IEEE TRANSACTIONS ON ENERGY CONVERSION, VOL. 19, NO. 3, SEPTEMBER 2004

469

Design and Implementation of PLC-Based

Monitoring Control System for Induction Motor

Maria G. Ioannides, Senior Member, IEEE

Abstract—The implementation of a monitoring and control

system for the induction motor based on programmable logic con-

troller (PLC) technology is described. Also, the implementation of

the hardware and software for speed control and protection with

the results obtained from tests on induction motor performance

is provided. The PLC correlates the operational parameters to

the speed requested by the user and monitors the system during

normal operation and under trip conditions. Tests of the induction

motor system driven by inverter and controlled by PLC prove a

higher accuracy in speed regulation as compared to a conventional

V f control system. The efficiency of PLC control is increased

at high speeds up to 95% of the synchronous speed. Thus, PLC

proves themselves as a very versatile and effective tool in industrial

control of electric drives.

Index Terms—Computer-controlled systems,

monitoring, electric drives,

logic

programmable

drives, voltage control.

computerized

induction motors, motion control,

(PLCs), variable-frequency

controllers

I. INTRODUCTION

S INCE technology for motion control of electric drives be-

came available, the use of programmable logic controllers

(PLCs) with power electronics in electric machines applications

has been introduced in the manufacturing automation [1], [2].

This use offers advantages such as lower voltage drop when

turned on and the ability to control motors and other equip-

ment with a virtually unity power factor [3]. Many factories

use PLCs in automation processes to diminish production cost

and to increase quality and reliability [4]–[9]. Other applica-

tions include machine tools with improved precision comput-

erized numerical control (CNC) due to the use of PLCs [10].

To obtain accurate industrial electric drive systems, it is nec-

essary to use PLCs interfaced with power converters, personal

computers, and other electric equipment [11]–[13]. Neverthe-

less, this makes the equipment more sophisticated, complex, and

expensive [14], [15].

Few papers were published concerning dc machines con-

trolled by PLCs. They report both the implementation of the

fuzzy method for speed control of a dc motor/generator set

using a PLC to change the armature voltage [16], and the

incorporation of an adaptive controller based on the self-tuning

regulator technology into an existing industrial PLC [17]. Also,

other types of machines were interfaced with PLCs. Thereby,

an industrial PLC was used for controlling stepper motors

Manuscript received December 2, 2002. Paper no. TEC-00004-2002. This

work was supported by the National Technical University of Athens.

The author is with the Faculty of Electrical and Computer Engineering of

the National Technical University of Athens, Athens 15773, Greece (e-mail:

mioannid@ece.ntua.gr).

Digital Object Identifier 10.1109/TEC.2003.822303

in a five-axis rotor position, direction and speed, reducing

the number of circuit components, lowering the cost, and

enhancing reliability [18]. For switched reluctance motors as

a possible alternative to adjustable speed ac and dc drives, a

single chip logic controller for controlling torque and speed

uses a PLC to implement the digital logic coupled with a power

controller [19]. Other reported application concerns a linear

induction motor for passenger elevators with a PLC achieving

the control of the drive system and the data acquisition [20].

To monitor power quality and identify the disturbances that

disrupt production of an electric plant, two PLCs were used to

determine the sensitivity of the equipment [21].

Only few papers were published in the field of induction

motors with PLCs. A power factor controller for a three-phase

induction motor utilizes PLC to improve the power factor and

to keep its voltage to frequency ratio constant under the whole

control conditions [3]. The vector control integrated circuit

uses a complex programmable logic device (CPLD) and integer

arithmetic for the voltage or current regulation of three-phase

pulse-width modulation (PWM) inverters [22].

Many applications of induction motors require besides the

motor control functionality, the handling of several specific

analog and digital I/O signals, home signals,

trip signals,

on/off/reverse commands. In such cases, a control unit in-

volving a PLC must be added to the system structure. This

paper presents a PLC-based monitoring and control system

for a three-phase induction motor. It describes the design and

implementation of the configured hardware and software. The

test results obtained on induction motor performance show

improved efficiency and increased accuracy in variable-load

constant-speed-controlled operation. Thus, the PLC correlates

and controls the operational parameters to the speed set point

requested by the user and monitors the induction motor system

during normal operation and under trip conditions.

II. PLC AS SYSTEM CONTROLLER

A PLC is a microprocessor-based control system, designed

for automation processes in industrial environments. It uses a

programmable memory for the internal storage of user-orien-

tated instructions for implementing specific functions such as

arithmetic, counting, logic, sequencing, and timing [23], [24].

A PLC can be programmed to sense, activate, and control in-

dustrial equipment and, therefore, incorporates a number of I/O

points, which allow electrical signals to be interfaced. Input de-

vices and output devices of the process are connected to the

PLC and the control program is entered into the PLC memory

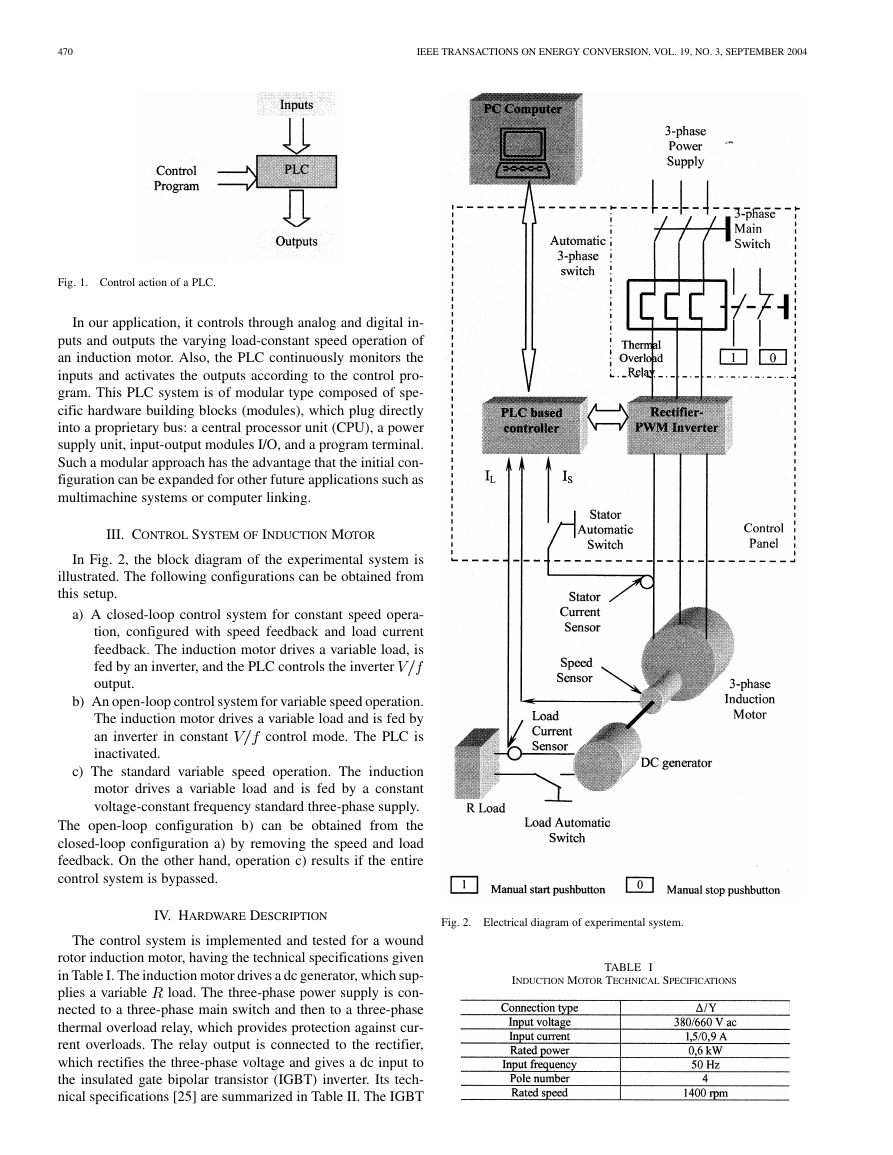

(Fig. 1).

0885-8969/04$20.00 © 2004 IEEE

�

470

IEEE TRANSACTIONS ON ENERGY CONVERSION, VOL. 19, NO. 3, SEPTEMBER 2004

Fig. 1. Control action of a PLC.

In our application, it controls through analog and digital in-

puts and outputs the varying load-constant speed operation of

an induction motor. Also, the PLC continuously monitors the

inputs and activates the outputs according to the control pro-

gram. This PLC system is of modular type composed of spe-

cific hardware building blocks (modules), which plug directly

into a proprietary bus: a central processor unit (CPU), a power

supply unit, input-output modules I/O, and a program terminal.

Such a modular approach has the advantage that the initial con-

figuration can be expanded for other future applications such as

multimachine systems or computer linking.

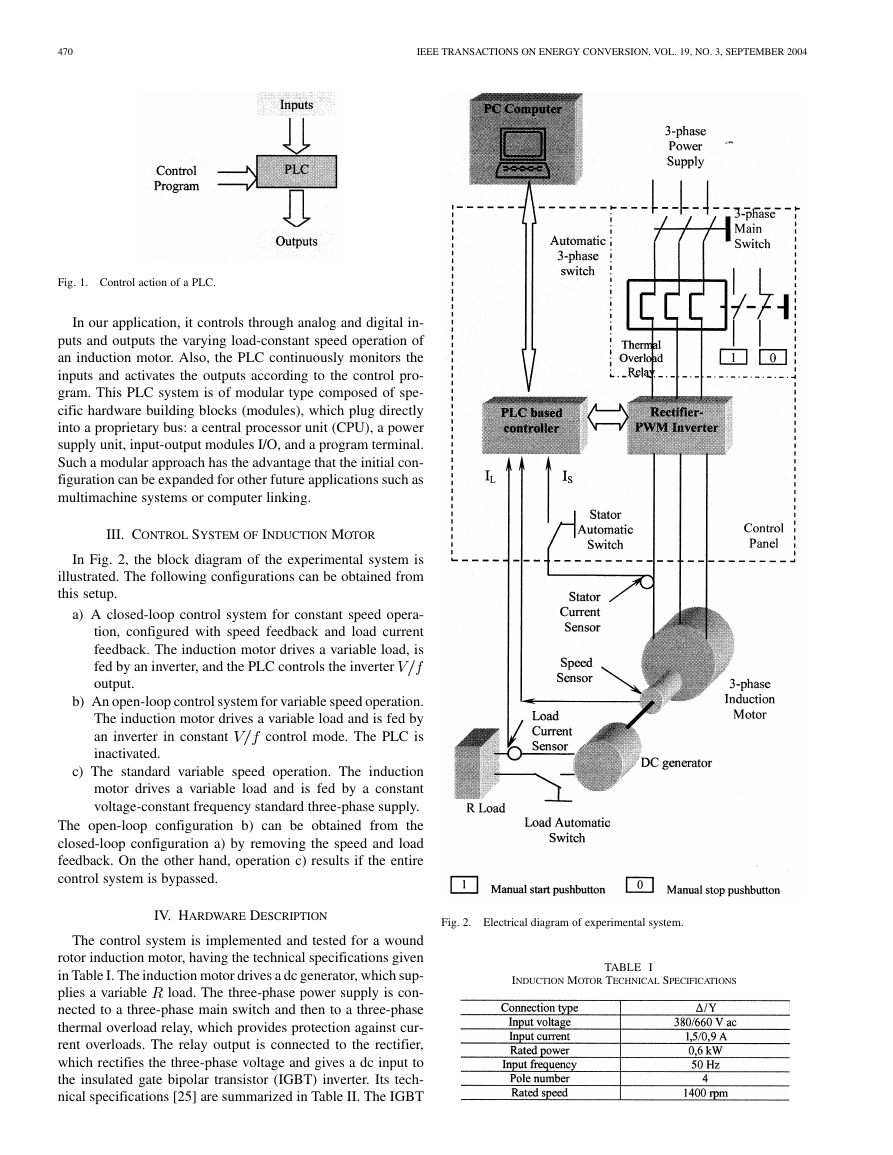

III. CONTROL SYSTEM OF INDUCTION MOTOR

In Fig. 2, the block diagram of the experimental system is

illustrated. The following configurations can be obtained from

this setup.

a) A closed-loop control system for constant speed opera-

tion, configured with speed feedback and load current

feedback. The induction motor drives a variable load, is

fed by an inverter, and the PLC controls the inverter

output.

b) An open-loop control system for variable speed operation.

The induction motor drives a variable load and is fed by

control mode. The PLC is

an inverter in constant

inactivated.

c) The standard variable speed operation. The induction

motor drives a variable load and is fed by a constant

voltage-constant frequency standard three-phase supply.

The open-loop configuration b) can be obtained from the

closed-loop configuration a) by removing the speed and load

feedback. On the other hand, operation c) results if the entire

control system is bypassed.

IV. HARDWARE DESCRIPTION

Fig. 2. Electrical diagram of experimental system.

The control system is implemented and tested for a wound

rotor induction motor, having the technical specifications given

in Table I. The induction motor drives a dc generator, which sup-

load. The three-phase power supply is con-

plies a variable

nected to a three-phase main switch and then to a three-phase

thermal overload relay, which provides protection against cur-

rent overloads. The relay output is connected to the rectifier,

which rectifies the three-phase voltage and gives a dc input to

the insulated gate bipolar transistor (IGBT) inverter. Its tech-

nical specifications [25] are summarized in Table II. The IGBT

INDUCTION MOTOR TECHNICAL SPECIFICATIONS

TABLE I

�

IOANNIDES: DESIGN AND IMPLEMENTATION OF PLC-BASED MONITORING CONTROL SYSTEM FOR INDUCTION MOTOR

471

TABLE II

INVERTER TECHNICAL SPECIFICATIONS

inverter converts the dc voltage input to three-phase voltage

output, which is supplied to the stator of the induction motor.

On the other hand, the inverter is interfaced to the PLC-based

controller.

This controller is implemented on a PLC modular system

[5], [26]–[28]. The PLC architecture refers to its internal hard-

ware and software. As a microprocessor-based system, the PLC

system hardware is designed and built up with the following

modules [29]–[37]:

central processor unit (CPU);

discrete output module (DOM);

discrete input module (DIM);

analog outputs module (AOM)

analog inputs module (AIM)

power supply.

Other details of the PLC configuration are shown in Tables III

and IV.

A speed sensor is used for the speed feedback, a current

sensor is used for the load current feedback, and a second

current sensor is connected to the stator circuits [32]. Thus,

the two feedback loops of the closed-loop system are setup by

using the load current sensor, the speed sensor, and the AIM.

A tachogenerator (permanent magnet dc motor) is used for

speed sensing. The induction machine drives its shaft mechani-

cally and an output voltage is produced, the magnitude of which

is proportional to the speed of rotation. Polarity depends on the

direction of rotation. The voltage signal from the tachogener-

ator must match the specified voltage range of the AIM (0–5 V

dc and 200-k internal resistance). Other PLC external control

circuits are designed using a low-voltage supply of 24 V dc.

For the manual control, the scheme is equipped with start,

stop, and trip push buttons, as well as with a forward and back-

ward direction selector switch. As shown in Fig. 2, all of the

described components: a main switch, an automatic three-phase

switch, an automatic single phase switch, a three-phase thermal

overload relay, a load automatic switch, signal lamps (forward,

backward, start, stop, trip), push buttons (start, stop, trip), a se-

lector switch (for the forward/backward direction of rotation), a

speed selector, a gain selector, as well as the PLC modules and

the rectifier-inverter are installed in a control panel. The pro-

gram is downloaded into the PLC from a personal computer PC

and an RS232 serial interface.

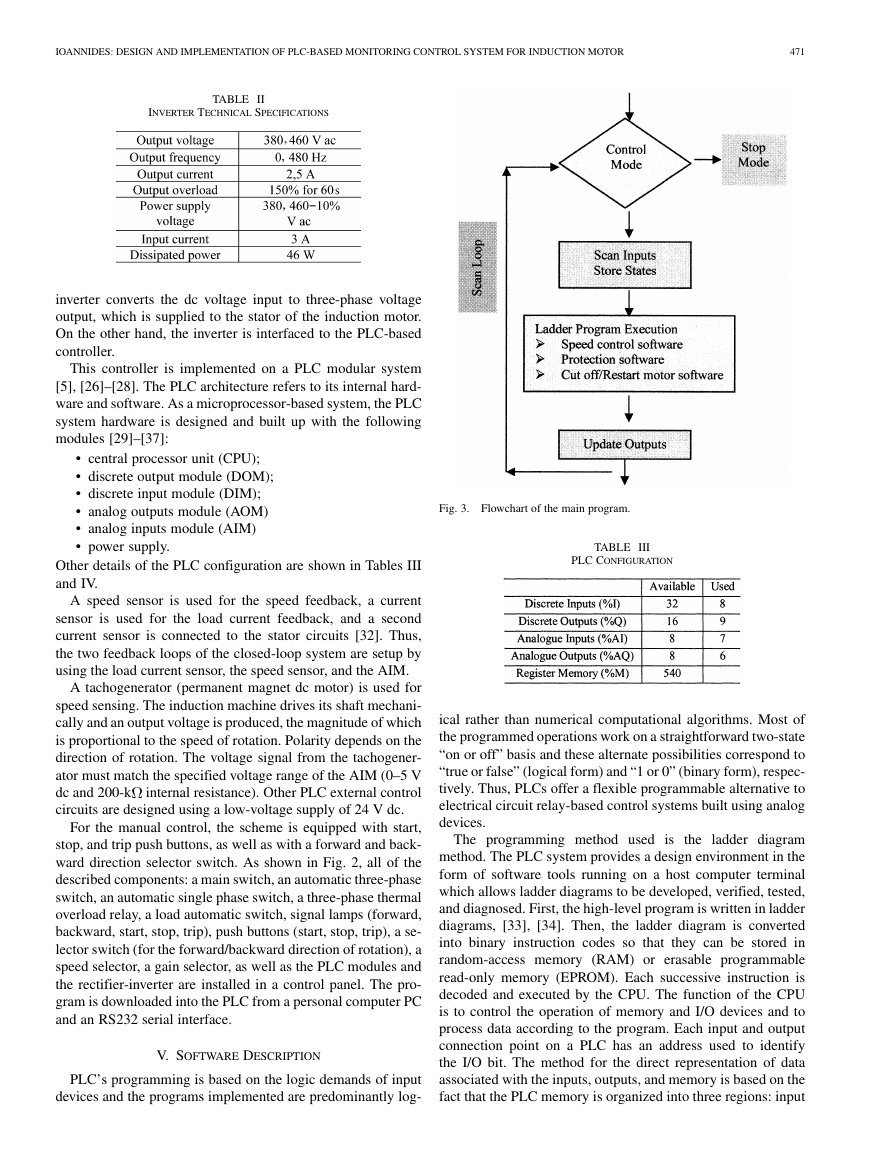

V. SOFTWARE DESCRIPTION

PLC’s programming is based on the logic demands of input

devices and the programs implemented are predominantly log-

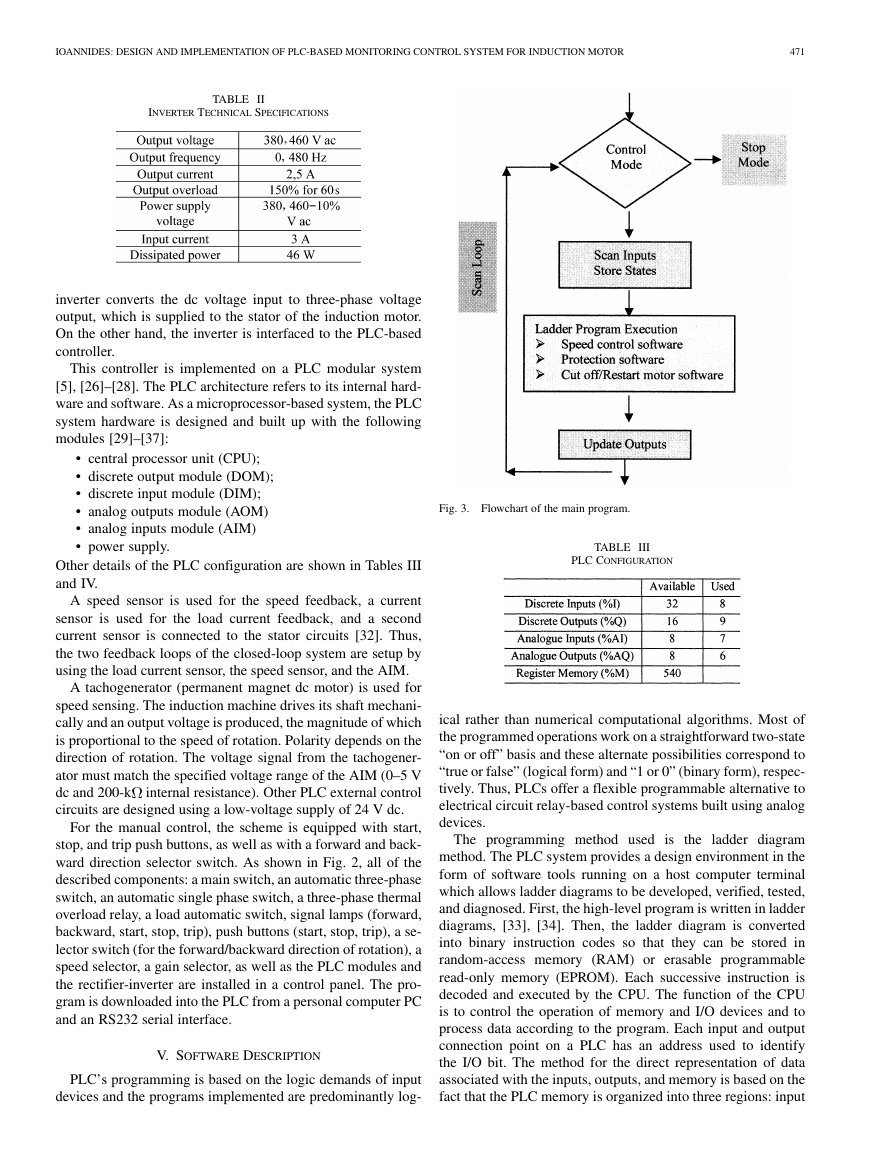

Fig. 3. Flowchart of the main program.

TABLE III

PLC CONFIGURATION

ical rather than numerical computational algorithms. Most of

the programmed operations work on a straightforward two-state

“on or off” basis and these alternate possibilities correspond to

“true or false” (logical form) and “1 or 0” (binary form), respec-

tively. Thus, PLCs offer a flexible programmable alternative to

electrical circuit relay-based control systems built using analog

devices.

The programming method used is the ladder diagram

method. The PLC system provides a design environment in the

form of software tools running on a host computer terminal

which allows ladder diagrams to be developed, verified, tested,

and diagnosed. First, the high-level program is written in ladder

diagrams, [33], [34]. Then, the ladder diagram is converted

into binary instruction codes so that they can be stored in

random-access memory (RAM) or erasable programmable

read-only memory (EPROM). Each successive instruction is

decoded and executed by the CPU. The function of the CPU

is to control the operation of memory and I/O devices and to

process data according to the program. Each input and output

connection point on a PLC has an address used to identify

the I/O bit. The method for the direct representation of data

associated with the inputs, outputs, and memory is based on the

fact that the PLC memory is organized into three regions: input

�

472

IEEE TRANSACTIONS ON ENERGY CONVERSION, VOL. 19, NO. 3, SEPTEMBER 2004

TABLE IV

PLC MODULES AND I/O DESIGNATION

image memory (I), output image memory (Q), and internal

memory (M). Any memory location is referenced directly using

%I, %Q, and %M (Table III).

The PLC program uses a cyclic scan in the main program loop

such that periodic checks are made to the input variables (Fig. 3).

The program loop starts by scanning the inputs to the system

and storing their states in fixed memory locations (input image

memory I). The ladder program is then executed rung-by-rung.

Scanning the program and solving the logic of the various ladder

rungs determine the output states. The updated output states are

stored in fixed memory locations (output image memory Q).

The output values held in memory are then used to set and reset

the physical outputs of the PLC simultaneously at the end of the

program scan. For the given PLC, the time taken to complete

one cycle or the scan time is 0, 18 ms/K (for 1000 steps) and

with a maximum program capacity of 1000 steps.

The development system comprises a host computer (PC)

connected via an RS232 port to the target PLC. The host

computer provides the software environment to perform file

editing, storage, printing, and program operation monitoring.

The process of developing the program to run on the PLC

consists of: using an editor to draw the source ladder program,

converting the source program to binary object code which

will run on the PLC’s microprocessor and downloading the

object code from the PC to the PLC system via the serial

communication port. The PLC system is online when it is in

active control of the machine and monitors any data to check

for correct operation.

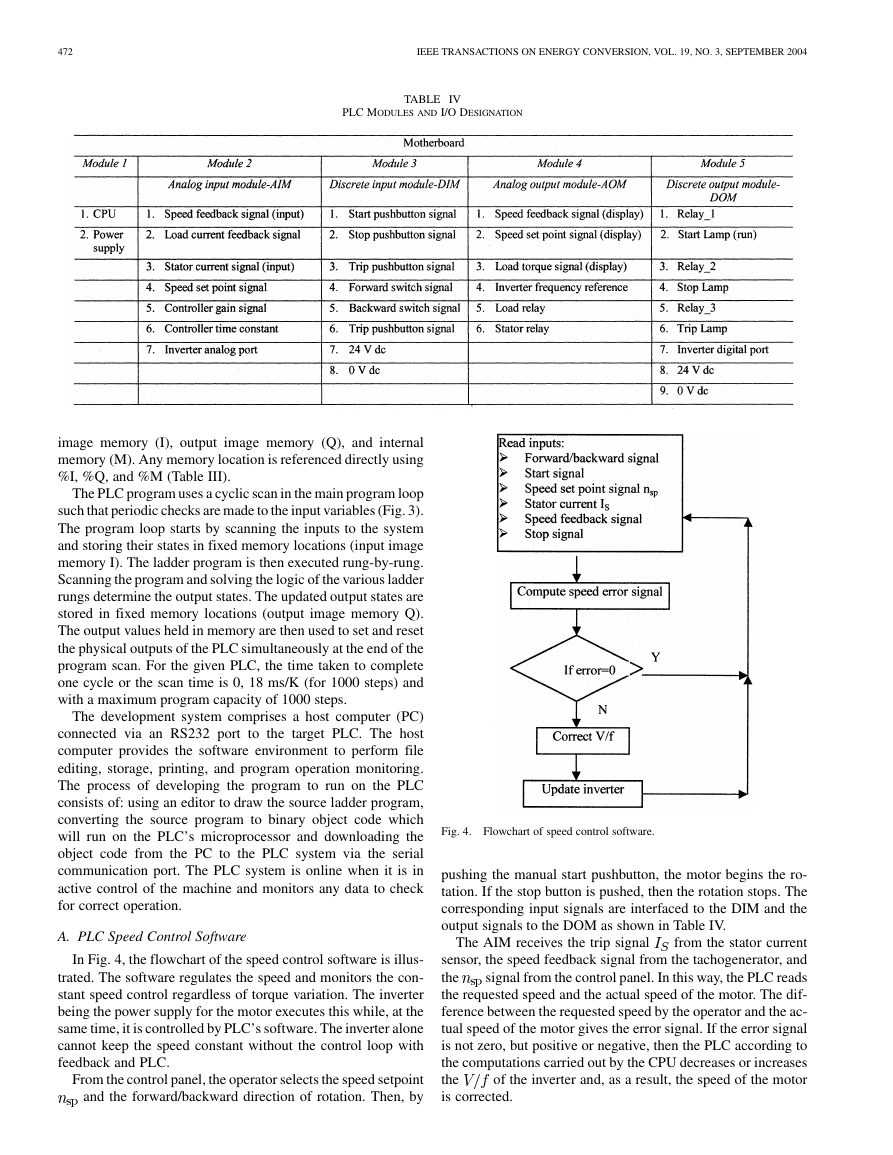

A. PLC Speed Control Software

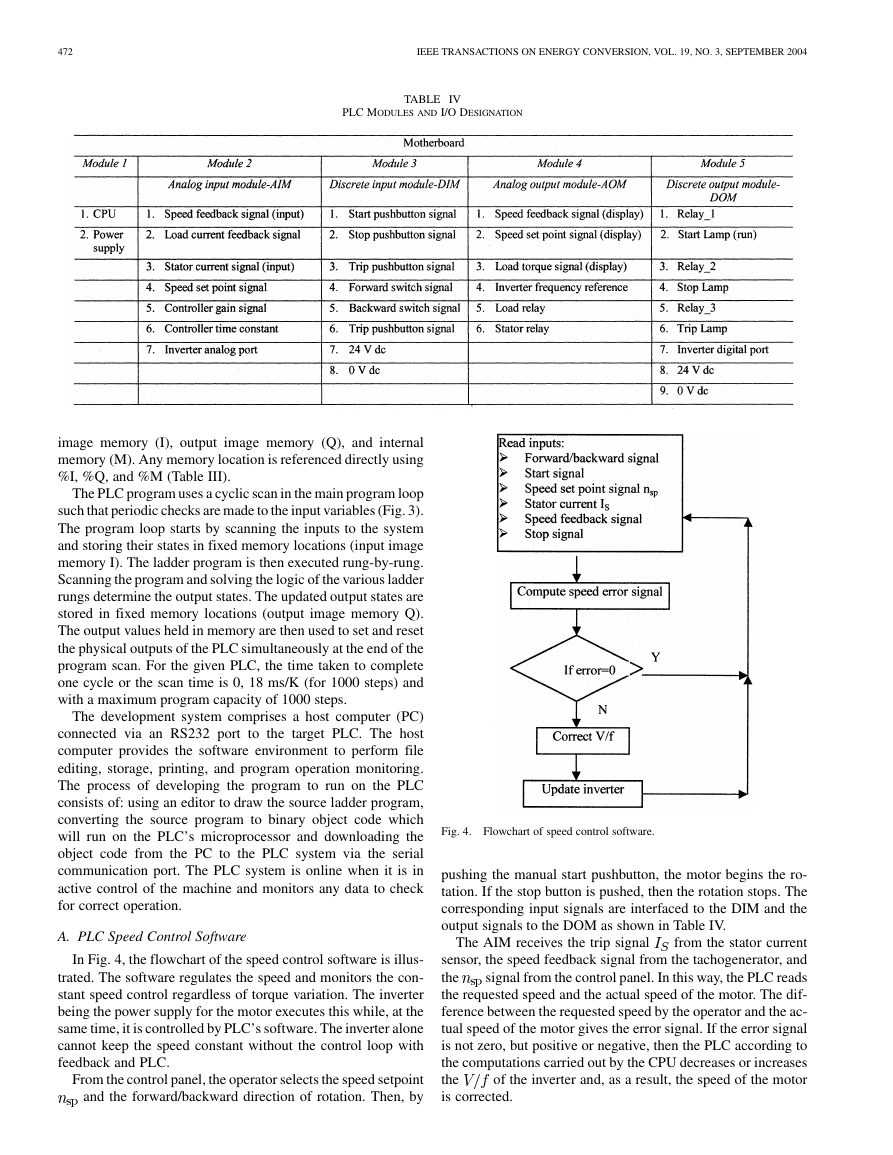

In Fig. 4, the flowchart of the speed control software is illus-

trated. The software regulates the speed and monitors the con-

stant speed control regardless of torque variation. The inverter

being the power supply for the motor executes this while, at the

same time, it is controlled by PLC’s software. The inverter alone

cannot keep the speed constant without the control loop with

feedback and PLC.

From the control panel, the operator selects the speed setpoint

and the forward/backward direction of rotation. Then, by

Fig. 4. Flowchart of speed control software.

pushing the manual start pushbutton, the motor begins the ro-

tation. If the stop button is pushed, then the rotation stops. The

corresponding input signals are interfaced to the DIM and the

output signals to the DOM as shown in Table IV.

The AIM receives the trip signal

from the stator current

sensor, the speed feedback signal from the tachogenerator, and

the

signal from the control panel. In this way, the PLC reads

the requested speed and the actual speed of the motor. The dif-

ference between the requested speed by the operator and the ac-

tual speed of the motor gives the error signal. If the error signal

is not zero, but positive or negative, then the PLC according to

the computations carried out by the CPU decreases or increases

the

of the inverter and, as a result, the speed of the motor

is corrected.

�

IOANNIDES: DESIGN AND IMPLEMENTATION OF PLC-BASED MONITORING CONTROL SYSTEM FOR INDUCTION MOTOR

473

During motor operation, it is not possible to reverse its direc-

tion of rotation by changing the switch position. Before direc-

tion reversal, the stop button must be pushed.

For motor protection against overloading currents during

the following commands were pro-

starting and loading,

grammed into the software.

i) Forward/backward signal is input to DIM.

, the load current

ii) Speed setpoint signal

, the stator

, and the speed feedback signal are input to

current

AIM.

iii) At no load

than 20% or

, if the speed set point is lower

r/min, the motor will not start.

iv) At an increased load over 0, 4 N m (40% of rated

, and a speed setpoint lower than 40%

r/min, the motor will not start.

torque),

or

v) If the load is increased more than 1, 0 N m (rated torque)

and if the speed set point exceeds 100% or

r/min, the motor enters the cutoff procedure.

vi) In all other situations, the motor enters in the speed con-

trol mode and the speed control software is executed as

described in Subsection A.

C. Cutoff and Restart Motor Software

In Fig. 6, the flowchart of this software is shown.

In overloading situations, the motor is cut off and the trip

lamp (yellow) is lit. The operator must release the thermal

relays and then must turn off the trip lamp by pushing trip

or stop button. The thermal relays are set to the motor rated

current 1, 5 A. Following this, the motor can be started

again.

The motor can be cut off by the operator pushing the stop

button: the display of the actual speed is set to zero, the

start lamp (green) turns off, and the stop lamp (red) turns

on and remains lit for 3 s.

The load must be disconnected immediately after the

motor cuts off and before the drive system is restarted.

The motor will not start before 3 s after cutoff even if the

start button is pushed.

VI. RESULTS

The system was tested during operation with varying loads

including tests on induction motor speed control performance

and tests for trip situations. The PLC monitors the motor oper-

ation and correlates the parameters according to the software.

At the beginning, for reference purposes, the performance of

induction motor supplied from a standard 380 V, 50-Hz network

was measured. Then, the experimental control system was op-

erated between no load and full load (1, 0 N m) in the two

different modes described in Section III:

a) induction motor fed by the inverter and with PLC control;

b) induction motor fed by the inverter.

The range of load torque and of speed corresponds to the de-

sign of the PLC hardware and software as described in the pre-

vious sections.

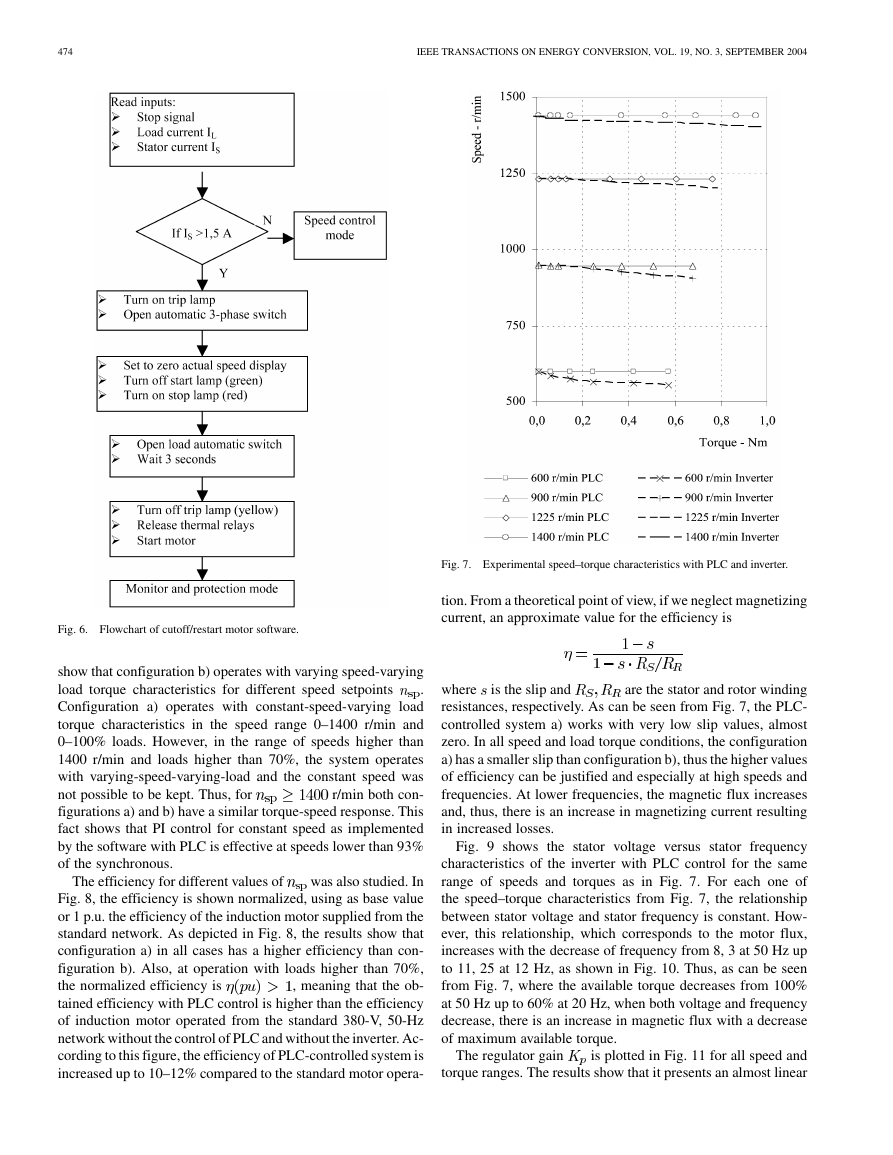

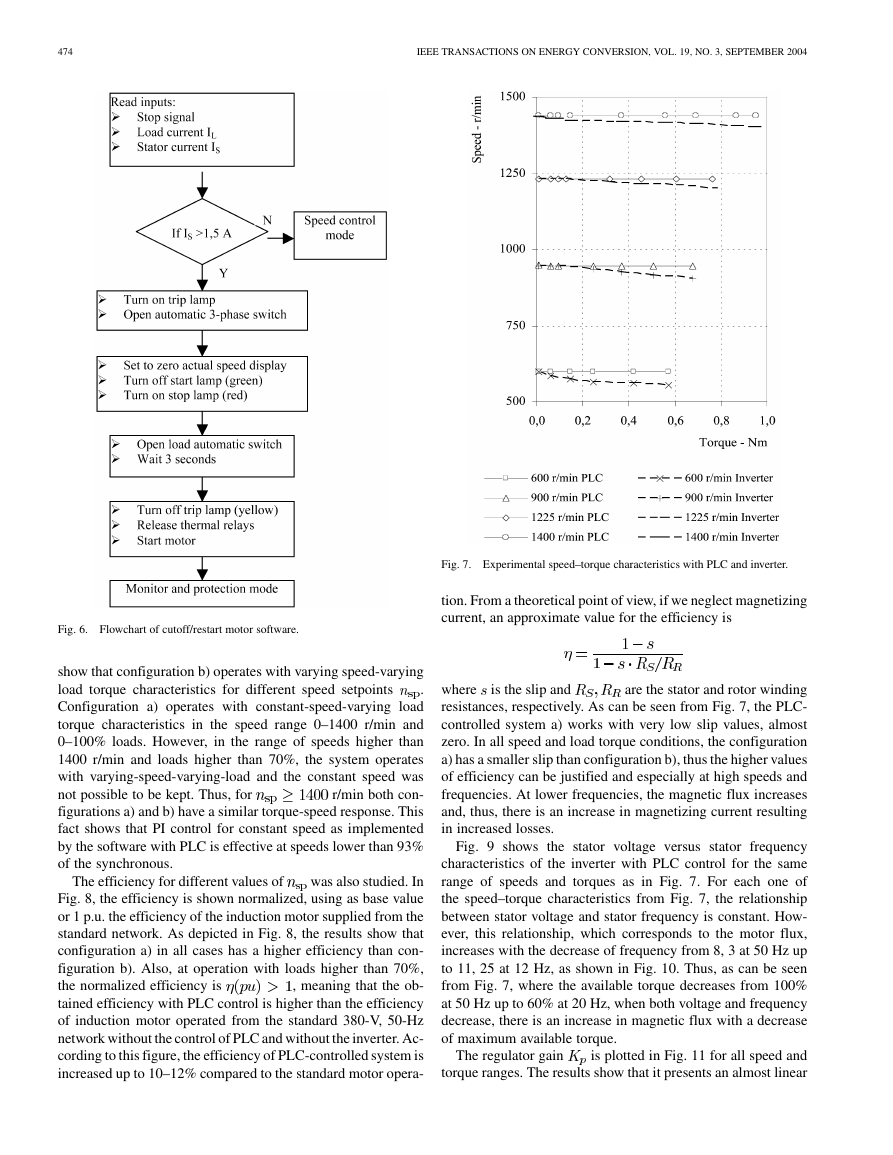

The speed versus torque characteristics were studied in the

range 500–1500 r/min and is illustrated in Fig. 7. The results

Fig. 5. Flowchart of monitor and protection software.

The implemented control is of proportional and integral (PI)

type (i.e., the error signal is multiplied by gain

, integrated,

and added to the requested speed). As a result, the control signal

is sent to the DOM and connected to the digital input of the

inverter to control

variations. At the beginning, the operator

by using a rotary resistor mounted on the

selects the gain

control panel (gain adjust) and the AIM receives its voltage drop

as controller gain signal (0–10 V).

The requested speed

is selected using a rotary resistor

and the AIM reads this signal. Its value is sent to the AOM and

displayed at the control panel (speed set point display). Another

display of the control panel shows the actual speed computed

from the speed feedback signal. A third display shows the load

torque computed from the load current signal in Newton-meters

(N m). Their corresponding signals are output to the AOM

(Table IV).

B. Monitor and Protection Software

In Fig. 5, the flowchart of this software is shown.

�

474

IEEE TRANSACTIONS ON ENERGY CONVERSION, VOL. 19, NO. 3, SEPTEMBER 2004

Fig. 6. Flowchart of cutoff/restart motor software.

show that configuration b) operates with varying speed-varying

.

load torque characteristics for different speed setpoints

Configuration a) operates with constant-speed-varying load

torque characteristics in the speed range 0–1400 r/min and

0–100% loads. However, in the range of speeds higher than

1400 r/min and loads higher than 70%, the system operates

with varying-speed-varying-load and the constant speed was

r/min both con-

not possible to be kept. Thus, for

figurations a) and b) have a similar torque-speed response. This

fact shows that PI control for constant speed as implemented

by the software with PLC is effective at speeds lower than 93%

of the synchronous.

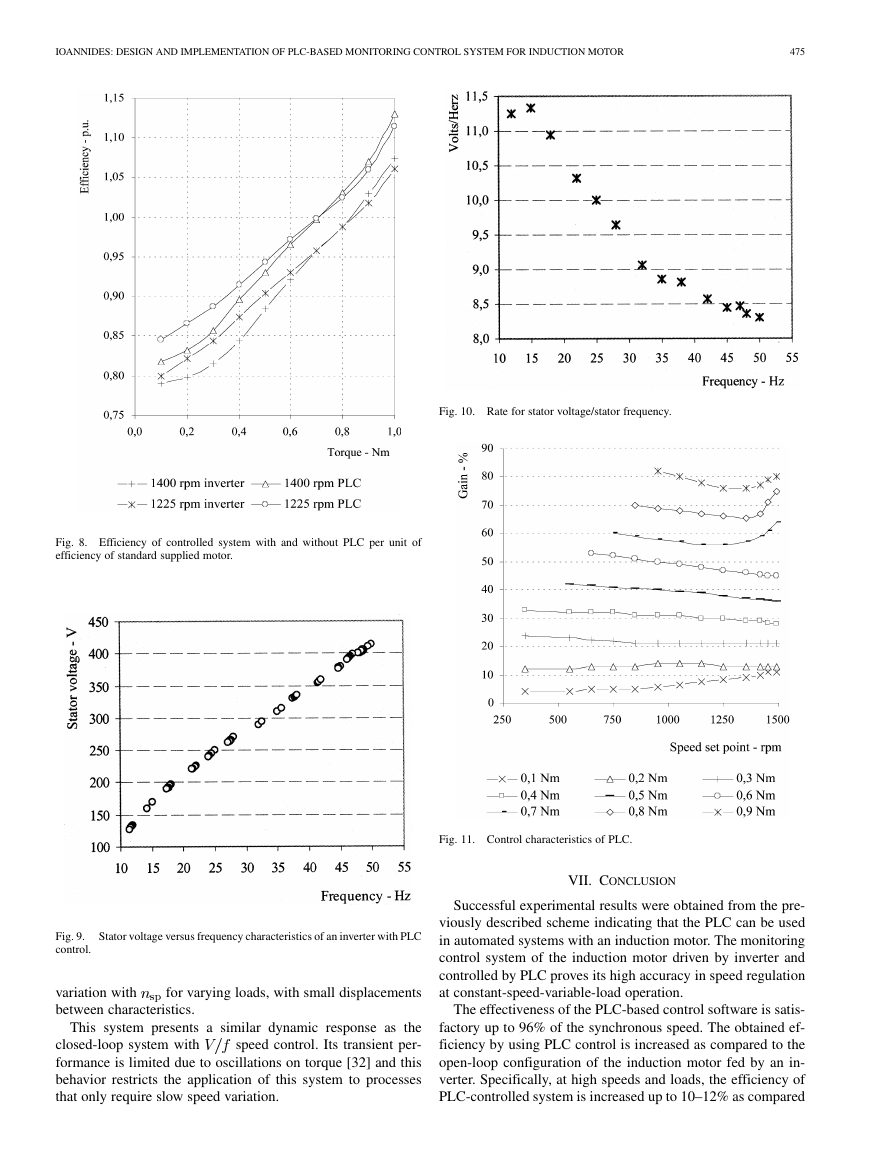

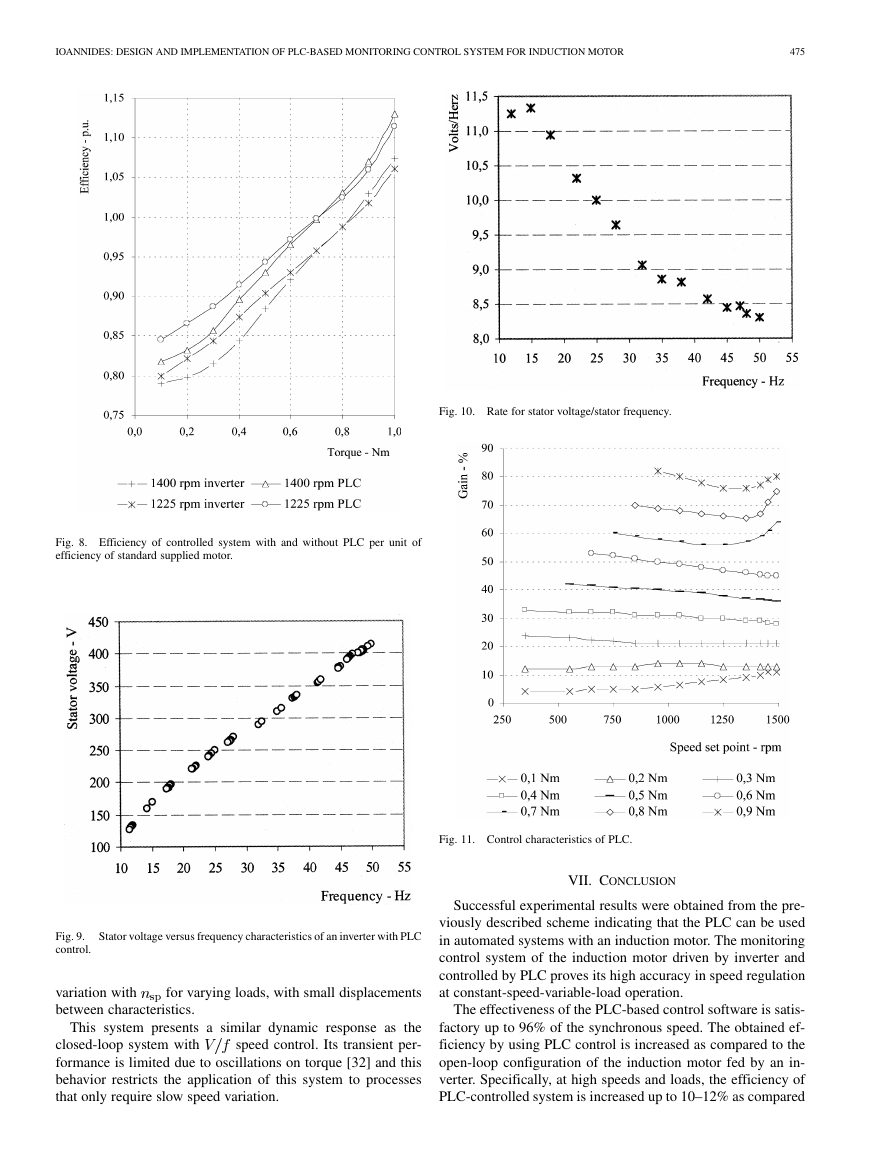

The efficiency for different values of

was also studied. In

Fig. 8, the efficiency is shown normalized, using as base value

or 1 p.u. the efficiency of the induction motor supplied from the

standard network. As depicted in Fig. 8, the results show that

configuration a) in all cases has a higher efficiency than con-

figuration b). Also, at operation with loads higher than 70%,

, meaning that the ob-

the normalized efficiency is

tained efficiency with PLC control is higher than the efficiency

of induction motor operated from the standard 380-V, 50-Hz

network without the control of PLC and without the inverter. Ac-

cording to this figure, the efficiency of PLC-controlled system is

increased up to 10–12% compared to the standard motor opera-

Fig. 7. Experimental speed–torque characteristics with PLC and inverter.

tion. From a theoretical point of view, if we neglect magnetizing

current, an approximate value for the efficiency is

is the slip and

where

are the stator and rotor winding

resistances, respectively. As can be seen from Fig. 7, the PLC-

controlled system a) works with very low slip values, almost

zero. In all speed and load torque conditions, the configuration

a) has a smaller slip than configuration b), thus the higher values

of efficiency can be justified and especially at high speeds and

frequencies. At lower frequencies, the magnetic flux increases

and, thus, there is an increase in magnetizing current resulting

in increased losses.

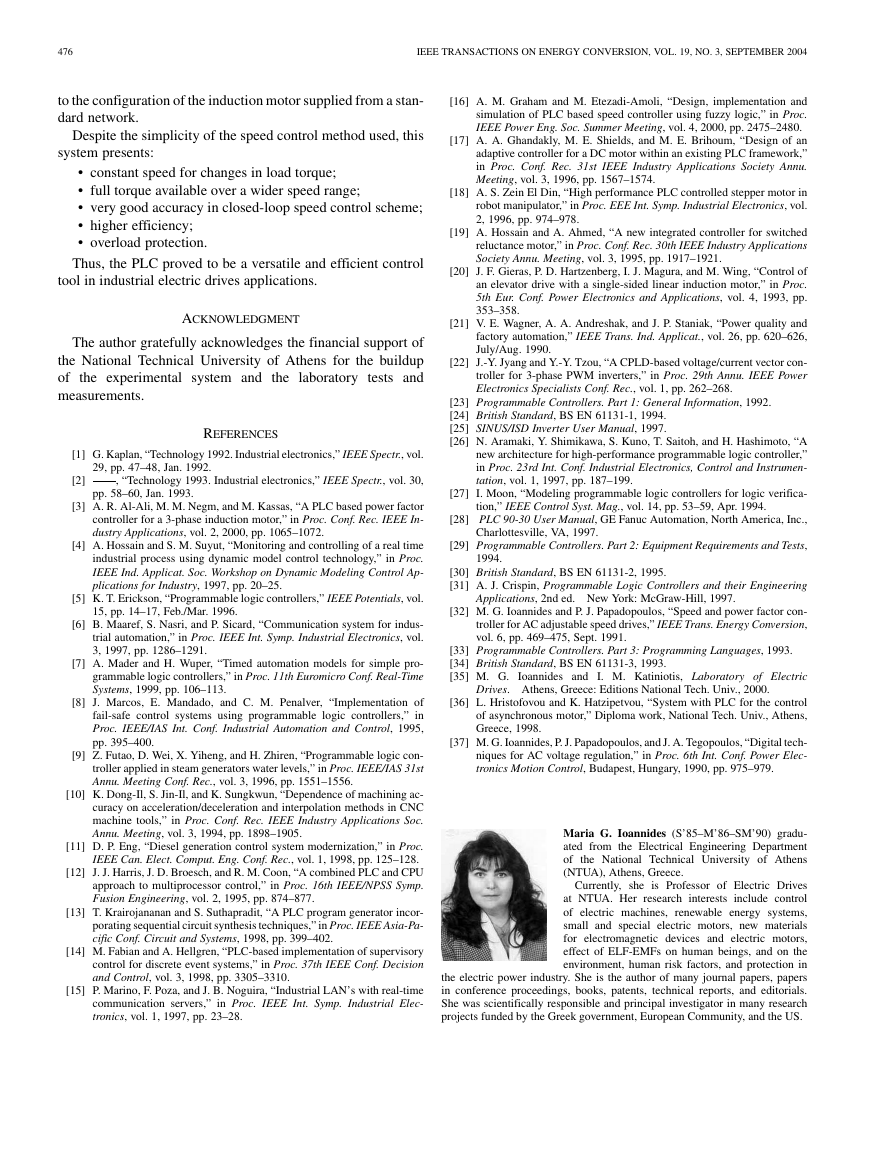

Fig. 9 shows the stator voltage versus stator frequency

characteristics of the inverter with PLC control for the same

range of speeds and torques as in Fig. 7. For each one of

the speed–torque characteristics from Fig. 7, the relationship

between stator voltage and stator frequency is constant. How-

ever, this relationship, which corresponds to the motor flux,

increases with the decrease of frequency from 8, 3 at 50 Hz up

to 11, 25 at 12 Hz, as shown in Fig. 10. Thus, as can be seen

from Fig. 7, where the available torque decreases from 100%

at 50 Hz up to 60% at 20 Hz, when both voltage and frequency

decrease, there is an increase in magnetic flux with a decrease

of maximum available torque.

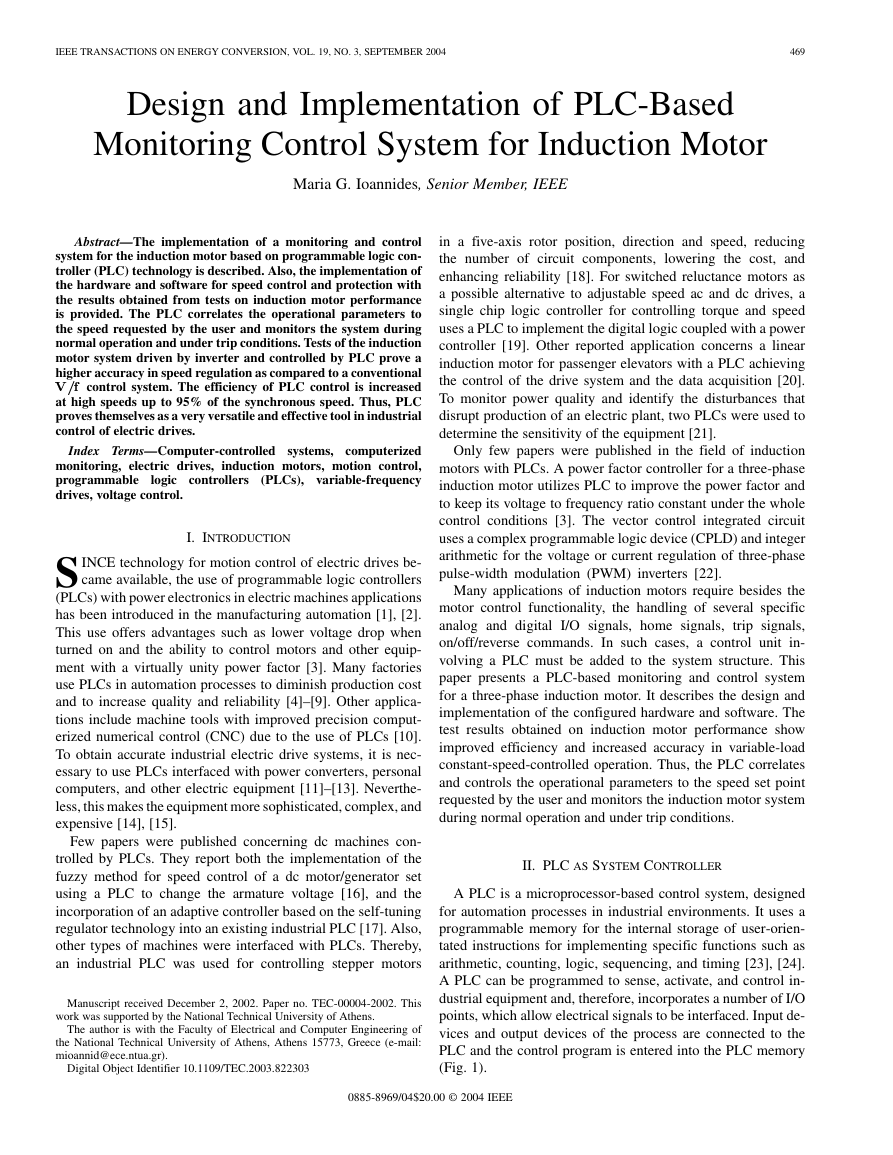

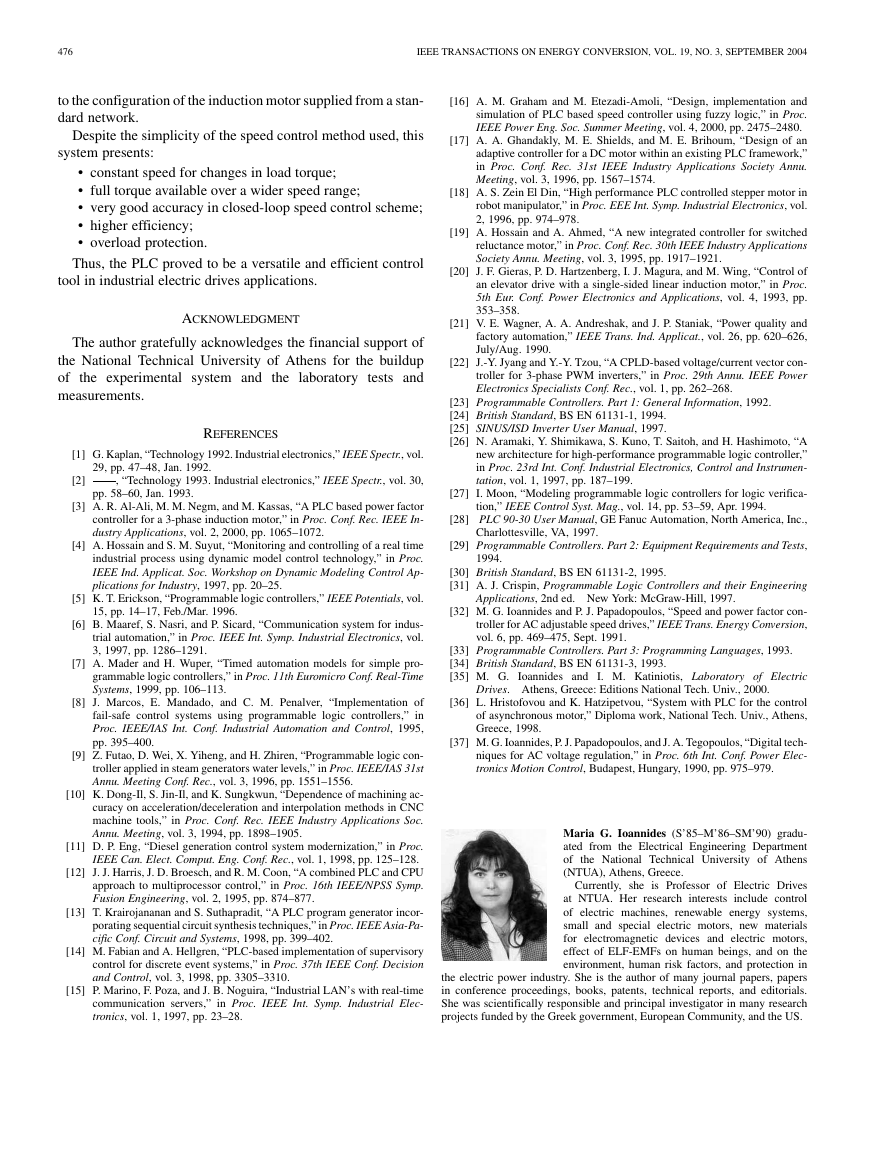

The regulator gain

is plotted in Fig. 11 for all speed and

torque ranges. The results show that it presents an almost linear

�

IOANNIDES: DESIGN AND IMPLEMENTATION OF PLC-BASED MONITORING CONTROL SYSTEM FOR INDUCTION MOTOR

475

Fig. 10. Rate for stator voltage/stator frequency.

Fig. 8. Efficiency of controlled system with and without PLC per unit of

efficiency of standard supplied motor.

Fig. 9.

control.

Stator voltage versus frequency characteristics of an inverter with PLC

variation with

between characteristics.

for varying loads, with small displacements

This system presents a similar dynamic response as the

speed control. Its transient per-

closed-loop system with

formance is limited due to oscillations on torque [32] and this

behavior restricts the application of this system to processes

that only require slow speed variation.

Fig. 11. Control characteristics of PLC.

VII. CONCLUSION

Successful experimental results were obtained from the pre-

viously described scheme indicating that the PLC can be used

in automated systems with an induction motor. The monitoring

control system of the induction motor driven by inverter and

controlled by PLC proves its high accuracy in speed regulation

at constant-speed-variable-load operation.

The effectiveness of the PLC-based control software is satis-

factory up to 96% of the synchronous speed. The obtained ef-

ficiency by using PLC control is increased as compared to the

open-loop configuration of the induction motor fed by an in-

verter. Specifically, at high speeds and loads, the efficiency of

PLC-controlled system is increased up to 10–12% as compared

�

476

IEEE TRANSACTIONS ON ENERGY CONVERSION, VOL. 19, NO. 3, SEPTEMBER 2004

to the configuration of the induction motor supplied from a stan-

dard network.

Despite the simplicity of the speed control method used, this

system presents:

constant speed for changes in load torque;

full torque available over a wider speed range;

very good accuracy in closed-loop speed control scheme;

higher efficiency;

overload protection.

Thus, the PLC proved to be a versatile and efficient control

tool in industrial electric drives applications.

ACKNOWLEDGMENT

The author gratefully acknowledges the financial support of

the National Technical University of Athens for the buildup

of the experimental system and the laboratory tests and

measurements.

REFERENCES

[1] G. Kaplan, “Technology 1992. Industrial electronics,” IEEE Spectr., vol.

29, pp. 47–48, Jan. 1992.

[2]

, “Technology 1993. Industrial electronics,” IEEE Spectr., vol. 30,

pp. 58–60, Jan. 1993.

[3] A. R. Al-Ali, M. M. Negm, and M. Kassas, “A PLC based power factor

controller for a 3-phase induction motor,” in Proc. Conf. Rec. IEEE In-

dustry Applications, vol. 2, 2000, pp. 1065–1072.

[4] A. Hossain and S. M. Suyut, “Monitoring and controlling of a real time

industrial process using dynamic model control technology,” in Proc.

IEEE Ind. Applicat. Soc. Workshop on Dynamic Modeling Control Ap-

plications for Industry, 1997, pp. 20–25.

[5] K. T. Erickson, “Programmable logic controllers,” IEEE Potentials, vol.

15, pp. 14–17, Feb./Mar. 1996.

[6] B. Maaref, S. Nasri, and P. Sicard, “Communication system for indus-

trial automation,” in Proc. IEEE Int. Symp. Industrial Electronics, vol.

3, 1997, pp. 1286–1291.

[7] A. Mader and H. Wuper, “Timed automation models for simple pro-

grammable logic controllers,” in Proc. 11th Euromicro Conf. Real-Time

Systems, 1999, pp. 106–113.

[8] J. Marcos, E. Mandado, and C. M. Penalver, “Implementation of

fail-safe control systems using programmable logic controllers,” in

Proc. IEEE/IAS Int. Conf. Industrial Automation and Control, 1995,

pp. 395–400.

[9] Z. Futao, D. Wei, X. Yiheng, and H. Zhiren, “Programmable logic con-

troller applied in steam generators water levels,” in Proc. IEEE/IAS 31st

Annu. Meeting Conf. Rec., vol. 3, 1996, pp. 1551–1556.

[10] K. Dong-Il, S. Jin-Il, and K. Sungkwun, “Dependence of machining ac-

curacy on acceleration/deceleration and interpolation methods in CNC

machine tools,” in Proc. Conf. Rec. IEEE Industry Applications Soc.

Annu. Meeting, vol. 3, 1994, pp. 1898–1905.

[11] D. P. Eng, “Diesel generation control system modernization,” in Proc.

IEEE Can. Elect. Comput. Eng. Conf. Rec., vol. 1, 1998, pp. 125–128.

[12] J. J. Harris, J. D. Broesch, and R. M. Coon, “A combined PLC and CPU

approach to multiprocessor control,” in Proc. 16th IEEE/NPSS Symp.

Fusion Engineering, vol. 2, 1995, pp. 874–877.

[13] T. Krairojananan and S. Suthapradit, “A PLC program generator incor-

porating sequential circuit synthesis techniques,” in Proc. IEEE Asia-Pa-

cific Conf. Circuit and Systems, 1998, pp. 399–402.

[14] M. Fabian and A. Hellgren, “PLC-based implementation of supervisory

control for discrete event systems,” in Proc. 37th IEEE Conf. Decision

and Control, vol. 3, 1998, pp. 3305–3310.

[15] P. Marino, F. Poza, and J. B. Noguira, “Industrial LAN’s with real-time

communication servers,” in Proc. IEEE Int. Symp. Industrial Elec-

tronics, vol. 1, 1997, pp. 23–28.

[16] A. M. Graham and M. Etezadi-Amoli, “Design, implementation and

simulation of PLC based speed controller using fuzzy logic,” in Proc.

IEEE Power Eng. Soc. Summer Meeting, vol. 4, 2000, pp. 2475–2480.

[17] A. A. Ghandakly, M. E. Shields, and M. E. Brihoum, “Design of an

adaptive controller for a DC motor within an existing PLC framework,”

in Proc. Conf. Rec. 31st IEEE Industry Applications Society Annu.

Meeting, vol. 3, 1996, pp. 1567–1574.

[18] A. S. Zein El Din, “High performance PLC controlled stepper motor in

robot manipulator,” in Proc. EEE Int. Symp. Industrial Electronics, vol.

2, 1996, pp. 974–978.

[19] A. Hossain and A. Ahmed, “A new integrated controller for switched

reluctance motor,” in Proc. Conf. Rec. 30th IEEE Industry Applications

Society Annu. Meeting, vol. 3, 1995, pp. 1917–1921.

[20] J. F. Gieras, P. D. Hartzenberg, I. J. Magura, and M. Wing, “Control of

an elevator drive with a single-sided linear induction motor,” in Proc.

5th Eur. Conf. Power Electronics and Applications, vol. 4, 1993, pp.

353–358.

[21] V. E. Wagner, A. A. Andreshak, and J. P. Staniak, “Power quality and

factory automation,” IEEE Trans. Ind. Applicat., vol. 26, pp. 620–626,

July/Aug. 1990.

[22] J.-Y. Jyang and Y.-Y. Tzou, “A CPLD-based voltage/current vector con-

troller for 3-phase PWM inverters,” in Proc. 29th Annu. IEEE Power

Electronics Specialists Conf. Rec., vol. 1, pp. 262–268.

[23] Programmable Controllers. Part 1: General Information, 1992.

[24] British Standard, BS EN 61131-1, 1994.

[25] SINUS/ISD Inverter User Manual, 1997.

[26] N. Aramaki, Y. Shimikawa, S. Kuno, T. Saitoh, and H. Hashimoto, “A

new architecture for high-performance programmable logic controller,”

in Proc. 23rd Int. Conf. Industrial Electronics, Control and Instrumen-

tation, vol. 1, 1997, pp. 187–199.

[27] I. Moon, “Modeling programmable logic controllers for logic verifica-

tion,” IEEE Control Syst. Mag., vol. 14, pp. 53–59, Apr. 1994.

[28] PLC 90-30 User Manual, GE Fanuc Automation, North America, Inc.,

Charlottesville, VA, 1997.

[29] Programmable Controllers. Part 2: Equipment Requirements and Tests,

1994.

[30] British Standard, BS EN 61131-2, 1995.

[31] A. J. Crispin, Programmable Logic Controllers and their Engineering

Applications, 2nd ed. New York: McGraw-Hill, 1997.

[32] M. G. Ioannides and P. J. Papadopoulos, “Speed and power factor con-

troller for AC adjustable speed drives,” IEEE Trans. Energy Conversion,

vol. 6, pp. 469–475, Sept. 1991.

[33] Programmable Controllers. Part 3: Programming Languages, 1993.

[34] British Standard, BS EN 61131-3, 1993.

[35] M. G.

Ioannides and I. M. Katiniotis, Laboratory of Electric

Drives. Athens, Greece: Editions National Tech. Univ., 2000.

[36] L. Hristofovou and K. Hatzipetvou, “System with PLC for the control

of asynchronous motor,” Diploma work, National Tech. Univ., Athens,

Greece, 1998.

[37] M. G. Ioannides, P. J. Papadopoulos, and J. A. Tegopoulos, “Digital tech-

niques for AC voltage regulation,” in Proc. 6th Int. Conf. Power Elec-

tronics Motion Control, Budapest, Hungary, 1990, pp. 975–979.

Maria G. Ioannides (S’85–M’86–SM’90) gradu-

ated from the Electrical Engineering Department

of the National Technical University of Athens

(NTUA), Athens, Greece.

Currently, she is Professor of Electric Drives

at NTUA. Her research interests include control

of electric machines, renewable energy systems,

small and special electric motors, new materials

for electromagnetic devices and electric motors,

effect of ELF-EMFs on human beings, and on the

environment, human risk factors, and protection in

the electric power industry. She is the author of many journal papers, papers

in conference proceedings, books, patents, technical reports, and editorials.

She was scientifically responsible and principal investigator in many research

projects funded by the Greek government, European Community, and the US.

�

2023年江西萍乡中考道德与法治真题及答案.doc

2023年江西萍乡中考道德与法治真题及答案.doc 2012年重庆南川中考生物真题及答案.doc

2012年重庆南川中考生物真题及答案.doc 2013年江西师范大学地理学综合及文艺理论基础考研真题.doc

2013年江西师范大学地理学综合及文艺理论基础考研真题.doc 2020年四川甘孜小升初语文真题及答案I卷.doc

2020年四川甘孜小升初语文真题及答案I卷.doc 2020年注册岩土工程师专业基础考试真题及答案.doc

2020年注册岩土工程师专业基础考试真题及答案.doc 2023-2024学年福建省厦门市九年级上学期数学月考试题及答案.doc

2023-2024学年福建省厦门市九年级上学期数学月考试题及答案.doc 2021-2022学年辽宁省沈阳市大东区九年级上学期语文期末试题及答案.doc

2021-2022学年辽宁省沈阳市大东区九年级上学期语文期末试题及答案.doc 2022-2023学年北京东城区初三第一学期物理期末试卷及答案.doc

2022-2023学年北京东城区初三第一学期物理期末试卷及答案.doc 2018上半年江西教师资格初中地理学科知识与教学能力真题及答案.doc

2018上半年江西教师资格初中地理学科知识与教学能力真题及答案.doc 2012年河北国家公务员申论考试真题及答案-省级.doc

2012年河北国家公务员申论考试真题及答案-省级.doc 2020-2021学年江苏省扬州市江都区邵樊片九年级上学期数学第一次质量检测试题及答案.doc

2020-2021学年江苏省扬州市江都区邵樊片九年级上学期数学第一次质量检测试题及答案.doc 2022下半年黑龙江教师资格证中学综合素质真题及答案.doc

2022下半年黑龙江教师资格证中学综合素质真题及答案.doc