THE I2C-BUS SPECIFICATION

VERSION 2.1

JANUARY 2000

�

Philips Semiconductors

The I2C-bus specification

CONTENTS

1

1.1

1.2

1.3

1.4

2

2.1

2.2

3

4

5

6

6.1

6.2

7

7.1

7.2

8

8.1

8.2

8.3

9

10

10.1

10.1.1

10.1.2

10.1.3

11

12

13

13.1

13.2

13.3

PREFACE . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Version 1.0 - 1992. . . . . . . . . . . . . . . . . . . . 3

Version 2.0 - 198. . . . . . . . . . . . . . . . . . . . . 3

Version 2.1 - 1999. . . . . . . . . . . . . . . . . . . . 3

Purchase of Philips I2C-bus components . . 3

THE I2C-BUS BENEFITS DESIGNERS

AND MANUFACTURERS. . . . . . . . . . . . . . .4

Designer benefits . . . . . . . . . . . . . . . . . . . . 4

Manufacturer benefits . . . . . . . . . . . . . . . . . 6

INTRODUCTION TO THE I2C-BUS

SPECIFICATION . . . . . . . . . . . . . . . . . . . . .6

THE I2C-BUS CONCEPT . . . . . . . . . . . . . . .6

GENERAL CHARACTERISTICS . . . . . . . . .8

BIT TRANSFER . . . . . . . . . . . . . . . . . . . . . .8

Data validity . . . . . . . . . . . . . . . . . . . . . . . . 8

START and STOP conditions . . . . . . . . . . . 9

TRANSFERRING DATA . . . . . . . . . . . . . . .10

Byte format . . . . . . . . . . . . . . . . . . . . . . . . 10

Acknowledge. . . . . . . . . . . . . . . . . . . . . . . 10

ARBITRATION AND CLOCK

GENERATION . . . . . . . . . . . . . . . . . . . . . .11

Synchronization . . . . . . . . . . . . . . . . . . . . 11

Arbitration . . . . . . . . . . . . . . . . . . . . . . . . . 12

Use of the clock synchronizing

mechanism as a handshake . . . . . . . . . . . 13

FORMATS WITH 7-BIT ADDRESSES . . . .13

7-BIT ADDRESSING . . . . . . . . . . . . . . . . .15

Definition of bits in the first byte . . . . . . . . 15

General call address . . . . . . . . . . . . . . . . . 16

START byte . . . . . . . . . . . . . . . . . . . . . . . 17

CBUS compatibility . . . . . . . . . . . . . . . . . . 18

EXTENSIONS TO THE STANDARD-

MODE I2C-BUS SPECIFICATION . . . . . . .19

FAST-MODE. . . . . . . . . . . . . . . . . . . . . . . .19

Hs-MODE . . . . . . . . . . . . . . . . . . . . . . . . . .20

High speed transfer. . . . . . . . . . . . . . . . . . 20

Serial data transfer format in Hs-mode . . . 21

Switching from F/S- to Hs-mode and

back . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

2

13.4

13.5

13.5.1

13.5.2

13.5.3

14

14.1

14.2

14.3

15

15.1

15.2

16

16.1

17

17.1

17.2

17.3

17.4

17.5

18

18.1

18.1.1

19

20

Hs-mode devices at lower speed modes. . 24

Mixed speed modes on one serial bus

system . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

F/S-mode transfer in a mixed-speed bus

system . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Hs-mode transfer in a mixed-speed bus

system . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Timing requirements for the bridge in a

mixed-speed bus system . . . . . . . . . . . . . . 27

10-BIT ADDRESSING . . . . . . . . . . . . . . . . 27

Definition of bits in the first two bytes. . . . . 27

Formats with 10-bit addresses. . . . . . . . . . 27

General call address and start byte with

10-bit addressing . . . . . . . . . . . . . . . . . . . . 30

ELECTRICAL SPECIFICATIONS

AND TIMING FOR I/O STAGES

AND BUS LINES . . . . . . . . . . . . . . . . . . . . 30

Standard- and Fast-mode devices. . . . . . . 30

Hs-mode devices . . . . . . . . . . . . . . . . . . . . 34

ELECTRICAL CONNECTIONS OF

I2C-BUS DEVICES TO THE BUS LINES . 37

Maximum and minimum values of

resistors Rp and Rs for Standard-mode

I2C-bus devices . . . . . . . . . . . . . . . . . . . . . 39

APPLICATION INFORMATION . . . . . . . . . 41

Slope-controlled output stages of

Fast-mode I2C-bus devices . . . . . . . . . . . . 41

Switched pull-up circuit for Fast-mode

I2C-bus devices . . . . . . . . . . . . . . . . . . . . . 41

Wiring pattern of the bus lines . . . . . . . . . . 42

Maximum and minimum values of

resistors Rp and Rs for Fast-mode

I2C-bus devices . . . . . . . . . . . . . . . . . . . . . 42

Maximum and minimum values of

resistors Rp and Rs for Hs-mode

I2C-bus devices . . . . . . . . . . . . . . . . . . . . . 42

BI-DIRECTIONAL LEVEL SHIFTER

FOR F/S-MODE I2C-BUS SYSTEMS . . . . 42

Connecting devices with different

logic levels . . . . . . . . . . . . . . . . . . . . . . . . . 43

Operation of the level shifter . . . . . . . . . . . 44

DEVELOPMENT TOOLS AVAILABLE

FROM PHILIPS . . . . . . . . . . . . . . . . . . . . . 45

SUPPORT LITERATURE . . . . . . . . . . . . . 46

�

Philips Semiconductors

The I2C-bus specification

1 PREFACE

1.1

Version 1.0 - 1992

This version of the 1992 I2C-bus specification includes the

following modifications:

• Programming of a slave address by software has been

omitted. The realization of this feature is rather

complicated and has not been used.

• The “low-speed mode” has been omitted. This mode is,

in fact, a subset of the total I2C-bus specification and

need not be specified explicitly.

• The Fast-mode is added. This allows a fourfold increase

of the bit rate up to 400 kbit/s. Fast-mode devices are

downwards compatible i.e. they can be used in a 0 to

100 kbit/s I2C-bus system.

• 10-bit addressing is added. This allows 1024 additional

slave addresses.

• Slope control and input filtering for Fast-mode devices is

specified to improve the EMC behaviour.

NOTE: Neither the 100 kbit/s I2C-bus system nor the

100 kbit/s devices have been changed.

1.2

Version 2.0 - 1998

The I2C-bus has become a de facto world standard that is

now implemented in over 1000 different ICs and licensed

to more than 50 companies. Many of today’s applications,

however, require higher bus speeds and lower supply

voltages. This updated version of the I2C-bus specification

meets those requirements and includes the following

modifications:

• The High-speed mode (Hs-mode) is added. This allows

an increase in the bit rate up to 3.4 Mbit/s. Hs-mode

devices can be mixed with Fast- and Standard-mode

devices on the one I2C-bus system with bit rates from 0

to 3.4 Mbit/s.

• The low output level and hysteresis of devices with a

supply voltage of 2 V and below has been adapted to

meet the required noise margins and to remain

compatible with higher supply voltage devices.

• The 0.6 V at 6 mA requirement for the output stages of

Fast-mode devices has been omitted.

• The fixed input levels for new devices are replaced by

bus voltage-related levels.

• Application information for bi-directional level shifter is

added.

1.3

Version 2.1 - 2000

Version 2.1 of the I2C-bus specification includes the

following minor modifications:

• After a repeated START condition in Hs-mode, it is

possible to stretch the clock signal SCLH (see

Section 13.2 and Figs 22, 25 and 32).

• Some timing parameters in Hs-mode have been relaxed

(see Tables 6 and 7).

1.4

Purchase of Philips I2C-bus components

Purchase of Philips I2C components conveys a license under the Philips’ I2C patent to use the

components in the I2C system provided the system conforms to the I2C specification defined by

Philips.

3

�

Philips Semiconductors

The I2C-bus specification

2

THE I2C-BUS BENEFITS DESIGNERS AND

MANUFACTURERS

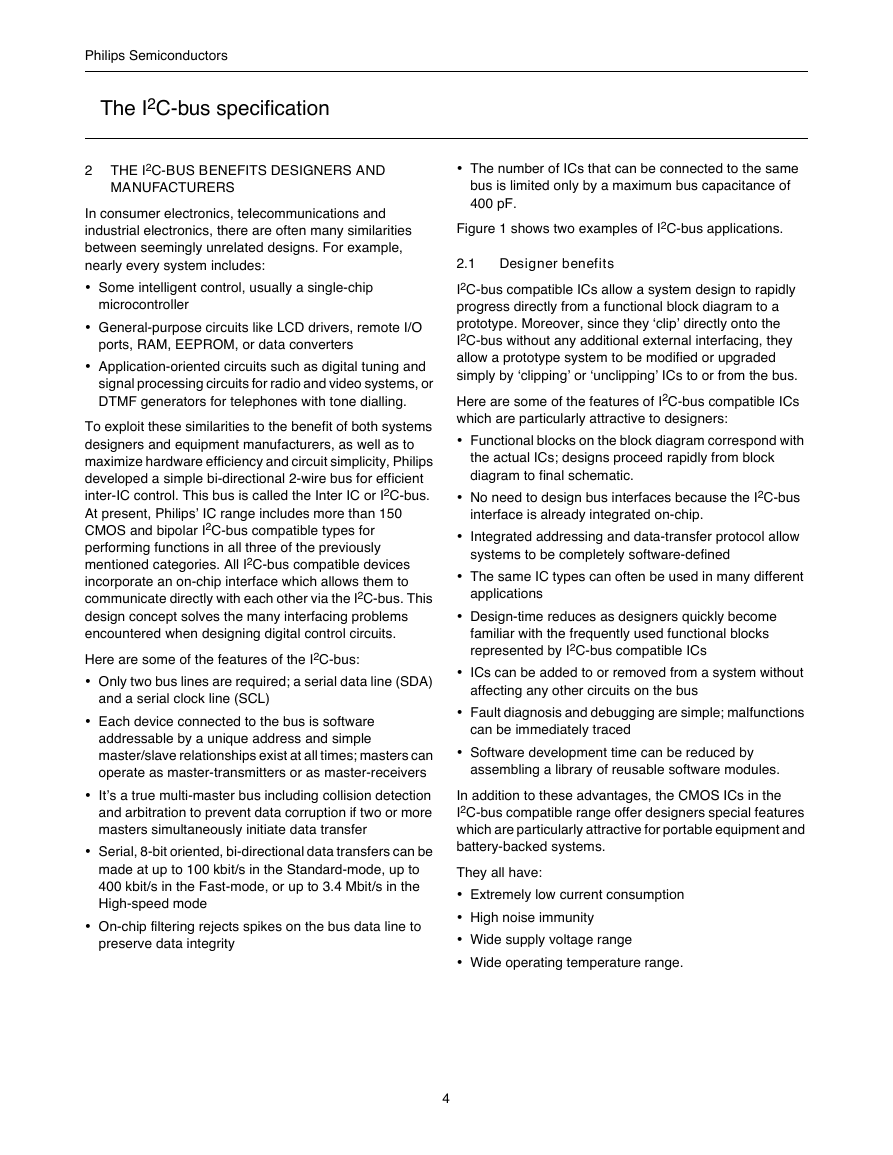

In consumer electronics, telecommunications and

industrial electronics, there are often many similarities

between seemingly unrelated designs. For example,

nearly every system includes:

• Some intelligent control, usually a single-chip

microcontroller

• General-purpose circuits like LCD drivers, remote I/O

ports, RAM, EEPROM, or data converters

• Application-oriented circuits such as digital tuning and

signal processing circuits for radio and video systems, or

DTMF generators for telephones with tone dialling.

To exploit these similarities to the benefit of both systems

designers and equipment manufacturers, as well as to

maximize hardware efficiency and circuit simplicity, Philips

developed a simple bi-directional 2-wire bus for efficient

inter-IC control. This bus is called the Inter IC or I2C-bus.

At present, Philips’ IC range includes more than 150

CMOS and bipolar I2C-bus compatible types for

performing functions in all three of the previously

mentioned categories. All I2C-bus compatible devices

incorporate an on-chip interface which allows them to

communicate directly with each other via the I2C-bus. This

design concept solves the many interfacing problems

encountered when designing digital control circuits.

Here are some of the features of the I2C-bus:

• Only two bus lines are required; a serial data line (SDA)

and a serial clock line (SCL)

• Each device connected to the bus is software

addressable by a unique address and simple

master/slave relationships exist at all times; masters can

operate as master-transmitters or as master-receivers

• It’s a true multi-master bus including collision detection

and arbitration to prevent data corruption if two or more

masters simultaneously initiate data transfer

• Serial, 8-bit oriented, bi-directional data transfers can be

made at up to 100 kbit/s in the Standard-mode, up to

400 kbit/s in the Fast-mode, or up to 3.4 Mbit/s in the

High-speed mode

• On-chip filtering rejects spikes on the bus data line to

preserve data integrity

• The number of ICs that can be connected to the same

bus is limited only by a maximum bus capacitance of

400 pF.

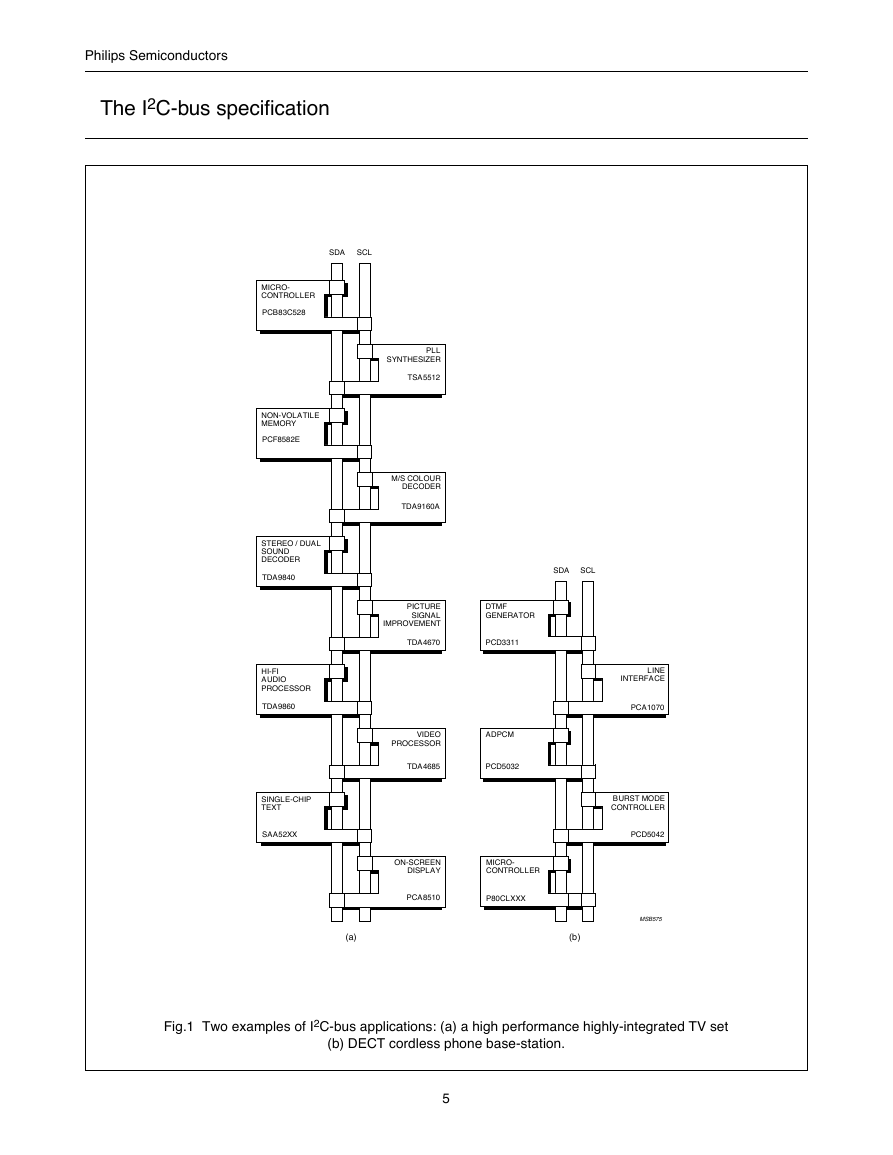

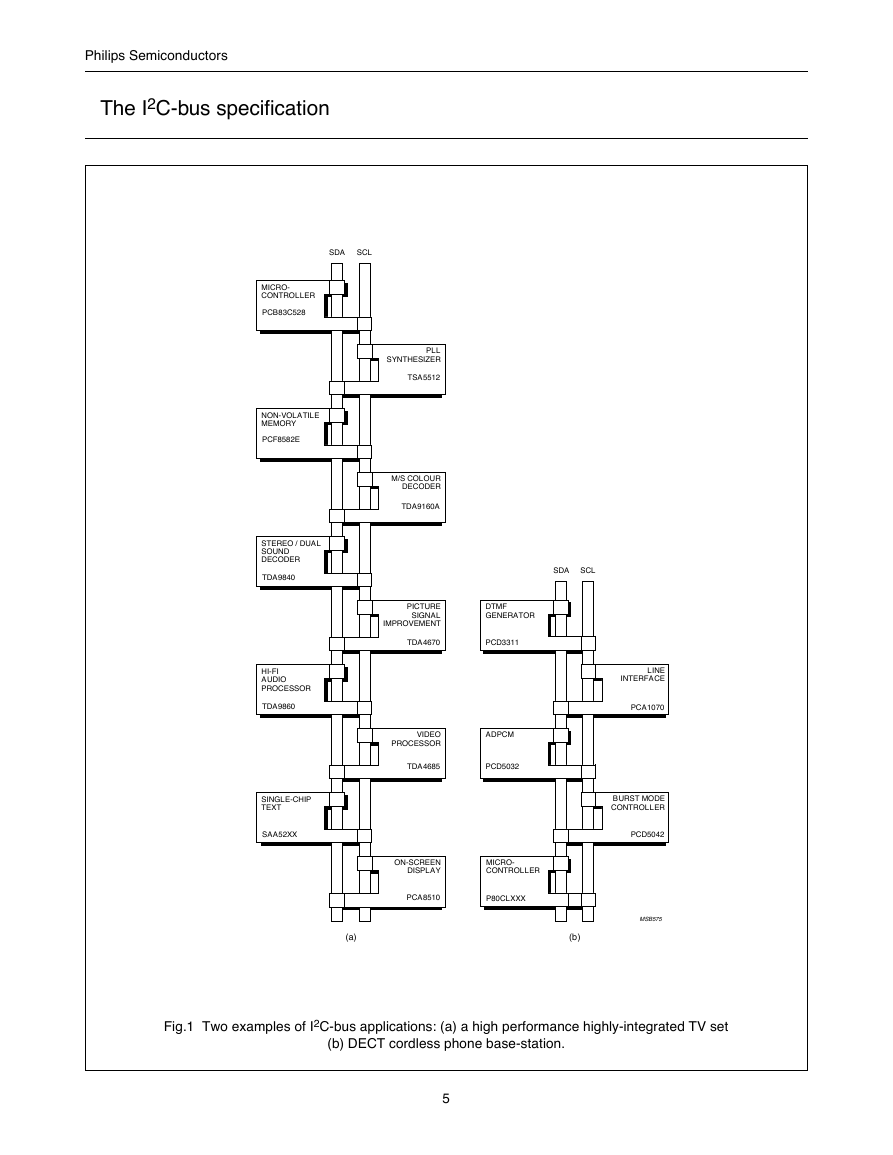

Figure 1 shows two examples of I2C-bus applications.

2.1

Designer benefits

I2C-bus compatible ICs allow a system design to rapidly

progress directly from a functional block diagram to a

prototype. Moreover, since they ‘clip’ directly onto the

I2C-bus without any additional external interfacing, they

allow a prototype system to be modified or upgraded

simply by ‘clipping’ or ‘unclipping’ ICs to or from the bus.

Here are some of the features of I2C-bus compatible ICs

which are particularly attractive to designers:

• Functional blocks on the block diagram correspond with

the actual ICs; designs proceed rapidly from block

diagram to final schematic.

• No need to design bus interfaces because the I2C-bus

interface is already integrated on-chip.

• Integrated addressing and data-transfer protocol allow

systems to be completely software-defined

• The same IC types can often be used in many different

applications

• Design-time reduces as designers quickly become

familiar with the frequently used functional blocks

represented by I2C-bus compatible ICs

• ICs can be added to or removed from a system without

affecting any other circuits on the bus

• Fault diagnosis and debugging are simple; malfunctions

can be immediately traced

• Software development time can be reduced by

assembling a library of reusable software modules.

In addition to these advantages, the CMOS ICs in the

I2C-bus compatible range offer designers special features

which are particularly attractive for portable equipment and

battery-backed systems.

They all have:

• Extremely low current consumption

• High noise immunity

• Wide supply voltage range

• Wide operating temperature range.

4

�

Philips Semiconductors

The I2C-bus specification

handbook, full pagewidth

SDA

SCL

MICRO-

CONTROLLER

PCB83C528

NON-VOLATILE

MEMORY

PCF8582E

STEREO / DUAL

SOUND

DECODER

TDA9840

HI-FI

AUDIO

PROCESSOR

TDA9860

SINGLE-CHIP

TEXT

SAA52XX

PLL

SYNTHESIZER

TSA5512

M/S COLOUR

DECODER

TDA9160A

SDA SCL

PICTURE

SIGNAL

IMPROVEMENT

DTMF

GENERATOR

TDA4670

PCD3311

VIDEO

PROCESSOR

ADPCM

TDA4685

PCD5032

LINE

INTERFACE

PCA1070

BURST MODE

CONTROLLER

PCD5042

ON-SCREEN

DISPLAY

MICRO-

CONTROLLER

PCA8510

P80CLXXX

(a)

MSB575

(b)

Fig.1 Two examples of I2C-bus applications: (a) a high performance highly-integrated TV set

(b) DECT cordless phone base-station.

5

�

Philips Semiconductors

The I2C-bus specification

2.2

Manufacturer benefits

I2C-bus compatible ICs don’t only assist designers, they

also give a wide range of benefits to equipment

manufacturers because:

• The simple 2-wire serial I2C-bus minimizes

interconnections so ICs have fewer pins and there are

not so many PCB tracks; result - smaller and less

expensive PCBs

• The completely integrated I2C-bus protocol eliminates

the need for address decoders and other ‘glue logic’

• The multi-master capability of the I2C-bus allows rapid

testing and alignment of end-user equipment via

external connections to an assembly-line

• The availability of I2C-bus compatible ICs in SO (small

outline), VSO (very small outline) as well as DIL

packages reduces space requirements even more.

These are just some of the benefits. In addition, I2C-bus

compatible ICs increase system design flexibility by

allowing simple construction of equipment variants and

easy upgrading to keep designs up-to-date. In this way, an

entire family of equipment can be developed around a

basic model. Upgrades for new equipment, or

enhanced-feature models (i.e. extended memory, remote

control, etc.) can then be produced simply by clipping the

appropriate ICs onto the bus. If a larger ROM is needed,

it’s simply a matter of selecting a micro-controller with a

larger ROM from our comprehensive range. As new ICs

supersede older ones, it’s easy to add new features to

equipment or to increase its performance by simply

unclipping the outdated IC from the bus and clipping on its

successor.

3

INTRODUCTION TO THE I2C-BUS SPECIFICATION

For 8-bit oriented digital control applications, such as those

requiring microcontrollers, certain design criteria can be

established:

• A complete system usually consists of at least one

microcontroller and other peripheral devices such as

memories and I/O expanders

• The cost of connecting the various devices within the

system must be minimized

• A system that performs a control function doesn’t

require high-speed data transfer

• Overall efficiency depends on the devices chosen and

the nature of the interconnecting bus structure.

To produce a system to satisfy these criteria, a serial bus

structure is needed. Although serial buses don’t have the

throughput capability of parallel buses, they do require

less wiring and fewer IC connecting pins. However, a bus

is not merely an interconnecting wire, it embodies all the

formats and procedures for communication within the

system.

Devices communicating with each other on a serial bus

must have some form of protocol which avoids all

possibilities of confusion, data loss and blockage of

information. Fast devices must be able to communicate

with slow devices. The system must not be dependent on

the devices connected to it, otherwise modifications or

improvements would be impossible. A procedure has also

to be devised to decide which device will be in control of

the bus and when. And, if different devices with different

clock speeds are connected to the bus, the bus clock

source must be defined. All these criteria are involved in

the specification of the I2C-bus.

4

THE I2C-BUS CONCEPT

The I2C-bus supports any IC fabrication process (NMOS,

CMOS, bipolar). Two wires, serial data (SDA) and serial

clock (SCL), carry information between the devices

connected to the bus. Each device is recognized by a

unique address (whether it’s a microcontroller, LCD driver,

memory or keyboard interface) and can operate as either

a transmitter or receiver, depending on the function of the

device. Obviously an LCD driver is only a receiver,

whereas a memory can both receive and transmit data. In

addition to transmitters and receivers, devices can also be

considered as masters or slaves when performing data

transfers (see Table 1). A master is the device which

initiates a data transfer on the bus and generates the clock

signals to permit that transfer. At that time, any device

addressed is considered a slave.

6

�

Philips Semiconductors

The I2C-bus specification

Table 1 Definition of I2C-bus terminology

TERM

Transmitter

Receiver

Master

Slave

Multi-master

Arbitration

DESCRIPTION

The device which sends data to the

bus

The device which receives data from

the bus

The device which initiates a transfer,

generates clock signals and

terminates a transfer

The device addressed by a master

More than one master can attempt to

control the bus at the same time

without corrupting the message

Procedure to ensure that, if more

than one master simultaneously tries

to control the bus, only one is allowed

to do so and the winning message is

not corrupted

Synchronization Procedure to synchronize the clock

signals of two or more devices

The I2C-bus is a multi-master bus. This means that more

than one device capable of controlling the bus can be

connected to it. As masters are usually micro-controllers,

let’s consider the case of a data transfer between two

microcontrollers connected to the I2C-bus (see Fig.2).

This highlights the master-slave and receiver-transmitter

relationships to be found on the I2C-bus. It should be noted

that these relationships are not permanent, but only

depend on the direction of data transfer at that time. The

transfer of data would proceed as follows:

1) Suppose microcontroller A wants to send information to

microcontroller B:

• microcontroller A (master), addresses microcontroller B

(slave)

• microcontroller A (master-transmitter), sends data to

microcontroller B (slave- receiver)

• microcontroller A terminates the transfer

2) If microcontroller A wants to receive information from

microcontroller B:

• microcontroller A (master) addresses microcontroller B

(slave)

• microcontroller A (master- receiver) receives data from

microcontroller B (slave- transmitter)

• microcontroller A terminates the transfer.

Even in this case, the master (microcontroller A) generates

the timing and terminates the transfer.

The possibility of connecting more than one

microcontroller to the I2C-bus means that more than one

master could try to initiate a data transfer at the same time.

To avoid the chaos that might ensue from such an event -

an arbitration procedure has been developed. This

procedure relies on the wired-AND connection of all I2C

interfaces to the I2C-bus.

If two or more masters try to put information onto the bus,

the first to produce a ‘one’ when the other produces a

‘zero’ will lose the arbitration. The clock signals during

arbitration are a synchronized combination of the clocks

generated by the masters using the wired-AND connection

to the SCL line (for more detailed information concerning

arbitration see Section 8).

MICRO -

CONTROLLER

A

LCD

DRIVER

STATIC

RAM OR

EEPROM

SDA

SCL

GATE

ARRAY

ADC

MBC645

MICRO -

CONTROLLER

B

Fig.2 Example of an I2C-bus configuration using two microcontrollers.

7

�

Philips Semiconductors

The I2C-bus specification

Generation of clock signals on the I2C-bus is always the

responsibility of master devices; each master generates its

own clock signals when transferring data on the bus. Bus

clock signals from a master can only be altered when they

are stretched by a slow-slave device holding-down the

clock line, or by another master when arbitration occurs.

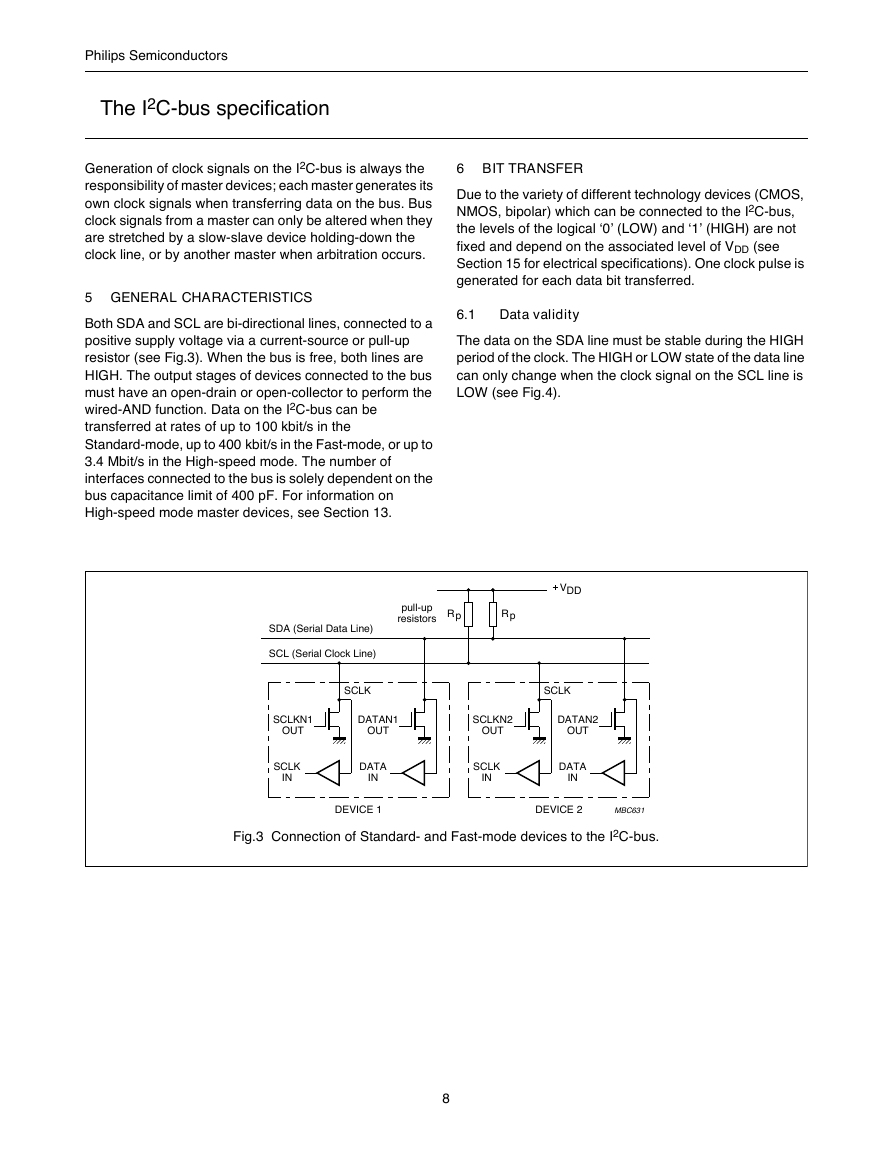

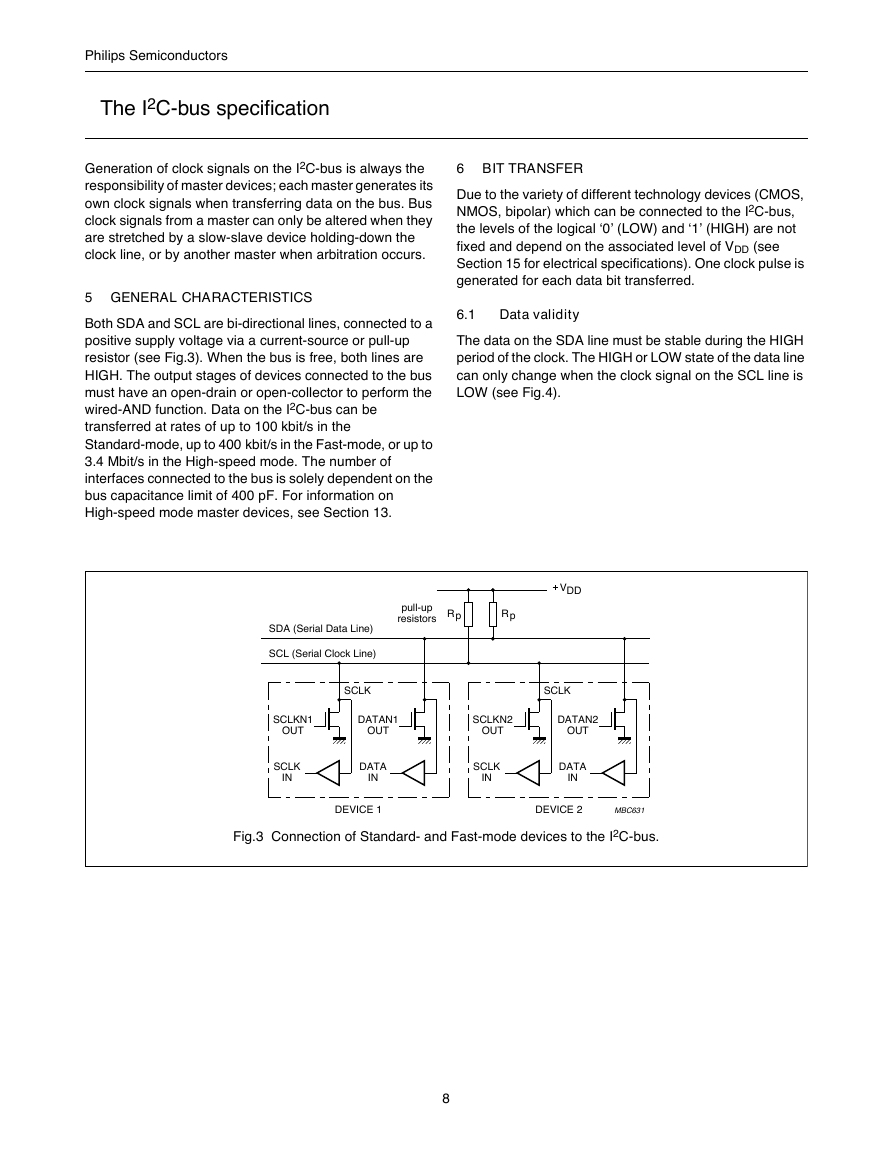

5 GENERAL CHARACTERISTICS

Both SDA and SCL are bi-directional lines, connected to a

positive supply voltage via a current-source or pull-up

resistor (see Fig.3). When the bus is free, both lines are

HIGH. The output stages of devices connected to the bus

must have an open-drain or open-collector to perform the

wired-AND function. Data on the I2C-bus can be

transferred at rates of up to 100 kbit/s in the

Standard-mode, up to 400 kbit/s in the Fast-mode, or up to

3.4 Mbit/s in the High-speed mode. The number of

interfaces connected to the bus is solely dependent on the

bus capacitance limit of 400 pF. For information on

High-speed mode master devices, see Section 13.

6 BIT TRANSFER

Due to the variety of different technology devices (CMOS,

NMOS, bipolar) which can be connected to the I2C-bus,

the levels of the logical ‘0’ (LOW) and ‘1’ (HIGH) are not

fixed and depend on the associated level of VDD (see

Section 15 for electrical specifications). One clock pulse is

generated for each data bit transferred.

6.1

Data validity

The data on the SDA line must be stable during the HIGH

period of the clock. The HIGH or LOW state of the data line

can only change when the clock signal on the SCL line is

LOW (see Fig.4).

pull-up

resistors

Rp

Rp

VDD

SDA (Serial Data Line)

SCL (Serial Clock Line)

SCLK

SCLK

SCLKN1

OUT

DATAN1

OUT

SCLKN2

OUT

DATAN2

OUT

SCLK

IN

DATA

IN

SCLK

IN

DATA

IN

DEVICE 1

DEVICE 2

MBC631

Fig.3 Connection of Standard- and Fast-mode devices to the I2C-bus.

8

�

2023年江西萍乡中考道德与法治真题及答案.doc

2023年江西萍乡中考道德与法治真题及答案.doc 2012年重庆南川中考生物真题及答案.doc

2012年重庆南川中考生物真题及答案.doc 2013年江西师范大学地理学综合及文艺理论基础考研真题.doc

2013年江西师范大学地理学综合及文艺理论基础考研真题.doc 2020年四川甘孜小升初语文真题及答案I卷.doc

2020年四川甘孜小升初语文真题及答案I卷.doc 2020年注册岩土工程师专业基础考试真题及答案.doc

2020年注册岩土工程师专业基础考试真题及答案.doc 2023-2024学年福建省厦门市九年级上学期数学月考试题及答案.doc

2023-2024学年福建省厦门市九年级上学期数学月考试题及答案.doc 2021-2022学年辽宁省沈阳市大东区九年级上学期语文期末试题及答案.doc

2021-2022学年辽宁省沈阳市大东区九年级上学期语文期末试题及答案.doc 2022-2023学年北京东城区初三第一学期物理期末试卷及答案.doc

2022-2023学年北京东城区初三第一学期物理期末试卷及答案.doc 2018上半年江西教师资格初中地理学科知识与教学能力真题及答案.doc

2018上半年江西教师资格初中地理学科知识与教学能力真题及答案.doc 2012年河北国家公务员申论考试真题及答案-省级.doc

2012年河北国家公务员申论考试真题及答案-省级.doc 2020-2021学年江苏省扬州市江都区邵樊片九年级上学期数学第一次质量检测试题及答案.doc

2020-2021学年江苏省扬州市江都区邵樊片九年级上学期数学第一次质量检测试题及答案.doc 2022下半年黑龙江教师资格证中学综合素质真题及答案.doc

2022下半年黑龙江教师资格证中学综合素质真题及答案.doc