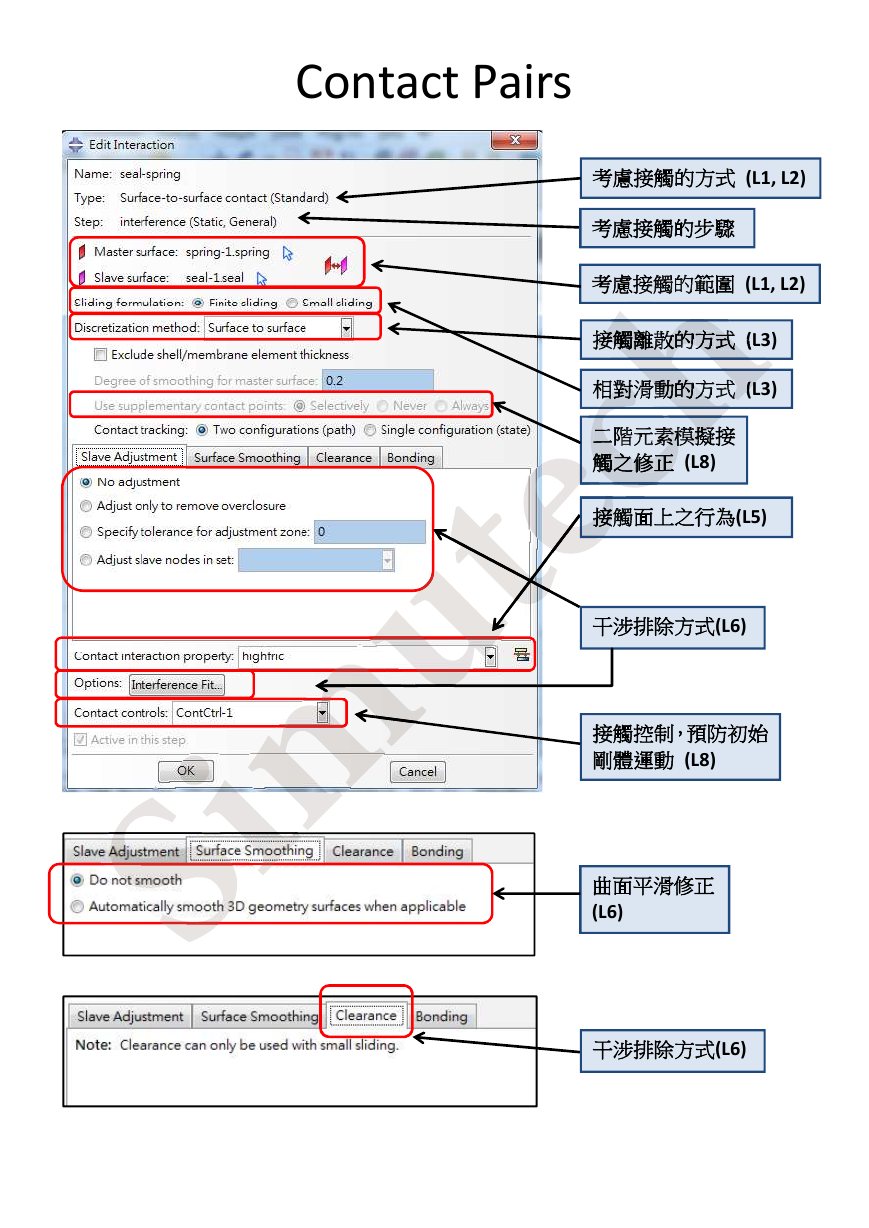

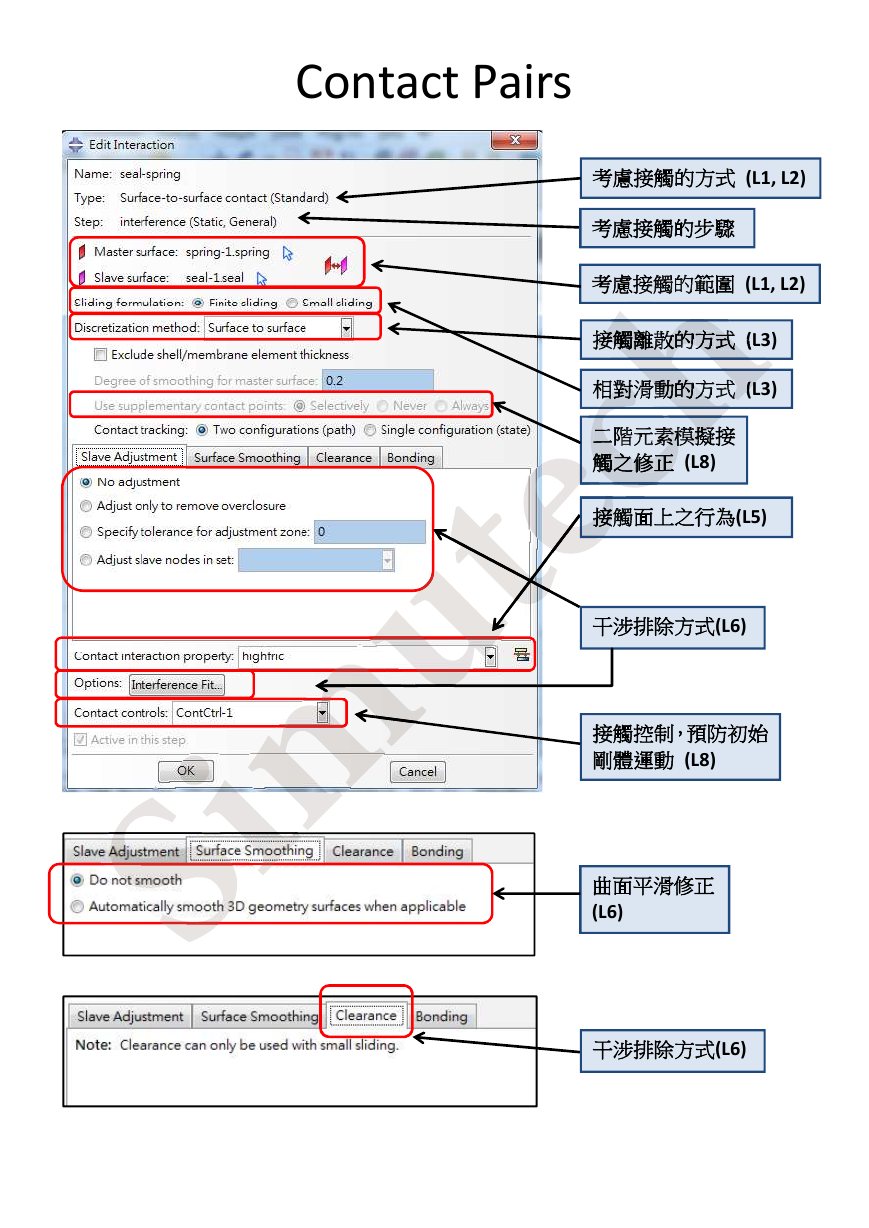

Contact Pairs

(L1, L2)

(L1, L2)

(L3)

(L3)

(L3)

(L8)

(L5)

(L6)

(L8)

(L6)

(L6)

�

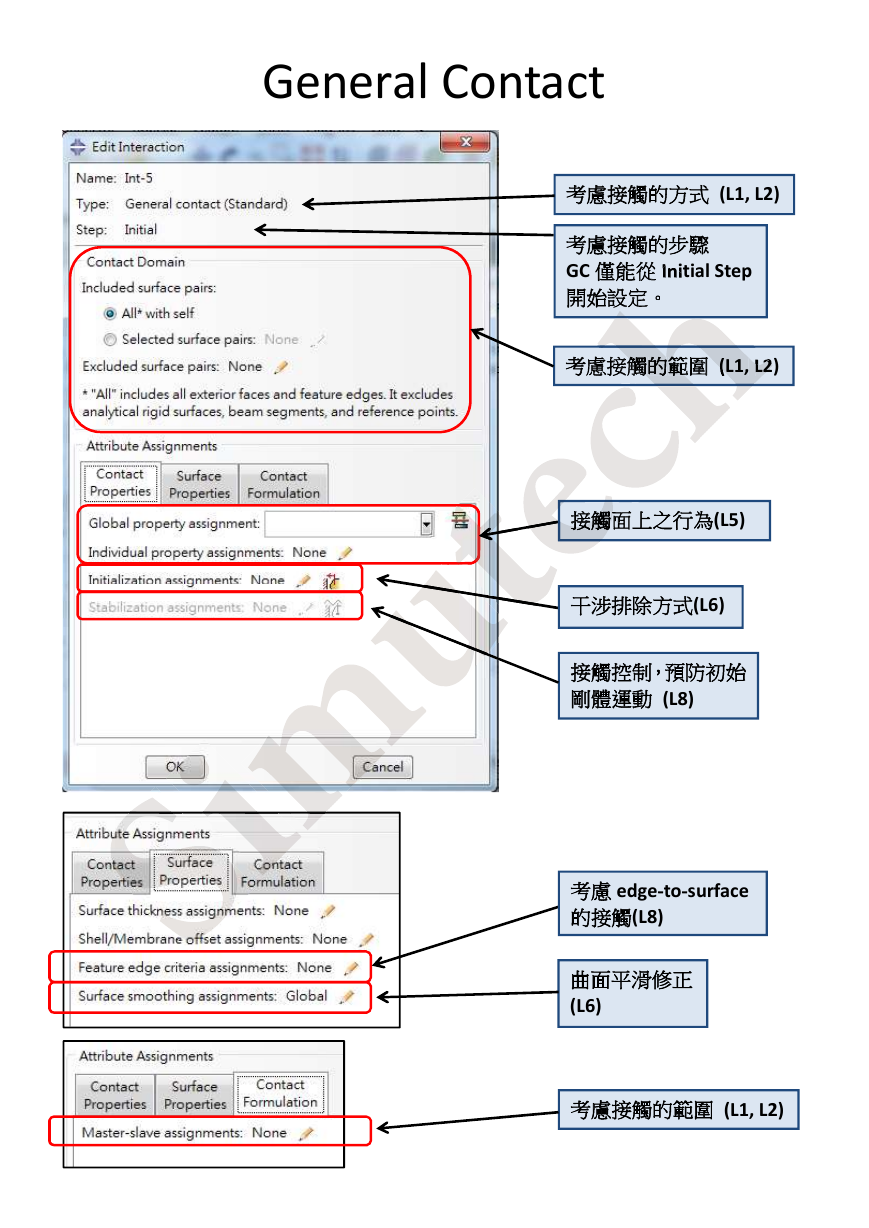

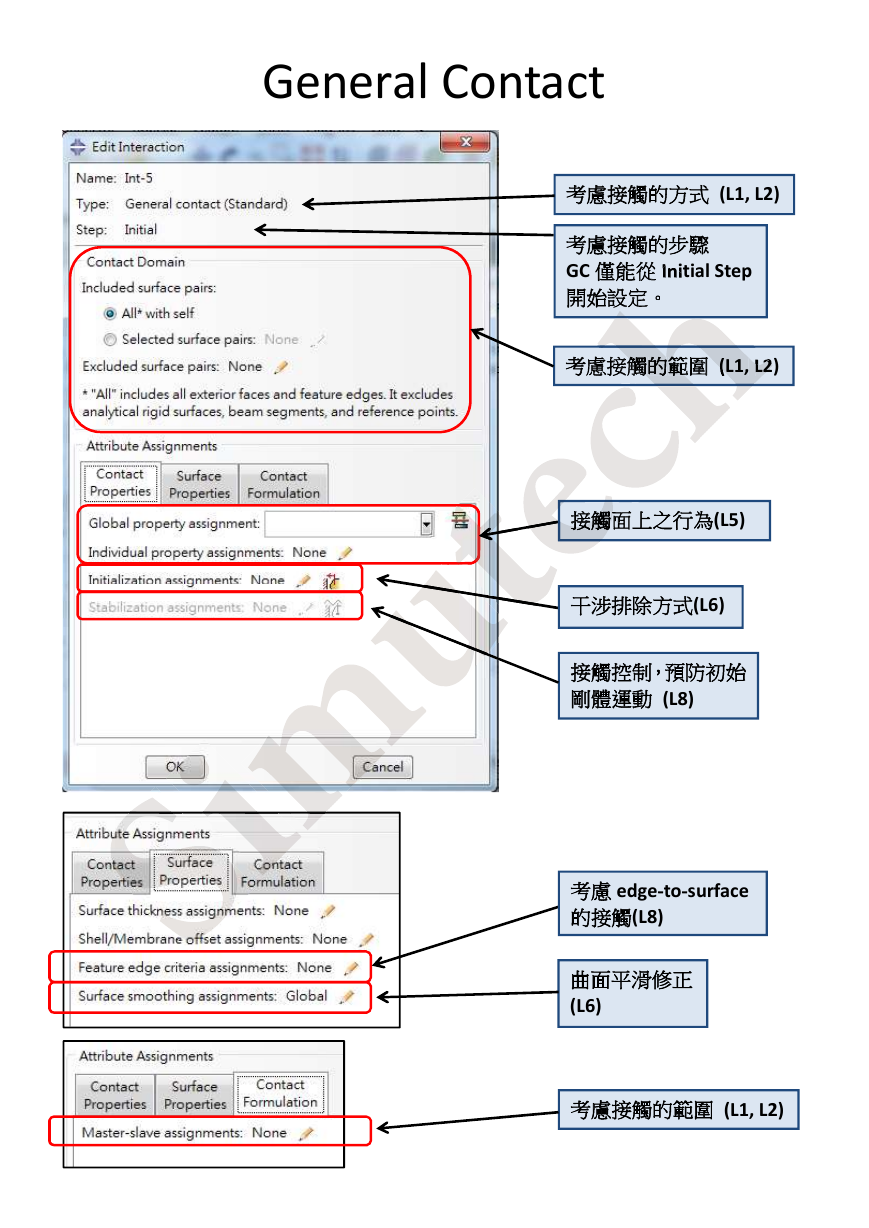

General Contact

(L1, L2)

GC

Initial Step

(L1, L2)

(L1, L2)

(L5)

(L6)

(L8)

edge to surface

(L8)

(L6)

(L1, L2)

�

L1.1

L1.2

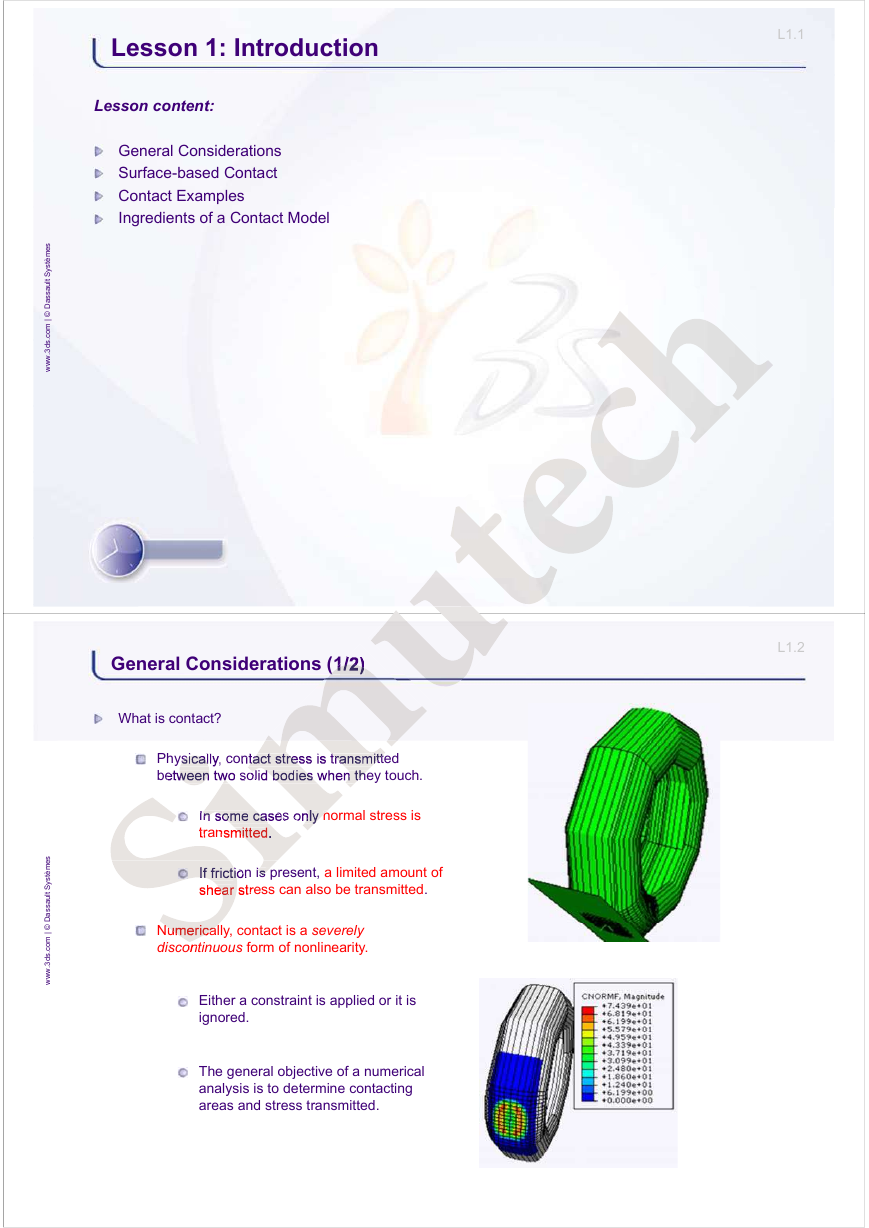

Lesson 1: Introduction

Lesson content:

General Considerations

Surface-based Contact

Contact Examples

Ingredients of a Contact Model

s

e

m

è

t

s

y

S

t

l

u

a

s

s

a

D

©

|

m

o

c

.

s

d

3

w

w

w

.

s

e

m

è

t

s

y

S

t

l

u

a

s

s

a

D

©

|

m

o

c

.

s

d

3

w

w

w

.

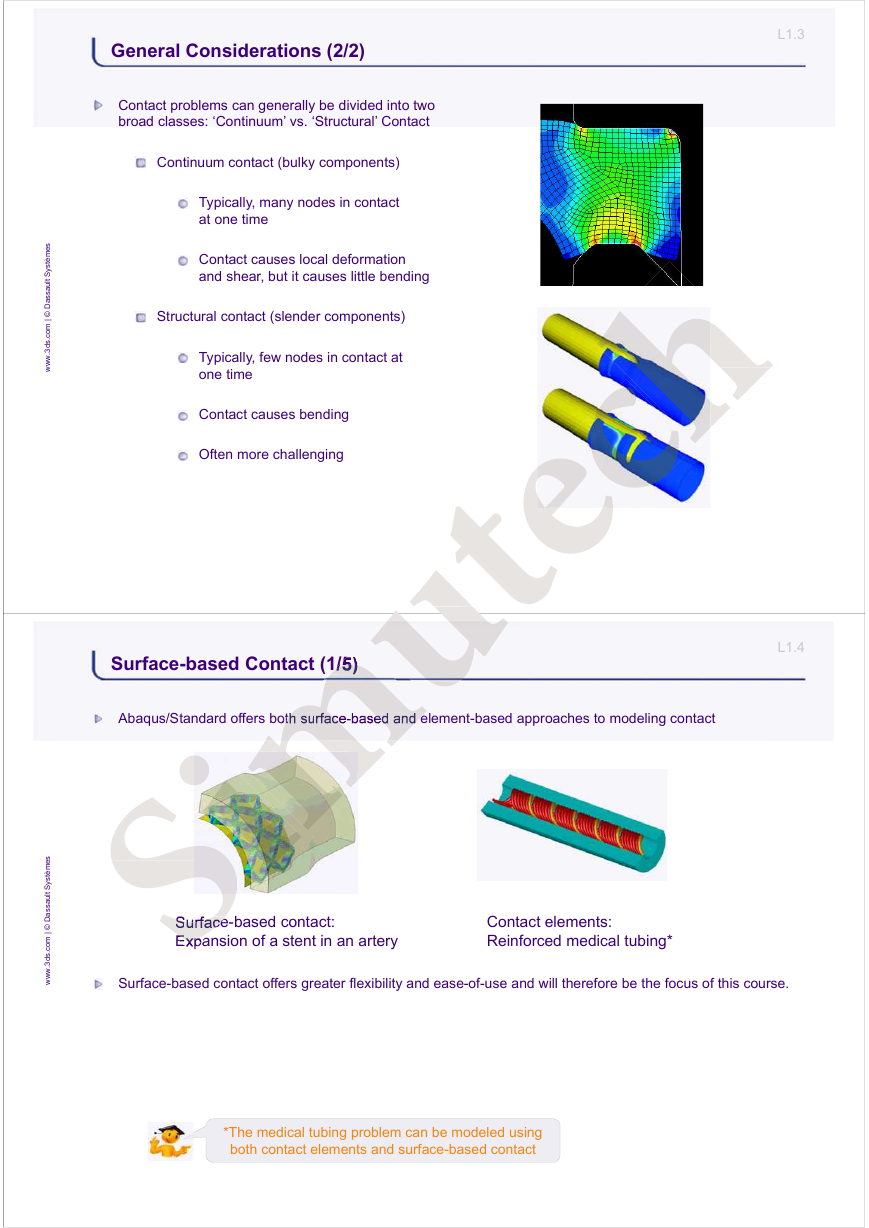

General Considerations (1/2)

What is contact?

Physically, contact stress is transmitted

between two solid bodies when they touch.

In some cases only normal stress is

transmitted.

If friction is present, a limited amount of

shear stress can also be transmitted.

Numerically, contact is a severely

discontinuous form of nonlinearity.

Either a constraint is applied or it is

ignored.

The general objective of a numerical

analysis is to determine contacting

areas and stress transmitted.

�

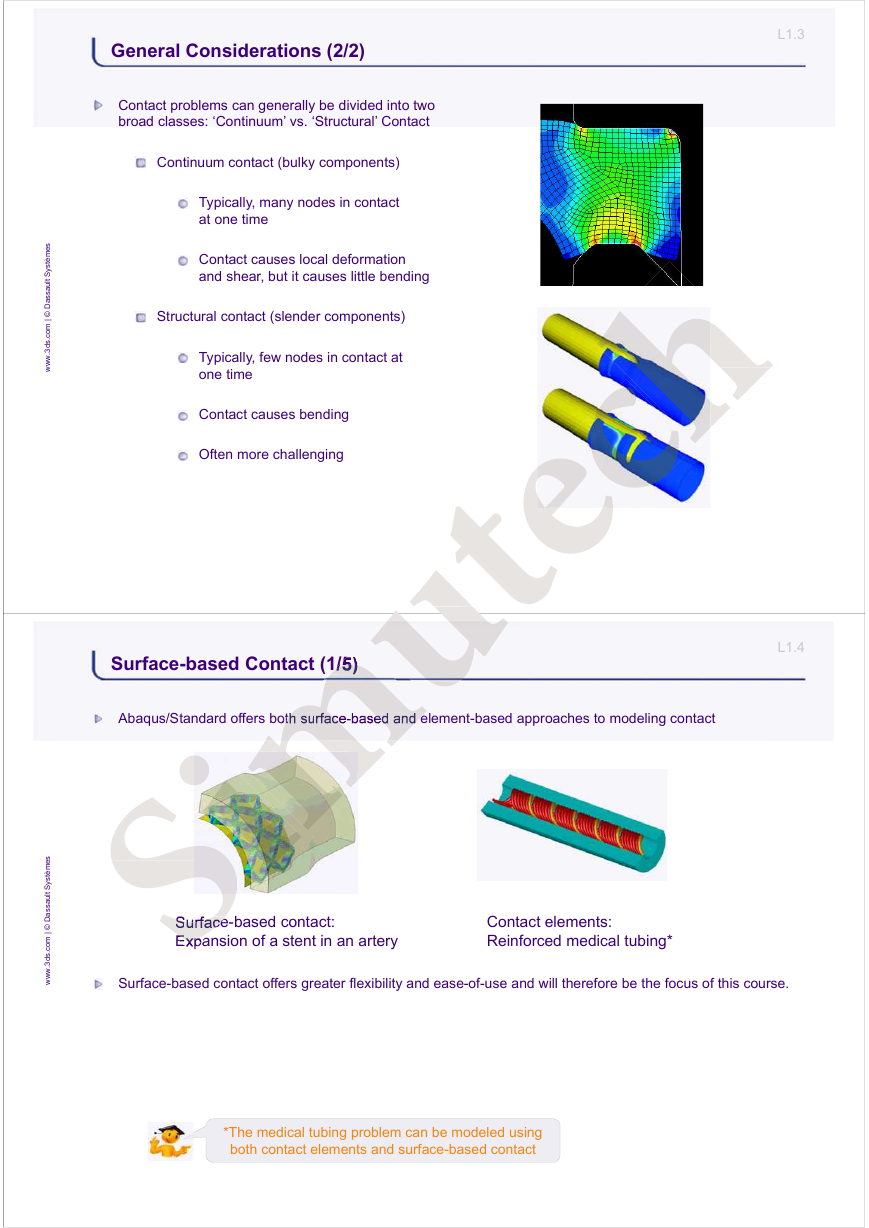

General Considerations (2/2)

Contact problems can generally be divided into two

broad classes: ‘Continuum’ vs. ‘Structural’ Contact

Continuum contact (bulky components)

Typically, many nodes in contact

at one time

Contact causes local deformation

and shear, but it causes little bending

Structural contact (slender components)

Typically, few nodes in contact at

one time

Contact causes bending

Often more challenging

Surface-based Contact (1/5)

Abaqus/Standard offers both surface-based and element-based approaches to modeling contact

L1.3

L1.4

Surface-based contact:

Expansion of a stent in an artery

Contact elements:

Reinforced medical tubing*

Surface-based contact offers greater flexibility and ease-of-use and will therefore be the focus of this course.

*The medical tubing problem can be modeled using

both contact elements and surface-based contact

s

e

m

è

t

s

y

S

t

l

u

a

s

s

a

D

©

|

m

o

c

.

s

d

3

w

w

w

.

s

e

m

è

t

s

y

S

t

l

u

a

s

s

a

D

©

|

m

o

c

.

s

d

3

w

w

w

.

�

L1.5

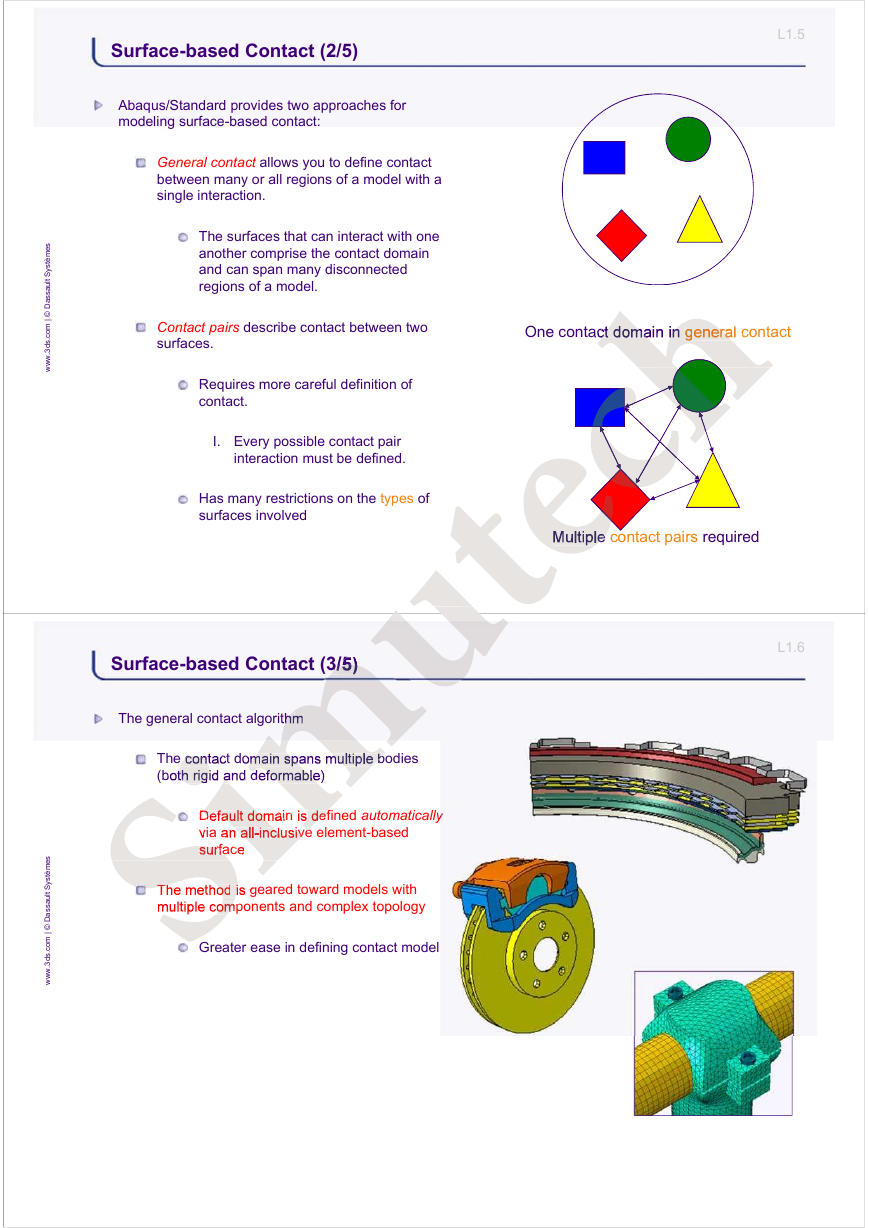

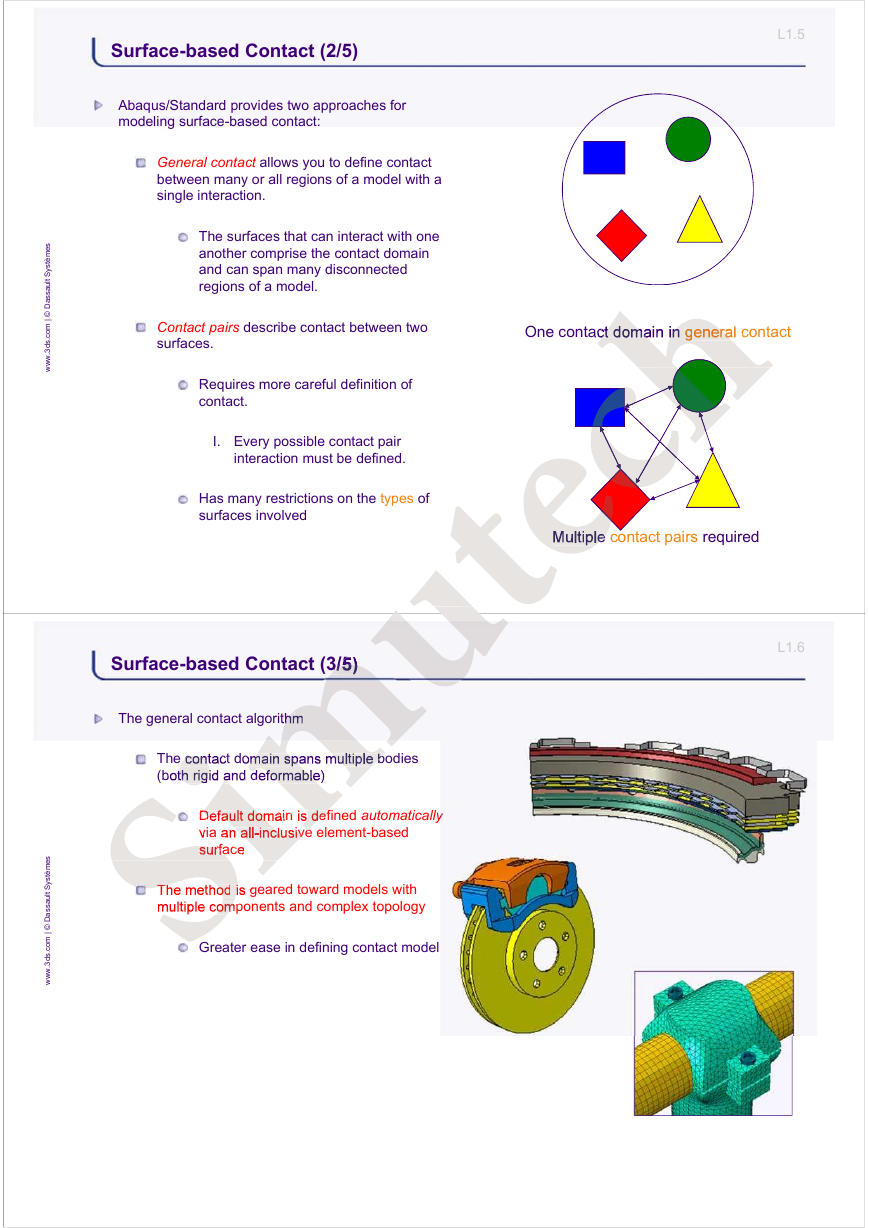

Surface-based Contact (2/5)

Abaqus/Standard provides two approaches for

modeling surface-based contact:

General contact allows you to define contact

between many or all regions of a model with a

single interaction.

The surfaces that can interact with one

another comprise the contact domain

and can span many disconnected

regions of a model.

Contact pairs describe contact between two

surfaces.

One contact domain in general contact

Multiple contact pairs required

L1.6

Requires more careful definition of

contact.

I. Every possible contact pair

interaction must be defined.

Has many restrictions on the types of

surfaces involved.

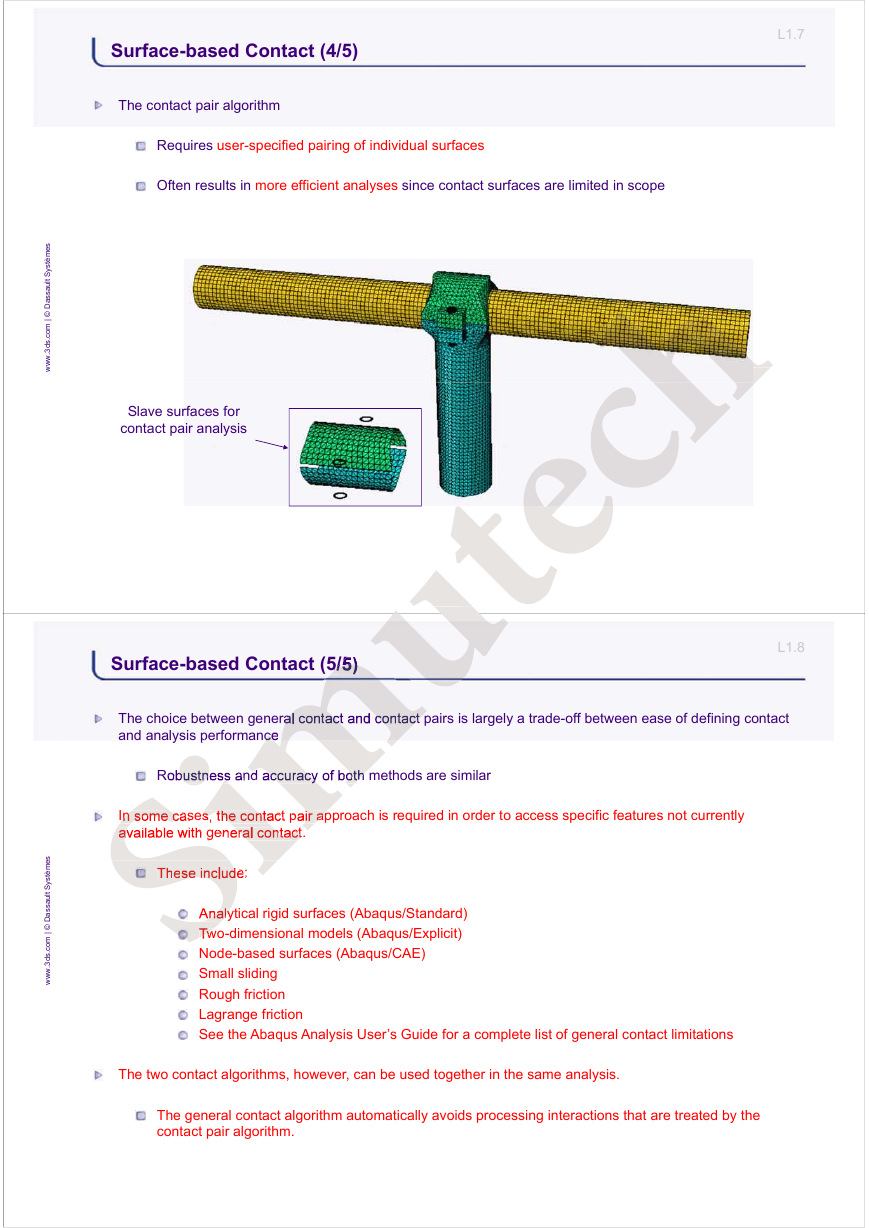

Surface-based Contact (3/5)

The general contact algorithm

The contact domain spans multiple bodies

(both rigid and deformable)

Default domain is defined automatically

via an all-inclusive element-based

surface

The method is geared toward models with

multiple components and complex topology

Greater ease in defining contact model

s

e

m

è

t

s

y

S

t

l

u

a

s

s

a

D

©

|

m

o

c

.

s

d

3

w

w

w

.

s

e

m

è

t

s

y

S

t

l

u

a

s

s

a

D

©

|

m

o

c

.

s

d

3

w

w

w

.

�

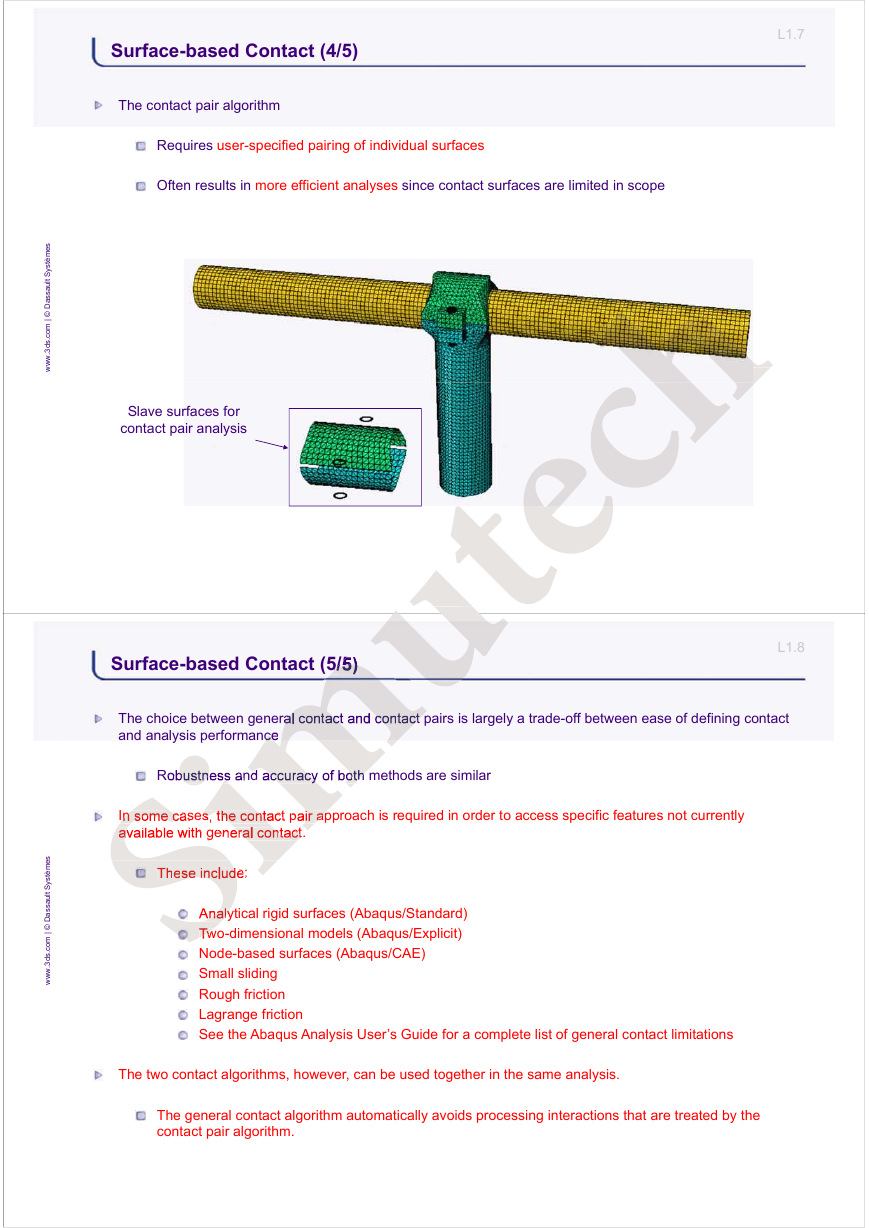

Surface-based Contact (4/5)

The contact pair algorithm

Requires user-specified pairing of individual surfaces

Often results in more efficient analyses since contact surfaces are limited in scope

s

e

m

è

t

s

y

S

t

l

L1.7

L1.8

u

a

s

s

a

D

©

|

m

o

c

.

s

d

3

w

w

w

.

s

e

m

è

t

s

y

S

t

l

u

a

s

s

a

D

©

|

m

o

c

.

s

d

3

w

w

w

.

Slave surfaces for

contact pair analysis

Surface-based Contact (5/5)

The choice between general contact and contact pairs is largely a trade-off between ease of defining contact

and analysis performance

Robustness and accuracy of both methods are similar

In some cases, the contact pair approach is required in order to access specific features not currently

available with general contact.

These include:

Analytical rigid surfaces (Abaqus/Standard)

Two-dimensional models (Abaqus/Explicit)

Node-based surfaces (Abaqus/CAE)

Small sliding

Rough friction

Lagrange friction

See the Abaqus Analysis User’s Guide for a complete list of general contact limitations

The two contact algorithms, however, can be used together in the same analysis.

The general contact algorithm automatically avoids processing interactions that are treated by the

contact pair algorithm.

�

L1.9

L1.10

Contact Examples (1/5)

Types of contact

Various factors influence a contact analysis, including:

Deformable or rigid surfaces

Slender or bulky components

Degree of confinement and compressibility of components

Two-surface contact or self contact

Finite-sliding or small-sliding contact formulation

Interaction properties (friction, thermal, etc.)

The above factors include physical and numerical aspects

The user is responsible for defining the physical aspects of a model

The user and Abaqus control various numerical aspects

Examples representing different “classes” of contact problems follow

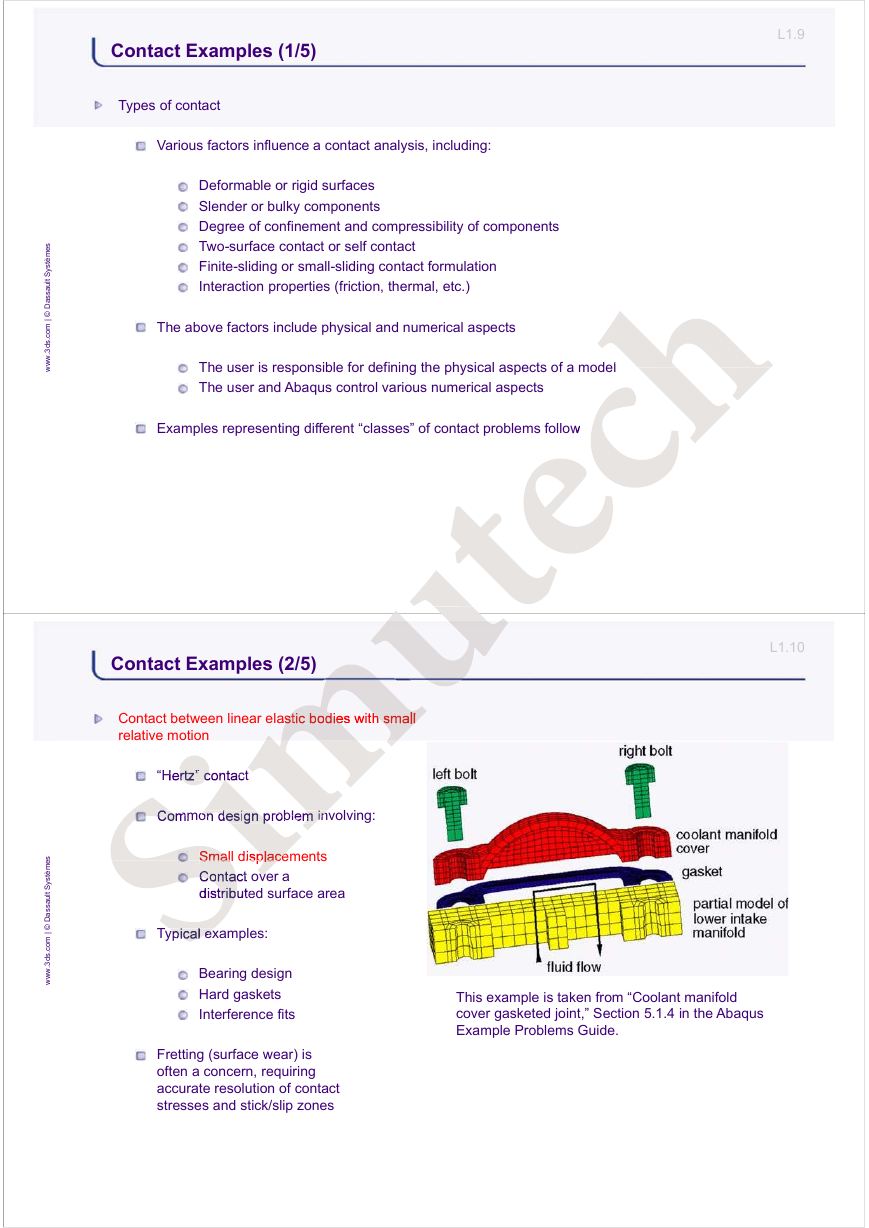

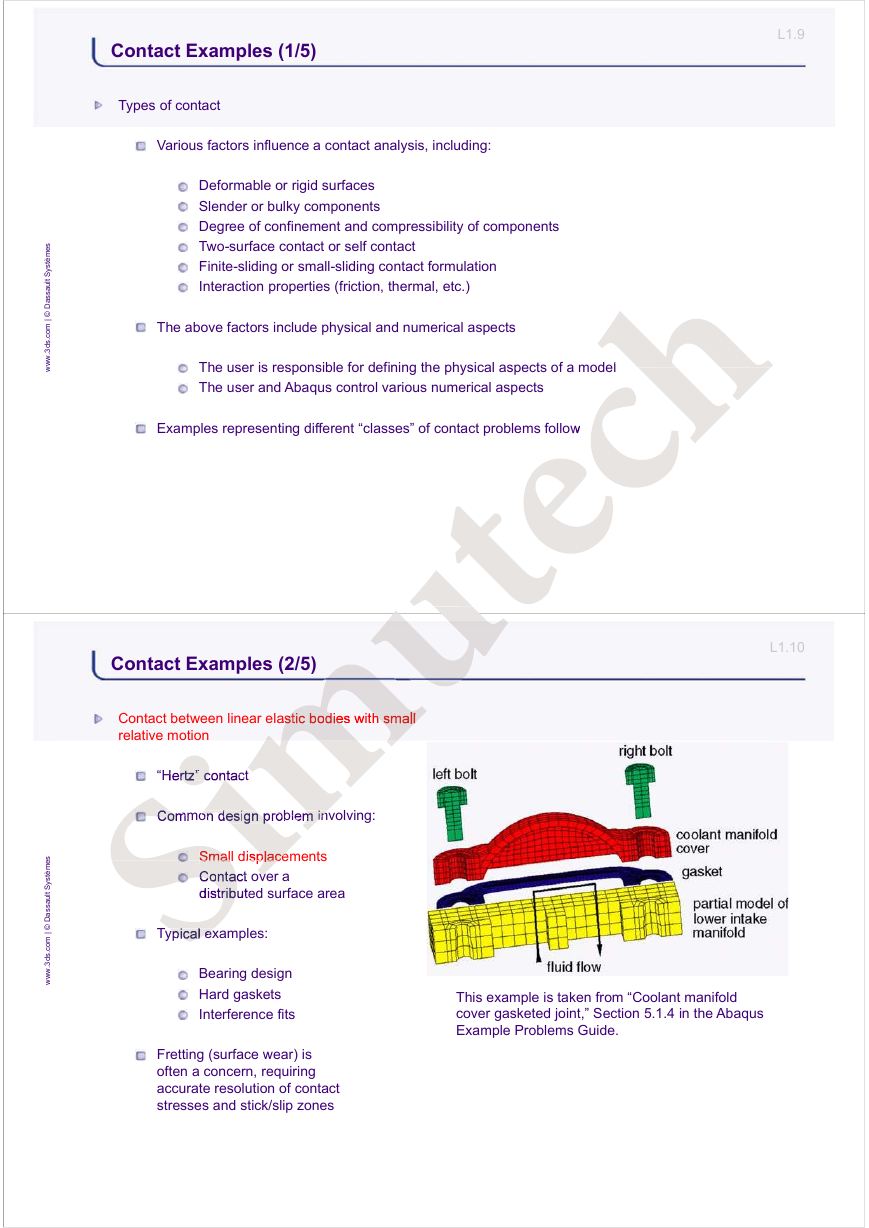

Contact Examples (2/5)

Contact between linear elastic bodies with small

relative motion

“Hertz” contact

Common design problem involving:

Small displacements

Contact over a

distributed surface area

Typical examples:

Bearing design

Hard gaskets

Interference fits

Fretting (surface wear) is

often a concern, requiring

accurate resolution of contact

stresses and stick/slip zones

This example is taken from “Coolant manifold

cover gasketed joint,” Section 5.1.4 in the Abaqus

Example Problems Guide.

s

e

m

è

t

s

y

S

t

l

u

a

s

s

a

D

©

|

m

o

c

.

s

d

3

w

w

w

.

s

e

m

è

t

s

y

S

t

l

u

a

s

s

a

D

©

|

m

o

c

.

s

d

3

w

w

w

.

�

L1.11

L1.12

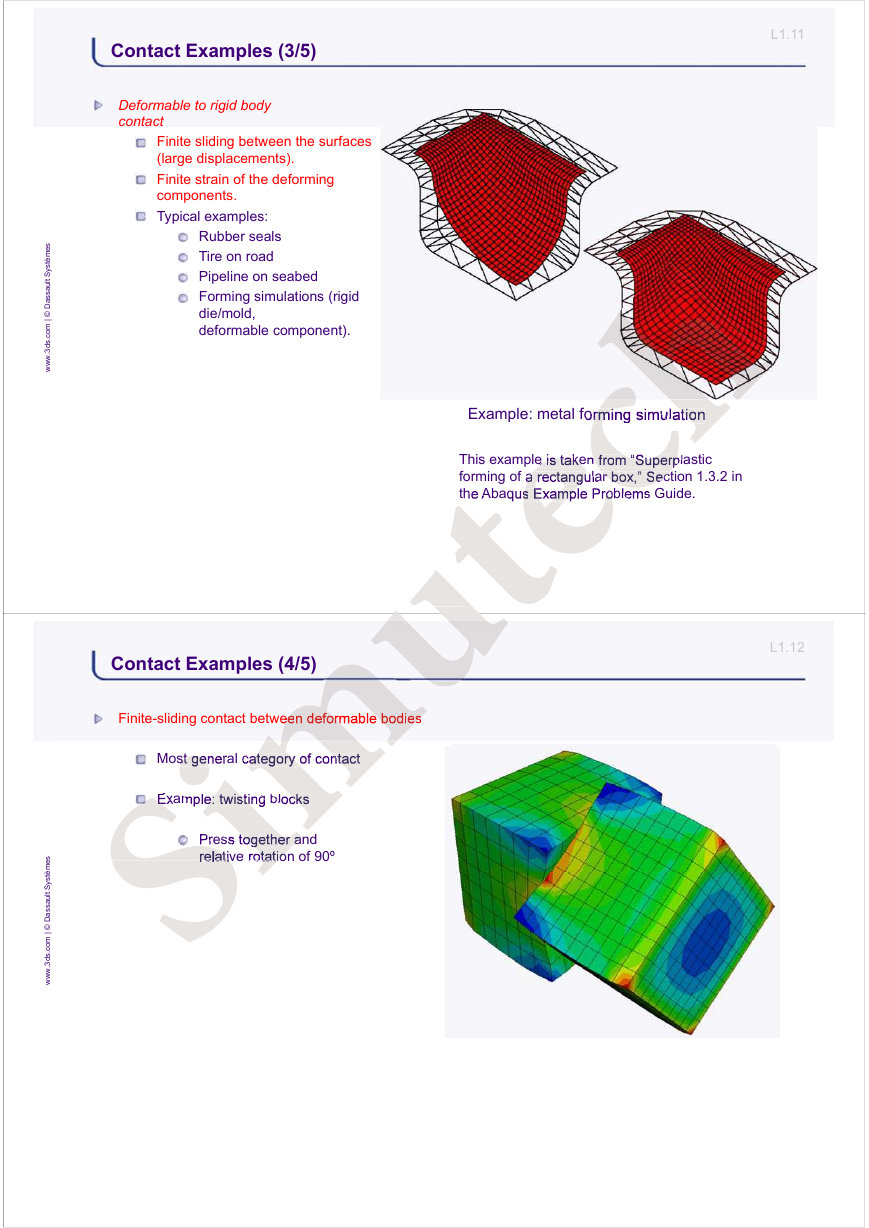

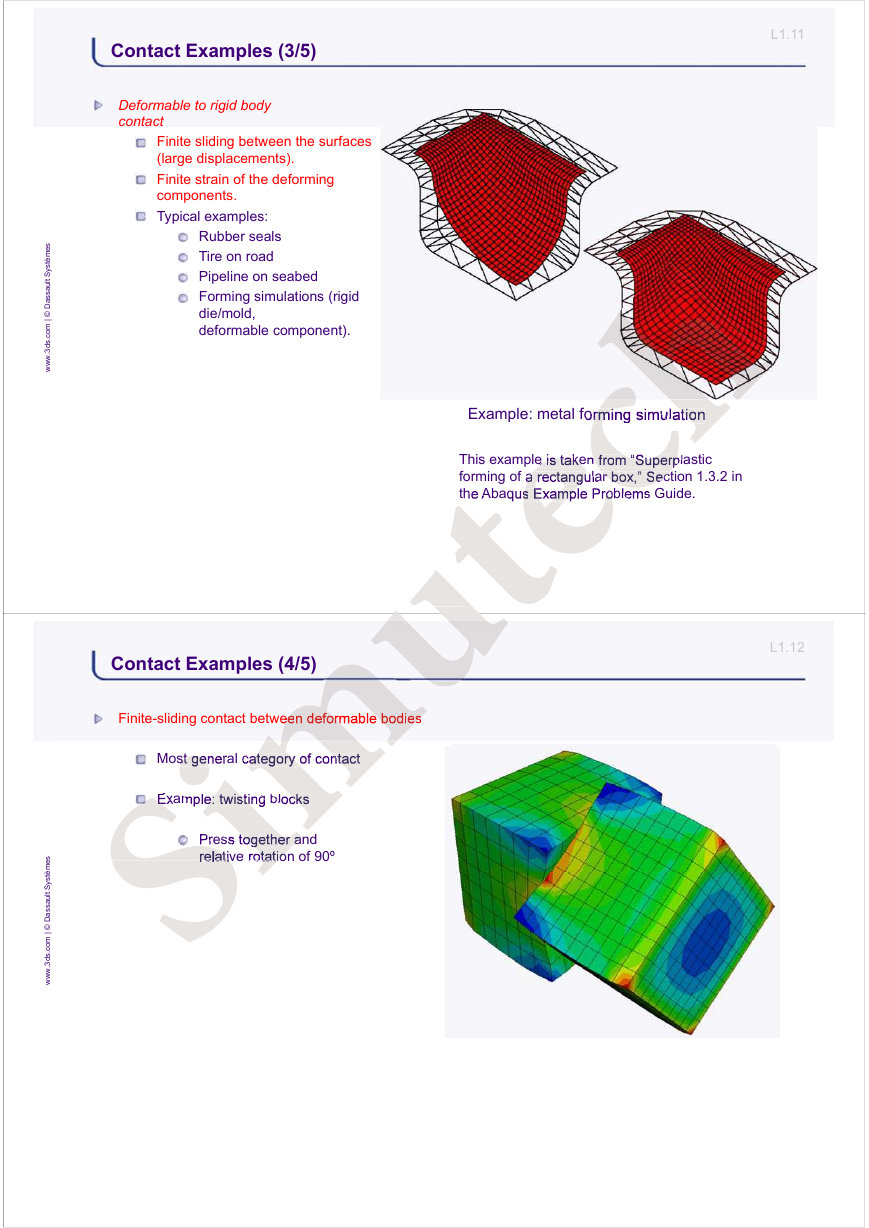

Example: metal forming simulation

This example is taken from “Superplastic

forming of a rectangular box,” Section 1.3.2 in

the Abaqus Example Problems Guide.

Contact Examples (3/5)

Deformable to rigid body

contact

Finite sliding between the surfaces

(large displacements).

Finite strain of the deforming

components.

Typical examples:

Rubber seals

Tire on road

Pipeline on seabed

Forming simulations (rigid

die/mold,

deformable component).

Contact Examples (4/5)

Finite-sliding contact between deformable bodies

Most general category of contact

Example: twisting blocks

Press together and

relative rotation of 90º

s

e

m

è

t

s

y

S

t

l

u

a

s

s

a

D

©

|

m

o

c

.

s

d

3

w

w

w

.

s

e

m

è

t

s

y

S

t

l

u

a

s

s

a

D

©

|

m

o

c

.

s

d

3

w

w

w

.

�

2023年江西萍乡中考道德与法治真题及答案.doc

2023年江西萍乡中考道德与法治真题及答案.doc 2012年重庆南川中考生物真题及答案.doc

2012年重庆南川中考生物真题及答案.doc 2013年江西师范大学地理学综合及文艺理论基础考研真题.doc

2013年江西师范大学地理学综合及文艺理论基础考研真题.doc 2020年四川甘孜小升初语文真题及答案I卷.doc

2020年四川甘孜小升初语文真题及答案I卷.doc 2020年注册岩土工程师专业基础考试真题及答案.doc

2020年注册岩土工程师专业基础考试真题及答案.doc 2023-2024学年福建省厦门市九年级上学期数学月考试题及答案.doc

2023-2024学年福建省厦门市九年级上学期数学月考试题及答案.doc 2021-2022学年辽宁省沈阳市大东区九年级上学期语文期末试题及答案.doc

2021-2022学年辽宁省沈阳市大东区九年级上学期语文期末试题及答案.doc 2022-2023学年北京东城区初三第一学期物理期末试卷及答案.doc

2022-2023学年北京东城区初三第一学期物理期末试卷及答案.doc 2018上半年江西教师资格初中地理学科知识与教学能力真题及答案.doc

2018上半年江西教师资格初中地理学科知识与教学能力真题及答案.doc 2012年河北国家公务员申论考试真题及答案-省级.doc

2012年河北国家公务员申论考试真题及答案-省级.doc 2020-2021学年江苏省扬州市江都区邵樊片九年级上学期数学第一次质量检测试题及答案.doc

2020-2021学年江苏省扬州市江都区邵樊片九年级上学期数学第一次质量检测试题及答案.doc 2022下半年黑龙江教师资格证中学综合素质真题及答案.doc

2022下半年黑龙江教师资格证中学综合素质真题及答案.doc