GP2Y1010AU0F Compact Optical Dust Sensor

GP2Y1010AU0F

■ Compliance

1. Compliant with RoHS directive (2002/95/EC)

■ Applications

1. Detecting of dust in the air.

2. Example: Air purifier, Air conditioner, Air monitor

■ Description

GP2Y1010AU0F is a dust sensor by optical sensing

system.

An infrared emitting diode (IRED) and an phototran-

sistor are diagonally arranged into this device.

It detects the reflected light of dust in air.

Especially, it is effective to detect very fine particle

like the cigarette smoke.

In addition it can distinguish smoke from house dust

by pulse pattern of output voltage.

■ Features

1. Compact, thin package (46.0 × 30.0 × 17.6 mm)

2. Low consumption current (Icc: MAX. 20 mA)

3. The presence of dust can be detected by the

photometry of only one pulse

4. Enable to distinguish smoke from house dust

5. Lead-free and RoHS directive compliant

Notice The content of data sheet is subject to change without prior notice.

In the absence of confirmation by device specification sheets, SHARP takes no responsibility for any defects that may occur in equipment using any SHARP

devices shown in catalogs, data books, etc. Contact SHARP in order to obtain the latest device specification sheets before using any SHARP device.

1

Sheet No.: E4-A01501EN

Date Dec. 1. 2006

© SHARP Corporation

�

GP2Y1010AU0F

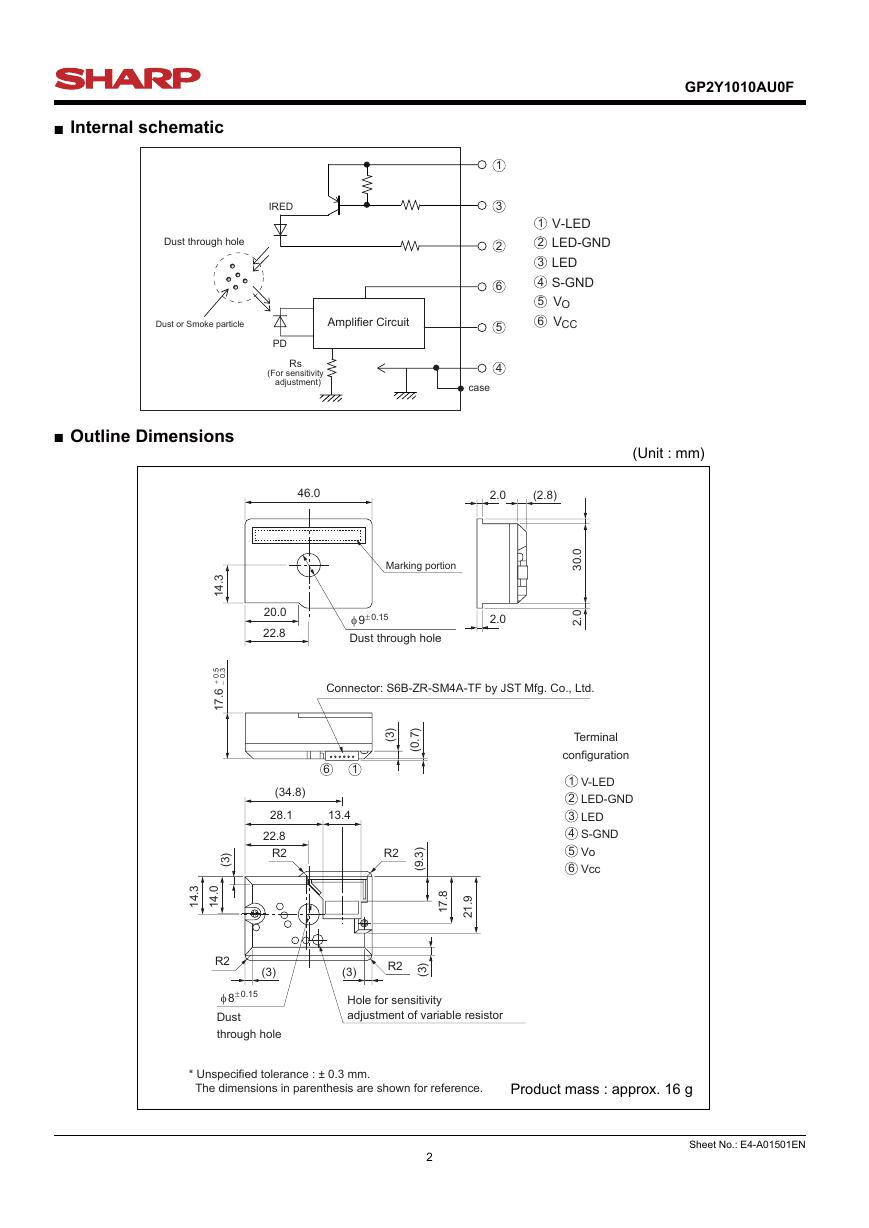

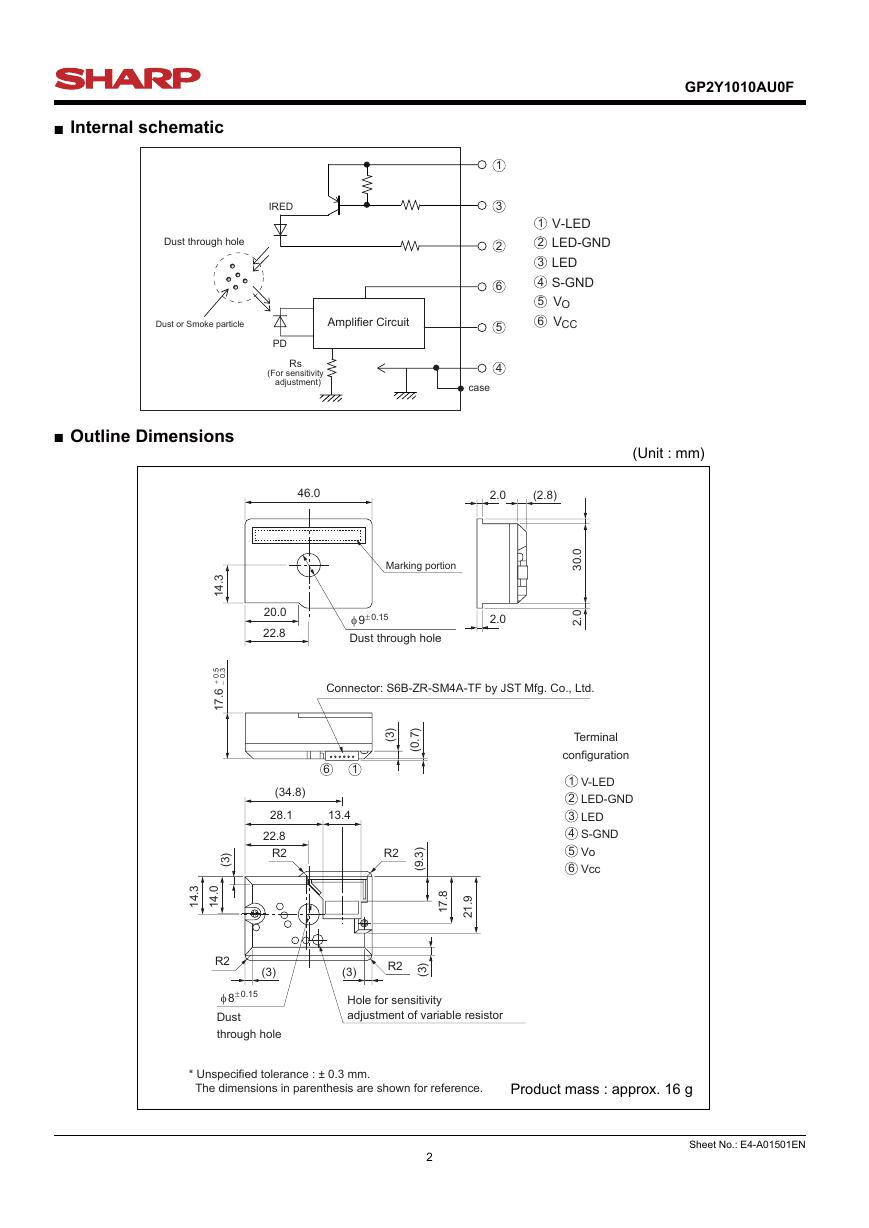

■ Internal schematic

IRED

Dust through hole

Dust or Smoke particle

Amplifier Circuit

PD

Rs

(For sensitivity

adjustment)

1

3

2

6

5

4

case

1

2

3

4

5

6

V-LED

LED-GND

LED

S-GND

VO

VCC

■ Outline Dimensions

46.0

2.0

(2.8)

(Unit : mm)

3

.

4

1

Marking portion

20.0

22.8

φ9± 0.15

Dust through hole

2.0

0

.

0

3

0

.

2

5

3

.

.

0

0

+

−

6

.

7

1

)

3

(

3

.

4

1

.

0

4

1

Connector: S6B-ZR-SM4A-TF by JST Mfg. Co., Ltd.

6

1

13.4

(34.8)

28.1

22.8

R2

)

3

(

)

7

.

0

(

R2

)

3

.

9

(

8

.

7

1

.

9

1

2

Terminal

configuration

1

2

3

4

5

6

V-LED

LED-GND

LED

S-GND

Vo

Vcc

R2

(3)

φ8± 0.15

Dust

through hole

(3)

R2

)

3

(

Hole for sensitivity

adjustment of variable resistor

* Unspecified tolerance : ± 0.3 mm.

The dimensions in parenthesis are shown for reference.

Product mass : approx. 16 g

2

Sheet No.: E4-A01501EN

�

GP2Y1010AU0F

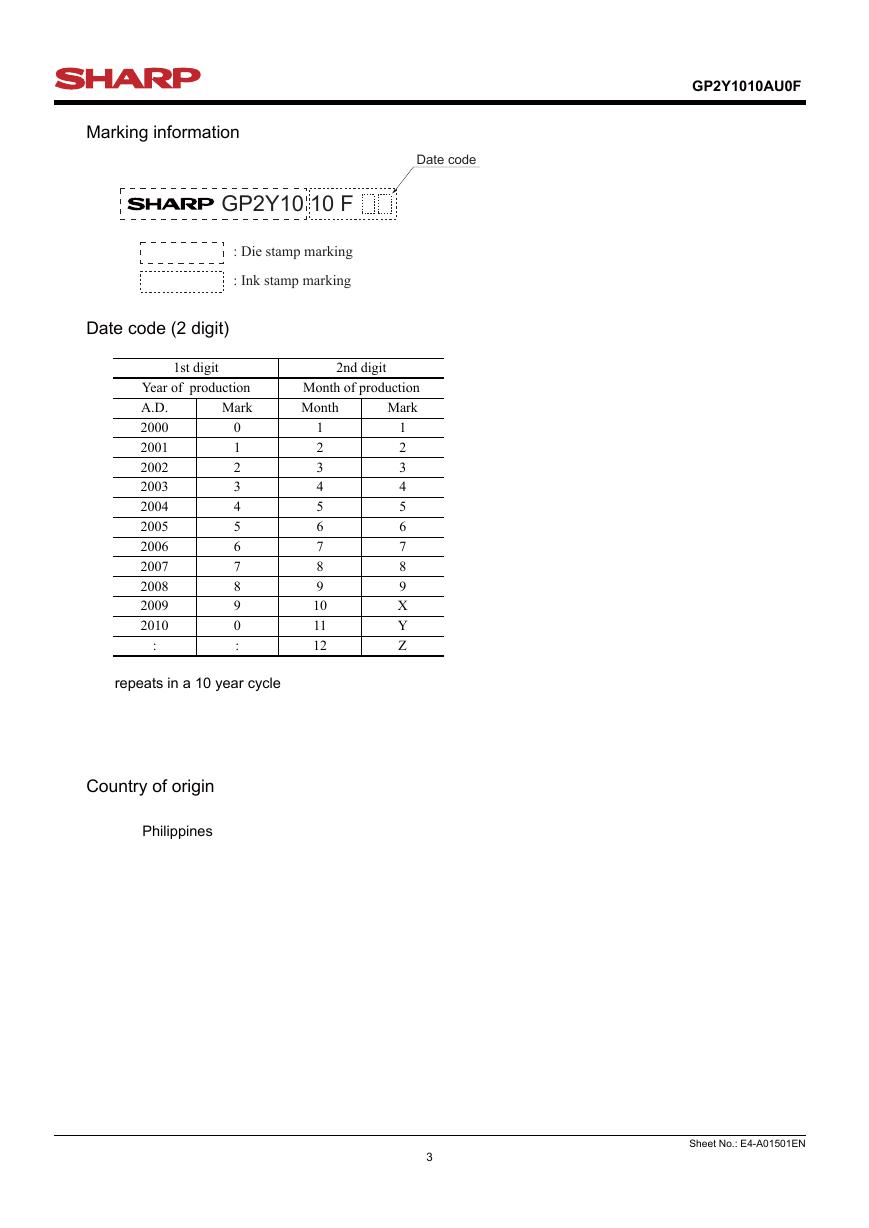

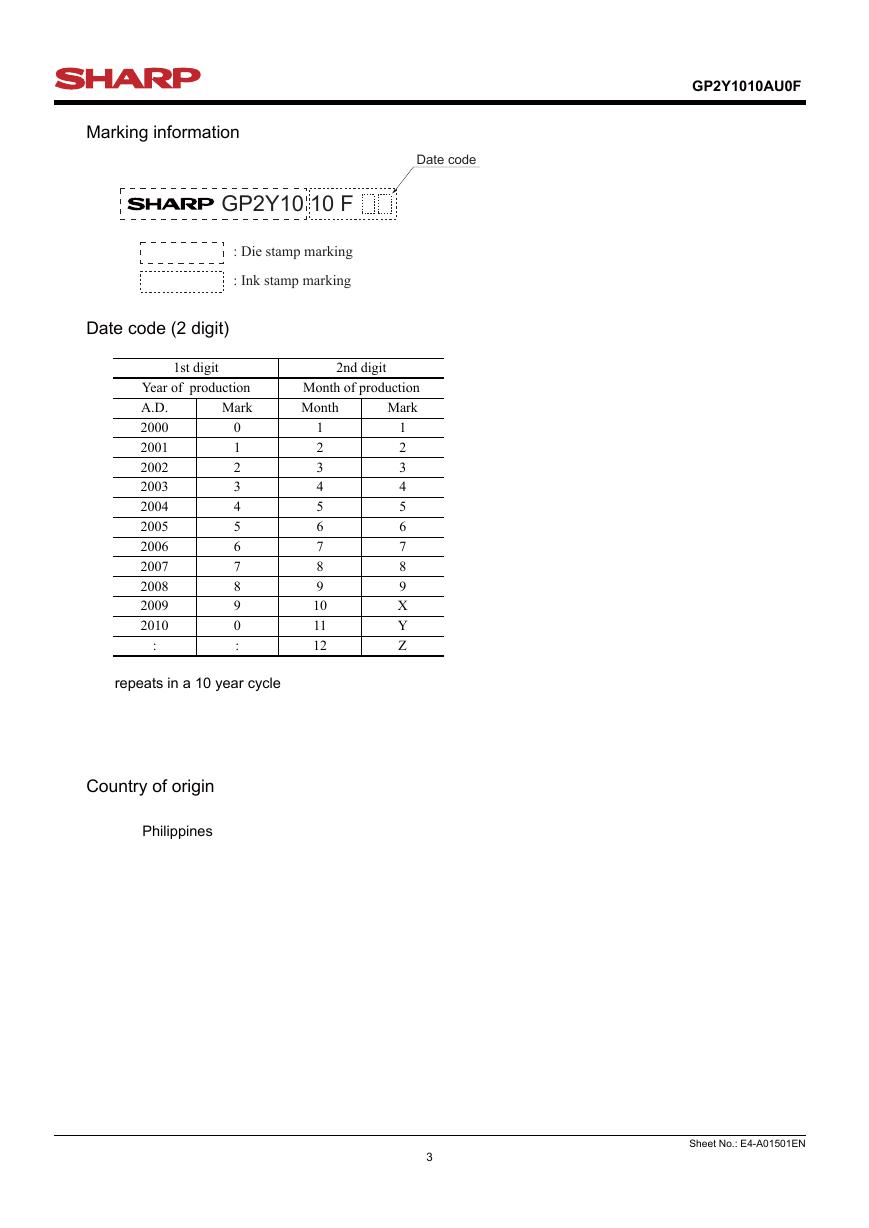

Marking information

Date code

GP2Y10 10 F

: Die stamp marking

: Ink stamp marking

Date code (2 digit)

1st digit

Year of production

A.D.

Mark

2000

2001

2002

2003

2004

2005

2006

2007

2008

2009

2010

0

1

2

3

4

5

6

7

8

9

0

:

:

2nd digit

Month of production

Month

Mark

1

2

3

4

5

6

7

8

9

10

11

12

1

2

3

4

5

6

7

8

9

X

Y

Z

repeats in a 10 year cycle

Country of origin

Philippines

3

Sheet No.: E4-A01501EN

�

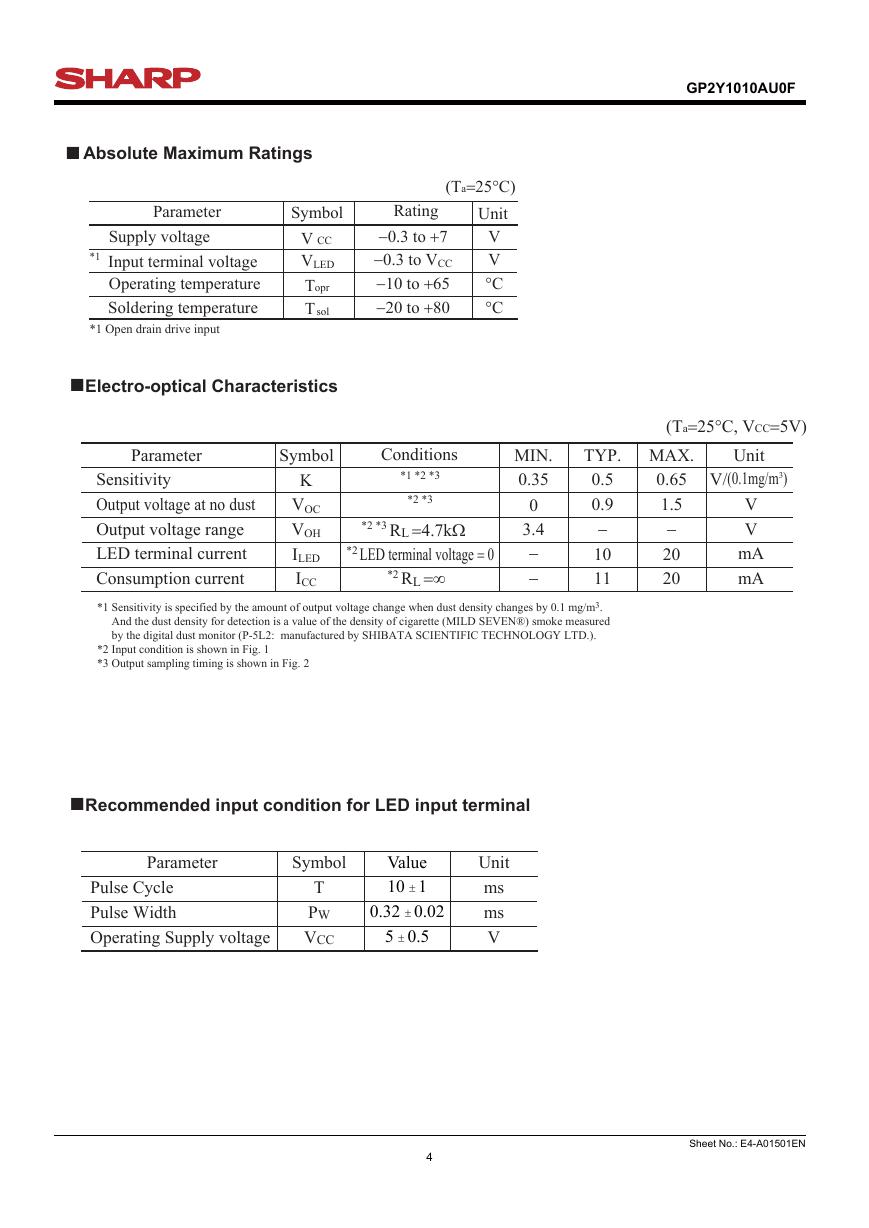

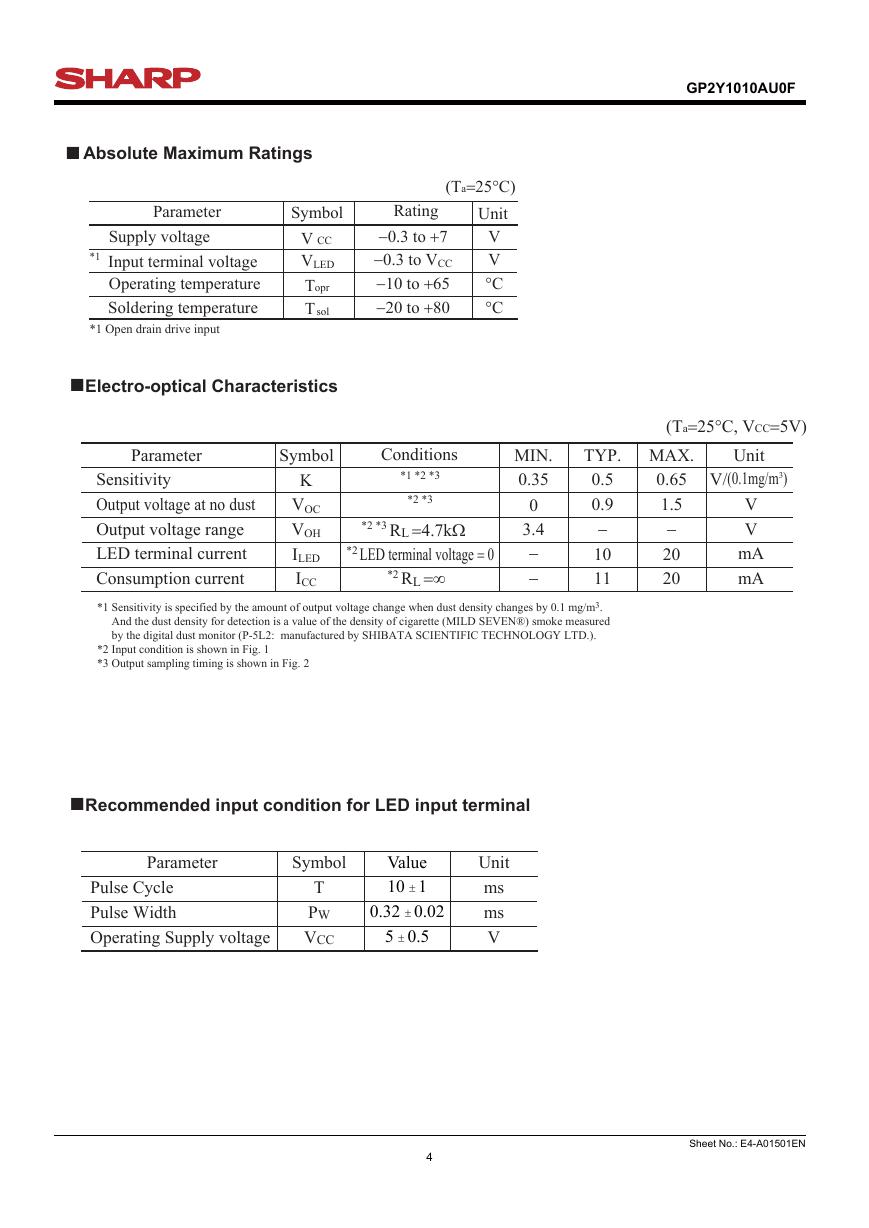

■

Absolute Maximum Ratings

*1

Parameter

Supply voltage

Input terminal voltage

Operating temperature

Soldering temperature

*1 Open drain drive input

CC

Symbol

V

V

LED

T

opr

T

sol

■

Electro-optical Characteristics

(Ta=25°C)

Unit

V

V

°C

°C

Rating

−0.3 to +7

−0.3 to VCC

−10 to +65

−20 to +80

Parameter

Symbol

Conditions

*1 *2 *3

*2 *3

TYP.

0.5

Sensitivity

Output voltage at no dust

0.9

Output voltage range

−

LED terminal current

10

11

Consumption current

*1 Sensitivity is specified by the amount of output voltage change when dust density changes by 0.1 mg/m3.

And the dust density for detection is a value of the density of cigarette (MILD SEVEN®) smoke measured

by the digital dust monitor (P-5L2: manufactured by SHIBATA SCIENTIFIC TECHNOLOGY LTD.).

*2 Input condition is shown in Fig. 1

*3 Output sampling timing is shown in Fig. 2

MIN.

0.35

0

3.4

−

−

K

VOC

VOH

ILED

ICC

*2 LED terminal voltage = 0

*2 *3 RL =4.7kΩ

*2 RL =∞

GP2Y1010AU0F

(Ta=25°C, VCC=5V)

MAX.

0.65

1.5

−

20

20

Unit

V/(0.1mg/m3)

V

V

mA

mA

■ Recommended input condition for LED input terminal

Parameter

Symbol

Pulse Cycle

Pulse Width

Operating Supply voltage

T

PW

VCC

Value

10 ± 1

0.32 ± 0.02

5 ± 0.5

Unit

ms

ms

V

4

Sheet No.: E4-A01501EN

�

GP2Y1010AU0F

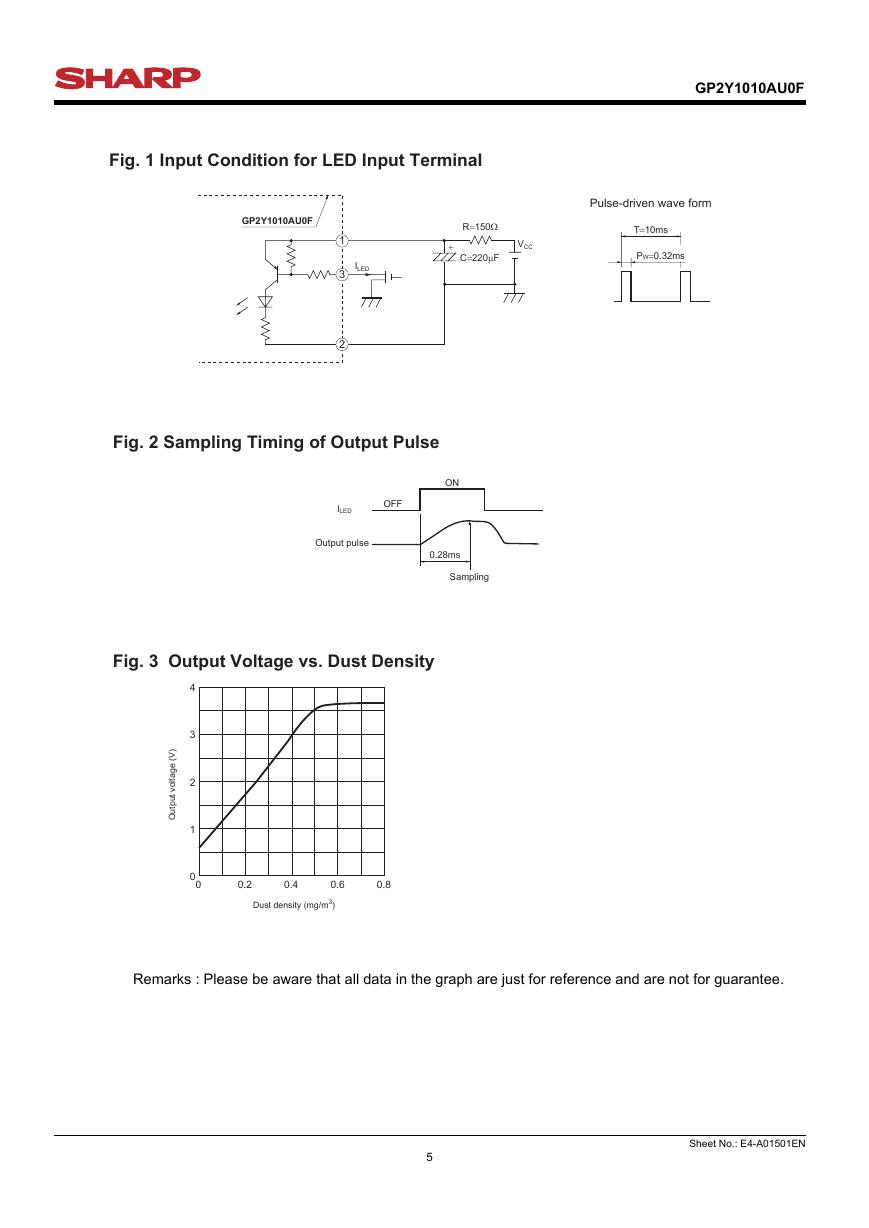

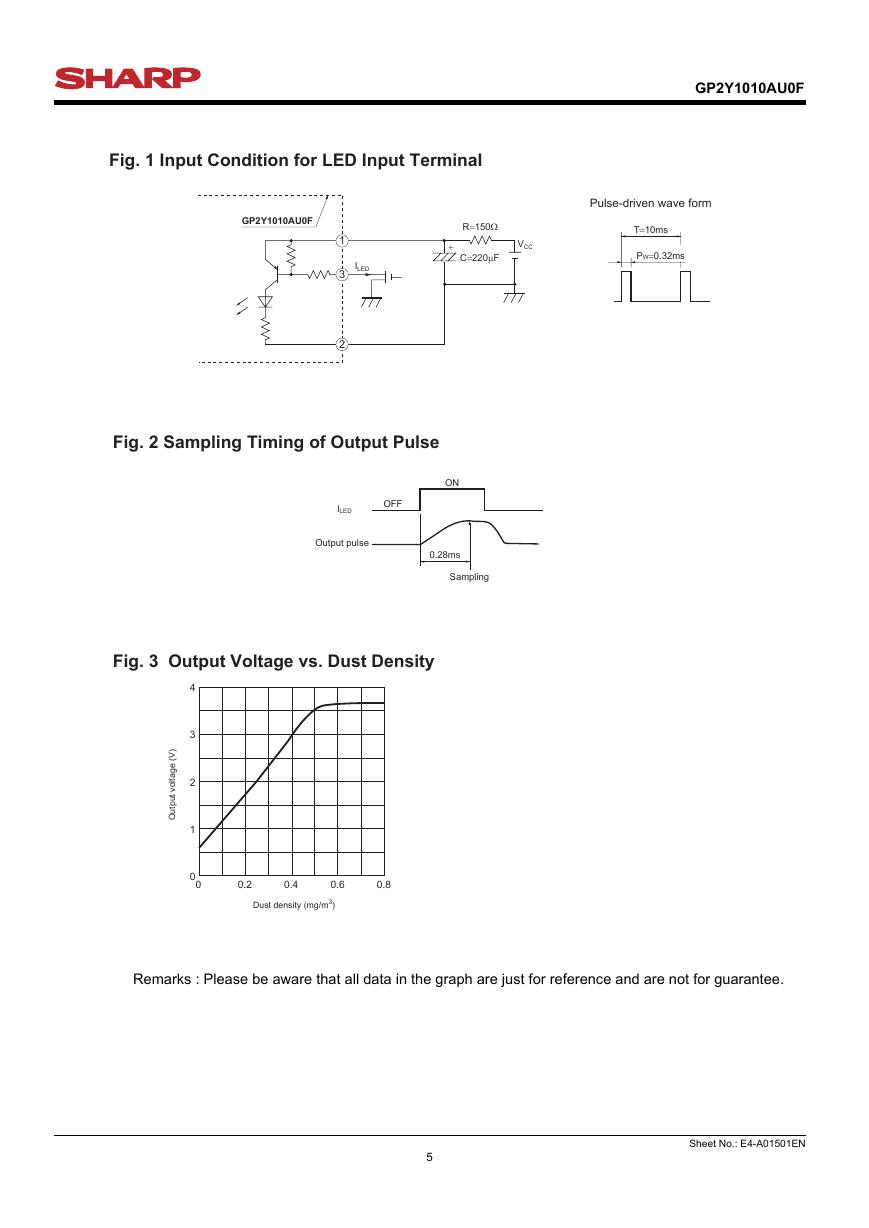

Fig. 1 Input Condition for LED Input Terminal

R=150Ω

+

C=220μF

VCC

Pulse-driven wave form

T=10ms

PW=0.32ms

GP2Y1010AU0F

ILED

1

3

2

Fig. 2 Sampling Timing of Output Pulse

ILED

OFF

Output pulse

ON

0.28ms

Sampling

Fig. 3 Output Voltage vs. Dust Density

)

V

(

e

g

a

t

l

o

v

t

u

p

t

u

O

4

3

2

1

0

0

0.2

0.4

0.6

0.8

Dust density (mg/m3)

Remarks : Please be aware that all data in the graph are just for reference and are not for guarantee.

5

Sheet No.: E4-A01501EN

�

GP2Y1010AU0F

● Notes

1 Connection of case and GND

Case material use conductive resin as cover case {printed model No.} and metal {test terminal side}

as bottom cover. The metal case connects with GND in sensor.

2 Cleaning

Please don’t do cleaning, because there is a case that this device is not satisfied with its characteristics

by cleaning.

3 Pulse input range

Please subject to recommendation as regard input condition for LED in order to keep reliability.

4 Dust adhesion

There is a case that this product does not detect the dust density correctly, since the dust adhered to

the inside of the dust through hole may project into the detecting space which consist of emitter and

detector light axis. Please take the structure and mechanism of the equipment into consideration to

avoid the influence of adhered dust. And when the dust is adhered, please consider the maintenance

such as vacuuming or blowing off the dust by air.

In addition, please pay attention to structure and placing location of the application to avoid any

adhesive particle like oil, etc. to gets into the device. If it sticks to optical part, malfunction may occur.

5 Light output

In circuit designing, make allowance for the degradation of the light emitting diode output that results

from long continuous operation. (50% degradation/5 years)

6 Sensitivity adjustment VR

VR for sensitivity adjustment is set up at shipping from sharp. Please do not touch the VR or

Electro-optical characteristics specified on the specification will be invalid.

7 Resolution

Please do not disassemble the device such as removing tapping screw and so on. Even if the device

is reassembled, it may not satisfy the specification.

8 Application to fire alarm

Please do not use this device for a fire alarm application. When using this device to application other

than air purifying and equipment with air purifying function, please inform us before usage.

9 Noise influence

If the sensor is located close to noise generator (ex. Electric dust collector, etc. ), the sensor output

may be affected by leaded noise. On top of that noise from power supply line also may affect the

sensor output. When desinging the system, please consider the effect from noise.

10 Vibration influence

The sensor may change its value under mechanical oscillation. Before usage, please make sure

that the device works normally in the application.

11 Incident light influence

There is a case that the sensor output may be affected when outer-light comes through dust through

hole on printed side. In order to avoid any influence from outer-light, please locate the printed side

of sensor facing to inside of the application.

12 When inside of the sensor is moisturized, this product does not keep its proper function. Please

design the application so that moisturization of the sensor does not happen.

6

Sheet No.: E4-A01501EN

�

GP2Y1010AU0F

● Presence of ODC etc.

This product shall not contain the following materials.

And they are not used in the production process for this product.

Regulation substances : CFCs, Halon, Carbon tetrachloride, 1.1.1-Trichloroethane (Methylchloroform)

Specific brominated flame retardants such as the PBB and PBDE are not used in this product at all.

This product shall not contain the following materials banned in the RoHS Directive (2002/95/EC).

• Lead, Mercury, Cadmium, Hexavalent chromium, Polybrominated biphenyls (PBB),

Polybrominated diphenyl ethers (PBDE).

7

Sheet No.: E4-A01501EN

�

GP2Y1010AU0F

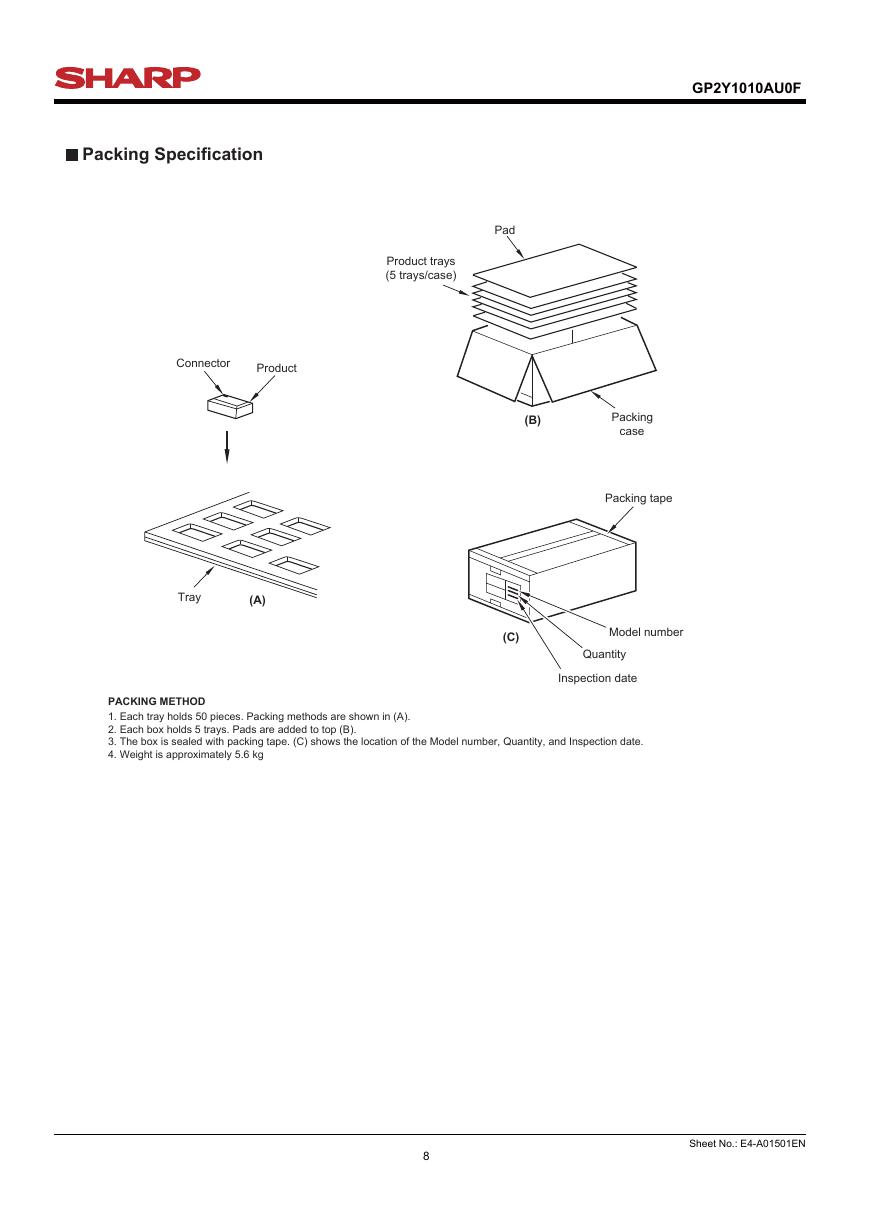

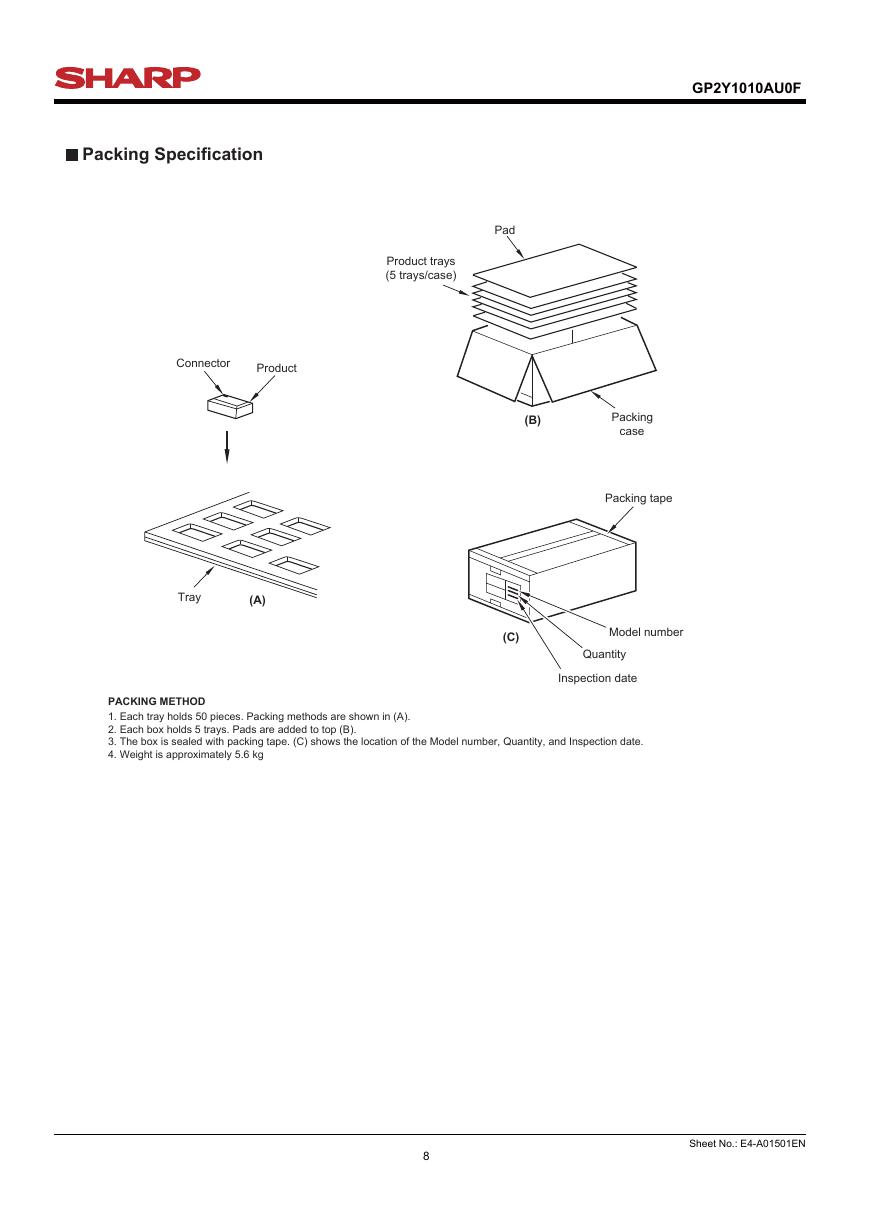

Packing Specification

Pad

Product trays

(5 trays/case)

Connector

Product

Tray

(A)

(B)

Packing

case

Packing tape

(C)

Model number

Quantity

Inspection date

PACKING METHOD

1. Each tray holds 50 pieces. Packing methods are shown in (A).

2. Each box holds 5 trays. Pads are added to top (B).

3. The box is sealed with packing tape. (C) shows the location of the Model number, Quantity, and Inspection date.

4. Weight is approximately 5.6 kg

8

Sheet No.: E4-A01501EN

�

V2版本原理图(Capacitive-Fingerprint-Reader-Schematic_V2).pdf

V2版本原理图(Capacitive-Fingerprint-Reader-Schematic_V2).pdf 摄像头工作原理.doc

摄像头工作原理.doc VL53L0X简要说明(En.FLVL53L00216).pdf

VL53L0X简要说明(En.FLVL53L00216).pdf 原理图(DVK720-Schematic).pdf

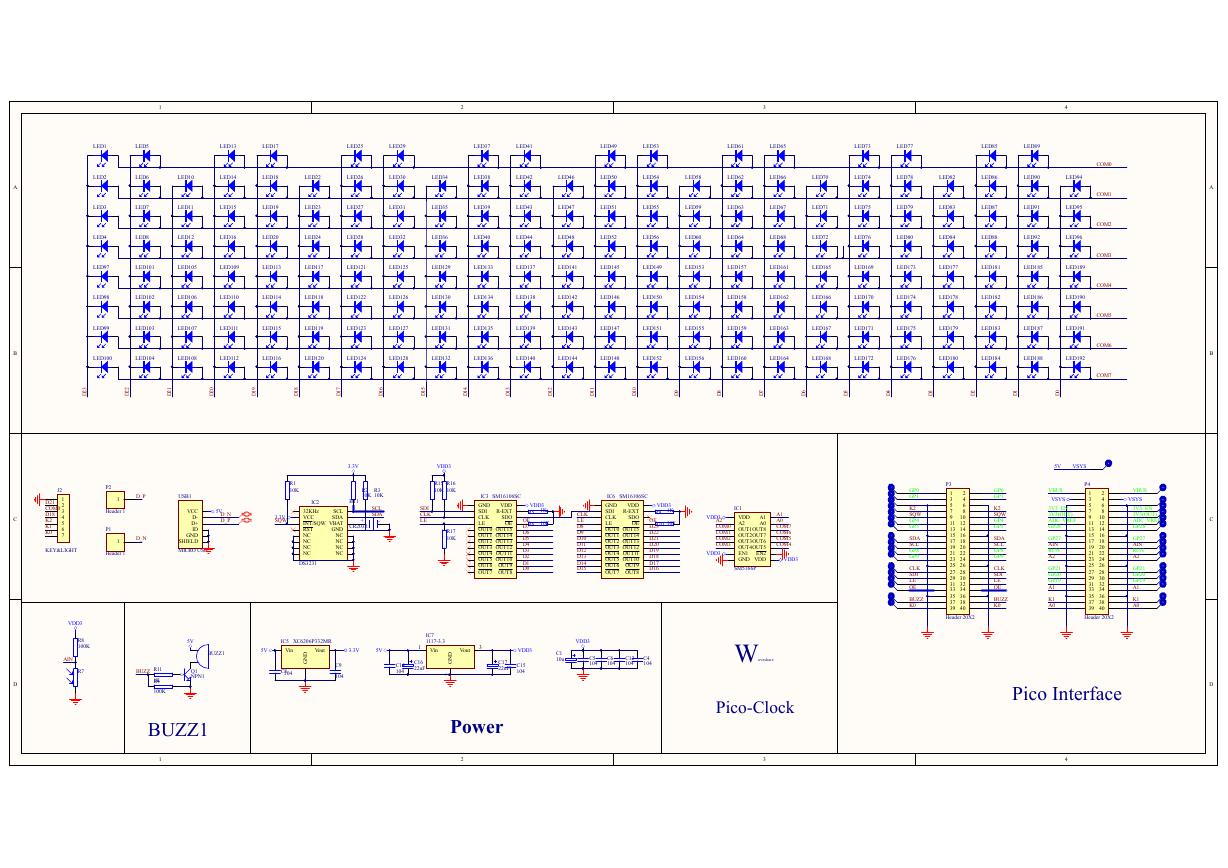

原理图(DVK720-Schematic).pdf 原理图(Pico-Clock-Green-Schdoc).pdf

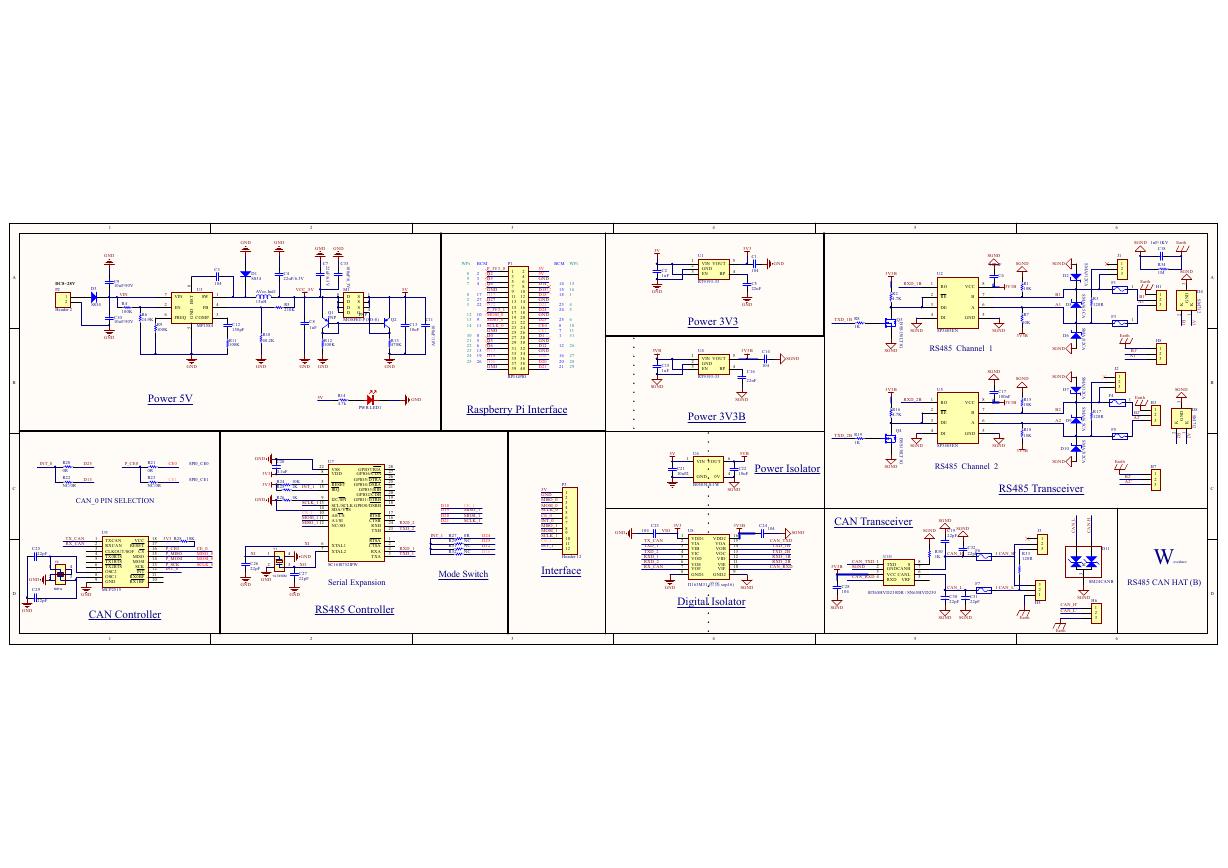

原理图(Pico-Clock-Green-Schdoc).pdf 原理图(RS485-CAN-HAT-B-schematic).pdf

原理图(RS485-CAN-HAT-B-schematic).pdf File:SIM7500_SIM7600_SIM7800 Series_SSL_Application Note_V2.00.pdf

File:SIM7500_SIM7600_SIM7800 Series_SSL_Application Note_V2.00.pdf ADS1263(Ads1262).pdf

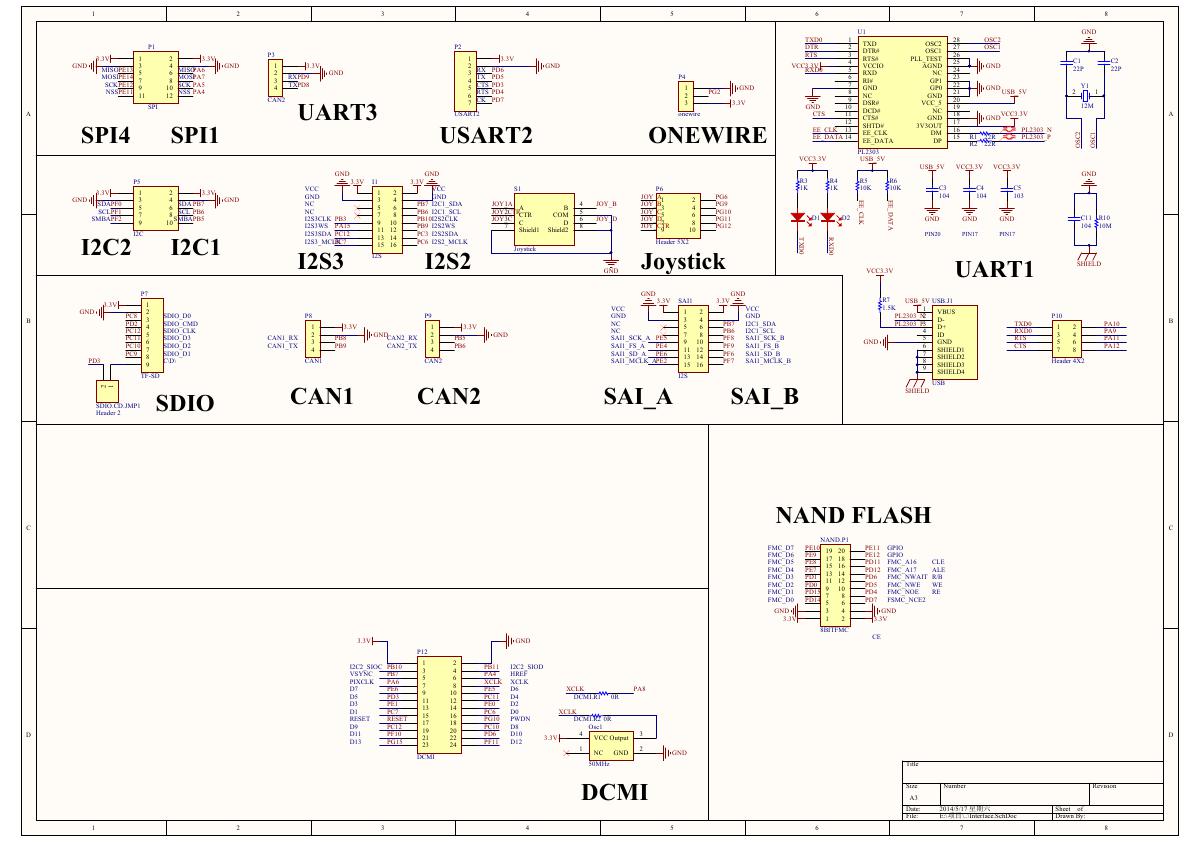

ADS1263(Ads1262).pdf 原理图(Open429Z-D-Schematic).pdf

原理图(Open429Z-D-Schematic).pdf 用户手册(Capacitive_Fingerprint_Reader_User_Manual_CN).pdf

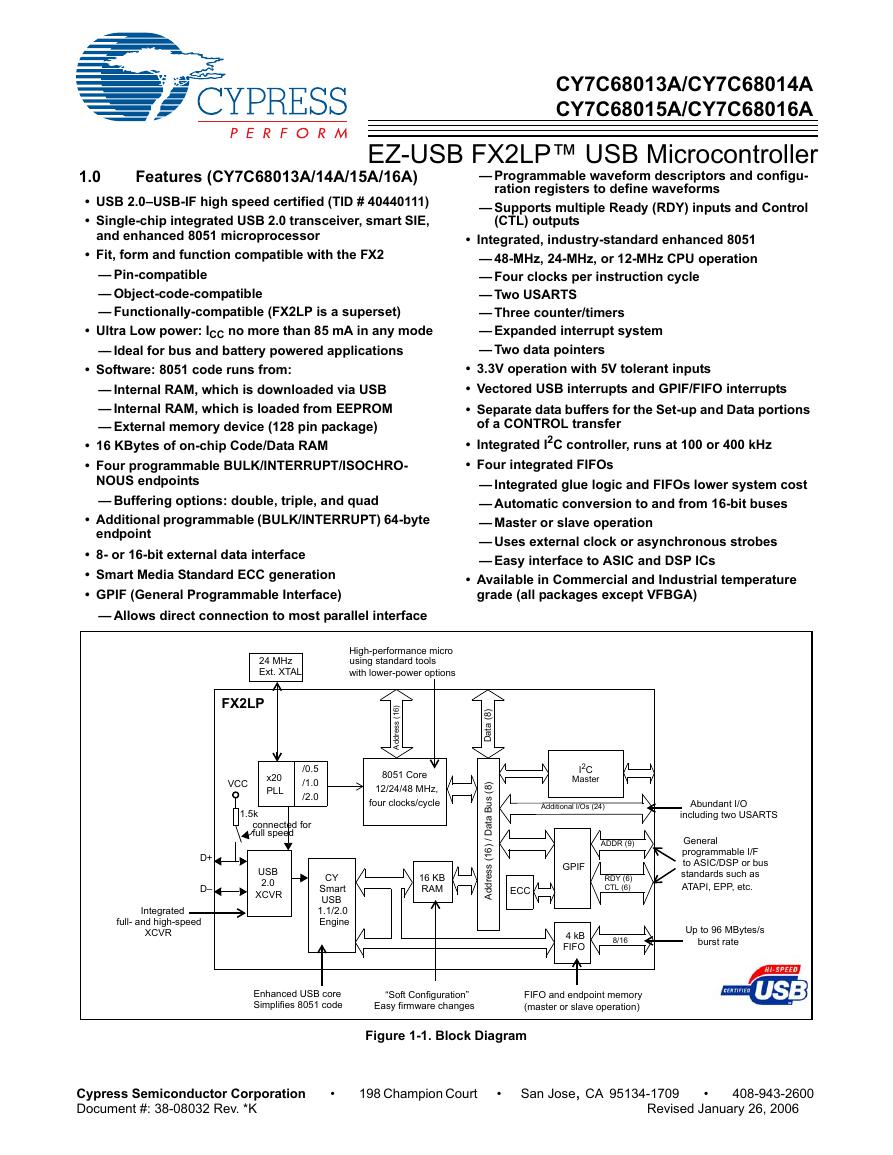

用户手册(Capacitive_Fingerprint_Reader_User_Manual_CN).pdf CY7C68013A(英文版)(CY7C68013A).pdf

CY7C68013A(英文版)(CY7C68013A).pdf TechnicalReference_Dem.pdf

TechnicalReference_Dem.pdf