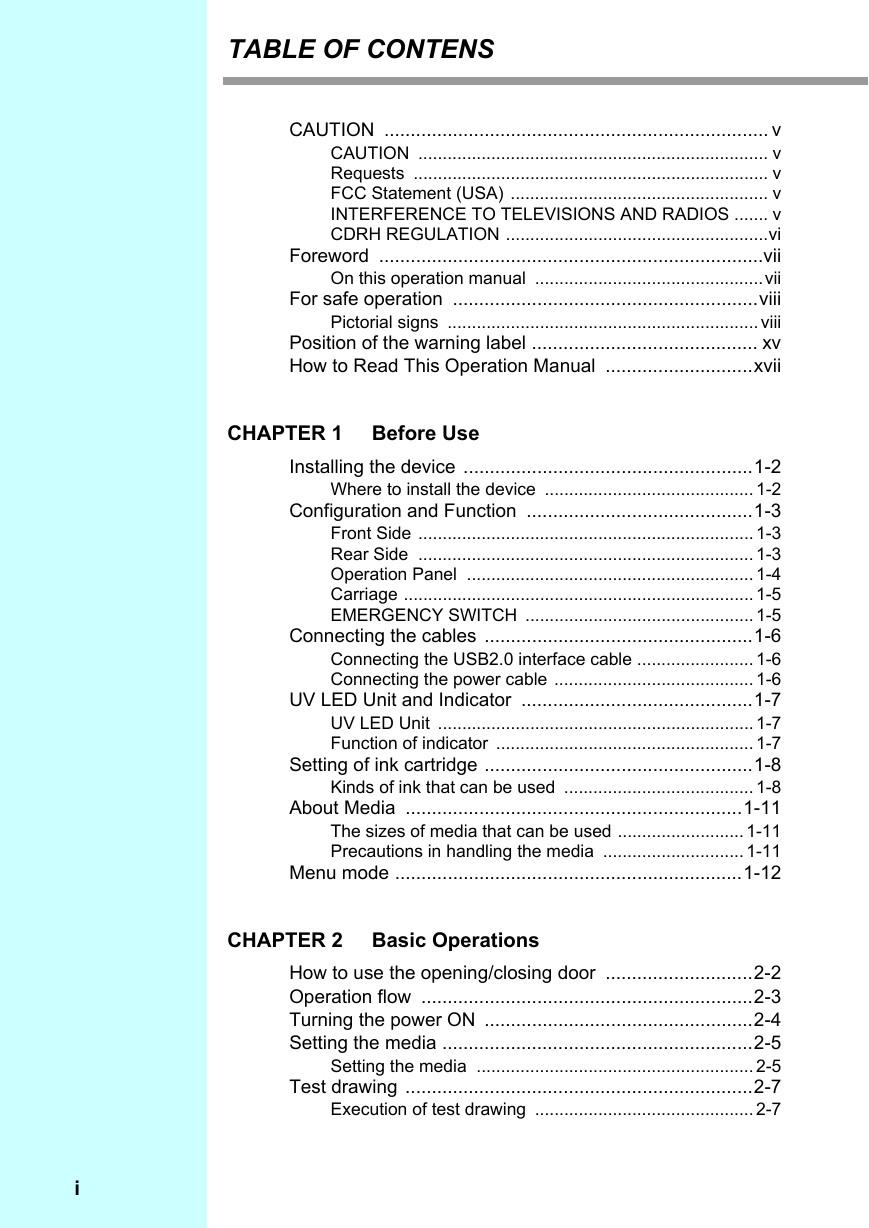

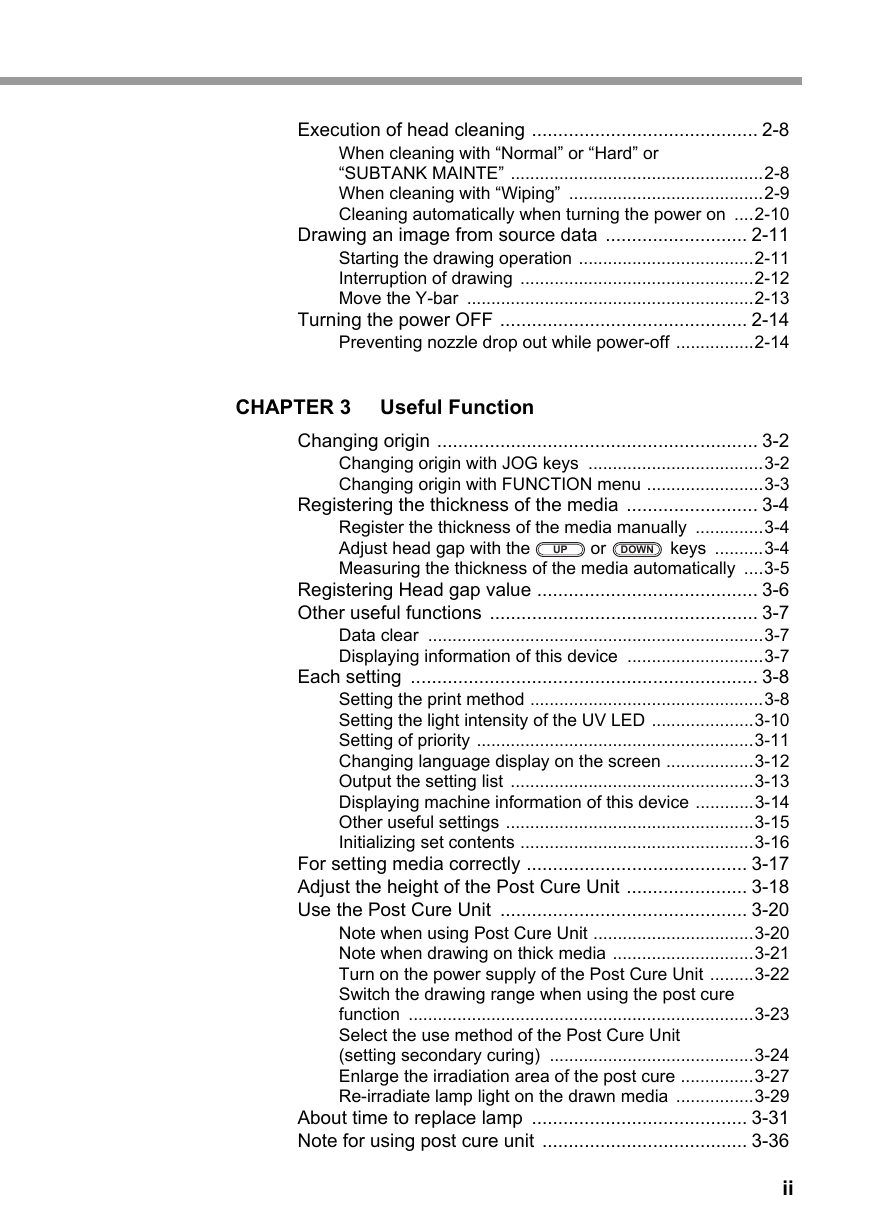

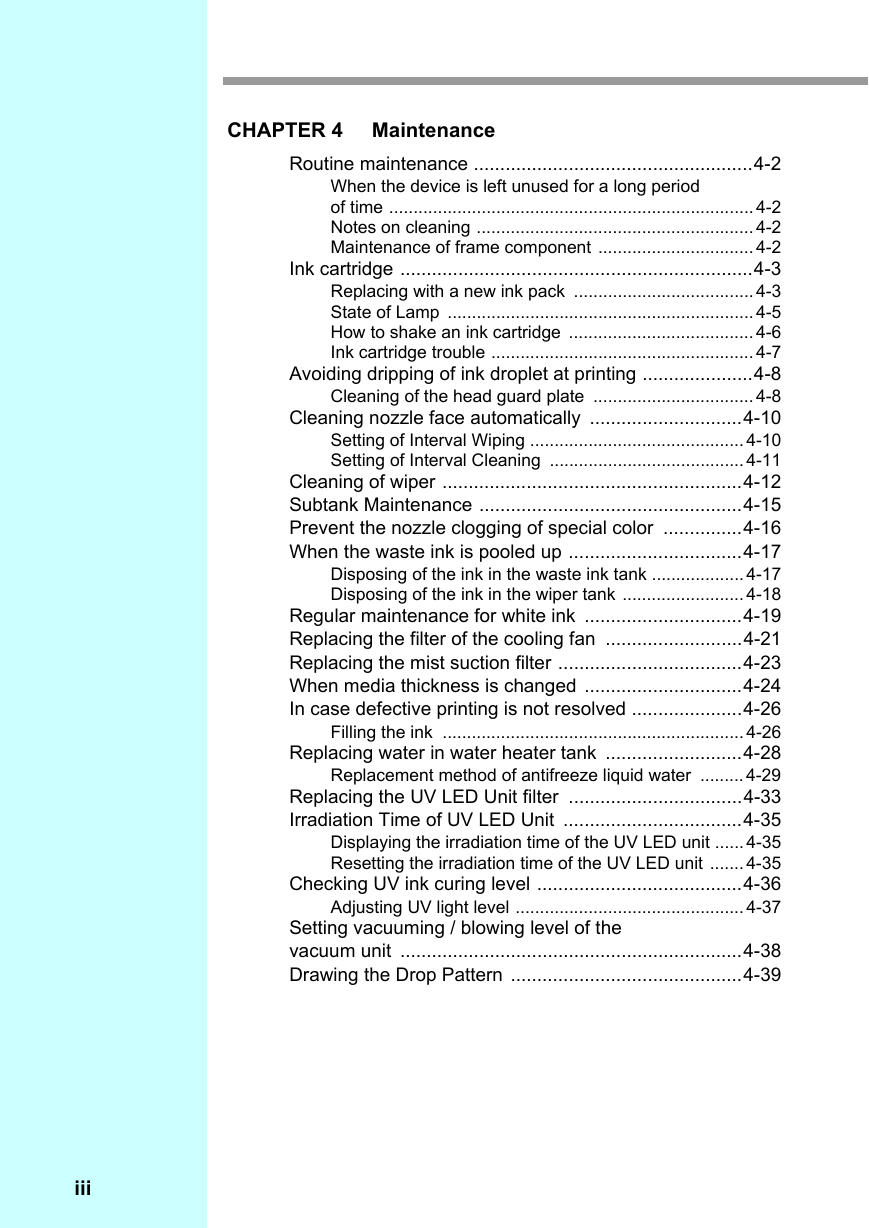

TABLE OF CONTENS

CAUTION

CAUTION

Requests

FCC Statement (USA)

INTERFERENCE TO TELEVISIONS AND RADIOS

CDRH REGULATION

Foreword

On this operation manual

For safe operation

Pictorial signs

Example of pictorial signs

Never do the following

Precautions for use

Notices for installation

Position of the warning label

How to Read This Operation Manual

CHAPTER 1 Before Use

Installing the device

Where to install the device

Configuration and Function

Front Side

Rear Side

Operation Panel

Function of Jog Keys

Carriage

EMERGENCY SWITCH

Connecting the cables

Connecting the USB2.0 interface cable

Connecting the power cable

UV LED Unit and Indicator

UV LED Unit

Function of indicator

Setting of ink cartridge

Kinds of ink that can be used

Precautions at the time of setting the ink cartridge

Precautions in handling ink cartridge

Precautions in handling an unused slot

About Media

The sizes of media that can be used

Precautions in handling the media

Menu mode

CHAPTER 2 Basic Operations

How to use the opening/closing door

When setting the media

When drawing the image

Operation flow

Turning the power ON

Setting the media

Setting the media

On the absorption area

Test drawing

Execution of test drawing

Execution of head cleaning

When cleaning with “Normal” or “Hard” or “SUBTANK MAINTE”

When cleaning with “Wiping”

Cleaning automatically when turning the power on

Drawing an image from source data

Starting the drawing operation

Interruption of drawing

Move the Y-bar

Setting the view position

Evacuation of Y-bar from the table

Turning the power OFF

Preventing nozzle drop out while power-off

When turning the power OFF

CHAPTER 3 Useful Function

Changing origin

Changing origin with JOG keys

Changing origin with FUNCTION menu

Registering the thickness of the media

Register the thickness of the media manually

Adjust head gap with the [UP] or [DOWN] keys

Measuring the thickness of the media automatically

Registering Head gap value

Other useful functions

Data clear

Displaying information of this device

Each setting

Setting the print method

Setting the light intensity of the UV LED

Setting of priority

Changing language display on the screen

Output the setting list

Displaying machine information of this device

Other useful settings

Initializing set contents

For setting media correctly

Arrangement of guide holes

Adjust the height of the Post Cure Unit

Use the Post Cure Unit

Note when using Post Cure Unit

Note when drawing on thick media

Attach the UV shade curtain

Turn on the power supply of the Post Cure Unit

Switch the drawing range when using the post cure function

Select the use method of the Post Cure Unit (setting secondary curing)

When [DRAWING RANGE] is “Cure Print”

When [DRAWING RANGE] is “after print”

Enlarge the irradiation area of the post cure

Re-irradiate lamp light on the drawn media

Setting method of area for irradiating lamp light

About time to replace lamp

Note for using post cure unit

If you cannot keep the head gap properly/evenly

When performing long hours of continuous printing

CHAPTER 4 Maintenance

Routine maintenance

When the device is left unused for a long period of time

Notes on cleaning

Maintenance of frame component

Ink cartridge

Replacing with a new ink pack

Replacement of ink packs

State of Lamp

Cartridges that cannot be used (Lights in red)

Conditions for cartridge switching

How to shake an ink cartridge

Ink cartridge trouble

Warnings and operations

Avoiding dripping of ink droplet at printing

Cleaning of the head guard plate

Cleaning nozzle face automatically

Setting of Interval Wiping

Setting of Interval Cleaning

Cleaning of wiper

Subtank Maintenance

Prevent the nozzle clogging of special color

When the waste ink is pooled up

Disposing of the ink in the waste ink tank

Disposing of the ink in the wiper tank

Regular maintenance for white ink

Replacing the filter of the cooling fan

Replacing the mist suction filter

When media thickness is changed

Samples of pattern drawn

In case defective printing is not resolved

Filling the ink

Replacing water in water heater tank

Replacement method of antifreeze liquid water

Replacing using water heater exchange mode

Replacing when the power is turned OFF

Replacing the UV LED Unit filter

Irradiation Time of UV LED Unit

Displaying the irradiation time of the UV LED unit

Resetting the irradiation time of the UV LED unit

Checking UV ink curing level

Adjusting UV light level

Setting vacuuming / blowing level of the vacuum unit

Drawing the Drop Pattern

CHAPTER 5 In Case of Trouble

Before taking a phenomenon as a trouble

The device cannot be energized

The device cannot perform printing

Display [ WATER NOT READY ]

If image quality declines

Resolving nozzle clogging

Stopping the unit during the operation

Even when ink remains, [INK NEAR END] is displayed

Troubles for which error messages are given on the LCD

Errors accompanied by warnings

Error message

CHAPTER 6 Appendix

Specifications

Basic unit specifications

Specifications for ink

Function Flowchart

2023年江西萍乡中考道德与法治真题及答案.doc

2023年江西萍乡中考道德与法治真题及答案.doc 2012年重庆南川中考生物真题及答案.doc

2012年重庆南川中考生物真题及答案.doc 2013年江西师范大学地理学综合及文艺理论基础考研真题.doc

2013年江西师范大学地理学综合及文艺理论基础考研真题.doc 2020年四川甘孜小升初语文真题及答案I卷.doc

2020年四川甘孜小升初语文真题及答案I卷.doc 2020年注册岩土工程师专业基础考试真题及答案.doc

2020年注册岩土工程师专业基础考试真题及答案.doc 2023-2024学年福建省厦门市九年级上学期数学月考试题及答案.doc

2023-2024学年福建省厦门市九年级上学期数学月考试题及答案.doc 2021-2022学年辽宁省沈阳市大东区九年级上学期语文期末试题及答案.doc

2021-2022学年辽宁省沈阳市大东区九年级上学期语文期末试题及答案.doc 2022-2023学年北京东城区初三第一学期物理期末试卷及答案.doc

2022-2023学年北京东城区初三第一学期物理期末试卷及答案.doc 2018上半年江西教师资格初中地理学科知识与教学能力真题及答案.doc

2018上半年江西教师资格初中地理学科知识与教学能力真题及答案.doc 2012年河北国家公务员申论考试真题及答案-省级.doc

2012年河北国家公务员申论考试真题及答案-省级.doc 2020-2021学年江苏省扬州市江都区邵樊片九年级上学期数学第一次质量检测试题及答案.doc

2020-2021学年江苏省扬州市江都区邵樊片九年级上学期数学第一次质量检测试题及答案.doc 2022下半年黑龙江教师资格证中学综合素质真题及答案.doc

2022下半年黑龙江教师资格证中学综合素质真题及答案.doc