TABLE OF CONTENTS

WARNING

CAUTION

CHAPTER 1 SET-UP

INSTALLATION SITE

Blower installation area

Effective cutting area

CHECKING THE ACCESSORIES

CONFIGURATION AND FUNCTION

Main unit

Right-hand side face of the electrical box

Blower unit

Head

Operation panel

CONNECTING THE CABLES

Connecting the signal wire cable for the blower

Connecting the interface cable

Connecting the power cable

Turning the power on/off

Turning the power on

Turning the power off

Emergency stop

How to stop the device in an emergency

How to reset the emergency stop

LOCAL/REMOTE MODES

LOCAL mode and the indication on the LCD

REMOTE mode and the indications on the LCD

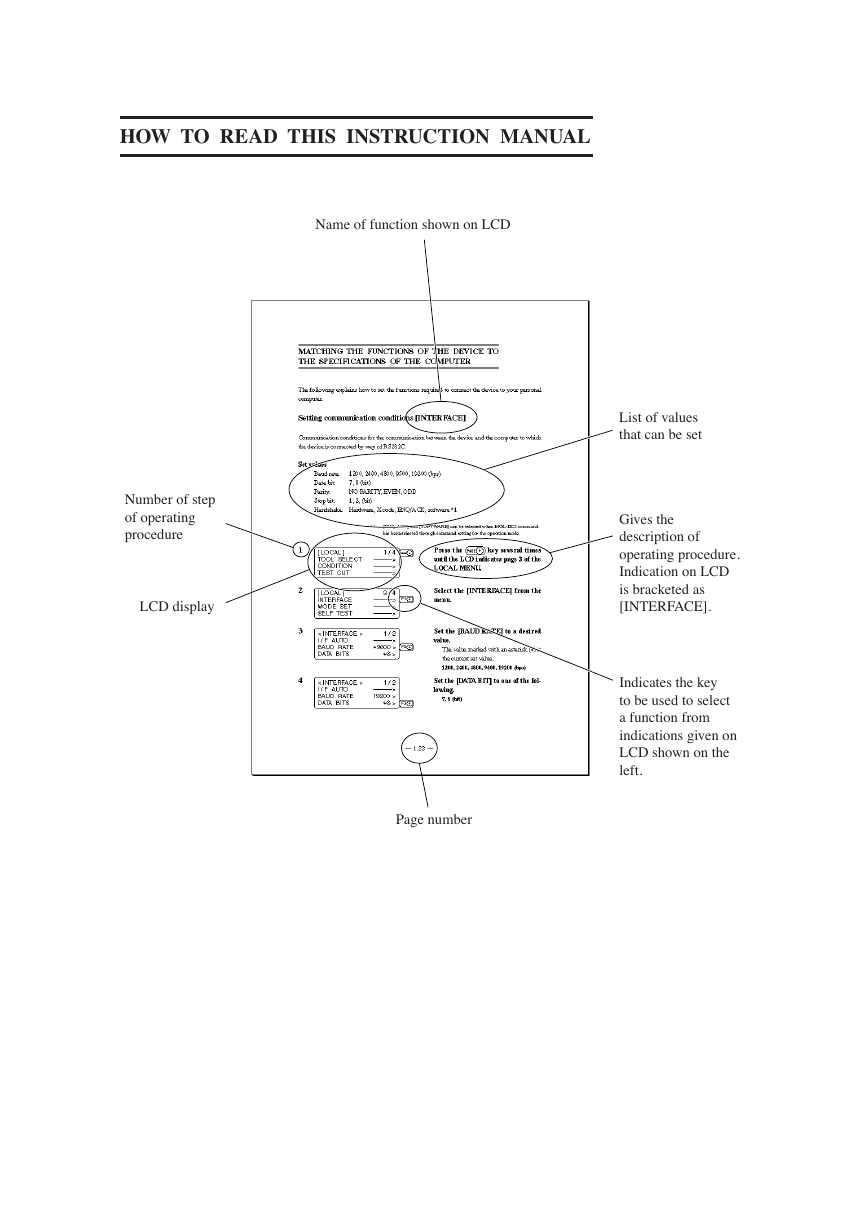

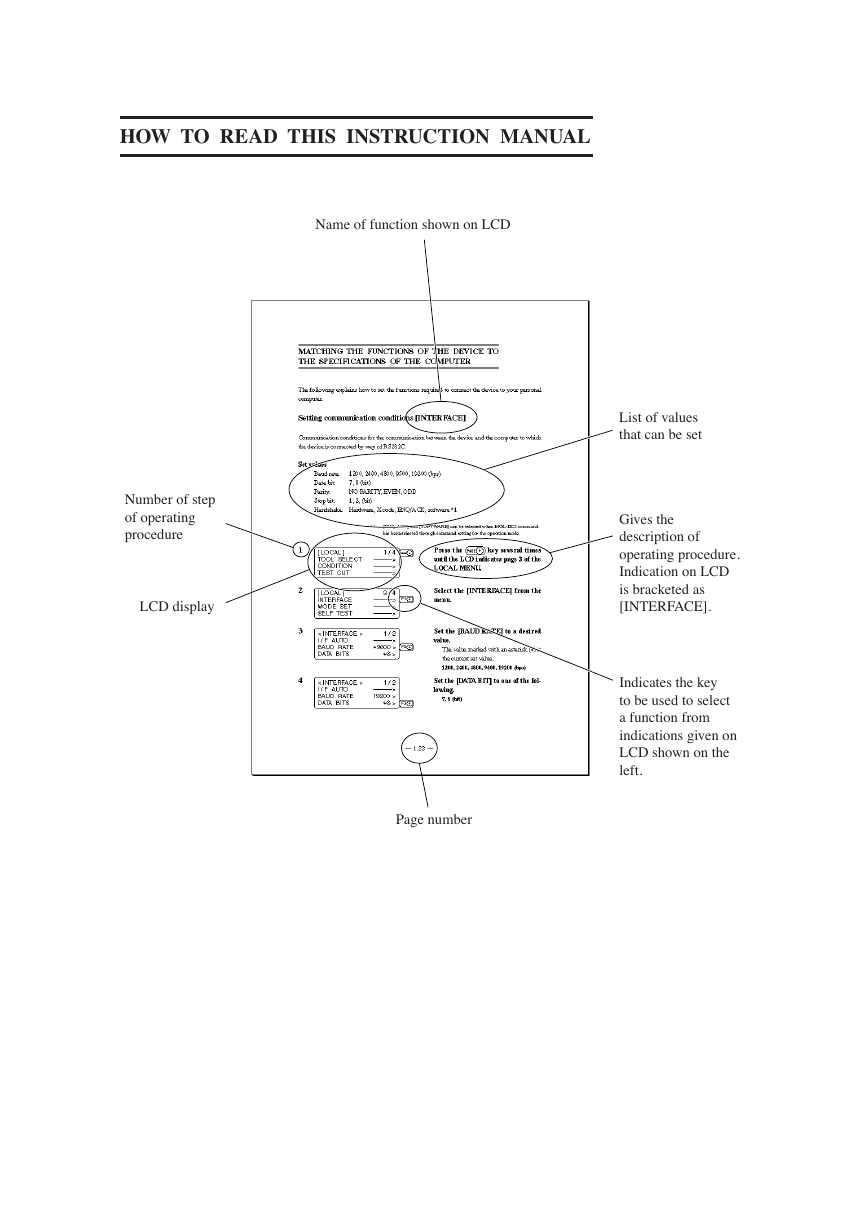

Matching the functions of the device

CHAPTER 2 BASIC OPERATION

Basic operation on the LOCAL menu

LOCAL menu

MODE SET menu

Basic operation on the LOCAL menu

Basic operation flow chart

Moving the head

Moving the head by "VIEW" function

Moving the head by the jog keys

Fixing a work

Fixing a work that is comparatively light in weight

Fixing heavy-weight packing etc.

Adjusting the blade AND THE PEN

Cutter holders 4N and 10N (for unit C)

Cutter holder 2N (for unit B)

Reciprocal cutter holder (for unit B)

Crease plate (for unit C of RC head)

Swievel cutter (optional)

ATTACHING THE TOOLS

Attaching the pen and the swievel blade

Attaching the tangential cutter

Attaching the reciprocal cutter (cutter holder)

Installing the crease roller

ADJUSTING THE HEIGHT OF THE HEAD

ATTACHING THE WORK HOLDER

SELECTING A TOOL [TOOL SELECT]

SETTING CUTTING CONDITIONS [CONDITION]

Setting items

Set values

Plotting conditions for pens

Cutting conditions for the tangential cutter

Marking conditions for the crease roller

Cutting conditions for the swievel blade

Setting cutting conditions

CHECKING CUTTING CONDITIONS [TEST CUT]

Checking the status of tools

Pen

Tangential cutter

Crease roller

Swievel blade

Checking the status of tools

SETTING THE CUTTING AREA [CUT AREA]

SETTING THE ORIGIN (ORIGIN FOR PLOTTING)

INTERRUPTION OF PROCESSING

How to interrupt/resume the process

Functions that can be specified after the interruption

Interruption of processing [DATA CLEAR]

CHAPTER 3 WHEN ABNORMAL CONDITIONS ARE ENCOUNTERED

If any of the below-stated phenomena takes place

Flowchart of checking and adjusting procedures

General explanation of the adjustment of tools

Adjustment of the cutter

Adjustment of the eccentricity

Adjustment of the q angle

Adjustment of the offset

Adjustment of the roller

How to adjust the tools

If there is a sign of failure

The device not at all actuates even when the power to the device is turned on.

The device fails to actuate even when data is transmitted from CAD.

Error arises when transmitting data.

There is no reciprocal vibration.

The tool drags on the sheet of paper.

Dotted lines or blurred lines are plotted.

Errors that can be corrected by users

Errors that cannot be corrected by users

CHAPTER 4 APPLICATION FUNCTIONS

Assignment of pen numbers [MODE SET] > [PEN ASIGN]

Re-cut of the same data [COPY]

Setting the number cut function

Setting the ONE-stroke cutting

Setting the cutter stroke [MODE SET] > [Z STROKE]

Setting the unit to be used for indication

Setting the DUMMY CUT operation

INTERFACE of communication conditions [INTEFACE]

Alignment of mechanical axes

CHAPTER 5 SELF-TEST

Confirmation of cutting quality

Cutting quality * / Sample *** / Circle cutting R = ***

Dump test [SELF TEST]

Executing the data dump

Execution of the parameter dump

APPENDIX

REPLACING TH BLADE TIPS

LOCAL MENU STRUCTURE

OUTPUT SAMPLES

SPECIFICATIONS

MAINTENANCE

OPTIONAL ACCESSORIES

2023年江西萍乡中考道德与法治真题及答案.doc

2023年江西萍乡中考道德与法治真题及答案.doc 2012年重庆南川中考生物真题及答案.doc

2012年重庆南川中考生物真题及答案.doc 2013年江西师范大学地理学综合及文艺理论基础考研真题.doc

2013年江西师范大学地理学综合及文艺理论基础考研真题.doc 2020年四川甘孜小升初语文真题及答案I卷.doc

2020年四川甘孜小升初语文真题及答案I卷.doc 2020年注册岩土工程师专业基础考试真题及答案.doc

2020年注册岩土工程师专业基础考试真题及答案.doc 2023-2024学年福建省厦门市九年级上学期数学月考试题及答案.doc

2023-2024学年福建省厦门市九年级上学期数学月考试题及答案.doc 2021-2022学年辽宁省沈阳市大东区九年级上学期语文期末试题及答案.doc

2021-2022学年辽宁省沈阳市大东区九年级上学期语文期末试题及答案.doc 2022-2023学年北京东城区初三第一学期物理期末试卷及答案.doc

2022-2023学年北京东城区初三第一学期物理期末试卷及答案.doc 2018上半年江西教师资格初中地理学科知识与教学能力真题及答案.doc

2018上半年江西教师资格初中地理学科知识与教学能力真题及答案.doc 2012年河北国家公务员申论考试真题及答案-省级.doc

2012年河北国家公务员申论考试真题及答案-省级.doc 2020-2021学年江苏省扬州市江都区邵樊片九年级上学期数学第一次质量检测试题及答案.doc

2020-2021学年江苏省扬州市江都区邵樊片九年级上学期数学第一次质量检测试题及答案.doc 2022下半年黑龙江教师资格证中学综合素质真题及答案.doc

2022下半年黑龙江教师资格证中学综合素质真题及答案.doc