Foreword

Acknowledgements

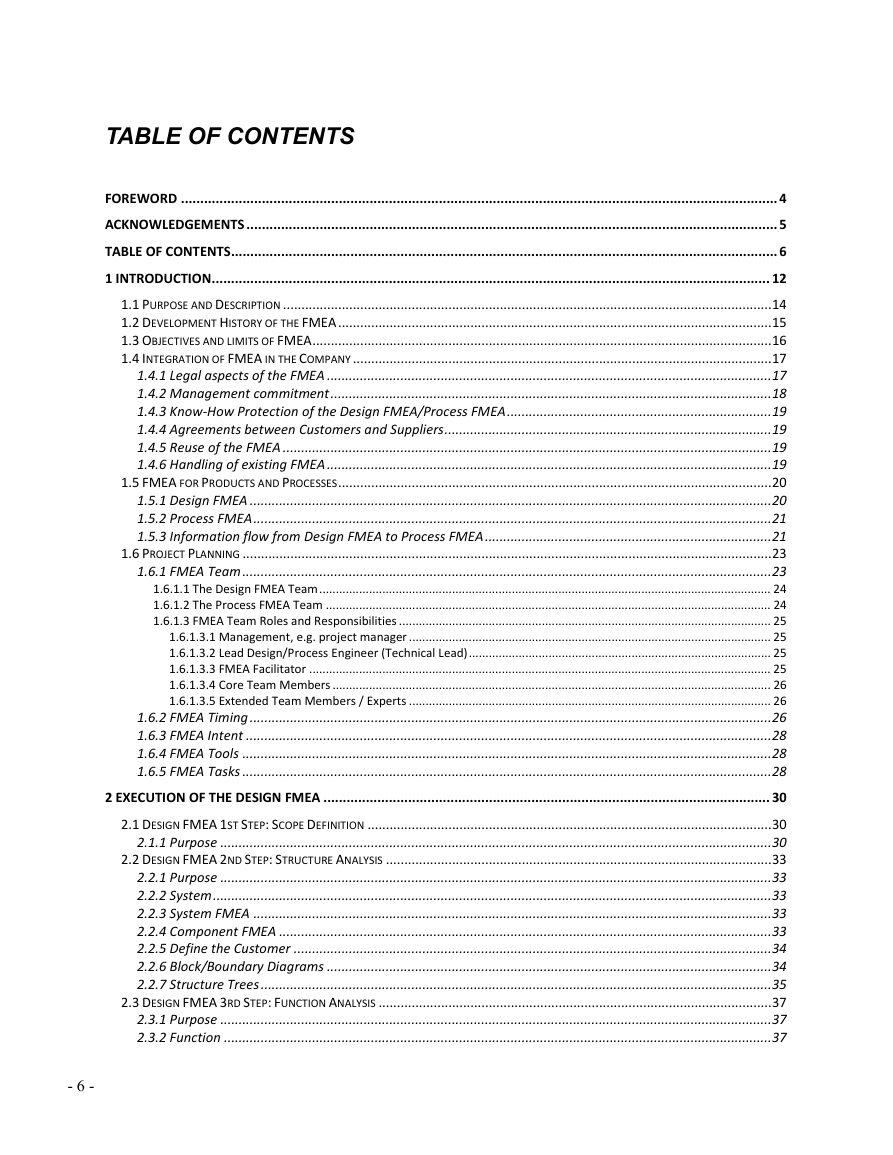

Table of Contents

1 IntroDuction

1.1 Purpose and Description

1.2 Development History of the FMEA

1.3 Objectives and limits of FMEA

1.4 Integration of FMEA in the Company

1.4.1 Legal aspects of the FMEA

1.4.2 Management commitment

1.4.3 Know-How Protection of the Design FMEA/Process FMEA

1.4.4 Agreements between Customers and Suppliers

1.4.5 Reuse of the FMEA

1.4.6 Handling of existing FMEA

1.5 FMEA for Products and Processes

1.5.1 Design FMEA

1.5.2 Process FMEA

1.5.3 Information flow from Design FMEA to Process FMEA

1.6 Project Planning

1.6.1 FMEA Team

1.6.1.1 The Design FMEA Team

1.6.1.2 The Process FMEA Team

1.6.1.3 FMEA Team Roles and Responsibilities

1.6.1.3.1 Management, e.g. project manager

1.6.1.3.2 Lead Design/Process Engineer (Technical Lead)

1.6.1.3.3 FMEA Facilitator

1.6.1.3.4 Core Team Members

1.6.1.3.5 Extended Team Members / Experts

1.6.2 FMEA Timing

1.6.3 FMEA Intent

1.6.4 FMEA Tools

1.6.5 FMEA Tasks

2 Execution of the Design FMEA

2.1 Design FMEA 1st Step: Scope Definition

2.1.1 Purpose

2.2 Design FMEA 2nd Step: Structure Analysis

2.2.1 Purpose

2.2.2 System

2.2.3 System FMEA

2.2.4 Component FMEA

2.2.5 Define the Customer

2.2.6 Block/Boundary Diagrams

2.2.7 Structure Trees

2.3 Design FMEA 3rd Step: Function Analysis

2.3.1 Purpose

2.3.2 Function

2.3.3 Interface

2.3.4 Requirements

2.3.5 Product Characteristic

2.3.6 Parameter Diagram (P-Diagram)

2.3.7 Visualization of functional relationships

2.4 Design FMEA 4th Step: Failure Analysis

2.4.1 Purpose

2.4.2 Failures

2.4.3 The Failure Chain

2.4.4 Failure Network and Chain Analysis

2.4.5 Failure Effects

2.4.6 Failure Mode

2.4.7 Failure Cause

2.4.8 Summary

2.5 Design FMEA 5th Step: Risk Analysis

2.5.1 Purpose

2.5.2 Design Controls

2.5.3 Current Prevention Controls (PC)

2.5.4 Current Detection Controls (DC)

2.5.5 Confirmation of Current Prevention and Detection Controls

2.5.6 Evaluations

2.5.7 Severity (S)

2.5.8 Occurrence (O)

2.5.9 Detection (D)

2.5.10 Action Priority (AP)

2.6 Design FMEA 6th Step: Optimization

2.6.1 Purpose

2.6.2 Assignment of Responsibilities

2.6.3 Status of the Actions

2.6.4 Assessment of Action Effectiveness

2.6.5 Continual Improvement

2.7 FMEA Results Documentation

3 Execution of the Process FMEA (PFMEA)

3.1 Process FMEA 1st Step: Scope Definition

3.1.1 Purpose

3.2 Process FMEA 2nd Step: Structure Analysis

3.2.1 Purpose

3.2.2 Process Flow Diagram

3.2.3 Structure Tree

3.3 Process FMEA 3rd Step: Function Analysis

3.3.1 Purpose

3.3.2 Function

3.3.3 Requirement(s)

3.3.4 Visualization of functional relationships

3.4 Process FMEA 4th Step: Failure Analysis

3.4.1 Purpose

3.4.2 Failures

3.4.3 Failure Chain

3.4.4 Failure Network and Chain Analysis

3.4.5 Failure Effects

3.4.6 Failure mode

3.4.7 Failure Cause:

3.4.7.1 Man

3.4.7.2 Machine

3.4.7.3 Material (indirect)

3.4.7.4 Environment

3.4.8 Summary

3.5 Process FMEA 5th Step: Risk Analysis

3.5.1 Purpose

3.5.2 Current Prevention Controls (PC)

3.5.3 Process planning

3.5.4 Production process

3.5.5 Current Detection Controls (DC)

3.5.6 Current Prevention and Detection Controls

3.5.7 Evaluations

3.5.8 Severity (S)

3.5.9 Occurrence (O)

3.5.10 Detection (D)

3.5.11 Action Priority (AP)

3.6 Process FMEA 6th Step: Optimization

3.6.1 Purpose

3.6.2 Assignment of Responsibilities

3.6.3 Status of the Actions

3.6.4 Assessment of Action Effectiveness

3.6.5 Continual Improvement

3.7 FMEA Results Documentation

4 Supplemental FMEA for Monitoring and System Response (FMEA-MSR)

4.1 FMEA-MSR 1st Step: Scope Definition

4.2 FMEA-MSR 2nd Step: Structure Analysis

4.2.1 Block (Boundary) Diagrams

4.2.2 Structure Trees

4.3 FMEA-MSR 3rd Step: Function Analysis

4.4 FMEA-MSR 4th Step: Failure Analysis

4.5 FMEA-MSR 5th Step: Risk Analysis

4.5.1 Purpose

4.5.2 Rationale for Frequency Rating

4.5.3 Current Monitoring Controls (MC)

4.5.4 Evaluations

4.5.5 Severity (S)

4.5.6 Frequency (F)

4.5.7 Monitoring (M)

4.5.8 Action Priority (AP) for FMEA-MSR

4.6 FMEA-MSR 6th Step: Optimization

4.6.1 Purpose

4.6.2 Assignment of Responsibilities

4.6.3 Status of the Actions

4.6.4 Assessment of Action Effectiveness

4.6.5 Continual Improvement

4.7 FMEA Results Documentation

ANNEX

A1 Additions

A1.1 Special Characteristics

A1.2 Form Sheets

A1.2.1 Design Failure Mode and Effects Analysis (DESIGN FMEA) Hints

A1.2.2 Design Failure Mode and Effects Analysis (DESIGN FMEA) with Monitoring and System Response (FMEA-MSR) Hints

A1.2.3 Process Failure Mode and Effects Analysis (PROCESS FMEA) Hints

A2 Further Application Fields

A2.1 FMEA for Software Scopes

A2.1.1 Objective of the Software Scopes Inspection

A2.1.2 FMEA in the Software Development Process

A2.2 FMEA for Machine and Facility Manufacturers

A3 FMEA Review (Draft)

A3.1 DFMEA Review

A3.2 PFMEA Review

A4 Bibliography

2023年江西萍乡中考道德与法治真题及答案.doc

2023年江西萍乡中考道德与法治真题及答案.doc 2012年重庆南川中考生物真题及答案.doc

2012年重庆南川中考生物真题及答案.doc 2013年江西师范大学地理学综合及文艺理论基础考研真题.doc

2013年江西师范大学地理学综合及文艺理论基础考研真题.doc 2020年四川甘孜小升初语文真题及答案I卷.doc

2020年四川甘孜小升初语文真题及答案I卷.doc 2020年注册岩土工程师专业基础考试真题及答案.doc

2020年注册岩土工程师专业基础考试真题及答案.doc 2023-2024学年福建省厦门市九年级上学期数学月考试题及答案.doc

2023-2024学年福建省厦门市九年级上学期数学月考试题及答案.doc 2021-2022学年辽宁省沈阳市大东区九年级上学期语文期末试题及答案.doc

2021-2022学年辽宁省沈阳市大东区九年级上学期语文期末试题及答案.doc 2022-2023学年北京东城区初三第一学期物理期末试卷及答案.doc

2022-2023学年北京东城区初三第一学期物理期末试卷及答案.doc 2018上半年江西教师资格初中地理学科知识与教学能力真题及答案.doc

2018上半年江西教师资格初中地理学科知识与教学能力真题及答案.doc 2012年河北国家公务员申论考试真题及答案-省级.doc

2012年河北国家公务员申论考试真题及答案-省级.doc 2020-2021学年江苏省扬州市江都区邵樊片九年级上学期数学第一次质量检测试题及答案.doc

2020-2021学年江苏省扬州市江都区邵樊片九年级上学期数学第一次质量检测试题及答案.doc 2022下半年黑龙江教师资格证中学综合素质真题及答案.doc

2022下半年黑龙江教师资格证中学综合素质真题及答案.doc