Table of Contents

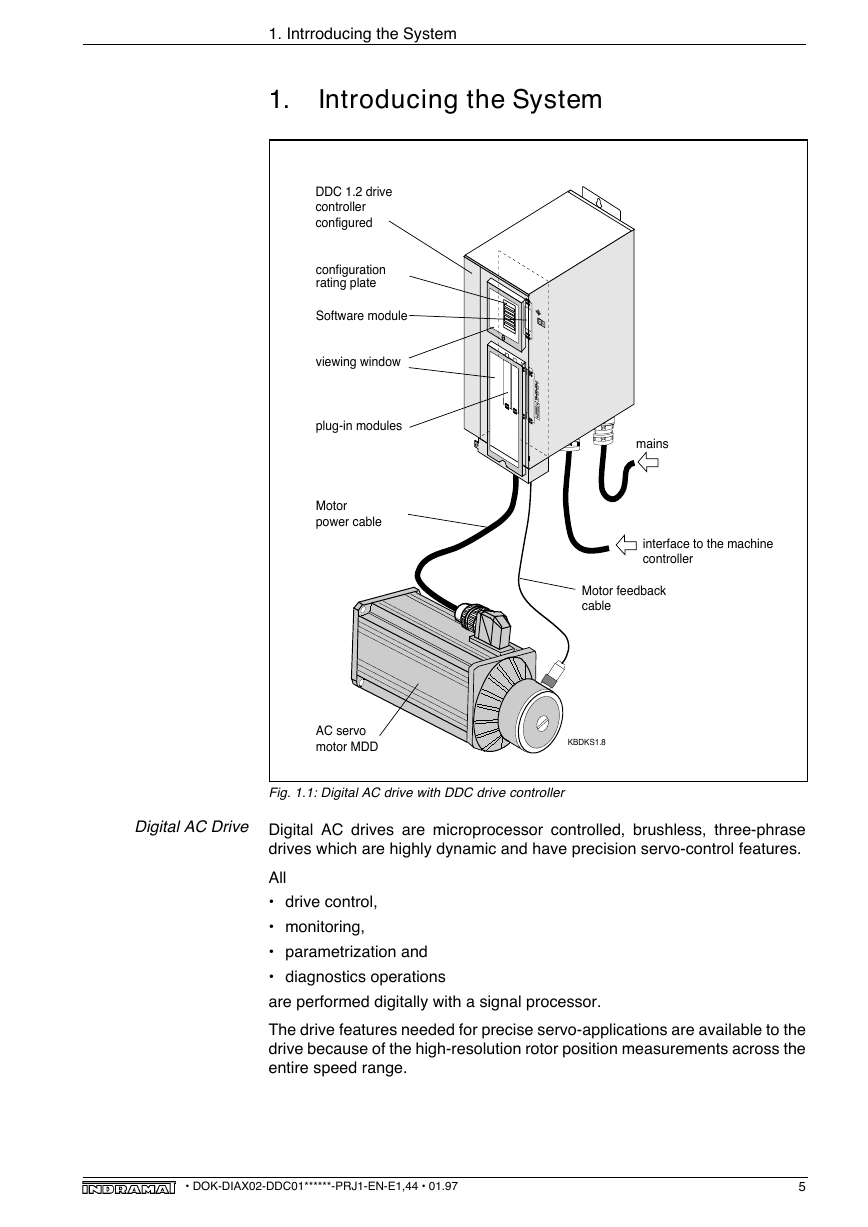

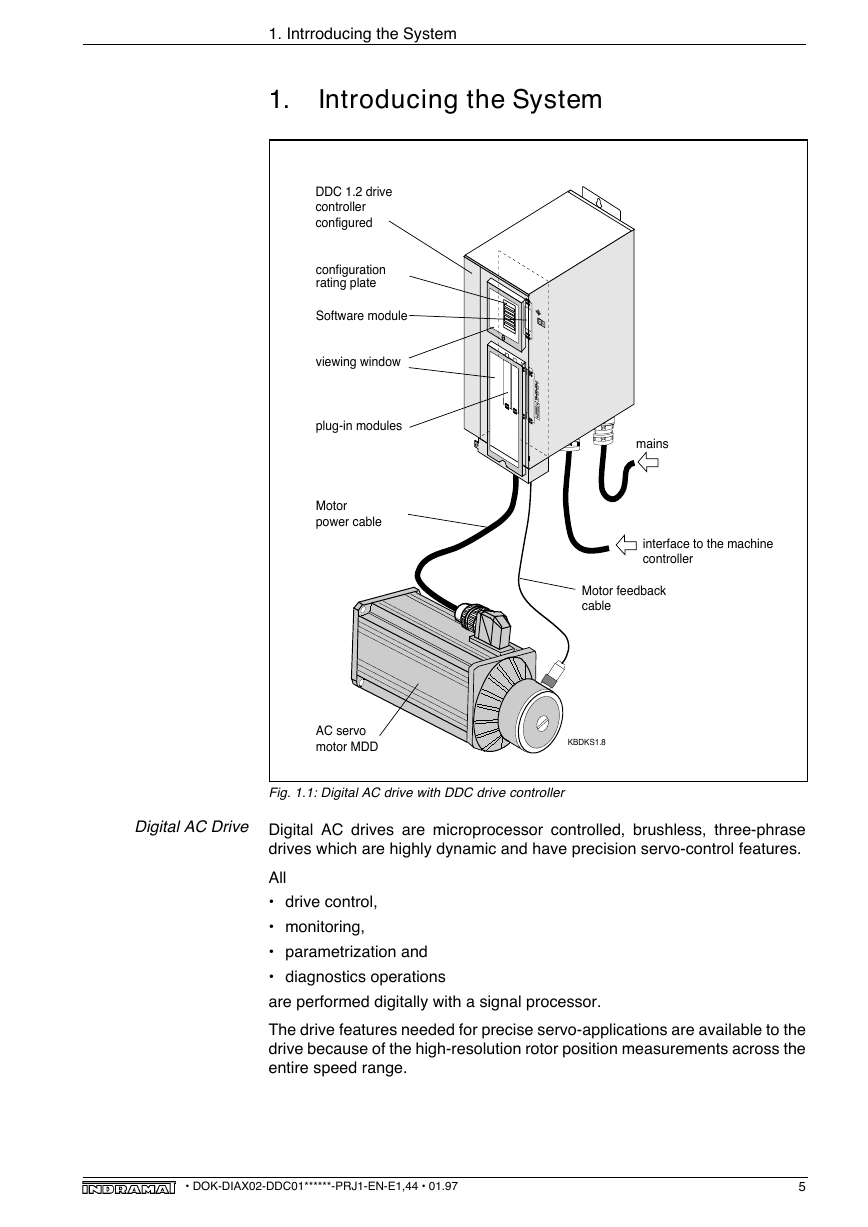

1. Introducing the System

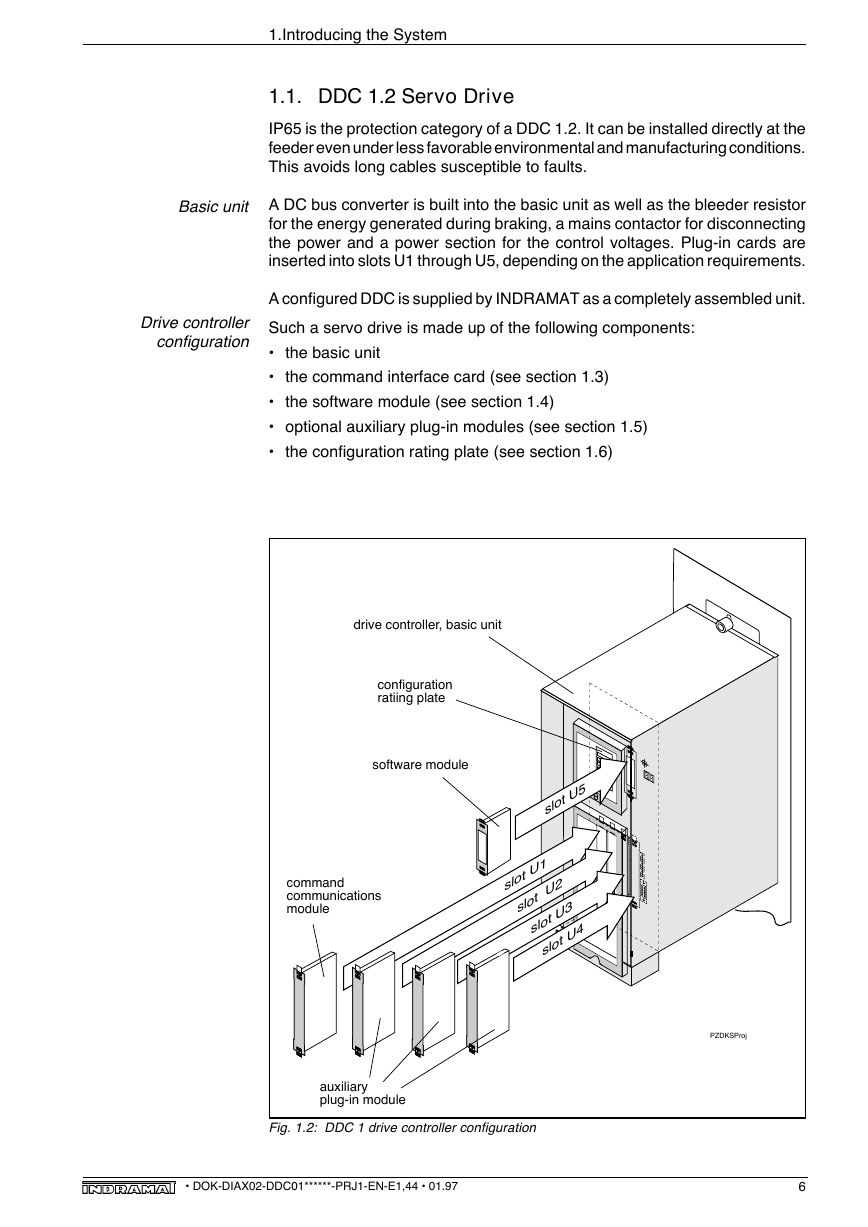

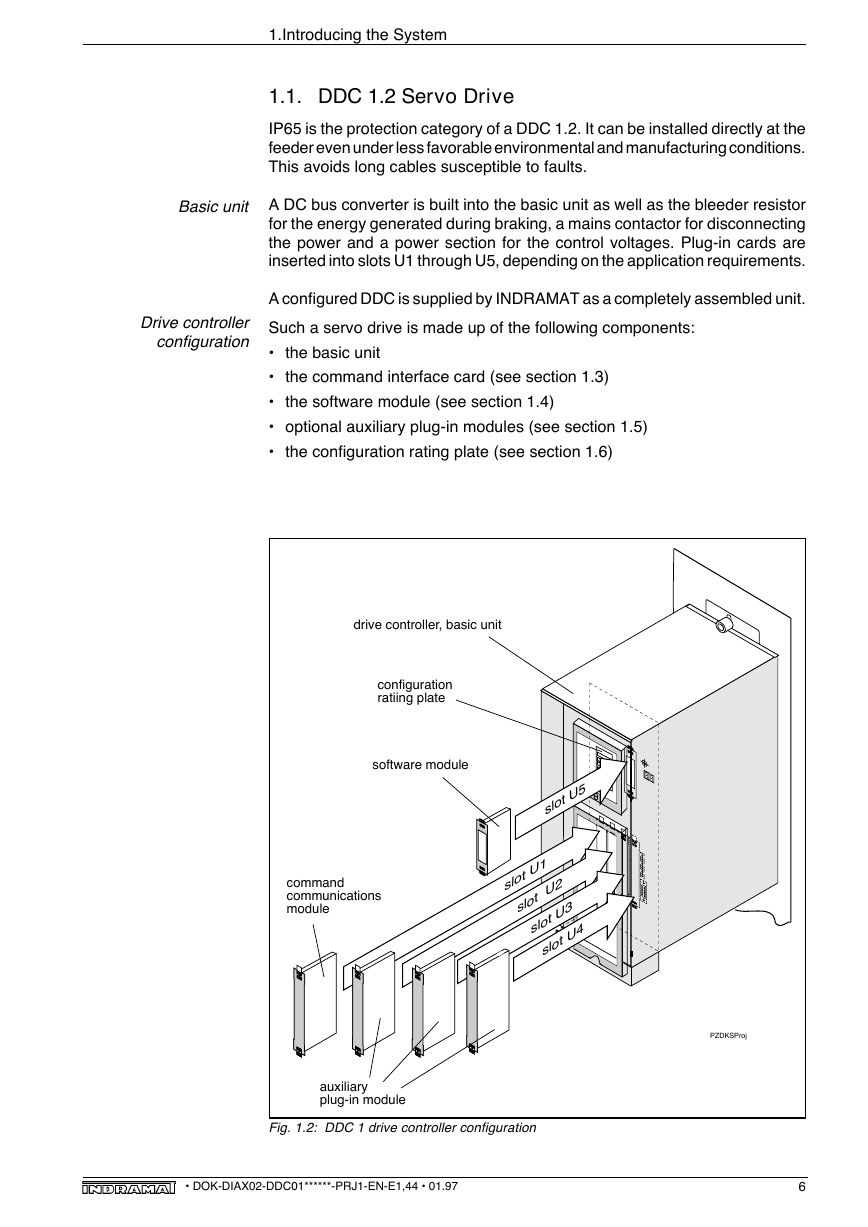

1.1. DDC 1.2 Servo Drive

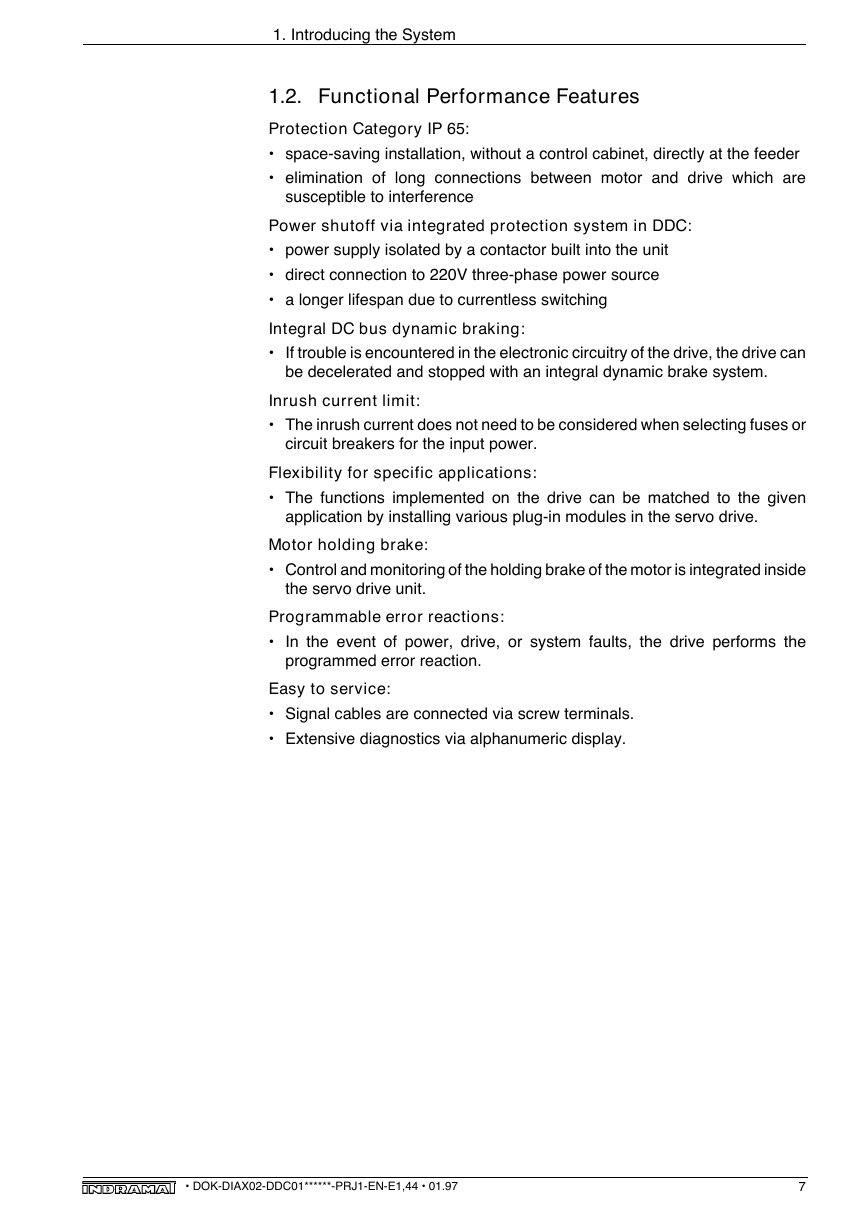

1.2. Functional Performance Features

1.3. Command Interface Card

1.4 Software Module

1.5. Auxiliary Plug-In Cards

1.6 Configuration Rating Plate

2. Technical Data / Ambient Conditions

2.1. Data Sheet

2.2. Operating Conditions

3. Electrical Connections -Installation Guidelines

3.1. Terminal diagram

3.2. Power Connections

3.3. Grounding Conditions

3.4. Power Connection cross sections and Fuses

3.5. Transformers

3.6. DST Three-Phase Autotransformers for Mounting in Control Enclosures

3.7. DLT Three-Phase Isolating Transformers for Mounting in Control Enclosures

3.8. Three-Phase Autotransformers in IP 55 Housing

3.9. Motor Power Connection

3.10. Motor Feedback Connection

3.11. Interface to NC Control Unit

3.12. Control Circuit of the DDC Mains Contactor

3.13. Control Circuit in the DDC with Dynamic Braking

3.14. Control circuit of the DDC Mains Contactor Without Dynamic Braking

3.15. Control Circuit of the DDC Mains Contactor with E-Stop Relays

3.16. Control Inputs

3.17. Signal and Diagnostics Outputs

3.18. Signal Voltages

3.19. Reading Drive Parameters

3.20. Regenerated Power

3.21. Fault Current Protective Device

3.22. High-Voltage Testing

4. Mounting the DDC 1.2

4.1. DDC 1.2-N - dimensional data

4.2. Front View of DDC 1.2-N

4.3. Power Connections

4.4. Minimum Clearances

5. Ordering Information

5.1. Type Codes for the DDC 1.2

5.2. Accessories for Connections

5.3. Item List

6. Index

Index

Symbole

15 inputs

16 outputs

A

Absolute encoder emulator

Accessories for Connections

Additional protective device

Advantage when replacing unit

Alphanumeric display

Ambient Conditions

ANALOG interface

Autotransformers

Autotransformers in IP 55 housing

Auxiliary Plug-In Cards

B

B6 switches

Basic unit

Bb contact

Bend radii of INDRAMAT cables

Bleeder Prewarning

Bleeder resistor

C

Cable for three-phase connections

Circuit breakers

Command Interface Card

Connected load

Connecting accessories

Connection voltage

Connector assignments for DSF and RSF

Conneting accessories

Continuous bleeder power

D

Data Sheet

DC bus converter

DC bus dynamic brake

DC bus dynamic braking

DDC 1.1 terminal diagram

DDC 1.2

DDC 1.2-N - dimensional data

DEA

DEA 5.1

DEA 6.1

DEF 1.1

Digital AC Drive

Digital servo feedback

DLC 1.1

DLC single-axis positioning module

DLC single-axis postioning module

DLF 1.1

DLT Three-Phase Isolating Transformers

Drive controller configuration

Drive enable

DSF

DSM 2.1

DSS 1.1

DSS 1.3

DST ... /G/ type transformers

DST Three-Phase Autotransformers

Duplication

Dynamic Braking

E

E mode of installation

E-stop

E-Stop Relays

Electrical Connections

EN 60204

Exchanging binary signals

F

Fault Current Protective Device

Feedback Connection

FI current limiting circuit breakers

Frequency

Fuses

G

gL class fuses

Grounded threephase systems

Grounding the Supply System

H

High-resolution positioning interface

High-Voltage Testing

Holding brakes

Humidity

I

IKL 232

IKL 241

IKL 243

IKL 244

IKL 245

Increased ambient temperatures

Incremental encoder emulator

Incremental position interface

Individual cable parts

Individual IP 65 connectors

Inductance motors

INK 202

INK 203

INK 204

INK 205

INK 206

INK 250

INK 391

Input/output interface

Inrush current limit

Installation above 1000 meters

Interface to NC Control Unit

IP 00

IP65

Isolating transformers

Isolation transformer

K

K1

K3

K4

M

Machine-dependent values

Mains Contactor

Maximum cable length

Minimum Clearances

Motor power cable capacity

N

Non-periodic overvoltages

O

Operating Conditions

Operating principles

Operating software

Outputs AK1 and AK2

P

PC with a VT 100 emulation program

Permissible overvoltage levels

Positioning module

Power Connection Diameters and Fuses

Power Connections

Power OFF

Power ON

Power shutoff

Power supply cable

R

Radio interference transmission

Reading Drive Parameters

Ready state

Ready-made cables

Ready-made INDRAMAT cables

Regenerated Power

Resolver feedback

rf interference suppression

Rotary drive energy

RS 232 Interface

RSF

S

Safety Clearances

SERCOS interface

SERCOS interface DSS card

Service life

Signal and Diagnostics Outputs

Signal path diagram

Signal Voltages

Slow-blow fuses

Soft start

Software Module

SSI standards

Standard software module

Supply line diameters

T

Technical Data

Terminal X4

Three-Phase Autotransformers

TN mains

Transformers

TT mains

Type Codes

U

U1

U5

UD contact

Ungrounded threephase systems

User-specific parameters

V

VT 100 terminal

X

X5

X7

X8

Z

Zero potential contact

2023年江西萍乡中考道德与法治真题及答案.doc

2023年江西萍乡中考道德与法治真题及答案.doc 2012年重庆南川中考生物真题及答案.doc

2012年重庆南川中考生物真题及答案.doc 2013年江西师范大学地理学综合及文艺理论基础考研真题.doc

2013年江西师范大学地理学综合及文艺理论基础考研真题.doc 2020年四川甘孜小升初语文真题及答案I卷.doc

2020年四川甘孜小升初语文真题及答案I卷.doc 2020年注册岩土工程师专业基础考试真题及答案.doc

2020年注册岩土工程师专业基础考试真题及答案.doc 2023-2024学年福建省厦门市九年级上学期数学月考试题及答案.doc

2023-2024学年福建省厦门市九年级上学期数学月考试题及答案.doc 2021-2022学年辽宁省沈阳市大东区九年级上学期语文期末试题及答案.doc

2021-2022学年辽宁省沈阳市大东区九年级上学期语文期末试题及答案.doc 2022-2023学年北京东城区初三第一学期物理期末试卷及答案.doc

2022-2023学年北京东城区初三第一学期物理期末试卷及答案.doc 2018上半年江西教师资格初中地理学科知识与教学能力真题及答案.doc

2018上半年江西教师资格初中地理学科知识与教学能力真题及答案.doc 2012年河北国家公务员申论考试真题及答案-省级.doc

2012年河北国家公务员申论考试真题及答案-省级.doc 2020-2021学年江苏省扬州市江都区邵樊片九年级上学期数学第一次质量检测试题及答案.doc

2020-2021学年江苏省扬州市江都区邵樊片九年级上学期数学第一次质量检测试题及答案.doc 2022下半年黑龙江教师资格证中学综合素质真题及答案.doc

2022下半年黑龙江教师资格证中学综合素质真题及答案.doc