SEMI E30-1103

GENERIC MODEL FOR COMMUNICATIONS AND CONTROL OF

MANUFACTURING EQUIPMENT (GEM)

This standard was technically approved by the Global Information & Control Committee and is the direct

responsibility of the Japanese Information & Control Committee. Current edition approved by the Japanese

Regional Standards Committee on August 8, 2003. Initially available at www.semi.org October 2003; to be

published November 2003. Originally published in 1992; previously published July 2003.

CONTENTS

1 Introduction

1.1 Revision History

1.2 Scope

1.3 Intent

Figure 1.1, GEM Scope

1.4 Overview

Figure 1.2, GEM Components

1.5 Applicable Documents

2 Definitions

3 State Models

3.1 State Model Methodology

3.2 Communications State Model

Figure 3.0, Example Equipment Component Overview

Figure 3.2.1, Communications State Diagram

Table 3.2, Communications State Transition Table

3.3 Control State Model

Figure 3.3, Control State Model

Table 3.3, CONTROL State Transition Table

3.4 Equipment Processing States

Figure 3.4, Processing State Diagram

Table 3.4, Processing State Transition Table

4 Equipment Capabilities and Scenarios

4.1 Establish Communications

4.2 Data Collection

Figure 4.2.1, Limit Combination Illustration: Control

Application

Figure 4.2.2, Elements of One Limit

Figure 4.2.3, Limit State Model

Table 4.2, Limit State Transition Table

4.3 Alarm Management

Figure 4.3, State Diagram for Alarm ALIDn

Table 4.3.1, Alarm State Transition Table

Table 4.3.2

4.4 Remote Control

4.5 Equipment Constants

4.6 Process Program Management

4.7 Material Movement

4.8 Equipment Terminal Services

4.9 Error Messages

4.10 Clock

4.11 Spooling

Figure 4.11, Spooling State Diagram

Table 4.11, Spooling State Transition

4.12 Control

5 Data Items

5.1 Data Item Restrictions

5.2 Variable Item List

6 Collection Events

Table 6.1, GEM Defined Collection Events

7 SECS-II Message Subset

STREAM 1: Equipment Status

STREAM 2: Equipment Control and Diagnostics

STREAM 5: Exception (Alarm) Reporting

STREAM 6: Data Collection

STREAM 7: Process Program Load

STREAM 9: System Errors

STREAM 10: Terminal Services

STREAM 14: Object Services

STREAM 15: Recipe Management

1

SEMI E30-1103 © SEMI 1992, 2003

�

8 GEM Compliance

Figure A.7.2, Environment Monitoring Example

8.1 Fundamental GEM Requirements

Figure A.7.3, Calibration Counter Example

A.8 Recipe Parameter Modification for Process and

Equipment Control

A.8.1 Introduction

A.8.2 Equipment Constants

A.8.3 Example

Figure A.8.1, CMP Single Wafer “Polishing” System

with Host Recipe Parameter Modification Capability

Index

Figure 8.1, GEM Requirements and Capabilities

Table 8.1, Fundamental GEM Requirements

8.2 GEM Capabilities

Table 8.2, Section References for GEM Capabilities

8.3 Definition of GEM Compliance

8.4 Documentation

Figure 8.2, Host View of GEM

Table 8.3, GEM Compliance Statement

Table 8.4, SML Notation

A. Application Notes

A.1 Factory Operational Script

A.1.1 Anytime Capabilities

A.1.2 System Initialization and Synchronization

A.1.3 Production Set-Up

A.1.4 Processing

A.1.5 Post-Processing

A.2 Equipment Front Panel

A.2.1 Displays and Indicators

A.2.2 Switches/Buttons

A.3 Examples of Equipment Alarms

Table A.3, Alarm Examples Per Equipment Configura-

tion

A.4 Trace Data Collection Example

A.5 Harel Notation

Figure A.5.1, Harel Statechart Symbols

Figure A.5.2, Example of OR Substates

Figure A.5.3, Example of AND Substates

A.5.1 State Definitions

A.5.2 Transition Table

Table A.5, Transition Table for Motor Example

A.6 Example Control Model Application

A.7 Examples of Limits Monitoring

A.7.1 Introduction

A.7.2 Examples

Figure A.7.1, Valve Monitoring Example

SEMI E30-1103 © SEMI 1992, 2003

2

�

SEMI E30-1103

GENERIC MODEL FOR COMMUNICATIONS AND CONTROL OF

MANUFACTURING EQUIPMENT (GEM)

This standard was technically approved by the Global Information & Control Committee and is the direct

responsibility of the Japanese Information & Control Committee. Current edition approved by the Japanese

Regional Standards Committee on August 8, 2003. Initially available at www.semi.org October 2003; to be

published November 2003. Originally published in 1992; previously published July 2003.

1 Introduction

1.1 Revision History — This is the first release of the

GEM standard.

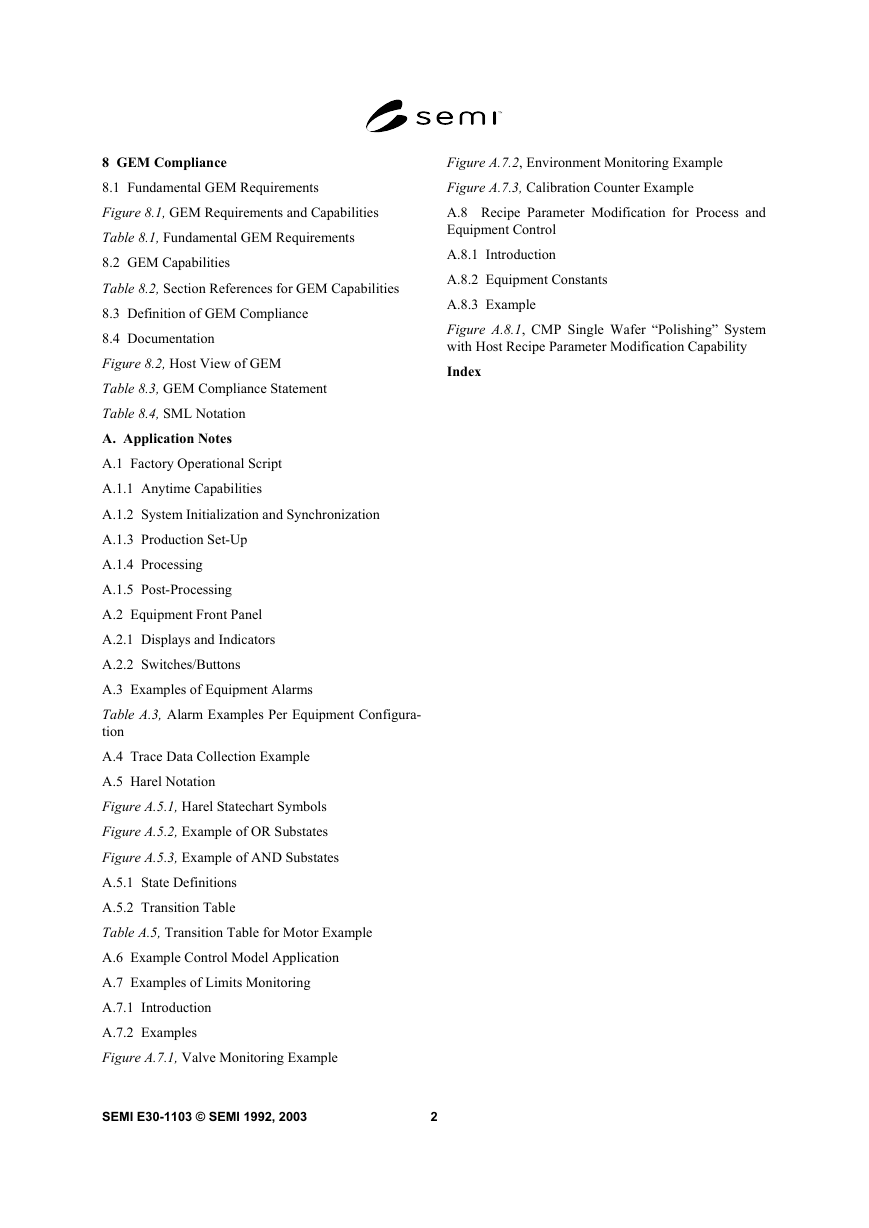

1.2 Scope — The scope of the GEM standard is limited

to defining the behavior of semiconductor equipment as

viewed through a communications link. The SEMI E5

(SECS-II) standard provides the definition of messages

and related data items exchanged between host and

equipment. The GEM standard defines which SECS-II

messages should be used, in what situations, and what

the resulting activity should be. Figure 1.1 illustrates

the

relationship of GEM, SECS-II and other

communications alternatives.

The GEM standard does NOT attempt to define the

behavior of the host computer in the communications

link. The host computer may initiate any GEM message

scenario at any time and the equipment shall respond as

described in the GEM standard. When a GEM message

scenario is initiated by either the host or equipment, the

equipment shall behave in the manner described in the

GEM standard when the host uses the appropriate GEM

messages.

Figure 1.1

GEM Scope

in

The capabilities described

this standard are

specifically designed to be independent of lower-level

communications protocols and connection schemes

(e.g., SECS-I, SMS, point-to-point, connection-oriented

or connectionless). Use of those types of standards is

not required or precluded by this standard.

NOTICE: This standard does not purport to address

safety issues, if any, associated with its use. It is the

responsibility of the users of this standard to establish

appropriate safety and health practices and determine

the applicability of regulatory or other limitations prior

to use.

programs

automation

1.3 Intent — GEM defines a standard implementation

of SECS-II for all semiconductor manufacturing

equipment. The GEM standard defines a common set of

equipment behavior and communications capabilities

that provide the functionality and flexibility to support

the manufacturing

of

semiconductor device manufacturers. Equipment

suppliers may provide additional SECS-II functionality

not included in GEM as long as the additional

functionality does not conflict with any of the behavior

or capabilities defined in GEM. Such additions may

include SECS-II messages, collection events, alarms,

remote command codes, processing states, variable data

items

(data values, status values or equipment

constants), or other functionality that is unique to a

class (etchers, steppers, etc.) or specific instance of

equipment.

GEM is intended to produce economic benefits for both

device manufacturers

suppliers.

Equipment suppliers benefit from the ability to develop

and market a single SECS-II interface that satisfies

most customers. Device manufacturers benefit from the

increased functionality and standardization of the

SECS-II interface across all manufacturing equipment.

This standardization reduces the cost of software

development for both equipment suppliers and device

manufacturers. By reducing costs and

increasing

functionality, device manufacturers can automate

semiconductor factories more quickly and effectively.

The flexibility provided by the GEM standard also

enables device manufacturers to implement unique

automation solutions within a common

industry

framework.

and

equipment

3

SEMI E30-1103 © SEMI 1992, 2003

�

The GEM standard is intended to specify the following:

— A model of the behavior to be exhibited by

in a

semiconductor manufacturing equipment

SECS-II communication environment,

— A description of information and control functions

semiconductor manufacturing

a

in

needed

environment,

— A definition of the basic SECS-II communications

semiconductor manufacturing

capabilities of

equipment,

— A single consistent means of accomplishing an

action when SECS-II provides multiple possible

methods, and

— Standard message dialogues necessary to achieve

useful communications capabilities.

The GEM standard contains two types of requirements:

— fundamental GEM requirements and

Equipment suppliers should work with their customers

to determine which additional GEM capabilities should

be implemented for a specific type of equipment.

Because the capabilities defined in the GEM standard

the factory

were specifically developed

semiconductor

automation

manufacturers,

that most device

manufacturers will

the GEM

capabilities that apply to a particular type of equipment.

Some device manufacturers may not require all the

GEM capabilities due to differences in their factory

automation strategies.

requirements

it

require most of

to meet

of

is anticipated

1.4 Overview — The GEM standard is divided into

sections as described below.

Section 1 — Introduction

This section provides the revision history, scope and

intent of the GEM standard. It also provides an

overview of the structure of the document and a list of

related documents.

— requirements of additional GEM capabilities.

Section 2 — Definitions

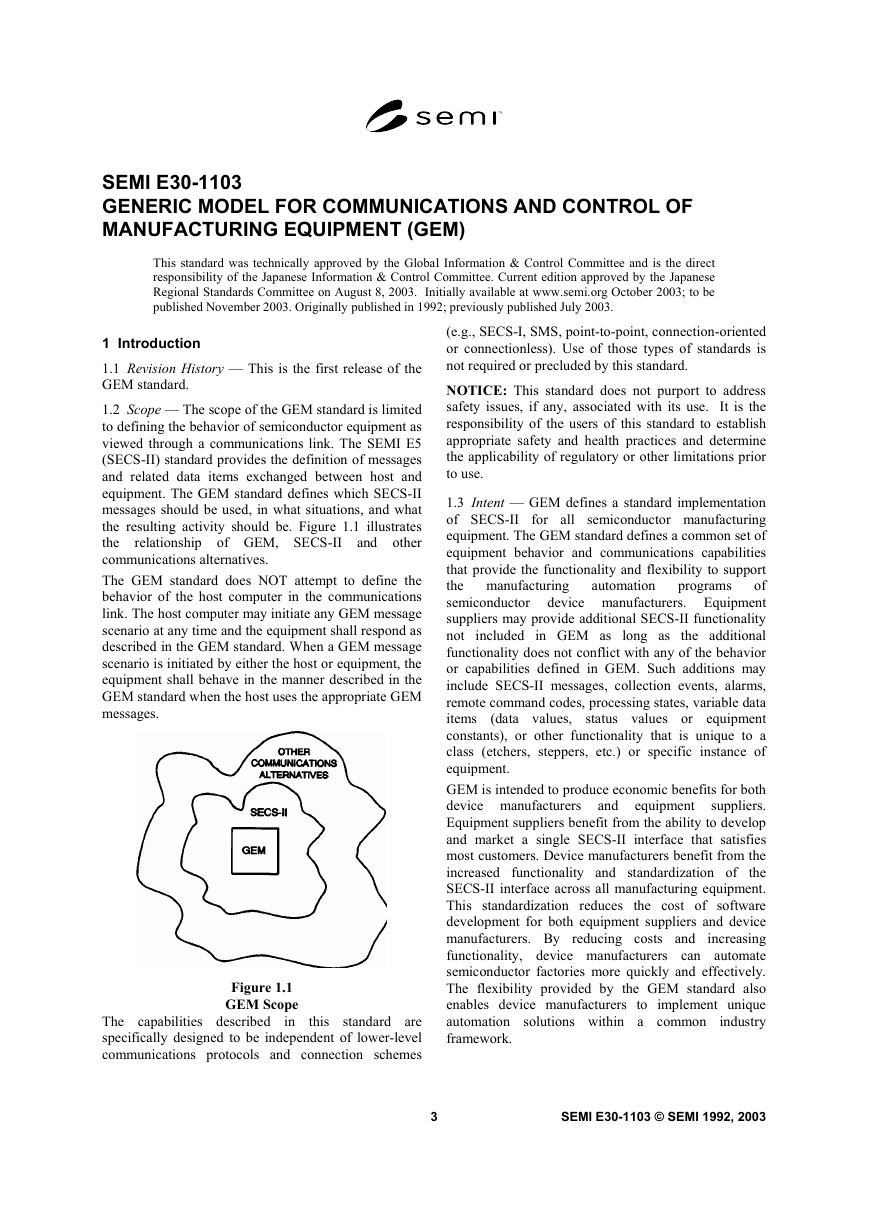

form

requirements

fundamental GEM

The

the

foundation of the GEM standard. The additional GEM

capabilities provide functionality required for some

types of factory automation or functionality applicable

to specific types of equipment. A detailed list of the

fundamental GEM requirements and additional GEM

capabilities can be found

in Chapter 8, GEM

Compliance. Figure 1.2 illustrates the components of

the GEM standard.

This section provides definitions of

throughout the document.

terms used

Section 3 — State Models

This section describes the conventions used throughout

this document to depict state models. It also describes

the basic state models that apply to all semiconductor

manufacturing equipment and that pertain to more than

a single capability. State models describe the behavior

of the equipment from a host perspective.

Section 4 — Capabilities and Scenarios

This section provides a detailed description of the

communications capabilities defined for semiconductor

manufacturing equipment. The description of each

capability

definitions,

requirements, and scenarios that shall be supported.

purpose,

includes

the

Section 5 — Data Definitions

This section provides a reference to the Data Item

Dictionary and Variable Item Dictionary found in

SEMI Standard E5. The first subsection shows those

data items from SECS-II which have been restricted in

their use (i.e., allowed formats). The second subsection

lists variable data items that are available to the host for

data collection and shows any restrictions on their

SECS-II definitions.

Section 6 — Collection Events

This section provides a list of required collection events

and their associated data.

Figure 1.2

GEM Components

SEMI E30-1103 © SEMI 1992, 2003

4

�

Section 7 — SECS Message Subset

1.5 Applicable Documents

This section provides a composite list of the SECS-II

messages required to implement all capabilities defined

in the GEM standard.

Section 8 — GEM Compliance

the

section describes

This

fundamental GEM

requirements and additional GEM capabilities and

provides references to other sections of the standard

where detailed requirements are located. This section

also defines standard terminology and documentation

that can be used by equipment suppliers and device

manufacturers

this

standard.

to describe compliance with

Section A — Application Notes

These

provide

information and examples.

sections

additional

explanatory

Section A.1 — Factory Operational Script

This section provides an overview of how the required

SECS capabilities may be used in the context of a

typical factory operation sequence. This section is

organized according to the sequence in which actions

are typically performed.

Section A.2 — Equipment Front Panel

This section provides guidance in implementing the

required front panel buttons, indicators, and switches as

defined in this document. A summary of the front panel

requirements is provided.

Section A.3 — Examples of Equipment Alarms

This section provides examples of alarms related to

various equipment configurations.

Section A.4 — Trace Data Collection Example

This section provides an example of trace initialization

by the host and the periodic trace data messages that

might be sent by the equipment.

Section A.5 — Harel Notation

This section explains David Harel’s “Statechart”

notation that is used throughout this document to depict

state models.

Section A.6 — Example Control Model Application

This section provides one example of a host’s

interaction with an equipment’s control model.

Section A.7 — Examples of Limits Monitoring

This section contains four limits monitoring examples

to help clarify the use of limits and to illustrate typical

applications.

following SEMI

1.5.1 SEMI Standards — The

standards are related to the GEM standard. The specific

portions of

these standards referenced by GEM

constitute provisions of the GEM standard.

SEMI E4 — SEMI Equipment Communications

Standard 1 — Message Transfer (SECS-I)

SEMI E5 — SEMI Equipment Communications

Standard 2 — Message Content (SECS-II)

SEMI E13 — Standard

Communication Standard Message Service (SMS)

for SEMI Equipment

SEMI E23 — Specification for Cassette Transfer

Parallel I/O Interface

1.5.2 Other References

Harel, D., “Statecharts: A Visual Formalism for

Complex Systems,” Science of Computer Programming

8 (1987) 231-2741.

NOTICE: As listed or revised, all documents cited

shall be the latest publications of adopted standards.

2 Definitions

2.1 alarm — An alarm is related to any abnormal

situation on the equipment that may endanger people,

equipment, or material being processed. Such abnormal

situations are defined by the equipment manufacturer

based on physical safety

limitations. Equipment

activities potentially impacted by the presence of an

alarm shall be inhibited.

2.1.1 Note that exceeding control limits associated

with process tolerance does not constitute an alarm nor

do normal equipment events such as the start or

completion of processing.

2.2 capabilities — Capabilities

are operations

performed by semiconductor manufacturing equipment.

These

the

communications interface using sequences of SECS-II

messages (or scenarios). An example of a capability is

the setting and clearing of alarms.

operations

initiated

are

through

2.3 collection event — A collection event is an event

(or grouping of related events) on the equipment that is

considered to be significant to the host.

2.4 communication failure — A communication failure

is said to occur when an established communications

link is broken. Such failures are protocol specific. Refer

to the appropriate protocol standard (e.g., SEMI E4 or

1 Elsevier Science, P.O. Box 945, New York, NY 10159-0945,

http://www.elvesier.nl/homepage/browse.htt

5

SEMI E30-1103 © SEMI 1992, 2003

�

SEMI E37) for a protocol-specific definition of

communication failure.

2.5 communication fault — A communication fault

occurs when the equipment does not receive an

expected message, or when either a transaction timer or

a conversation timer expires.

2.6 control — To control is to exercise directing

influence.

2.7 equipment model — An equipment model is a

definition based on capabilities, scenarios, and SECS-II

messages that manufacturing equipment should perform

to support an automated manufacturing environment.

(See also Generic Equipment Model.)

2.8 event — An event is a detectable occurrence

significant to the equipment.

2.9 GEM compliance — The term “GEM Compliance”

is defined with respect to individual GEM capabilities

to indicate adherence to the GEM standard for a

specific capability. Section 8 includes more detail on

GEM Compliance.

2.10 Generic Equipment Model — The Generic

Equipment Model is used as a reference model for any

type of equipment. It contains functionality that can

apply to most equipment, but does not address unique

requirements of specific equipment.

2.11 host — The SEMI E4 and E5 standards define

Host as “the intelligent system that communicates with

the equipment.”

2.12 message fault — A message fault occurs when the

equipment receives a message that it cannot process

because of a defect in the message.

2.13 operational script — An operational script is a

collection of scenarios arranged in a sequence typical of

actual factory operations. Example sequences are

system initialization powerup, machine setup, and

processing.

2.14 operator — A human who operates the equipment

to perform its intended function (e.g., processing). The

operator typically interacts with the equipment via the

equipment supplied operator console.

2.15 process unit — A process unit refers to the

material that is typically processed as a unit via single

run command, process program, etc. Common process

units are wafers, cassettes, magazines, and boats.

2.16 processing cycle — A processing cycle is a

sequence wherein all of the material contained in a

typical process unit is processed. This is often used as a

measure of action or time.

SEMI E30-1103 © SEMI 1992, 2003

6

2.17 scenario — A scenario is a group of SECS-II

messages arranged

to perform a

capability. Other information may also be included in a

scenario for clarity.

in a sequence

2.18 SECS-I — SEMI Equipment Communications

Standard 1 (SEMI E4). This standard specifies a

method for a message transfer protocol with electrical

signal levels based upon EIA RS232-C.

2.19 SECS-II — SEMI Equipment Communications

Standard 2 (SEMI E5). This standard specifies a group

of messages and the respective syntax and semantics

for

relating

semiconductor

manufacturing equipment control.

those messages

to

2.20 SMS — SECS Message Service. An alternative to

SECS-I to be used when sending SECS-II formatted

messages over a network.

2.21 state model — A State Model is a collection of

states and state transitions that combine to describe the

behavior of a system. This model includes definition of

the

the

actions/reactions possible within a state, the events that

trigger transitions to other states, and the process of

transitioning between states.

conditions

delineate

that

a

state,

2.22 system default — Refers to state(s) in the

equipment behavioral model that are expected to be

active at the end of system initialization. It also refers to

the value(s) that specified equipment variables are

expected to contain at the end of system initialization.

2.23 system initialization — The process that an

equipment performs at power-up, system activation,

and/or system reset. This process is expected to prepare

the equipment to operate properly and according to the

equipment behavioral models.

2.24 user — A human or humans who represent the

factory and enforce the factory operation model. A user

is considered to be responsible for many setup and

configuration activities that cause the equipment to best

conform to factory operations practices.

3 State Models

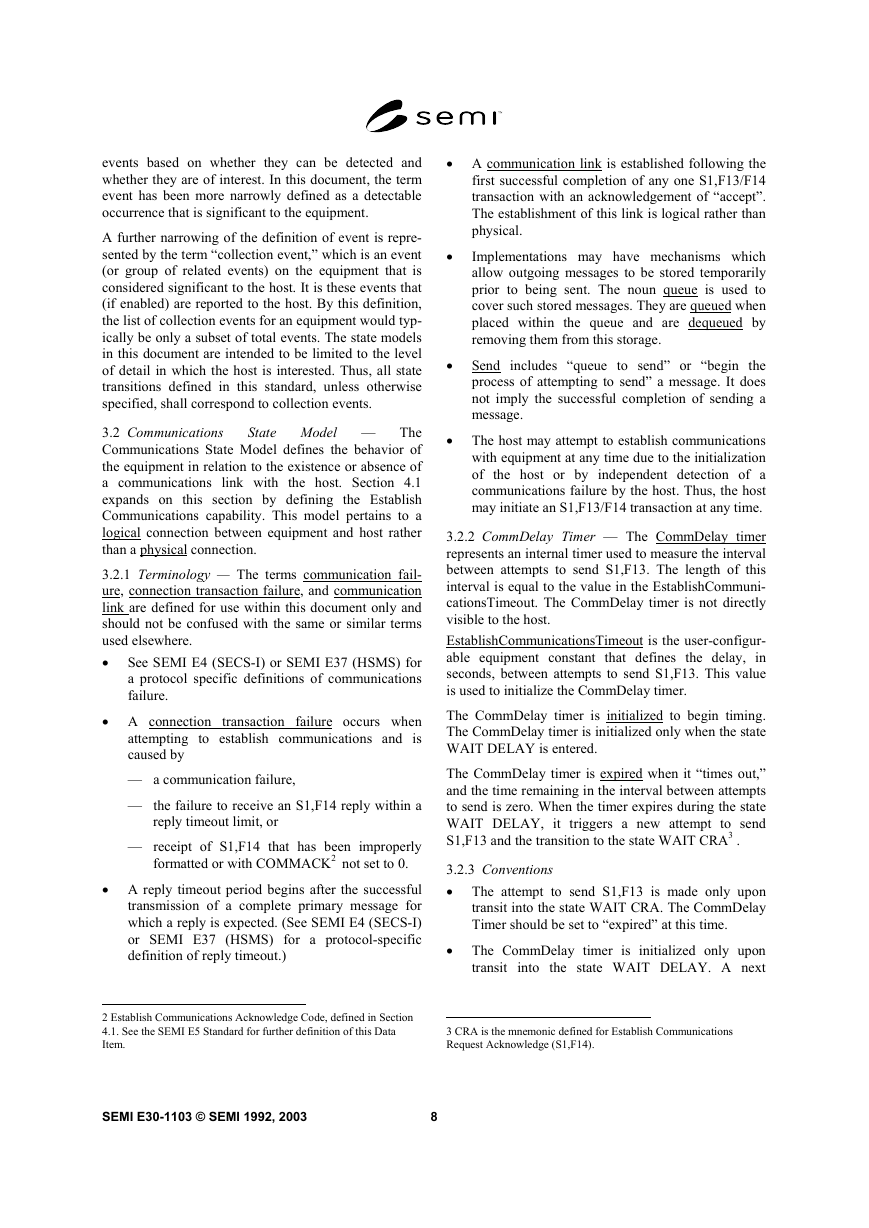

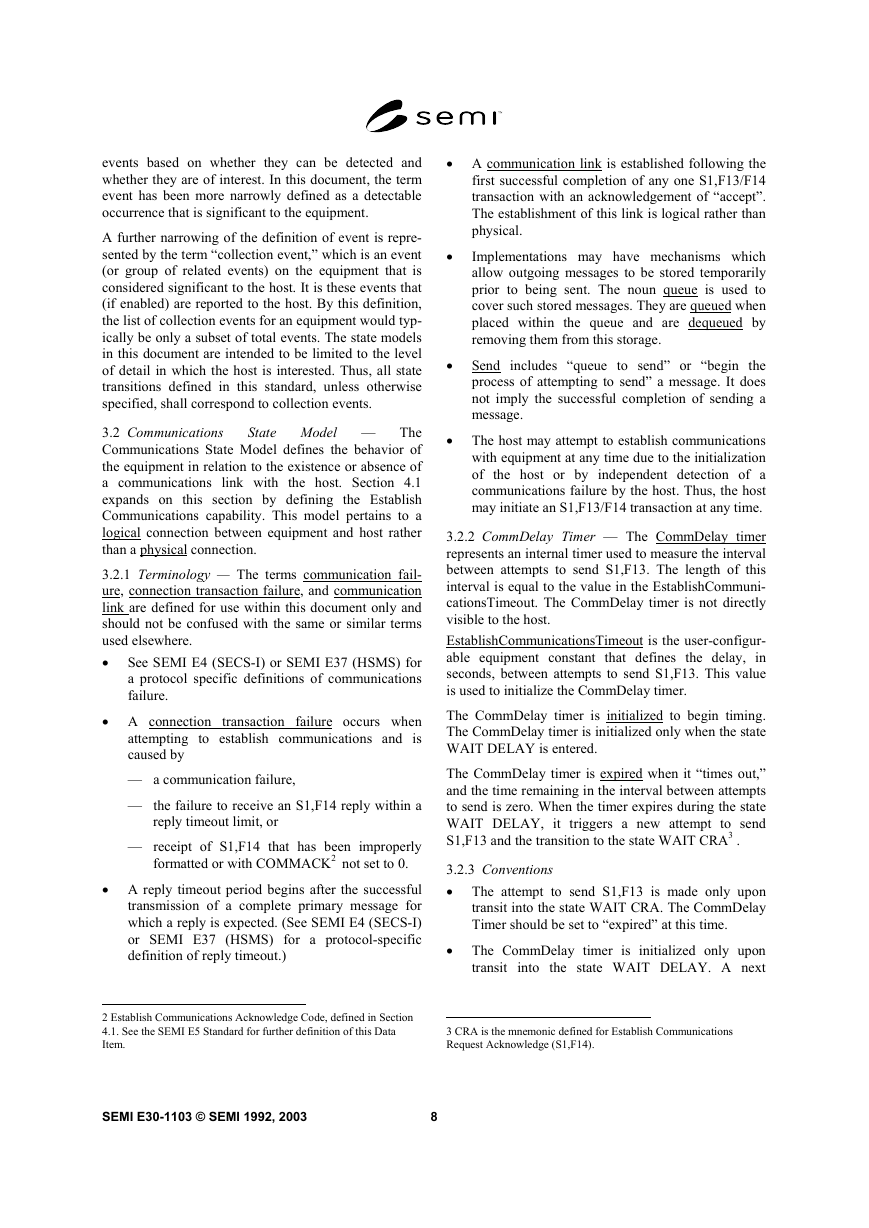

The following sections contain state models for

semiconductor manufacturing equipment. These state

models describe the behavior of the equipment from a

host perspective in a compact and easy to understand

format. State models for different equipment will be

identical in some areas (e.g., communications), but may

vary in other areas (e.g., processing). It is desirable to

divide the equipment into parallel components that can

be modeled separately and then combined. An example

of a component overview of an equipment is provided

as Figure 3.0.

�

document

Equipment manufacturers must

the

operation-al behavior of their equipment using state

model meth-odology. State models are discussed in

Sections 3.1 and A.5 and in a referenced article.

Documentation of a state model shall include the

following three elements:

— A state diagram showing the possible states of the

system or components of a system and all of the

possible transitions from one state to another. The

states and transitions must each be labeled. Use of

the Harel notation (see A.5) is recommended.

— A transition table listing each transition, the

beginning and end states, what stimulus triggers

the transition, and any actions taken as a result of

the transition.

— A definition of each state specifying system

behavior when that state is active.

Examples of the above elements are provided in

Section A.5.

Example Equipment Component Overview

Figure 3.0

The benefits of providing state models are:

1. State machine models are a useful specification

tool,

2. A host system can anticipate machine behavior

based upon the state model,

3. End-users and equipment programmers have a

common description of machine behavior from

which to work,

4. “Legal” operations can be defined pertaining to

any machine state,

5. External event notifications can be related to

internal state transitions,

6. External commands can be related

to state

transitions,

7. State model components describing different

aspects of machine control can be related to one

another (example: processing state model with

material transport state model; processing state

model with internal machine safety systems).

illustrate

the relationships of

3.1 State Model Methodology — To document the

expected functionality of

the various capabilities

described in this document, the “Statechart” notation

developed by David Harel has been adopted. An article

by Harel is listed in Section 1.5 and should be

considered “must” reading for a full understanding of

the notation. The convention used in this and following

sections is to describe the dynamic functionality of a

capability with three items: a textual description of each

state or substate defined, a table that describes the

possible transitions from one state to another, and a

graphical figure that uses the symbols defined by Harel

to

the states and

transitions. The combination of these items define the

state model for a system or component. A summary of

the Harel notation and a more detailed description of

the text, table, and figure used to define behavior with

this methodology is contained in the Application Note

A.5.

The basic unit of a state model is the state. A state is a

static set of conditions. If the conditions are met, the

state is current. These conditions might involve sensor

readings, switch positions, time of day, etc. Also part of

a state definition is a description of reactions to specific

stimuli (e.g., if message Sx,Fy is received, generate

reply message Sx,Fy + 1). Stimuli may be quite varied

but for semiconductor equipment would

include

received SECS messages, expired timers, operator input

at an equipment terminal, and changes in sensor

readings.

To help clarify the interpretation of this document and

the state models described herein, it is useful to distin-

guish between a state and an event and the relationship

of one to the other. An event is dynamic rather than

static. It represents a change in conditions, or more

specifically, the awareness of such a change. An event

might involve a sensor reading exceeding a limit, a

switch changing position, or a time limit exceeded.

A change to a new active state (state transition) must

always be prompted by a change in conditions, and thus

an event. In addition, a state transition may itself be

termed an event. In fact, there are many events that may

occur on an equipment, so it is important to classify

7

SEMI E30-1103 © SEMI 1992, 2003

�

events based on whether they can be detected and

whether they are of interest. In this document, the term

event has been more narrowly defined as a detectable

occurrence that is significant to the equipment.

A further narrowing of the definition of event is repre-

sented by the term “collection event,” which is an event

(or group of related events) on the equipment that is

considered significant to the host. It is these events that

(if enabled) are reported to the host. By this definition,

the list of collection events for an equipment would typ-

ically be only a subset of total events. The state models

in this document are intended to be limited to the level

of detail in which the host is interested. Thus, all state

transitions defined in this standard, unless otherwise

specified, shall correspond to collection events.

State Model —

3.2 Communications

The

Communications State Model defines the behavior of

the equipment in relation to the existence or absence of

a communications link with the host. Section 4.1

expands on this section by defining the Establish

Communications capability. This model pertains to a

logical connection between equipment and host rather

than a physical connection.

3.2.1 Terminology — The terms communication fail-

ure, connection transaction failure, and communication

link are defined for use within this document only and

should not be confused with the same or similar terms

used elsewhere.

See SEMI E4 (SECS-I) or SEMI E37 (HSMS) for

a protocol specific definitions of communications

failure.

A connection transaction failure occurs when

attempting to establish communications and is

caused by

— a communication failure,

— the failure to receive an S1,F14 reply within a

reply timeout limit, or

— receipt of S1,F14 that has been improperly

formatted or with COMMACK2 not set to 0.

A reply timeout period begins after the successful

transmission of a complete primary message for

which a reply is expected. (See SEMI E4 (SECS-I)

or SEMI E37 (HSMS) for a protocol-specific

definition of reply timeout.)

A communication link is established following the

first successful completion of any one S1,F13/F14

transaction with an acknowledgement of “accept”.

The establishment of this link is logical rather than

physical.

Implementations may have mechanisms which

allow outgoing messages to be stored temporarily

prior to being sent. The noun queue is used to

cover such stored messages. They are queued when

placed within the queue and are dequeued by

removing them from this storage.

Send includes “queue to send” or “begin the

process of attempting to send” a message. It does

not imply the successful completion of sending a

message.

The host may attempt to establish communications

with equipment at any time due to the initialization

of the host or by independent detection of a

communications failure by the host. Thus, the host

may initiate an S1,F13/F14 transaction at any time.

3.2.2 CommDelay Timer — The CommDelay timer

represents an internal timer used to measure the interval

between attempts to send S1,F13. The length of this

interval is equal to the value in the EstablishCommuni-

cationsTimeout. The CommDelay timer is not directly

visible to the host.

EstablishCommunicationsTimeout is the user-configur-

able equipment constant that defines the delay, in

seconds, between attempts to send S1,F13. This value

is used to initialize the CommDelay timer.

The CommDelay timer is initialized to begin timing.

The CommDelay timer is initialized only when the state

WAIT DELAY is entered.

The CommDelay timer is expired when it “times out,”

and the time remaining in the interval between attempts

to send is zero. When the timer expires during the state

WAIT DELAY, it triggers a new attempt to send

S1,F13 and the transition to the state WAIT CRA3 .

3.2.3 Conventions

The attempt to send S1,F13 is made only upon

transit into the state WAIT CRA. The CommDelay

Timer should be set to “expired” at this time.

The CommDelay timer is initialized only upon

transit into the state WAIT DELAY. A next

2 Establish Communications Acknowledge Code, defined in Section

4.1. See the SEMI E5 Standard for further definition of this Data

Item.

3 CRA is the mnemonic defined for Establish Communications

Request Acknowledge (S1,F14).

SEMI E30-1103 © SEMI 1992, 2003

8

�

2023年江西萍乡中考道德与法治真题及答案.doc

2023年江西萍乡中考道德与法治真题及答案.doc 2012年重庆南川中考生物真题及答案.doc

2012年重庆南川中考生物真题及答案.doc 2013年江西师范大学地理学综合及文艺理论基础考研真题.doc

2013年江西师范大学地理学综合及文艺理论基础考研真题.doc 2020年四川甘孜小升初语文真题及答案I卷.doc

2020年四川甘孜小升初语文真题及答案I卷.doc 2020年注册岩土工程师专业基础考试真题及答案.doc

2020年注册岩土工程师专业基础考试真题及答案.doc 2023-2024学年福建省厦门市九年级上学期数学月考试题及答案.doc

2023-2024学年福建省厦门市九年级上学期数学月考试题及答案.doc 2021-2022学年辽宁省沈阳市大东区九年级上学期语文期末试题及答案.doc

2021-2022学年辽宁省沈阳市大东区九年级上学期语文期末试题及答案.doc 2022-2023学年北京东城区初三第一学期物理期末试卷及答案.doc

2022-2023学年北京东城区初三第一学期物理期末试卷及答案.doc 2018上半年江西教师资格初中地理学科知识与教学能力真题及答案.doc

2018上半年江西教师资格初中地理学科知识与教学能力真题及答案.doc 2012年河北国家公务员申论考试真题及答案-省级.doc

2012年河北国家公务员申论考试真题及答案-省级.doc 2020-2021学年江苏省扬州市江都区邵樊片九年级上学期数学第一次质量检测试题及答案.doc

2020-2021学年江苏省扬州市江都区邵樊片九年级上学期数学第一次质量检测试题及答案.doc 2022下半年黑龙江教师资格证中学综合素质真题及答案.doc

2022下半年黑龙江教师资格证中学综合素质真题及答案.doc