Bosch Sensortec | BMP388 Datasheet

1 | 57

BMP388

Digital pressure sensor

BMP388 – Datasheet

Document revision

1.1

Document release date

March 2018

Document number

BST-BMP388-DS001-01

Technical reference code(s)

0 273 300 511

Notes

Data and descriptions in this document are subject to change without notice.

Product photos and pictures are for illustration purposes only and may differ

from the real product appearance.

Modifications reserved |Data subject not change without notice | Printed in Germany

Document number: BST-BMEP388-DS001-01 Revision_1.1_032018

�

Bosch Sensortec | BMP388 Datasheet

BMP388

Digital pressure sensor

2 | 57

The BMP388 is a digital sensor with pressure and temperature measurement based on proven sensing principles. The sensor

module is housed in an extremely compact 10-pin metal-lid LGA package with a footprint of only 2.0 × 2.0 mm² and max 0.8

mm package height. Its small dimensions and its low power consumption of 3.4 µA @1Hz allow the implementation in battery

driven devices such as mobile phones, GPS modules or watches.

Typical applications

Vertical velocity indication (e.g. rise/sink speed)

Internet of things

Enhancement of GPS navigation

(e.g. time-to-first-fix improvement, dead-reckoning, slope detection)

Indoor navigation & localization (floor detection, elevator detection)

Outdoor navigation, leisure and sports applications

Weather forecast

Health care applications (e.g. spirometry)

Fitness applications like enhancement of calorie detection

AR & VR applications

Context awareness

Target Devices

Flying toys

Drones

Handsets such as mobile phones, tablet PCs, GPS devices

Navigation systems

Portable health care devices

Home weather stations

Watches

White goods

Modifications reserved |Data subject not change without notice | Printed in Germany

Document number: BST-BMEP388-DS001-01 Revision_1.1_032018

�

Bosch Sensortec | BMP388 Datasheet

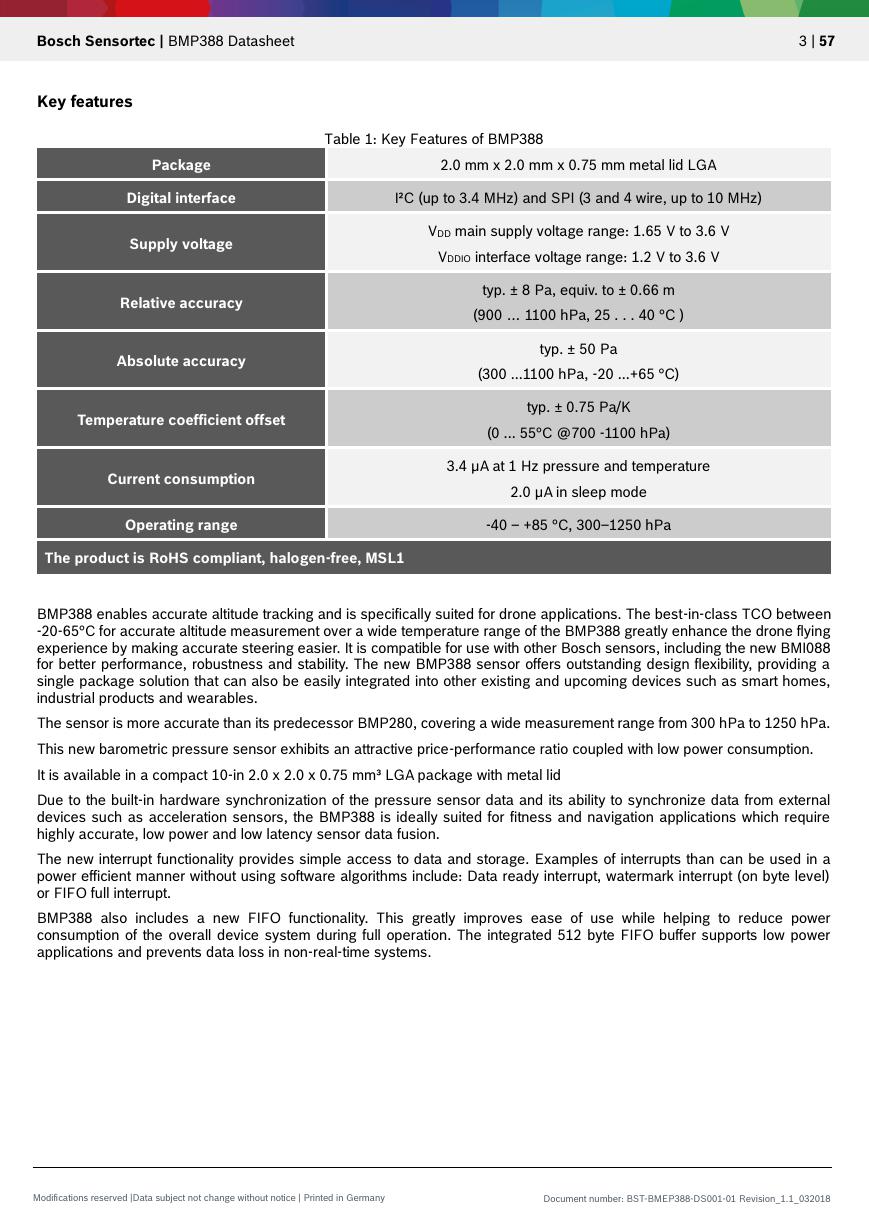

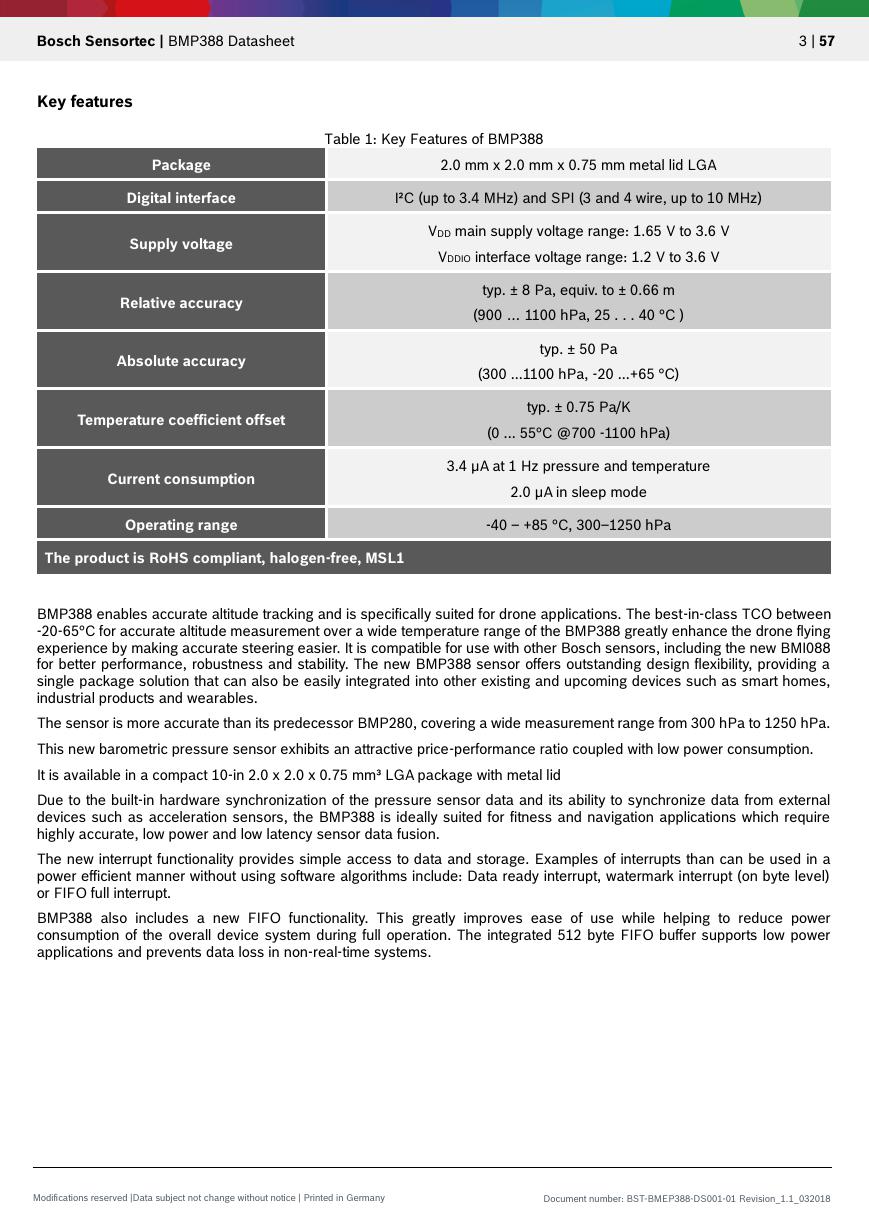

Key features

3 | 57

Package

2.0 mm x 2.0 mm x 0.75 mm metal lid LGA

Table 1: Key Features of BMP388

Digital interface

I²C (up to 3.4 MHz) and SPI (3 and 4 wire, up to 10 MHz)

Supply voltage

Relative accuracy

Absolute accuracy

Temperature coefficient offset

Current consumption

VDD main supply voltage range: 1.65 V to 3.6 V

VDDIO interface voltage range: 1.2 V to 3.6 V

typ. ± 8 Pa, equiv. to ± 0.66 m

(900 … 1100 hPa, 25 . . . 40 °C )

typ. ± 50 Pa

(300 ...1100 hPa, -20 ...+65 °C)

typ. ± 0.75 Pa/K

(0 ... 55°C @700 -1100 hPa)

3.4 µA at 1 Hz pressure and temperature

2.0 µA in sleep mode

Operating range

-40 ‒ +85 °C, 300‒1250 hPa

The product is RoHS compliant, halogen-free, MSL1

BMP388 enables accurate altitude tracking and is specifically suited for drone applications. The best-in-class TCO between

-20-65°C for accurate altitude measurement over a wide temperature range of the BMP388 greatly enhance the drone flying

experience by making accurate steering easier. It is compatible for use with other Bosch sensors, including the new BMI088

for better performance, robustness and stability. The new BMP388 sensor offers outstanding design flexibility, providing a

single package solution that can also be easily integrated into other existing and upcoming devices such as smart homes,

industrial products and wearables.

The sensor is more accurate than its predecessor BMP280, covering a wide measurement range from 300 hPa to 1250 hPa.

This new barometric pressure sensor exhibits an attractive price-performance ratio coupled with low power consumption.

It is available in a compact 10-in 2.0 x 2.0 x 0.75 mm³ LGA package with metal lid

Due to the built-in hardware synchronization of the pressure sensor data and its ability to synchronize data from external

devices such as acceleration sensors, the BMP388 is ideally suited for fitness and navigation applications which require

highly accurate, low power and low latency sensor data fusion.

The new interrupt functionality provides simple access to data and storage. Examples of interrupts than can be used in a

power efficient manner without using software algorithms include: Data ready interrupt, watermark interrupt (on byte level)

or FIFO full interrupt.

BMP388 also includes a new FIFO functionality. This greatly improves ease of use while helping to reduce power

consumption of the overall device system during full operation. The integrated 512 byte FIFO buffer supports low power

applications and prevents data loss in non-real-time systems.

Modifications reserved |Data subject not change without notice | Printed in Germany

Document number: BST-BMEP388-DS001-01 Revision_1.1_032018

�

Bosch Sensortec | BMP388 Datasheet

4 | 57

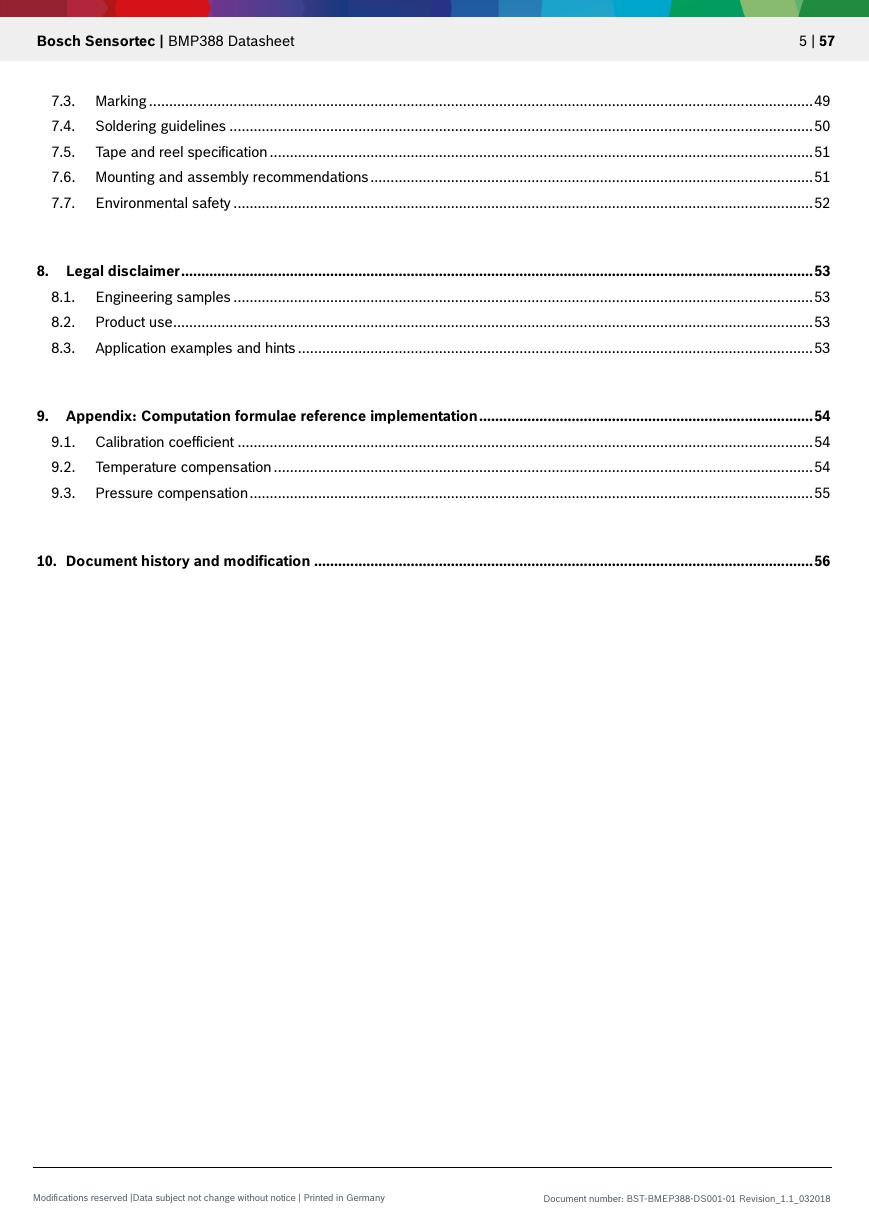

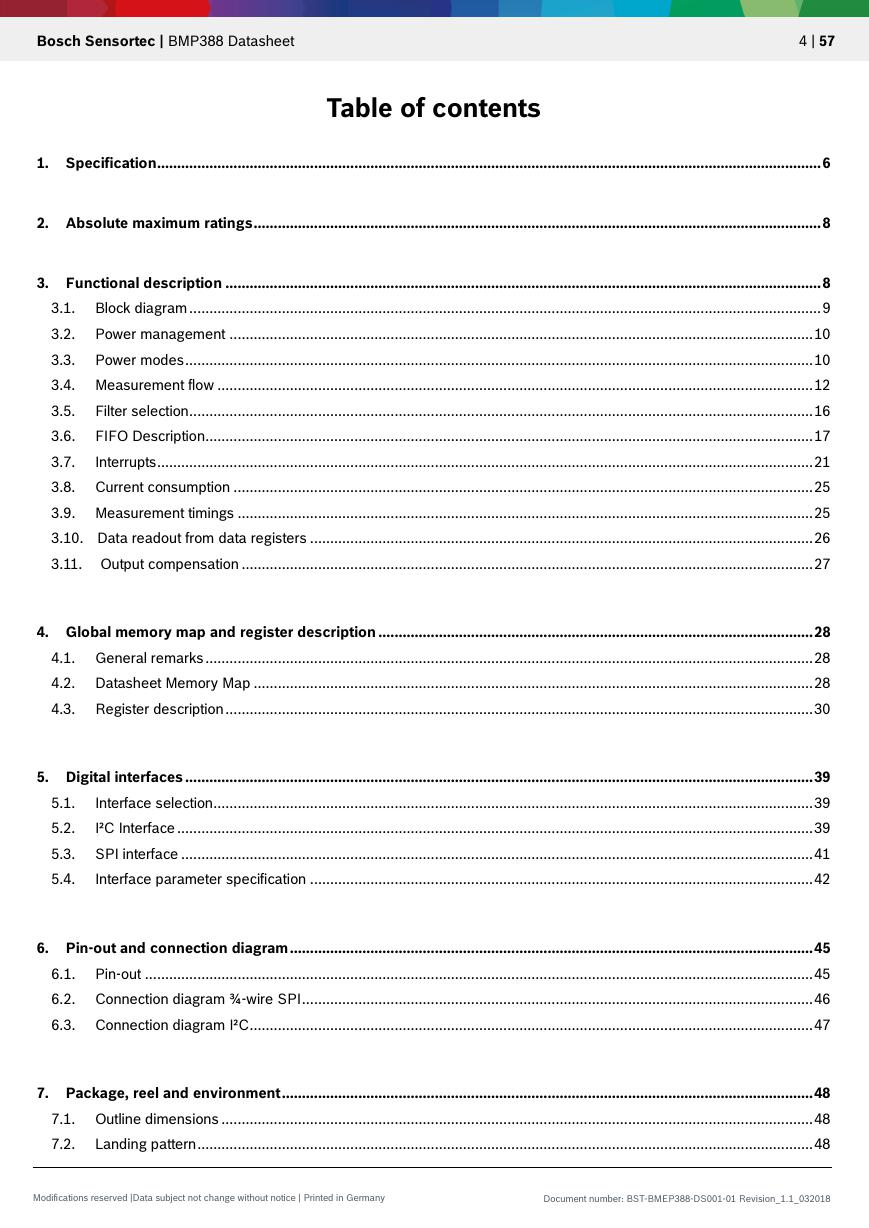

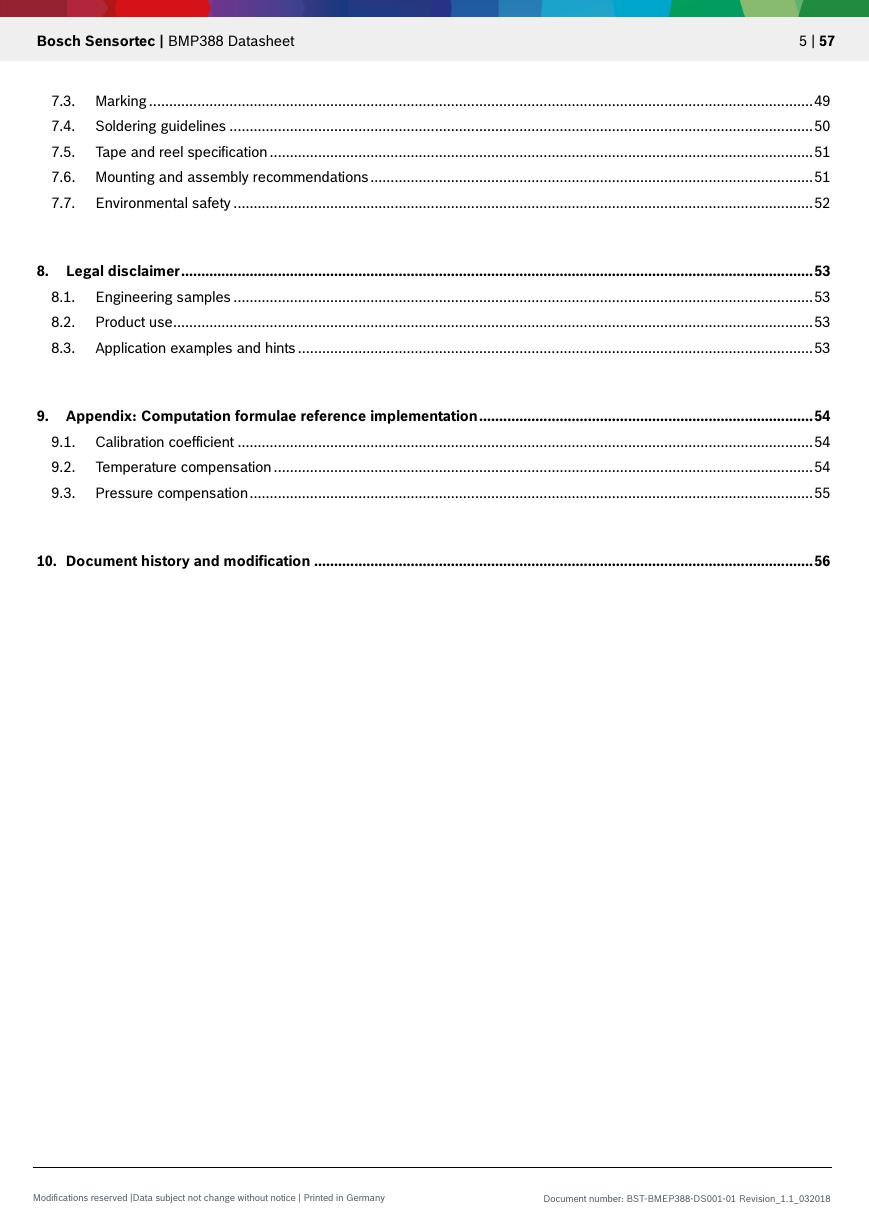

Table of contents

1. Specification ..................................................................................................................................................................... 6

2. Absolute maximum ratings ............................................................................................................................................. 8

3. Functional description .................................................................................................................................................... 8

3.1. Block diagram ............................................................................................................................................................. 9

3.2. Power management ................................................................................................................................................. 10

3.3. Power modes ............................................................................................................................................................ 10

3.4. Measurement flow .................................................................................................................................................... 12

3.5. Filter selection ........................................................................................................................................................... 16

3.6. FIFO Description....................................................................................................................................................... 17

3.7.

Interrupts ................................................................................................................................................................... 21

3.8. Current consumption ................................................................................................................................................ 25

3.9. Measurement timings ............................................................................................................................................... 25

3.10. Data readout from data registers ............................................................................................................................. 26

3.11. Output compensation .............................................................................................................................................. 27

4. Global memory map and register description ............................................................................................................ 28

4.1. General remarks ....................................................................................................................................................... 28

4.2. Datasheet Memory Map ........................................................................................................................................... 28

4.3. Register description .................................................................................................................................................. 30

5. Digital interfaces ............................................................................................................................................................ 39

5.1.

Interface selection..................................................................................................................................................... 39

5.2.

I²C Interface .............................................................................................................................................................. 39

5.3. SPI interface ............................................................................................................................................................. 41

5.4.

Interface parameter specification ............................................................................................................................. 42

6. Pin-out and connection diagram .................................................................................................................................. 45

6.1. Pin-out ...................................................................................................................................................................... 45

6.2. Connection diagram ¾-wire SPI ............................................................................................................................... 46

6.3. Connection diagram I²C ............................................................................................................................................ 47

7. Package, reel and environment .................................................................................................................................... 48

7.1. Outline dimensions ................................................................................................................................................... 48

7.2. Landing pattern ......................................................................................................................................................... 48

Modifications reserved |Data subject not change without notice | Printed in Germany

Document number: BST-BMEP388-DS001-01 Revision_1.1_032018

�

Bosch Sensortec | BMP388 Datasheet

5 | 57

7.3. Marking ..................................................................................................................................................................... 49

7.4. Soldering guidelines ................................................................................................................................................. 50

7.5. Tape and reel specification ....................................................................................................................................... 51

7.6. Mounting and assembly recommendations .............................................................................................................. 51

7.7. Environmental safety ................................................................................................................................................ 52

8. Legal disclaimer ............................................................................................................................................................. 53

8.1. Engineering samples ................................................................................................................................................ 53

8.2. Product use ............................................................................................................................................................... 53

8.3. Application examples and hints ................................................................................................................................ 53

9. Appendix: Computation formulae reference implementation ................................................................................... 54

9.1. Calibration coefficient ............................................................................................................................................... 54

9.2. Temperature compensation ...................................................................................................................................... 54

9.3. Pressure compensation ............................................................................................................................................ 55

10. Document history and modification ............................................................................................................................ 56

Modifications reserved |Data subject not change without notice | Printed in Germany

Document number: BST-BMEP388-DS001-01 Revision_1.1_032018

�

Bosch Sensortec | BMP388 Datasheet

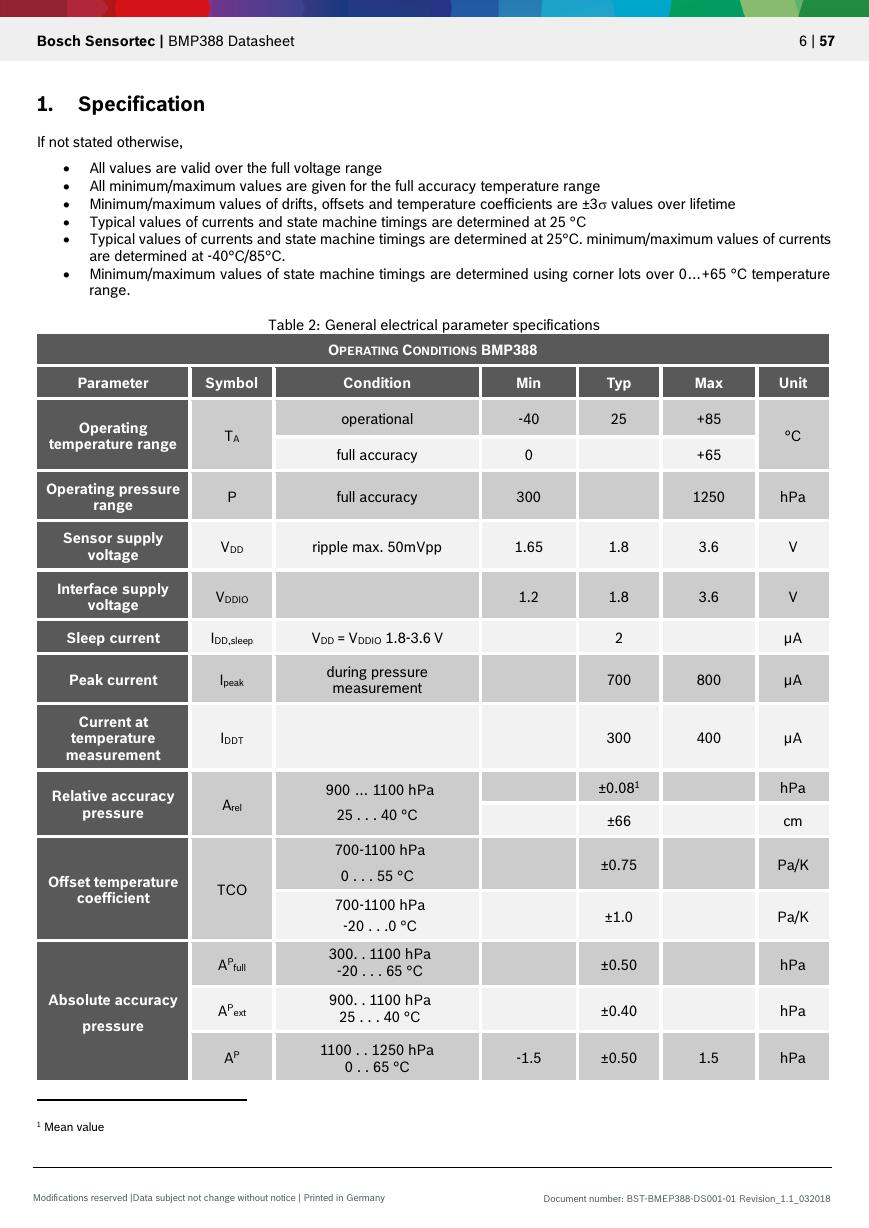

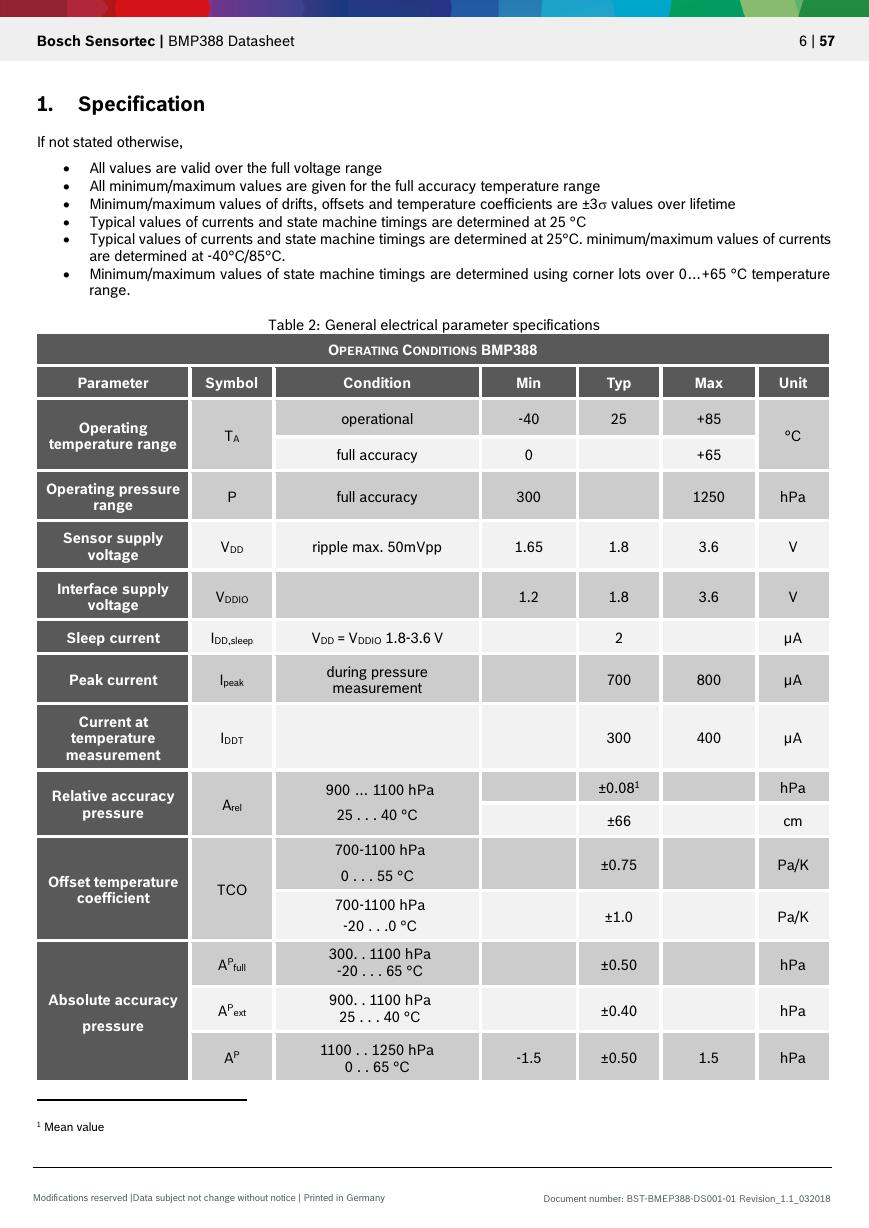

1. Specification

If not stated otherwise,

6 | 57

All values are valid over the full voltage range

All minimum/maximum values are given for the full accuracy temperature range

Minimum/maximum values of drifts, offsets and temperature coefficients are ±3 values over lifetime

Typical values of currents and state machine timings are determined at 25 °C

Typical values of currents and state machine timings are determined at 25°C. minimum/maximum values of currents

are determined at -40°C/85°C.

Minimum/maximum values of state machine timings are determined using corner lots over 0…+65 °C temperature

range.

Table 2: General electrical parameter specifications

OPERATING CONDITIONS BMP388

Parameter

Symbol

Condition

Operating

temperature range

Operating pressure

range

TA

P

operational

full accuracy

full accuracy

Min

-40

0

300

Typ

25

Max

Unit

+85

+65

°C

1250

hPa

Sensor supply

voltage

Interface supply

voltage

VDD

ripple max. 50mVpp

1.65

1.8

VDDIO

1.2

3.6

3.6

1.8

2

V

V

µA

µA

700

800

300

400

µA

±0.081

±66

±0.75

±1.0

±0.50

±0.40

hPa

cm

Pa/K

Pa/K

hPa

hPa

-1.5

±0.50

1.5

hPa

Sleep current

IDD,sleep

VDD = VDDIO 1.8-3.6 V

during pressure

measurement

900 … 1100 hPa

25 . . . 40 °C

700-1100 hPa

0 . . . 55 °C

700-1100 hPa

-20 . . .0 °C

300. . 1100 hPa

-20 . . . 65 °C

900. . 1100 hPa

25 . . . 40 °C

1100 . . 1250 hPa

0 . . 65 °C

Peak current

Ipeak

Current at

temperature

measurement

Relative accuracy

pressure

IDDT

Arel

Offset temperature

coefficient

TCO

Absolute accuracy

pressure

AP

full

AP

ext

AP

1 Mean value

Modifications reserved |Data subject not change without notice | Printed in Germany

Document number: BST-BMEP388-DS001-01 Revision_1.1_032018

�

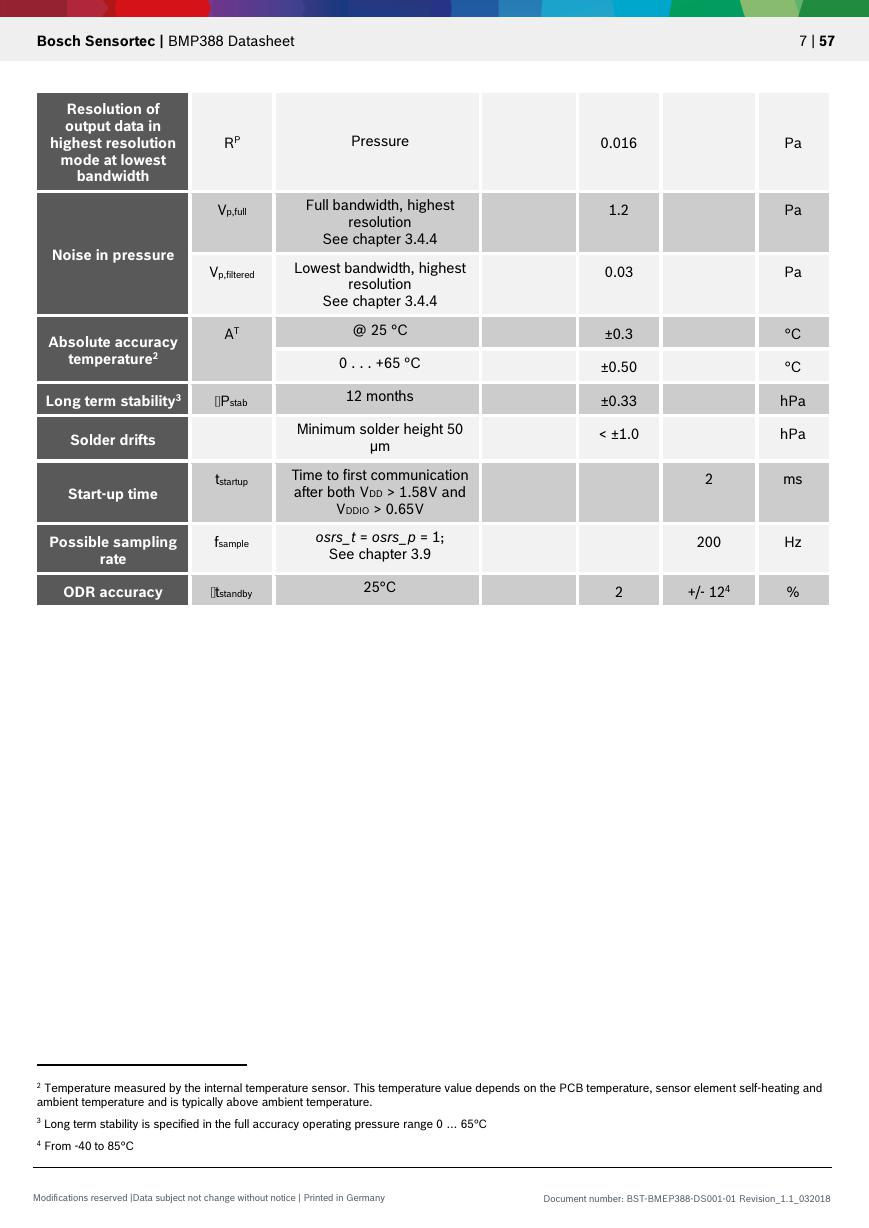

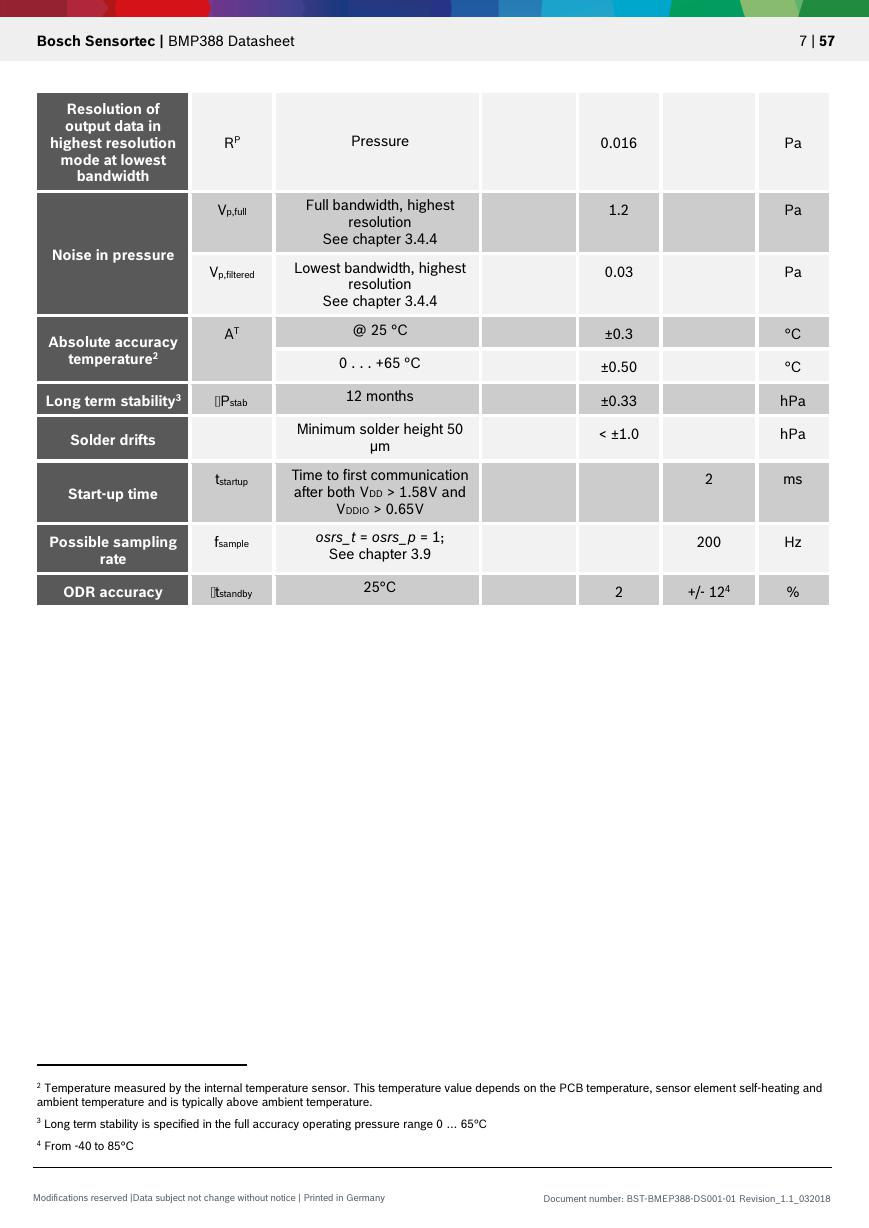

Bosch Sensortec | BMP388 Datasheet

RP

Pressure

Resolution of

output data in

highest resolution

mode at lowest

bandwidth

Noise in pressure

Absolute accuracy

temperature2

Vp,full

Vp,filtered

AT

Full bandwidth, highest

resolution

See chapter 3.4.4

Lowest bandwidth, highest

resolution

See chapter 3.4.4

@ 25 °C

0 . . . +65 °C

12 months

Long term stability3

Pstab

Solder drifts

Start-up time

tstartup

Minimum solder height 50

µm

Time to first communication

after both VDD > 1.58V and

VDDIO > 0.65V

Possible sampling

fsample

rate

osrs_t = osrs_p = 1;

See chapter 3.9

ODR accuracy

tstandby

25°C

7 | 57

Pa

Pa

Pa

°C

°C

hPa

hPa

2

ms

200

Hz

0.016

1.2

0.03

±0.3

±0.50

±0.33

< ±1.0

2

+/- 124

%

2 Temperature measured by the internal temperature sensor. This temperature value depends on the PCB temperature, sensor element self-heating and

ambient temperature and is typically above ambient temperature.

3 Long term stability is specified in the full accuracy operating pressure range 0 … 65°C

4 From -40 to 85°C

Modifications reserved |Data subject not change without notice | Printed in Germany

Document number: BST-BMEP388-DS001-01 Revision_1.1_032018

�

Bosch Sensortec | BMP388 Datasheet

8 | 57

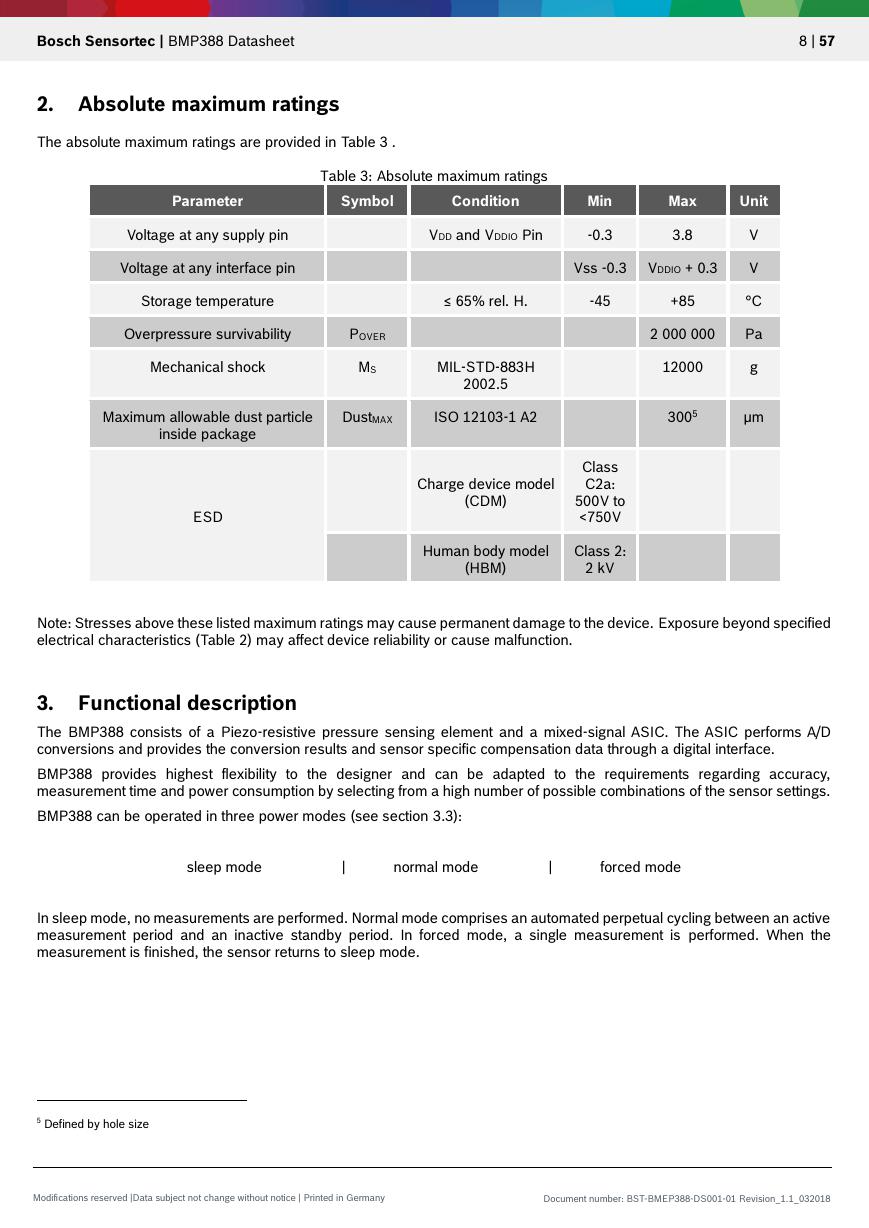

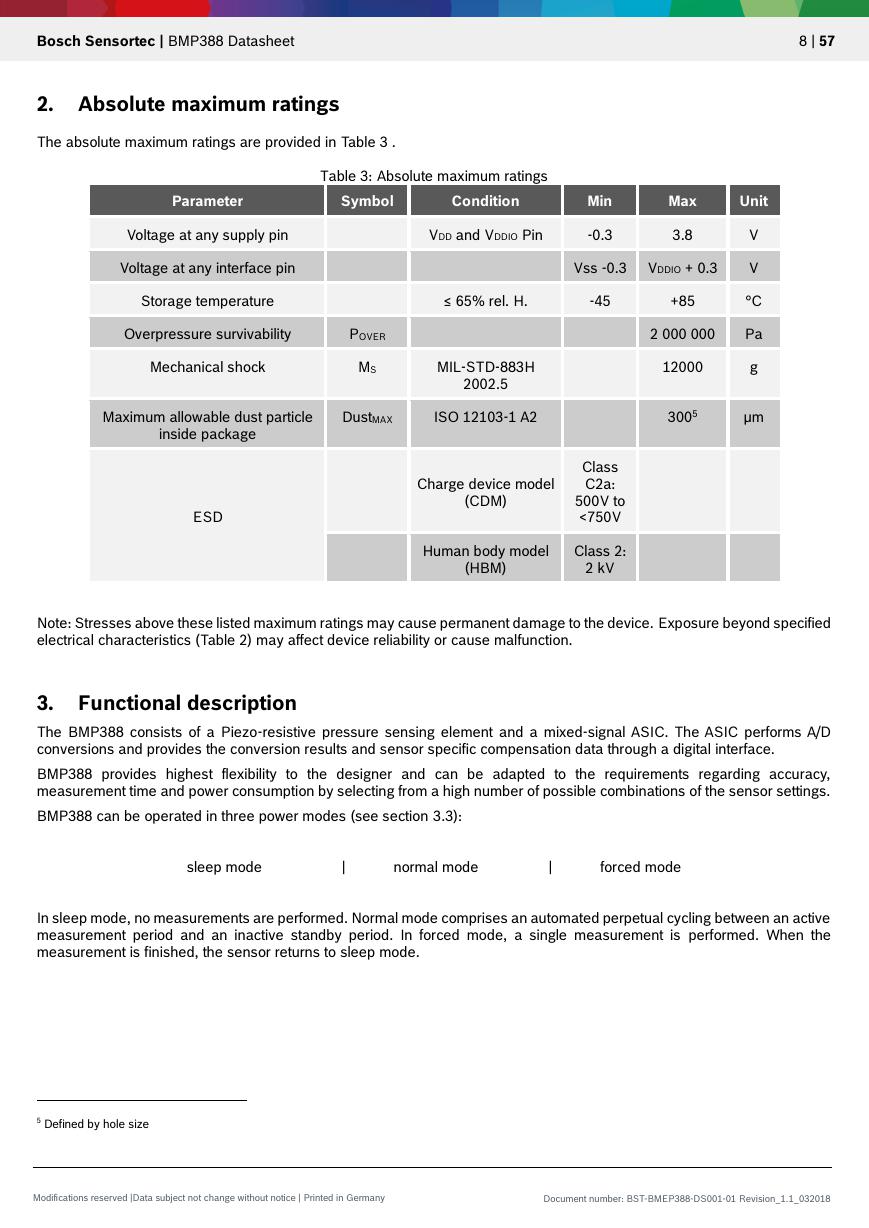

2. Absolute maximum ratings

The absolute maximum ratings are provided in Table 3 .

Table 3: Absolute maximum ratings

Parameter

Symbol

Condition

Min

Max

Unit

Voltage at any supply pin

Voltage at any interface pin

Storage temperature

VDD and VDDIO Pin

-0.3

3.8

Vss -0.3 VDDIO + 0.3

V

V

≤ 65% rel. H.

-45

+85

°C

Overpressure survivability

POVER

Mechanical shock

MS

MIL-STD-883H

2002.5

Maximum allowable dust particle

DustMAX

ISO 12103-1 A2

inside package

2 000 000

Pa

12000

g

3005

µm

ESD

Charge device model

(CDM)

Class

C2a:

500V to

<750V

Human body model

Class 2:

(HBM)

2 kV

Note: Stresses above these listed maximum ratings may cause permanent damage to the device. Exposure beyond specified

electrical characteristics (Table 2) may affect device reliability or cause malfunction.

3. Functional description

The BMP388 consists of a Piezo-resistive pressure sensing element and a mixed-signal ASIC. The ASIC performs A/D

conversions and provides the conversion results and sensor specific compensation data through a digital interface.

BMP388 provides highest flexibility to the designer and can be adapted to the requirements regarding accuracy,

measurement time and power consumption by selecting from a high number of possible combinations of the sensor settings.

BMP388 can be operated in three power modes (see section 3.3):

sleep mode

|

normal mode

|

forced mode

In sleep mode, no measurements are performed. Normal mode comprises an automated perpetual cycling between an active

measurement period and an inactive standby period. In forced mode, a single measurement is performed. When the

measurement is finished, the sensor returns to sleep mode.

5 Defined by hole size

Modifications reserved |Data subject not change without notice | Printed in Germany

Document number: BST-BMEP388-DS001-01 Revision_1.1_032018

�

V2版本原理图(Capacitive-Fingerprint-Reader-Schematic_V2).pdf

V2版本原理图(Capacitive-Fingerprint-Reader-Schematic_V2).pdf 摄像头工作原理.doc

摄像头工作原理.doc VL53L0X简要说明(En.FLVL53L00216).pdf

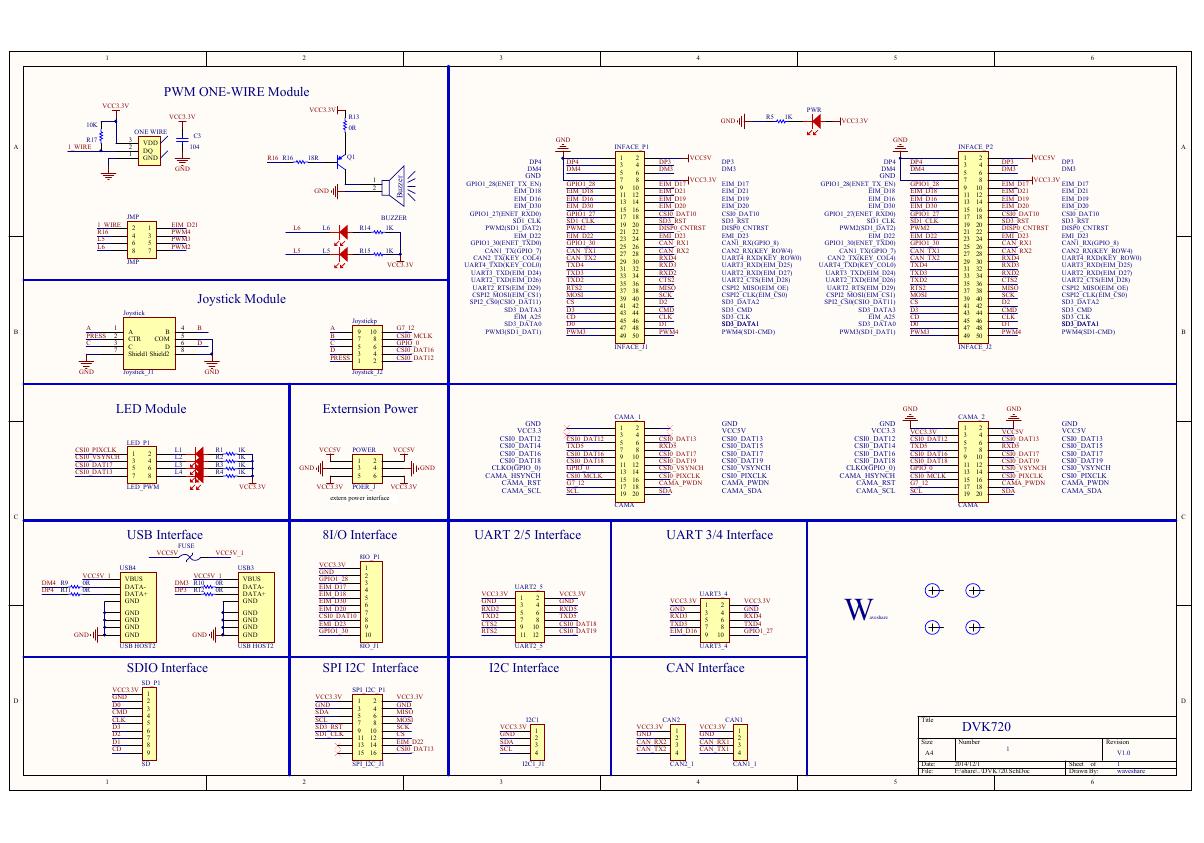

VL53L0X简要说明(En.FLVL53L00216).pdf 原理图(DVK720-Schematic).pdf

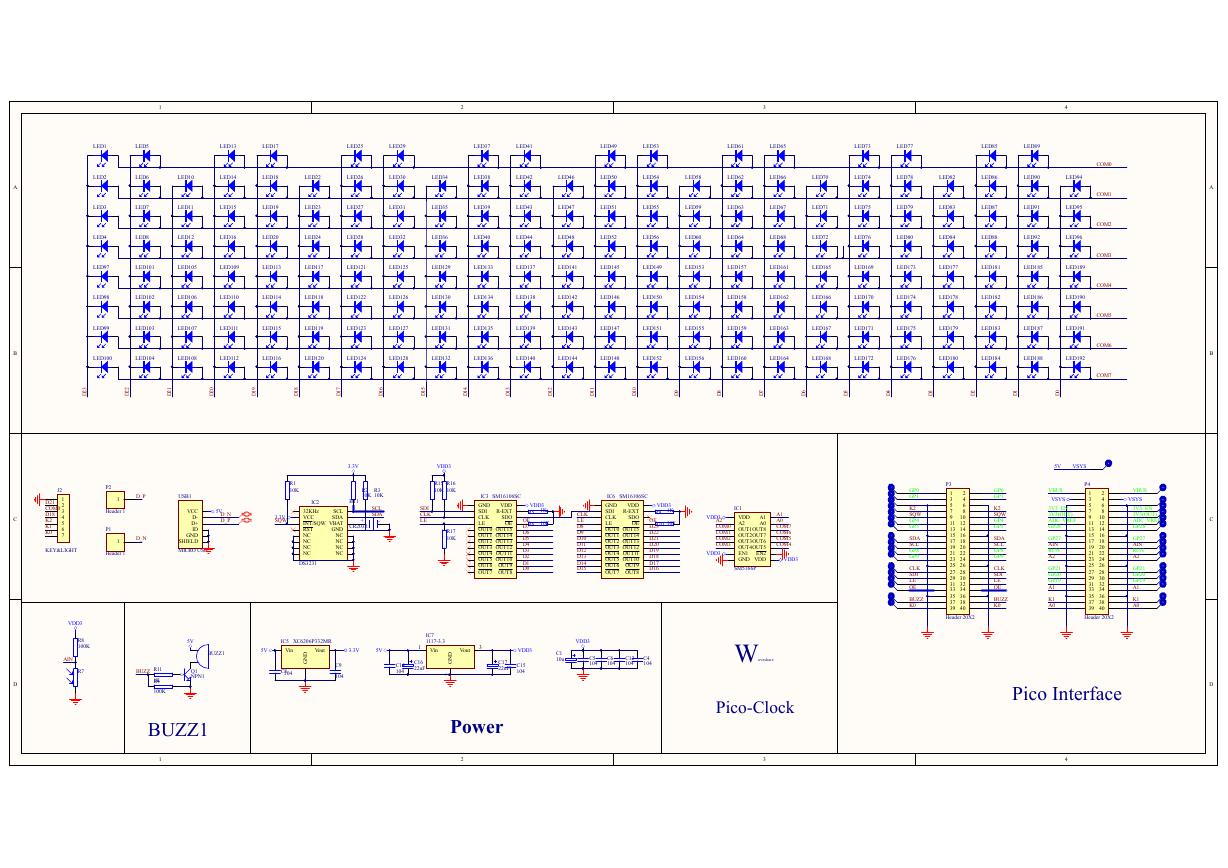

原理图(DVK720-Schematic).pdf 原理图(Pico-Clock-Green-Schdoc).pdf

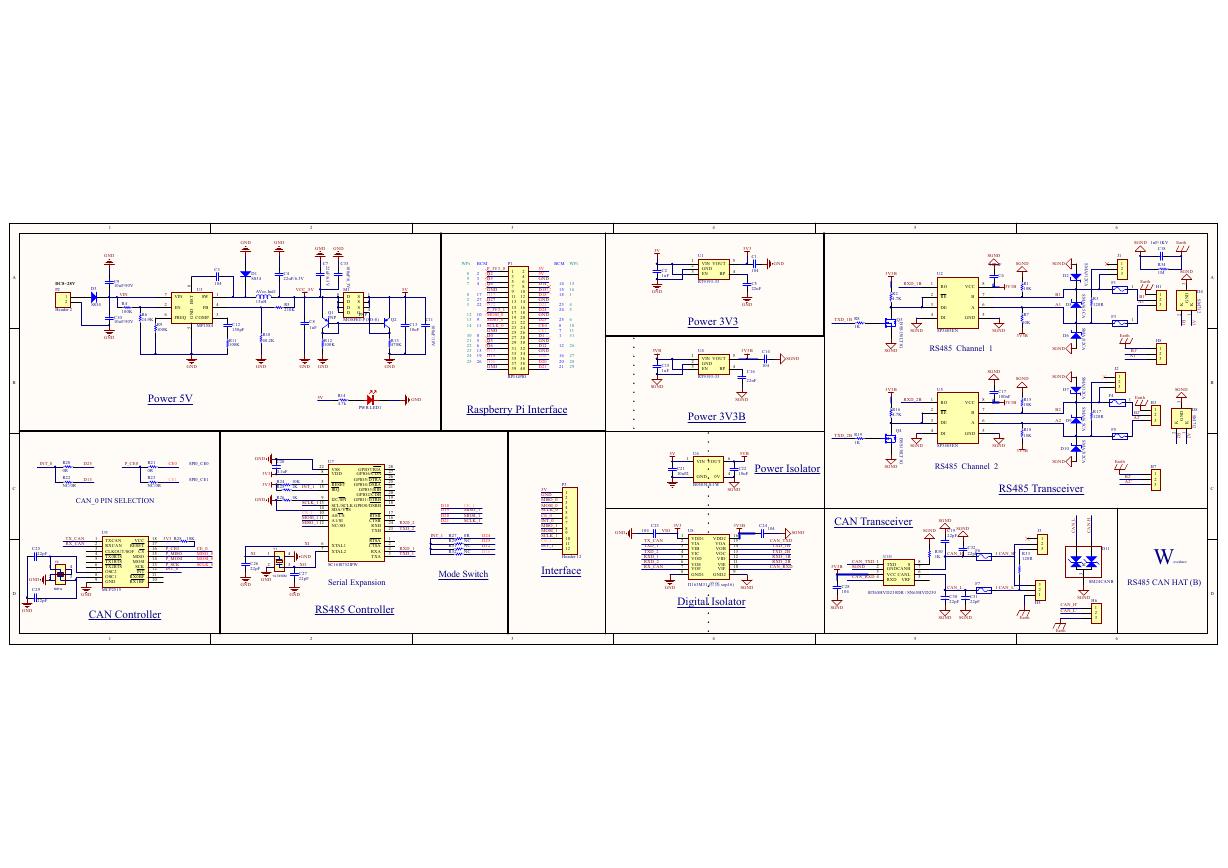

原理图(Pico-Clock-Green-Schdoc).pdf 原理图(RS485-CAN-HAT-B-schematic).pdf

原理图(RS485-CAN-HAT-B-schematic).pdf File:SIM7500_SIM7600_SIM7800 Series_SSL_Application Note_V2.00.pdf

File:SIM7500_SIM7600_SIM7800 Series_SSL_Application Note_V2.00.pdf ADS1263(Ads1262).pdf

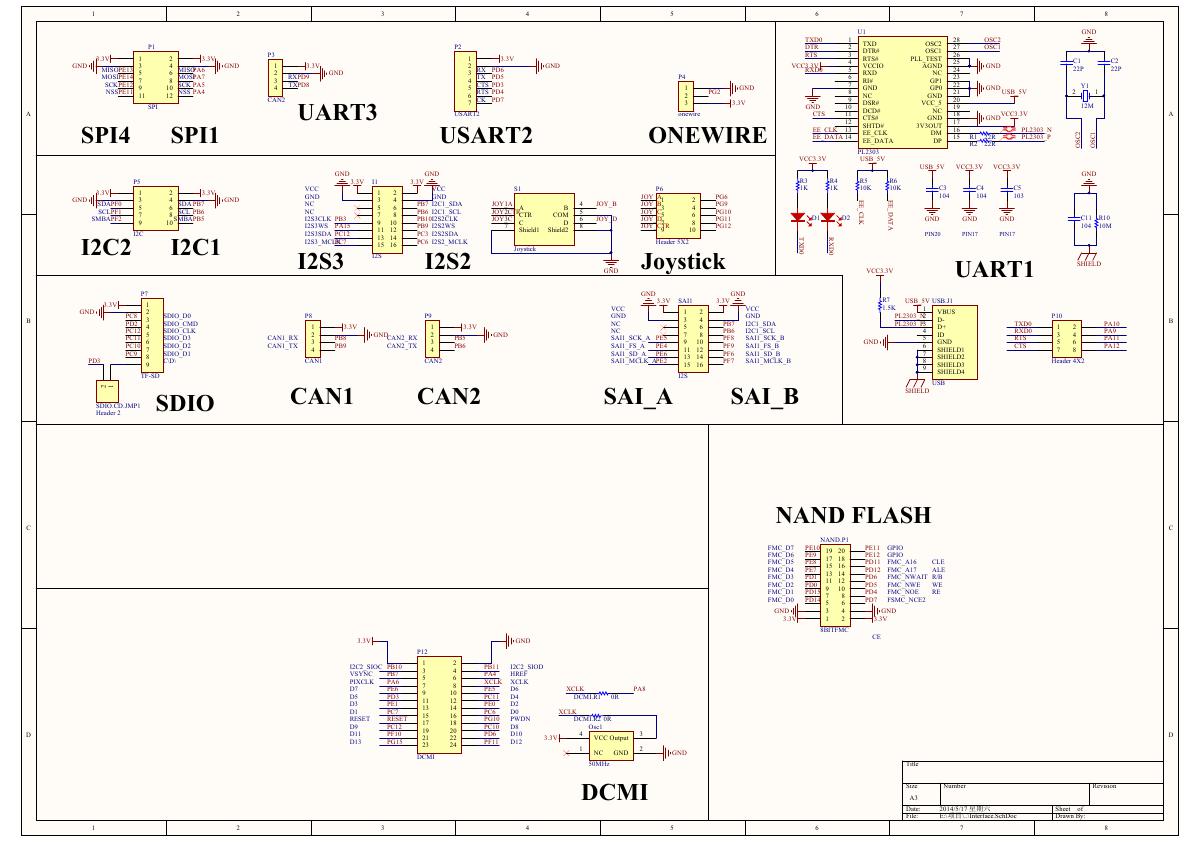

ADS1263(Ads1262).pdf 原理图(Open429Z-D-Schematic).pdf

原理图(Open429Z-D-Schematic).pdf 用户手册(Capacitive_Fingerprint_Reader_User_Manual_CN).pdf

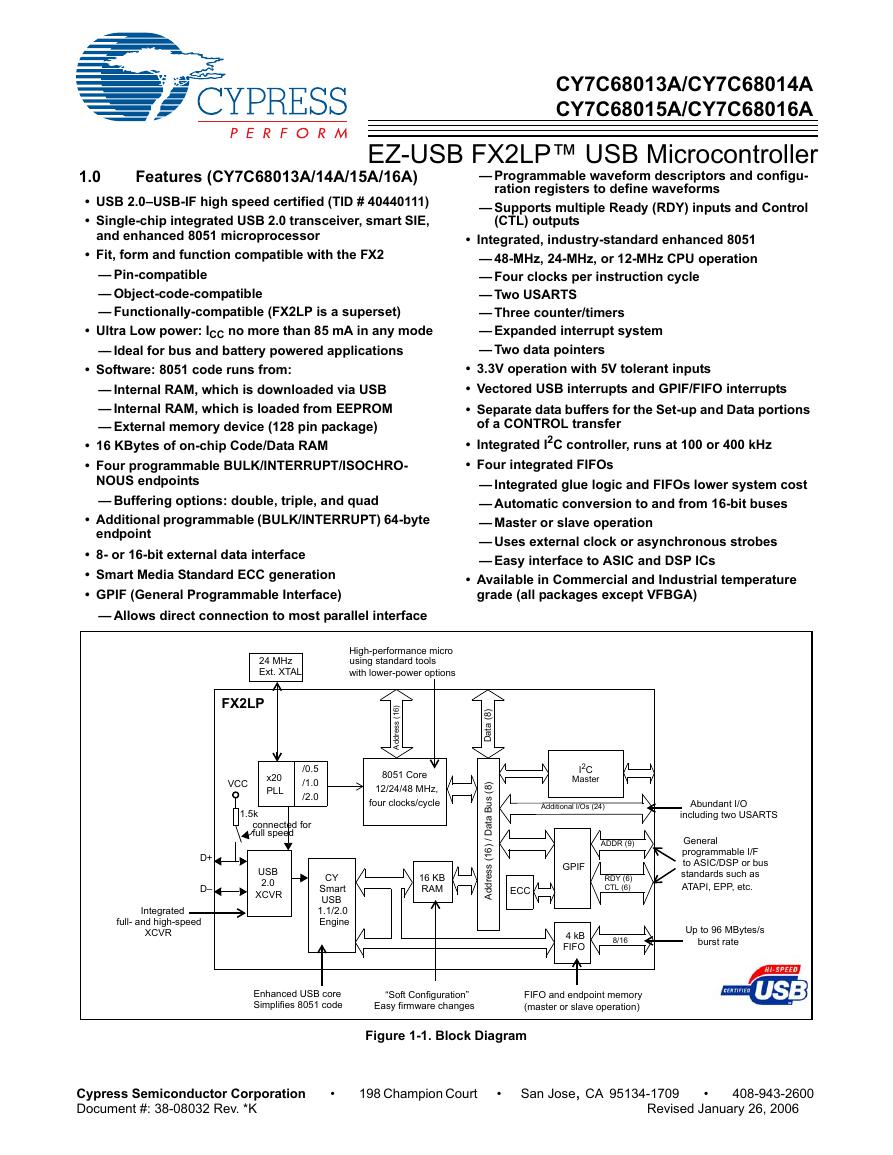

用户手册(Capacitive_Fingerprint_Reader_User_Manual_CN).pdf CY7C68013A(英文版)(CY7C68013A).pdf

CY7C68013A(英文版)(CY7C68013A).pdf TechnicalReference_Dem.pdf

TechnicalReference_Dem.pdf