COLOUR VIDEO COPY PROCESSOR

MODEL

CP800E

OPERATION MANUAL

CP800

MONITOR

MEMORY

PRINT

OPEN

POWER

REMOTE

THIS OPERATION MANUAL IS IMPORTANT

TO YOU.

PLEASE READ IT BEFORE USING YOUR

COLOUR VIDEO COPY PROCESSOR.

This video copy processor complies with the requirements of the EC Directive

89/336/EEC, 73/23/EEC, 93/42/EEC and 93/68/EEC.

The electro-magnetic susceptibility has been chosen at a level that gains

proper operation in residential areas, on business and light industrial premises

and on small-scale enterprises, inside as well as outside of the buildings. All

places of operation are characterised by their connection to the public low

voltage power supply system.

�

CONTENTS

Contents

Safety precautions ................................................................................ 1-3

Special features .................................................................................... 4

Features and functions .......................................................................... 5-7

Front panel ............................................................................................. 5

Rear panel ............................................................................................. 6

Remote control ....................................................................................... 7

Connections .......................................................................................... 8-13

Connection with a monitor ..................................................................... 8-10

Connection with video or S-video signal equipment .............................. 10

Connection with RGB analog signal equipment ..................................... 11

Connection with RS-232C equipment .................................................... 12-13

Before operation .................................................................................... 14-18

Paper sheet set and ink sheet ................................................................ 14

Removing transport screw and protective cushion ................................ 14-15

Installation of print paper ........................................................................ 15-16

Installation of ink sheet .......................................................................... 16-17

Usage and keeping of paper sheet set .................................................. 18

Printing (Basic) ...................................................................................... 19-25

Before printing ........................................................................................ 19-21

Memory print .......................................................................................... 22-25

Memorizing and printing an image ...................................................... 22

Selecting memorized image to print .................................................... 23

Image memorizing with page increment set on .................................. 23

Image size and number of memory pages .......................................... 24

Multiple copy or continuous printing .................................................... 25

Printing (Special) ................................................................................... 26-31

Multi print ............................................................................................... 26-27

Separate print ........................................................................................ 28

External remote terminal 1 ..................................................................... 29

External remote terminal 2 ..................................................................... 30-31

Setting the functions (Menu chart) ........................................................ 32-35

Monitor display chart .............................................................................. 32-33

LCD display chart ................................................................................... 34-35

Adjustments & settings (MAIN MENU).................................................. 36-44

MAIN MENU items ................................................................................. 36

Operating MAIN MENU .......................................................................... 36-37

COLOR ADJ (Colour adjustment) .......................................................... 38

ANALOG ADJ (Analog image adjustment) ......................................... 38

INPUT (Signal selection) ........................................................................ 38

ADDITIONAL (Special print setting) ....................................................... 39

PRINT (Print setting) .............................................................................. 40-41

COMMENT (Making a comment) ........................................................... 42-43

SIZE/TIMING (Setting size and timing) .................................................. 43-44

Adjustments & settings (SERVICE MENU) ........................................... 45-50

SERVICE MENU items .......................................................................... 45

Operating SERVICE MENU ................................................................... 45

KEY SET (Setting functions of buttons) ................................................. 46-47

SIGNAL SET1(Signal setting display) .................................................... 47-48

SIGNAL SET2(Signal setting display) .................................................... 48

PRINT SET (Print setting display) .......................................................... 48-49

SYSTEM SET(System setting display) .................................................. 49

REMOTE SET(Remote signal setting display) ....................................... 49-50

PREVIOUS ERROR(Error display) ........................................................ 50

Adjusting image without using remote control ....................................... 50

Error messages ..................................................................................... 51

Before calling for service ....................................................................... 52-53

Overcoming paper jams ........................................................................ 54

Cleaning ................................................................................................ 55-56

Spec & options ...................................................................................... 57

�

SAFETY PRECAUTIONS

In the interest of safety, please observe the following precautions:

POWER REQUIREMENT

This Colour Video Copy Processor is designed for operation on 220-240V, 50Hz AC. Never connect to any outlet or power

supply having a different voltage or frequency.

WARNING: THIS APPARATUS MUST BE EARTHED.

AVERTISSEMENT: CET APPAREIL DOIT ETRE MIS A LA TERRE.

PROTECTIVE MEASURES

IF ABNORMALITIES ARISE, ....

Use of the unit during emission of smoke or abnormal sounds (without adopting countermeasures) is dangerous. In such a

case, unplug the power cord from the source outlet immediately, and request maintenance service from the sales dealer.

NEVER INSERT ANY OBJECT INTO THE UNIT

Foreign objects of any kind inserted into this unit constitute a safety hazard and can cause extensive damage.

DO NOT PLACE ANYTHING ON THE COLOUR VIDEO COPY PROCESSOR

Heavy objects placed on the Colour Video Copy Processor can cause damage or obstruct proper ventilation.

PROTECT THE POWER CORD

Damage to the power cord may cause fire or shock hazard. When unplugging, hold by the plug only and remove carefully.

DO NOT PLACE WATER CONTAINERS ON THE UNIT

Do not place flower vases, and other water-holding containers on the device. If, for some reason, water seeps to the inside of

the unit, unplug the power cord from the source outlet, and contact the sales dealer. If used without corrective measures, the

unit may be damaged.

“In the interest of safety, avoid handling of liquids near the unit.”

DO NOT REMOVE THE CABINET

Touching internal parts is dangerous, besides, it may lead to malfunction. Contact the sales dealer to carry out internal checks

and adjustments. Before opening the cover for eliminating a jammed paper, etc., be sure to disconnect the power cord plug.

UNPLUG THE POWER CORD DURING A LONG ABSENCE

Turn off the MAIN power switch and unplug the power cord during a long absence.

WHEN TRANSPORTING THE UNIT

When transporting the unit, remove the sheet cartridge and paper from the paper cassette, and insert the protective cushion into

its compartment. Make sure to screw the printing unit down.

BE CAREFUL AROUND PRINT PAPER EXIT SLOT

Do not insert your hand or any material into the paper exit slot during printing.

Do not touch the cutter blade inside the paper exit slot.

Otherwise, your finger will be injured.

DO NOT TOUCH THE THERMAL HEAD

Do not touch your hand to the thermal head (located inside the unit).

The thermal head is heated to high temperature.

This may cause injury.

BE CAREFUL WITH THE PRINTING UNIT

Do not move the unit while the printing unit is sliding out. This may cause injury.

Be careful not to catch your finger in the printing unit while the printing unit is being retracted into the unit.

CONNECTION CABLES

Use the provided power cord and the composite video signal cable. When connecting the unit with an equipment with RS-232C

interface, use the RS-232C crossover cable.

1

P

R

E

C

A

U

T

O

N

S

I

F

E

A

T

U

R

E

S

C

O

N

N

E

C

T

O

N

S

I

P

R

E

P

A

R

A

T

O

N

I

I

P

R

N

T

N

G

I

A

D

J

U

S

T

M

E

N

T

S

S

H

O

O

T

N

G

I

T

R

O

U

B

L

E

-

O

T

H

E

R

S

�

SAFETY PRECAUTIONS

INSTALLATION LOCATIONS

MAINTAIN GOOD VENTILATION

Ventilation slots and holes are provided on the top, sides and bottom of this unit. Place the unit on a hard and level surface and

locate at least 10cm from walls to insure proper ventilation. When putting the unit on the system rack, take a space between the

unit and the back of the rack.

UNSUITABLE LOCATIONS

Avoid shaky places or hot-springs areas where hydrogen sulfide and acidic ions are likely to be generated.

PLACES WITH HIGH HUMIDITY AND DUST

Do not place the unit locations with high humidity and dust. They can cause extensive damage. Avoid places where unit is likely

to be exposed to oily fumes and vapours.

PLACES NOT LIKELY TO BE EXTREMELY HOT

Places exposed to direct sunlight, or near heating appliances can attain extremely high temperatures, which may deform the

cabinet, or can become a prime cause of damage.

PLACE THE UNIT ON A HORIZONTAL LEVEL

The unit is likely to be affected if it is placed in slanted conditions or in unstable places.

PROTECT AGAINST DEW FORMATION

In extremely cold regions, if the unit is moved quickly from an extremely cold place to warmer one, dew is likely to be formed.

If dew is formed, printing is not possible.

OPERATING AMBIENT TEMPERATURE RANGE

The operating ambient temperature range is 41 F - 104 F (5 C to 40 C), and humidity of 20 - 80%. When using the unit on the

system rack, be sure to keep this ambient temperature inside the rack.

FOR LONG OPERATING LIFE

UNSUITABLE MATERIALS FOR THE COLOUR VIDEO COPY PROCESSOR

Coat flaking and deformation are likely to occur if the unit is wiped with chemical dusters, benzine, thinner or any other solvent, if

rubber or PVC items are left in contact with the unit for extended duration, or if the unit is sprayed with insecticide.

CARE OF THE CABINET

Unplug and clean with a soft cloth slightly moistened with a mild soap and water solution. Allow to dry completely before

operating. Never use petroleum base solutions or abrasive cleaners.

HEAD ABRASION

The thermal head, like the video head, wears out. When it is abraded, it becomes hard to print out fine details of the picture. In

such a case, it is necessary to replace the thermal head. Consult with the sales dealer for replacing the head.

CONNECTING DEVICES

Read thoroughly “Operating Precautions” of the instruction booklets for the devices connected with the Colour Video Copy

Processor.

The power cord must be disconnected after printing is over.

CAUTION ON RELOCATING

When transporting this unit, make sure it is not likely to be subjected to impacts. They can be a prime cause for damage.

Further, make sure to disconnect the power cord from the power outlet, and the cables from the connected devices.

2

�

SAFETY CHECKS

Periods: According to the recommendations of the manufacturer of the medical device.

Scope:

a) Visual inspection

Housing, leads, controls, displays, labels/markings, accessories, operation manual.

b) Functionality test

Testing of functions (according to operation manual) as well as compatibility and usability of device and

accessories.

c) Electrical test

Testing of electrical safety of the system according to EN60601-1.

High humidity or dust

Avoid locations with high humidity and dust in order to avoid malfunctioning of the device.

Also avoid locations subject to corrosive gasses and smoke.

Heat

Direct sunlight, heaters or other heat sources may deform the housing and subsequently cause malfunctioning.

TECHNICAL DESCRIPTIONS

The supplier will make available on request such circuit diagrams, component part lists, descriptions, calibration instructions or

other information which will assist the USER’s appropriately qualified technical personnel to repair those parts of the

EQUIPMENT which are classified by the manufacturer as repairable.

The use of ACCESSORY equipment not complying with the equivalent safety requirements of this equipment may lead to a

reduced level of the resulting system.

Consideration relating to the choice shall include:

- use of the accessory in the PATIENT VICINITY.

- evidence that the safety certification of the ACCESSORY has been performed in accordance to the appropriate EN60601-1

and/or EN60601-1-1 harmonized national standard.

The transportation and storage environmental conditions are:

Temperature :

Humidity

:

Note: The above transportation environmental conditions indicate the storage environmental conditions during transport.

-20 C - +60 C (-4 F - +140 F)

90% RH or less at 40 C (104 F)

OTHER CAUTIONS

Dust or other foreign matter adhering to the print paper or the sheet cartridge, or deformation resulting from exposure to

extremely low or high temperatures could cause loss of colour, uneven colour or lines, or wrinkles in the print images.

If there is noise or vibration in the VCR still-image or playback picture, the print image may be distorted or the upper part may be

crooked.

NOTE:

YOUR UNDERSTANDING IS REQUESTED FOR THE LOSS OF IMAGES IN MEMORY DUE TO THE SUDDEN

OCCURRENCE OF A MALFUNCTION.

As for paper sheet set, refer to Page 14, “Paper sheet set and ink sheet”.

This product is to be employed with medical equipment, just for

reference purpose, not for medical diagnostic purpose.

3

P

R

E

C

A

U

T

O

N

S

I

F

E

A

T

U

R

E

S

C

O

N

N

E

C

T

O

N

S

I

P

R

E

P

A

R

A

T

O

N

I

I

P

R

N

T

N

G

I

A

D

J

U

S

T

M

E

N

T

S

S

H

O

O

T

N

G

I

T

R

O

U

B

L

E

-

O

T

H

E

R

S

�

SPECIAL FEATURES

SPECIAL FEATURES

AVAILABLE IN VARIOUS MEDICAL FIELDS, INCLUDING ENDOSCOPY DIAGNOSIS

3 kinds of colouring characteristics (gamma curve) are employed, which are the best for medical diagnostic devices, including

endoscope requiring precise images and ultrasound diagnostic equipment etc. The colour is reproducible for each diagnostic

equipment with easy operation. Each gamma curve is adjustable for each user flexibly.

2 PRINT SIZES ARE AVAILABLE ACCORDING TO THE PURPOSE

2 printing sizes, L size (A5 size or equivalent : max.117 x 155 mm (4.61 x 6.1 inches)) and S size (A6 size or equivalent:

max.117 x 88 mm(4.61 x 3.47 inches)), are selectable.

MULTI PRINT FUNCTION BY THE CAPACIOUS FRAME MEMORY

Large capacity of frame memory can store max.16 images (in 4 sheets) in multi-4-image mode. CP800E can store an image

during its printing, so the time of diagnosis will be shorten remarkably.

HIGH SPEED PRINTING

Printing speed is approx. 26 seconds (in S size print). Using a roll paper shortens the time for installing and removing.

LARGE CAPACITY OF PRINTING

Maximum number of printing (S size) is 160 printings per a roll paper. The large capacity of roll paper printing reduces a time of

exchanges.

POSSIBLE OF A5 SIZE PRINTING IN HIGH QUALITY

High quality print is available in sublimation dye thermal method which is superior in repeatability of images. It also employs 256

gradients and about 16,700,000 colours in each YMC. A5 size printing helps its uses widely.

MULTI PRINT FOR VARIOUS DEMANDINGS

2, 4, and 6 images of multi print are available. Several multi print modes are selectable according to demanding.

WIDE COMPATIBILITY WITH A VARIETY OF INTERFACE AND SYSTEMS

(1)

(2)

(3)

(4)

(5)

(6)

(7)

(8)

3 types (RGB/S-Video/Composite-Video) of input and output image signals

Input and output control signals from RS-232C/Rear remote interfaces

2 mode operation function responding to foot switch input

Fixing function to internal sync. signal avoiding the loop phenomena of sync. signal

Stroboscope sync. function responding to retinal camera system

Image adjusting function such as contrast, brightness, depth etc. of printing image

Letters printing function printing max.48 characters

Capable of storing 4 kinds of setting and adjustment according to each using condition

4

�

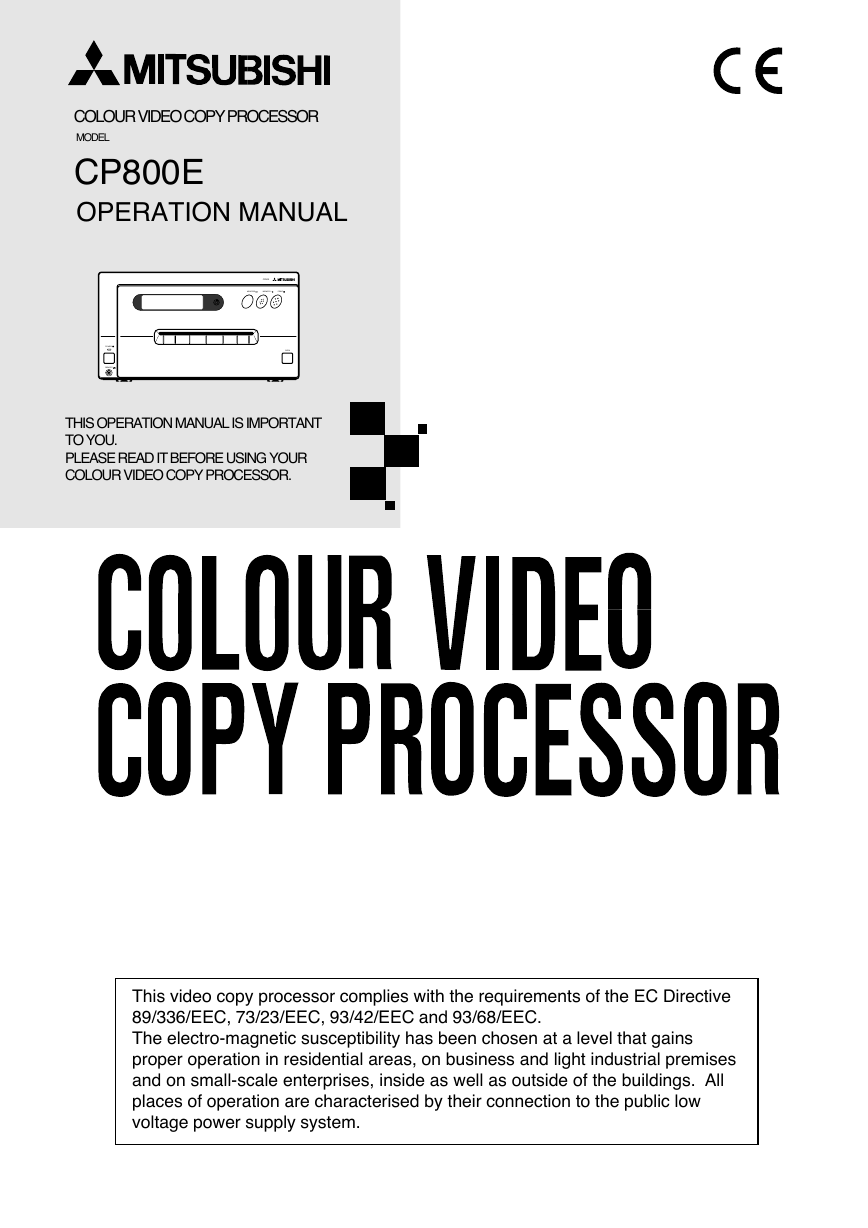

FEATURES & FUNCTIONS

FRONT PANEL

3

4

5

6

7

CP800

MONITOR

MEMORY

PRINT

P

R

E

P

A

R

A

T

O

N

S

I

F

E

A

T

U

R

E

S

C

O

N

N

E

C

T

O

N

S

I

P

R

E

P

A

R

A

T

O

N

I

I

P

R

N

T

N

G

I

A

D

J

U

S

T

M

E

N

T

S

S

H

O

O

T

N

G

I

T

R

O

U

B

L

E

-

O

T

H

E

R

S

5

9

8

OPEN

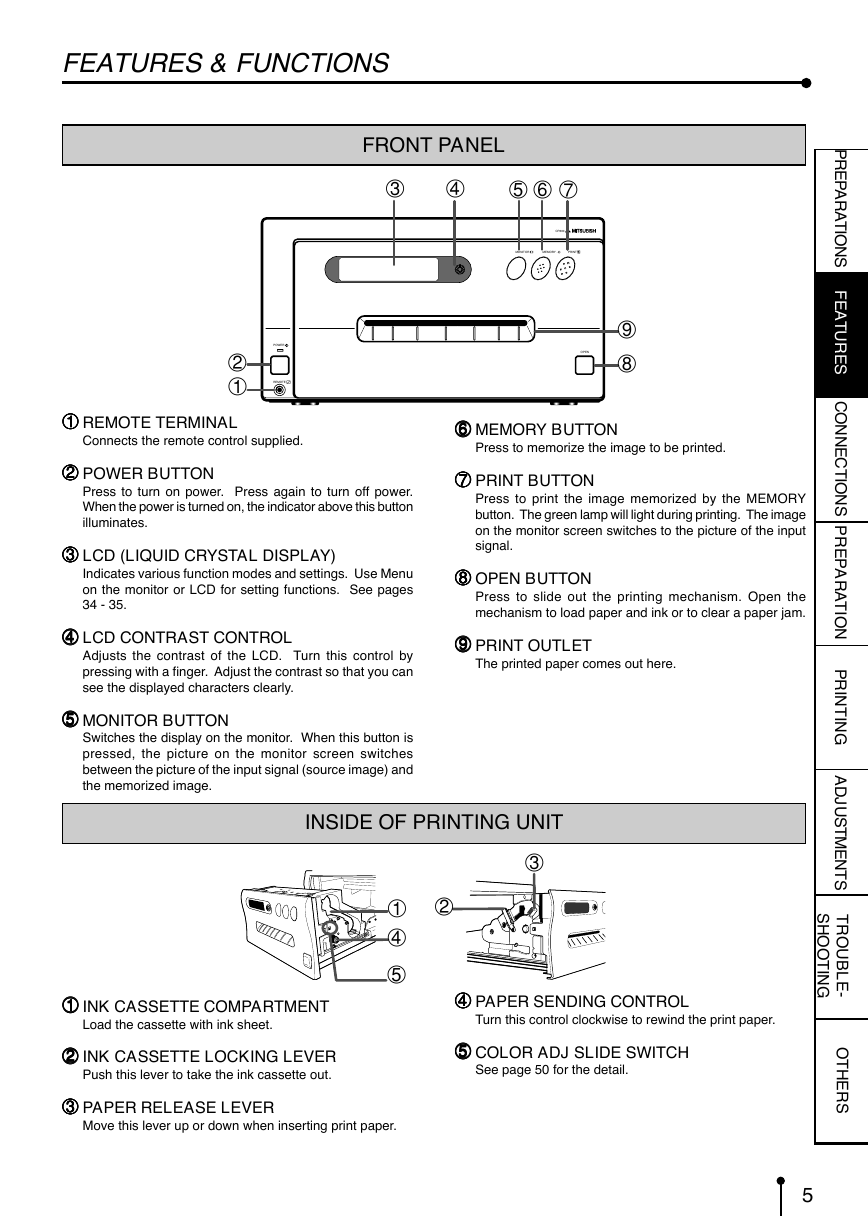

66666 MEMORY BUTTON

Press to memorize the image to be printed.

77777 PRINT BUTTON

Press to print the image memorized by the MEMORY

button. The green lamp will light during printing. The image

on the monitor screen switches to the picture of the input

signal.

88888 OPEN BUTTON

Press to slide out the printing mechanism. Open the

mechanism to load paper and ink or to clear a paper jam.

99999 PRINT OUTLET

The printed paper comes out here.

POWER

REMOTE

2

1

11111 REMOTE TERMINAL

Connects the remote control supplied.

22222 POWER BUTTON

Press to turn on power. Press again to turn off power.

When the power is turned on, the indicator above this button

illuminates.

33333 LCD (LIQUID CRYSTAL DISPLAY)

Indicates various function modes and settings. Use Menu

on the monitor or LCD for setting functions. See pages

34 - 35.

44444 LCD CONTRAST CONTROL

Adjusts the contrast of the LCD. Turn this control by

pressing with a finger. Adjust the contrast so that you can

see the displayed characters clearly.

55555 MONITOR BUTTON

Switches the display on the monitor. When this button is

pressed, the picture on the monitor screen switches

between the picture of the input signal (source image) and

the memorized image.

INSIDE OF PRINTING UNIT

3

2

1

4

5

11111 INK CASSETTE COMPARTMENT

Load the cassette with ink sheet.

22222 INK CASSETTE LOCKING LEVER

Push this lever to take the ink cassette out.

33333 PAPER RELEASE LEVER

Move this lever up or down when inserting print paper.

44444 PAPER SENDING CONTROL

Turn this control clockwise to rewind the print paper.

55555 COLOR ADJ SLIDE SWITCH

See page 50 for the detail.

�

FEATURES & FUNCTIONS

REAR PANEL

1

2

3 4 5

1

2

RS-232C

REMOTE

SCREW

S-VIDEO

VIDEO

9

8

R G/G+SYNC

B H+V-SYNC

R G/G+SYNC B H+V-SYNC

IN

OUT

AC IN

POWER

ON OFF

75W

/

HIGH

75W

75W

75W

HIGH

75W

HIGH

HIGH HIGH

IMPEDANCE

RGB

75W

/

HIGH

75W

HIGH

SYNC

75W

/

HIGH

75W

HIGH

6

7

Potential equalization connector

This is used to equalize the potential of the

equipment connected to the unit.

For details, refer to the installation

instruction of the equipment to be

connected.

11111 S-VIDEO INPUT/OUTPUT TERMINAL

66666 AC LINE SOCKET

Use these terminals to connect to S-VIDEO signal

equipment. See pages 10.

Connects to the provided power cord. Insert the cord firmly.

77777 IMPEDANCE SWITCH

22222 VIDEO SIGNAL INPUT/OUTPUT TERMINAL

Use these terminals to connect this unit to VIDEO signal

equipment. See pages 10.

[IMPEDANCE RGB SYNC.]

This is a 75W HIGH/75W

for RGB or Sync. signal.

/HIGH impedance selection switch

33333 RS-232C PORT

Use these terminals to connect this unit to a device

equipped with RS-232C interface. See pages 12 for

connection.

44444 EXTERNAL REMOTE TERMINAL 1

This connection is for use by system integrators to

memorize and print. Set the button function MEM & PRN

to ON for memory and print images. It is necessary to

make a circuit for remote control to use this input. See

page 29.

55555 EXTERNAL REMOTE TERMINAL 2

This terminal is for use by system intergrators for custom

control. It is necessary to make a circuit for remote control

to use the functions. See page 30.

88888 RGB ANALOG OUTPUT TERMINALS

[R G/G+SYNC B H+V-SYNC]

This is a monitor output terminal for a RGB analog signal.

The sync. signal can be selected between 0.3V (H+V-

SYNC) and TTL (H+V-SYNC) signals. See page 11.

99999 RGB ANALOG INPUT TERMINALS

[R G/G+SYNC B H+V-SYNC]

This is a BNC type input terminal for a RGB analog signal.

The sync. signal can be automatically selected between

H/V composite and SYNC. ON GREEN (sync. signal

imposed on the green video signal) signals. See page 11

for switch setting.

6

�

2023年江西萍乡中考道德与法治真题及答案.doc

2023年江西萍乡中考道德与法治真题及答案.doc 2012年重庆南川中考生物真题及答案.doc

2012年重庆南川中考生物真题及答案.doc 2013年江西师范大学地理学综合及文艺理论基础考研真题.doc

2013年江西师范大学地理学综合及文艺理论基础考研真题.doc 2020年四川甘孜小升初语文真题及答案I卷.doc

2020年四川甘孜小升初语文真题及答案I卷.doc 2020年注册岩土工程师专业基础考试真题及答案.doc

2020年注册岩土工程师专业基础考试真题及答案.doc 2023-2024学年福建省厦门市九年级上学期数学月考试题及答案.doc

2023-2024学年福建省厦门市九年级上学期数学月考试题及答案.doc 2021-2022学年辽宁省沈阳市大东区九年级上学期语文期末试题及答案.doc

2021-2022学年辽宁省沈阳市大东区九年级上学期语文期末试题及答案.doc 2022-2023学年北京东城区初三第一学期物理期末试卷及答案.doc

2022-2023学年北京东城区初三第一学期物理期末试卷及答案.doc 2018上半年江西教师资格初中地理学科知识与教学能力真题及答案.doc

2018上半年江西教师资格初中地理学科知识与教学能力真题及答案.doc 2012年河北国家公务员申论考试真题及答案-省级.doc

2012年河北国家公务员申论考试真题及答案-省级.doc 2020-2021学年江苏省扬州市江都区邵樊片九年级上学期数学第一次质量检测试题及答案.doc

2020-2021学年江苏省扬州市江都区邵樊片九年级上学期数学第一次质量检测试题及答案.doc 2022下半年黑龙江教师资格证中学综合素质真题及答案.doc

2022下半年黑龙江教师资格证中学综合素质真题及答案.doc