Z-Excursion Universal Sampler (ZEUS®)

Integrator Manual

�

TABLE OF CONTENTS

Table of Contents

1

Introduction ............................................................................... 6

1.1

Intended Use of ZEUS .................................................................... 6

1.2 About this Manual .......................................................................... 6

2 Safety Precautions and Hazards ............................................ 7

2.1 General Precautions ....................................................................... 7

2.1.1 ZEUS Pipetting Module ....................................................... 7

2.1.2 Operating ZEUS .................................................................. 7

2.2 Environmental Influence ................................................................. 8

2.3 Electrical Safety Precautions .......................................................... 8

2.4 Chemical, Radioactive or Biological Hazard Precautions ............... 9

3 Product Description .................................................................. 9

3.1 General Description ........................................................................ 9

3.2 Hardware Description ..................................................................... 9

3.2.1 General Overview ................................................................ 9

3.2.2 Pipetting Head Technology ............................................... 11

3.2.3 Unsurpassed Accuracy and Precision with CO-RE Tips ..... 11

3.3 Automated Pipetting Process ....................................................... 12

3.3.1 Pipetting Process .............................................................. 12

3.3.2 Liquid Level Detection (LLD) .............................................. 12

3.3.3 Qualitative Pipetting Monitoring (QPM) .............................. 13

3.3.4 Anti-Droplet Control (ADC) ................................................ 14

4 Getting Started ........................................................................ 14

4.1 Unpacking .................................................................................... 14

4.2 Hardware Installation .................................................................... 15

4.3 Hamilton CAN Communication .................................................... 16

4.3.1 General .............................................................................. 16

4.3.2 Example ............................................................................ 16

4.3.3

Identifier ............................................................................. 17

4.3.4 Handshake ........................................................................ 17

4.3.5 Data safety ........................................................................ 18

4.4 Power and CAN Connection ........................................................ 21

Z-Excursion Universal Sampler (ZEUS) Integrator Manual

3

�

TABLE OF CONTENTS

TABLE OF CONTENTS

5 Programming Basic Functions .............................................. 22

5.1 Data Transfer Format .................................................................... 22

5.2 Validating Connection and CAN Communication ......................... 23

5.3 Precautions prior to Operation ...................................................... 24

5.4

Initialization Commands ............................................................... 24

5.5 Z-Drive Commands ...................................................................... 25

5.6 Tip Handling Commands ............................................................. 26

5.7 Liquid Handling Commands ......................................................... 28

5.8 Switch Off Commands .................................................................. 30

5.9 Volume Check Commands .......................................................... 31

5.10 Status Request Commands ......................................................... 32

5.11 Special Commands ...................................................................... 36

5.12 Parameter Tables .......................................................................... 37

5.12.1 Container Geometry Table ................................................ 37

5.12.2 Deck Geometry Table ....................................................... 40

5.12.3 Tip Type Table ................................................................... 42

5.12.4 Liquid Class Table ............................................................. 43

5.13 Run Error Messages ..................................................................... 44

5.14 Firmware download ...................................................................... 55

5.14.1 Typical Firmware Update Process ..................................... 55

5.14.2 Download Commands ...................................................... 55

5.14.3 Status Requests ................................................................ 56

5.14.4 Special Commands ........................................................... 57

5.14.5 Error Messages ................................................................. 57

6 Creating a Liquid Class .......................................................... 58

6.1 Concept of Liquid Classes ........................................................... 58

6.2 Setting the Liquid Class Parameters ............................................ 58

6.3 Gravimetric Calibration ................................................................. 64

6.4 Settings for Qualitative Pipetting Monitoring (QPM) ...................... 68

6.4.1 Successful Aspiration and Dispensing .............................. 68

6.4.2 Tip Clogging ...................................................................... 69

6.4.3 Aspiration of Air ................................................................. 69

6.4.4 Aspiration of Foam ............................................................ 70

7 Maintenance ............................................................................ 74

7.1 Cleaning ZEUS ............................................................................. 74

7.2 Recommended Maintenance ....................................................... 75

7.2.1 Daily Maintenance ............................................................. 75

7.2.2 Weekly Maintenance ......................................................... 76

7.2.3 Yearly Maintenance ........................................................... 76

8 ZEUS Module Qualification ................................................... 77

8.1 Module Qualification at Hamilton Factory ..................................... 77

8.2 Recommended Qualification Procedures ..................................... 77

8.3

Installation Qualification ................................................................ 78

8.4 Operation Qualification ................................................................. 78

8.5 Performance Qualification ............................................................ 79

9 Troubleshooting ...................................................................... 80

9.1 Getting Technical Support ............................................................ 80

9.2 Controlling the Functionality of pLLD and cLLD ........................... 80

9.3 Controlling Aspiration and Dispensing .......................................... 81

9.4 Returning ZEUS for Repair ........................................................... 83

10 Technical Specifications ........................................................ 83

11 Ordering Information .............................................................. 86

11.1 ZEUS Pipetting Module ................................................................ 86

11.2 Disposable CO-RE Tips ............................................................... 86

11.3 Accessories and Spare Parts ....................................................... 87

12 Appendices .............................................................................. 87

12.1 Appendix A: ASCII Chart .............................................................. 87

Hamilton Warranty

Please refer to the General Terms of Sale (GTS).

Important Notice

This guide may not be used or reproduced in any way whatsoever without the express

written consent of Hamilton Bonaduz AG. Copyright © 2011 Hamilton Bonaduz AG,

All Rights Reserved. Contents of this manual are subject to change without prior notice.

Technical modifications reserved. Greatest possible care was used on the correctness

of the information in this guide. If errors should be discovered nevertheless, Hamilton is

pleased to be informed about it. Regardless of this, Hamilton cannot assume a liability for

any errors in this manual or for their consequences.

5

Z-Excursion Universal Sampler (ZEUS) Integrator Manual�

INTRODUCTION

1 Introduction

1.1 Intended Use of ZEUS

Hamilton Z-Excursion Universal Sampler (ZEUS) is a fully automated, self-contained, ready-to-go

liquid handling module for integration in instruments requiring on-board pipetting. ZEUS is based

on Hamilton‘s revolutionary air-displacement pipetting technology and uses disposable tips to

avoid carry-over. The module is equipped with Qualitative Pipette Monitoring (QPM) to ensure

successful pipetting. ZEUS can pipette volumes in the range of 1 μL to 1000 μL.

ZEUS is a component for a liquid handling device and as a component cannot comply to in vitro

diagnostic requirements or Title 21 Part 11. Only the complete liquid handling platform may be

certified for in vitro diagnostic uses by the instrument manufacturer.

1.2 About this Manual

This Manual is designed to support the integration engineer during integration, operation

and qualification of ZEUS. You should read through the entire Manual before beginning to install

and operate the pipetting module. It describes the features of ZEUS and its integration in liquid

handling devices. Both the hardware and the communication between the pipetting module and

the liquid handling platform are detailed in this manual. After reading this manual the integration

engineer should be capable of operating ZEUS.

Throughout this manual, following conventions are used to highlight various kinds of information:

ATTENTION! Essential information for avoiding personal injury or damage

to equipment.

NOTE: Important instructions or interesting information.

SAFETY PRECAUTIONS AND HAZARDS

2 Safety Precautions and Hazards

ATTENTION! Read the following safety notices carefully before installing

and operating the OEM Pipetting Module.

2.1 General Precautions

2.1.1 ZEUS Pipetting Module

The operator of ZEUS must be familiar with this manual. The procedures contained within this

manual have been tested by the manufacturer and are deemed to be fully functional. Any devia-

tion from the procedures given here may lead to malfunctions or even damages.

Use adequate enclosure of ZEUS to ensure appropriate user protection.

For safe and correct use of ZEUS, it is essential that both operating and service personnel follow

generally accepted safety procedures as well as the safety instructions given in this document,

the ZEUS Manual.

Any collisions of the pipetting module with other

components have to be ruled out.

Cleaning, dismantling, and maintenance should only

be performed by personnel trained in such work,

and who are aware of the possible hazards involved.

Only certified technicians are authorized to perform

mechanical maintenance on ZEUS.

ATTENTION! Teaching of

ZEUS and accurate definition

of the Container Geometry and

Deck Geometry parameters is

required prior operation.

For repair or shipment, all mechanical parts must be put in their rest positions. Any ZEUS sent

away for repair must always be decontaminated (see Chapter 9.4). The pipetting module must

be sent back in the original reusable packaging box. There must not be any labware including

tip on the pipetting module during transportation.

Only original ZEUS-approved parts, tools and accessories (e.g. pipetting tips) may be used with

the pipetting module (see Chapter 11). The use of any other parts, any alterations or modifica-

tions to the system may be dangerous and will void the warranty.

2.1.2 Operating ZEUS

When using the ZEUS, Good Laboratory Practices (GLP) must be observed. Suitable protective

clothing, safety glasses and protective gloves must be worn, particularly when dealing with a

malfunction of the instrument where the risk of contamination from spilled liquids exists.

Adequate protection including clothing and ventilation must be provided if dangerous liquids are

7

Z-Excursion Universal Sampler (ZEUS) Integrator Manual�

SAFETY PRECAUTIONS AND HAZARDS

SAFETY PRECAUTIONS AND HAZARDS

used in the analytical work. In case of incidental spillage, carefully wipe with a dry cloth, taking

into account the nature of the spilled liquid and the necessary safety precautions.

During operations, stand clear of any moving parts or the working deck of the instrument.

Do not attempt to disable any security measure.

The instrument developer is responsible for the use of the appropriate probe, materials (e.g. pipet-

ting tips, containers), and parameters (e.g. liquid class, container geometry, tip type) consistent

with the validated application. Ensure the use of tips of the appropriate size. Failure to do so may

lead to pipetting error, contamination or damages to ZEUS. Make sure that the pipetted samples

are consistent with the samples used for performance validation. Generally, it is recommended to

centrifuge the samples to avoid foam, bubbles or clot formation.

Pipetting accuracy and precision may not be ensured in case of process interruption. As a conse-

quence it is recommended to discard the pipetted sample and repeat the required pipetting steps.

2.2 Environmental Influence

The accuracy and the precision of pipetting with ZEUS are highly influenced by the laboratory envi-

ronmental conditions. Temperature, humidity and air pressure of the laboratory should be controlled

to achieve specified accuracy and precision. When working with samples, which will be used in

particularly sensitive tests, take the evaporation and condensation that may occur into account.

During operation, ZEUS should be shielded from direct sunlight and intense artificial light.

ATTENTION! Hamilton will not take liability if damage arises from the

improper handling of liquids.

2.3 Electrical Safety Precautions

Do not connect the pipetting module to a power source of any voltage beyond the range stated

on the power rating Technical Specifications (see Chapter 10). Only use a cable which conforms

to the given specifications (see chapter 4.4). Make sure the cable is intact and properly plugged

to avoid any short circuit. Connect the power ground of the ZEUS module to the ground of the

instrument housing. Failure to do so will impair the functionality of the capacitive LLD.

Keep ZEUS away from other equipment that emits electromagnetic radio frequency fields, and

minimize static electricity in the immediate environment of the pipetting module.

ATTENTION! Switch off the main power and unplug the FCC cable before

dismounting ZEUS.

2.4 Chemical, Radioactive or Biological Hazard Precautions

Selection of the appropriate safety level and implementation of the required safety measures for

working with ZEUS is the sole responsibility of the user.

If ZEUS becomes contaminated with biohazardous, radioactive or chemical material, it should

be cleaned in accordance with the maintenance procedures given in the Chapter 6. Always de-

contaminate your instrument and replace the samples on the instrument in case a tip detaches,

to avoid cross-contamination and pipetting errors. Failure to observe and carry out the mainte-

nance procedures may impair the reliability and correct functioning of the pipetting module.

If working with hazardous samples observe and carry out the maintenance procedures, pay-

ing particular attention to cleaning and decontamination. Use filter tips and do not reuse tips

to avoid cross-contamination. Design your waste container to avoid spillage during tip discard.

Wear gloves during the cleaning process. Any surfaces on which liquid is spilled must be

decontaminated.

Do not use disinfecting materials which contain hypochlorite (Javelle water, Chlorox) or

bleaching fluids.

3 Product Description

3.1 General Description

ZEUS is a self-contained pipetting module designed for integration into instruments requiring

on-board liquid handling. It is based on Hamilton’s revolutionary air-displacement pipetting

technology and uses disposable tips to avoid any sample carry-over. The z-motion is integrated

in order to facilitate integration of the module. The pipetting module is also equipped with Quali-

tative Pipetting Monitoring (QPM) to ensure successful pipetting. Both capacitive and pressure

liquid level detections are integrated and may even be combined for demanding applications.

3.2 Hardware Description

3.2.1 General Overview

ZEUS is composed of two subunits: the pipetting drive subunit and the z-drive subunit. The

pipetting subunit contains the pipetting head that picks up tips, the pipetting drive that

moves the plunger, and the sensor board that controls the tip presence, the pipetting, and the

self-monitoring functions. The z-drive subunit consists of the z-drive and the main board and

controls the movement of the pipetting module along the z-axis.

9

Z-Excursion Universal Sampler (ZEUS) Integrator Manual�

PRODUCT DESCRIPTION

PRODUCT DESCRIPTION

Pipetting drive

Sensor board

Tip ejection sleeve

Disposable tip

Figure 1: Hardware overview.

3.2.2 Pipetting Head Technology

ZEUS is based on an innovative air-displace-

ment technology. Air displacement means that

the liquid is aspirated into and dispensed from a

disposable tip by the movement of a plunger,

similar to the functioning of hand pipettes. Air

displacement enables the use of consumable

pipetting tips which limits cross-contamination

and sample carry-over. The plunger seal is

positioned at the lowest possible position to

limit the size of the air cushion above the liquid

(Figure 2). This feature limits the influence of

the environment and of the liquid properties for

improved accuracy and precision.

Figure 2:

Innovative pipetting head technology.

Pressure

sensor

Plunger

Seal

Disposable tip

Liquid

Sample tube

Air

3.2.3 Unsurpassed Accuracy and Precision with CO-RE Tips

Z-drive

Power

and CAN

connector

Main board

Attachment

lip

Attachment

groove

Ejection

sleeve

Air tight

seal

Hamilton CO-RE tips are the highest quality

tips available for precise and accurate pipet-

ting. They have been designed to solve the

problems of sealing and alignment plagued

by press-fit pickup techniques. ZEUS

has a spring loaded attachment lip which

compresses and expands at low force to fit

the symmetrical circular attachment groove

of the CO-RE tip. This mechanism ensures

straight alignment between the tip and the

pipetting channel. At the same time the

spring expands the elastomer seal radially

which provides air-tight sealing of the tip.

Figure 3:

Precise attachment of CO-RE tips on ZEUS.

11

Z-Excursion Universal Sampler (ZEUS) Integrator Manual�

PRODUCT DESCRIPTION

PRODUCT DESCRIPTION

3.3 Automated Pipetting Process

3.3.1 Pipetting Process

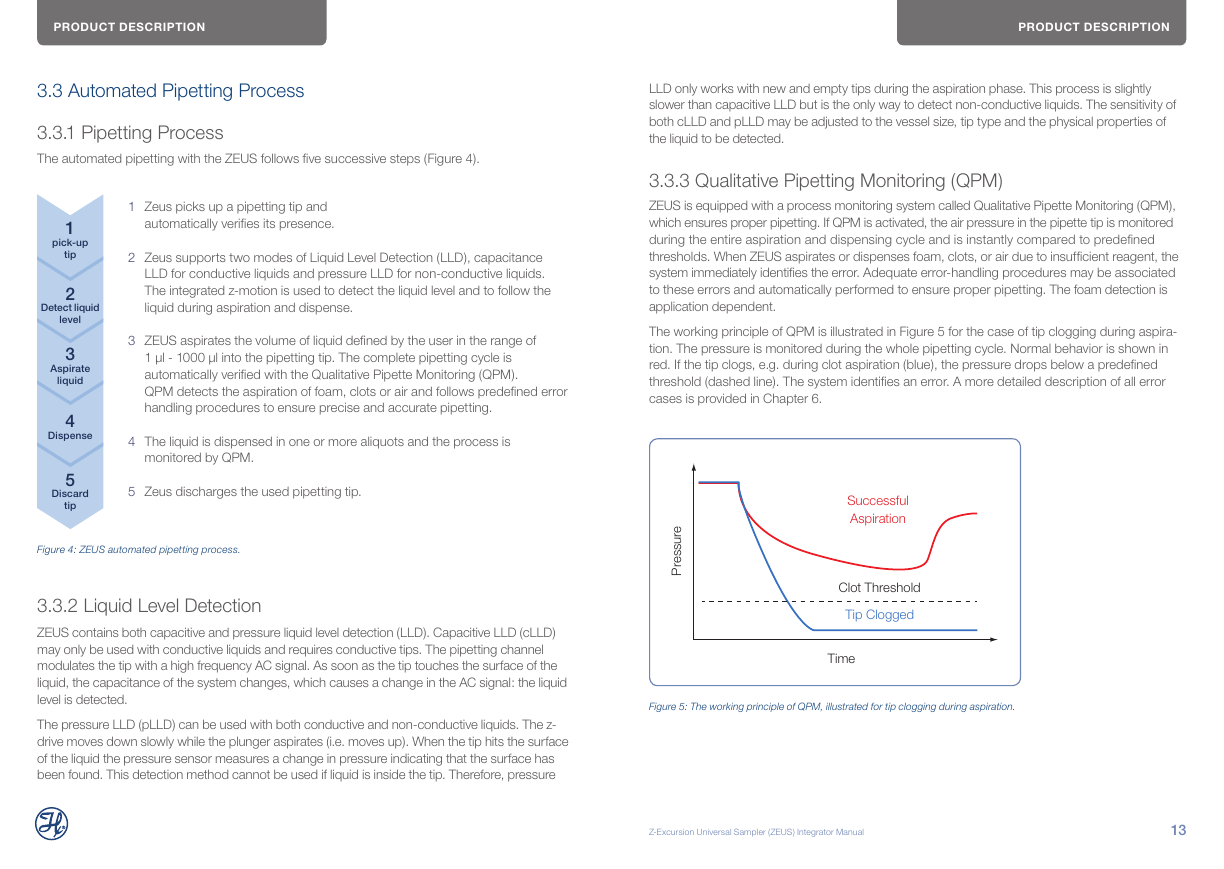

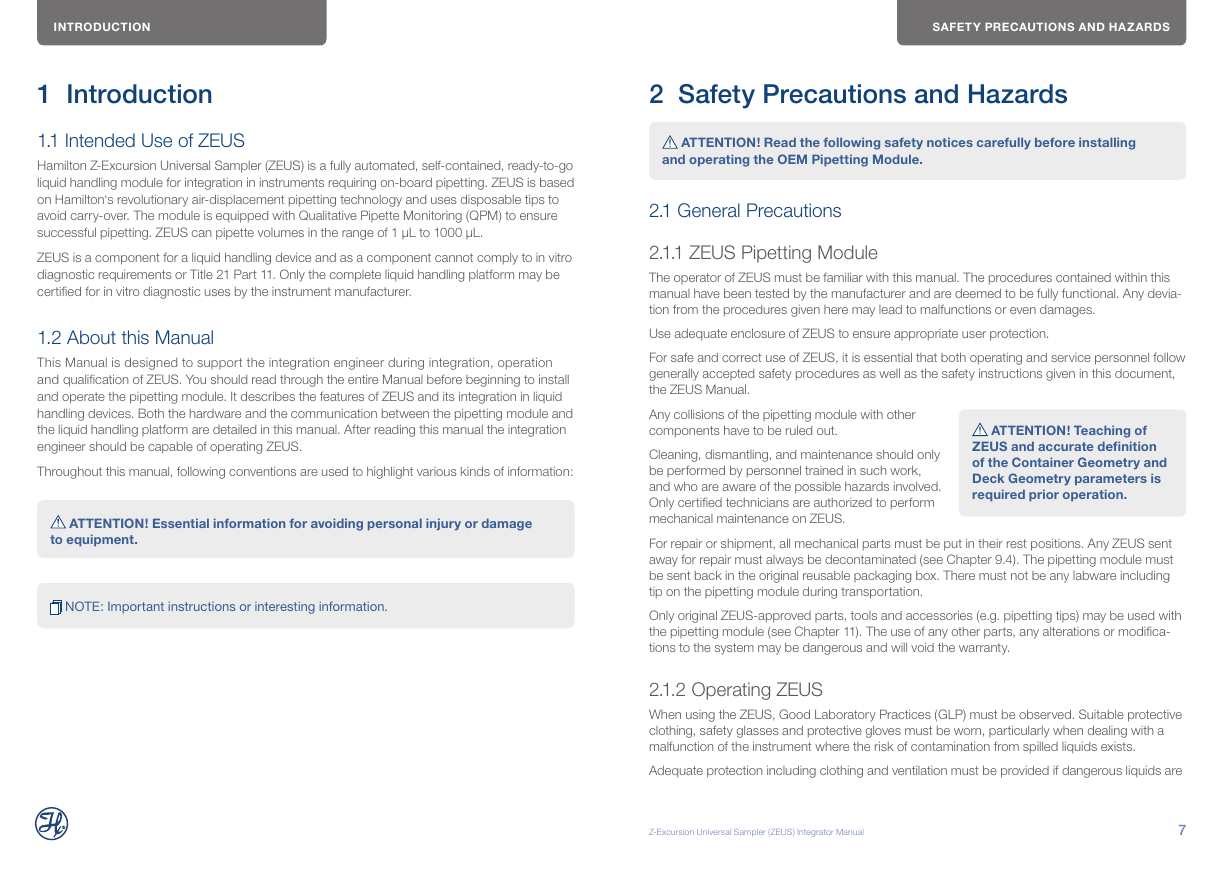

The automated pipetting with the ZEUS follows five successive steps (Figure 4).

1 Zeus picks up a pipetting tip and

automatically verifies its presence.

2 Zeus supports two modes of Liquid Level Detection (LLD), capacitance

LLD for conductive liquids and pressure LLD for non-conductive liquids.

The integrated z-motion is used to detect the liquid level and to follow the

liquid during aspiration and dispense.

3 ZEUS aspirates the volume of liquid defined by the user in the range of

1 μl - 1000 μl into the pipetting tip. The complete pipetting cycle is

automatically verified with the Qualitative Pipette Monitoring (QPM).

QPM detects the aspiration of foam, clots or air and follows predefined error

handling procedures to ensure precise and accurate pipetting.

4 The liquid is dispensed in one or more aliquots and the process is

monitored by QPM.

5 Zeus discharges the used pipetting tip.

1

tip

pick-up

2

level

Detect liquid

3

liquid

Aspirate

4

Dispense

5

tip

Discard

Figure 4: ZEUS automated pipetting process.

3.3.2 Liquid Level Detection

ZEUS contains both capacitive and pressure liquid level detection (LLD). Capacitive LLD (cLLD)

may only be used with conductive liquids and requires conductive tips. The pipetting channel

modulates the tip with a high frequency AC signal. As soon as the tip touches the surface of the

liquid, the capacitance of the system changes, which causes a change in the AC signal: the liquid

level is detected.

The pressure LLD (pLLD) can be used with both conductive and non-conductive liquids. The z-

drive moves down slowly while the plunger aspirates (i.e. moves up). When the tip hits the surface

of the liquid the pressure sensor measures a change in pressure indicating that the surface has

been found. This detection method cannot be used if liquid is inside the tip. Therefore, pressure

LLD only works with new and empty tips during the aspiration phase. This process is slightly

slower than capacitive LLD but is the only way to detect non-conductive liquids. The sensitivity of

both cLLD and pLLD may be adjusted to the vessel size, tip type and the physical properties of

the liquid to be detected.

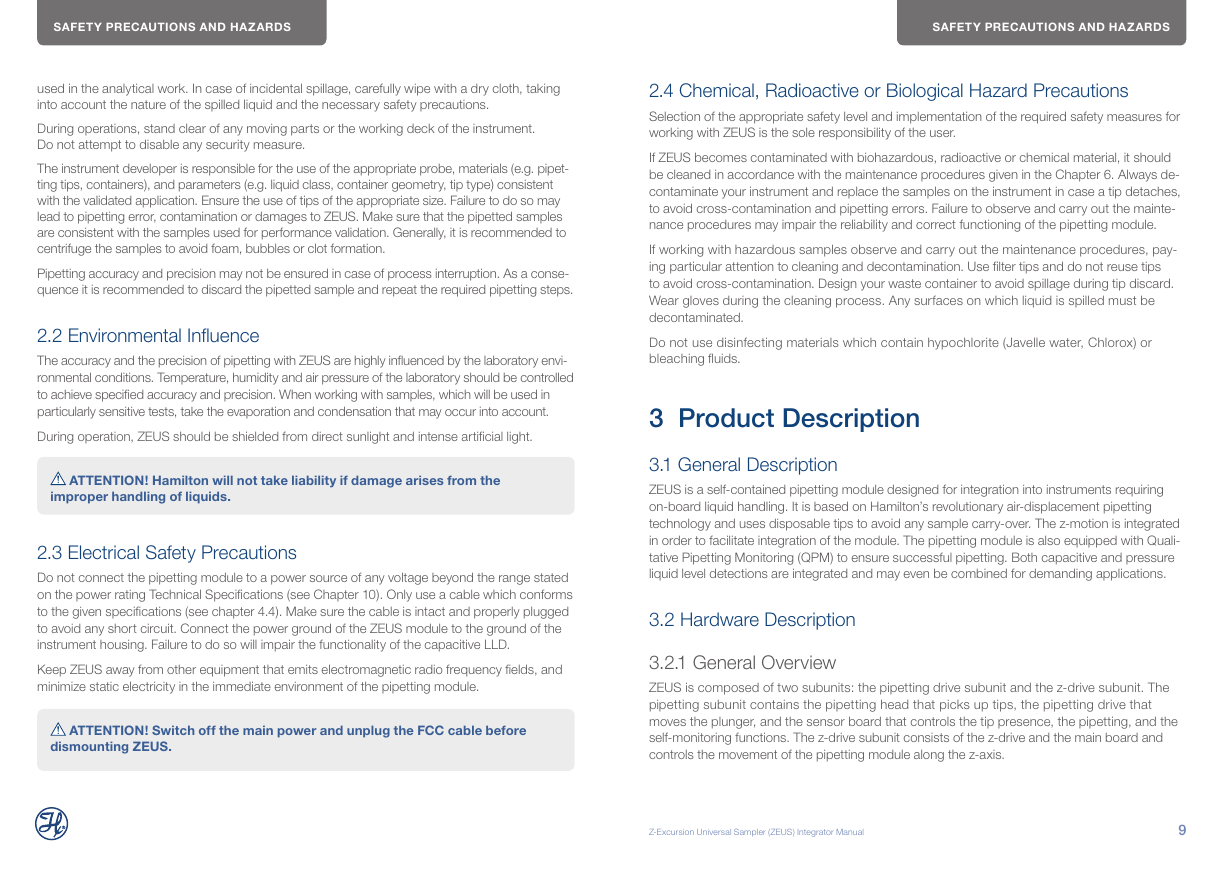

3.3.3 Qualitative Pipetting Monitoring (QPM)

ZEUS is equipped with a process monitoring system called Qualitative Pipette Monitoring (QPM),

which ensures proper pipetting. If QPM is activated, the air pressure in the pipette tip is monitored

during the entire aspiration and dispensing cycle and is instantly compared to predefined

thresholds. When ZEUS aspirates or dispenses foam, clots, or air due to insufficient reagent, the

system immediately identifies the error. Adequate error-handling procedures may be associated

to these errors and automatically performed to ensure proper pipetting. The foam detection is

application dependent.

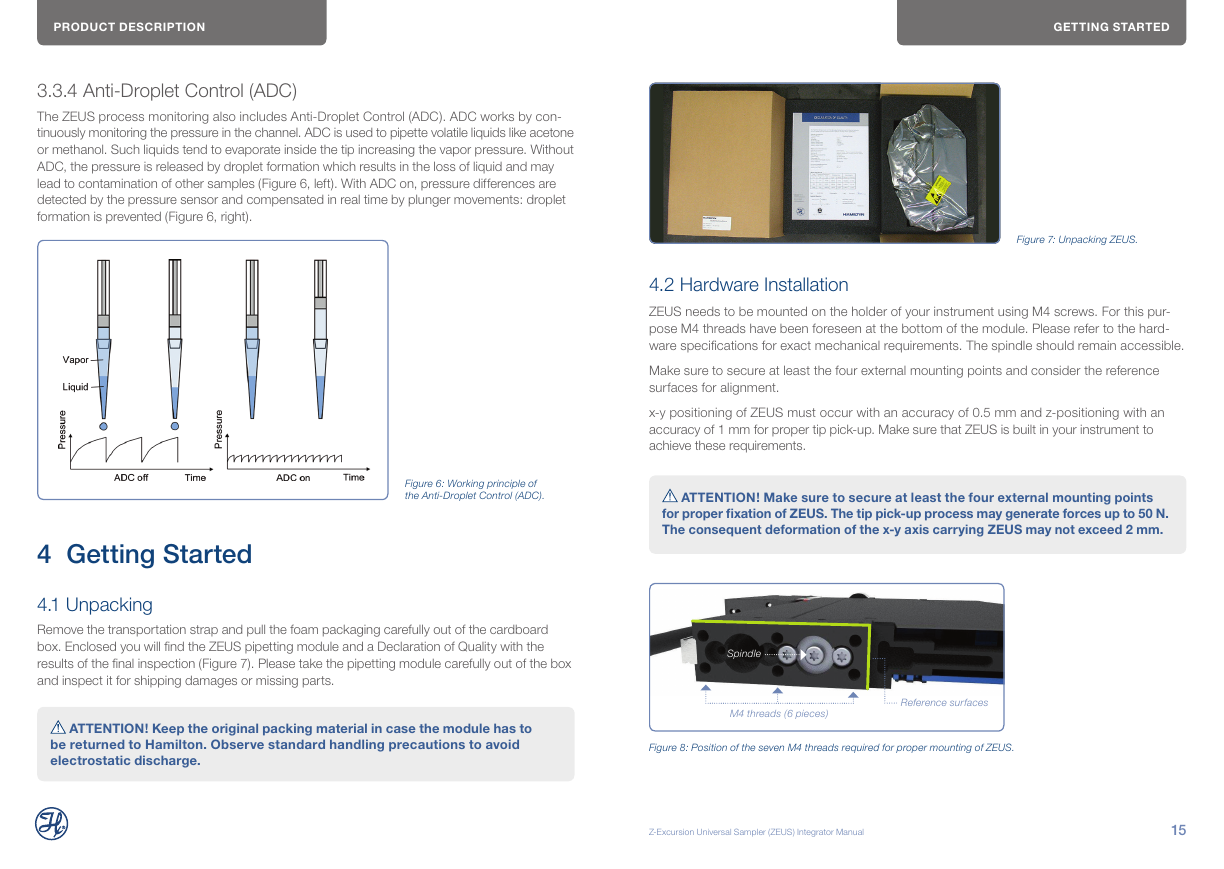

The working principle of QPM is illustrated in Figure 5 for the case of tip clogging during aspira-

tion. The pressure is monitored during the whole pipetting cycle. Normal behavior is shown in

red. If the tip clogs, e.g. during clot aspiration (blue), the pressure drops below a predefined

threshold (dashed line). The system identifies an error. A more detailed description of all error

cases is provided in Chapter 6.

e

r

u

s

s

e

r

P

Successful

Aspiration

Clot Threshold

Tip Clogged

Time

Figure 5: The working principle of QPM, illustrated for tip clogging during aspiration.

13

Z-Excursion Universal Sampler (ZEUS) Integrator Manual�

PRODUCT DESCRIPTION

GETTING STARTED

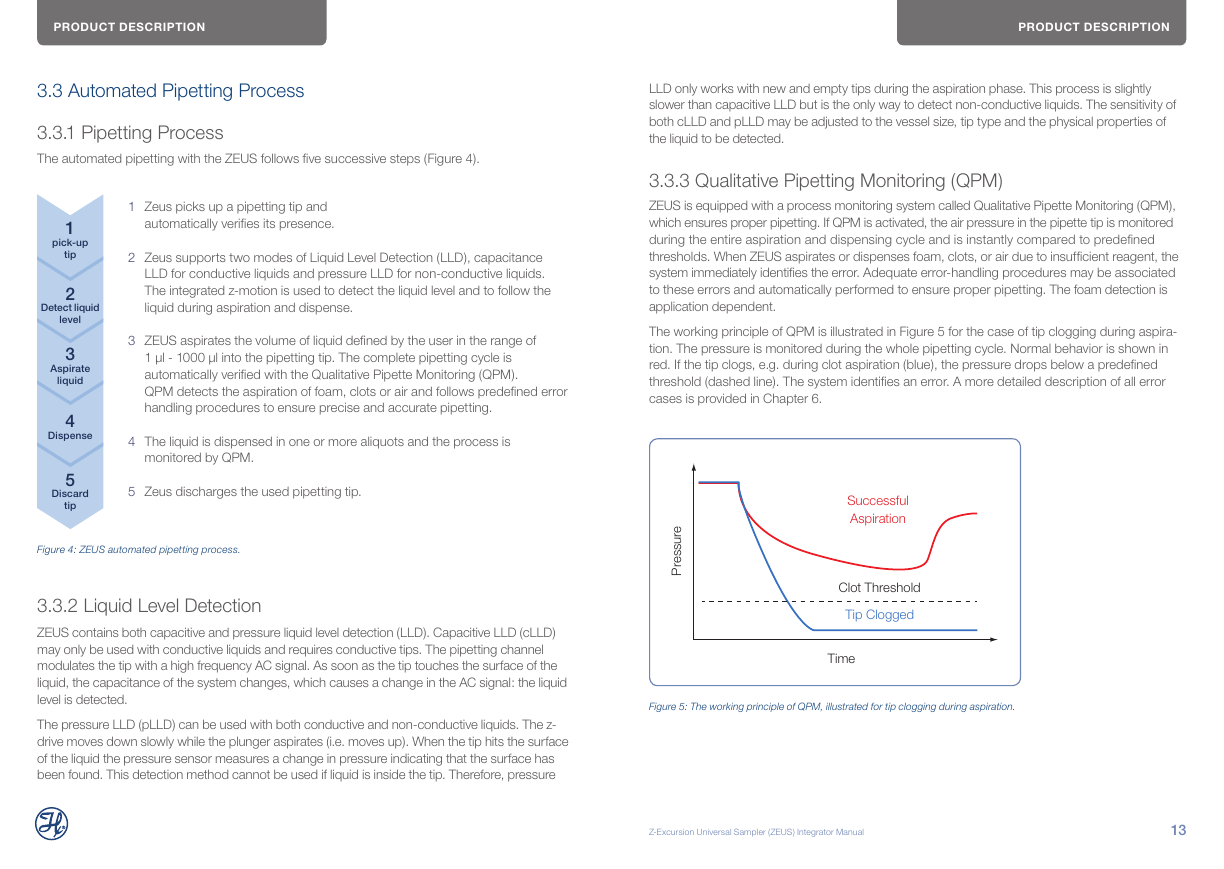

3.3.4 Anti-Droplet Control (ADC)

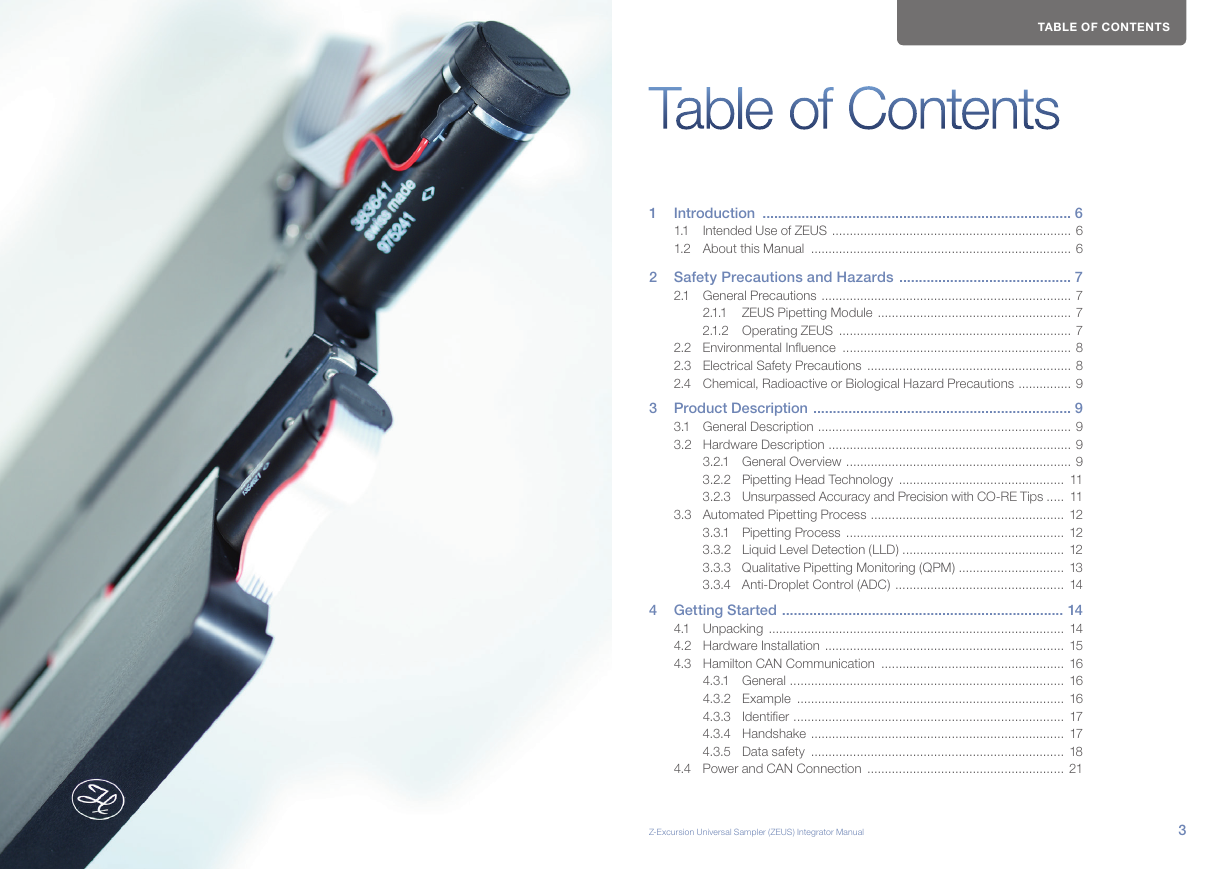

The ZEUS process monitoring also includes Anti-Droplet Control (ADC). ADC works by con-

tinuously monitoring the pressure in the channel. ADC is used to pipette volatile liquids like acetone

or methanol. Such liquids tend to evaporate inside the tip increasing the vapor pressure. Without

ADC, the pressure is released by droplet formation which results in the loss of liquid and may

lead to contamination of other samples (Figure 6, left). With ADC on, pressure differences are

detected by the pressure sensor and compensated in real time by plunger movements: droplet

formation is prevented (Figure 6, right).

Figure 7: Unpacking ZEUS.

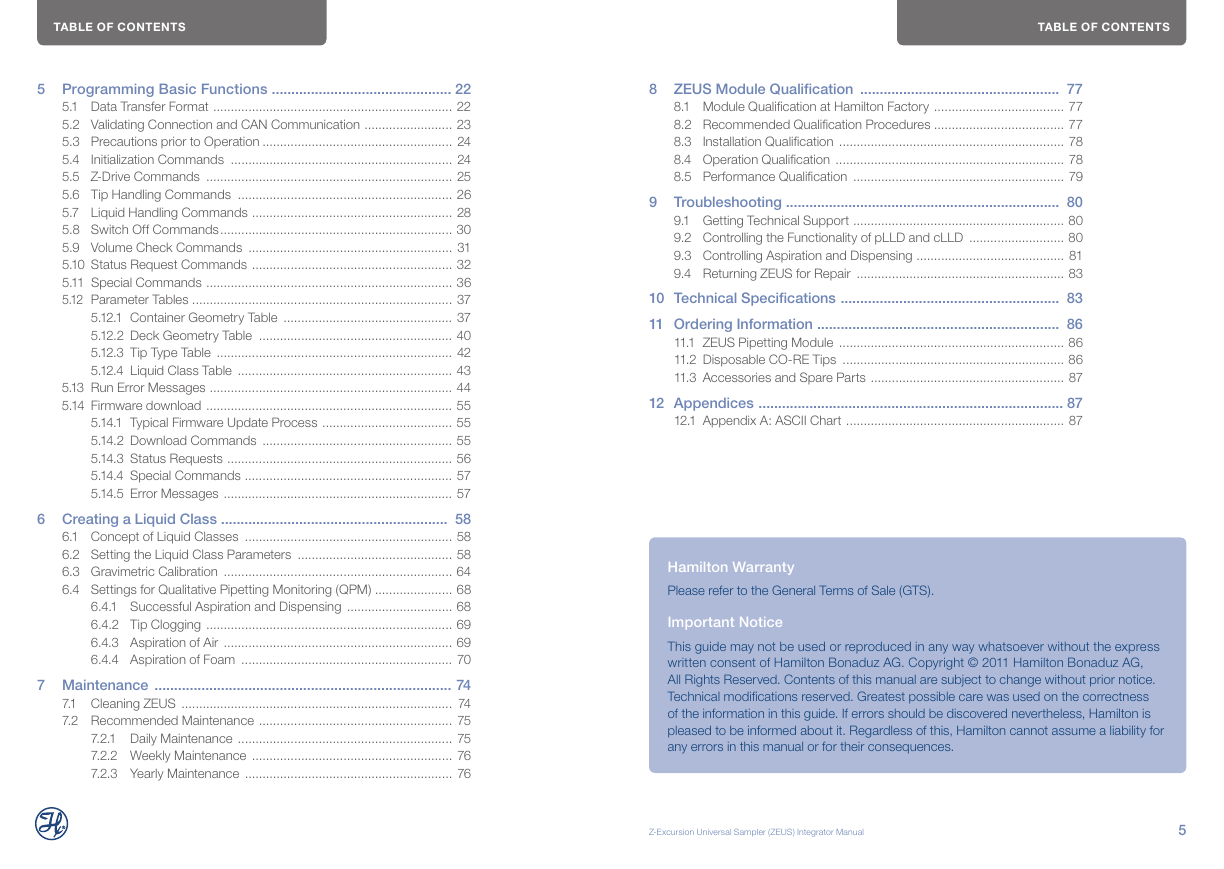

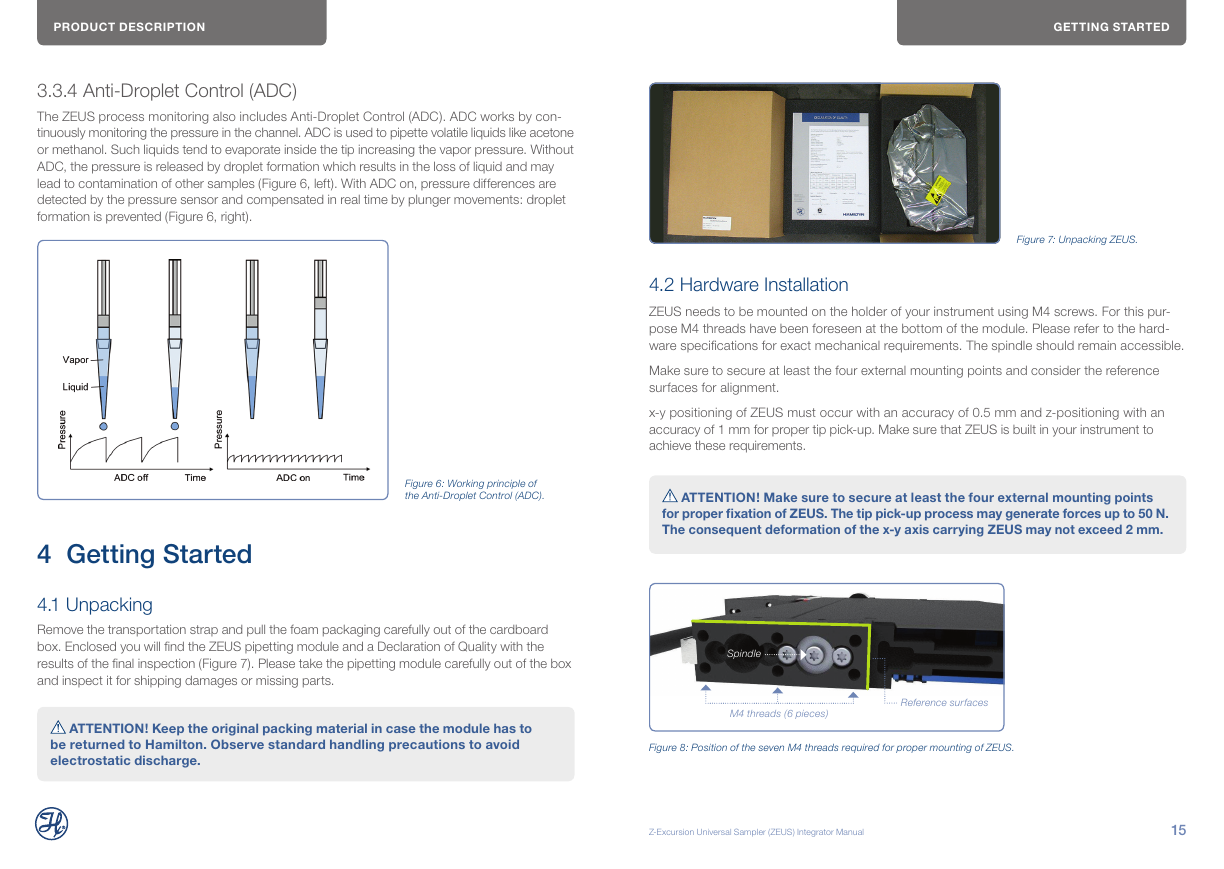

4.2 Hardware Installation

ZEUS needs to be mounted on the holder of your instrument using M4 screws. For this pur-

pose M4 threads have been foreseen at the bottom of the module. Please refer to the hard-

ware specifications for exact mechanical requirements. The spindle should remain accessible.

Make sure to secure at least the four external mounting points and consider the reference

surfaces for alignment.

x-y positioning of ZEUS must occur with an accuracy of 0.5 mm and z-positioning with an

accuracy of 1 mm for proper tip pick-up. Make sure that ZEUS is built in your instrument to

achieve these requirements.

4 Getting Started

Figure 6: Working principle of

the Anti-Droplet Control (ADC).

ATTENTION! Make sure to secure at least the four external mounting points

for proper fixation of ZEUS. The tip pick-up process may generate forces up to 50 N.

The consequent deformation of the x-y axis carrying ZEUS may not exceed 2 mm.

4.1 Unpacking

Remove the transportation strap and pull the foam packaging carefully out of the cardboard

box. Enclosed you will find the ZEUS pipetting module and a Declaration of Quality with the

results of the final inspection (Figure 7). Please take the pipetting module carefully out of the box

and inspect it for shipping damages or missing parts.

Spindle

ATTENTION! Keep the original packing material in case the module has to

be returned to Hamilton. Observe standard handling precautions to avoid

electrostatic discharge.

M4 threads (6 pieces)

Reference surfaces

Figure 8: Position of the seven M4 threads required for proper mounting of ZEUS.

15

Z-Excursion Universal Sampler (ZEUS) Integrator Manual�

2023年江西萍乡中考道德与法治真题及答案.doc

2023年江西萍乡中考道德与法治真题及答案.doc 2012年重庆南川中考生物真题及答案.doc

2012年重庆南川中考生物真题及答案.doc 2013年江西师范大学地理学综合及文艺理论基础考研真题.doc

2013年江西师范大学地理学综合及文艺理论基础考研真题.doc 2020年四川甘孜小升初语文真题及答案I卷.doc

2020年四川甘孜小升初语文真题及答案I卷.doc 2020年注册岩土工程师专业基础考试真题及答案.doc

2020年注册岩土工程师专业基础考试真题及答案.doc 2023-2024学年福建省厦门市九年级上学期数学月考试题及答案.doc

2023-2024学年福建省厦门市九年级上学期数学月考试题及答案.doc 2021-2022学年辽宁省沈阳市大东区九年级上学期语文期末试题及答案.doc

2021-2022学年辽宁省沈阳市大东区九年级上学期语文期末试题及答案.doc 2022-2023学年北京东城区初三第一学期物理期末试卷及答案.doc

2022-2023学年北京东城区初三第一学期物理期末试卷及答案.doc 2018上半年江西教师资格初中地理学科知识与教学能力真题及答案.doc

2018上半年江西教师资格初中地理学科知识与教学能力真题及答案.doc 2012年河北国家公务员申论考试真题及答案-省级.doc

2012年河北国家公务员申论考试真题及答案-省级.doc 2020-2021学年江苏省扬州市江都区邵樊片九年级上学期数学第一次质量检测试题及答案.doc

2020-2021学年江苏省扬州市江都区邵樊片九年级上学期数学第一次质量检测试题及答案.doc 2022下半年黑龙江教师资格证中学综合素质真题及答案.doc

2022下半年黑龙江教师资格证中学综合素质真题及答案.doc