Operating Instructions

Compact

FullRange™ Gauge

FPM sealed

PKR 251

BG 805 155 BE / B (2005-08)

1

�

Table of Contents

Product Identification

Validity

Intended Use

Functional Principle

1 Safety

1.1 Symbols Used

1.2 Personnel Qualifications

1.3 Safety Information

1.4 Liability and Warranty

2 Technical Data

3 Installation

3.1 Installation

3.1.1 Removing the Magnet Unit (Only for Gauges With CF Flanges)

3.2 Electrical Connection

3.2.1 Use With a Pfeiffer Vacuum Measurement Unit

3.2.2 Use With Another Evaluation Unit

4 Operation

4.1 Measurement Principle, Measuring Behavior

5 Maintenance

5.1 Adjusting the Gauge

5.2 Cleaning the Gauge / Replacing Parts

5.2.1 Disassembling the Gauge

5.2.2 Cleaning the Gauge

5.2.3 Reassembling the Gauge

5.3 What to Do in Case of Problems

6 Removing the Gauge From the Vacuum System

7 Returning the Product

8 Accessories

9 Spare Parts

10 Disposal

Appendix

A: Measuring Signal vs. Pressure

B: Gas Type Dependence

Declaration of Contamination

For cross references within this document, the symbol (→ XY) is used, for

references to other documents, the symbol (→ [Z]).

3

3

3

3

4

4

4

4

4

5

8

8

9

9

9

10

12

12

14

14

15

16

17

18

19

20

21

21

22

23

24

24

26

28

2

BG 805 155 BE / B (2005-08) PKR 251

�

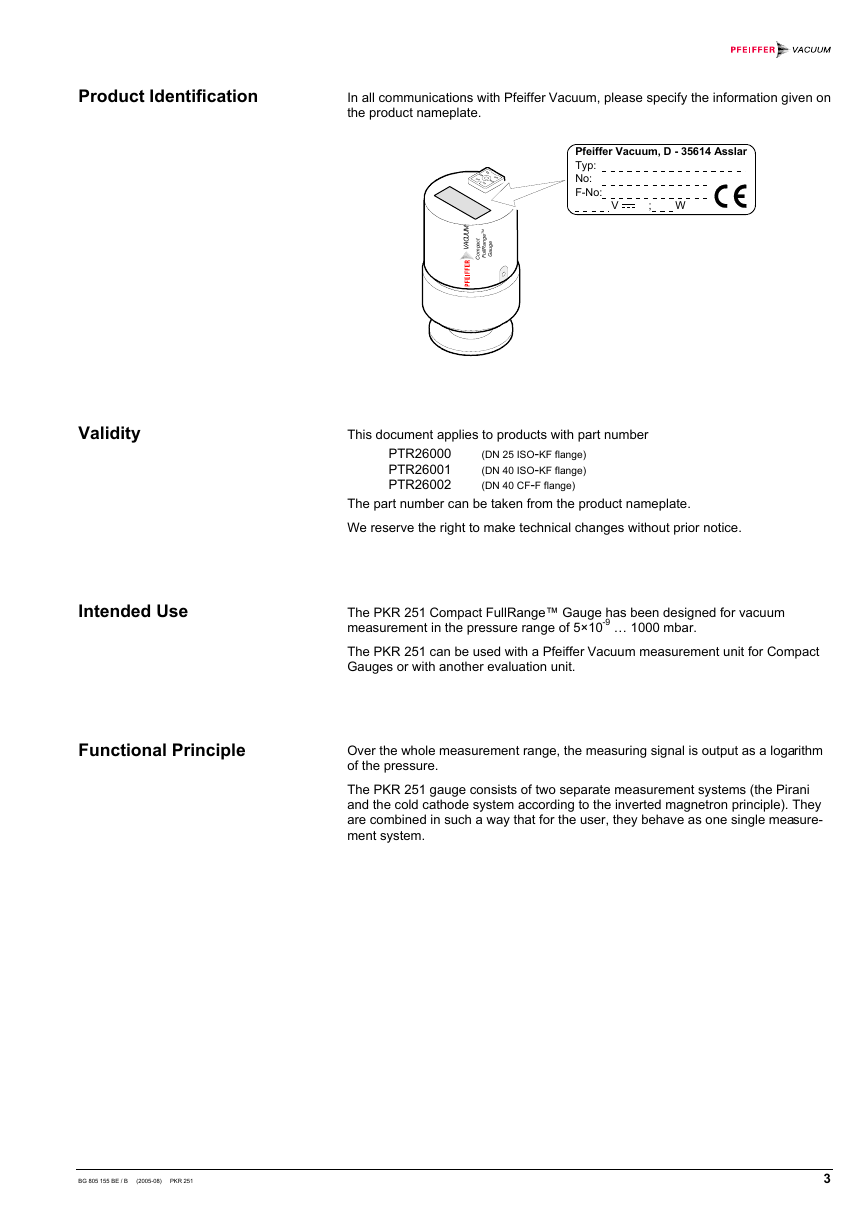

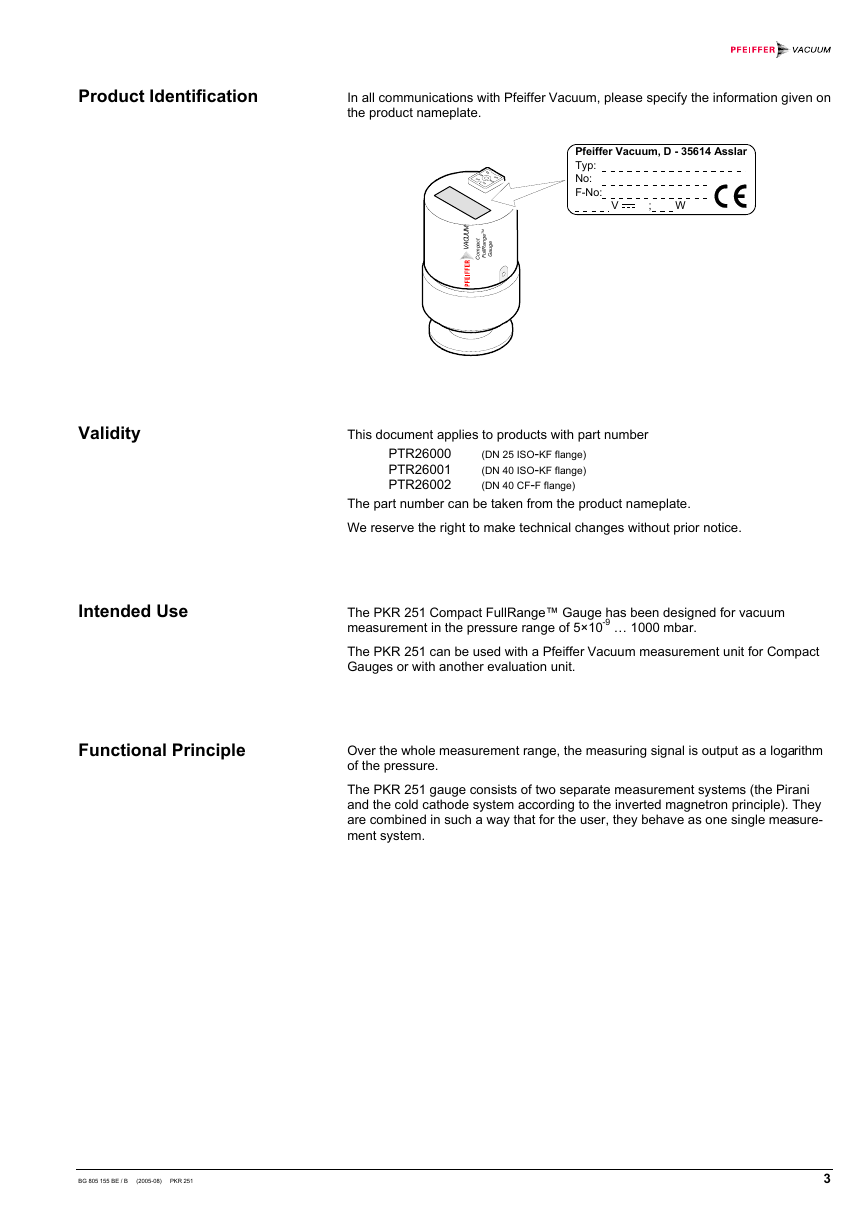

Product Identification

In all communications with Pfeiffer Vacuum, please specify the information given on

the product nameplate.

Pfeiffer Vacuum, D - 35614 Asslar

Typ:

No:

F-No:

V ; W

M

U

U

C

A

V

M

T

e

g

n

a

R

l

l

u

F

t

c

a

p

m

o

C

e

g

u

a

G

Validity

Intended Use

This document applies to products with part number

PTR26000

PTR26001

PTR26002

(DN 25 ISO-KF flange)

(DN 40 ISO-KF flange)

(DN 40 CF-F flange)

The part number can be taken from the product nameplate.

We reserve the right to make technical changes without prior notice.

The PKR 251 Compact FullRange™ Gauge has been designed for vacuum

measurement in the pressure range of 5×10-9 … 1000 mbar.

The PKR 251 can be used with a Pfeiffer Vacuum measurement unit for Compact

Gauges or with another evaluation unit.

Functional Principle

Over the whole measurement range, the measuring signal is output as a logarithm

of the pressure.

The PKR 251 gauge consists of two separate measurement systems (the Pirani

and the cold cathode system according to the inverted magnetron principle). They

are combined in such a way that for the user, they behave as one single measure-

ment system.

BG 805 155 BE / B (2005-08) PKR 251

3

�

1 Safety

1.1 Symbols Used

DANGER

Information on preventing any kind of physical injury.

WARNING

Information on preventing extensive equipment and environmental damage.

Caution

Information on correct handling or use. Disregard can lead to malfunctions or

minor equipment damage.

1.2 Personnel Qualifications

Skilled personnel

1.3 Safety Information

1.4 Liability and Warranty

All work described in this document may only be carried out by persons who

have suitable technical training and the necessary experience or who have been

instructed by the custodian of the product.

• Adhere to the applicable regulations and take the necessary precautions for the

process media used.

Consider possible reactions between the materials (→ 7) and the process

media.

Consider possible reactions of the process media due to the heat generated by

the product.

• Adhere to the applicable regulations and take the necessary precautions for all

work you are going to do and consider the safety information in this document.

• Before you begin to work, find out whether any vacuum components are con-

taminated. Adhere to the relevant regulations and take the necessary pre-

cautions when handling contaminated parts.

Pass on the safety information to other users.

Pfeiffer Vacuum assumes no liability and the warranty becomes null and void if the

custodian or third parties

• disregard the information in this document

• use the product in a non-conforming manner

• make any kind of changes (modifications, alterations etc.) to the product

• use the product with accessories not listed in the corresponding product

documentation.

The custodian assumes the responsibility in conjunction with the process media

used.

4

BG 805 155 BE / B (2005-08) PKR 251

�

2 Technical Data

Admissible temperatures

Storage

Operation

Bakeout

Relative humidity

Use

Measurement range (air, N2)

Accuracy

Reproducibility

Gas type dependence

Adjustment

Pirani measurement circuit

trimmer potentiometer

trimmer potentiometer

Cold cathode measurement circuit

-40 °C … +65 °C

+ 5 °C … +55 °C

+150 °C (without electronics unit and

magnetic shielding)

max. 80% at temperatures ≤+31 °C

decreasing to 50% at +40 °C

indoors only

altitude up to 2000 m (6600 ft)

5×10-9 … 1000 mbar

≈±30%

in the range 1×10-8 … 100 mbar

≈±5%

in the range 1×10-8 … 100 mbar

→ Appendix B

(→ 14)

at <1×10-4 mbar

(while depressing the pin)

at atmospheric pressure

no adjustment (the gauge is adjusted at

the factory and requires no main-

tenance)

Type of protection

Maximum pressure (absolute)

IP 40

10 bar

only for inert gases <55 °C

Supply

DANGER

The gauge may only be connected to supply or measurement units

that conform to the requirements of a grounded protective extra-low

voltage (SELV-E according to EN 61010). The connection to the

gauge has to be fused.1)

Voltage at the gauge

Power consumption

Fuse1)

15.0 … 30.0 VDC (max. ripple 1 Vpp)

≤2 W

≤1 AT

The minimum voltage of the power supply must be increased proportionally to the

length of the measuring cable.

Voltage at the supply unit with

maximum cable length

16.0 … 30.0 VDC (max. ripple 1 Vpp)

Electrical connection

Cable

Maximum cable length

Hirschmann compact connector

type GO 6, 6 pins, male

5 poles plus screening

75 m (0.25 mm² conductor)

100 m (0.34 mm² conductor)

300 m (1.0 mm² conductor)

BG 805 155 BE / B (2005-08) PKR 251

1) Pfeiffer Vacuum measurement and control units for Compact Gauges fulfill

these requirements.

5

�Operating voltage

(in the measuring chamber)

Operating current

(in the measuring chamber)

Output signal (measuring signal)

Voltage range

Relationship voltage-pressure

Error signals

Output impedance

Minimum load

Response time

p > 10-6 mbar

p = 10-8 mbar

Gauge identification

Pirani-only mode

Combined Pirani / cold cathode

mode

The following conditions must be

fulfilled:

Polarity

Measurement

with constant current

with constant voltage

Grounding concept

Vacuum flange-measurement

common

Supply common-signal common

≤3.3 kV

≤500 µA

≈0 V … ≈+10.5 V

logarithmic, increase 0.6 V / decade

(→ Appendix A)

<0.5 V (no supply)

>9.5 V (Pirani measurement element

defective; filament rupture)

2×10 Ω

10 kΩ, short-circuit proof

pressure dependent

≈10 ms

≈1 s

→ Figure 1

11.1 kΩ resistor referenced to supply

common

9.1 kΩ resistor referenced to supply

common

The polarity of pin 1 referenced to

supply common is always positive.

measurement current within range

0.2 … 0.3 mA

measurement voltage within range

2 … 3 V

→ Figure 1

connected via 10 kΩ

(max. voltage differential

with respect to safety

±50 V

with respect to accuracy ±10 V)

conducted separately; differential

measurement recommended for cable

lengths ≥6 m

6

BG 805 155 BE / B (2005-08) PKR 251

�

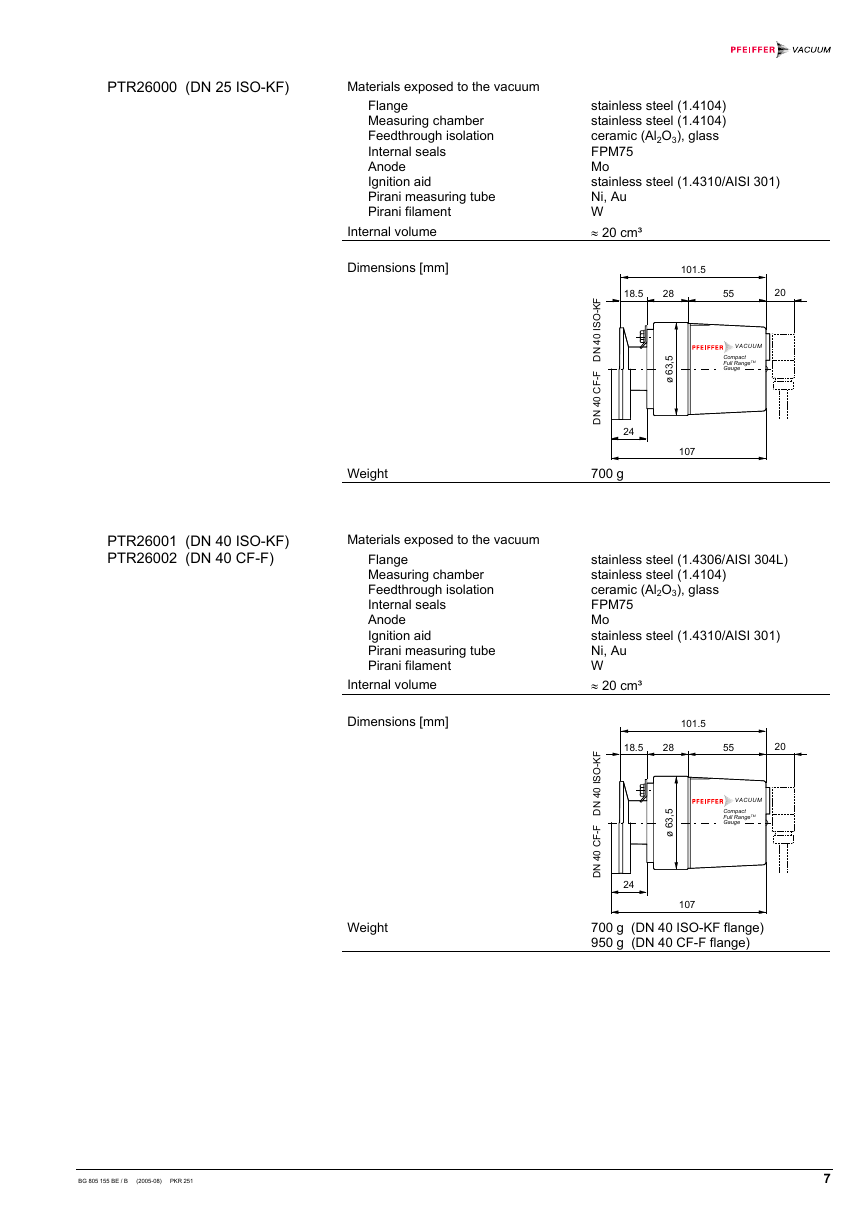

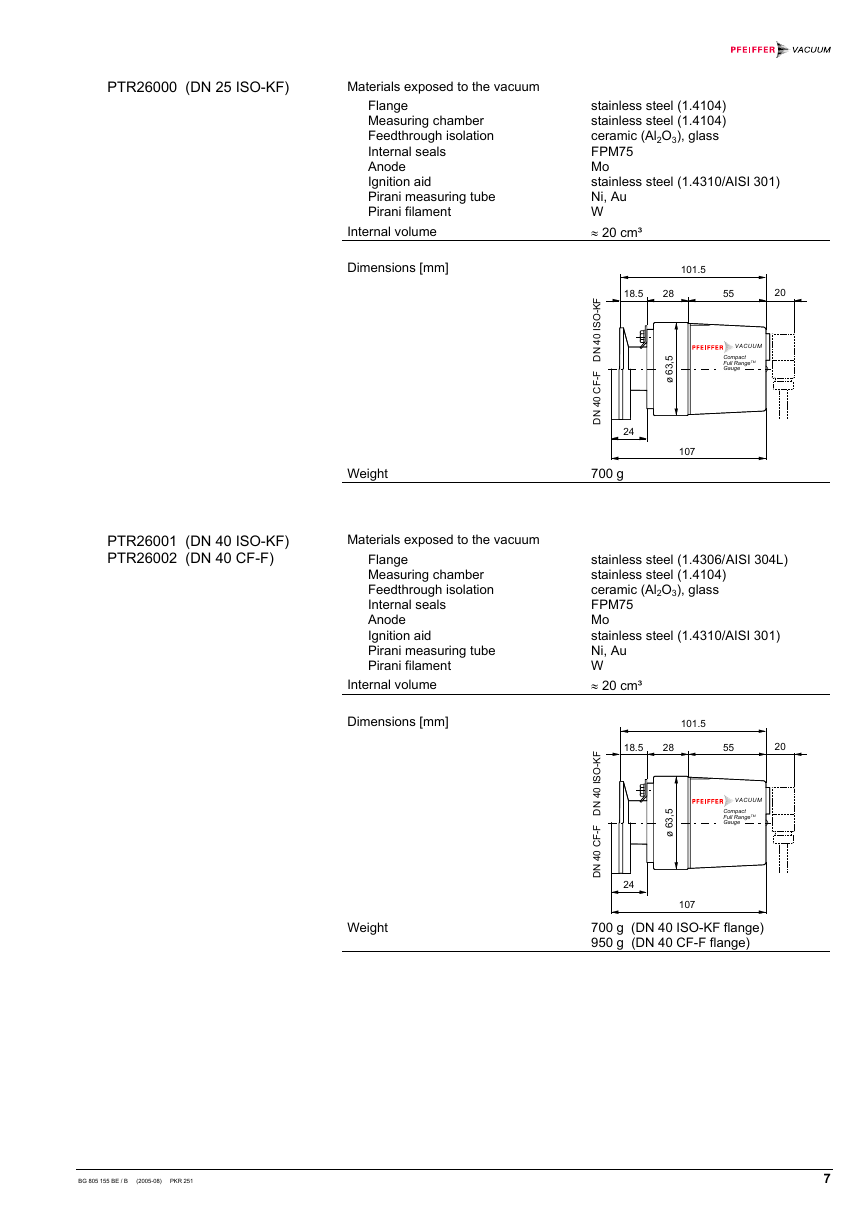

PTR26000 (DN 25 ISO-KF)

Materials exposed to the vacuum

Flange

Measuring chamber

Feedthrough isolation

Internal seals

Anode

Ignition aid

Pirani measuring tube

Pirani filament

Internal volume

Dimensions [mm]

stainless steel (1.4104)

stainless steel (1.4104)

ceramic (Al2O3), glass

FPM75

Mo

stainless steel (1.4310/AISI 301)

Ni, Au

W

≈ 20 cm³

101.5

18.5

28

55

20

-

F

K

O

S

I

0

4

N

D

F

-

F

C

0

4

N

D

VACUUM

Compact

Full RangeTM

Gauge

5

,

3

6

ø

24

107

PTR26001 (DN 40 ISO-KF)

PTR26002 (DN 40 CF-F)

Weight

700 g

Materials exposed to the vacuum

Flange

Measuring chamber

Feedthrough isolation

Internal seals

Anode

Ignition aid

Pirani measuring tube

Pirani filament

Internal volume

Dimensions [mm]

stainless steel (1.4306/AISI 304L)

stainless steel (1.4104)

ceramic (Al2O3), glass

FPM75

Mo

stainless steel (1.4310/AISI 301)

Ni, Au

W

≈ 20 cm³

101.5

18.5

28

55

20

-

F

K

O

S

I

0

4

N

D

F

-

F

C

0

4

N

D

VACUUM

Compact

Full RangeTM

Gauge

5

,

3

6

ø

24

107

Weight

700 g (DN 40 ISO-KF flange)

950 g (DN 40 CF-F flange)

BG 805 155 BE / B (2005-08) PKR 251

7

�

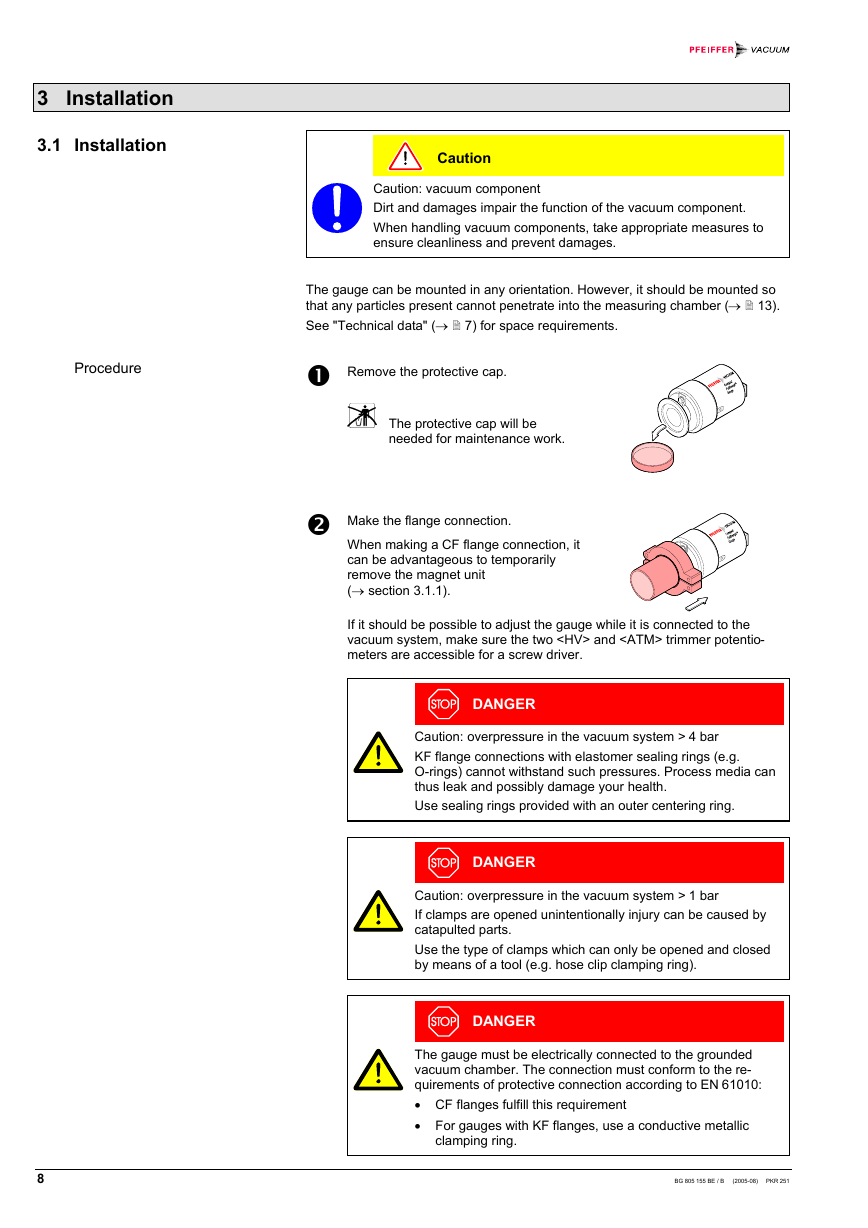

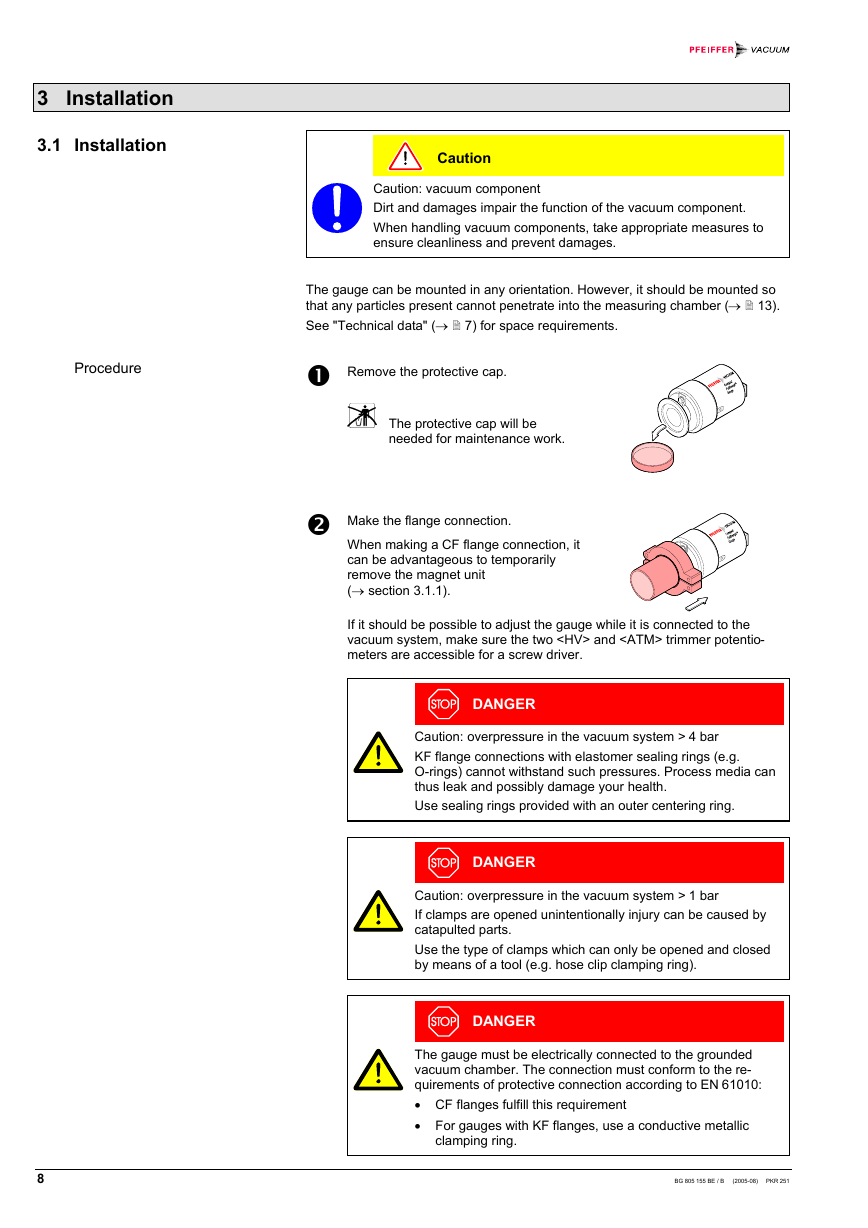

3 Installation

3.1 Installation

Caution

Caution: vacuum component

Dirt and damages impair the function of the vacuum component.

When handling vacuum components, take appropriate measures to

ensure cleanliness and prevent damages.

The gauge can be mounted in any orientation. However, it should be mounted so

that any particles present cannot penetrate into the measuring chamber (→ 13).

See "Technical data" (→ 7) for space requirements.

Procedure

Remove the protective cap.

The protective cap will be

needed for maintenance work.

Make the flange connection.

When making a CF flange connection, it

can be advantageous to temporarily

remove the magnet unit

(→ section 3.1.1).

If it should be possible to adjust the gauge while it is connected to the

vacuum system, make sure the two

and trimmer potentio-

meters are accessible for a screw driver.

DANGER

Caution: overpressure in the vacuum system > 4 bar

KF flange connections with elastomer sealing rings (e.g.

O-rings) cannot withstand such pressures. Process media can

thus leak and possibly damage your health.

Use sealing rings provided with an outer centering ring.

DANGER

Caution: overpressure in the vacuum system > 1 bar

If clamps are opened unintentionally injury can be caused by

catapulted parts.

Use the type of clamps which can only be opened and closed

by means of a tool (e.g. hose clip clamping ring).

DANGER

The gauge must be electrically connected to the grounded

vacuum chamber. The connection must conform to the re-

quirements of protective connection according to EN 61010:

• CF flanges fulfill this requirement

• For gauges with KF flanges, use a conductive metallic

clamping ring.

8

BG 805 155 BE / B (2005-08) PKR 251

�

2023年江西萍乡中考道德与法治真题及答案.doc

2023年江西萍乡中考道德与法治真题及答案.doc 2012年重庆南川中考生物真题及答案.doc

2012年重庆南川中考生物真题及答案.doc 2013年江西师范大学地理学综合及文艺理论基础考研真题.doc

2013年江西师范大学地理学综合及文艺理论基础考研真题.doc 2020年四川甘孜小升初语文真题及答案I卷.doc

2020年四川甘孜小升初语文真题及答案I卷.doc 2020年注册岩土工程师专业基础考试真题及答案.doc

2020年注册岩土工程师专业基础考试真题及答案.doc 2023-2024学年福建省厦门市九年级上学期数学月考试题及答案.doc

2023-2024学年福建省厦门市九年级上学期数学月考试题及答案.doc 2021-2022学年辽宁省沈阳市大东区九年级上学期语文期末试题及答案.doc

2021-2022学年辽宁省沈阳市大东区九年级上学期语文期末试题及答案.doc 2022-2023学年北京东城区初三第一学期物理期末试卷及答案.doc

2022-2023学年北京东城区初三第一学期物理期末试卷及答案.doc 2018上半年江西教师资格初中地理学科知识与教学能力真题及答案.doc

2018上半年江西教师资格初中地理学科知识与教学能力真题及答案.doc 2012年河北国家公务员申论考试真题及答案-省级.doc

2012年河北国家公务员申论考试真题及答案-省级.doc 2020-2021学年江苏省扬州市江都区邵樊片九年级上学期数学第一次质量检测试题及答案.doc

2020-2021学年江苏省扬州市江都区邵樊片九年级上学期数学第一次质量检测试题及答案.doc 2022下半年黑龙江教师资格证中学综合素质真题及答案.doc

2022下半年黑龙江教师资格证中学综合素质真题及答案.doc