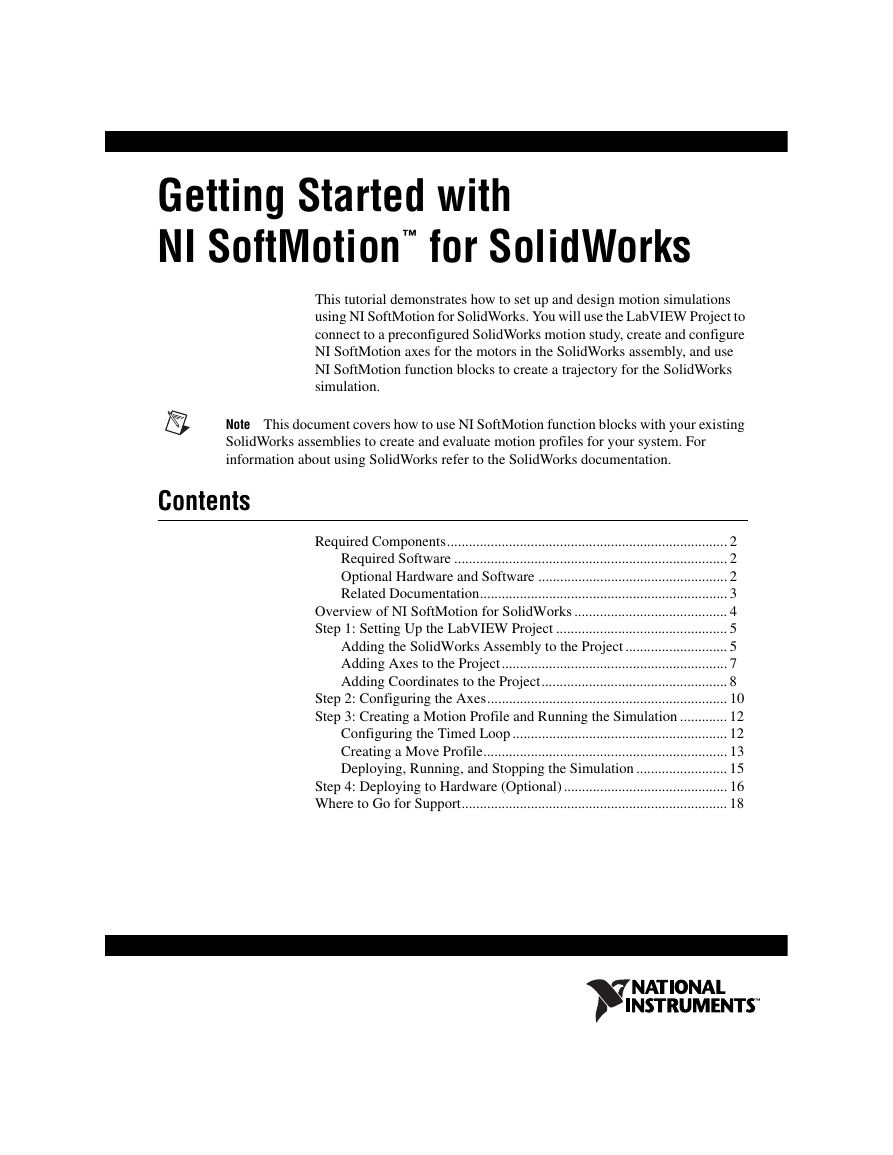

Getting Started with

NI SoftMotion for SolidWorks

™

This tutorial demonstrates how to set up and design motion simulations

using NI SoftMotion for SolidWorks. You will use the LabVIEW Project to

connect to a preconfigured SolidWorks motion study, create and configure

NI SoftMotion axes for the motors in the SolidWorks assembly, and use

NI SoftMotion function blocks to create a trajectory for the SolidWorks

simulation.

Note This document covers how to use NI SoftMotion function blocks with your existing

SolidWorks assemblies to create and evaluate motion profiles for your system. For

information about using SolidWorks refer to the SolidWorks documentation.

Contents

Required Components............................................................................. 2

Required Software ........................................................................... 2

Optional Hardware and Software .................................................... 2

Related Documentation.................................................................... 3

Overview of NI SoftMotion for SolidWorks .......................................... 4

Step 1: Setting Up the LabVIEW Project ............................................... 5

Adding the SolidWorks Assembly to the Project ............................ 5

Adding Axes to the Project.............................................................. 7

Adding Coordinates to the Project................................................... 8

Step 2: Configuring the Axes.................................................................. 10

Step 3: Creating a Motion Profile and Running the Simulation ............. 12

Configuring the Timed Loop ........................................................... 12

Creating a Move Profile................................................................... 13

Deploying, Running, and Stopping the Simulation ......................... 15

Step 4: Deploying to Hardware (Optional) ............................................. 16

Where to Go for Support......................................................................... 18

�

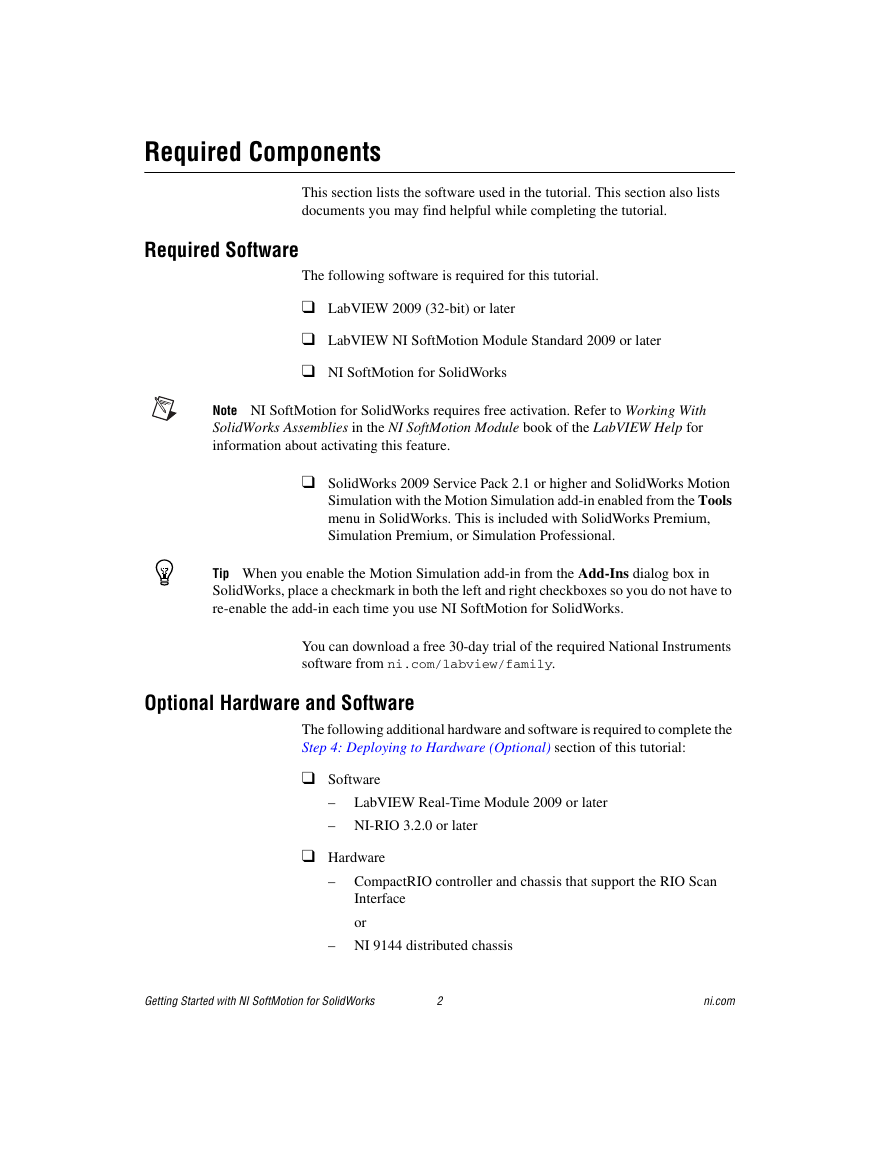

Required Components

This section lists the software used in the tutorial. This section also lists

documents you may find helpful while completing the tutorial.

Required Software

The following software is required for this tutorial.

❑ LabVIEW 2009 (32-bit) or later

❑ LabVIEW NI SoftMotion Module Standard 2009 or later

❑ NI SoftMotion for SolidWorks

Note NI SoftMotion for SolidWorks requires free activation. Refer to Working With

SolidWorks Assemblies in the NI SoftMotion Module book of the LabVIEW Help for

information about activating this feature.

❑ SolidWorks 2009 Service Pack 2.1 or higher and SolidWorks Motion

Simulation with the Motion Simulation add-in enabled from the Tools

menu in SolidWorks. This is included with SolidWorks Premium,

Simulation Premium, or Simulation Professional.

Tip When you enable the Motion Simulation add-in from the Add-Ins dialog box in

SolidWorks, place a checkmark in both the left and right checkboxes so you do not have to

re-enable the add-in each time you use NI SoftMotion for SolidWorks.

You can download a free 30-day trial of the required National Instruments

software from ni.com/labview/family.

Optional Hardware and Software

The following additional hardware and software is required to complete the

Step 4: Deploying to Hardware (Optional) section of this tutorial:

❑ Software

LabVIEW Real-Time Module 2009 or later

–

– NI-RIO 3.2.0 or later

❑ Hardware

– CompactRIO controller and chassis that support the RIO Scan

Interface

or

– NI 9144 distributed chassis

Getting Started with NI SoftMotion for SolidWorks

2

ni.com

�

Two NI 9512 single-axis stepper drive interface modules

Power supply for the controller

–

–

– A separate power supply for the modules

–

Ethernet connection and cable

Tip Even if you do not have the hardware used in this tutorial, you can follow the steps

and perform offline configuration to learn concepts about using CompactRIO with

LabVIEW.

Related Documentation

The following documents contain information that you may find helpful as

you read this tutorial:

LabVIEW Help—Use the LabVIEW Help to access information about

LabVIEW programming concepts, step-by-step instructions for using

LabVIEW, and reference information about LabVIEW VIs, functions,

palettes, menus, tools, properties, methods, events, dialog boxes, and

so on. The LabVIEW Help also lists the LabVIEW documentation

resources available from National Instruments. Access the LabVIEW

Help by selecting Help»Search the LabVIEW Help.

Getting Started with LabVIEW—Use this document as a tutorial to

familiarize yourself with the LabVIEW graphical programming

environment and the basic LabVIEW features you use to build data

acquisition and instrument control applications. Access the Getting

Started with LabVIEW PDF by selecting Start»All Programs»

National Instruments»LabVIEW»LabVIEW Manuals»

LV_Getting_Started.pdf.

LabVIEW NI SoftMotion Module Help—Use this help file to learn

about using NI SoftMotion in LabVIEW including information about

function blocks and using NI SoftMotion with the LabVIEW Project.

To access this help file from LabVIEW, select Help»Search the

LabVIEW Help, then expand the LabVIEW NI SoftMotion Module

book on the Contents tab.

SolidWorks Help

•

Note Refer to the software documentation for installation information.

© National Instruments Corporation

3

Getting Started with NI SoftMotion for SolidWorks

�

Overview of NI SoftMotion for SolidWorks

Using NI SoftMotion with SolidWorks to simulate your system with actual

motion profiles allows you to simulate mechanical dynamics, including

mass and friction effects, cycle times, and individual component

performance before specifying a single physical part and connecting it to

an actual control algorithm. Digital prototyping offers the ability to

visualize and optimize the design and evaluate different design concepts

before incurring the cost of physical prototypes.

Integrating motion simulation with CAD simplifies design because the

simulation uses information that already exists in the CAD model, such as

assembly mates, couplings, and material mass properties. LabVIEW

provides an easy to use, high-level function block programming language

for programming the motion control system that is easy enough for users

with little or no previous motion control programming experience.

Typical applications for the LabVIEW NI SoftMotion Module with

NI SoftMotion for SolidWorks include the following:

Motion trajectory design—You can build complex motion profiles

containing a series of sequential or concurrent move operations

composed of multi-axis straight-line moves, contoured moves,

arc moves, and even complex moves using electronic gearing and

camming.

Visualization—By animating your 3D SolidWorks assembly using

the motion control profiles and timing/sequencing logic you have

designed in LabVIEW, you can quickly evaluate the feasibility of the

overall conceptual design for your machine.

Visualizing the working machine as a virtual prototype helps to

validate the overall conceptual design for the machine very early in the

development. This fosters better communication with customers and

between design team members and helps to close the loop on the

design requirements, must-have features, and engineering trade-offs.

Collision detection—The collision detection feature in SolidWorks

enables you to validate your motion profile designs using your actual

3D CAD model. You can check for interferences, evaluate the need for

interlock control logic to prevent collisions, optimize your motion

profiles to minimize unnecessary dead time, quickly evaluate what-if

scenarios, and safely test new control system logic without the risk of

damaging your physical machine. After your machine has been

designed, prototyped and deployed to the field, collision detection can

also be used to validate new motion profiles before downloading them

to machines operating at your customer site; reducing the risk of

unplanned downtime due to programming mistakes.

Getting Started with NI SoftMotion for SolidWorks

4

ni.com

�

Throughput time studies—By validating your motion system design

using a simulation that includes the actual motion profile constraints

and the mechanical dynamics of your machine such as mass and

friction, you can accurately calculate an estimate for the cycle time

throughput of your machine.

Motor, drive, and transmission sizing—Motor torque and velocity

requirements depend on the acceleration characteristics of your motion

profile and the mechanical dynamics of the payload and transmission

components such as lead screws. Using NI SoftMotion, you can

calculate the required motor torque and velocity charts for your motion

profiles.

Step 1: Setting Up the LabVIEW Project

Before you can start designing motion profiles for your SolidWorks

simulation, you need to import the information from your SolidWorks

assembly into the LabVIEW Project and create NI SoftMotion axes for the

simulated motors included in your assembly.

Tip Refer to Working with SolidWorks Assemblies in the NI SoftMotion Module book of

the LabVIEW Help for a list of caveats and recommendations to consider when creating

and using SolidWorks assemblies with NI SoftMotion.

Adding the SolidWorks Assembly to the Project

Complete the following steps to add the SolidWorks assembly to the

LabVIEW Project:

1. Launch SolidWorks and open the Sorting Machine.SLDASM file

from the \examples\motion\SoftMotion\

SolidWorks CoSimulation\Sorting Machine (SolidWorks

Files) directory. This model simulates an assembly that takes test

tubes from one location and moves them to another.

This tutorial focuses on using an arc move to move the test tubes to a

rotary table. At this point, the assembly and motion study must be

ready to simulate with all the constraints and motors properly

configured. Refer to the SolidWorks Help for more information about

setting up a SolidWorks assembly.

Tip Use the NI Example Finder, available in LabVIEW at Help»Find Examples to find

additional examples using NI SoftMotion for SolidWorks.

© National Instruments Corporation

5

Getting Started with NI SoftMotion for SolidWorks

�

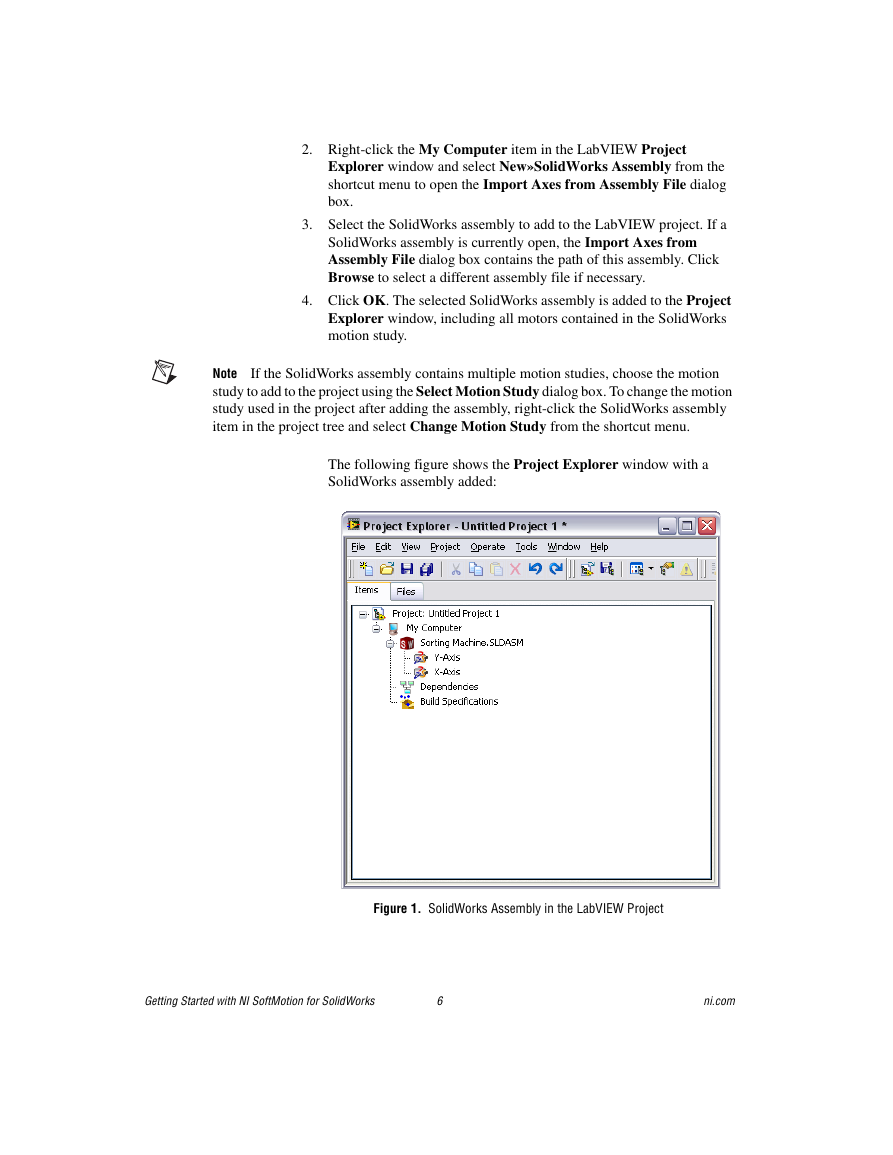

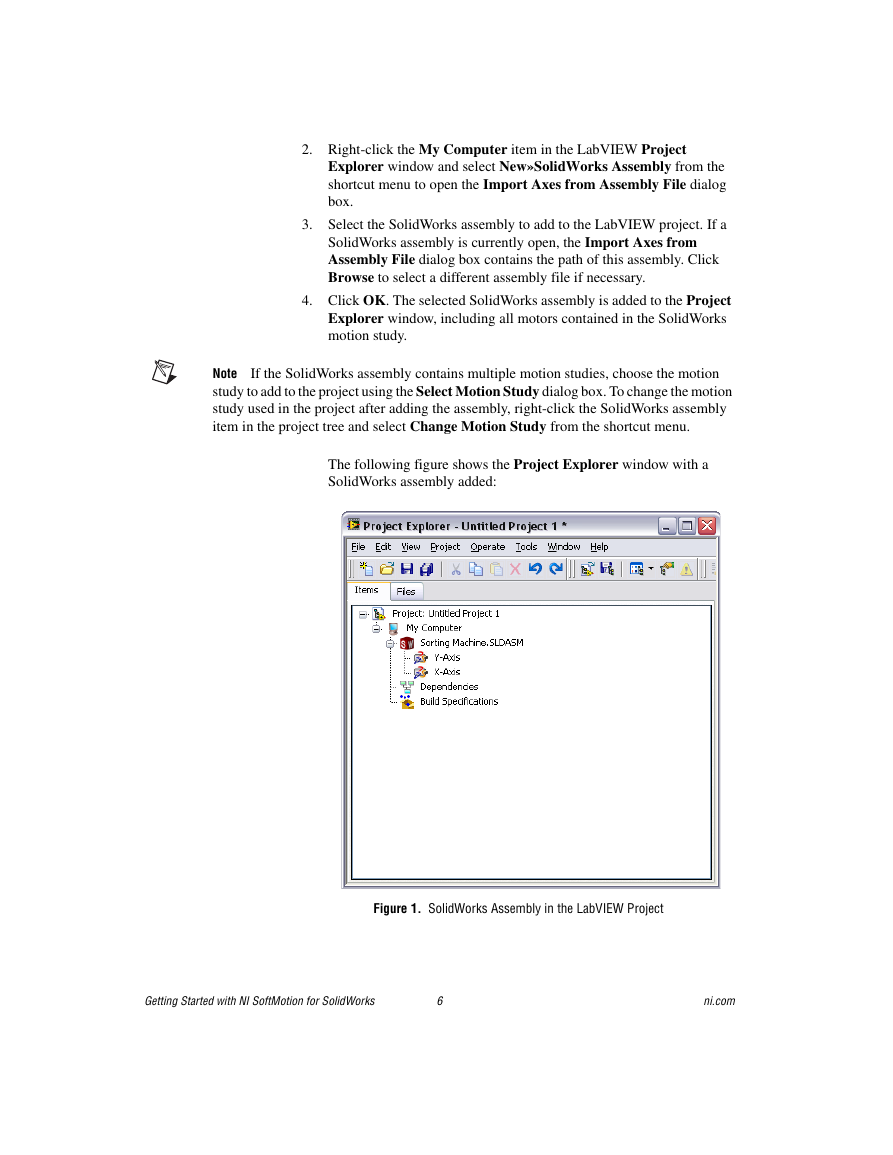

2. Right-click the My Computer item in the LabVIEW Project

Explorer window and select New»SolidWorks Assembly from the

shortcut menu to open the Import Axes from Assembly File dialog

box.

3. Select the SolidWorks assembly to add to the LabVIEW project. If a

SolidWorks assembly is currently open, the Import Axes from

Assembly File dialog box contains the path of this assembly. Click

Browse to select a different assembly file if necessary.

4. Click OK. The selected SolidWorks assembly is added to the Project

Explorer window, including all motors contained in the SolidWorks

motion study.

If the SolidWorks assembly contains multiple motion studies, choose the motion

Note

study to add to the project using the Select Motion Study dialog box. To change the motion

study used in the project after adding the assembly, right-click the SolidWorks assembly

item in the project tree and select Change Motion Study from the shortcut menu.

The following figure shows the Project Explorer window with a

SolidWorks assembly added:

Figure 1. SolidWorks Assembly in the LabVIEW Project

Getting Started with NI SoftMotion for SolidWorks

6

ni.com

�

5. Right-click the SolidWorks assembly in the Project Explorer window

and select Properties from the shortcut menu to open the Assembly

Properties dialog box. In the Data Logging Properties section,

specify a name for the log file and place a checkmark in the Log Data

checkbox. This will log position, velocity, acceleration, and torque

data for the simulation to the specified file name in LabVIEW

Measurement (.lvm) format.

Note Each simulation overwrites the selected log file. To create a new log file for the next

simulation you must change the file name before starting the simulation.

Adding Axes to the Project

To simulate using the SolidWorks motors included in the model, you need

to associate the motors with NI SoftMotion axes. The NI SoftMotion axes

are used when creating motion profiles using the NI SoftMotion function

blocks. Complete the following steps to add NI SoftMotion axes to the

project:

1. Right-click on My Computer and select New»NI SoftMotion Axis

from the shortcut menu to open the Axis Manager dialog box, shown

in Figure 2.

2. Select Add New Axis. The new axis automatically binds to an

available SolidWorks motor. Double-click the axis name to rename the

axis and give it a descriptive name.

Figure 2. Axis Manager Dialog Box

3. Click Add New Axis until all available SolidWorks motors are

associated with NI SoftMotion axes.

© National Instruments Corporation

7

Getting Started with NI SoftMotion for SolidWorks

�

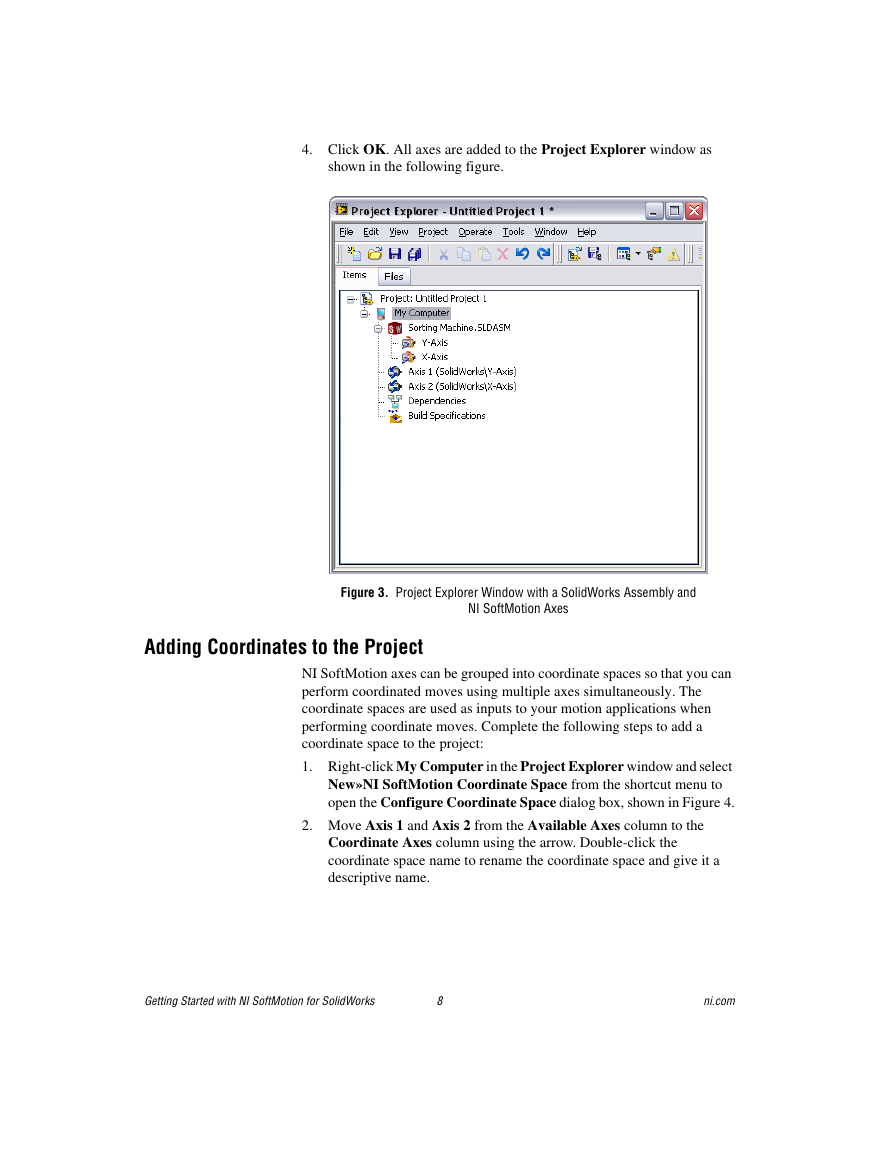

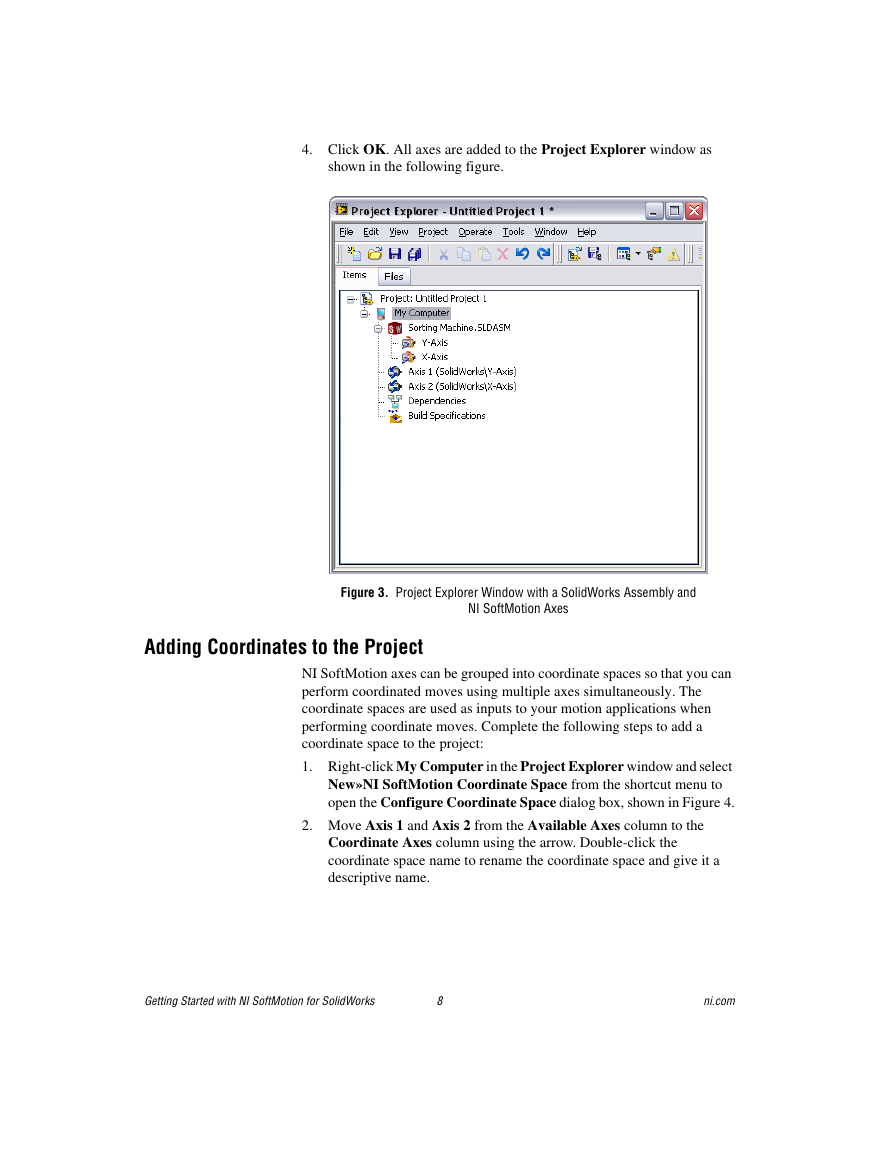

4. Click OK. All axes are added to the Project Explorer window as

shown in the following figure.

Figure 3. Project Explorer Window with a SolidWorks Assembly and

NI SoftMotion Axes

Adding Coordinates to the Project

NI SoftMotion axes can be grouped into coordinate spaces so that you can

perform coordinated moves using multiple axes simultaneously. The

coordinate spaces are used as inputs to your motion applications when

performing coordinate moves. Complete the following steps to add a

coordinate space to the project:

1. Right-click My Computer in the Project Explorer window and select

New»NI SoftMotion Coordinate Space from the shortcut menu to

open the Configure Coordinate Space dialog box, shown in Figure 4.

2. Move Axis 1 and Axis 2 from the Available Axes column to the

Coordinate Axes column using the arrow. Double-click the

coordinate space name to rename the coordinate space and give it a

descriptive name.

Getting Started with NI SoftMotion for SolidWorks

8

ni.com

�

2023年江西萍乡中考道德与法治真题及答案.doc

2023年江西萍乡中考道德与法治真题及答案.doc 2012年重庆南川中考生物真题及答案.doc

2012年重庆南川中考生物真题及答案.doc 2013年江西师范大学地理学综合及文艺理论基础考研真题.doc

2013年江西师范大学地理学综合及文艺理论基础考研真题.doc 2020年四川甘孜小升初语文真题及答案I卷.doc

2020年四川甘孜小升初语文真题及答案I卷.doc 2020年注册岩土工程师专业基础考试真题及答案.doc

2020年注册岩土工程师专业基础考试真题及答案.doc 2023-2024学年福建省厦门市九年级上学期数学月考试题及答案.doc

2023-2024学年福建省厦门市九年级上学期数学月考试题及答案.doc 2021-2022学年辽宁省沈阳市大东区九年级上学期语文期末试题及答案.doc

2021-2022学年辽宁省沈阳市大东区九年级上学期语文期末试题及答案.doc 2022-2023学年北京东城区初三第一学期物理期末试卷及答案.doc

2022-2023学年北京东城区初三第一学期物理期末试卷及答案.doc 2018上半年江西教师资格初中地理学科知识与教学能力真题及答案.doc

2018上半年江西教师资格初中地理学科知识与教学能力真题及答案.doc 2012年河北国家公务员申论考试真题及答案-省级.doc

2012年河北国家公务员申论考试真题及答案-省级.doc 2020-2021学年江苏省扬州市江都区邵樊片九年级上学期数学第一次质量检测试题及答案.doc

2020-2021学年江苏省扬州市江都区邵樊片九年级上学期数学第一次质量检测试题及答案.doc 2022下半年黑龙江教师资格证中学综合素质真题及答案.doc

2022下半年黑龙江教师资格证中学综合素质真题及答案.doc