figure 2: Jumpers and connectors position

The following tables provide the connector details for the Arduino UNO R3 and ST Morpho,

respectively.

Connector Pin(1)

Signal

Remarks

Table 1: Arduino UNO R3 connector table

CN5

CN9

1

2

3

4

5

6

7

3

4

5

6

7

L6474

STBY\\RESET

PWM1

SPI CS

SPI MOSI

SPI MISO

SPI SCK

Ground

L6474 FLAG

output

See Section 2.1: "Selecting the chip select and clock

lines of the SPI"

See Section 2.2: "Multi motor configuration"

See Section 2.1: "Selecting the chip select and clock

lines of the SPI"

See Section 2.2: "Multi motor configuration"

PWM2\\SPI SCK

See Section 2.2: "Multi motor configuration" and Section

2.1: "Selecting the chip select and clock lines of the

SPI"

DIR2

DIR3

PWM3

See Section 2.2: "Multi motor configuration"

4/9

DocID027377 Rev 2

�

UM1857

Hardware description and configuration

Connector Pin(1)

Signal

Remarks

8

2

6

7

3

DIR1

VDD

Ground

Ground

SPI CS

CN6

CN8

Notes:

(1)All the non-listed pins are not connected.

See Section 2.1: "Selecting the chip select and clock

lines of the SPI"

Connector Pin(1)

Signal

Remarks

Table 2: ST Morpho connector table

9

Ground

11

SPI SCK

13

15

SPI MISO

SPI MOSI

17

SPI CS

See Section 2.1: "Selecting the chip select and clock

lines of the SPI"

See Section 2.2: "Multi motor configuration"

See Section 2.1: "Selecting the chip select and clock

lines of the SPI"

19

PWM1

See Section 2.2: "Multi motor configuration"

L6474

STBY\\RESET

CN10

21

23

25

27

29

DIR1

PWM3

DIR3

DIR2

31

PWM2

33

12

20

22

L6474 FLAG

output

VDD

Ground

Ground

32

SPI CS

CN7

Notes:

(1)All the non-listed pins are not connected.

See Section 2.2: "Multi motor configuration"

See Section 2.1: "Selecting the chip select and clock

lines of the SPI" and Section 2.2: "Multi motor

configuration"

See Section 2.1: "Selecting the chip select and clock

lines of the SPI"

DocID027377 Rev 2

5/9

�

Hardware description and configuration

2.1

Selecting the chip select and clock lines of the SPI

UM1857

The chip select and the clock lines of the SPI interface can be selected through dedicated

resistors as indicated in Table 3: "Chip select line selection" and Table 4: "Chip select line

selection".

Table 3: Chip select line selection

R15

Not mounted

R25

0R

CS line

CN5 pin 3, CN10 pin 17 (default)

0R

Not mounted

CN8 pin 3, CN7 pin 32

R23

0R

Table 4: Chip select line selection

R24

CS line

Not mounted

CN5 pin 6, CN10 pin 9 (default)

Not mounted

0R

CN9 pin 4, CN10 pin 31

When the alternative clock line is selected (CN9 pin 4, CN10 pin 31) the PWM2 signal is no

longer available for multi-motor configurations (see Section 2.2: "Multi motor

configuration").

2.2

Multi motor configuration

The expansion boards can be stacked on a single STM32 Nucleo board in order to drive up

to three stepper motors (one for each motor).

The configuration can be changed by mounting the necessary resistors from R1 to R12 as

listed in the Table 5. The other resistors are not mounted.

By default, the stepper driver board is configured for a single motor setup, so board

configurations for multi-motor setups must be changed before stacking the boards on the

STM32 Nucleo.

Table 5: Multi-motor setup table

Number of motors

Board

STCK\\DIR

Mounted resistors

(0R)

1

2

3

-

PWM1\\DIR1

R1, R4, R7, R12

1 (bottom)

2 (top)

1 (bottom)

2

3 (top)

PWM1\\DIR1

R1, R4, R7, R10

PWM2\\DIR2

R2, R5, R8, R12

PWM1\\DIR1

R1, R4, R7, R10

PWM2\\DIR2

R2, R5, R8, R11

PWM3\\DIR3

R3, R6, R9, R12

If the alternative SPI clock line is selected (see Section 2.1: "Selecting the chip select and

clock lines of the SPI") the PWM2 step clock is no longer available and the multi-motor

setup is limited to two motors maximum.

The Table 6: "Multi-motor setup with alternative SPI clock line" shows the proper

configuration in this case.

6/9

DocID027377 Rev 2

�

UM1857

Hardware description and configuration

Table 6: Multi-motor setup with alternative SPI clock line

Number of motors

Board

STCK\\DIR

Mounted resistors

(0R)

2

1 (bottom)

2 (top)

PWM1\\DIR1

R1, R4, R7, R10

PWM3\\DIR2

R2, R6, R8, R12

DocID027377 Rev 2

7/9

�

Revision history

3

Revision history

UM1857

Table 7: Document revision history

Date

Revision

Changes

16-Mar-2015

30-Mar-2015

1

2

Initial release.

Updated Section 1: "Getting started".

8/9

DocID027377 Rev 2

�

V2版本原理图(Capacitive-Fingerprint-Reader-Schematic_V2).pdf

V2版本原理图(Capacitive-Fingerprint-Reader-Schematic_V2).pdf 摄像头工作原理.doc

摄像头工作原理.doc VL53L0X简要说明(En.FLVL53L00216).pdf

VL53L0X简要说明(En.FLVL53L00216).pdf 原理图(DVK720-Schematic).pdf

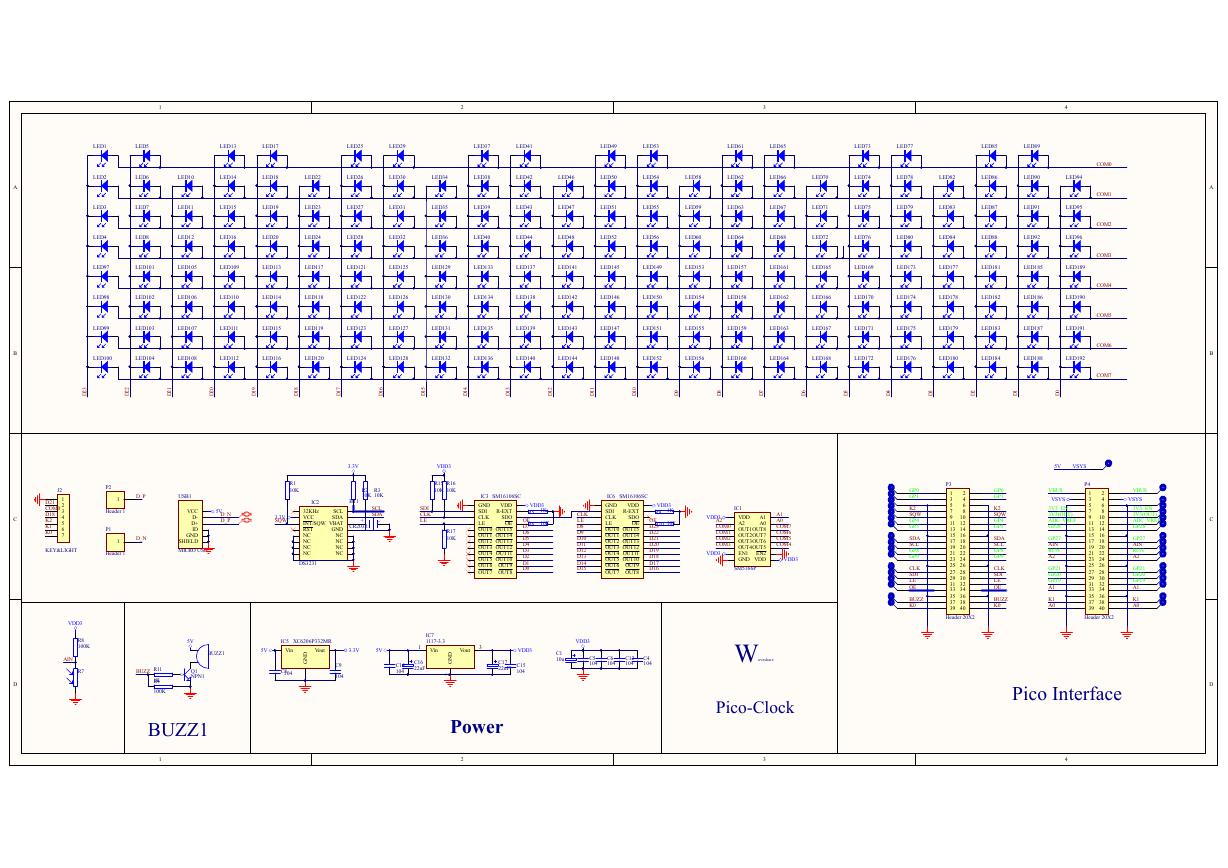

原理图(DVK720-Schematic).pdf 原理图(Pico-Clock-Green-Schdoc).pdf

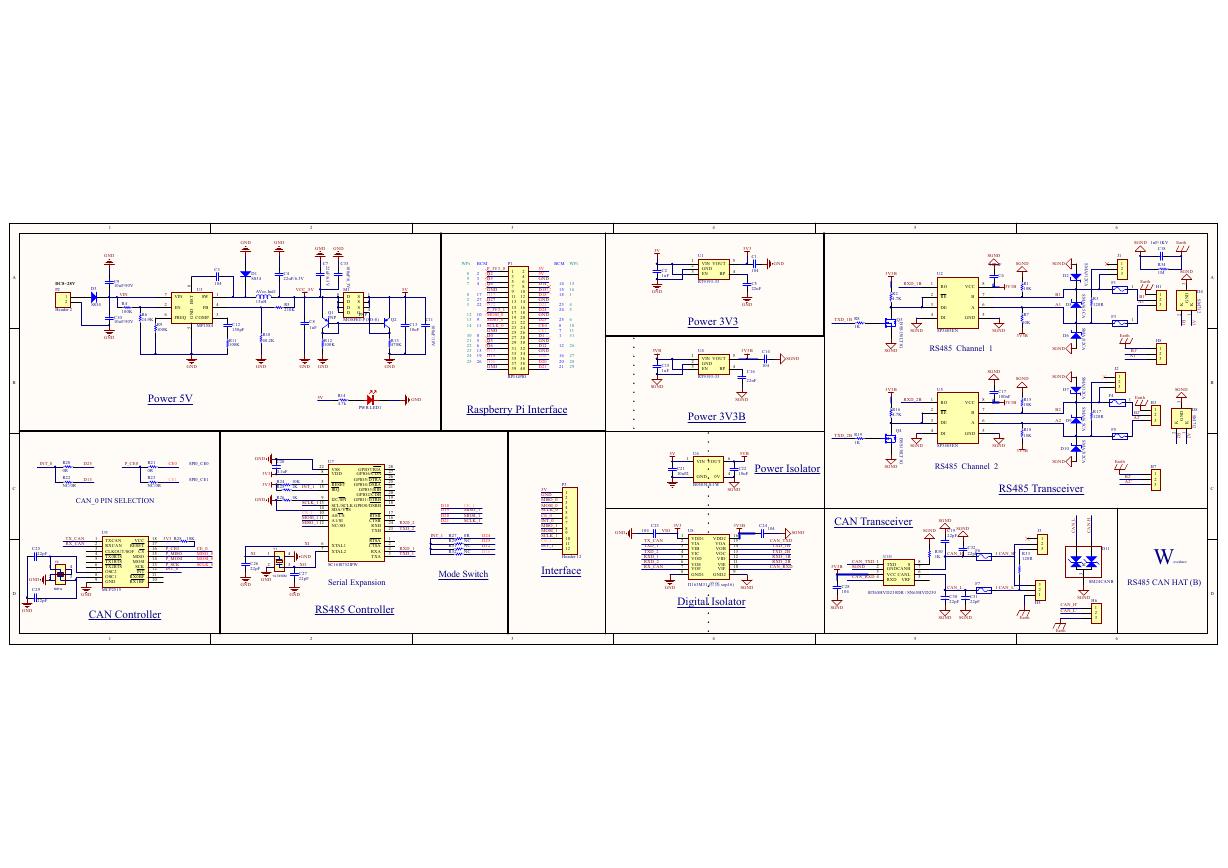

原理图(Pico-Clock-Green-Schdoc).pdf 原理图(RS485-CAN-HAT-B-schematic).pdf

原理图(RS485-CAN-HAT-B-schematic).pdf File:SIM7500_SIM7600_SIM7800 Series_SSL_Application Note_V2.00.pdf

File:SIM7500_SIM7600_SIM7800 Series_SSL_Application Note_V2.00.pdf ADS1263(Ads1262).pdf

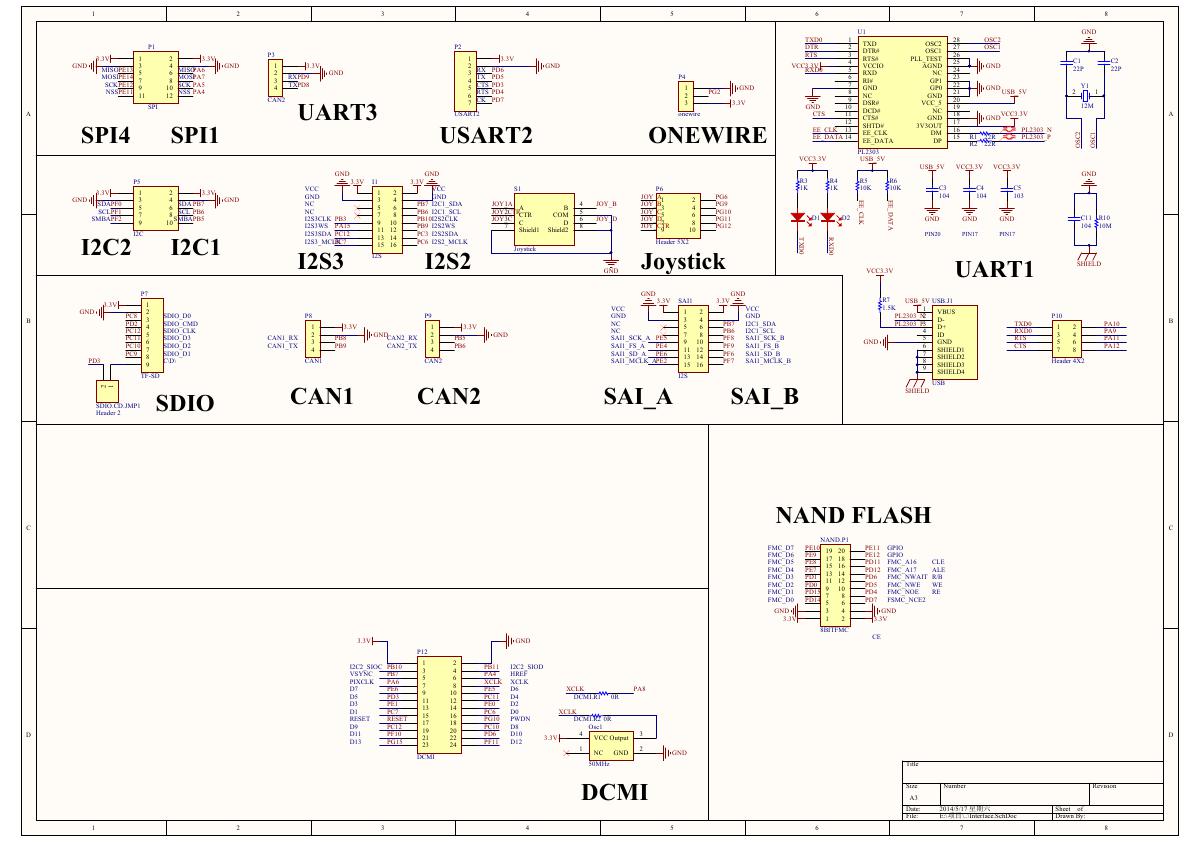

ADS1263(Ads1262).pdf 原理图(Open429Z-D-Schematic).pdf

原理图(Open429Z-D-Schematic).pdf 用户手册(Capacitive_Fingerprint_Reader_User_Manual_CN).pdf

用户手册(Capacitive_Fingerprint_Reader_User_Manual_CN).pdf CY7C68013A(英文版)(CY7C68013A).pdf

CY7C68013A(英文版)(CY7C68013A).pdf TechnicalReference_Dem.pdf

TechnicalReference_Dem.pdf