TABLE OF CONTENS

CAUTION

CAUTION

Requests

FCC Statement (USA)

Interference to televisions and radios

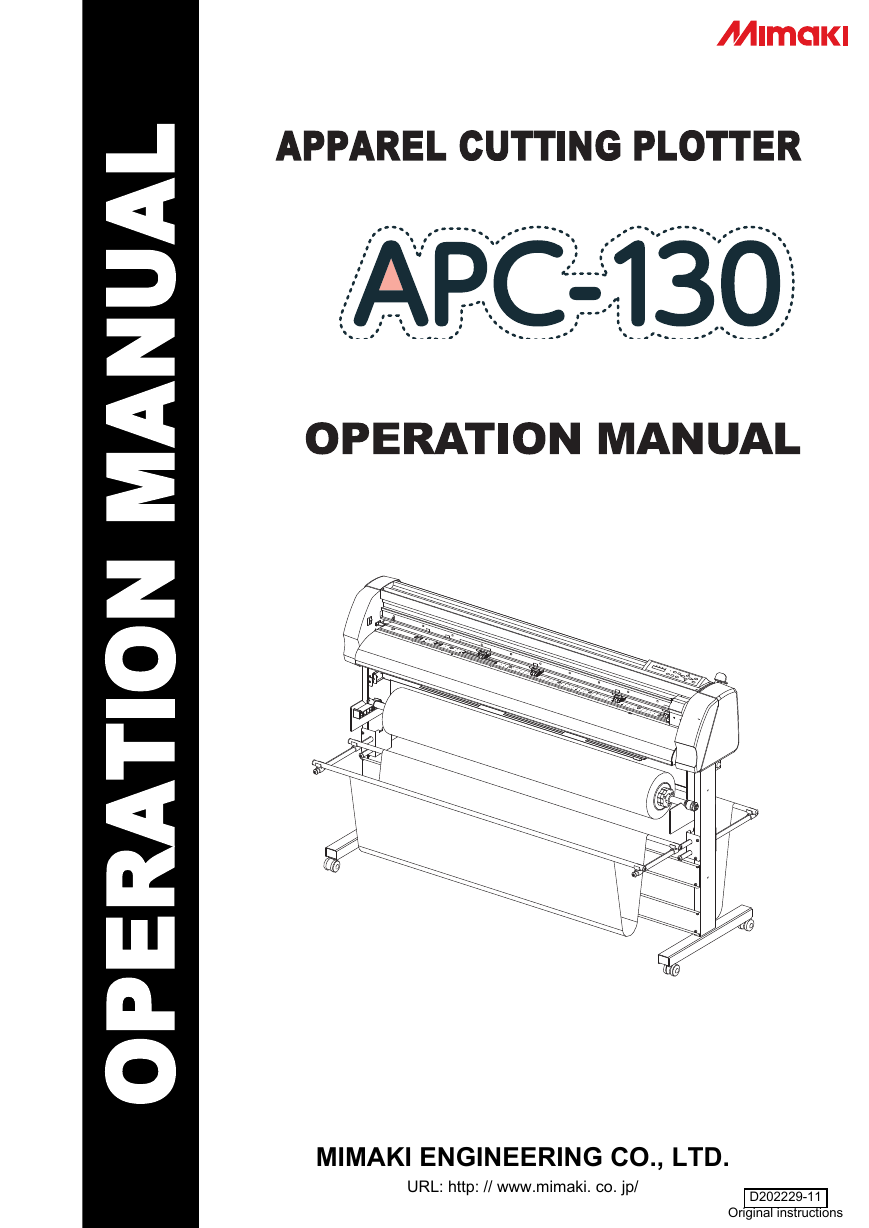

Foreword

On This Operation manual

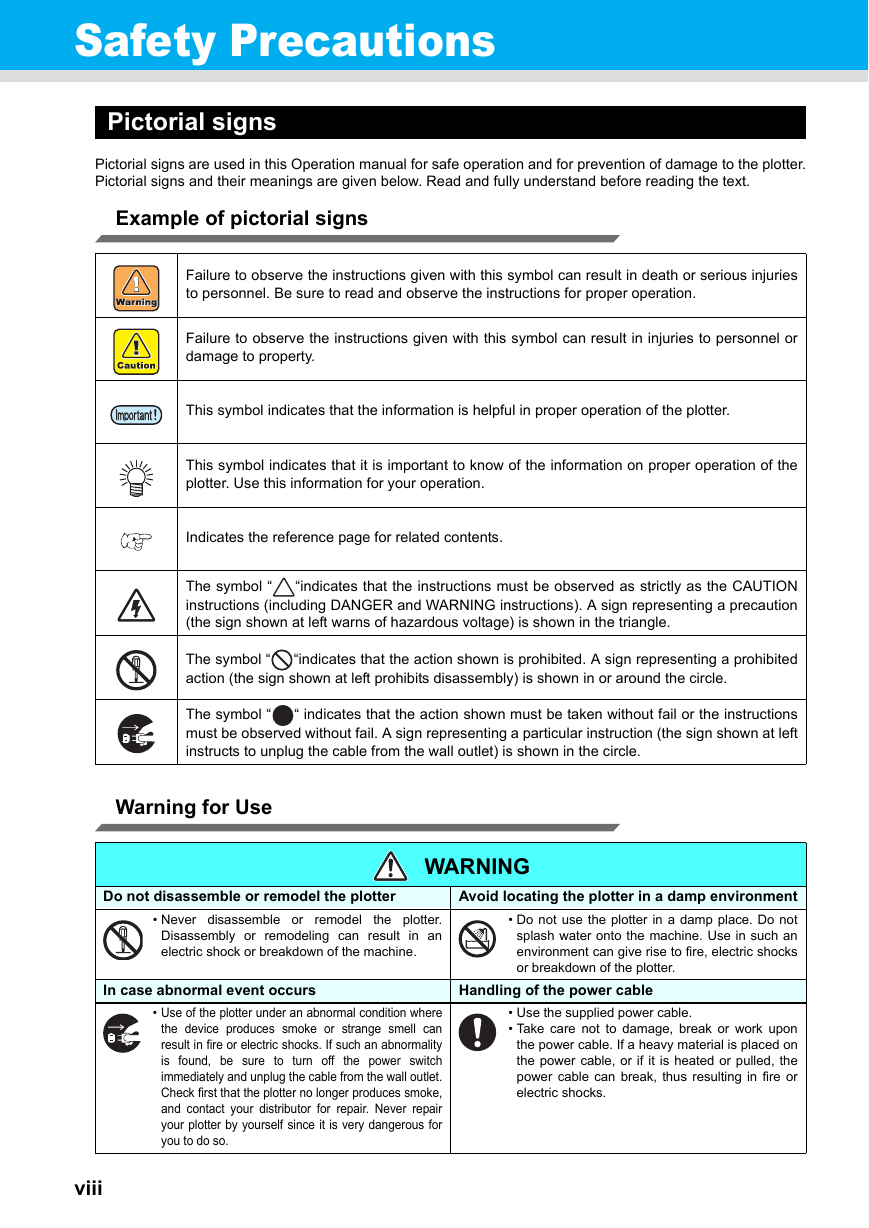

Safety Precautions

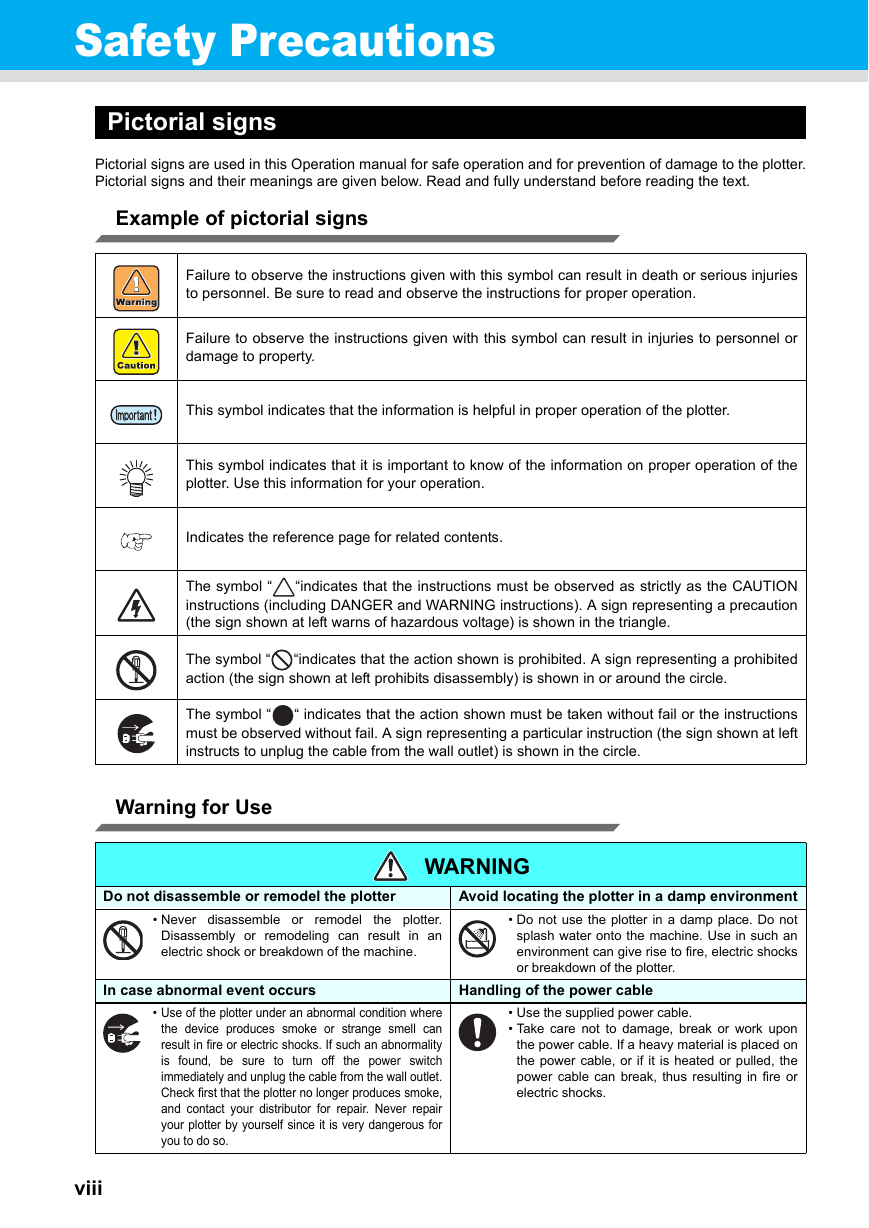

Pictorial signs

Example of pictorial signs

Warning for Use

Precaution for Use

Cautions on Installation

Safety Labels

How to Read This Operation Manual

Chapter 1 Before Use

Installing this machine

Where to install this machine

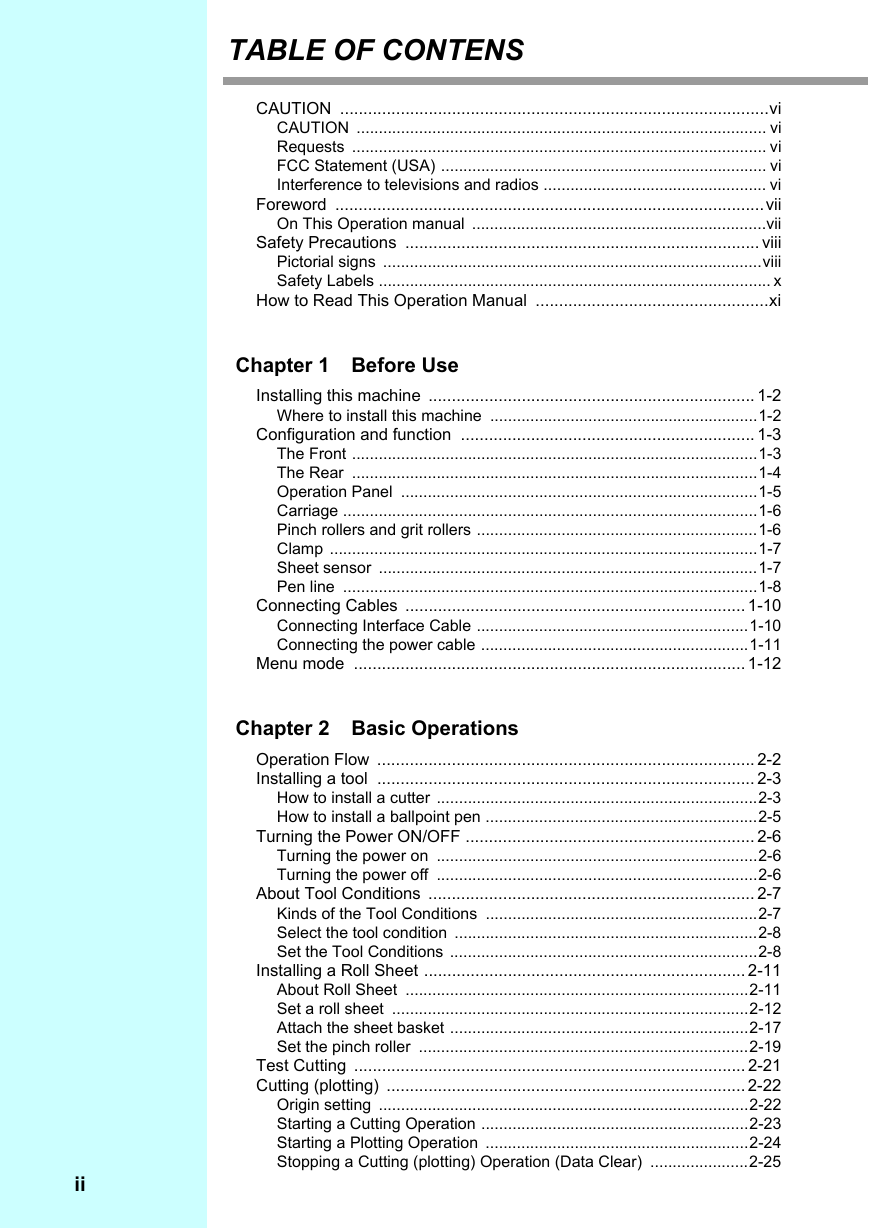

Configuration and function

The Front

The Rear

Operation Panel

Jog keys

Carriage

Pinch rollers and grit rollers

Clamp

Sheet sensor

Pen line

Replacing method of pen line

Connecting Cables

Connecting Interface Cable

Connecting USB Interface Cable

Connecting RS-232C Interface Cable

Connecting the power cable

Menu mode

Chapter 2 Basic Operations

Operation Flow

Installing a tool

How to install a cutter

Mounting a Cutter Blade

Adjusting the protrusion of the cutter blade

How to install the cutter holder

How to install a ballpoint pen

Turning the Power ON/OFF

Turning the power on

Turning the power off

About Tool Conditions

Kinds of the Tool Conditions

Select the tool condition

Set the Tool Conditions

Reference for cutting condition

Installing a Roll Sheet

About Roll Sheet

Usable Sizes of Sheet

Caution in Handling of Sheet

Set a roll sheet

About sheet detection

Attach the sheet basket

Set the pinch roller

About available area for cutting

Test Cutting

Cutting (plotting)

Origin setting

Starting a Cutting Operation

Starting a Plotting Operation

Suspension of cutting (plotting)

Stopping a Cutting (plotting) Operation (Data Clear)

Chapter 3 Extended Functions

Function by jog mode

Paper cut

Axial correction of two positions

Setting cut area

Digitizing operation

Perform Multiple Cutting (plotting)

Investigate the causes of cutting abnormality

About the Result of Sample Cutting

Cut the sample data “Cut”

Cut the sample data “LOGO”

Cut the sample data “RECTANGLE”

Distance correction

Sheet feed

Hold

Setting function

Setting the COMMAND

Setting the INTERFACE

Setting the Device No.

Setting the ORIGIN SELECT

Setting the AUTO CUT

Setting the ROTATION

Setting the BUZZER

Setting the PRIORITY

Setting the SHEET SENSOR

Setting the UP SPEED

Setting the JOG STEP

Setting the MM/INCH

Setting the PRE FEED

Setting the FEED OFFSET

Setting the DUMMY CUT

Setting the SHEET TYPE

Setting the SORTING

Setting the SORTING

Cancelling the Setting of the SORTING

Procedure for SORTING

Setting the OVER CUT

Setting the START MODE

Setting the IP x Distance

Setting the NRg!PG CHANGE

Setting the PEN No. ASSIGN

Setting the Tool Change

Initializing the Settings

Output the setting list

Output the received data in the ASCII code

Switch the language display on the screen

Chapter 4 Troubleshooting

Troubleshooting

Warning/Error Messages

Error Messages

Warning Messages

Chapter 5 Appendix

Specification

Maintenance

Cleaning the Exterior Surfaces

Cleaning the Platen

Function Flowchart

Function by the dedicated key

Function by the jog mode

Functions

2023年江西萍乡中考道德与法治真题及答案.doc

2023年江西萍乡中考道德与法治真题及答案.doc 2012年重庆南川中考生物真题及答案.doc

2012年重庆南川中考生物真题及答案.doc 2013年江西师范大学地理学综合及文艺理论基础考研真题.doc

2013年江西师范大学地理学综合及文艺理论基础考研真题.doc 2020年四川甘孜小升初语文真题及答案I卷.doc

2020年四川甘孜小升初语文真题及答案I卷.doc 2020年注册岩土工程师专业基础考试真题及答案.doc

2020年注册岩土工程师专业基础考试真题及答案.doc 2023-2024学年福建省厦门市九年级上学期数学月考试题及答案.doc

2023-2024学年福建省厦门市九年级上学期数学月考试题及答案.doc 2021-2022学年辽宁省沈阳市大东区九年级上学期语文期末试题及答案.doc

2021-2022学年辽宁省沈阳市大东区九年级上学期语文期末试题及答案.doc 2022-2023学年北京东城区初三第一学期物理期末试卷及答案.doc

2022-2023学年北京东城区初三第一学期物理期末试卷及答案.doc 2018上半年江西教师资格初中地理学科知识与教学能力真题及答案.doc

2018上半年江西教师资格初中地理学科知识与教学能力真题及答案.doc 2012年河北国家公务员申论考试真题及答案-省级.doc

2012年河北国家公务员申论考试真题及答案-省级.doc 2020-2021学年江苏省扬州市江都区邵樊片九年级上学期数学第一次质量检测试题及答案.doc

2020-2021学年江苏省扬州市江都区邵樊片九年级上学期数学第一次质量检测试题及答案.doc 2022下半年黑龙江教师资格证中学综合素质真题及答案.doc

2022下半年黑龙江教师资格证中学综合素质真题及答案.doc