PPC-5350GS Flat Panel PC

0-1

1

�

REVISION HISTORY

Title

Revision Number

1.0

ABOUT THIS MANUAL

PPC-5350GS Flat Panel PC User Manual

Description

Initial release

Date of Issue

July 2006

This document covers the description and installation instructions for the PPC-5350GS flat

panel PC.

COPYRIGHT NOTICE

This document is copyrighted 2006, by IEI Technology Corp. All rights are reserved. IEI

Technology Corp. reserves the rights to alter the products described in this manual at any

time without prior notice.

This document contains proprietary information protected by copyright. All rights are

reserved. No part of this manual may be reproduced by any mechanical, electronic, or

other means in any form without prior written permission of the manufacturer.

Information provided in this manual is intended to be accurate and reliable. However, IEI

Technology Corp. assumes no responsibility for use of this manual, nor for any

infringements upon the rights of third parties, which may result from such use.

TRADEMARKS

Intel is a registered trademark of Intel Corporation. AMI is registered trademarks of

American Megatrends Inc. Other product names mentioned herein are used for

identification purposes only and may be trademarks and/or registered trademarks of their

respective owners.

2

0-2

IEI® Technology, Corp.

�

PPC-5350GS Flat Panel PC

PACKING LIST

Before installing the LCD workstation, please make sure that the following items have been

shipped:

1 x Carton

1 x Power cable

1 x IDE cable

1 x CPU cooler

1 x Driver CD

1 x Supplementary screw set

If any of these items are missing or damaged, contact the distributor or sales

representative immediately.

PRECAUTIONS

SAFETY PRECAUTIONS

1. Prior to installing, moving, and modifying the workstation, make sure that

the unit’s power is turned off and the power cord is disconnected.

2. Do not apply voltage levels that exceed the specified voltage range.

Doing so may cause fire or an electrical shock.

3. Electric shock can occur if the panel is opened. Do not drop or insert

any objects into the ventilation openings of the workstation.

4. Only qualified engineers from certified system integrators or VARs are

allowed to make necessary functional modifications to the workstation,

e.g., adding a touch screen. IEI offers the customization service on a

pre-order basis.

If considerable amount of dust, water, or fluids entered the workstation,

turn off the power supply immediately, unplug the power cord, and contact

the vendor.

5.

6. Explosions may occur with installations in environments where flammable

gases are present.

7. Fault-tolerant and failsafe designs should be implemented with the use of

the series models on transportation vehicles, ships, safety/security

devices, or medical devices not related to life-support functionalities.

0-3

3

�

Users/integrators should take the responsibility for implementations with

adequate levels of reliability and safety.

8. Preventive designs should be implemented so as to avoid the

communications faults between the workstation and the

PC/workstation/terminals that controls it. 0.

HANDLING PRECAUTIONS

1. Do not drop the workstation against a hard surface. Doing so may

damage the display.

2. Do not strike or exert excessive force onto the touch panel.

3. Touching the touch panel using a sharp object may damage the LCD

panel.

4. Avoid environments exposed to direct sunlight, dust, or chemical vapors.

5. The workstation is actively cooled. In no circumstances should the

workstation operate with the openings obstructed by foreign objects.

However, the ambient temperature of the installation site should be

observed and controlled to avoid overheating the workstation.

6. Condensation might form inside the workstation chassis if exposed to

sudden changes in temperature.

7. Carefully route the power cord so that people cannot step on it. Do not

8.

9.

place anything over the power cord.

If the equipment should be left unused for an extended period of time,

disconnect it from the power source to avoid damage by transient

over-voltage.

If any of the following situations arises, get the equipment checked by

service personnel: 0.

o The power cord or plug is damaged.

o Liquid has penetrated into the equipment.

o The equipment has been exposed to moisture.

o The equipment does not work properly, or the user cannot get it to

work according to the user manual.

o The equipment has been dropped and damaged.

o The equipment shows obvious signs of breakage.

4

0-4

IEI® Technology, Corp.

�

PPC-5350GS Flat Panel PC

WARNING!

Any changes or modifications made to the equipment that are not

expressly approved by the relevant standards could void the authority to

operate the equipment.

ADDITIONAL INFORMATION

MAINTENANCE AND CLEANING

Note the following precautions before beginning to clean the LCD workstation.

When cleaning any single part or component of the computer, please read and understand

the details below fully.

Except for the properly installed front LCD panel, never spray or squirt liquids

directly onto any computer component. To clean the device, please rub it with

a piece of dry and soft cloth or a slightly moistened cloth with the exterior

casing.

The interior of the LCD workstation does not require cleaning. Keep fluids

away from the LCD workstation and the interior of it.

Be cautious of the tiny removable components when using a vacuum cleaner

to absorb the dirt on the floor.

Turn the system off before cleaning up the LCD workstation.

Never drop any tiny objects through the openings of the LCD workstation or

get circuit board damp or wet.

Be cautious of all kinds of cleaning solvents or chemicals when using it for the

sake of cleaning. Some individuals may be allergic to the ingredients.

Avoid any food, drink or cigarette around the LCD workstation.

0-5

5

�

CLEANING TOOLS

Although many companies have created products to help improve the process of cleaning

the computer and peripherals, users can also use household items to clean their

computers and peripherals. Below is a list of items to use while cleaning the computer or

computer peripherals.

Please keep in mind that some components in the computer may only be cleaned using a

product designed for cleaning that component, if this is the case it will be mentioned in the

cleaning tips.

Cloth - A piece of cloth is the best tool to use when rubbing up a component.

Although paper towels or tissues can be used on most hardware as well, it is l

recommended to rub it with a piece of cloth.

Water or rubbing alcohol – Moisten a piece of cloth a bit with some water or

rubbing alcohol and rub it on the computer.

Unknown solvents may be harmful to the plastics parts.

Vacuum cleaner - Absorb the dust, dirt, hair, cigarette particles, and other

particles out of a computer can be one of the best methods of cleaning a

computer. Over time these items can restrict the airflow in a computer and

cause circuitry to corrode.

Cotton swabs - Cotton swaps moistened with rubbing alcohol or water are

excellent tools for wiping hard to reach areas in the keyboard, mouse, and

other locations.

Foam swabs - Whenever possible it is better to use lint free swabs such as

foam swabs.

ESD PRECAUTIONS

Observe all conventional anti-ESD methods while handling the components contained

within the LCD should the need arise for adding a functionality. The use of a grounded

wrist strap and an anti-static work pad is recommended. Avoid dust and debris or other

static-accumulating materials in the work area.

6

0-6

IEI® Technology, Corp.

�

PPC-5350GS Flat Panel PC

MANUAL CONVENTIONS

WARNING!

Warnings appear where overlooked details may cause damage to the equipment or result

in personal injury. Warnings should be taken seriously. Warnings are easy to recognize.

The word “warning” is written as “WARNING,” both capitalized and bold and is followed by

text in italics. The italicized text is the warning message.

CAUTION!

Cautionary messages should also be heeded to reduce the chance of losing data or

damaging the system. Cautions are easy to recognize. The word “caution” is written as

“CAUTION,” both capitalized and bold and is followed by text in italics. The italicized text is

the cautionary message.

NOTE:

These messages inform the reader of essential but non-critical information. These

messages should be read carefully as any directions or instructions contained therein can

avoid making mistakes. Notes are easy to recognize. The word “note” is written as “NOTE,”

both capitalized and bold and is followed by text in italics. The italicized text is the

cautionary message.

Lists

Bulleted Lists: Bulleted lists are statements of non-sequential facts that can be read in

any order. Each statement is preceded by a round black dot “•” or bullets in other shapes.

Numbered Lists: Numbered lists describe sequential steps should be followed in order.

0-7

7

�

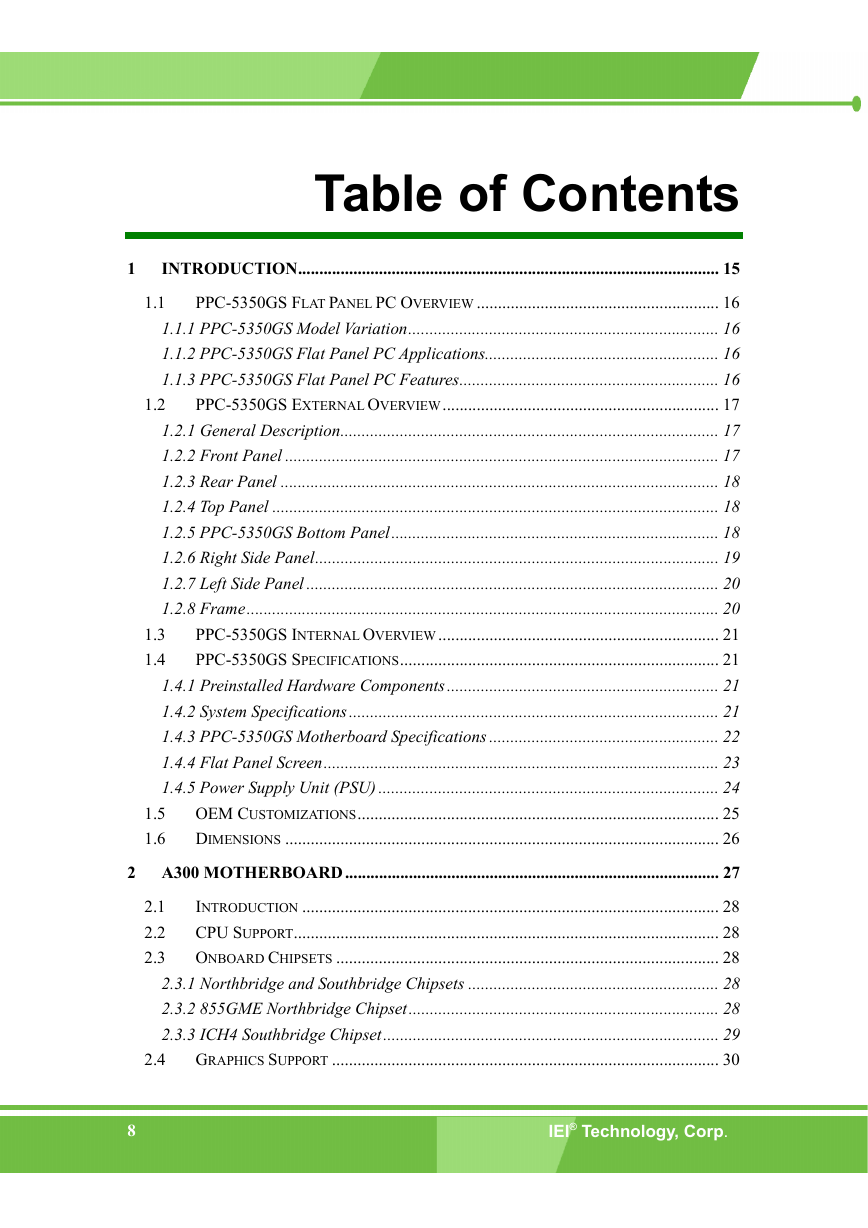

Table of Contents

1

INTRODUCTION................................................................................................... 15

1.1

1.2

PPC-5350GS FLAT PANEL PC OVERVIEW ......................................................... 16

1.1.1 PPC-5350GS Model Variation......................................................................... 16

1.1.2 PPC-5350GS Flat Panel PC Applications....................................................... 16

1.1.3 PPC-5350GS Flat Panel PC Features............................................................. 16

PPC-5350GS EXTERNAL OVERVIEW................................................................. 17

1.2.1 General Description......................................................................................... 17

1.2.2 Front Panel ...................................................................................................... 17

1.2.3 Rear Panel ....................................................................................................... 18

1.2.4 Top Panel ......................................................................................................... 18

1.2.5 PPC-5350GS Bottom Panel............................................................................. 18

1.2.6 Right Side Panel............................................................................................... 19

1.2.7 Left Side Panel ................................................................................................. 20

1.2.8 Frame............................................................................................................... 20

PPC-5350GS INTERNAL OVERVIEW.................................................................. 21

PPC-5350GS SPECIFICATIONS........................................................................... 21

1.4.1 Preinstalled Hardware Components................................................................ 21

1.4.2 System Specifications....................................................................................... 21

1.4.3 PPC-5350GS Motherboard Specifications ...................................................... 22

1.4.4 Flat Panel Screen............................................................................................. 23

1.4.5 Power Supply Unit (PSU) ................................................................................ 24

OEM CUSTOMIZATIONS..................................................................................... 25

DIMENSIONS ...................................................................................................... 26

1.3

1.4

1.5

1.6

2 A300 MOTHERBOARD........................................................................................ 27

2.1

2.2

2.3

INTRODUCTION .................................................................................................. 28

CPU SUPPORT.................................................................................................... 28

ONBOARD CHIPSETS .......................................................................................... 28

2.3.1 Northbridge and Southbridge Chipsets ........................................................... 28

2.3.2 855GME Northbridge Chipset......................................................................... 28

2.3.3 ICH4 Southbridge Chipset............................................................................... 29

GRAPHICS SUPPORT ........................................................................................... 30

2.4

8

0-8

IEI® Technology, Corp.

�

2023年江西萍乡中考道德与法治真题及答案.doc

2023年江西萍乡中考道德与法治真题及答案.doc 2012年重庆南川中考生物真题及答案.doc

2012年重庆南川中考生物真题及答案.doc 2013年江西师范大学地理学综合及文艺理论基础考研真题.doc

2013年江西师范大学地理学综合及文艺理论基础考研真题.doc 2020年四川甘孜小升初语文真题及答案I卷.doc

2020年四川甘孜小升初语文真题及答案I卷.doc 2020年注册岩土工程师专业基础考试真题及答案.doc

2020年注册岩土工程师专业基础考试真题及答案.doc 2023-2024学年福建省厦门市九年级上学期数学月考试题及答案.doc

2023-2024学年福建省厦门市九年级上学期数学月考试题及答案.doc 2021-2022学年辽宁省沈阳市大东区九年级上学期语文期末试题及答案.doc

2021-2022学年辽宁省沈阳市大东区九年级上学期语文期末试题及答案.doc 2022-2023学年北京东城区初三第一学期物理期末试卷及答案.doc

2022-2023学年北京东城区初三第一学期物理期末试卷及答案.doc 2018上半年江西教师资格初中地理学科知识与教学能力真题及答案.doc

2018上半年江西教师资格初中地理学科知识与教学能力真题及答案.doc 2012年河北国家公务员申论考试真题及答案-省级.doc

2012年河北国家公务员申论考试真题及答案-省级.doc 2020-2021学年江苏省扬州市江都区邵樊片九年级上学期数学第一次质量检测试题及答案.doc

2020-2021学年江苏省扬州市江都区邵樊片九年级上学期数学第一次质量检测试题及答案.doc 2022下半年黑龙江教师资格证中学综合素质真题及答案.doc

2022下半年黑龙江教师资格证中学综合素质真题及答案.doc