CAT24C32

32-Kb I2C CMOS Serial EEPROM

FEATURES

■ Supports Standard and Fast I2C Protocol

■ 1.8 V to 5.5 V Supply Voltage Range

■ 32-Byte Page Write Buffer

■ Hardware Write Protection for entire memory

■ Schmitt Triggers and Noise Suppression Filters

on I2C Bus Inputs (SCL and SDA).

■ Low power CMOS technology

■ 1,000,000 program/erase cycles

■ 100 year data retention

■ Industrial temperature range

■ RoHS-compliant 8-pin PDIP, SOIC, TSSOP and

TDFN packages

DEVICE DESCRIPTION

The CAT24C32 is a 32-Kb CMOS Serial EEPROM

devices, internally organized as 128 pages of 32 bytes

each.

It features a 32-byte page write buffer and supports

both the Standard (100 kHz) as well as Fast (400 kHz)

I2C protocol.

External address pins make it possible to address up to

eight CAT24C32 devices on the same bus.

For Ordering Information details, see page 15.

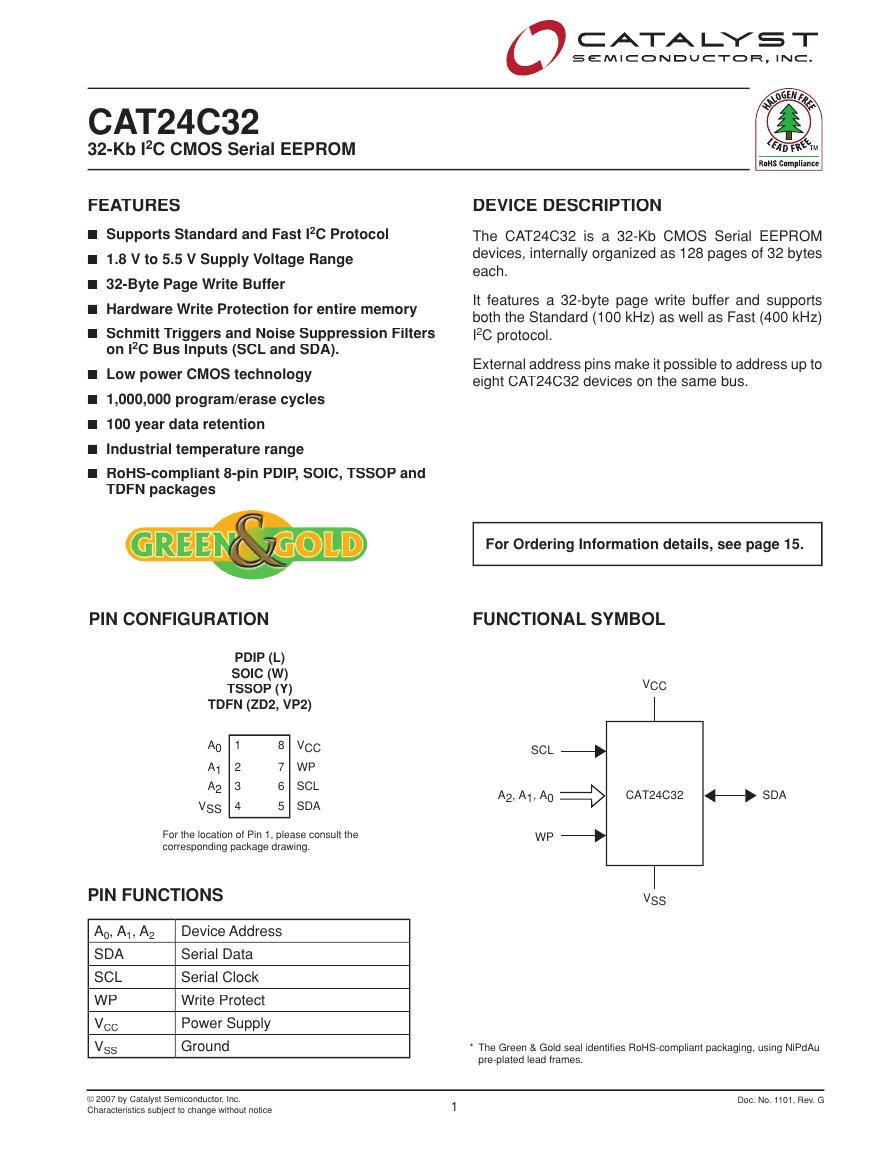

PIN CONFIGURATION

FUNCTIONAL SYMBOL

PDIP (L)

SOIC (W)

TSSOP (Y)

TDFN (ZD2, VP2)

A0

A1

A2

VSS

1

2

3

4

8

7

6

5

VCC

WP

SCL

SDA

VCC

SCL

A2, A1, A0

CAT24C32

SDA

For the location of Pin 1, please consult the

corresponding package drawing.

WP

PIN FUNCTIONS

A0, A1, A2

SDA

SCL

WP

VCC

VSS

Device Address

Serial Data

Serial Clock

Write Protect

Power Supply

Ground

VSS

* The Green & Gold seal identifi es RoHS-compliant packaging, using NiPdAu

pre-plated lead frames.

© 2007 by Catalyst Semiconductor, Inc.

Characteristics subject to change without notice

1

Doc. No. 1101, Rev. G

�

CAT24C32

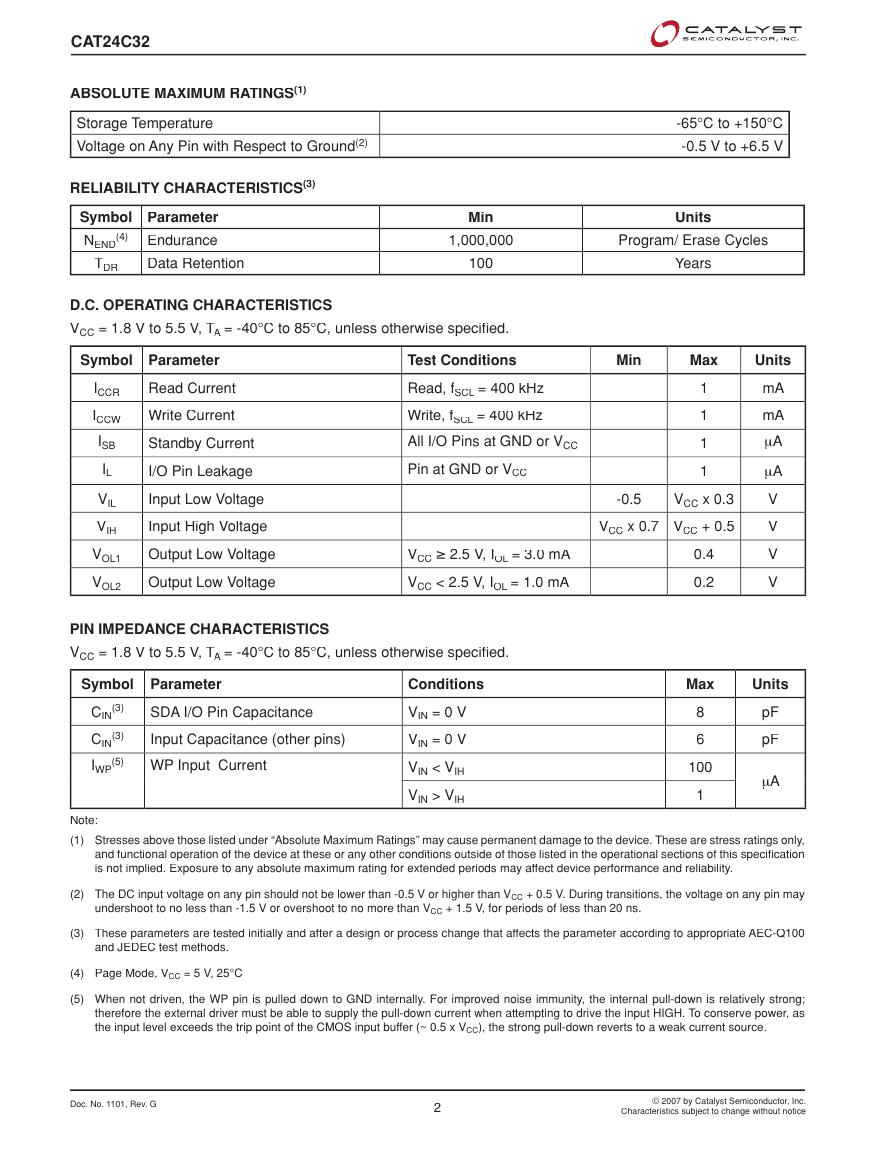

ABSOLUTE MAXIMUM RATINGS(1)

Storage Temperature

Voltage on Any Pin with Respect to Ground(2)

RELIABILITY CHARACTERISTICS(3)

Symbol Parameter

(4) Endurance

NEND

TDR

Data Retention

-65°C to +150°C

-0.5 V to +6.5 V

Min

1,000,000

100

Units

Program/ Erase Cycles

Years

D.C. OPERATING CHARACTERISTICS

= 1.8 V to 5.5 V, T = -40°C to 85°C, unless otherwise specifi ed.

= 1.8 V to 5.5 V, TA

VCC = 1.8 V to 5.5 V, TA

A = -40°C to 85°C, unless otherwise specifi ed.

A

Symbol Parameter

Test Conditions

Min

Max

Units

Read Current

ICCR

ICCW Write Current

ISB

IL

I/O Pin Leakage

Standby Current

VIL

VIH

VOL1

VOL2

Input Low Voltage

Input High Voltage

Output Low Voltage

Output Low Voltage

Read, fSCL = 400 kHz

SCL = 400 kHz

SCL

Write, fSCL = 400 kHz

SCL = 400 kHz

SCL

All I/O Pins at GND or VCC

Pin at GND or VCC

1

1

1

1

-0.5

VCC x 0.3

VCC x 0.7 VCC + 0.5

VCC ≥ 2.5 V, IOL = 3.0 mA

OL = 3.0 mA

OL

VCC < 2.5 V, IOL = 1.0 mA

OL = 1.0 mA

OL

0.4

0.2

mA

mA

μA

μA

V

V

V

V

PIN IMPEDANCE CHARACTERISTICS

= 1.8 V to 5.5 V, T = -40°C to 85°C, unless otherwise specifi ed.

= 1.8 V to 5.5 V, TA

VCC = 1.8 V to 5.5 V, TA

A = -40°C to 85°C, unless otherwise specifi ed.

A

Symbol Parameter

(3)

(3)

CIN

CIN

IWP

SDA I/O Pin Capacitance

Input Capacitance (other pins)

(5) WP Input Current

Conditions

VIN = 0 V

VIN = 0 V

VIN < VIH

VIN > VIH

Max

Units

8

6

100

1

pF

pF

μA

Note:

(1) Stresses above those listed under “Absolute Maximum Ratings” may cause permanent damage to the device. These are stress ratings only,

and functional operation of the device at these or any other conditions outside of those listed in the operational sections of this specifi cation

is not implied. Exposure to any absolute maximum rating for extended periods may affect device performance and reliability.

(2) The DC input voltage on any pin should not be lower than -0.5 V or higher than VCC + 0.5 V. During transitions, the voltage on any pin may

undershoot to no less than -1.5 V or overshoot to no more than VCC + 1.5 V, for periods of less than 20 ns.

(3) These parameters are tested initially and after a design or process change that affects the parameter according to appropriate AEC-Q100

and JEDEC test methods.

(4) Page Mode, VCC = 5 V, 25°C

(5) When not driven, the WP pin is pulled down to GND internally. For improved noise immunity, the internal pull-down is relatively strong;

therefore the external driver must be able to supply the pull-down current when attempting to drive the input HIGH. To conserve power, as

the input level exceeds the trip point of the CMOS input buffer (~ 0.5 x VCC), the strong pull-down reverts to a weak current source.

Doc. No. 1101, Rev. G

2

© 2007 by Catalyst Semiconductor, Inc.

Characteristics subject to change without notice

�

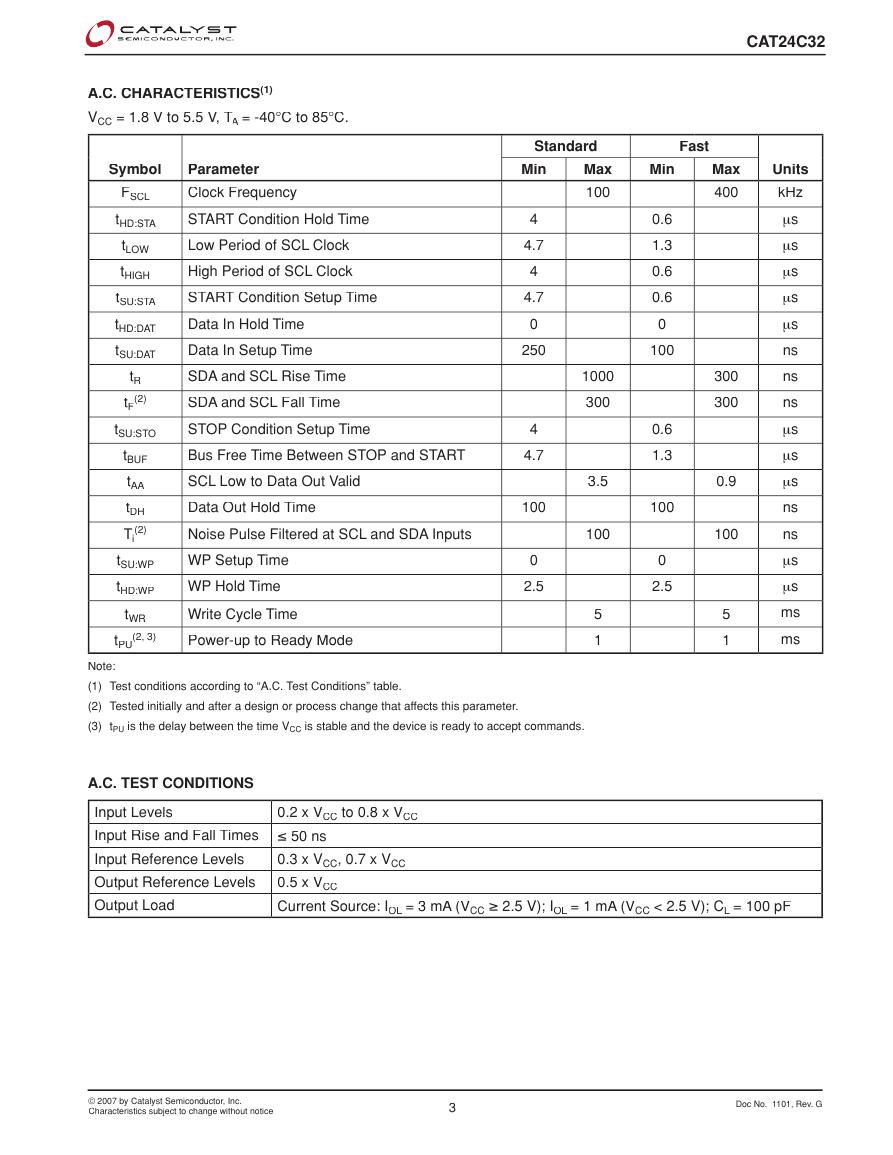

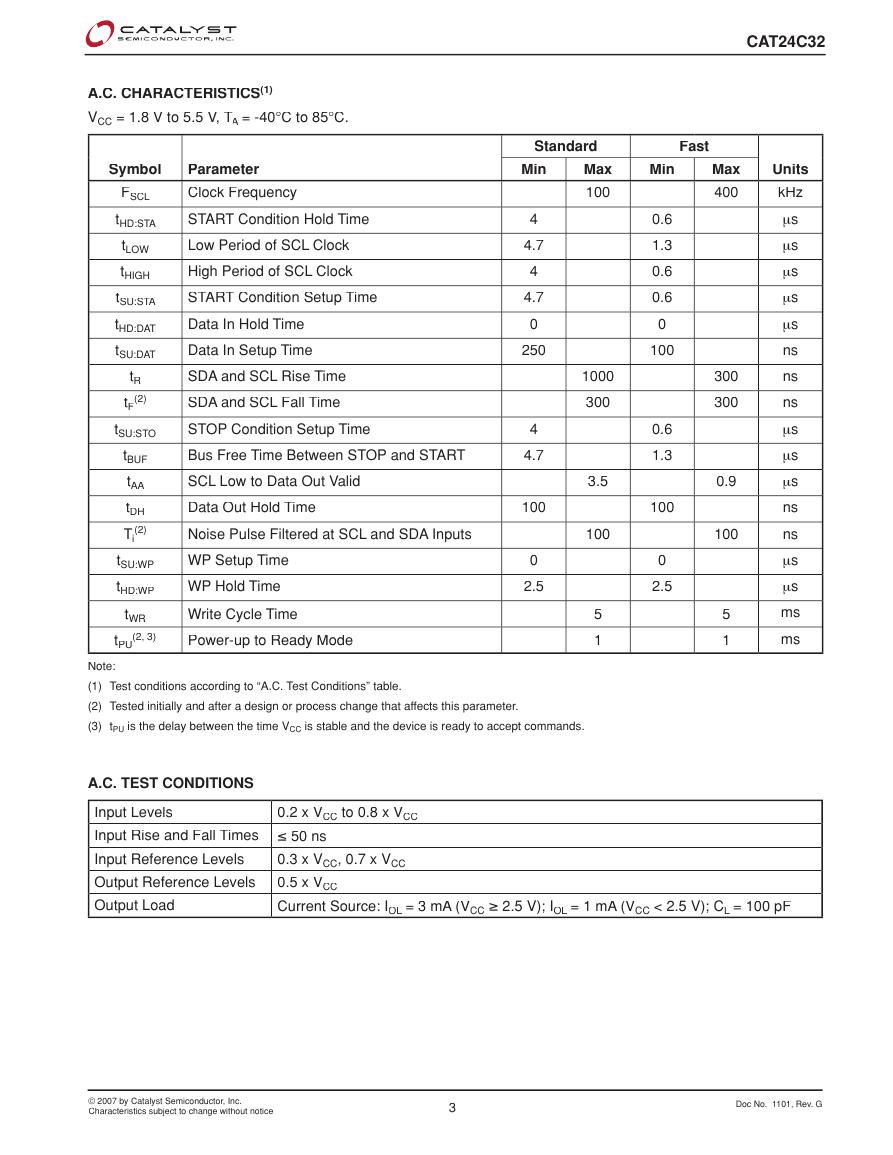

A.C. CHARACTERISTICS(1)

= 1.8 V to 5.5 V, T = -40°C to 85°C.

= 1.8 V to 5.5 V, TA

VCC = 1.8 V to 5.5 V, TA

A = -40°C to 85°C.

A

Symbol

FSCL

tHD:STA

tLOW

tHIGH

tSU:STA

tHD:DAT

tSU:DAT

tR

(2)

tF

tSU:STO

tBUF

tAA

tDH

(2)

Ti

tSU:WP

tHD:WP

tWR

(2, 3)

tPU

Parameter

Clock Frequency

START Condition Hold Time

Low Period of SCL Clock

High Period of SCL Clock

START Condition Setup Time

Data In Hold Time

Data In Setup Time

SDA and SCL Rise Time

SDA and SCL Fall Time

STOP Condition Setup Time

Bus Free Time Between STOP and START

SCL Low to Data Out Valid

Data Out Hold Time

Noise Pulse Filtered at SCL and SDA Inputs

WP Setup Time

WP Hold Time

Write Cycle Time

Power-up to Ready Mode

CAT24C32

Max

400

Units

kHz

μs

μs

μs

μs

μs

ns

ns

ns

μs

μs

μs

ns

ns

μs

μs

ms

ms

300

300

0.9

100

5

1

Standard

Fast

Min

0.6

1.3

0.6

0.6

0

100

0.6

1.3

100

0

2.5

Min

4

4.7

4

4.7

0

250

4

4.7

100

0

2.5

Max

100

1000

300

3.5

100

5

1

Note:

(1) Test conditions according to “A.C. Test Conditions” table.

(2) Tested initially and after a design or process change that affects this parameter.

(3) tPU is the delay between the time VCC is stable and the device is ready to accept commands.

A.C. TEST CONDITIONS

0.2 x VCC to 0.8 x VCC

Input Levels

Input Rise and Fall Times ≤ 50 ns

Input Reference Levels

Output Reference Levels

Output Load

0.3 x VCC, 0.7 x VCC

0.5 x VCC

Current Source: IOL = 3 mA (V

OL = 3 mA (V

OL

CC ≥ 2.5 V); IOL = 1 mA (V

OL = 1 mA (V

OL

CC < 2.5 V); CL = 100 pF

L = 100 pF

L

© 2007 by Catalyst Semiconductor, Inc.

Characteristics subject to change without notice

3

Doc No. 1101, Rev. G

�

CAT24C32

POWER-ON RESET (POR)

FUNCTIONAL DESCRIPTION

Each CAT24C32 incorporates Power-On Reset (POR)

circuitry which protects the internal logic against powering

up in the wrong state. The device will power up into

Standby mode after VCC exceeds the POR trigger level

and will power down into Reset mode when VCC drops

below the POR trigger level. This bi-directional POR

behavior protects the device against ‘brown-out’ failure

following a temporary loss of power.

PIN DESCRIPTION

SCL: The Serial Clock input pin accepts the clock signal

generated by the Master.

SDA: The Serial Data I/O pin accepts input data and

delivers output data. In transmit mode, this pin is open

drain. Data is acquired on the positive edge, and is

delivered on the negative edge of SCL.

A0, A1 and A2: The Address inputs set the device ad-

dress that must be matched by the corresponding Slave

address bits. The Address inputs are hard-wired HIGH

or LOW allowing for up to eight devices to be used

(cascaded) on the same bus. When left fl oating, these

pins are pulled LOW internally.

WP: When pulled HIGH, the Write Protect input pin

inhibits all write operations. When left fl oating, this pin

is pulled LOW internally.

The CAT24C32 supports the Inter-Integrated Circuit

(I2C) Bus protocol. The protocol relies on the use of a

Master device, which provides the clock and directs bus

traffi c, and Slave devices which execute requests. The

CAT24C32 operates as a Slave device. Both Master

and Slave can transmit or receive, but only the Master

can assign those roles.

I2C BUS PROTOCOL

The 2-wire I2C bus consists of two lines, SCL and SDA,

connected to the VCC supply via pull-up resistors. The

Master provides the clock to the SCL line, and either the

Master or the Slaves drive the SDA line. A ‘0’ is transmitted

by pulling a line LOW and a ‘1’ by letting it stay HIGH.

Data transfer may be initiated only when the bus is not

busy (see A.C. Characteristics). During data transfer,

SDA must remain stable while SCL is HIGH.

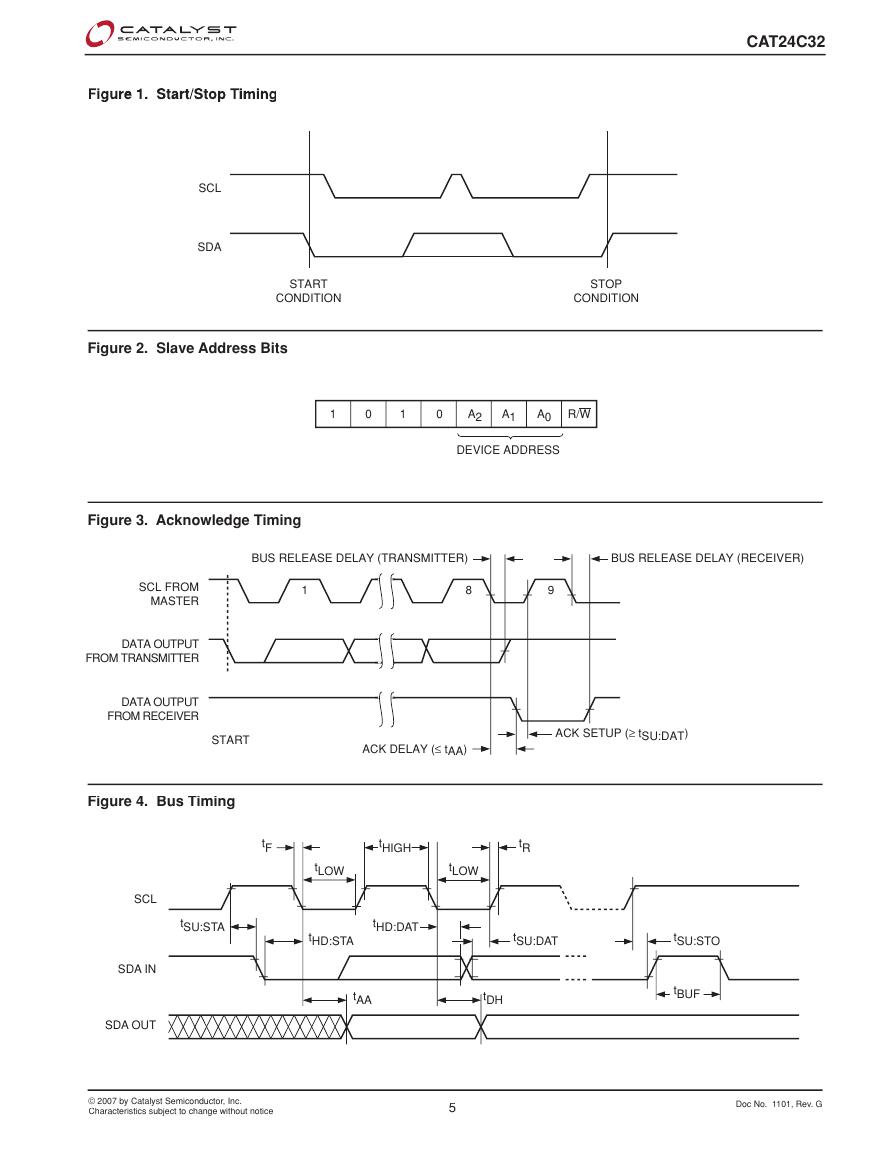

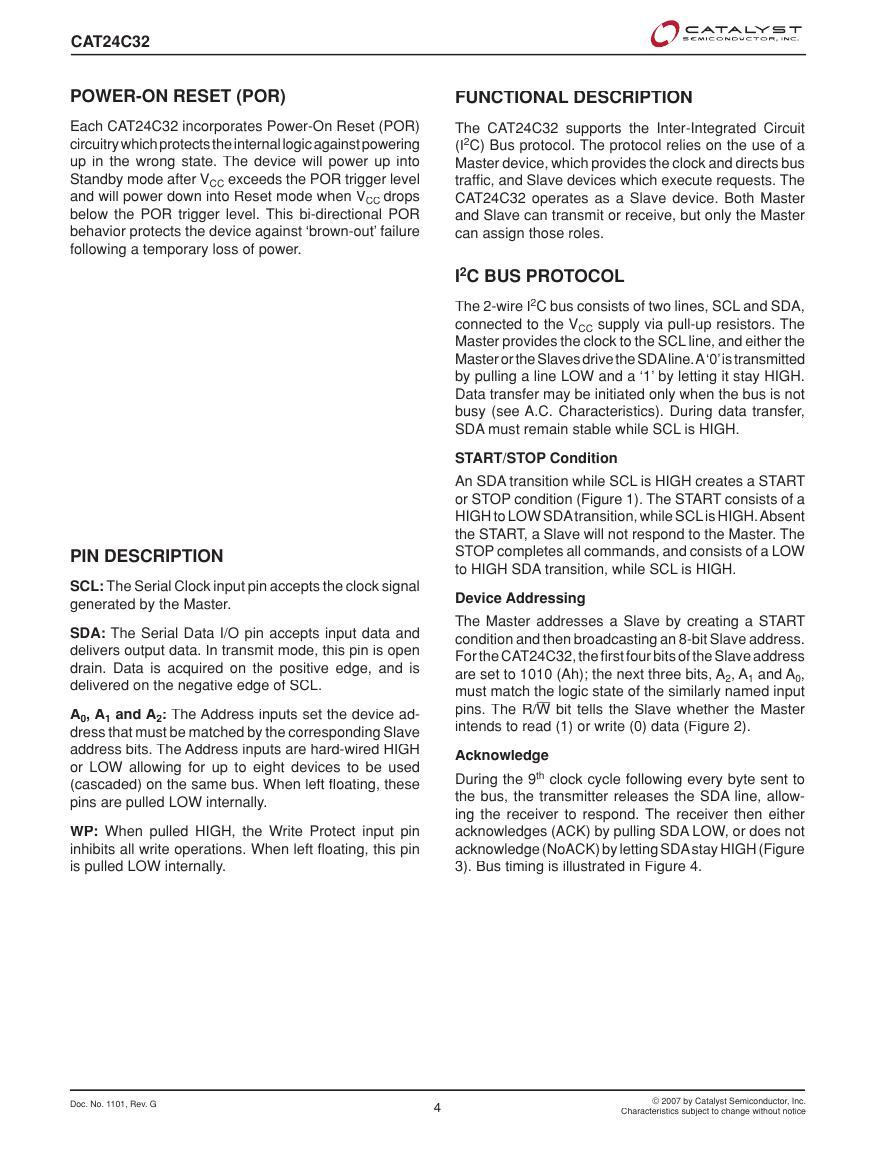

START/STOP Condition

An SDA transition while SCL is HIGH creates a START

or STOP condition (Figure 1). The START consists of a

HIGH to LOW SDA transition, while SCL is HIGH. Absent

the START, a Slave will not respond to the Master. The

STOP completes all commands, and consists of a LOW

to HIGH SDA transition, while SCL is HIGH.

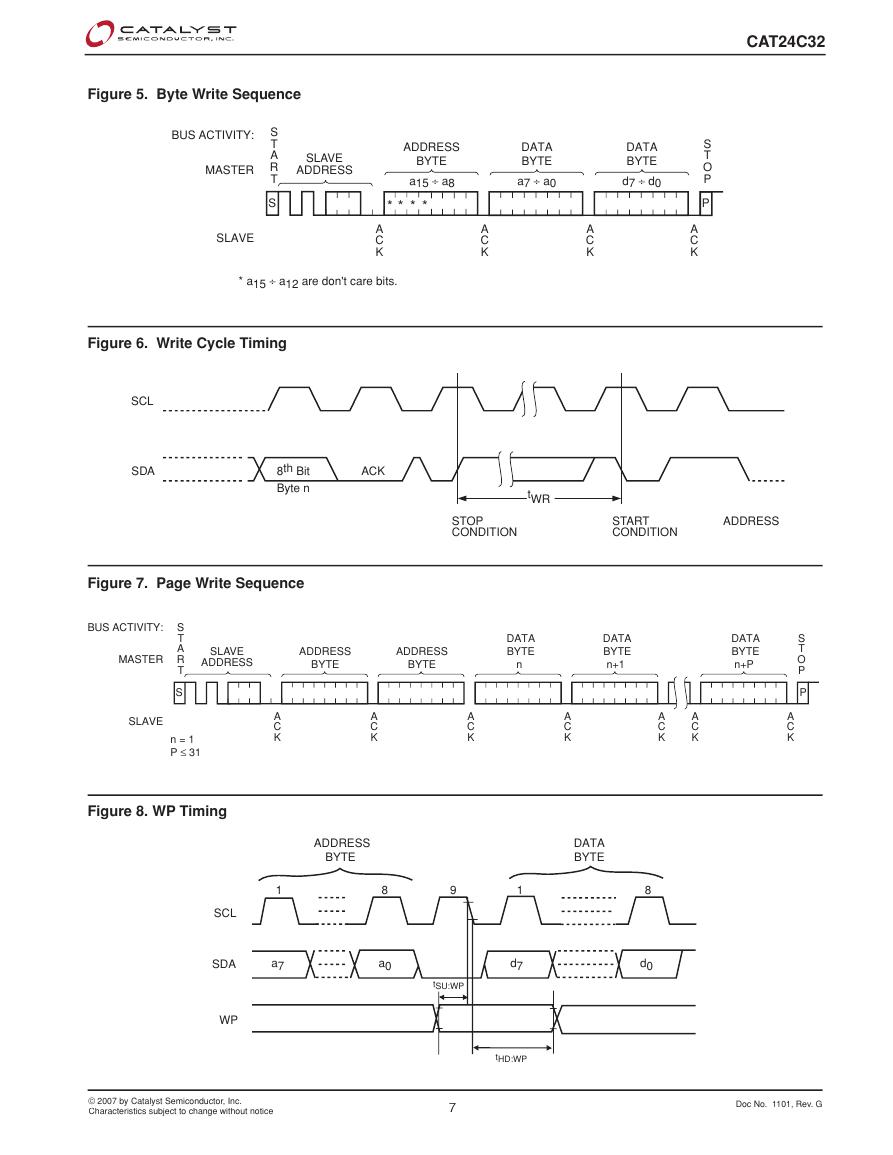

Device Addressing

The Master addresses a Slave by creating a START

condition and then broadcasting an 8-bit Slave address.

For the CAT24C32, the fi rst four bits of the Slave address

are set to 1010 (Ah); the next three bits, A2, A1 and A0,

must match the logic state of the similarly named input

pins. The R/W

pins. The R/W

pins. The R/

bit tells the Slave whether the Master

W bit tells the Slave whether the Master

W

intends to read (1) or write (0) data (Figure 2).

Acknowledge

During the 9th clock cycle following every byte sent to

the bus, the transmitter releases the SDA line, allow-

ing the receiver to respond. The receiver then either

acknowledges (ACK) by pulling SDA LOW, or does not

acknowledge (NoACK) by letting SDA stay HIGH (Figure

3). Bus timing is illustrated in Figure 4.

Doc. No. 1101, Rev. G

4

© 2007 by Catalyst Semiconductor, Inc.

Characteristics subject to change without notice

�

CAT24C32

Figure 1. Start/Stop Timing

SCL

SDA

START

CONDITION

STOP

CONDITION

Figure 2. Slave Address Bits

1

0

1

0

A2

A1

A0 R/W

DEVICE ADDRESS

Figure 3. Acknowledge Timing

BUS RELEASE DELAY (TRANSMITTER)

BUS RELEASE DELAY (RECEIVER)

1

8

9

SCL FROM

MASTER

DATA OUTPUT

FROM TRANSMITTER

DATA OUTPUT

FROM RECEIVER

START

ACK DELAY (≤ tAA)

ACK SETUP (≥ tSU:DAT)

Figure 4. Bus Timing

SCL

tSU:STA

SDA IN

SDA OUT

tF

tHIGH

tR

tLOW

tLOW

tHD:DAT

tHD:STA

tSU:DAT

tAA

tDH

tSU:STO

tBUF

© 2007 by Catalyst Semiconductor, Inc.

Characteristics subject to change without notice

5

Doc No. 1101, Rev. G

�

CAT24C32

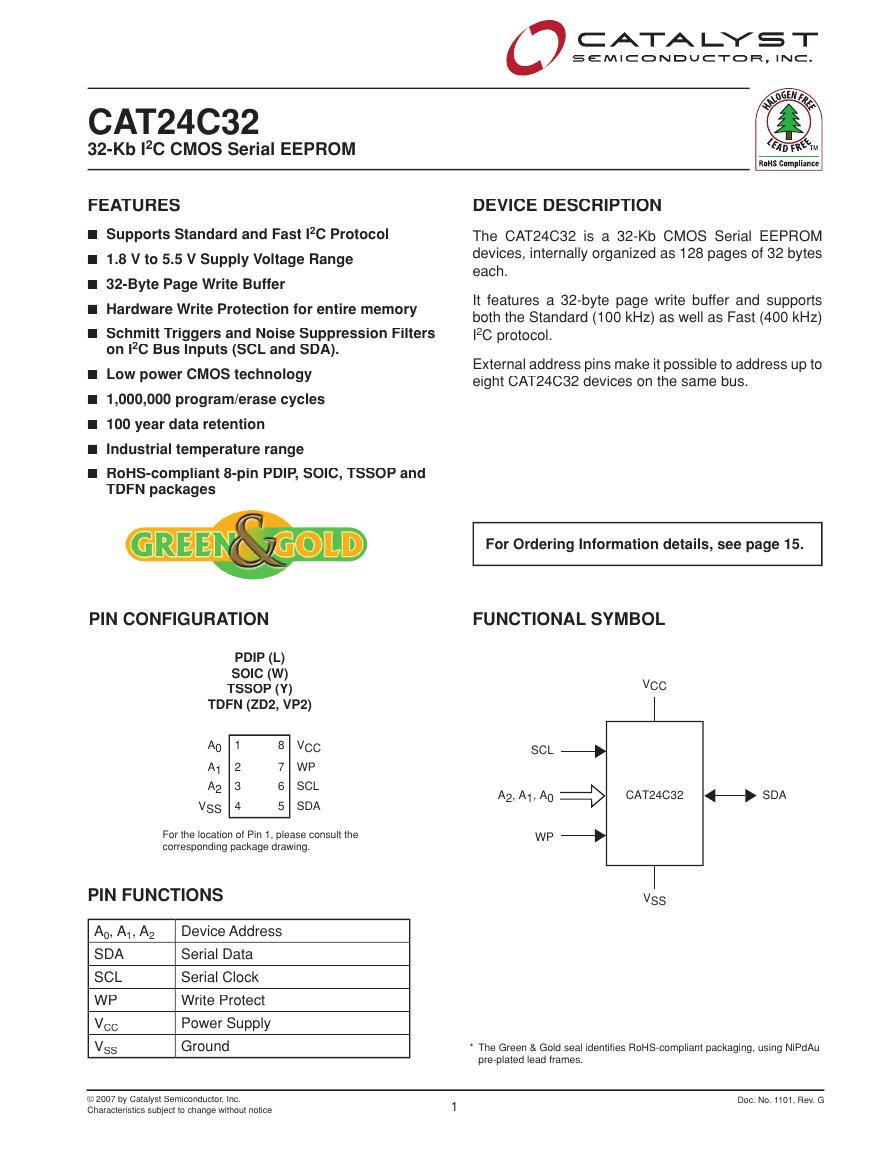

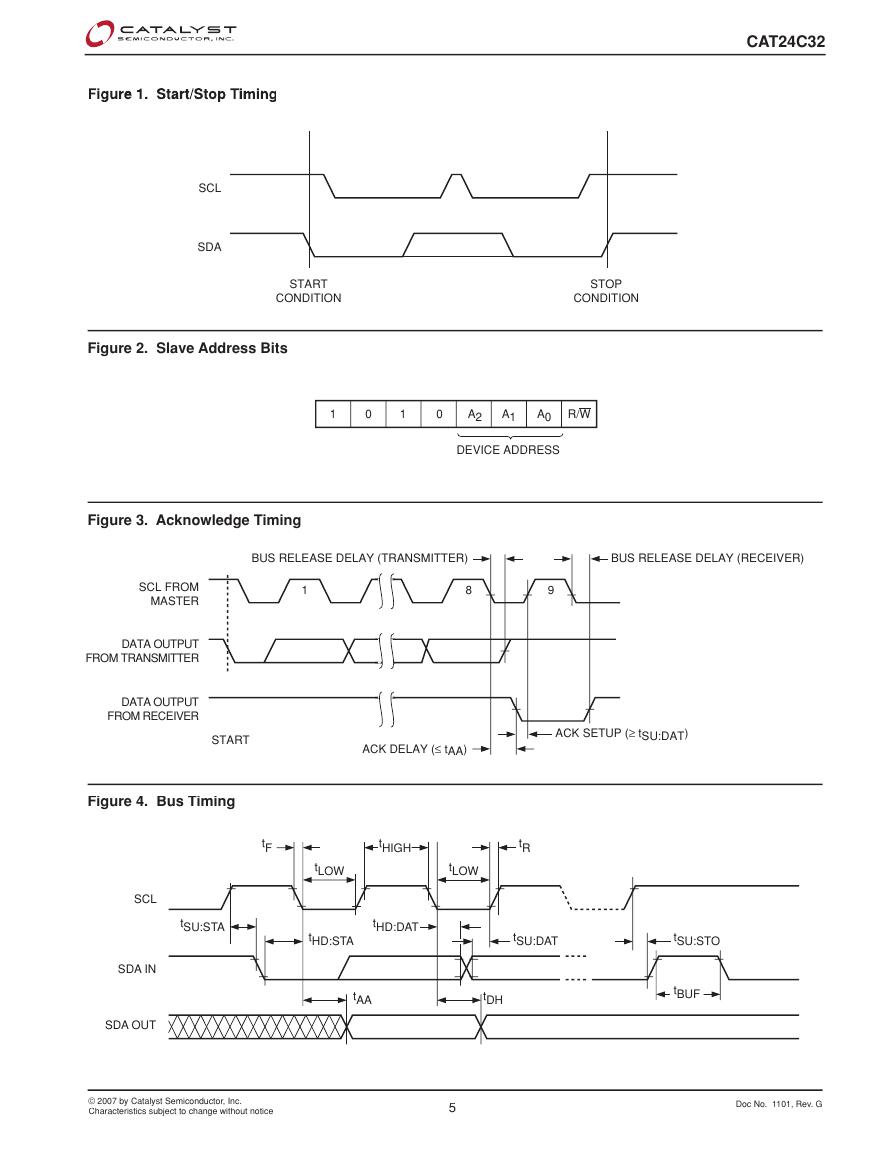

WRITE OPERATIONS

Byte Write

To write data to memory, the Master creates a START

condition on the bus and then broadcasts a Slave ad-

dress with the R/W

dress with the R/W

dress with the R/

bit set to ‘0’. The Master then sends

W bit set to ‘0’. The Master then sends

W

two address bytes and a data byte and concludes the

session by creating a STOP condition on the bus. The

Slave responds with ACK after every byte sent by the

Master (Figure 5). The STOP starts the internal Write

cycle, and while this operation is in progress (tWR), the

SDA output is tri-stated and the Slave does not acknowl-

edge the Master (Figure 6).

Page Write

The Byte Write operation can be expanded to Page

Write, by sending more than one data byte to the Slave

before issuing the STOP condition (Figure 7). Up to 32

distinct data bytes can be loaded into the internal Page

Write Buffer starting at the address provided by the

Master. The page address is latched, and as long as the

Master keeps sending data, the internal byte address is

incremented up to the end of page, where it then wraps

around (within the page). New data can therefore replace

data loaded earlier. Following the STOP, data loaded

during the Page Write session will be written to memory

in a single internal Write cycle (tWR).

Acknowledge Polling

As soon (and as long) as internal Write is in progress,

the Slave will not acknowledge the Master. This feature

enables the Master to immediately follow-up with a new

Read or Write request, rather than wait for the maximum

specifi ed Write time (tWR) to elapse. Upon receiving a

NoACK response from the Slave, the Master simply re-

peats the request until the Slave responds with ACK.

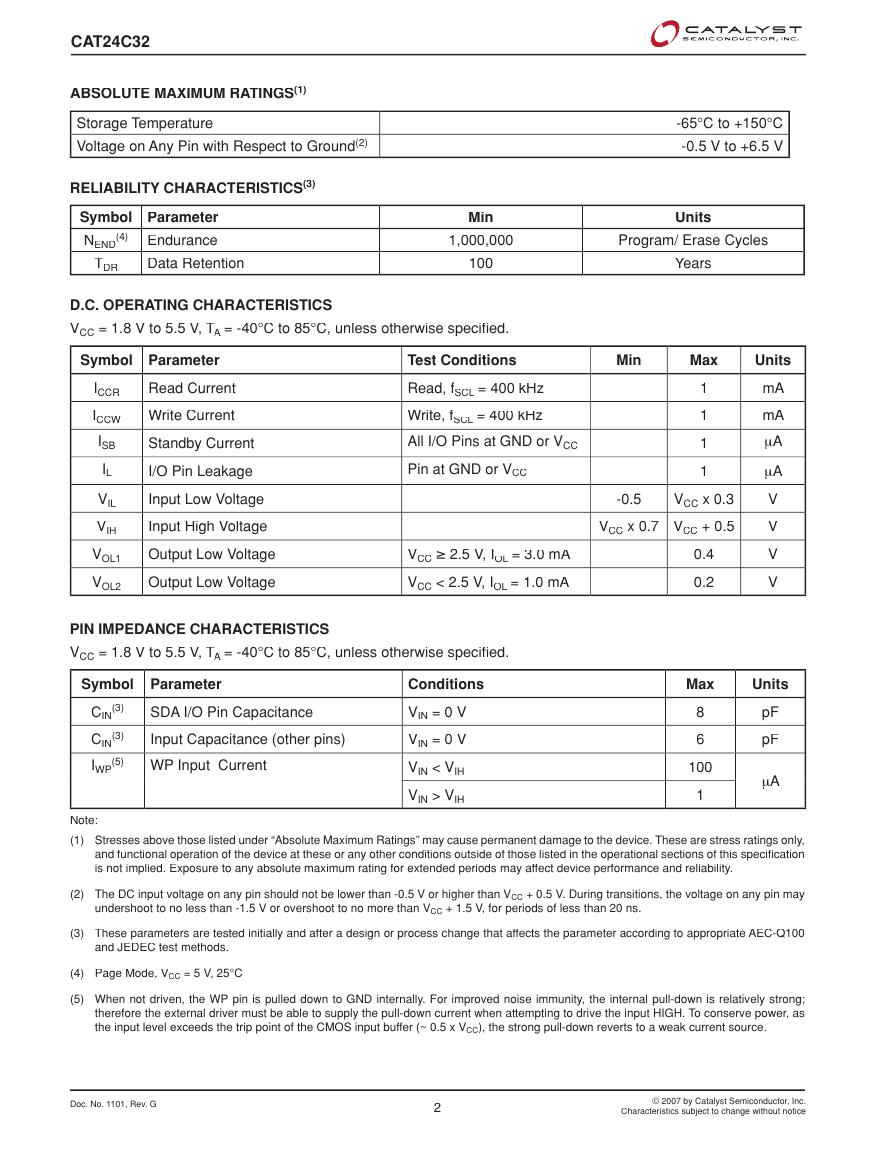

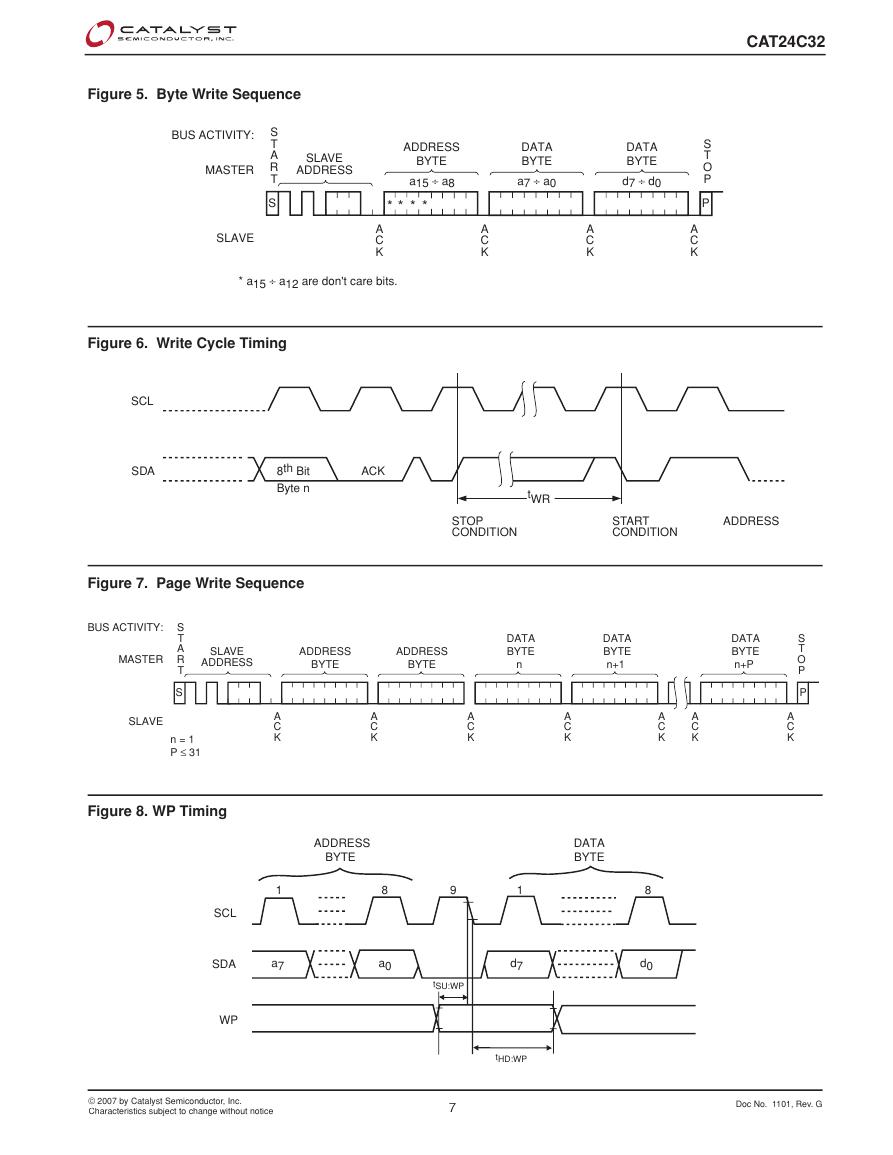

Hardware Write Protection

With the WP pin held HIGH, the entire memory is protected

against Write operations. If the WP pin is left fl oating or

is grounded, it has no impact on the Write operation. The

state of the WP pin is strobed on the last falling edge

of SCL immediately preceding the 1st data byte (Figure

8). If the WP pin is HIGH during the strobe interval, the

Slave will not acknowledge the data byte and the Write

request will be rejected.

Delivery State

The CAT24C32 is shipped erased, i.e., all bytes are

FFh.

Doc. No. 1101, Rev. G

6

© 2007 by Catalyst Semiconductor, Inc.

Characteristics subject to change without notice

�

CAT24C32

Figure 5. Byte Write Sequence

BUS ACTIVITY:

MASTER

S

T

A

R

T

S

SLAVE

SLAVE

ADDRESS

ADDRESS

BYTE

a15 ÷ a8

* *

**

DATA

BYTE

a7 ÷ a0

DATA

BYTE

d7 ÷ d0

A

C

K

A

C

K

A

C

K

S

T

O

P

P

A

C

K

* a15 ÷ a12 are don't care bits.

Figure 6. Write Cycle Timing

SCL

SDA

8th Bit

Byte n

ACK

tWR

STOP

CONDITION

START

CONDITION

ADDRESS

Figure 7. Page Write Sequence

SLAVE

ADDRESS

ADDRESS

BYTE

ADDRESS

BYTE

DATA

BYTE

n

DATA

BYTE

n+1

DATA

BYTE

n+P

A

C

K

A

C

K

A

C

K

A

C

K

A

C

K

S

T

O

P

P

A

C

K

BUS ACTIVITY:

MASTER

S

T

A

R

T

S

SLAVE

n = 1

P ≤ 31

Figure 8. WP Timing

SCL

A

C

K

1

ADDRESS

BYTE

DATA

BYTE

8

9

1

8

d0

SDA

a7

a0

d7

tSU:WP

WP

tHD:WP

© 2007 by Catalyst Semiconductor, Inc.

Characteristics subject to change without notice

7

Doc No. 1101, Rev. G

�

CAT24C32

READ OPERATIONS

Immediate Read

To read data from memory, the Master creates a START

condition on the bus and then broadcasts a Slave ad-

dress with the R/W

dress with the R/W

dress with the R/

bit set to ‘1’. The Slave responds with

W bit set to ‘1’. The Slave responds with

W

ACK and starts shifting out data residing at the current

address. After receiving the data, the Master responds

with NoACK and terminates the session by creating a

STOP condition on the bus (Figure 9). The Slave then

returns to Standby mode.

Selective Read

To read data residing at a specifi c address, the selected

address must fi rst be loaded into the internal address

register. This is done by starting a Byte Write sequence,

whereby the Master creates a START condition, then

broadcasts a Slave address with the R/W bit set to ‘0’

and then sends two address bytes to the Slave. Rather

than completing the Byte Write sequence by sending

data, the Master then creates a START condition and

broadcasts a Slave address with the R/W

broadcasts a Slave address with the R/W

broadcasts a Slave address with the R/

bit set to ‘1’.

W bit set to ‘1’.

W

The Slave responds with ACK after every byte sent by the

Master and then sends out data residing at the selected

address. After receiving the data, the Master responds

with NoACK and then terminates the session by creating

a STOP condition on the bus (Figure 10).

Sequential Read

If, after receiving data sent by the Slave, the Master

responds with ACK, then the Slave will continue transmit-

ting until the Master responds with NoACK followed by

STOP (Figure 11). During Sequential Read the internal

byte address is automatically incremented up to the end

of memory, where it then wraps around to the beginning

of memory.

Doc. No. 1101, Rev. G

8

© 2007 by Catalyst Semiconductor, Inc.

Characteristics subject to change without notice

�

V2版本原理图(Capacitive-Fingerprint-Reader-Schematic_V2).pdf

V2版本原理图(Capacitive-Fingerprint-Reader-Schematic_V2).pdf 摄像头工作原理.doc

摄像头工作原理.doc VL53L0X简要说明(En.FLVL53L00216).pdf

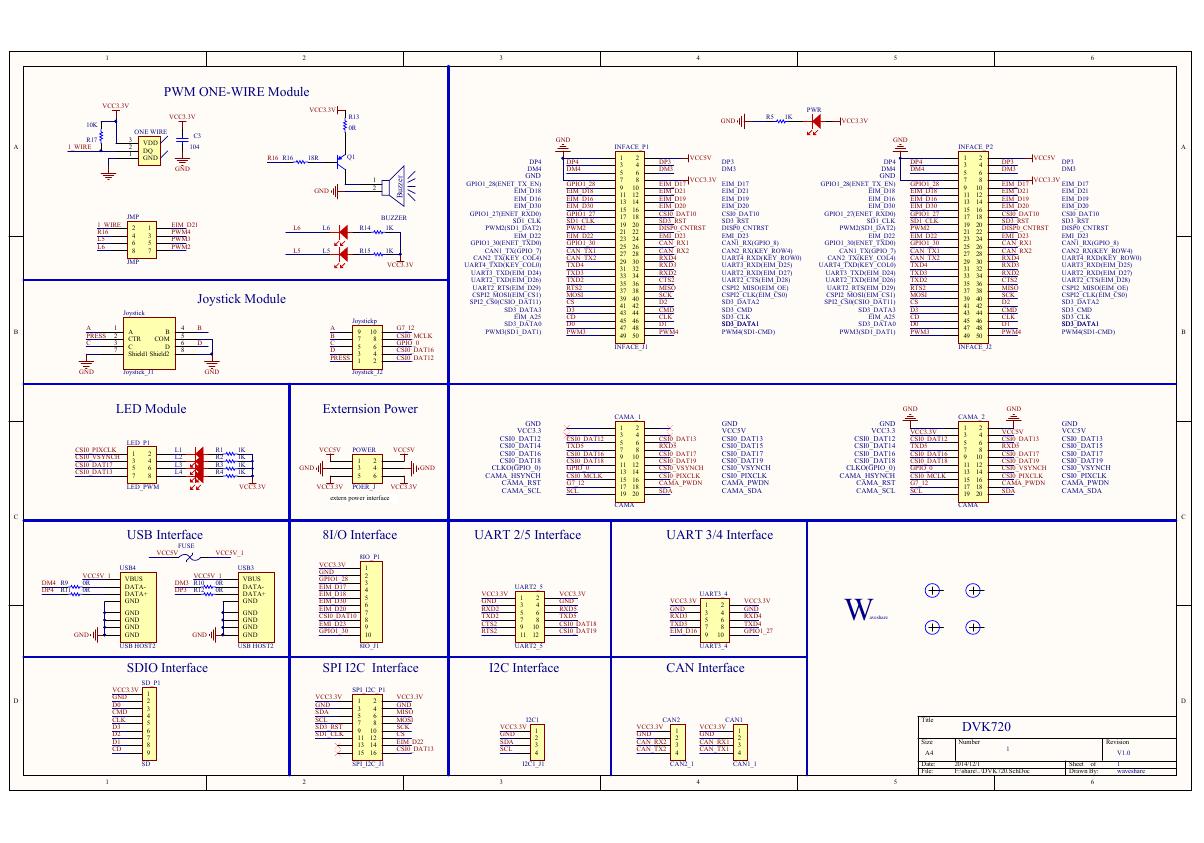

VL53L0X简要说明(En.FLVL53L00216).pdf 原理图(DVK720-Schematic).pdf

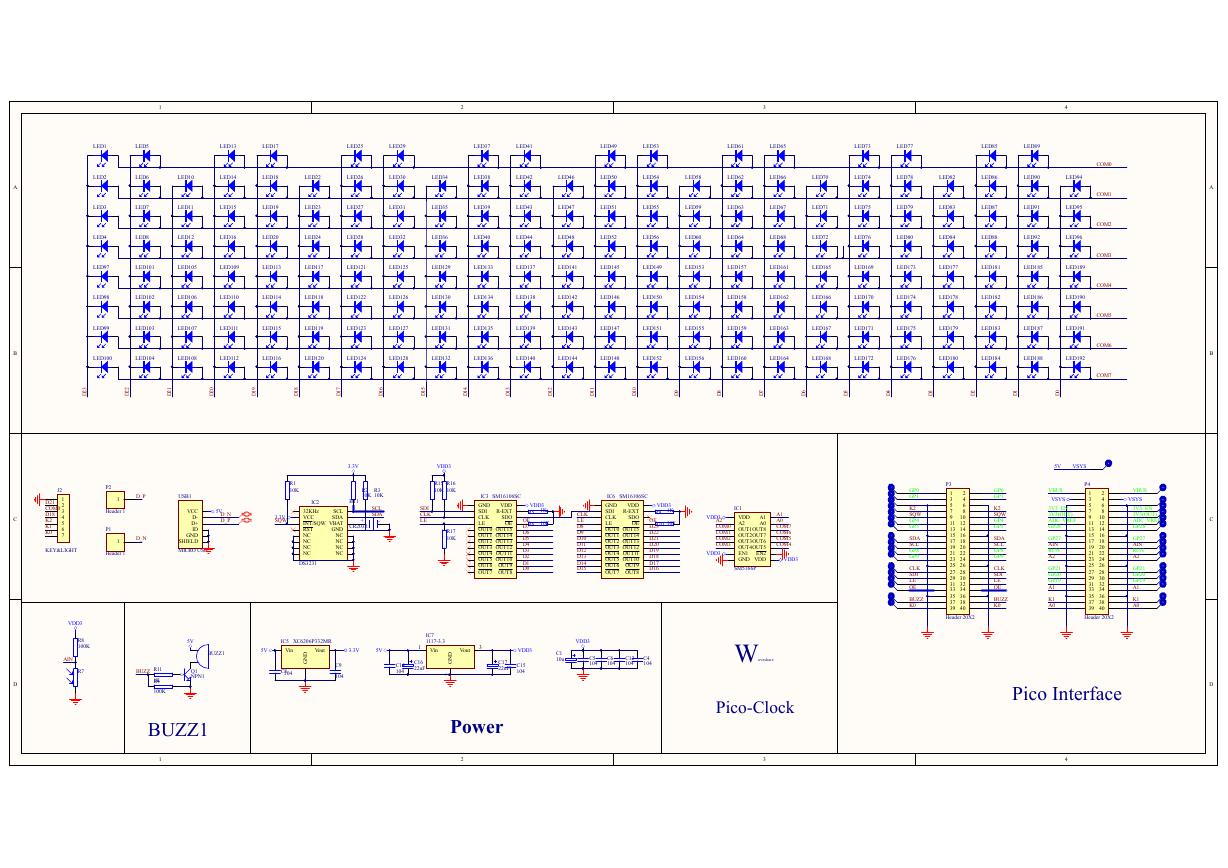

原理图(DVK720-Schematic).pdf 原理图(Pico-Clock-Green-Schdoc).pdf

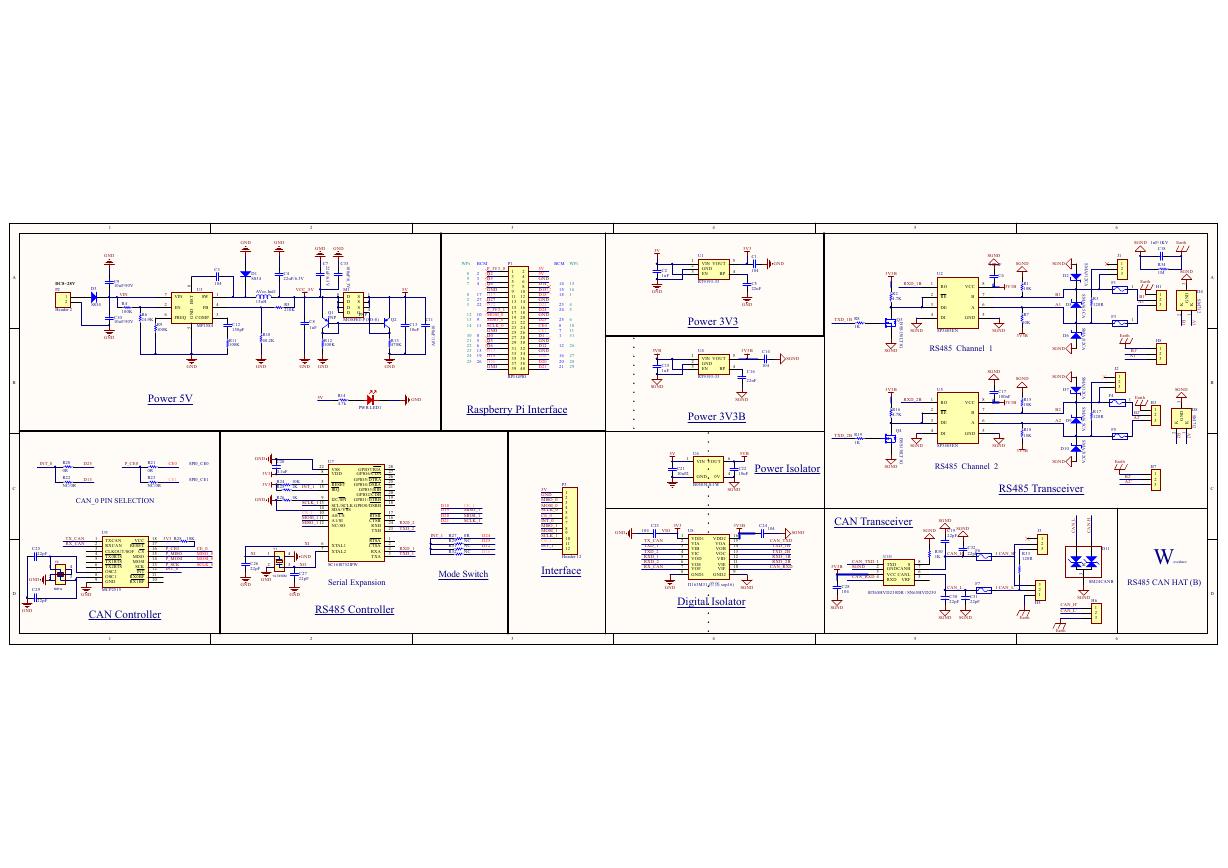

原理图(Pico-Clock-Green-Schdoc).pdf 原理图(RS485-CAN-HAT-B-schematic).pdf

原理图(RS485-CAN-HAT-B-schematic).pdf File:SIM7500_SIM7600_SIM7800 Series_SSL_Application Note_V2.00.pdf

File:SIM7500_SIM7600_SIM7800 Series_SSL_Application Note_V2.00.pdf ADS1263(Ads1262).pdf

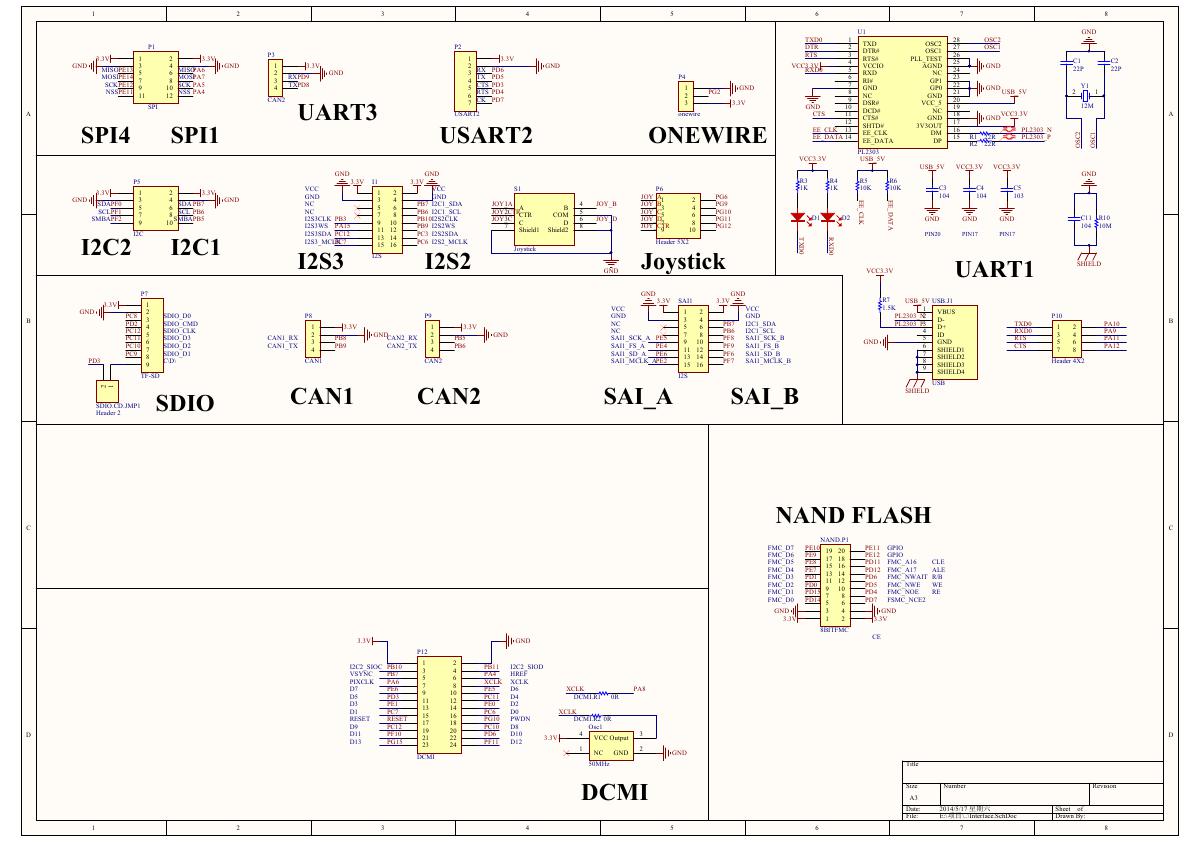

ADS1263(Ads1262).pdf 原理图(Open429Z-D-Schematic).pdf

原理图(Open429Z-D-Schematic).pdf 用户手册(Capacitive_Fingerprint_Reader_User_Manual_CN).pdf

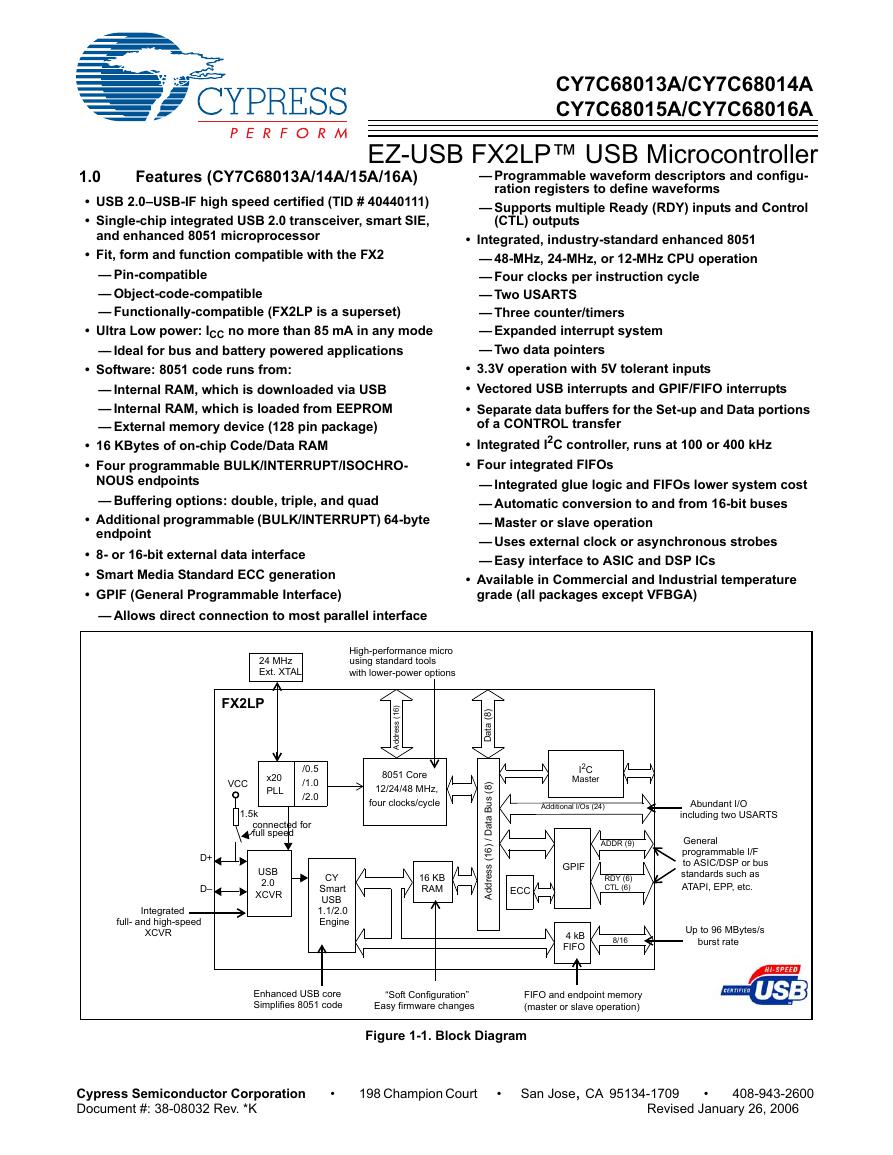

用户手册(Capacitive_Fingerprint_Reader_User_Manual_CN).pdf CY7C68013A(英文版)(CY7C68013A).pdf

CY7C68013A(英文版)(CY7C68013A).pdf TechnicalReference_Dem.pdf

TechnicalReference_Dem.pdf