Title

Reference Design Report for a 1.1 W Power

Factor Corrected LED Driver (Non-Isolated)

Using LinkSwitchTM-PL LNK454DG

Specification 85 VAC – 265 VAC, >0.85 PF Input;

2.5 V – 3.5 V, 366 mA 10% Output

Application

LED Driver for Candelabra Lamp Replacement

Author

Applications Engineering Department

Document

Number

Date

Revision

April 4, 2011

1.2

RDR-268

Summary and Features

Single stage power factor correction and accurate constant current (CC) output

Low cost, low component count and small PCB footprint solution

Superior performance and end user experience

o Clean monotonic start-up – no output blinking

o Fast start-up (<300 ms) – no perceptible delay

Universal input

Integrated protection and reliability features

o Output open-circuit protected / output short-circuit protected with auto-recovery

o Auto-recovering thermal shutdown with large hysteresis protects both components and printed

o No damage during brown out conditions

o Extended pin creepage distance between device DRAIN pin and other pins for reliable

circuit board

operation in high pollution and humid environments

Surge protected for high reliability

o Meets IEC ringwave and differential mode surge

Meets EN55015 conducted EMI

PF >0.9 at 115 VAC and PF>0.85 at 230 VAC

%ATHD <15% at 115 VAC and <25% at 230 VAC

Meets EN61000-3-2 harmonic current requirements

Power Integrations

5245 Hellyer Avenue, San Jose, CA 95138 USA.

Tel: +1 408 414 9200 Fax: +1 408 414 9201

www.powerint.com

�

04-Apr-11

RDR-268 1.1 W PF Corrected LED Power Supply

PATENT INFORMATION

The products and applications illustrated herein (including transformer construction and circuits external to the products) may be covered

by one or more U.S. and foreign patents, or potentially by pending U.S. and foreign patent applications assigned to Power Integrations. A

complete list of Power Integrations' patents may be found at www.powerint.com. Power Integrations grants its customers a license under

certain patent rights as set forth at .

Power Integrations, Inc.

Tel: +1 408 414 9200 Fax: +1 408 414 9201

www.powerint.com

Page 2 of 54

�

04-Apr-11

RDR-268 1.1 W PF Corrected LED Power Supply

Table of Contents

1

Introduction .................................................................................................................5

2 Power Supply Specification ........................................................................................8

3 Schematic ...................................................................................................................9

4 Circuit Description.....................................................................................................10

Input EMI Filtering and Input Rectification .........................................................10

4.1

4.2

LinkSwitch-PL Primary.......................................................................................10

4.3 Output Rectification ...........................................................................................11

4.4 Output Feedback ...............................................................................................11

5 PCB Layout...............................................................................................................12

6 Bill of Materials .........................................................................................................16

7 Transformer Design Spreadsheet.............................................................................17

8 Transformer Specification .........................................................................................19

Electrical Diagram..............................................................................................19

8.1

Electrical Specifications .....................................................................................19

8.2

8.3 Materials ............................................................................................................19

Transformer Build Diagram................................................................................20

8.4

8.5

Transformer Construction ..................................................................................20

8.6 Winding Illustrations...........................................................................................21

9 Performance Data.....................................................................................................23

9.1

Active Mode Efficiency.......................................................................................23

9.2 Harmonics .........................................................................................................24

9.3

Power Factor .....................................................................................................27

Line Regulation..................................................................................................28

9.4

Thermal Performance............................................................................................30

10.1 Thermal Set-up..................................................................................................30

10.2 Equipment Used ................................................................................................31

10.3 Thermal Result ..................................................................................................31

10.3.1 Startup at Low Temperatures .....................................................................31

10.3.2 Operation at Maximum Ambient .................................................................31

10.4 Thermal Scan ....................................................................................................32

10.4.1 Load: 3 V / 366 mA.....................................................................................32

11 Waveforms ............................................................................................................33

11.1 Drain Voltage and Current .................................................................................33

11.1.1 Normal Steady-State Operation..................................................................33

11.1.2 AC Start-up.................................................................................................35

11.1.3 Fault Conditions (Output Shorted / Open Circuit) .......................................36

11.2 Output Current Start-up Profile ..........................................................................37

Input and Output Waveforms.............................................................................38

11.3

11.3.1 Normal Operation (VIN, IIN, VO and IO).........................................................38

11.4 Line Transient Response...................................................................................39

11.5 Brownout ...........................................................................................................44

Line Surge.............................................................................................................45

12.1 Line Surge Drain Voltage waveforms. ...............................................................45

12.2 Conducted EMI..................................................................................................46

12

10

Page 3 of 54

Power Integrations

Tel: +1 408 414 9200 Fax: +1 408 414 9201

www.powerint.com

�

RDR-268 1.1 W PF Corrected LED Power Supply

04-Apr-11

12.3 Equipment: ........................................................................................................46

12.4 EMI Test Set-up ................................................................................................46

Output Current Production Distribution .................................................................51

Revision History ....................................................................................................53

13

14

Important Note:

This board is designed for non-isolated application and the engineering prototype has not

been agency approved. Therefore, all testing should be performed using an isolation

transformer to provide the AC input to the prototype board.

Power Integrations, Inc.

Tel: +1 408 414 9200 Fax: +1 408 414 9201

www.powerint.com

Page 4 of 54

�

04-Apr-11

RDR-268 1.1 W PF Corrected LED Power Supply

Introduction

1

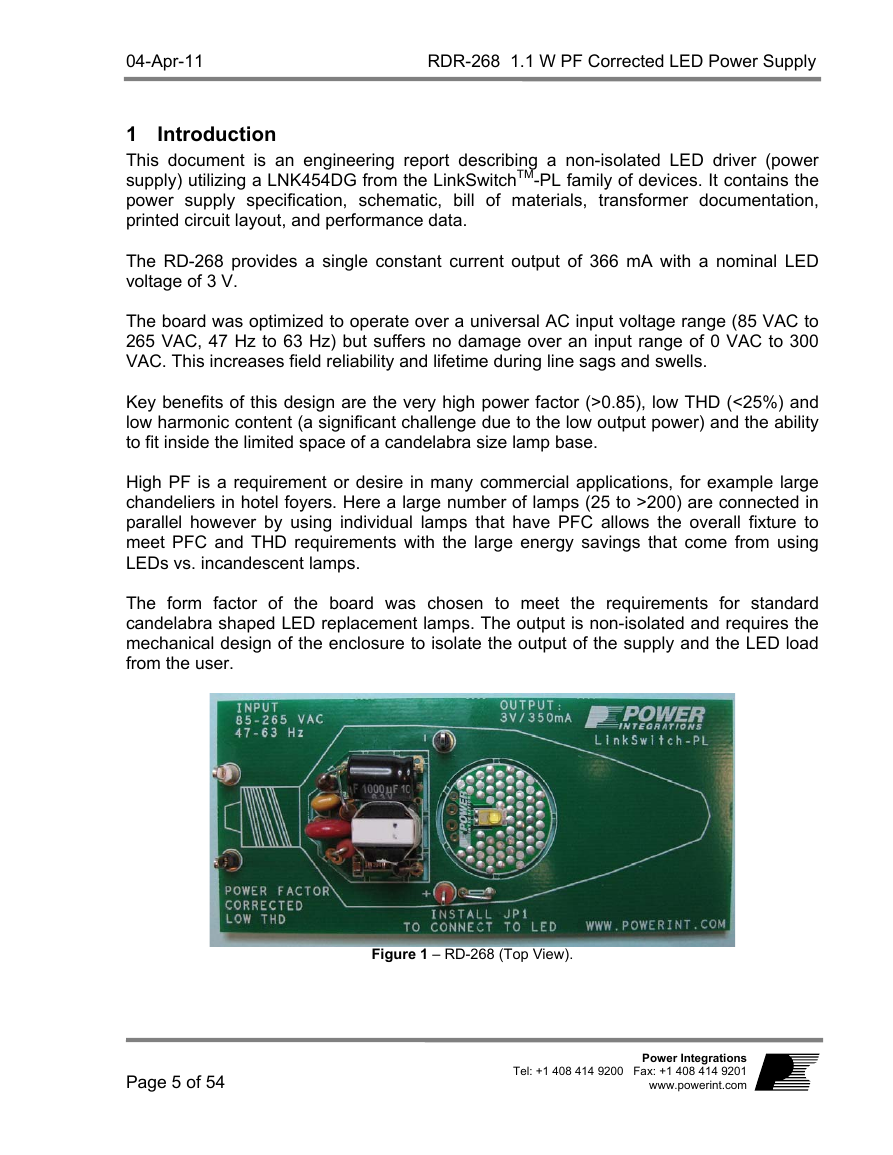

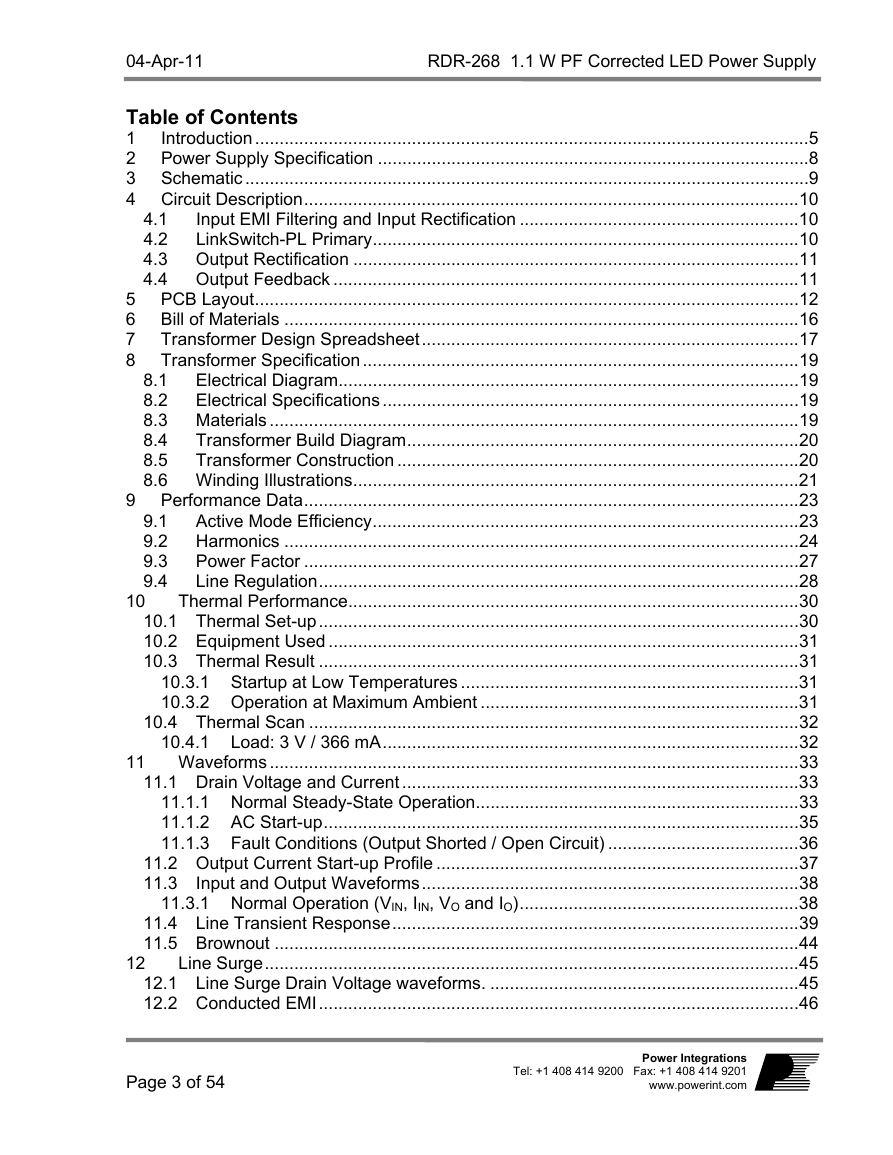

This document is an engineering report describing a non-isolated LED driver (power

supply) utilizing a LNK454DG from the LinkSwitchTM-PL family of devices. It contains the

power supply specification, schematic, bill of materials, transformer documentation,

printed circuit layout, and performance data.

The RD-268 provides a single constant current output of 366 mA with a nominal LED

voltage of 3 V.

The board was optimized to operate over a universal AC input voltage range (85 VAC to

265 VAC, 47 Hz to 63 Hz) but suffers no damage over an input range of 0 VAC to 300

VAC. This increases field reliability and lifetime during line sags and swells.

Key benefits of this design are the very high power factor (>0.85), low THD (<25%) and

low harmonic content (a significant challenge due to the low output power) and the ability

to fit inside the limited space of a candelabra size lamp base.

High PF is a requirement or desire in many commercial applications, for example large

chandeliers in hotel foyers. Here a large number of lamps (25 to >200) are connected in

parallel however by using individual lamps that have PFC allows the overall fixture to

meet PFC and THD requirements with the large energy savings that come from using

LEDs vs. incandescent lamps.

The form factor of the board was chosen to meet the requirements for standard

candelabra shaped LED replacement lamps. The output is non-isolated and requires the

mechanical design of the enclosure to isolate the output of the supply and the LED load

from the user.

Figure 1 – RD-268 (Top View).

Page 5 of 54

Power Integrations

Tel: +1 408 414 9200 Fax: +1 408 414 9201

www.powerint.com

�

RDR-268 1.1 W PF Corrected LED Power Supply

04-Apr-11

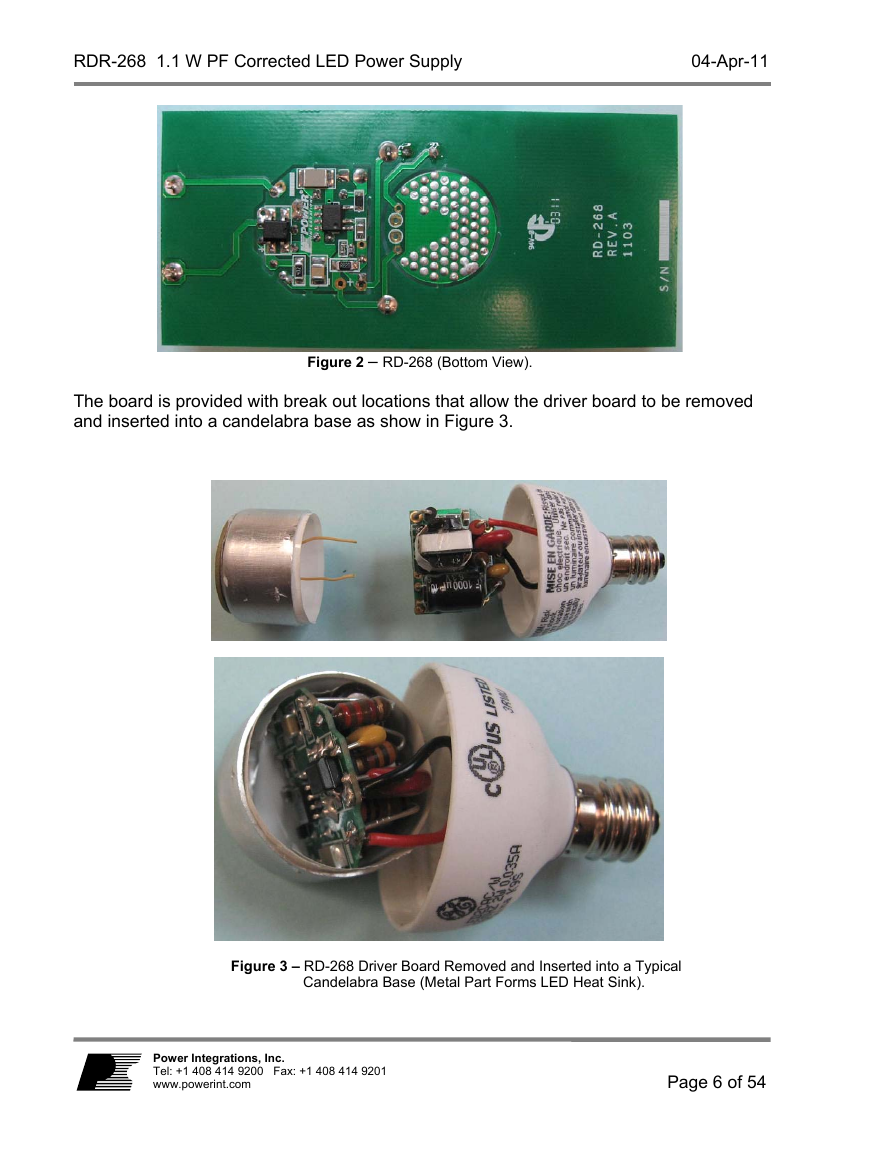

Figure 2 – RD-268 (Bottom View).

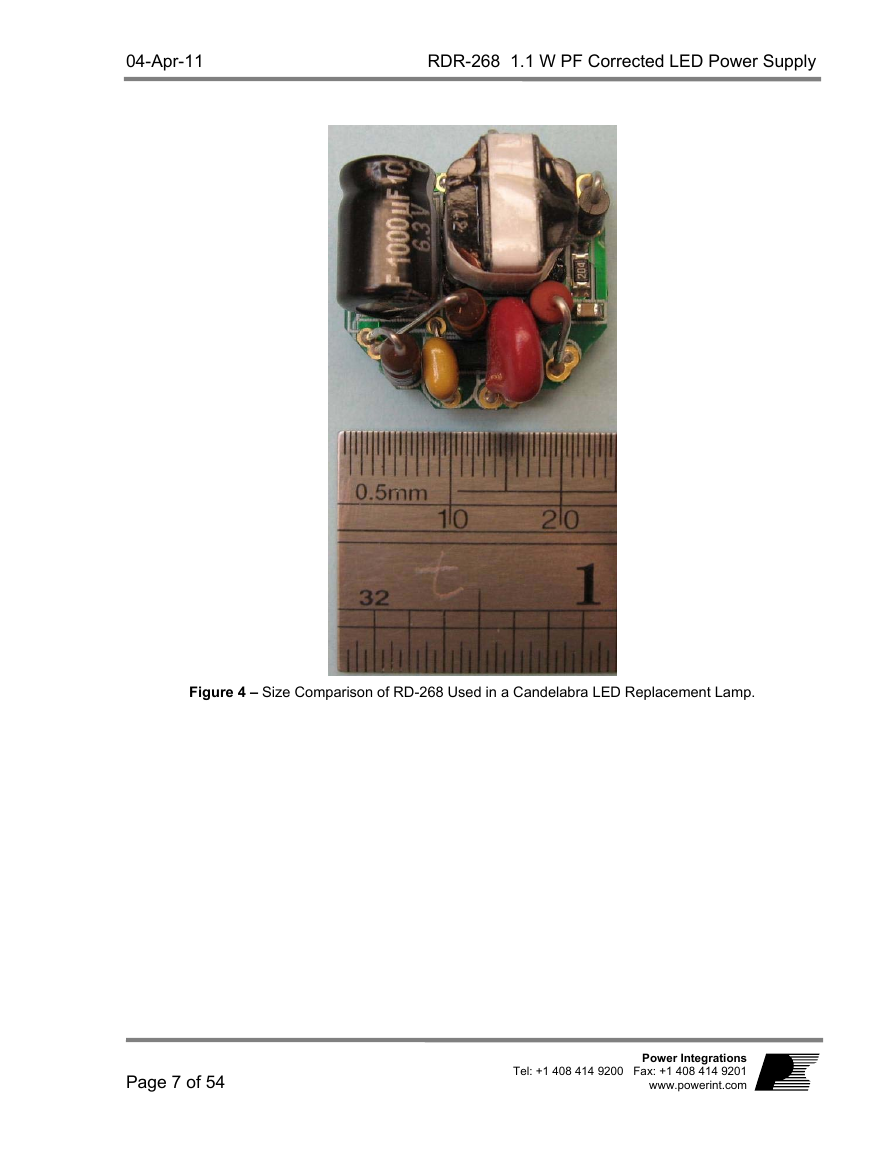

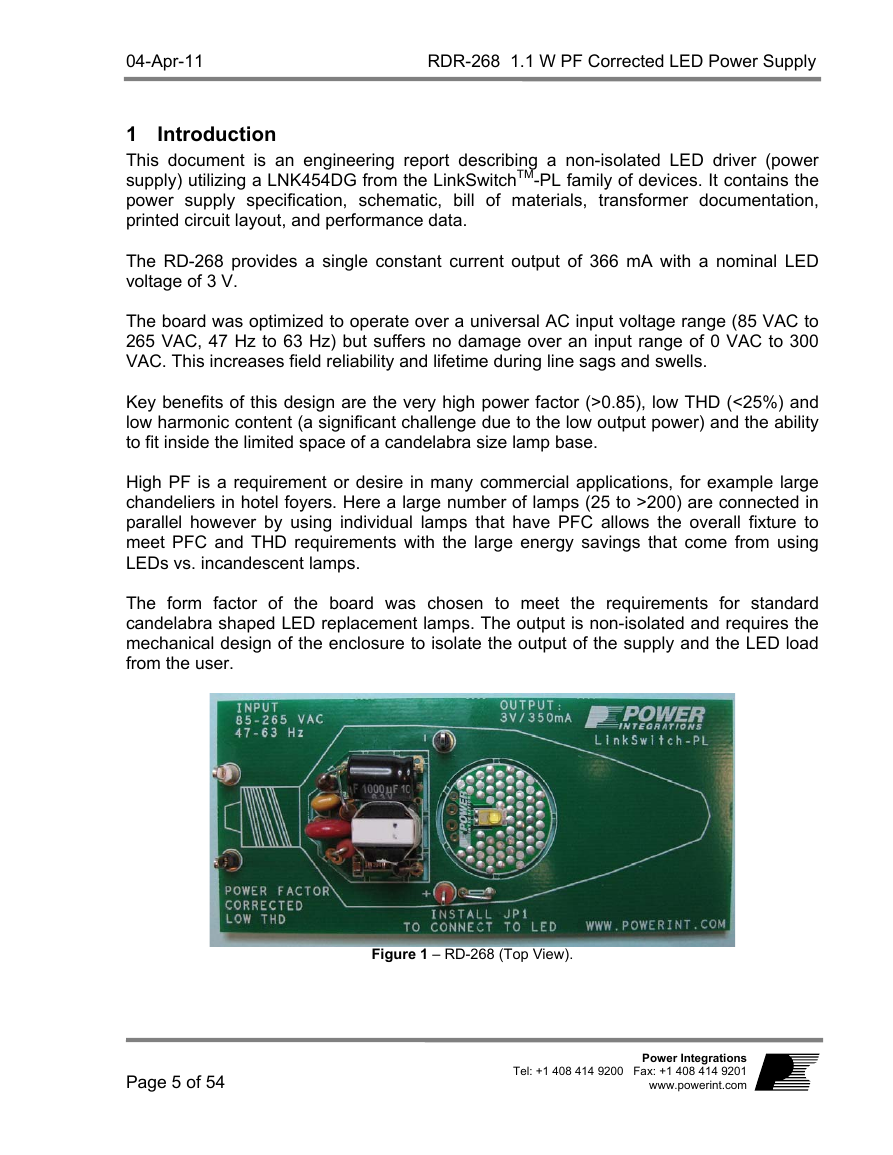

The board is provided with break out locations that allow the driver board to be removed

and inserted into a candelabra base as show in Figure 3.

Figure 3 – RD-268 Driver Board Removed and Inserted into a Typical

Candelabra Base (Metal Part Forms LED Heat Sink).

Power Integrations, Inc.

Tel: +1 408 414 9200 Fax: +1 408 414 9201

www.powerint.com

Page 6 of 54

�

04-Apr-11

RDR-268 1.1 W PF Corrected LED Power Supply

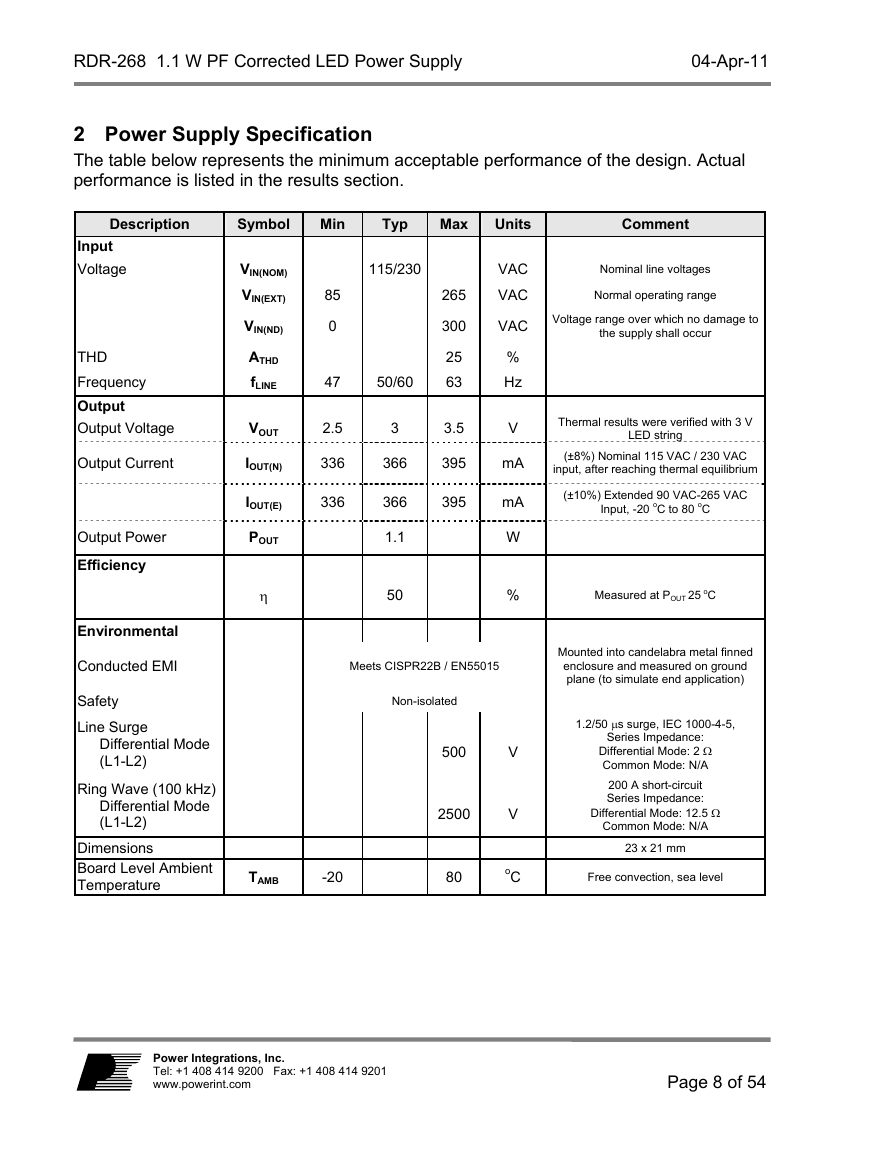

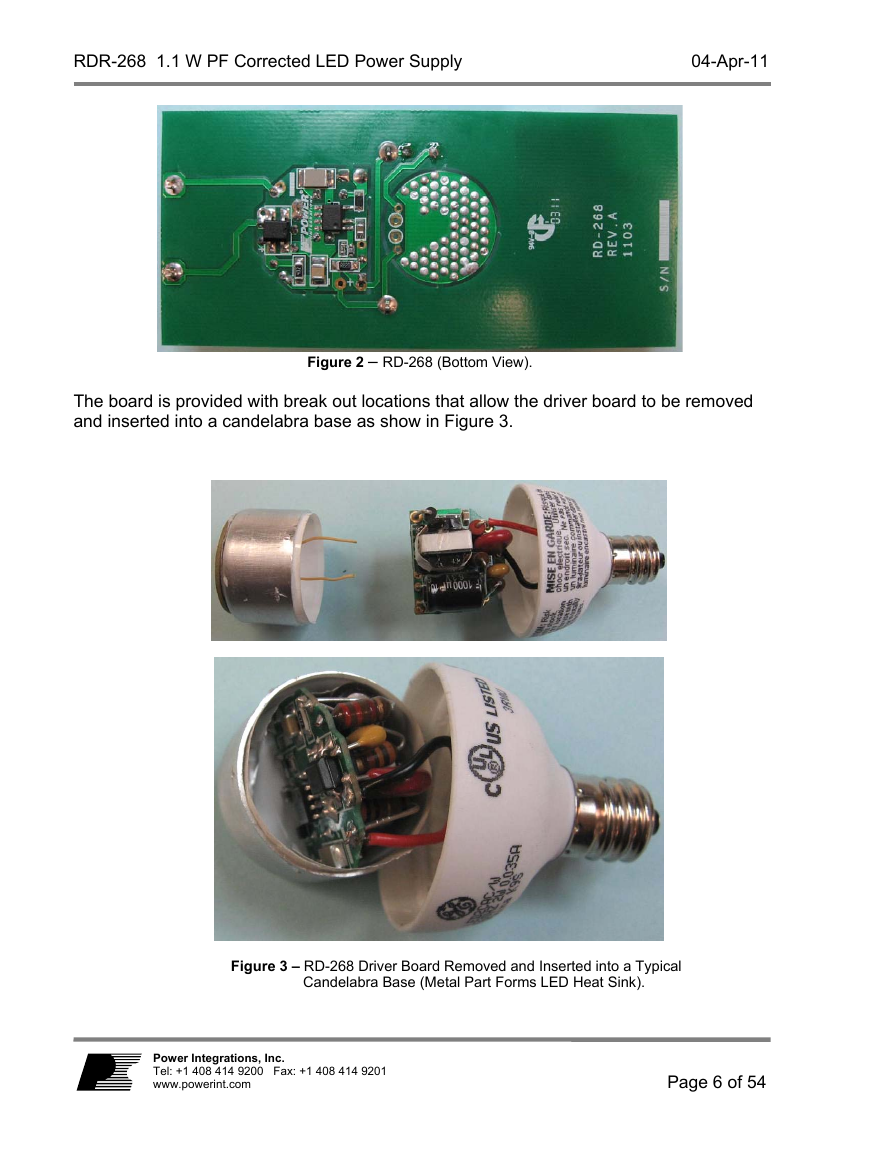

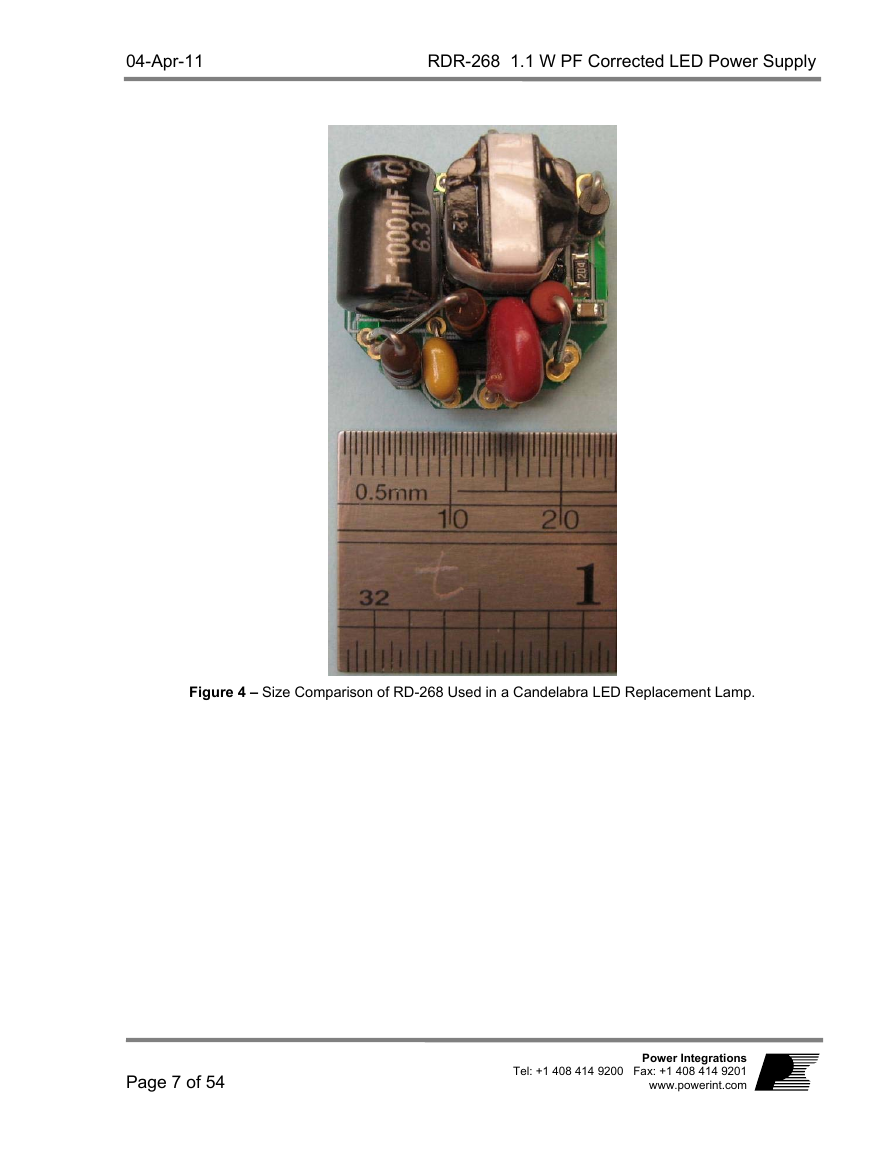

Figure 4 – Size Comparison of RD-268 Used in a Candelabra LED Replacement Lamp.

Page 7 of 54

Power Integrations

Tel: +1 408 414 9200 Fax: +1 408 414 9201

www.powerint.com

�

115/230

50/60

3

366

366

1.1

50

265

300

25

63

3.5

395

395

VAC

VAC

VAC

%

Hz

V

mA

mA

W

%

Meets CISPR22B / EN55015

Comment

Nominal line voltages

Normal operating range

Voltage range over which no damage to

the supply shall occur

Thermal results were verified with 3 V

LED string

(±8%) Nominal 115 VAC / 230 VAC

input, after reaching thermal equilibrium

(±10%) Extended 90 VAC-265 VAC

Input, -20 oC to 80 oC

Measured at POUT 25 oC

Mounted into candelabra metal finned

enclosure and measured on ground

plane (to simulate end application)

Input

Voltage

THD

Frequency

Output

Output Voltage

Output Current

Output Power

Efficiency

Environmental

Conducted EMI

Safety

Line Surge

Differential Mode

(L1-L2)

Ring Wave (100 kHz)

Differential Mode

(L1-L2)

Dimensions

Board Level Ambient

Temperature

VIN(NOM)

VIN(EXT)

VIN(ND)

ATHD

fLINE

VOUT

IOUT(N)

IOUT(E)

POUT

85

0

47

2.5

336

336

TAMB

-20

RDR-268 1.1 W PF Corrected LED Power Supply

04-Apr-11

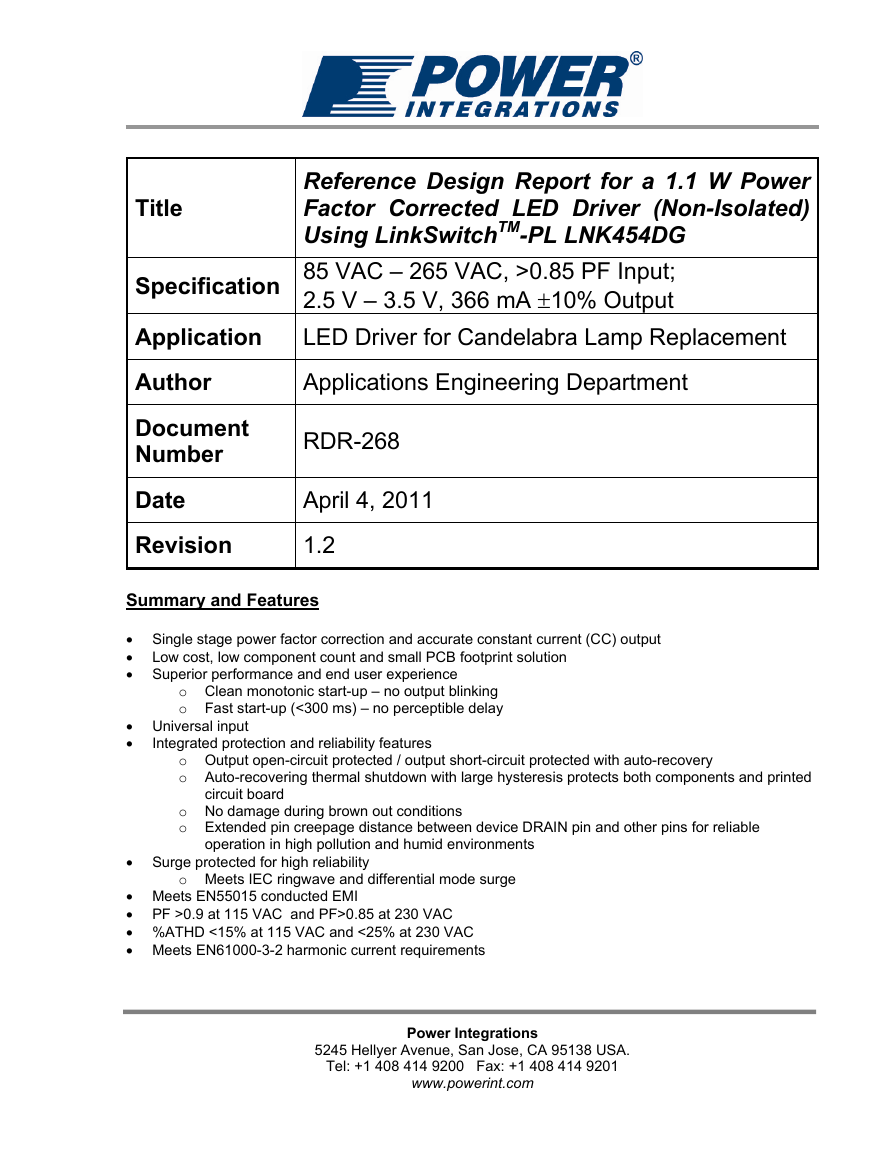

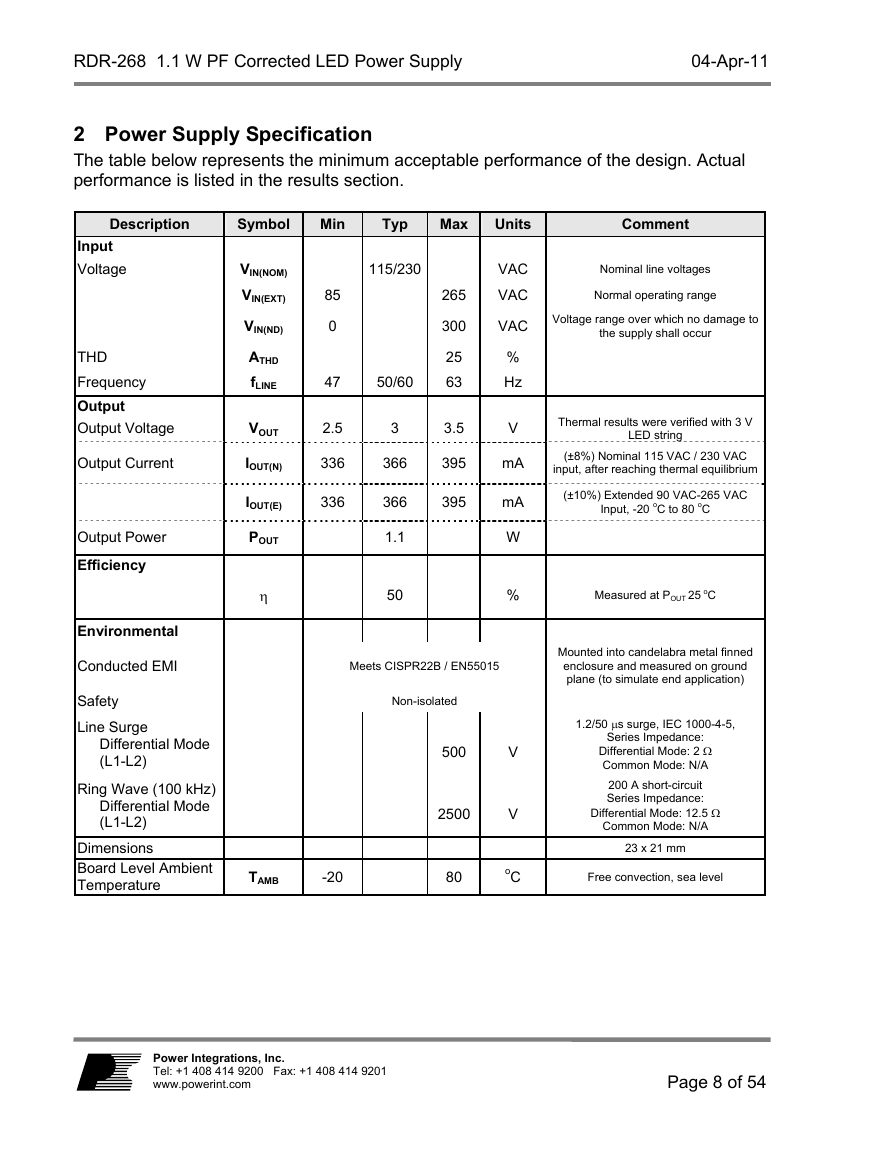

2 Power Supply Specification

The table below represents the minimum acceptable performance of the design. Actual

performance is listed in the results section.

Description

Symbol

Min

Typ

Max

Units

Non-isolated

500

2500

80

V

V

oC

1.2/50 s surge, IEC 1000-4-5,

Series Impedance:

Differential Mode: 2

Common Mode: N/A

200 A short-circuit

Series Impedance:

Differential Mode: 12.5

Common Mode: N/A

23 x 21 mm

Free convection, sea level

Power Integrations, Inc.

Tel: +1 408 414 9200 Fax: +1 408 414 9201

www.powerint.com

Page 8 of 54

�

2023年江西萍乡中考道德与法治真题及答案.doc

2023年江西萍乡中考道德与法治真题及答案.doc 2012年重庆南川中考生物真题及答案.doc

2012年重庆南川中考生物真题及答案.doc 2013年江西师范大学地理学综合及文艺理论基础考研真题.doc

2013年江西师范大学地理学综合及文艺理论基础考研真题.doc 2020年四川甘孜小升初语文真题及答案I卷.doc

2020年四川甘孜小升初语文真题及答案I卷.doc 2020年注册岩土工程师专业基础考试真题及答案.doc

2020年注册岩土工程师专业基础考试真题及答案.doc 2023-2024学年福建省厦门市九年级上学期数学月考试题及答案.doc

2023-2024学年福建省厦门市九年级上学期数学月考试题及答案.doc 2021-2022学年辽宁省沈阳市大东区九年级上学期语文期末试题及答案.doc

2021-2022学年辽宁省沈阳市大东区九年级上学期语文期末试题及答案.doc 2022-2023学年北京东城区初三第一学期物理期末试卷及答案.doc

2022-2023学年北京东城区初三第一学期物理期末试卷及答案.doc 2018上半年江西教师资格初中地理学科知识与教学能力真题及答案.doc

2018上半年江西教师资格初中地理学科知识与教学能力真题及答案.doc 2012年河北国家公务员申论考试真题及答案-省级.doc

2012年河北国家公务员申论考试真题及答案-省级.doc 2020-2021学年江苏省扬州市江都区邵樊片九年级上学期数学第一次质量检测试题及答案.doc

2020-2021学年江苏省扬州市江都区邵樊片九年级上学期数学第一次质量检测试题及答案.doc 2022下半年黑龙江教师资格证中学综合素质真题及答案.doc

2022下半年黑龙江教师资格证中学综合素质真题及答案.doc