Automotive

Engineering

Fundamentals

Richard Stone

and

Jeffrey K. Ball

mAE - Internationa/

Warrendale. Pa.

�

Allrightsreserved.Nopartofthispublicationmaybereproduced,storedinaretrievalsystem,ortransmitted,inanyformorbyanymeans,electronic,mechanical,photocopying,recording,orother-wise,withoutthepriorwrittenpermissionofSAE.Forpermissionandlicensingrequests,contact:SAEPermissions400CommonwealthDriveWarrendale,PA15096-0001USAE-mail:permissions@sae.orgTel:724-772-4028Fax:724-772-4891LibraryofCongressCataloging-in-PublicationDataStone,Richard.Automotiveengineeringfundamentals/RichardStoneandJeffreyK.Ball,p.cm.Includesbibliographicalreferencesandindex.ISBN0-7680-0987-11.Automobiles\p=m-\Designandconstruction.I.Ball,JeffreyK.II.Title.TL240.S8532004629.2'3\p=m-\dc222004041782SAE400CommonwealthDriveWarrendale,PA15096-0001USAE-mail:CustomerService@sae.orgTel:877-606-7323(insideUSAandCanada)724-776-4970(outsideUSA)Fax:724-776-1615Copyright\s=c\2004RichardStoneandJeffreyK.BallISBN0-7680-0987-1SAEOrderNo.R-199PrintedintheUnitedStatesofAmerica.�

Acknowledgments

The following figures in this book first appeared in Introduction to Internal Combustion

Engines, Third Edition, by Richard Stone, published by Palgrave Macmillan in 1999:

Figures 2.2,2.4 through 2.7,2.9,2.10,2.12 through 2.15,2.17 through 2.20,2.23 through

2.28, and 2.30 through 2.32.

�

Preface

This book arose from a need for an automotive engineering textbook that included analysis,

as well as descriptions of the hardware. Specifically, several courses in systems engineering

use the automobile as a basis. Additionally, many universities are now involved in collegiate

design competitions such as the SAE Mini Baja and Formula SAE competitions. This book

should be helpful to such teams as an introductory text and as a source for further references.

Given the broad scope of this topic, not every aspect of automotive engineering could be

covered while keeping the text to a reasonable and affordable size.

The book is aimed at third- to fourth-year engineering students and presupposes a certain

level of engineering background. However, the courses for which this book was written are

composed of engineering students from varied backgrounds to include mechanical, aeronau-

tical, electrical, and astronautical engineering. Thus, certain topics that would be a review for

mechanical engineering students may be an introduction to electrical engineers, and vice

versa. Furthermore, because the book is aimed at students, it sometimes has been necessary

to give only outline or simplified explanations. In such cases, numerous references have been

made to sources of other information.

Practicing engineers also should find this book useful when they need an overview of the

subject, or when they are working on particular aspects of automotive engineering that are

new to them.

Automotive engineering draws on almost all areas of engineering: thermodynamics and com-

bustion, fluid mechanics and heat transfer, mechanics, stress analysis, materials science, elec-

tronics and controls, dynamics, vibrations, machine design, linkages, and so forth. However,

automobiles also are subject to commercial considerations, such as economics, marketing,

and sales, and these aspects are discussed as they arise.

Again, to limit the scope of this project, several important automotive engineering concepts

are notable for their absence. Two examples notable for their absence are manufacturing and

structural design and crashworthiness. Neither of these topics was omitted because the topics

were deemed unimportant. Rather, they did not fit the particular curriculum this book tar-

geted. In short, topics that have been omitted are not intended to slight the importance of the

topics, but choices had to be made in the scope of the text.

The book has been organized to flow from the source of power (i.e., engine) through the

drivetrain to the road. Chapter 1 is a brief and selective historical overview. Again, topics for

Chapter 1 had to be limited to keep the scope reasonable, and the intent was to show the

progression of automotive engineering over the last 100 years. Undoubtedly, readers will

find several topics absent from the historical overview. Again, the absences are not intended

to minimize the importance of any development, but to limit the size of Chapter 1.

�

xiv

I

Automotive Engineering Fundamentals

Chapter 2 contains an overview of the thermodynamic principles common to internal com-

bustion engines and concludes with an extensive discussion of fuel cell principles and their

systems. The differing operations of spark ignition engines and compression ignition engines

are discussed in Chapters 3 and 4, respectively. Because many diesel engines now employ

forced induction, the topic of turbo- and supercharging is discussed in Chapter 4 as well.

Chapter 5 covers the ancillary systems associated with the engine and includes belt drives, air

conditioning, and the starting and charging systems.

Transmissions and drivelines are the topic of Chapter 6. This chapter includes discussion and

analysis of both manual and automatic transmissions, driveshaft design, and four- and all-

wheel-drive systems. The steering system is discussed in Chapter 7 and includes basic tech-

niques for analyzing vehicle dynamics and rollover. The suspension system is discussed in

Chapter 8, and basic models are provided as first-order analysis tools. The suspension system

is another topic that is worthy of a textbook in itself, but Chapter 8 provides students and

practicing engineers with several references to more detailed models and analysis techniques.

Brakes and tires are the topic of Chapter 9, and Chapter 10 discusses vehicle aerodynamics.

Because computer modeling is becoming increasingly important for the automotive engineer,

Chapter 11 discusses matching transmissions to engines and provides a link to a computer

model that is useful for predicting overall vehicle performance. Chapter 12 concludes the

book with two case studies chosen to highlight the advances made in automotive engineering

over the last century. The first case study is the Vauxhall 14-40, a vehicle that was studied

extensively by Sir Harry Ricardo in the 1920s. As a point of comparison, the second case

study is the Toyota Prius, which represents cutting-edge technology in a hybrid vehicle.

The material in the book has been used by the authors in teaching an automotive systems

analysis course and as part of a broad-based engineering degree course. These experiences

have been invaluable in preparing this manuscript, as has been the feedback from the stu-

dents. The material in the book comes from numerous sources. The published sources have

been acknowledged, but of greater importance have been the conversations and discussions

with colleagues and researchers involved in all areas of automotive engineering, especially

when they have provided us with copies of relevant publications.

We welcome criticisms or comments about the book, either concerning the details or the

overall concept.

Richard Stone

Jeff Ball

Autumn 2002

�

Table of Contents

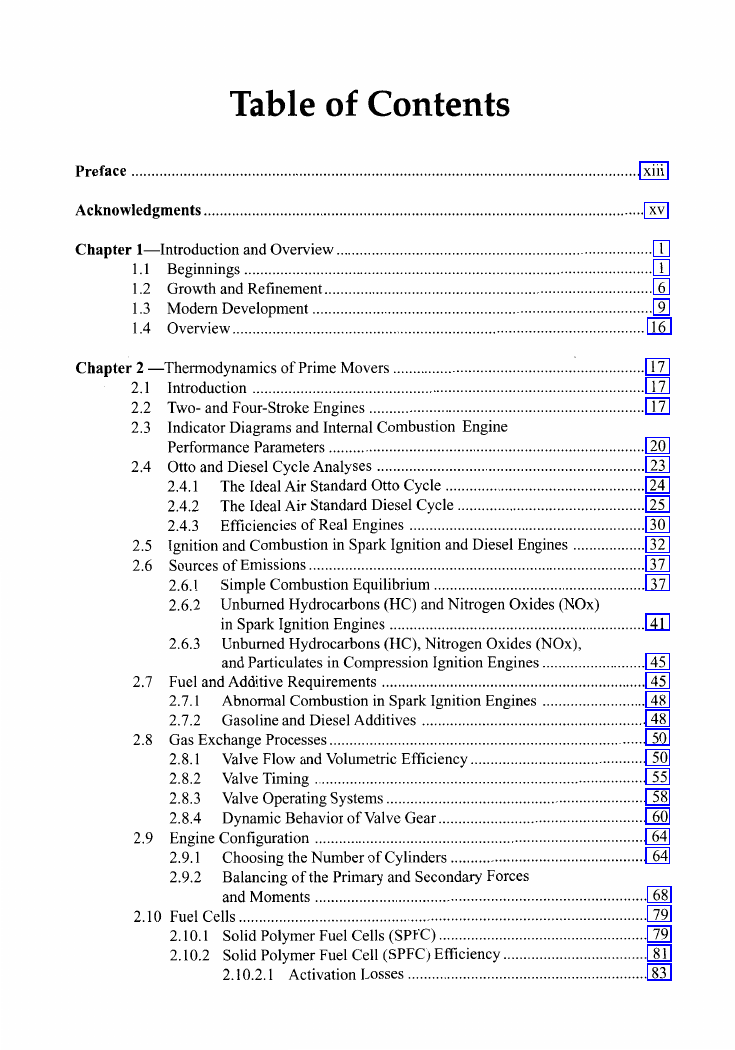

...

Preface ............................................................................................................................... xi11

Acknowledgments .............................................................................................................. xv

Chapter 1-Introduction and Overview ............................................................................... 1

1.1 Beginnings .................................................................................................... 1

1.2 Growth and Refinement ............................................................................... 6

1.3 Modern Development ..................................................................................... 9

1.4 Overview .................................................................................................... 16

Chapter 2 -Thermodynamics of Prime Movers ............................................................... 17

Introduction .................................................................................................. 17

Two- and Four-Stroke Engines ..................................................................... 17

Indicator Diagrams and Internal Combustion Engine

Performance Parameters ............................................................................... 20

Otto and Diesel Cycle Analyses ................................................................... 23

2.4.1 The Ideal Air Standard Otto Cycle .................................................. 24

2.4.2 The Ideal Air Standard Diesel Cycle ............................................... 25

2.4.3 Efficiencies of Real Engines ........................................................... 30

Ignition and Combustion in Spark Ignition and Diesel Engines .................. 32

Sources of Emissions .................................................................................. 37

2.6.1 Simple Combustion Equilibrium ..................................................... 37

2.6.2 Unburned Hydrocarbons (HC) and Nitrogen Oxides (NOx)

in Spark Ignition Engines ................................................................ 41

2.6.3 Unburned Hydrocarbons (HC), Nitrogen Oxides (NOx),

and Moments ................................................................................ 68

2.10 Fuel Cells ...................................................................................................... 79

2.10.1 Solid Polymer Fuel Cells (SPFC) .................................................... 79

81

2.10.2 Solid Polymer Fuel Cell (SPFC) Efficiency

83

....................................

............................................................

2.10.2.1 Activation Losses

and Particulates in Compression Ignition Engines

..........................

..................................................................

45

45

Fuel and Additive Requirements

2.7.1 Abnormal Combustion in Spark Ignition Engines .......................... 48

2.7.2 Gasoline and Diesel Additives ........................................................ 48

Gas Exchange Processes ............................................................................... 50

2.8.1 Valve Flow and Volumetric Efficiency ........................................ 50

2.8.2 Valve Timing ................................................................................... 55

58

2.8.3 Valve Operating Systems

2.8.4 Dynamic Behavior of Valve Gear ................................................... 60

64

Engine Configuration

64

2.9.1 Choosing the Number of Cylinders

2.9.2 Balancing of the Primary and Secondary Forces

...................................................................................

.................................................

.................................................................

�

vi

Automotive Engineering Fundamentals

2.10.2.2 Fuel Crossover and Internal Currents

85

2.10.2.3 Ohmic Losses .................................................................. 87

2.10.2.4 Mass Transfer Losses

87

2.10.2.5 Overall Response

88

......................................................

............................................................

.............................

2.10.3 Sources of Hydrogen for Solid Polymer Fuel Cells

(SPFC) ............................................................................................. 88

2.10.3.1 Steam Reforming (SR)

89

2.10.3.2 Partial Oxidation (POX) Reforming

90

2.10.3.3 Autothermal Reforming (AR)

90

2.10.3.4 Carbon Monoxide Clean-Up and Solid Polymer

Fuel Cell (SPFC) Operation on Reformed Fuel

....................................................

...............................

.........................................

2.10.3.5 Hydrogen Storage

2.10.4 Hydrogen Fuel Cell Systems

91

92

93

2.11 Concluding Remarks .................................................................................... 97

2.12 Problems

97

..............

............................................................

...........................................................

.......................................................................................................

Chapter 3-Spark

Ignition Engines

Introduction

3.1

3.2 Spark Ignition and Ignition Timing

Ignition System Overview

3.3 Mixture Preparation

3.4 Combustion System Design

3.5 Emissions Control

Ignition Timing Selection and Control

3.4.1 Port Injection Combustion Systems

3.4.2 Direct Injection Spark lgnition (DISI) Combustion Systems

3.5.1 Development of the Three-Way Catalyst

3.5.2 Durability

3.5.3 Catalyst Light-Off

3.5.4 Lean-Bum NOx-Reducing Catalysts, "DENOx"

.................................................................................

................................................................................................

............................................................

.............................................................

..........................................

....................................................................................

.........................................................................

...............................................

.........

.......................................................................................

......................................

.......................................................................................

..........................................................................

..........................

101

101

101

3.2.1

101

3.2.2 The Ignition Process ...................................................................... 105

3.2.3

107

109

113

113

116

120

121

124

125

126

127

127

128

132

3.7.1

132

3.7.2 Sensor Types ................................................................................. 134

3.7.2.1 Crankshaft SpeedPosition and Camshaft Position ....... 134

3.7.2.2 Throttle Position ............................................................ 136

3.7.2.3 Air Flow Rate ................................................................ 136

Inlet Manifold Absolute Pressure .................................. 137

3.7.2.4

3.7.2.5 Air Temperature and Coolant Temperature

137

3.7.2.6 Air-Fuel Ratio

137

3.7.2.7 Knock Detector ............................................................. 140

................................

................................................................................

.....................................................................

...................................................................................

3.6.1 Variable Valve Timing and Induction Tuning

3.6.2 Supercharging

...................

...............................................................

...........................................................................................

Introduction

3.6 Power Boosting

3.7 Engine Management Systems

�

Table of Contents

vii

Ignition Timing

3.8 Engine Management System Functions

3.8.1

3.8.2 Air-Fuel Ratio Control

3.8.3 Exhaust Gas Recirculation (EGR) Control

3.8.4 Additional Functions

3.8.5 Concluding Remarks on Engine Management Systems

142

142

143

144

144

146

3.9 Conclusions ................................................................................................ 147

3.10 Questions

147

......................................................

..............................................................................

...................................................................

...................................

.....................................................................

................

....................................................................................................

Chapter 4-Diesel Engines

Introduction

4.4 Diesel Engine Emissions and Their Control

4.4.1 Diesel Engine Emissions

4.4.2 Diesel Engine Emissions Control

4.3.1 Pump-Line-Injector (PLI) Systems

4.3.2 Electronic Unit Injectors (EUI)

4.3.3 Common Rail (CR) Fuel Injection Systems

4.1

4.2 Direct and Indirect Injection Combustion Chambers

4.3 Fuel Injection Equipment

149

149

150

152

153

155

156

157

157

158

158

159

161

161

164

169

4.6 Diesel Engine Management Systems

172

4.7 Concluding Remarks

175

4.8 Examples

177

4.9 Problems ..................................................................................................... 185

..............................................................................................

................................................................................................

.................................

...........................................................................

..............................................

.....................................................

..................................

...............................................

...............................................................

..................................................

................................

............................................................

.............................................................................................

...................................................................................

............................................................

...............................................

..........................................................

..................................................................................

....................................................................................................

4.4.2.1 Exhaust Gas Recirculation (EGR)

4.4.2.2

4.5 Turbocharging

4.5.1

4.5.2 Turbocharger Performance

4.5.3 Turbocharged Engine Performance

Particulate Traps

Introduction

Chapter 5-Ancillaries

Introduction

5.1

5.2 Lubrication System

.

5.2.1 1 Anti-Friction Bearings

5.2.1.2 Guide Bearings

5.2.1.3 Thrust Bearings

5.2.1.4

Journal Bearings

....................................................................................................

................................................................................................

.....................................................................................

189

189

189

5.2.1 Bearings ......................................................................................... 189

190

190

191

192

195

197

202

206

208

208

212

..................................................

..............................................................

.............................................................

............................................................

..........................................................................

....................................................

............................................................................

..........................................................................................

..................................................................................................

..............................................................................

...........................................................................................

5.2.2 Engine Lubricants

5.2.3 Lubrication of Journal Bearings

5.4.1 Flat Belt Drives

5.4.2 V-Belts

5.3.1 Coolant

5.3 Vehicle Cooling Systems

5.4 Drive Belts

�

2023年江西萍乡中考道德与法治真题及答案.doc

2023年江西萍乡中考道德与法治真题及答案.doc 2012年重庆南川中考生物真题及答案.doc

2012年重庆南川中考生物真题及答案.doc 2013年江西师范大学地理学综合及文艺理论基础考研真题.doc

2013年江西师范大学地理学综合及文艺理论基础考研真题.doc 2020年四川甘孜小升初语文真题及答案I卷.doc

2020年四川甘孜小升初语文真题及答案I卷.doc 2020年注册岩土工程师专业基础考试真题及答案.doc

2020年注册岩土工程师专业基础考试真题及答案.doc 2023-2024学年福建省厦门市九年级上学期数学月考试题及答案.doc

2023-2024学年福建省厦门市九年级上学期数学月考试题及答案.doc 2021-2022学年辽宁省沈阳市大东区九年级上学期语文期末试题及答案.doc

2021-2022学年辽宁省沈阳市大东区九年级上学期语文期末试题及答案.doc 2022-2023学年北京东城区初三第一学期物理期末试卷及答案.doc

2022-2023学年北京东城区初三第一学期物理期末试卷及答案.doc 2018上半年江西教师资格初中地理学科知识与教学能力真题及答案.doc

2018上半年江西教师资格初中地理学科知识与教学能力真题及答案.doc 2012年河北国家公务员申论考试真题及答案-省级.doc

2012年河北国家公务员申论考试真题及答案-省级.doc 2020-2021学年江苏省扬州市江都区邵樊片九年级上学期数学第一次质量检测试题及答案.doc

2020-2021学年江苏省扬州市江都区邵樊片九年级上学期数学第一次质量检测试题及答案.doc 2022下半年黑龙江教师资格证中学综合素质真题及答案.doc

2022下半年黑龙江教师资格证中学综合素质真题及答案.doc