Image and Vision Computing 23 (2005) 59–67

www.elsevier.com/locate/imavis

Complete calibration of a structured light stripe vision sensor through

planar target of unknown orientations

Fuqiang Zhou*, Guangjun Zhang

School of Instrument Science and Opto-electronics Engineering, Beijing University of Aeronautics and Astronautics, Beijing 100083, China

Received 30 January 2004; accepted 7 July 2004

Abstract

Structured light 3D vision inspection is a commonly used method for various 3D surface profiling techniques. In this paper, the

mathematical model of the structured light stripe vision sensor is established. We propose a flexible new approach to easily determine all

primitive parameters of a structured light stripe vision sensor. It is well suited for use without specialized knowledge of 3D geometry. The

technique only requires the sensor to observe a planar target shown at a few (at least two) different orientations. Either the sensor or the planar

target can be freely moved. The motion need not be known. A novel approach is proposed to generate sufficient non-collinear control points

for structured light stripe vision sensor calibration. Real data has been used to test the proposed technique, and very good result has been

obtained. Compared with classical techniques, which use expensive equipment such as two or three orthogonal planes, the proposed

technique is easy to use and flexible. It advances structured light vision one step from laboratory environments to real engineering 3D

metrology applications.

q 2004 Elsevier B.V. All rights reserved.

Keywords: Structured light; Calibration; Control points; Planar target; Vision inspection

1. Introduction

With the development of electronics, photo-electronics,

image processing and computer vision technique, vision

inspection has made giant strides in development. It is

becoming increasingly relevant in industry for dimensional

analysis, on-line inspection, component quality control and

solid modeling, such as the 3D contouring and gauging of

large-surface car parts and small-size microelectronic

components, and the fast-dimensional analysis of object in

relation to the recognition of targets by robots. And also it

played an important role in reverse engineering.

Recently, systems based on vision cameras allow

automated and non-contact 3D measurements, which are

based on two alternative techniques: stereovision and

triangulation from structured light stripe vision. Structured

light stripe vision inspection avoids the so-called corre-

spondence problem of passive stereo vision and has gained

* Corresponding author. Tel.: C86 10 82316930; fax: C86 10 82314804.

E-mail address: fuqiang_zhou@yahoo.com (F. Zhou).

0262-8856/$ - see front matter q 2004 Elsevier B.V. All rights reserved.

doi:10.1016/j.imavis.2004.07.006

the widest acceptance [1–4] in industry inspections due to

fast measuring speed, very simple optical arrangement, non-

contact, moderate accuracy, low cost, and robust nature in

the presence of ambient light source in situ. Since the early

1970s [5], research has been active on shape reconstruction

and object recognition by projecting structured light stripes

onto objects.

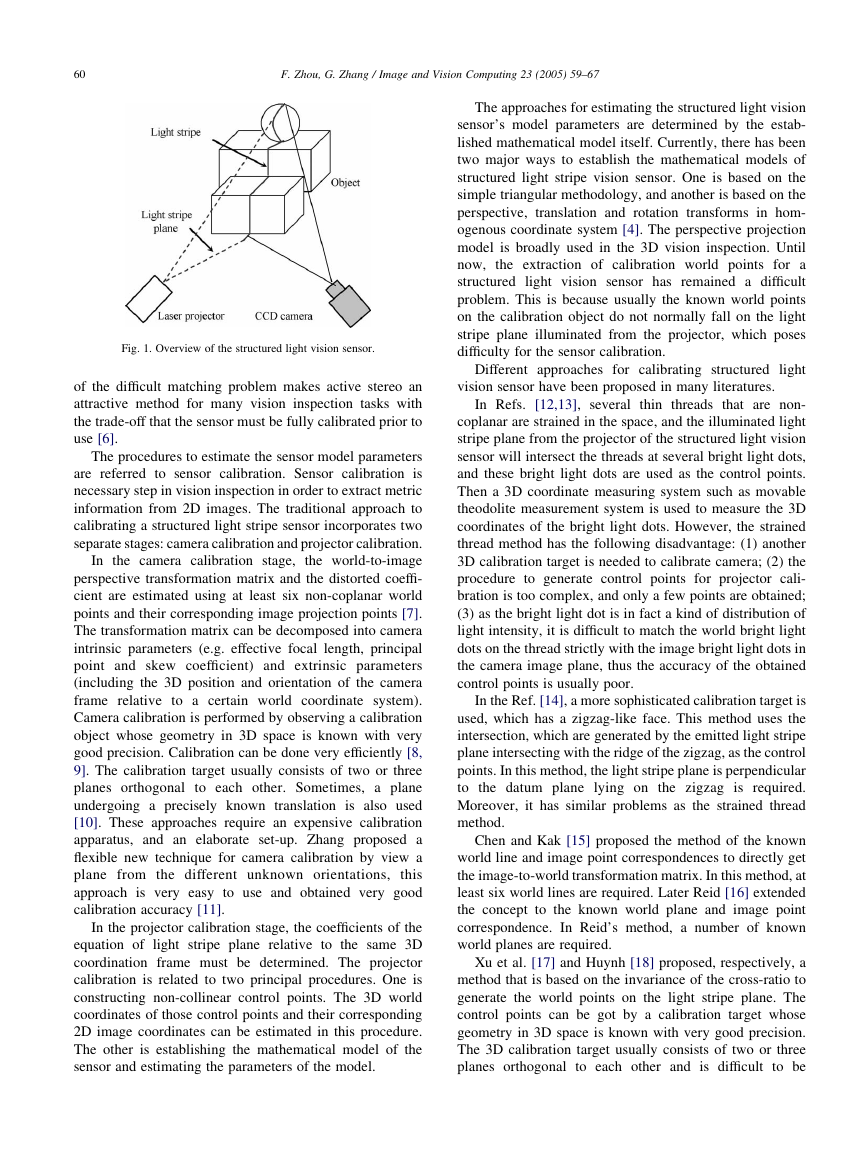

A basic structured light stripe vision sensor consists of

one camera and one laser projector, which together form an

active stereo pair. The projector is displaced relative to the

camera in space. For example, one of arrangements is

shown in Fig. 1, the light stripe is modulated by the depth of

the measured surface. Thus,

the deformed light stripe

contains rich 3D characteristic information of the object

surface. The camera captures the image of the object with

the deformed light stripe. The task of structured light vision

inspection is to acquire the 3D characteristic information of

the measured surface from the 2D deformed light stripe

image,

i.e. 3D reconstruction. A structured light stripe

vision sensor generates dense world points by sampling

image points on each light stripe in the image. The absence

�

60

F. Zhou, G. Zhang / Image and Vision Computing 23 (2005) 59–67

The approaches for estimating the structured light vision

sensor’s model parameters are determined by the estab-

lished mathematical model itself. Currently, there has been

two major ways to establish the mathematical models of

structured light stripe vision sensor. One is based on the

simple triangular methodology, and another is based on the

perspective, translation and rotation transforms in hom-

ogenous coordinate system [4]. The perspective projection

model is broadly used in the 3D vision inspection. Until

now,

the extraction of calibration world points for a

structured light vision sensor has remained a difficult

problem. This is because usually the known world points

on the calibration object do not normally fall on the light

stripe plane illuminated from the projector, which poses

difficulty for the sensor calibration.

Different approaches for calibrating structured light

vision sensor have been proposed in many literatures.

In Refs. [12,13], several

thin threads that are non-

coplanar are strained in the space, and the illuminated light

stripe plane from the projector of the structured light vision

sensor will intersect the threads at several bright light dots,

and these bright light dots are used as the control points.

Then a 3D coordinate measuring system such as movable

theodolite measurement system is used to measure the 3D

coordinates of the bright light dots. However, the strained

thread method has the following disadvantage: (1) another

3D calibration target is needed to calibrate camera; (2) the

procedure to generate control points for projector cali-

bration is too complex, and only a few points are obtained;

(3) as the bright light dot is in fact a kind of distribution of

light intensity, it is difficult to match the world bright light

dots on the thread strictly with the image bright light dots in

the camera image plane, thus the accuracy of the obtained

control points is usually poor.

In the Ref. [14], a more sophisticated calibration target is

used, which has a zigzag-like face. This method uses the

intersection, which are generated by the emitted light stripe

plane intersecting with the ridge of the zigzag, as the control

points. In this method, the light stripe plane is perpendicular

to the datum plane lying on the zigzag is required.

Moreover, it has similar problems as the strained thread

method.

Chen and Kak [15] proposed the method of the known

world line and image point correspondences to directly get

the image-to-world transformation matrix. In this method, at

least six world lines are required. Later Reid [16] extended

the concept to the known world plane and image point

correspondence. In Reid’s method, a number of known

world planes are required.

Xu et al. [17] and Huynh [18] proposed, respectively, a

method that is based on the invariance of the cross-ratio to

generate the world points on the light stripe plane. The

control points can be got by a calibration target whose

geometry in 3D space is known with very good precision.

The 3D calibration target usually consists of two or three

planes orthogonal

to be

to each other and is difficult

Fig. 1. Overview of the structured light vision sensor.

of the difficult matching problem makes active stereo an

attractive method for many vision inspection tasks with

the trade-off that the sensor must be fully calibrated prior to

use [6].

In the camera calibration stage,

The procedures to estimate the sensor model parameters

are referred to sensor calibration. Sensor calibration is

necessary step in vision inspection in order to extract metric

information from 2D images. The traditional approach to

calibrating a structured light stripe sensor incorporates two

separate stages: camera calibration and projector calibration.

the world-to-image

perspective transformation matrix and the distorted coeffi-

cient are estimated using at least six non-coplanar world

points and their corresponding image projection points [7].

The transformation matrix can be decomposed into camera

intrinsic parameters (e.g. effective focal length, principal

point and skew coefficient) and extrinsic parameters

(including the 3D position and orientation of the camera

frame relative to a certain world coordinate system).

Camera calibration is performed by observing a calibration

object whose geometry in 3D space is known with very

good precision. Calibration can be done very efficiently [8,

9]. The calibration target usually consists of two or three

planes orthogonal

to each other. Sometimes, a plane

undergoing a precisely known translation is also used

[10]. These approaches require an expensive calibration

apparatus, and an elaborate set-up. Zhang proposed a

flexible new technique for camera calibration by view a

plane from the different unknown orientations,

this

approach is very easy to use and obtained very good

calibration accuracy [11].

In the projector calibration stage, the coefficients of the

equation of light stripe plane relative to the same 3D

coordination frame must be determined. The projector

calibration is related to two principal procedures. One is

constructing non-collinear control points. The 3D world

coordinates of those control points and their corresponding

2D image coordinates can be estimated in this procedure.

The other is establishing the mathematical model of the

sensor and estimating the parameters of the model.

�

F. Zhou, G. Zhang / Image and Vision Computing 23 (2005) 59–67

61

2. Mathematical model of the structured light stripe

vision sensor

2.1. Camera model

manufactured accurately. It is also very difficult to capture

the good calibration image by simultaneously viewing the

different planes of

the 3D calibration object. These

approaches require an expensive calibration apparatus.

Besides the methods already mentioned, there are other

methods in the literature, such as, standard ruler calibration

target mounted on a step-motor-controlled stage with one

linear translation axis [19–21], a photoelectrical aiming

device combined with a 3D movable platform [22], and so

on. But because all these methods are demanding for the

precision of the moveable stage, inconvenient for operation,

and time-consuming in calibration, none of them is suitable

for or widely accepted on-line calibration.

To sum up, the methods of calibrating a structured light

vision sensor presented in the literature mainly have the

following drawbacks:

(1) it is difficult to generate large number of highly accurate

control points.

(2) some methods require an expensive calibration appar-

atus, and elaborate setup.

(3) the method is well unsuitable for on line sensor

calibration in situ.

These factors obstruct the improvement of the calibration

accuracy of structured light vision sensor and their

engineering 3D metrology applications.

In this paper, inspired by the work of Huynh and the work

of Zhang, we propose a novel approach that employs the

invariance of a cross-ratio to generate an arbitrary number of

control points on the light stripe plane by viewing a plane

from unknown orientations. The captured images of the

planar target can be used for camera calibration and projector

calibration simultaneously. The proposed techniques only

requires the camera to observe a planar target shown at a few

(at least two) different orientations. The target can be printed

on a laser printer and attached to a ‘reasonable’ planar surface

(e.g. a hard book cover). The planar target can be moved by

hand. The motion need not be known. In many respects the

approach taken here is similar to bundle adjustment

procedures used in photogrammetry in that a nonlinear

method is used to adjust the system parameters to best

accommodate all measured data. The difference is that in our

calibration approach, one of the components (the laser

striper) is not camera, although it can be considered in some

respects to be a special type of linear camera.

The paper is organized as follows. Section 2 introduces

the mathematical model of the structured light stripe vision

sensor. The model

includes the perspective projection

model of the camera and the projector model. Section 3

describes the procedure of calibrating the sensor. This

procedure includes camera calibration, constructing the

control points lying onto the light stripe plane and projector

calibration. Section 4 provides the experimental results.

Real data is used to validate the proposed technique.

; yn

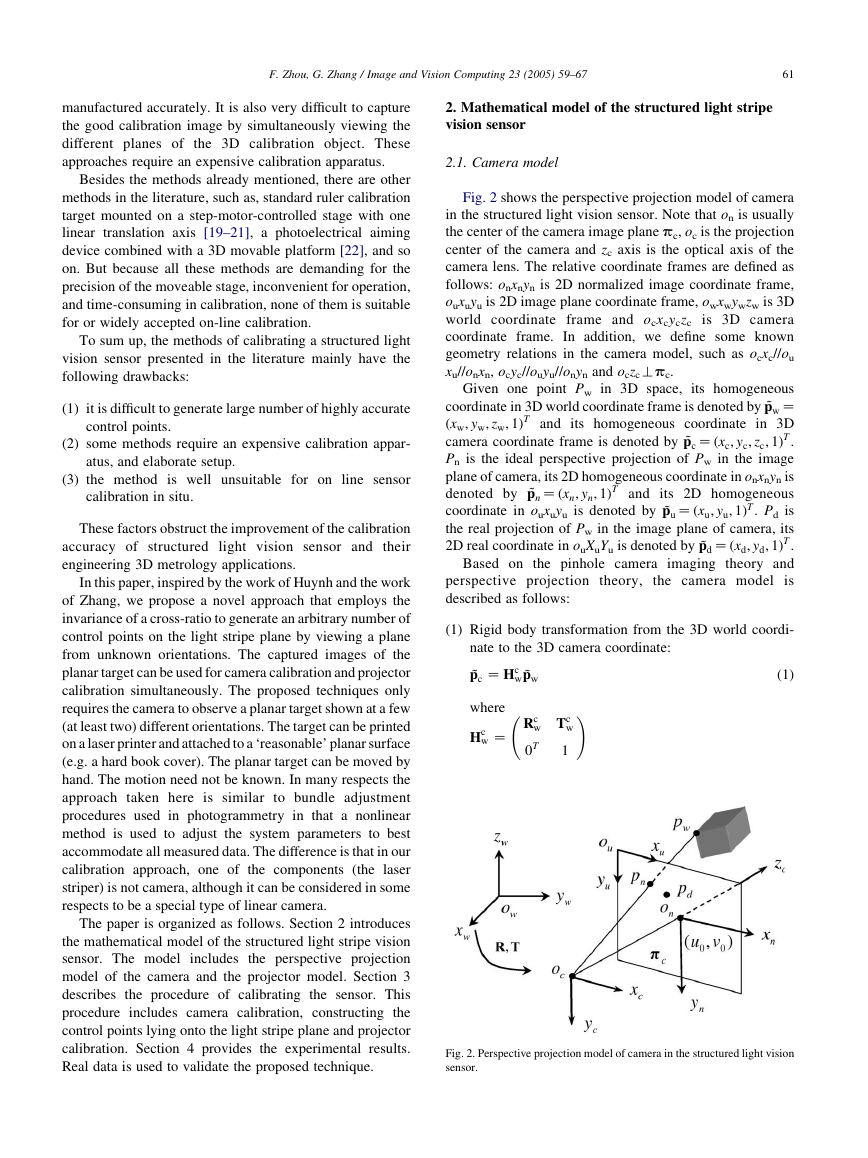

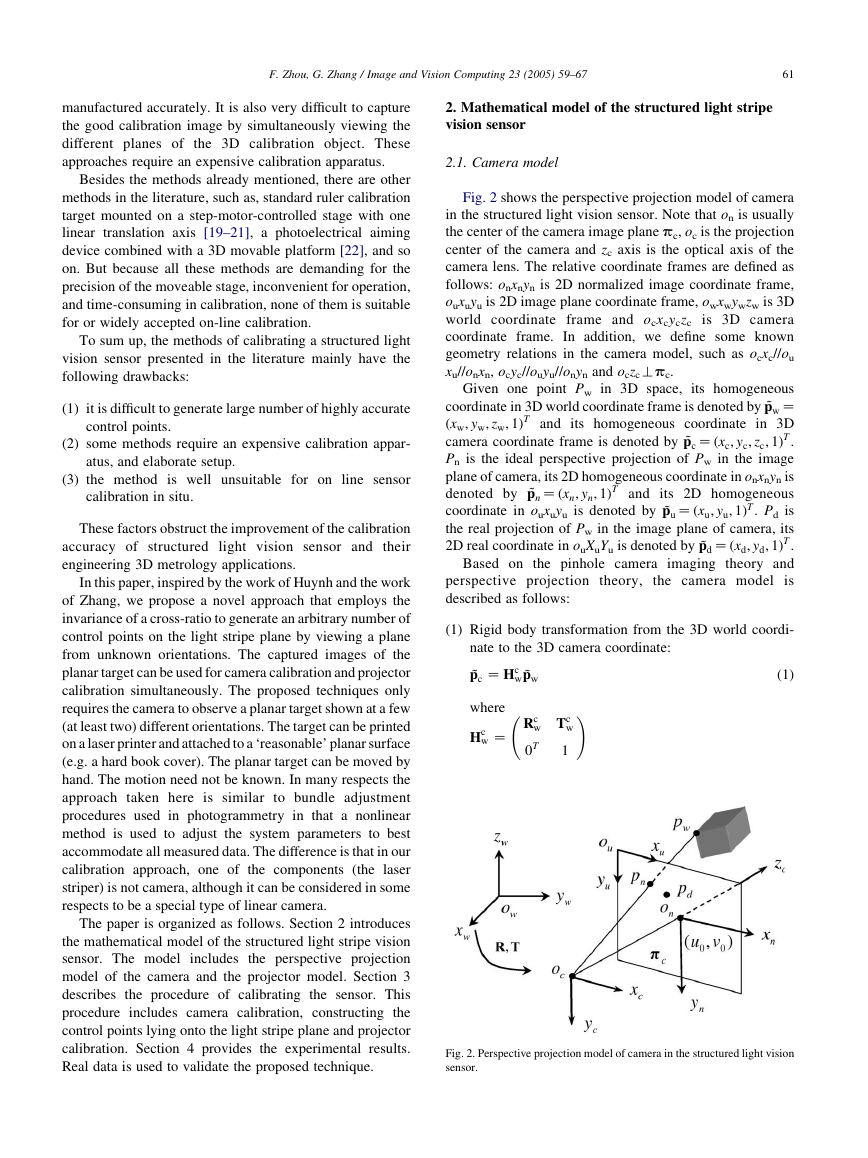

Fig. 2 shows the perspective projection model of camera

in the structured light vision sensor. Note that on is usually

the center of the camera image plane pc, oc is the projection

center of the camera and zc axis is the optical axis of the

camera lens. The relative coordinate frames are defined as

follows: onxnyn is 2D normalized image coordinate frame,

ouxuyu is 2D image plane coordinate frame, owxwywzw is 3D

world coordinate frame and ocxcyczc

is 3D camera

coordinate frame. In addition, we define some known

geometry relations in the camera model, such as ocxc//ou

xu//onxn, ocyc//ouyu//onyn and oczc

tpc.

Given one point Pw in 3D space,

its homogeneous

Z

coordinate in 3D world coordinate frame is denoted by ~pw

ðxw

; 1ÞT and its homogeneous coordinate in 3D

; 1ÞT .

camera coordinate frame is denoted by ~pc

Pn is the ideal perspective projection of Pw in the image

plane of camera, its 2D homogeneous coordinate in onxnyn is

; 1ÞT and its 2D homogeneous

denoted by ~pn

; 1ÞT . Pd is

coordinate in ouxuyu is denoted by ~pu

the real projection of Pw in the image plane of camera, its

; 1ÞT .

2D real coordinate in ouXuYu is denoted by ~pd

Based on the pinhole camera imaging theory and

is

; yu

Zðxd

the camera model

Zðxu

Zðxn

Zðxc

; yw

; zw

; yc

; zc

; yd

perspective projection theory,

described as follows:

(1) Rigid body transformation from the 3D world coordi-

nate to the 3D camera coordinate:

!

(1)

~pc

Z Hc

w ~pw

where

Hc

w

Z

Rc

w Tc

w

0T

1

Fig. 2. Perspective projection model of camera in the structured light vision

sensor.

�

62

F. Zhou, G. Zhang / Image and Vision Computing 23 (2005) 59–67

is 4!4 transformation matrix, which relates the world

coordinate frame to the camera coordinate frame. Tc

w is

3!1 translation vector and Rc

w is 3!3 orthogonal

rotation matrix.

(2) Transformation from the 3D camera coordinate to the

2D normalized image coordinate

l1 ~pn

ZðIj0Þ ~pc

; l1

s0

(2)

where I is 3!3 identity matrix, l1 is an arbitrary scale

factor.

(3) Transformation from the 2D normalized image coordi-

nate to the 2D undistorted image coordinate

l2 ~pu

Z A ~pn

; l2

s0

(3)

Fig. 3. Projector model of the structured light stripe vision sensor.

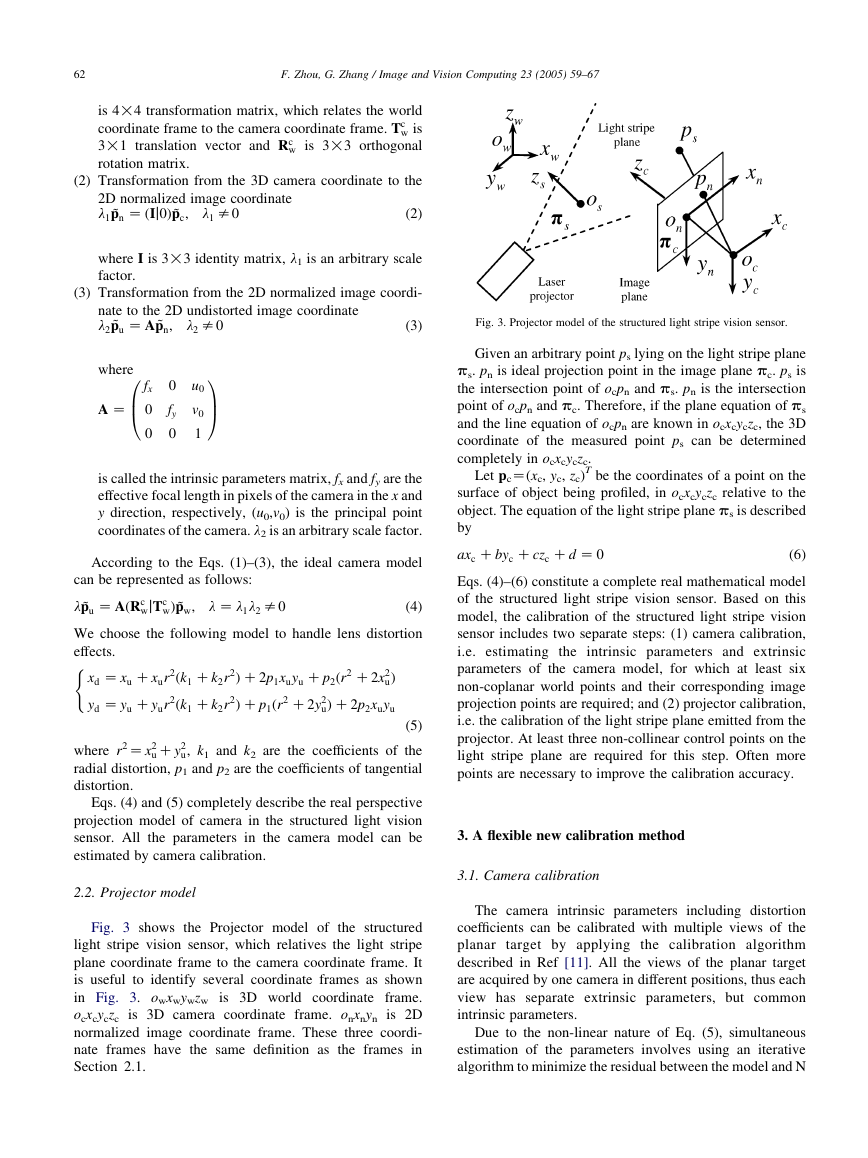

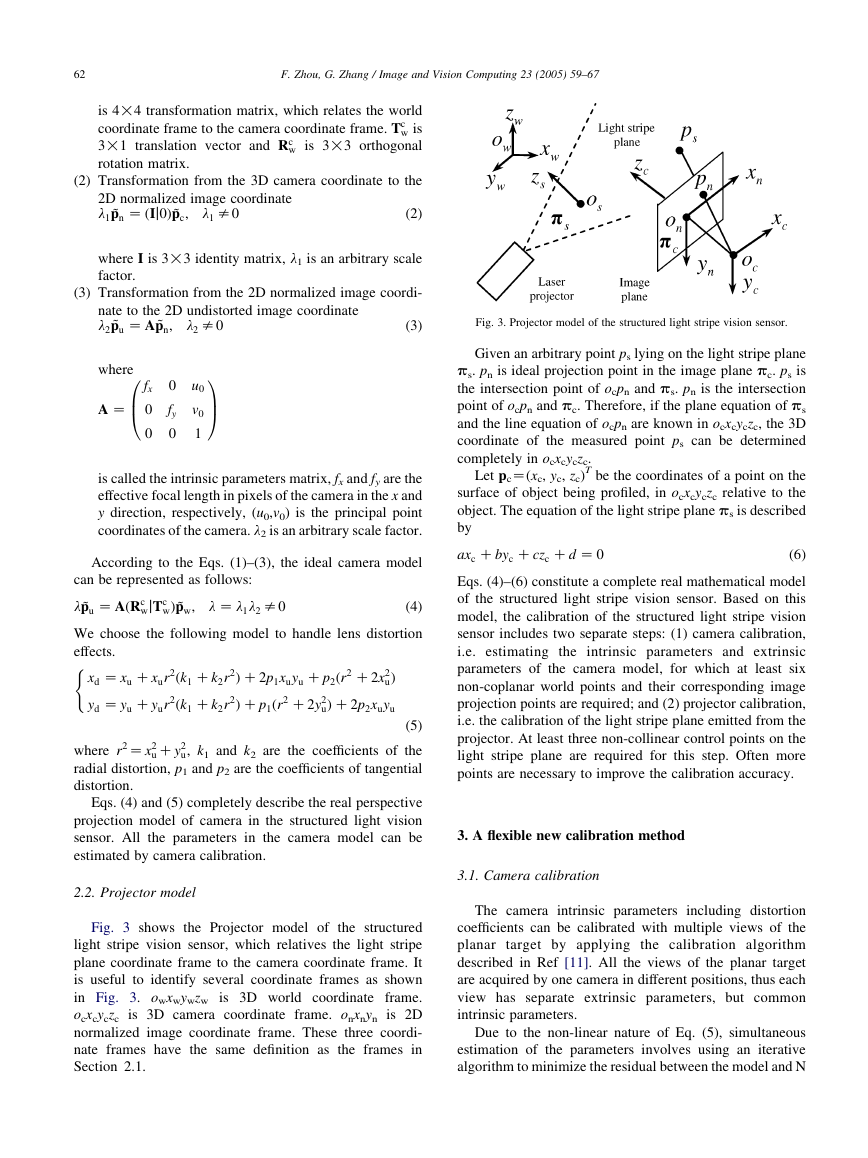

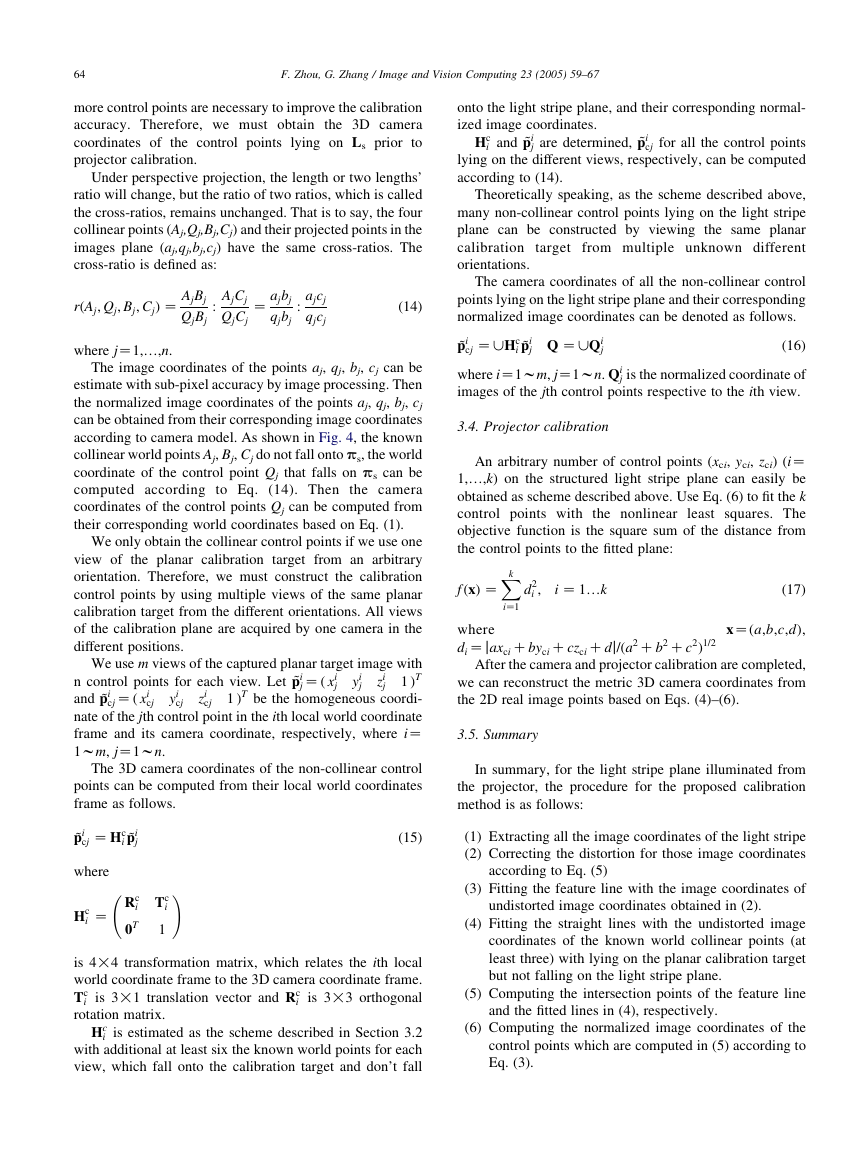

Given an arbitrary point ps lying on the light stripe plane

ps. pn is ideal projection point in the image plane pc. ps is

the intersection point of ocpn and ps. pn is the intersection

point of ocpn and pc. Therefore, if the plane equation of ps

and the line equation of ocpn are known in ocxcyczc, the 3D

coordinate of the measured point ps can be determined

completely in ocxcyczc.

Z(xc, yc, zc)T be the coordinates of a point on the

surface of object being profiled, in ocxcyczc relative to the

object. The equation of the light stripe plane ps is described

by

Let pc

axc

C byc

C czc

C d Z 0

(6)

Eqs. (4)–(6) constitute a complete real mathematical model

of the structured light stripe vision sensor. Based on this

model, the calibration of the structured light stripe vision

sensor includes two separate steps: (1) camera calibration,

i.e. estimating the intrinsic parameters and extrinsic

parameters of the camera model, for which at least six

non-coplanar world points and their corresponding image

projection points are required; and (2) projector calibration,

i.e. the calibration of the light stripe plane emitted from the

projector. At least three non-collinear control points on the

light stripe plane are required for this step. Often more

points are necessary to improve the calibration accuracy.

3. A flexible new calibration method

3.1. Camera calibration

The camera intrinsic parameters including distortion

coefficients can be calibrated with multiple views of the

planar

target by applying the calibration algorithm

described in Ref [11]. All the views of the planar target

are acquired by one camera in different positions, thus each

view has separate extrinsic parameters, but common

intrinsic parameters.

Due to the non-linear nature of Eq. (5), simultaneous

estimation of the parameters involves using an iterative

algorithm to minimize the residual between the model and N

0

B@

where

A Z

1

CA

fx

0

0

0

fy

0

u0

v0

1

is called the intrinsic parameters matrix, fx and fy are the

effective focal length in pixels of the camera in the x and

y direction, respectively, (u0,v0) is the principal point

coordinates of the camera. l2 is an arbitrary scale factor.

According to the Eqs. (1)–(3), the ideal camera model

can be represented as follows:

; l Z l1l2

Z AðRc

wÞ ~pw

wjTc

l ~pu

s0

(4)

(

We choose the following model to handle lens distortion

effects.

xd

yd

Z xu

Z yu

C xur2ðk1

C yur2ðk1

C k2r2Þ C 2p1xuyu

C k2r2Þ C p1ðr2 C 2y2

C p2ðr2 C 2x2

uÞ

uÞ C 2p2xuyu

(5)

C y2

where r2Z x2

u, k1 and k2 are the coefficients of the

u

radial distortion, p1 and p2 are the coefficients of tangential

distortion.

Eqs. (4) and (5) completely describe the real perspective

projection model of camera in the structured light vision

sensor. All the parameters in the camera model can be

estimated by camera calibration.

2.2. Projector model

Fig. 3 shows the Projector model of the structured

light stripe vision sensor, which relatives the light stripe

plane coordinate frame to the camera coordinate frame. It

is useful to identify several coordinate frames as shown

in Fig. 3. owxwywzw is 3D world coordinate frame.

ocxcyczc is 3D camera coordinate frame. onxnyn is 2D

normalized image coordinate frame. These three coordi-

nate frames have the same definition as the frames in

Section 2.1.

�

F. Zhou, G. Zhang / Image and Vision Computing 23 (2005) 59–67

63

observations. Typically, this procedure is performed with

least squares fitting, where the sum of squared residuals is

minimized. The objective function is then expressed as

F Z

K xdiÞ2 Cðymi

K ydiÞ2Þ

(7)

X

ððxmi

N

iZ1

where (xdi, ydi) is the real image coordinate and (xmi, ymi) is

the estimated image coordinate by 3D world point according

to the camera projective model.

Two coefficients for both radial and tangential distortion

are often enough [9]. Then, a total of eight

intrinsic

parameters are estimated. The more detailed algorithm is

described in Ref. [11].

3.2. Transformation from world coordinate frame to 3D

camera coordinate frame

Without loss of generality, we assume the calibration

Z0 of the local world coordinate frame

target plane is on zw

Let’s denote the ith column of the rotation matrix by ri.

From Eq. (4), we have

Z Að r1

l ~pu

r2 TÞ ~pw

(8)

by abuse of notation, we still use ~pw to denote the

homogeneous coordinate of a point on the calibration

; 1T. Therefore, a cali-

~pw

object’s plane,

i.e.

~pw and its image ~pu is related by

bration plane point

homography H:

Z½xw

; yw

l ~pu

Z H ~pw

with

8>>>>><

>>>>>:

(9)

r2 TÞ Zð h1 h2 h3 Þ

H Z Að r1

where hi denotes the ith column of the matrix H.

Given four or more points ~pwi, where iZ1,.,n for nR4,

in general position (i.e. no three points are collinear) on

calibration plane and their perspective projection ~pui under a

perspective center oc. If camera intrinsic parameters are

known, the transformation from world coordinate frame to

3D camera coordinate frame can be obtained as follows

[11]:

r1

Z lA

Z lA

r2

Z r1

r3

T Z lA

K1h1

K1h2

!r2

K1h3

where lZ 1=jjA

matrix relates the world coordinate frame to the camera

coordinate frame is expressed as:

K1h2jj. Then the rotation

K1h1jjZ 1=jjA

(10)

r2

r3 Þ

^R Zð r1

(11)

The matrix ^R does not satisfy the orthonormality constraint

of a standard rotation matrix, but we can normalize

and orthonormalize it using the singular value decompo-

sition (SVD):

^R Z UWVT

The orthonormal version of ^R is given by

R Z UW

(12)

(13)

0

VT

0Z diagð1; 1;jUVTjÞ.

whereW

In practice, the linear algorithm describes above is quite

noisy because nine parameters for a system of equations

with six degrees of freedom. However, the linear estimation

is close to the true solution to sever as a good initialization

for non-linear optimization technique. All the more accurate

parameters of the transformation from the world frame to

the camera frame can be estimated by Levenberg–

Marquardt non-linear optimization of the cost function

described in Eqs. (7) and (8).

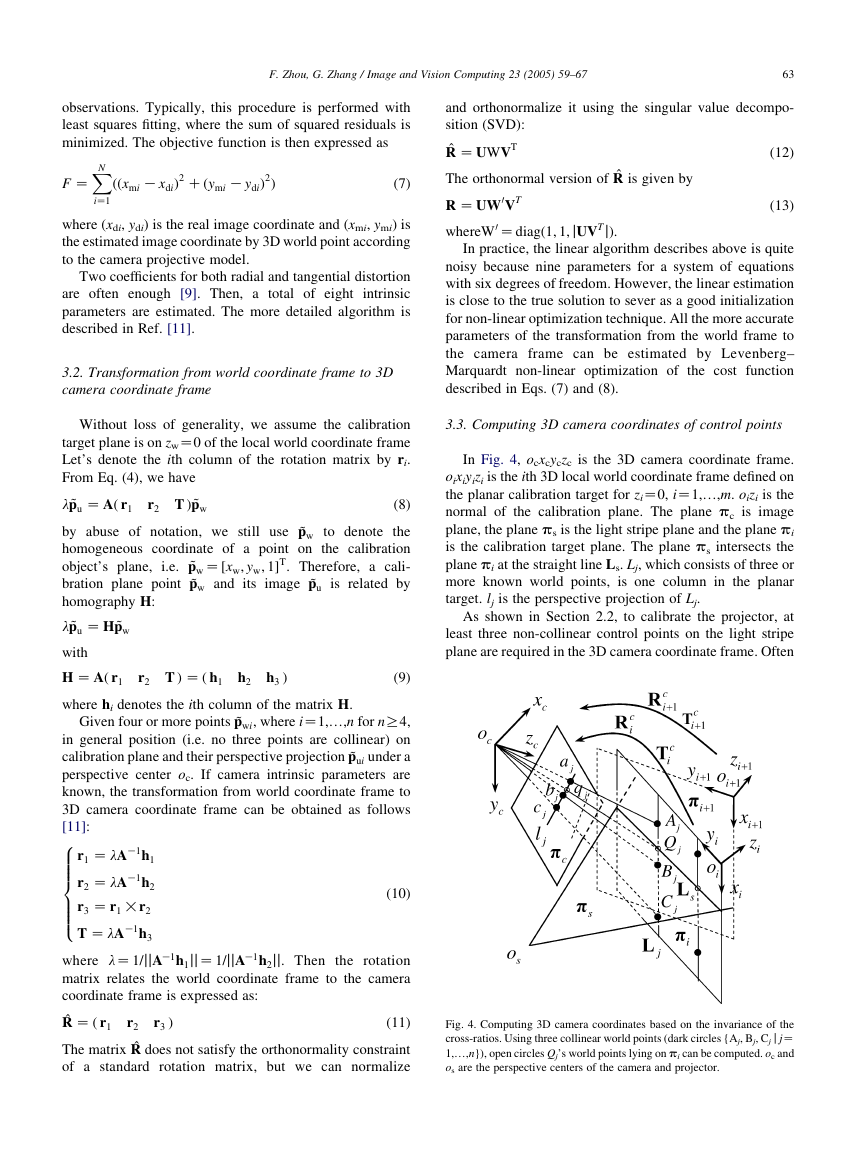

3.3. Computing 3D camera coordinates of control points

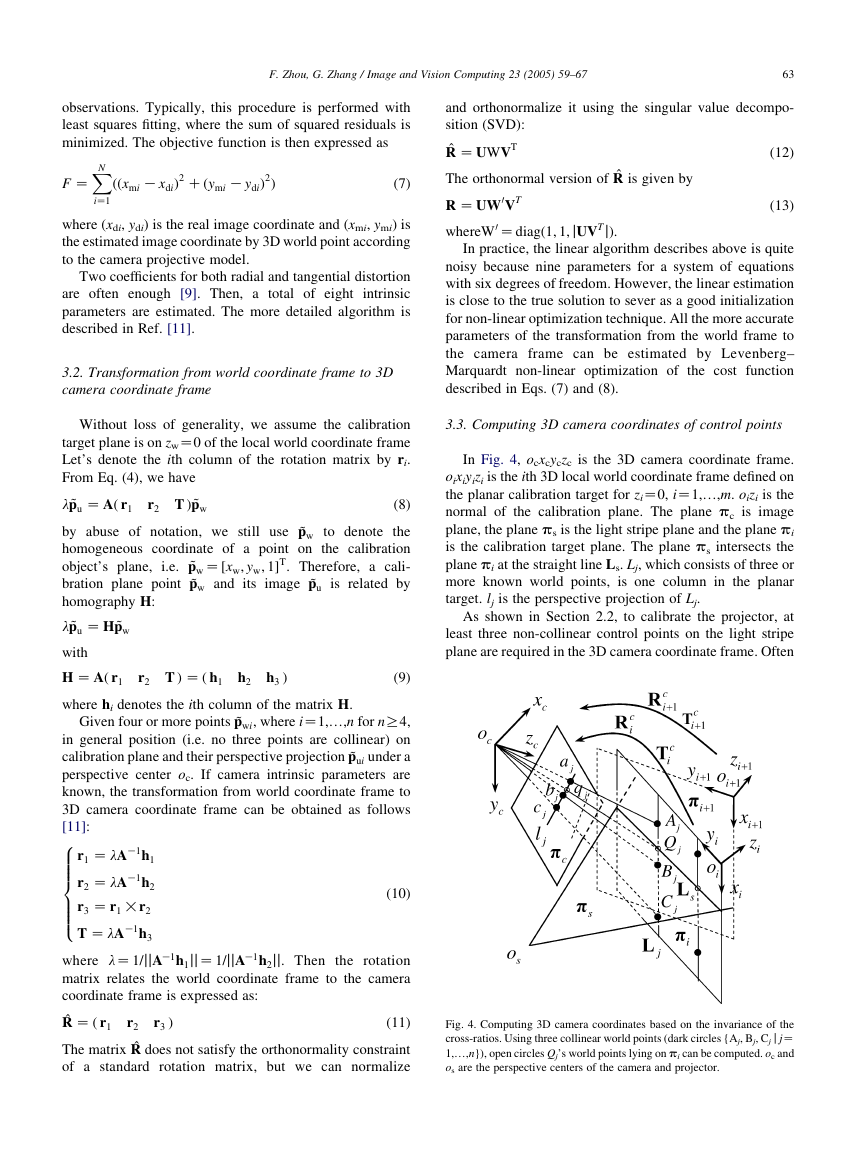

In Fig. 4, ocxcyczc is the 3D camera coordinate frame.

oixiyizi is the ith 3D local world coordinate frame defined on

the planar calibration target for ziZ0, iZ1,.,m. oizi is the

normal of the calibration plane. The plane pc is image

plane, the plane ps is the light stripe plane and the plane pi

is the calibration target plane. The plane ps intersects the

plane pi at the straight line Ls. Lj, which consists of three or

more known world points, is one column in the planar

target. lj is the perspective projection of Lj.

As shown in Section 2.2, to calibrate the projector, at

least three non-collinear control points on the light stripe

plane are required in the 3D camera coordinate frame. Often

Fig. 4. Computing 3D camera coordinates based on the invariance of the

cross-ratios. Using three collinear world points (dark circles {Aj, Bj, Cj j jZ

1,.,n}), open circles Qj’s world points lying on pi can be computed. oc and

os are the perspective centers of the camera and projector.

�

64

F. Zhou, G. Zhang / Image and Vision Computing 23 (2005) 59–67

more control points are necessary to improve the calibration

accuracy. Therefore, we must obtain the 3D camera

coordinates of the control points lying on Ls prior to

projector calibration.

Under perspective projection, the length or two lengths’

ratio will change, but the ratio of two ratios, which is called

the cross-ratios, remains unchanged. That is to say, the four

collinear points (Aj,Qj,Bj,Cj) and their projected points in the

images plane (aj,qj,bj,cj) have the same cross-ratios. The

cross-ratio is defined as:

rðAj

; Qj

; Bj

; CjÞ Z AjBj

QjBj

:

AjCj

QjCj

Z ajbj

qjbj

:

ajcj

qjcj

(14)

where jZ1,.,n.

The image coordinates of the points aj, qj, bj, cj can be

estimate with sub-pixel accuracy by image processing. Then

the normalized image coordinates of the points aj, qj, bj, cj

can be obtained from their corresponding image coordinates

according to camera model. As shown in Fig. 4, the known

collinear world points Aj, Bj, Cj do not fall onto ps, the world

coordinate of the control point Qj that falls on ps can be

computed according to Eq.

(14). Then the camera

coordinates of the control points Qj can be computed from

their corresponding world coordinates based on Eq. (1).

We only obtain the collinear control points if we use one

view of the planar calibration target from an arbitrary

orientation. Therefore, we must construct the calibration

control points by using multiple views of the same planar

calibration target from the different orientations. All views

of the calibration plane are acquired by one camera in the

different positions.

Zð xi

We use m views of the captured planar target image with

1ÞT

n control points for each view. Let ~pi

1ÞT be the homogeneous coordi-

j

and ~pi

cj

nate of the jth control point in the ith local world coordinate

frame and its camera coordinate, respectively, where iZ

1wm, jZ1wn.

Zð xi

yi

cj

zi

cj

yi

j

zi

j

cj

j

onto the light stripe plane, and their corresponding normal-

ized image coordinates.

Hc

i and ~pi

j are determined, ~pi

cj for all the control points

lying on the different views, respectively, can be computed

according to (14).

Theoretically speaking, as the scheme described above,

many non-collinear control points lying on the light stripe

plane can be constructed by viewing the same planar

calibration target

from multiple unknown different

orientations.

The camera coordinates of all the non-collinear control

points lying on the light stripe plane and their corresponding

normalized image coordinates can be denoted as follows.

i ~pi

ZgHc

j Q ZgQi

~pi

cj

where iZ1wm, jZ1wn. Qi

j is the normalized coordinate of

images of the jth control points respective to the ith view.

(16)

j

3.4. Projector calibration

An arbitrary number of control points (xci, yci, zci) (iZ

1,.,k) on the structured light stripe plane can easily be

obtained as scheme described above. Use Eq. (6) to fit the k

control points with the nonlinear

least squares. The

objective function is the square sum of the distance from

the control points to the fitted plane:

X

k

fðxÞ Z

iZ1

d2

i

;

i Z 1.k

(17)

xZ(a,b,c,d),

where

di

Zjaxci

C byci

C czci

C dj=ða2 C b2 C c2Þ1=2

After the camera and projector calibration are completed,

we can reconstruct the metric 3D camera coordinates from

the 2D real image points based on Eqs. (4)–(6).

3.5. Summary

The 3D camera coordinates of the non-collinear control

points can be computed from their local world coordinates

frame as follows.

In summary, for the light stripe plane illuminated from

the projector, the procedure for the proposed calibration

method is as follows:

!

~pi

cj

Z Hc

i ~pi

j

where

Z

Hc

i

Rc

i Tc

i

0T

1

is 4!4 transformation matrix, which relates the ith local

world coordinate frame to the 3D camera coordinate frame.

is 3!3 orthogonal

Tc

i

rotation matrix.

is 3!1 translation vector and Rc

i

Hc

i is estimated as the scheme described in Section 3.2

with additional at least six the known world points for each

view, which fall onto the calibration target and don’t fall

(15)

(1) Extracting all the image coordinates of the light stripe

(2) Correcting the distortion for those image coordinates

according to Eq. (5)

(3) Fitting the feature line with the image coordinates of

undistorted image coordinates obtained in (2).

(4) Fitting the straight lines with the undistorted image

coordinates of the known world collinear points (at

least three) with lying on the planar calibration target

but not falling on the light stripe plane.

(5) Computing the intersection points of the feature line

and the fitted lines in (4), respectively.

(6) Computing the normalized image coordinates of the

control points which are computed in (5) according to

Eq. (3).

�

F. Zhou, G. Zhang / Image and Vision Computing 23 (2005) 59–67

65

Fig. 5. Designed structured light vision sensor.

(7) Computing the cross-ratio as given by Eq. (14) for

each image line lj and computing the local world

coordinates.

(8) Computing the ith transformation Hc

i with another

feature points lying on the ith calibration plane but not

on the light stripe and their corresponding image

coordinates.

(9) Computing the 3D camera coordinates of the control

points.

(10) Estimating the equation of the light stripe plane in 3D

camera coordinate frame as described in Section 3.4.

Because our method uses unknown orientation planar

calibration target, the proposed calibration method can be

easily extended to handle an arbitrary large number of

control points. The calibration is very easy and flexible.

4. Experiments

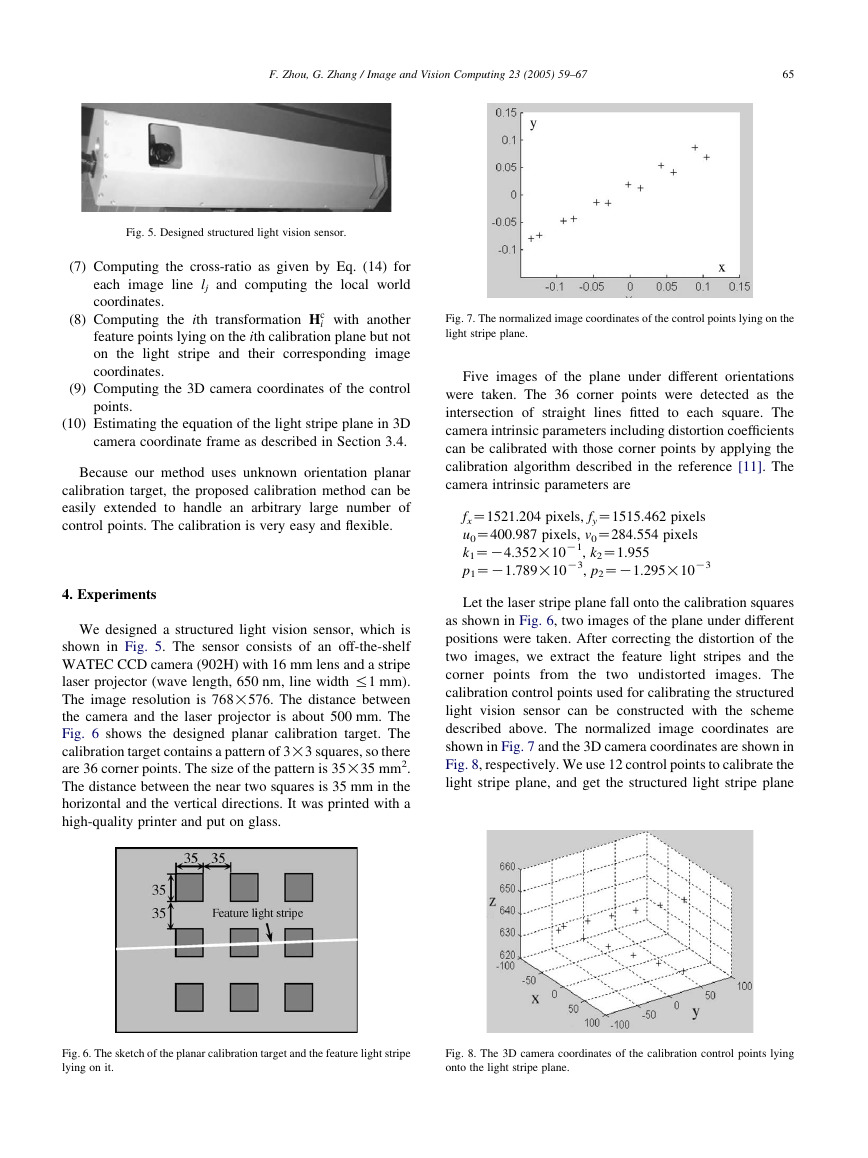

We designed a structured light vision sensor, which is

shown in Fig. 5. The sensor consists of an off-the-shelf

WATEC CCD camera (902H) with 16 mm lens and a stripe

laser projector (wave length, 650 nm, line width %1 mm).

The image resolution is 768!576. The distance between

the camera and the laser projector is about 500 mm. The

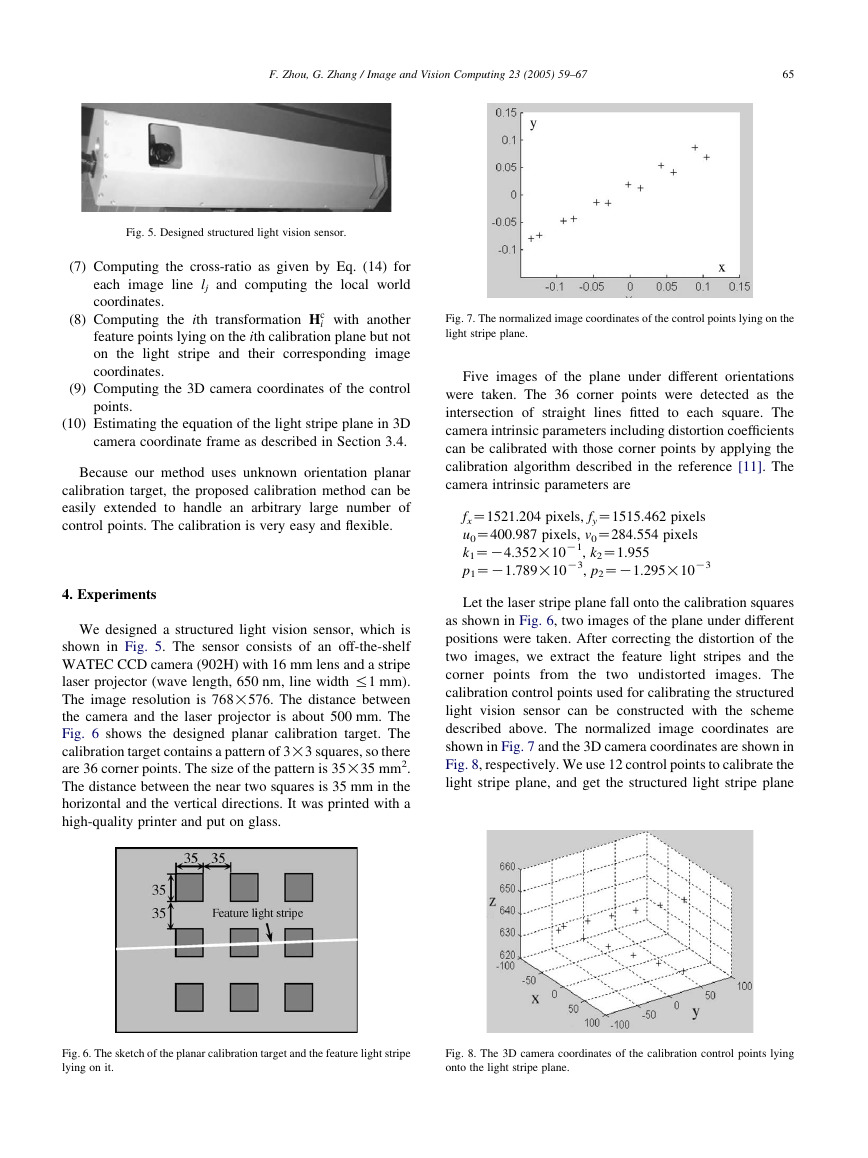

Fig. 6 shows the designed planar calibration target. The

calibration target contains a pattern of 3!3 squares, so there

are 36 corner points. The size of the pattern is 35!35 mm2.

The distance between the near two squares is 35 mm in the

horizontal and the vertical directions. It was printed with a

high-quality printer and put on glass.

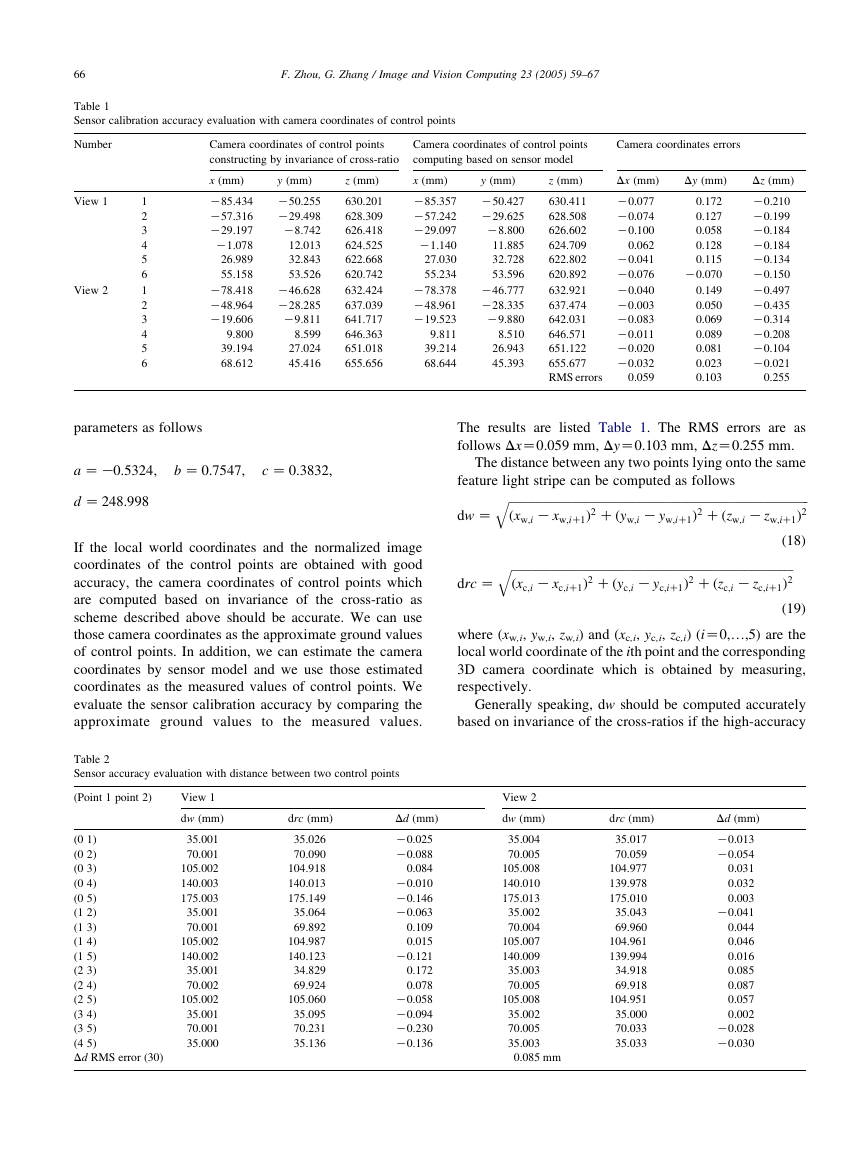

Fig. 7. The normalized image coordinates of the control points lying on the

light stripe plane.

Five images of the plane under different orientations

were taken. The 36 corner points were detected as the

intersection of straight lines fitted to each square. The

camera intrinsic parameters including distortion coefficients

can be calibrated with those corner points by applying the

calibration algorithm described in the reference [11]. The

camera intrinsic parameters are

fxZ1521.204 pixels, fyZ1515.462 pixels

u0Z400.987 pixels, v0Z284.554 pixels

k1ZK4.352!10

p1ZK1.789!10

K1, k2Z1.955

K3, p2ZK1.295!10

K3

Let the laser stripe plane fall onto the calibration squares

as shown in Fig. 6, two images of the plane under different

positions were taken. After correcting the distortion of the

two images, we extract the feature light stripes and the

corner points from the two undistorted images. The

calibration control points used for calibrating the structured

light vision sensor can be constructed with the scheme

described above. The normalized image coordinates are

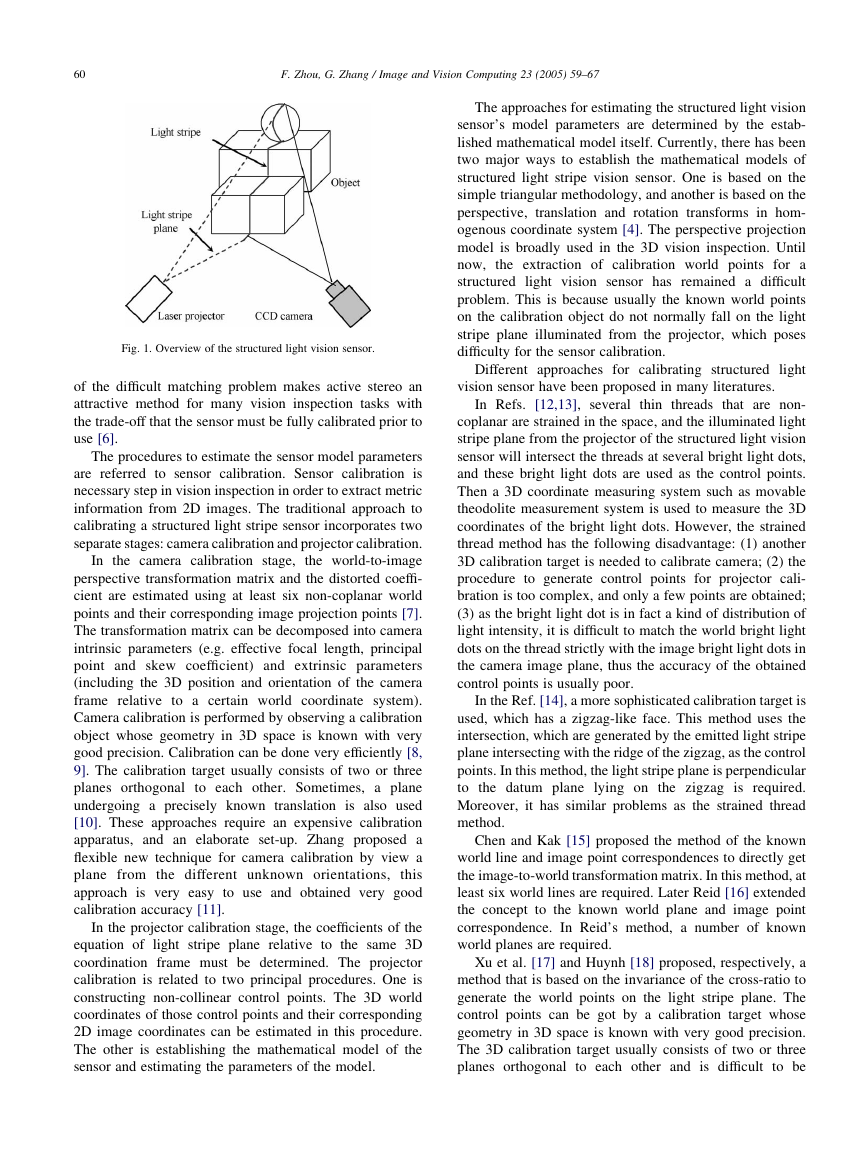

shown in Fig. 7 and the 3D camera coordinates are shown in

Fig. 8, respectively. We use 12 control points to calibrate the

light stripe plane, and get the structured light stripe plane

Fig. 6. The sketch of the planar calibration target and the feature light stripe

lying on it.

Fig. 8. The 3D camera coordinates of the calibration control points lying

onto the light stripe plane.

�

66

F. Zhou, G. Zhang / Image and Vision Computing 23 (2005) 59–67

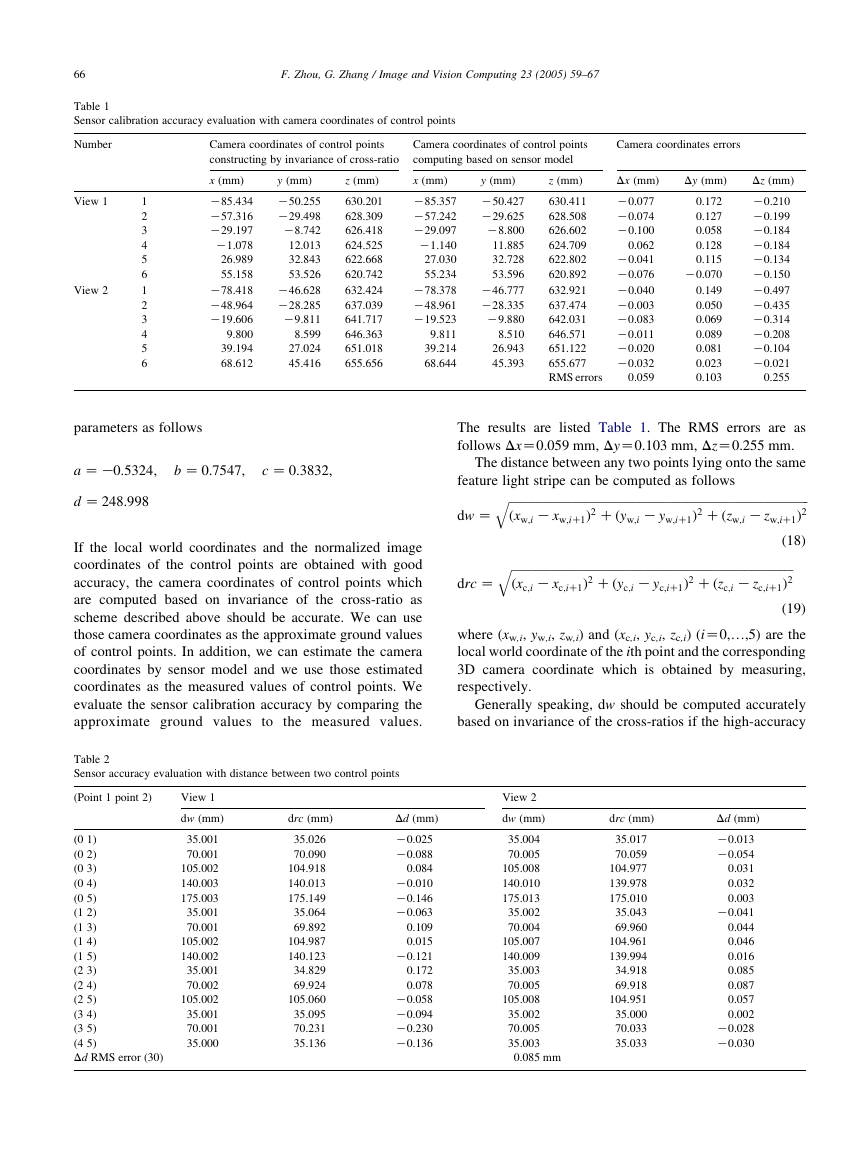

Table 1

Sensor calibration accuracy evaluation with camera coordinates of control points

Number

View 1

View 2

1

2

3

4

5

6

1

2

3

4

5

6

Camera coordinates of control points

constructing by invariance of cross-ratio

Camera coordinates of control points

computing based on sensor model

Camera coordinates errors

x (mm)

K85.434

K57.316

K29.197

K1.078

26.989

55.158

K78.418

K48.964

K19.606

9.800

39.194

68.612

y (mm)

K50.255

K29.498

K8.742

12.013

32.843

53.526

K46.628

K28.285

K9.811

8.599

27.024

45.416

z (mm)

630.201

628.309

626.418

624.525

622.668

620.742

632.424

637.039

641.717

646.363

651.018

655.656

x (mm)

K85.357

K57.242

K29.097

K1.140

27.030

55.234

K78.378

K48.961

K19.523

9.811

39.214

68.644

y (mm)

K50.427

K29.625

K8.800

11.885

32.728

53.596

K46.777

K28.335

K9.880

8.510

26.943

45.393

z (mm)

630.411

628.508

626.602

624.709

622.802

620.892

632.921

637.474

642.031

646.571

651.122

655.677

RMS errors

Dx (mm)

K0.077

K0.074

K0.100

0.062

K0.041

K0.076

K0.040

K0.003

K0.083

K0.011

K0.020

K0.032

0.059

Dy (mm)

0.172

0.127

0.058

0.128

0.115

K0.070

0.149

0.050

0.069

0.089

0.081

0.023

0.103

Dz (mm)

K0.210

K0.199

K0.184

K0.184

K0.134

K0.150

K0.497

K0.435

K0.314

K0.208

K0.104

K0.021

0.255

parameters as follows

a Z K0:5324;

b Z 0:7547;

c Z 0:3832;

d Z 248:998

If the local world coordinates and the normalized image

coordinates of the control points are obtained with good

accuracy, the camera coordinates of control points which

are computed based on invariance of the cross-ratio as

scheme described above should be accurate. We can use

those camera coordinates as the approximate ground values

of control points. In addition, we can estimate the camera

coordinates by sensor model and we use those estimated

coordinates as the measured values of control points. We

evaluate the sensor calibration accuracy by comparing the

approximate ground values to the measured values.

Table 2

Sensor accuracy evaluation with distance between two control points

(Point 1 point 2)

View 1

dw (mm)

drc (mm)

(0 1)

(0 2)

(0 3)

(0 4)

(0 5)

(1 2)

(1 3)

(1 4)

(1 5)

(2 3)

(2 4)

(2 5)

(3 4)

(3 5)

(4 5)

Dd RMS error (30)

35.001

70.001

105.002

140.003

175.003

35.001

70.001

105.002

140.002

35.001

70.002

105.002

35.001

70.001

35.000

35.026

70.090

104.918

140.013

175.149

35.064

69.892

104.987

140.123

34.829

69.924

105.060

35.095

70.231

35.136

Dd (mm)

K0.025

K0.088

0.084

K0.010

K0.146

K0.063

0.109

0.015

K0.121

0.172

0.078

K0.058

K0.094

K0.230

K0.136

The results are listed Table 1. The RMS errors are as

follows DxZ0.059 mm, DyZ0.103 mm, DzZ0.255 mm.

The distance between any two points lying onto the same

feature light stripe can be computed as follows

q

K xw;iC1Þ2 Cðyw;i

ffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffi

ðxw;i

K zw;iC1Þ2

q

ffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffi

K zc;iC1Þ2

ðxc;i

K yw;iC1Þ2 Cðzw;i

K xc;iC1Þ2 Cðyc;i

K yc;iC1Þ2 Cðzc;i

(18)

dw Z

drc Z

(19)

where (xw,i, yw,i, zw,i) and (xc,i, yc,i, zc,i) (iZ0,.,5) are the

local world coordinate of the ith point and the corresponding

3D camera coordinate which is obtained by measuring,

respectively.

Generally speaking, dw should be computed accurately

based on invariance of the cross-ratios if the high-accuracy

View 2

dw (mm)

35.004

70.005

105.008

140.010

175.013

35.002

70.004

105.007

140.009

35.003

70.005

105.008

35.002

70.005

35.003

0.085 mm

drc (mm)

35.017

70.059

104.977

139.978

175.010

35.043

69.960

104.961

139.994

34.918

69.918

104.951

35.000

70.033

35.033

Dd (mm)

K0.013

K0.054

0.031

0.032

0.003

K0.041

0.044

0.046

0.016

0.085

0.087

0.057

0.002

K0.028

K0.030

�

2023年江西萍乡中考道德与法治真题及答案.doc

2023年江西萍乡中考道德与法治真题及答案.doc 2012年重庆南川中考生物真题及答案.doc

2012年重庆南川中考生物真题及答案.doc 2013年江西师范大学地理学综合及文艺理论基础考研真题.doc

2013年江西师范大学地理学综合及文艺理论基础考研真题.doc 2020年四川甘孜小升初语文真题及答案I卷.doc

2020年四川甘孜小升初语文真题及答案I卷.doc 2020年注册岩土工程师专业基础考试真题及答案.doc

2020年注册岩土工程师专业基础考试真题及答案.doc 2023-2024学年福建省厦门市九年级上学期数学月考试题及答案.doc

2023-2024学年福建省厦门市九年级上学期数学月考试题及答案.doc 2021-2022学年辽宁省沈阳市大东区九年级上学期语文期末试题及答案.doc

2021-2022学年辽宁省沈阳市大东区九年级上学期语文期末试题及答案.doc 2022-2023学年北京东城区初三第一学期物理期末试卷及答案.doc

2022-2023学年北京东城区初三第一学期物理期末试卷及答案.doc 2018上半年江西教师资格初中地理学科知识与教学能力真题及答案.doc

2018上半年江西教师资格初中地理学科知识与教学能力真题及答案.doc 2012年河北国家公务员申论考试真题及答案-省级.doc

2012年河北国家公务员申论考试真题及答案-省级.doc 2020-2021学年江苏省扬州市江都区邵樊片九年级上学期数学第一次质量检测试题及答案.doc

2020-2021学年江苏省扬州市江都区邵樊片九年级上学期数学第一次质量检测试题及答案.doc 2022下半年黑龙江教师资格证中学综合素质真题及答案.doc

2022下半年黑龙江教师资格证中学综合素质真题及答案.doc