Contents

1. Introduction

2. Modbus Protocol

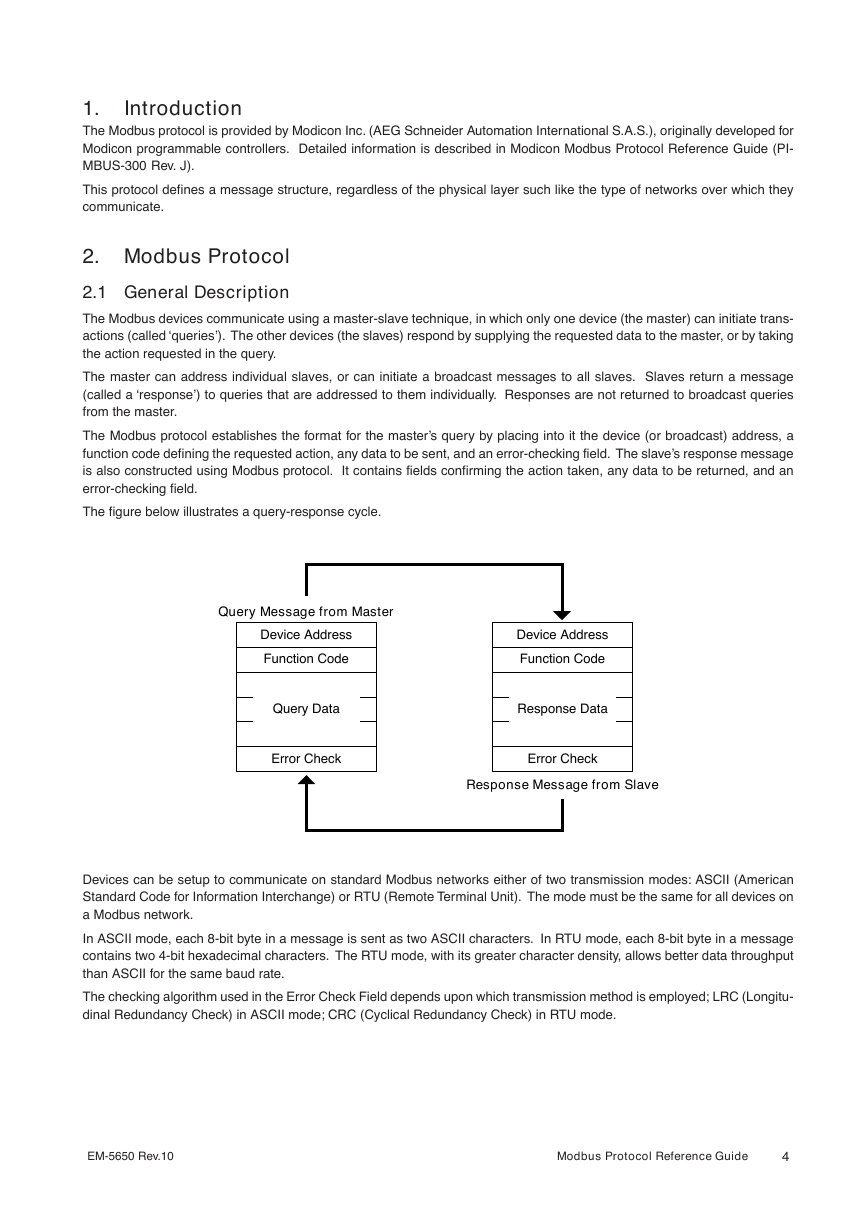

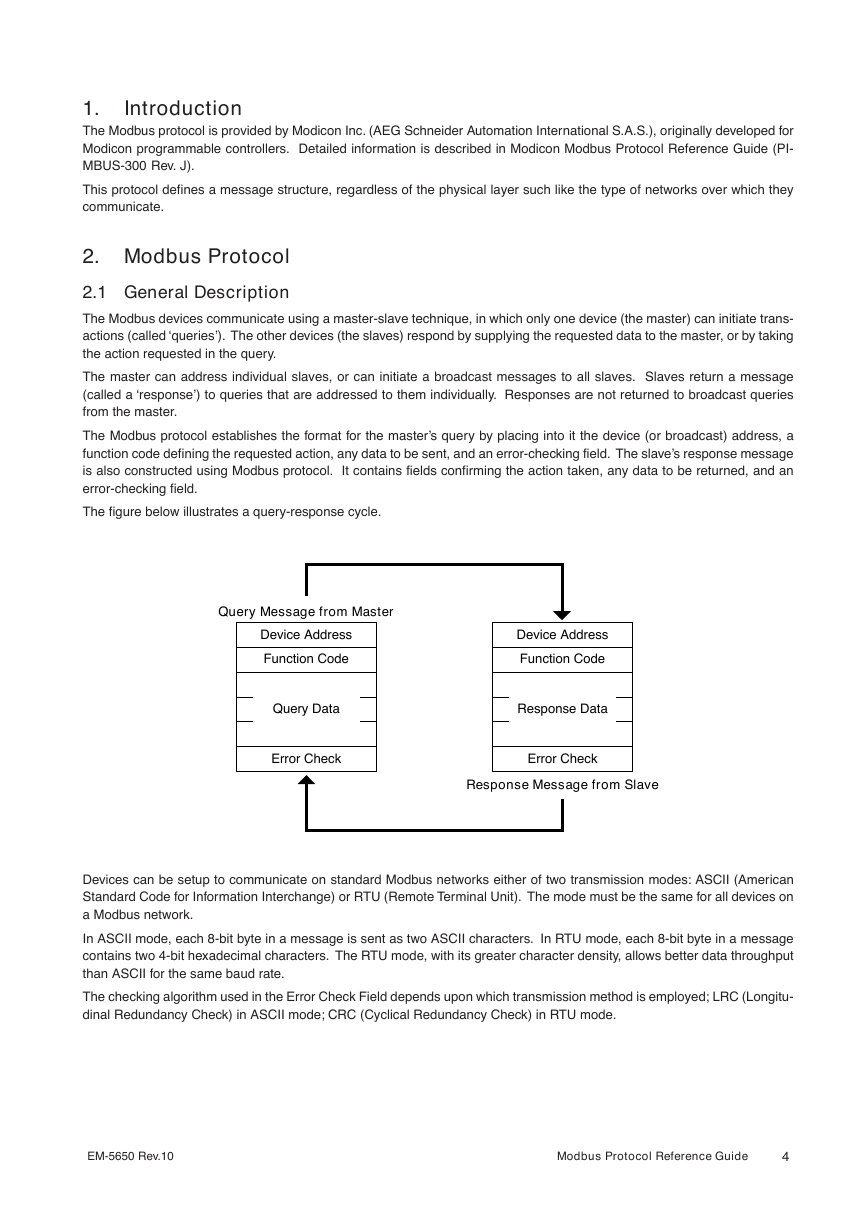

2.1 General Description

2.2 Modbus Message Framing

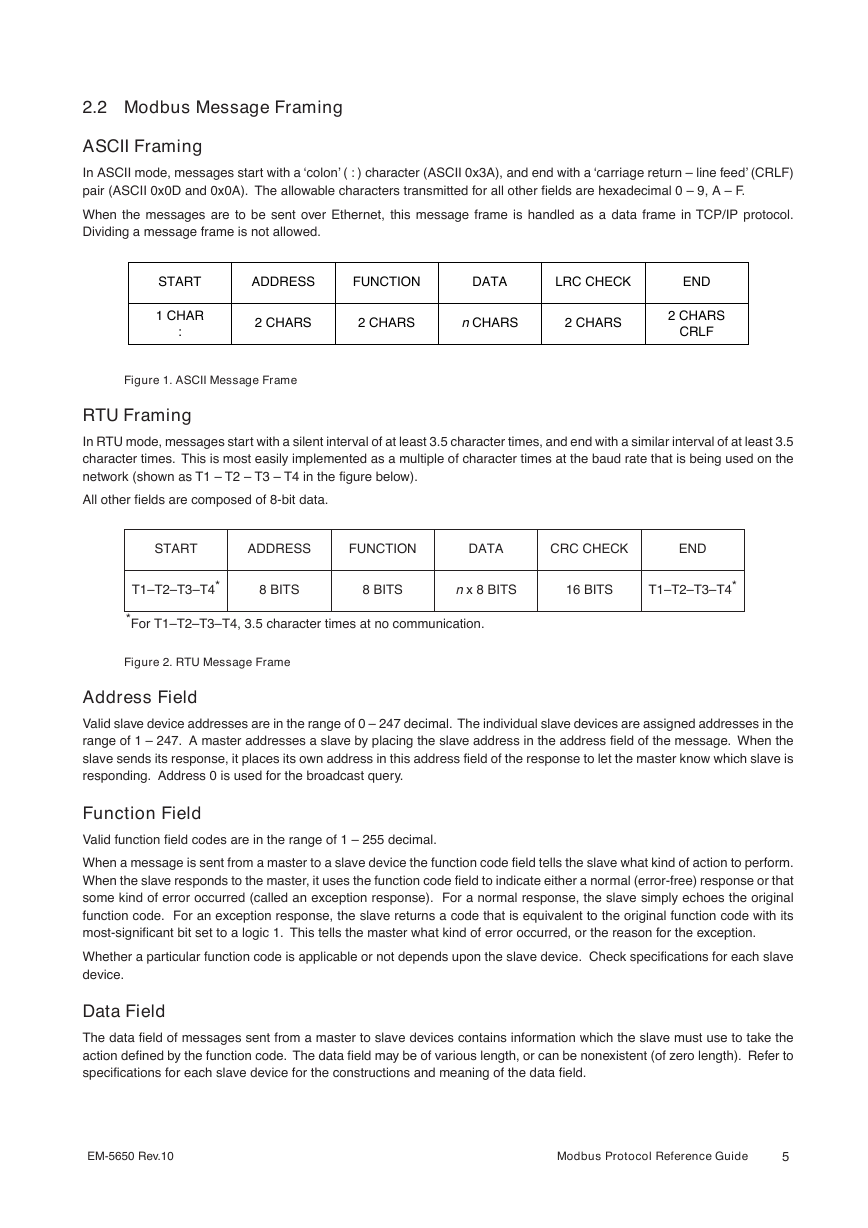

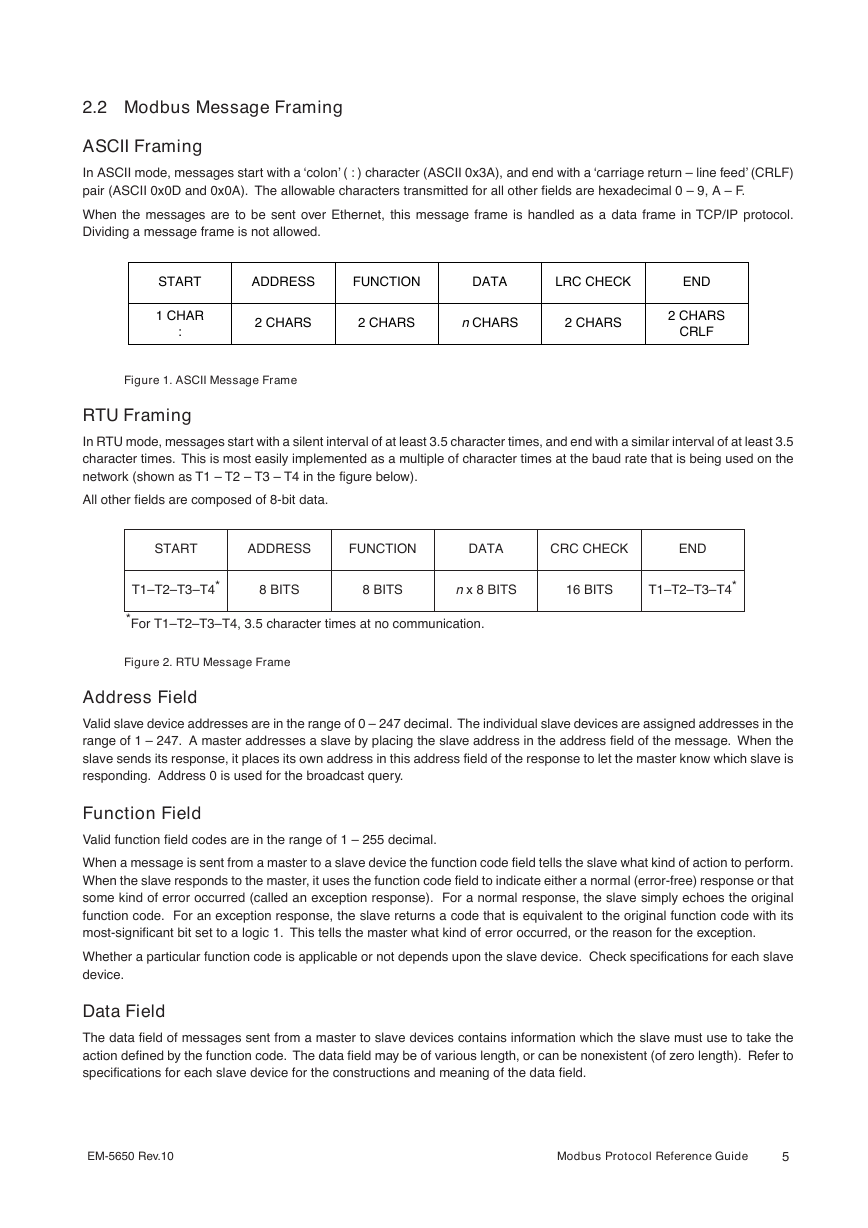

ASCII Framing

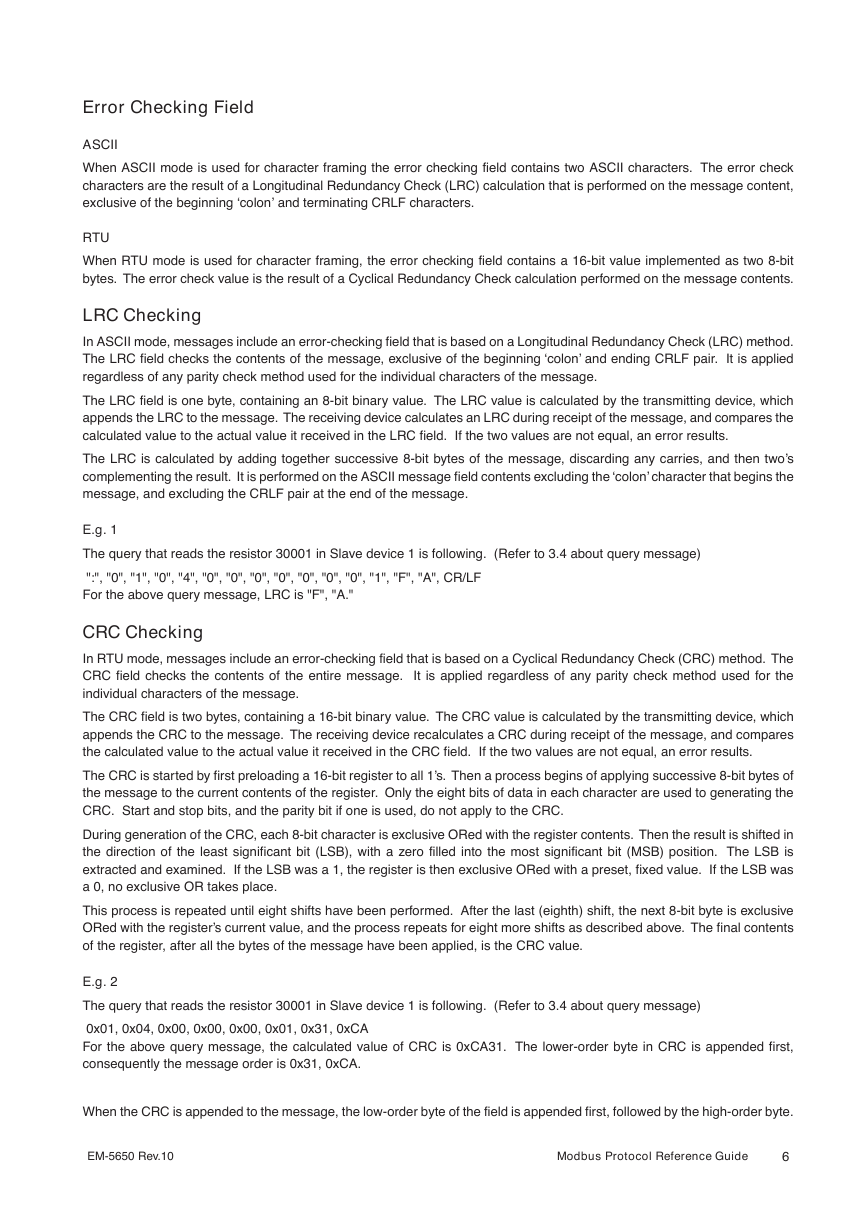

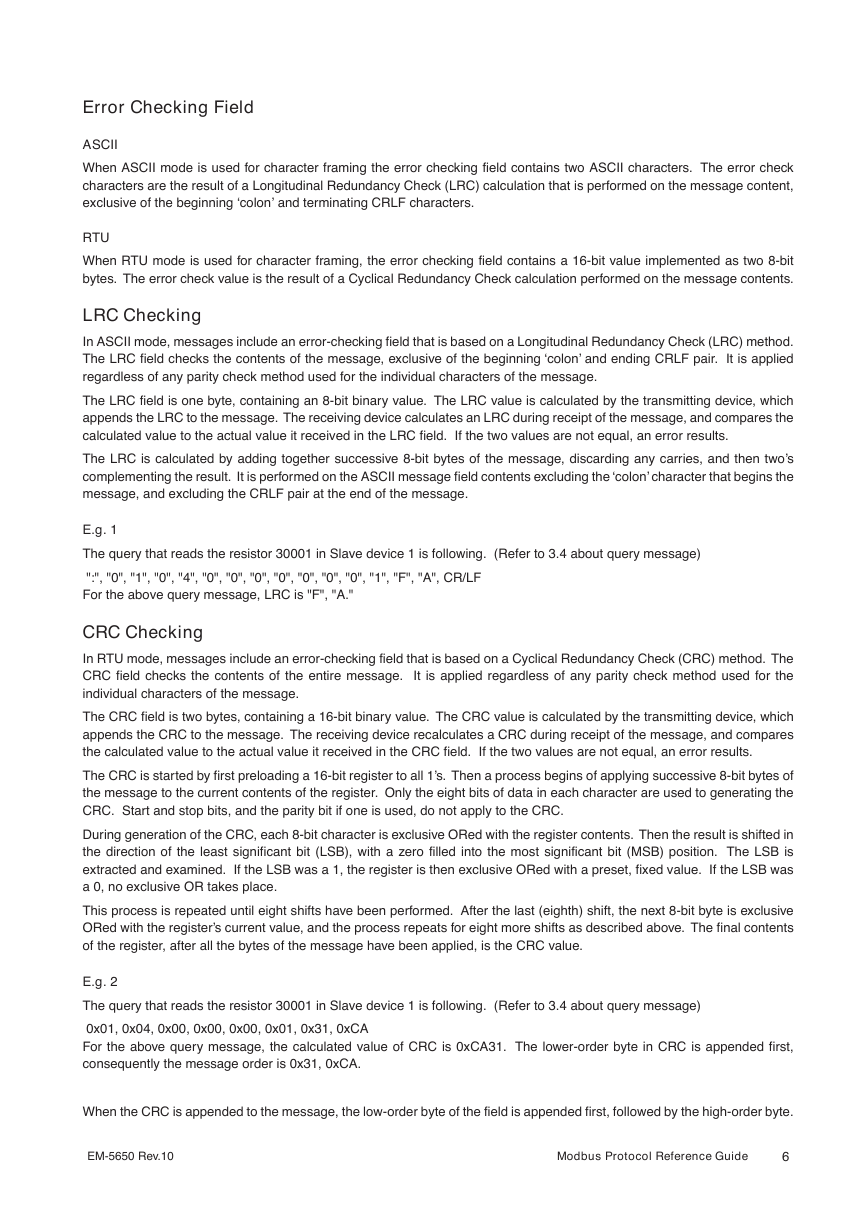

RTU Framing

Address Field

Function Field

Data Field

Error Checking Field

LRC Checking

CRC Checking

2.3 Modbus Function Formats

Data Address

Coil

Input Status

Input Register

Holding Register

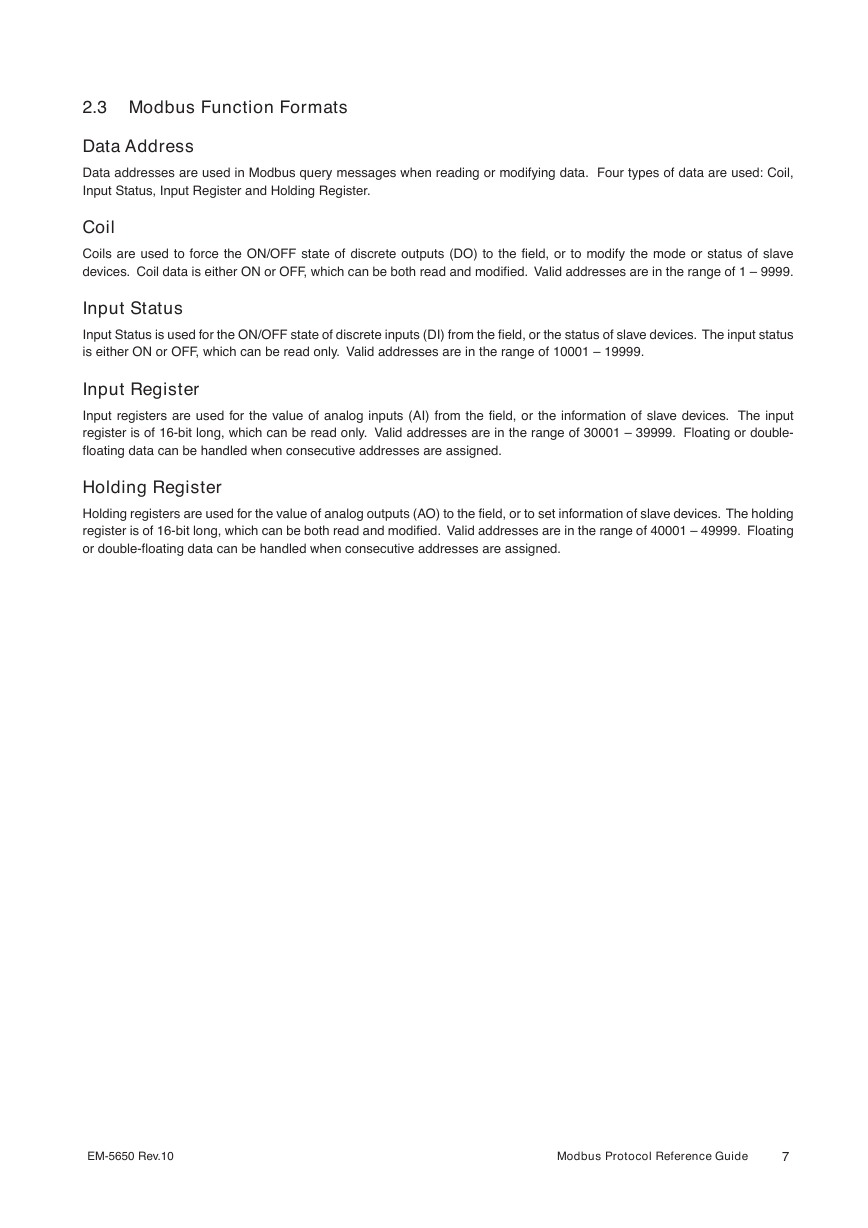

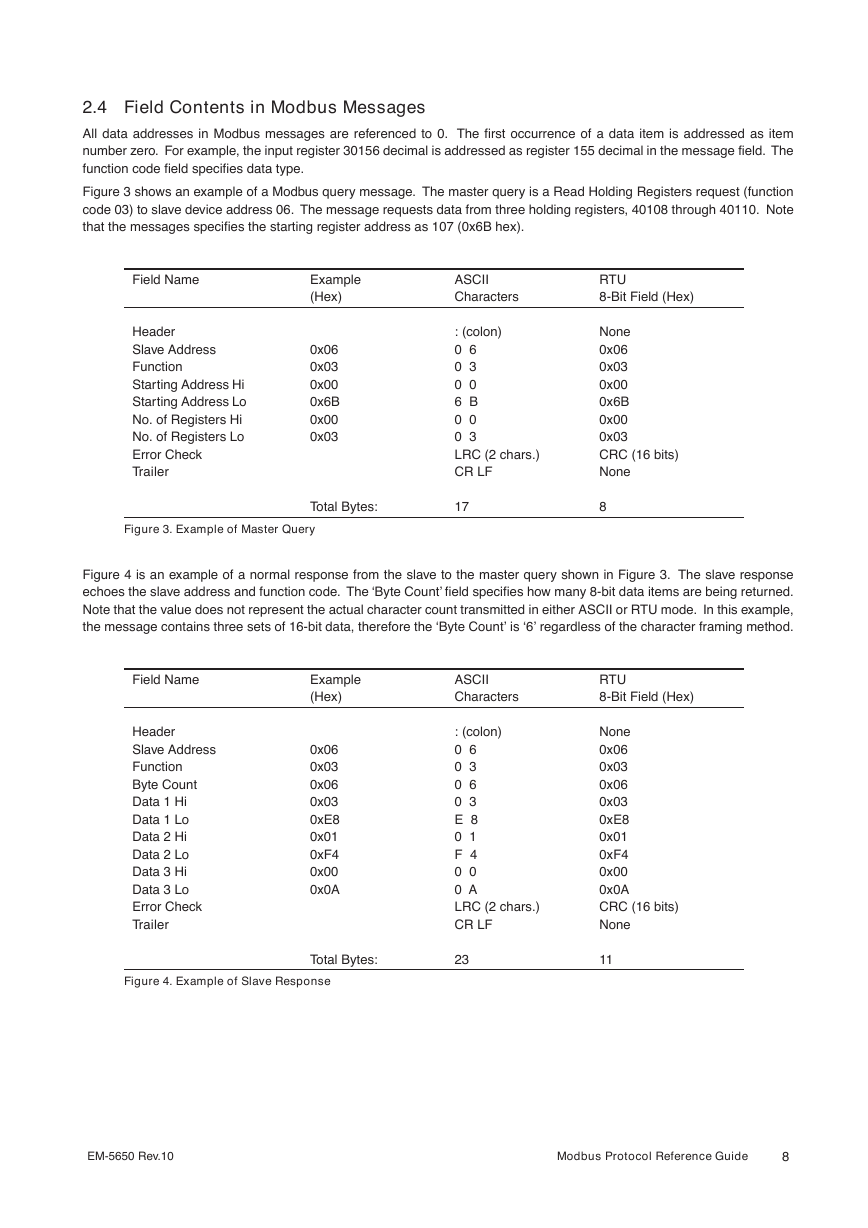

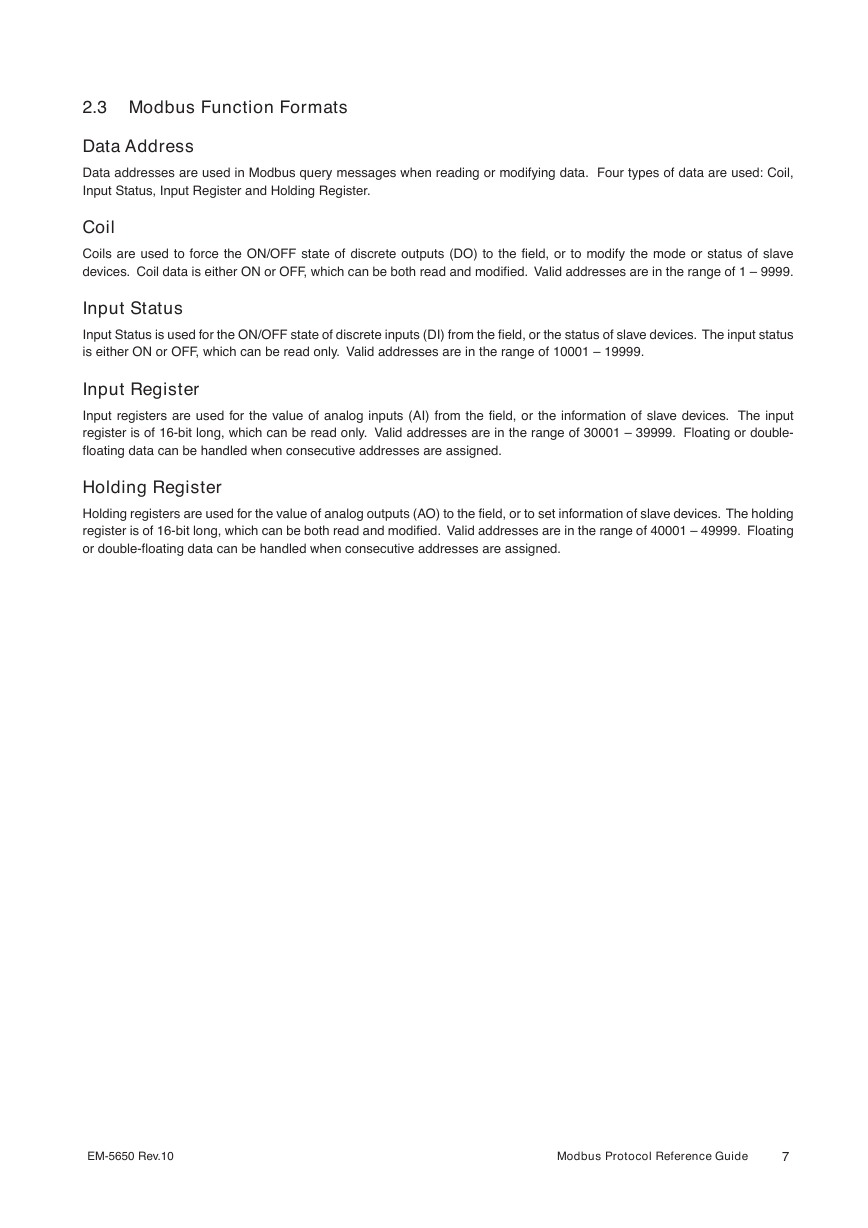

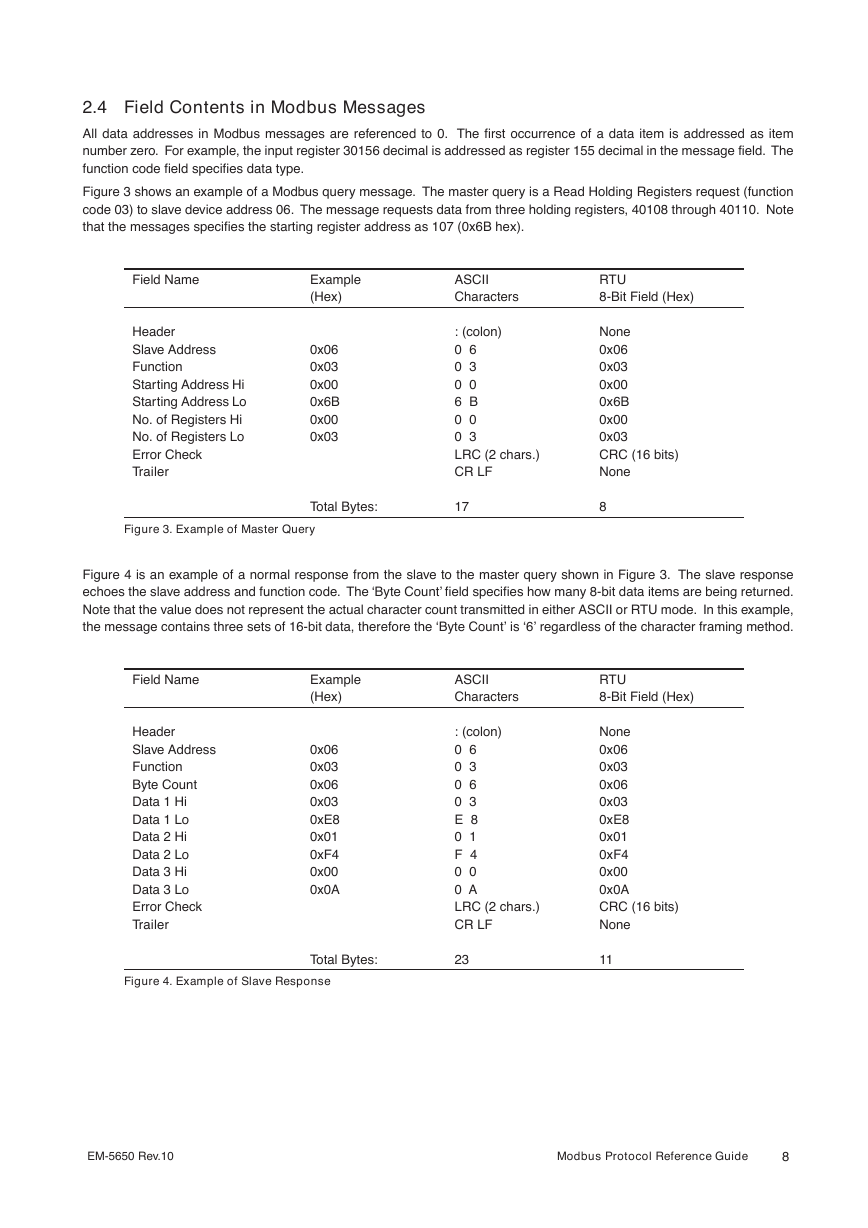

2.4 Field Contents in Modbus Messages

3. Modbus Function Codes

3.1 Read Coil Status (01)

3.2 Read Input Status (02)

3.3 Read Holding Register (03)

3.4 Read Input Register (04)

3.5 Force Single Coil (05)

3.6 Preset Single Register (06)

3.7 Diagnostics (08)

3.8 Fetch Communication Event Counter (11, 0x0B)

3.9 Fetch Communication Event Log (12, 0x0C)

3.10 Force Multiple Coils (15, 0x0F)

3.11 Preset Multiple Registers (16, 0x10)

3.12 Report Slave ID (17, 0x11)

4. Diagnostic Subfunctions (08)

4.1 Return Query Data (00)

4.2 Restart Communications Option (01)

4.3 Return Diagnostics Register (02)

4.4 Force Listen Only Mode (04)

4.5 Clear Counters and Diagnostic Register (10, 0x0A)

4.6 Return Bus Message Count (11, 0x0B)

4.7 Return Bus Communication Error Count (12, 0x0C)

4.8 Return Bus Exception Error Count (13, 0x0D)

4.9 Return Slave Message Count (14, 0x0E)

4.10 Return Slave No Response Count (15, 0x0F)

4.11 Return Slave Busy Count (17, 0x11)

4.12 Return Bus Character Overrun Count (18, 0x12)

5. Exception Responses

Appendix A. R1M Series Remote I/O Modbus Communications

A-1 Function Codes

A-2 Data Addresses

A-3 Input Data

A-4 Coils (DO) Description

DO (1 – 32)

Cold Junction Compensation SW (33 – 48)

A-5 Input Status (DI) Description

DI (10001 – 10032)

ADC Overrange (10033 – 10048)

A-6 Input Registers Description

Analog Input in % (30001 – 30016)

Analog Input in Engineering Unit (30017 – 30048)

Cold Junction Temperature (30049 – 30050)

Channel Status (30081 – 30096)

System Status (30513)

Model No. (30514 – 30521)

Serial No. (30522 – 30529)

Hardware Version No. (30530 – 30537)

Firmware Version No. (30538 – 30545)

A-7 Holding Registers Description

Analog Output in % (40001 – 40016)

Analog Output in Engineering Unit (40017 – 40048)

I/O Type No. (40145 – 40160)

Burnout Type (40161 – 40176)

Appendix B. R2M Remote I/O Modbus Communications

B-1 Function Codes

B-2 Data Addresses

B-3 Input Data

B-4 Coils (DO) Description

DO (1 – 32)

Cold Junction Compensation SW (33 – 40)

B-5 Input Status (DI) Description

DI (10001 – 10032)

ADC Overrange (10033 – 10040)

B-6 Input Registers Description

Analog Input in Engineering Unit (30017 – 30032)

Cold Junction Temperature (30049 – 30050)

Channel Status (30081 – 30088)

System Status (30513)

Model No. (30514 – 30521)

Serial No. (30522 – 30529)

Hardware Version No. (30530 – 30537)

Firmware Version No. (30538 – 30545)

B-7 Holding Registers Description

Input Filter Time Constant (40049 – 40050)

Input Type No. (40145 – 40152)

Burnout Type (40514)

Appendix C. Modbus TCP/IP Protocol

C-1 Introduction

C-2 Protocol Layout

C-3 Example

C-4 Point of Caution

2023年江西萍乡中考道德与法治真题及答案.doc

2023年江西萍乡中考道德与法治真题及答案.doc 2012年重庆南川中考生物真题及答案.doc

2012年重庆南川中考生物真题及答案.doc 2013年江西师范大学地理学综合及文艺理论基础考研真题.doc

2013年江西师范大学地理学综合及文艺理论基础考研真题.doc 2020年四川甘孜小升初语文真题及答案I卷.doc

2020年四川甘孜小升初语文真题及答案I卷.doc 2020年注册岩土工程师专业基础考试真题及答案.doc

2020年注册岩土工程师专业基础考试真题及答案.doc 2023-2024学年福建省厦门市九年级上学期数学月考试题及答案.doc

2023-2024学年福建省厦门市九年级上学期数学月考试题及答案.doc 2021-2022学年辽宁省沈阳市大东区九年级上学期语文期末试题及答案.doc

2021-2022学年辽宁省沈阳市大东区九年级上学期语文期末试题及答案.doc 2022-2023学年北京东城区初三第一学期物理期末试卷及答案.doc

2022-2023学年北京东城区初三第一学期物理期末试卷及答案.doc 2018上半年江西教师资格初中地理学科知识与教学能力真题及答案.doc

2018上半年江西教师资格初中地理学科知识与教学能力真题及答案.doc 2012年河北国家公务员申论考试真题及答案-省级.doc

2012年河北国家公务员申论考试真题及答案-省级.doc 2020-2021学年江苏省扬州市江都区邵樊片九年级上学期数学第一次质量检测试题及答案.doc

2020-2021学年江苏省扬州市江都区邵樊片九年级上学期数学第一次质量检测试题及答案.doc 2022下半年黑龙江教师资格证中学综合素质真题及答案.doc

2022下半年黑龙江教师资格证中学综合素质真题及答案.doc