MAKING MODERN LIVING POSSIBLE

Selection guide

VLT® DriveMotor FCM 106

VLT® DriveMotor FCP 106

IE4effi ciency

Meet tomorrow’s

demands today with the

VLT® DriveMotor FCM 106

factory mounted to an

IE4 rated permanent

magnet motor.

www.danfoss.com/fcm106

�

ONE DRIVE

TWO SOLUTIONS

FULL FLEXIBILITY

Select the drive component as a stand-

alone unit or factory mounted to a

high effi ciency permanent magnet

(PM) or induction motor (IM), and

enjoy the benefi ts of Danfoss’ new

VLT® DriveMotor.

With integrated fan, pump and basic industry features, and

VVC+ motor control, the VLT® DriveMotor is a space saving,

effi cient alternative to drive solutions in the 0.55-7.5 kW range.

Motor mounted for IE4 effi ciency

Available as a motor-mounted drive solution the VLT® Drive-

Motor FCM 106 can be delivered factory fi tted to either an IE 4

rated PM or IE 2 rated IM motor. This provides owners with an

opportunity to be well prepared for future demands already

today.

Standalone drive for your own motor

Alternatively, choose your own motor and attach the stand-

alone frequency converter, VLT® DriveMotor FCP 106, for full

fl exibility in motor choice, system design and energy effi ciency.

VLT® DriveMotor FCM 106

2

VLT® DriveMotor FCP 106

�

MAXIMIZE SYSTEM

EFFICIENCY WITH EC+

Easy maintenance

Component replacement as a result

of wear and tear is not always possible

without installing a complete new,

integrated system. The EC+ concept

answers this by making service and

maintenance easier, as only the aff ected

component needs to be repaired/

replaced in the event of malfunction.

Downtime is therefore reduced to a

minimum, as are maintenance costs due

to the fact that the EC+ concept is based

on standardized components, which can

be shipped at short notice and installed

with little eff ort.

Optimize PM motor performance

To make it possible for users to benefi t

from the high motor effi ciency on the

same level or above EC technology,

Danfoss has refi ned its VVC+ control

algorithm and optimized it for

permanent magnet motors. After

entering the relevant motor data, the

drive automatically optimizes the

performance of the application.

Free choice of technology

The EC+ concept allows manufacturers

to choose their preferred motor, fan/

pump from any supplier, as the same

Danfoss VLT drive is equally effi cient at

controlling PM or asynchronous motors.

By providing vendors with the freedom

to choose the optimal combination of

drive, motor and fan/pump it is possible

to achieve the best possible system

effi ciency.

This is a clear advantage compared to

integrated systems, where it often is

not possible to optimize the individual

components.

3

�

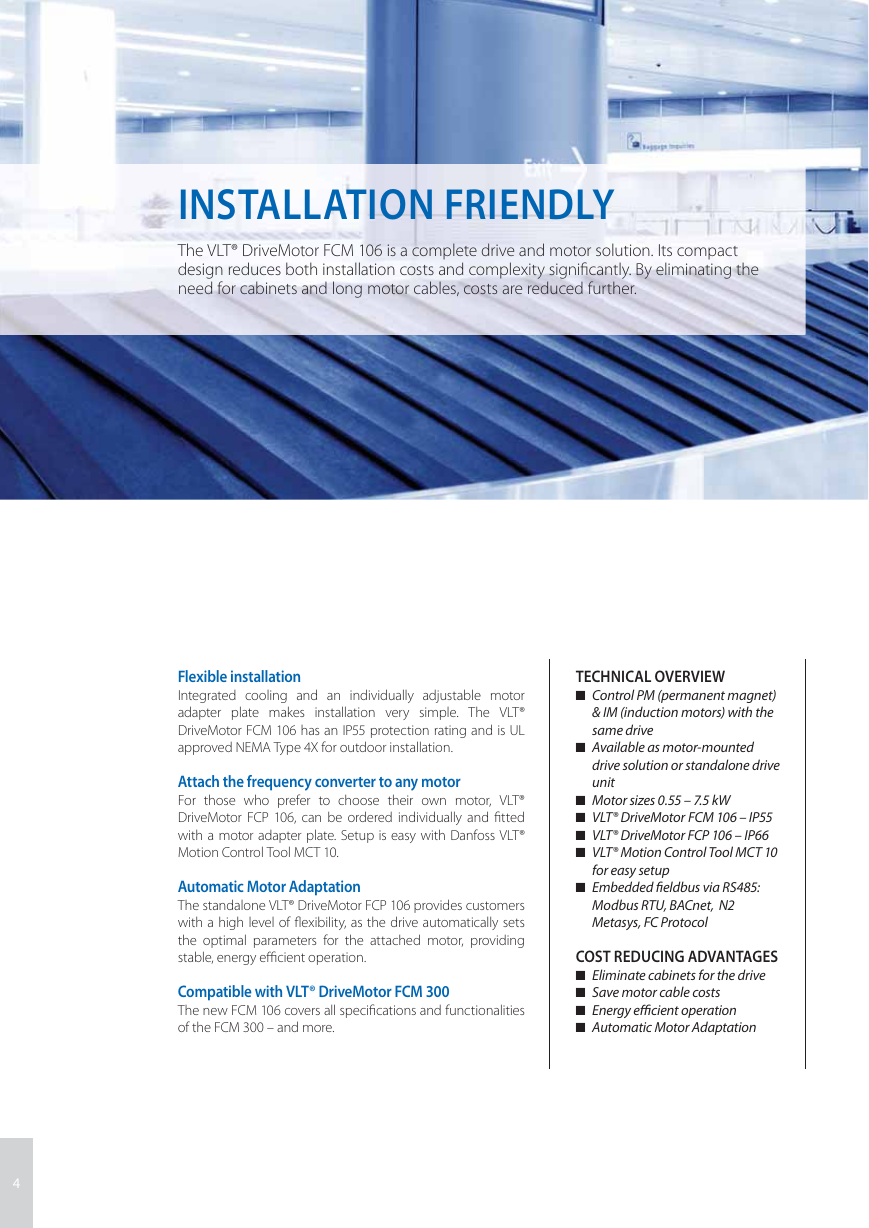

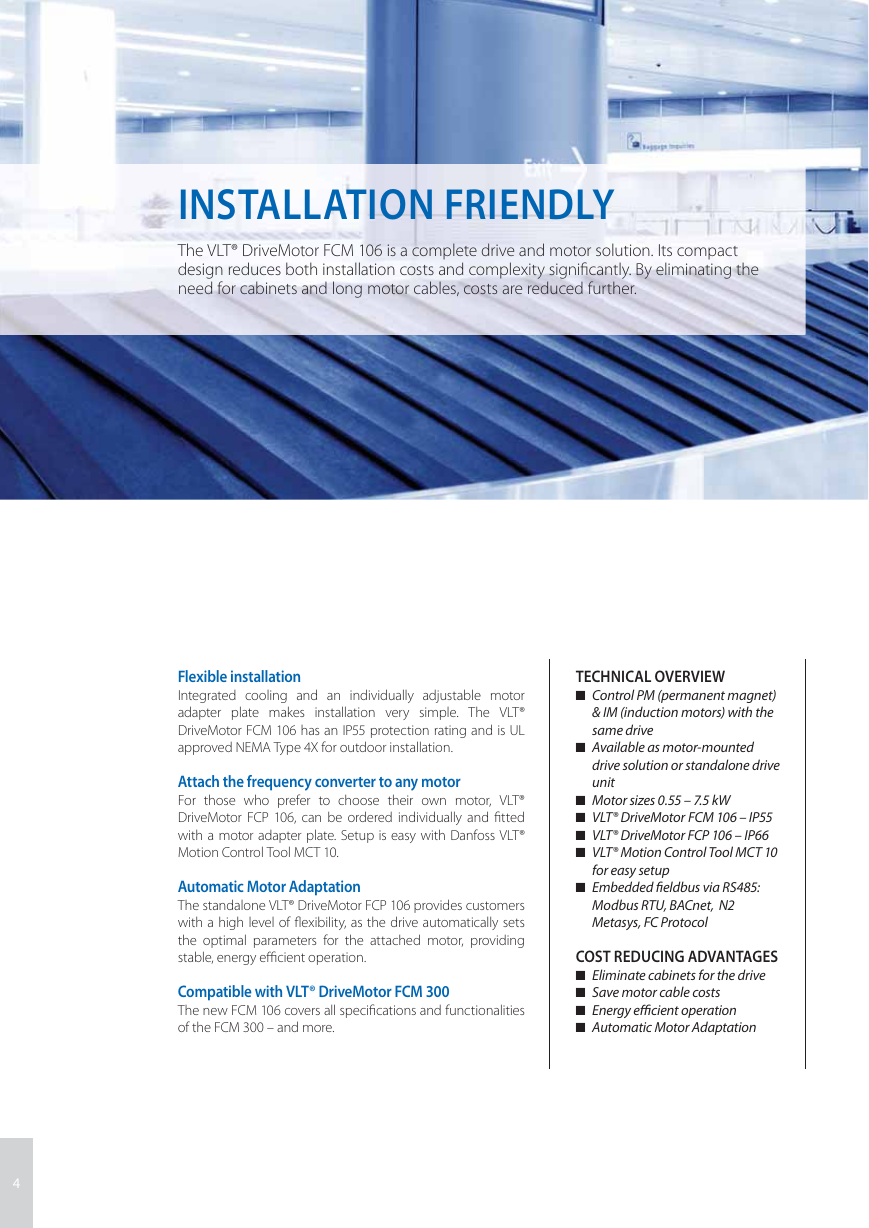

INSTALLATION FRIENDLY

The VLT® DriveMotor FCM 106 is a complete drive and motor solution. Its compact

design reduces both installation costs and complexity signifi cantly. By eliminating the

need for cabinets and long motor cables, costs are reduced further.

Flexible installation

Integrated cooling and an individually adjustable motor

adapter plate makes

installation very simple. The VLT®

DriveMotor FCM 106 has an IP55 protection rating and is UL

approved NEMA Type 4X for outdoor installation.

Attach the frequency converter to any motor

For those who prefer to choose their own motor, VLT®

DriveMotor FCP 106, can be ordered individually and fi tted

with a motor adapter plate. Setup is easy with Danfoss VLT®

Motion Control Tool MCT 10.

Automatic Motor Adaptation

The standalone VLT® DriveMotor FCP 106 provides customers

with a high level of fl exibility, as the drive automatically sets

the optimal parameters for the attached motor, providing

stable, energy effi cient operation.

Compatible with VLT® DriveMotor FCM 300

The new FCM 106 covers all specifi cations and functionalities

of the FCM 300 – and more.

4

TECHNICAL OVERVIEW

■ Control PM (permanent magnet)

& IM (induction motors) with the

same drive

■ Available as motor-mounted

drive solution or standalone drive

unit

■ Motor sizes 0.55 – 7.5 kW

■ VLT® DriveMotor FCM 106 – IP55

■ VLT® DriveMotor FCP 106 – IP66

■ VLT® Motion Control Tool MCT 10

for easy setup

■ Embedded fi eldbus via RS485:

Modbus RTU, BACnet, N2

Metasys, FC Protocol

COST REDUCING ADVANTAGES

■ Eliminate cabinets for the drive

■ Save motor cable costs

■ Energy effi cient operation

■ Automatic Motor Adaptation

�

BUILT-IN DC CHOKE

reduces THiD to

less than 46%. This

results in extended

drive lifetime and

minimized harmonic

load of mains.

CONSTANT TORQUE

at 160% overload in

industrial applications,

e.g. conveyors

INDUSTRIAL FEATURES

Built-in Smart Logic Controller

The Smart Logic Controller is a simple but clever way to keep

your drive, motor and application working together without

a PLC. The controller monitors a specifi ed event. When an

event occurs, the controller triggers a specifi ed act and starts

monitoring the next event, continuing for up to 20 steps

before returning to step one.

Motor thermistor

If increased temperature monitoring of the motor is required,

the motor thermistor can be monitored by connecting a

thermistor input to the drive. This secures that the motor

temperature does not exceed the specifi ed temperature

rating.

AC brake

Instead of a brake resistor the drive can ramp down induction

motors by absorbing the energy.

Control a mechanical brake via a signal

The drive can provide an output signal for an externally

mounted mechanical brake.

5

�

Stairwell pressurization

In the event of a fi re, the FCM/FCP

106 can maintain a higher level of air

pressure in stairwells than in other parts

of the building. This helps ensure that

fi re escapes remain free of smoke.

FAN FEATURES

VLT® DriveMotor FCP 106 and VLT®

DriveMotor FCM 106 are equipped

with basic air handling unit functions to

ensure safety, equipment reliability and

low noise operation.

Belt monitoring

Based on the speed/current the drive

can detect situations where the motor

has lost contact with the fan and raise

an alarm.

Flying start

This protective feature prevents

violent starts and wear and tear on the

equipment. By detecting the speed

and direction of a freely spinning fan

the drive can catch it at the correct

frequency.

Resonance monitoring

Using only a few keystrokes on the local

control panel (accessory) or via

VLT® Motion Control Tool MCT 10, the

drive can be set to avoid frequency

bands at which connected fans create

resonances in the ventilation system.

This reduces vibration, noise and

equipment wear.

Fire override mode

This setting prevents the drive from

stopping to protect itself and ensures

that vital fan operation is maintained for

as long as possible, regardless of control

signals, warnings or alarms.

PUMP FEATURES

Sleep mode

Sleep Mode keeps pump wear and

power consumption to an absolute

minimum. In low fl ow situations, the

VLT® DriveMotor will ramp up the pump

to boost the system pressure and then

stop. Monitoring the pressure, the

VLT® DriveMotor will restart when the

pressure falls below the required level.

Cascade controller

The embedded cascade controller in the

VLT® DriveMotor provides accurate fl ow,

pressure and level control to make

multi-pump systems work effi ciently. It

controls up to three pumps with two

operating direct on line.

Dry Run Detection*

Dry Run Detection helps protects

the pump from cavitation. The VLT®

DriveMotor constantly evaluates the

condition of the pump based on internal

frequency/power measurements. In

case of too low power consumption -

indicating a no- or low-fl ow condition –

the VLT® DriveMotor will stop the pump.

Check valve ramp*

This feature protects the check valve and

helps prevent water hammering. When

the pump ramps to stop, Check Valve

Ramp slows down the ramp and closes

the check valve softly. When the check

valve is closed, the fi nal ramp brings the

pump to a fast stop to prevent pump

cavitation.

End of Curve*

This feature detects pipe breakage and

high leakages to protect the pump from

cavitation damages and reduce water

losses. End-of-Curve triggers an alarm,

shuts off the pump and performs other

programmed actions whenever the

pump is found running at full speed

without creating the desired pressure.

* Will be released in 2015

SLEEP MODE

END OF CURVE

CHECK VALVE RAMP

6

�

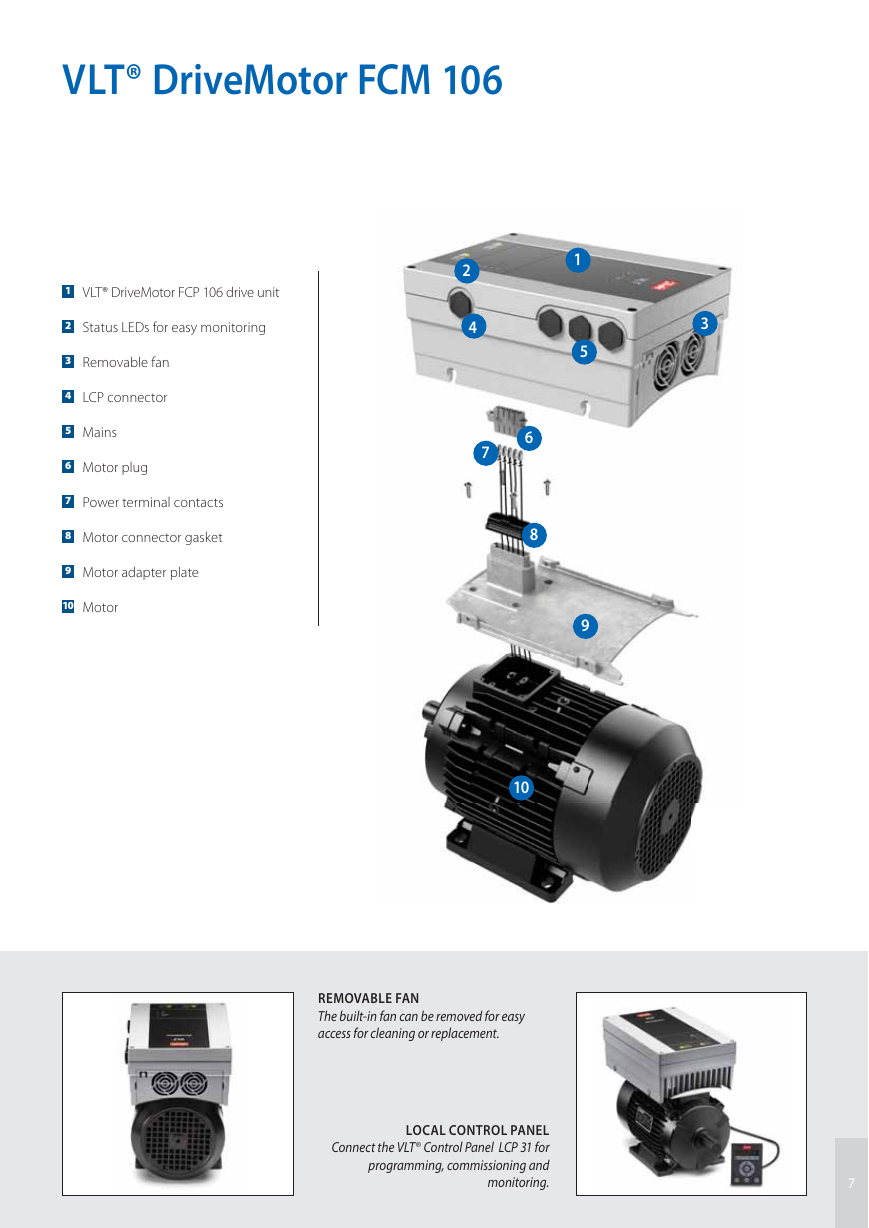

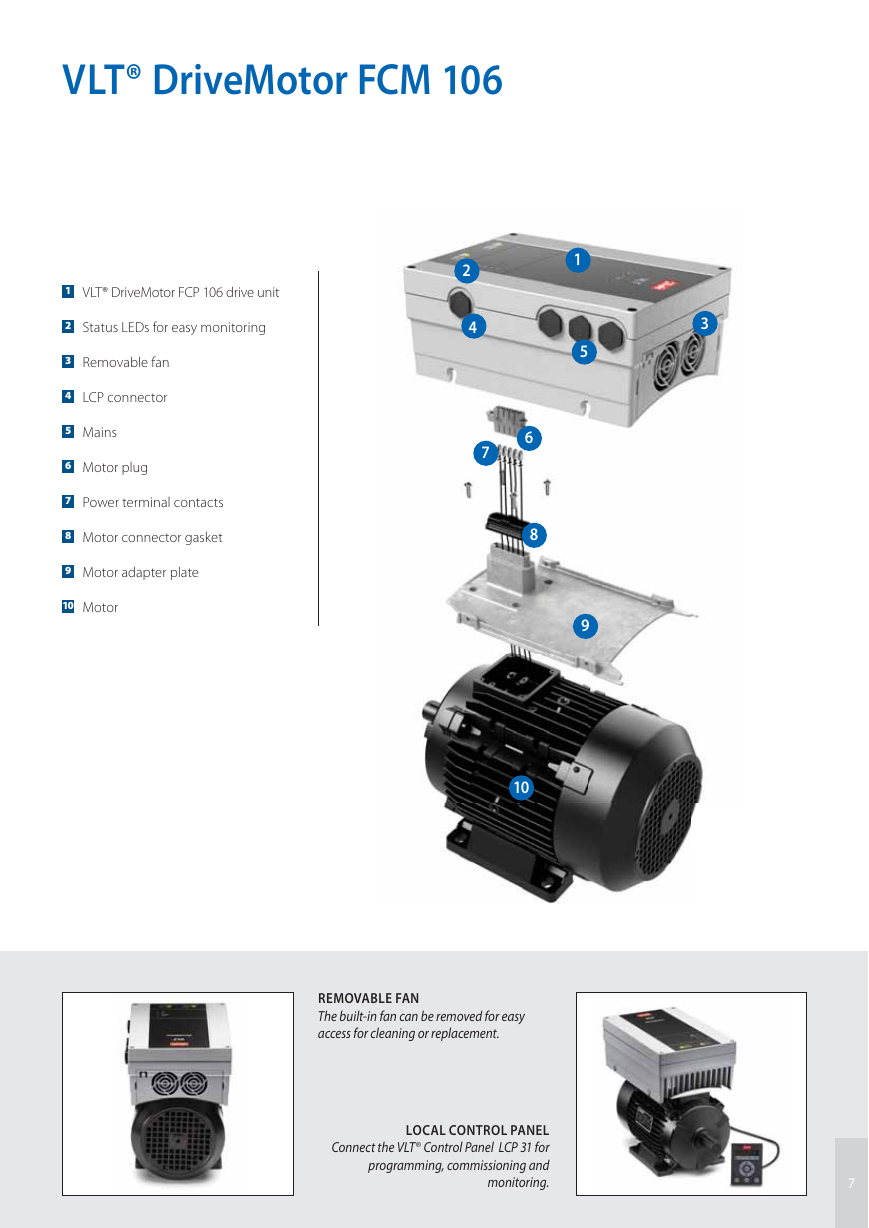

VLT® DriveMotor FCM 106

1 VLT® DriveMotor FCP 106 drive unit

2 Status LEDs for easy monitoring

3 Removable fan

4 LCP connector

5 Mains

6 Motor plug

7 Power terminal contacts

8 Motor connector gasket

9 Motor adapter plate

10 Motor

3

1

5

9

2

4

7

6

8

10

REMOVABLE FAN

The built-in fan can be removed for easy

access for cleaning or replacement.

LOCAL CONTROL PANEL

Connect the VLT® Control Panel LCP 31 for

programming, commissioning and

monitoring.

7

�

CONNECTION EXAMPLES

The numbers represent the terminals on the drive

3 Phase

power

input

+10V DC

0/-10V DC -

0/4-20 mA

0/-10V DC -

0/4-20 mA

L1

L2

L3

PE

50 (+10 V OUT)

53 (A IN)

54 (A IN)

55 (COM A IN/OUT)

42 0/4mA A OUT / DIG OUT

45 0/4mA A OUT / DIG OUT

12 (+24V OUT)

18 (DIGI IN)

19 (DIGI IN)

20 (COM D IN)

27 (DIGI IN)

29

(DIGI IN)

Group 5-*

24V (NPN)

0V (PNP)

24V (NPN)

0V (PNP)

24V (NPN)

0V (PNP)

24V (NPN)

0V (PNP)

PE

Placed in

motor plug

U

V

W

T1

T2

UDC-

UDC+

Relay 2

06

05

04

Relay 1

03

02

01

Bus ter.

1 O

N

2

ON=Terminated

OFF=Open

Bus ter.

RS-485

Interface

(N PS-485) 69

(P RS-485) 68

(COM RS-485) 61

.

0

1

0

1

4

A

N

5

9

1

Motor

Termistor

240V AC 3A

240V AC 3A

RS-485

(PNP) = Source

(NPN) = Sink

The diagram shows the terminals of the

VLT® DriveMotor FCM 106 and VLT®

DriveMotor FCP 106.

Users can set the mode of the analogue

inputs 53 and 54. The FCM/FCP 106 has

a RS485 interface as standard.

The RS485 terminations are integrated

in the drive (S801). The drive can be

equipped with a PROFIBUS** option if

necessary. To switch from NPN to PNP

logic for the digital signals, use param-

eter Group 5-*.

** Release 2015

8

�

2023年江西萍乡中考道德与法治真题及答案.doc

2023年江西萍乡中考道德与法治真题及答案.doc 2012年重庆南川中考生物真题及答案.doc

2012年重庆南川中考生物真题及答案.doc 2013年江西师范大学地理学综合及文艺理论基础考研真题.doc

2013年江西师范大学地理学综合及文艺理论基础考研真题.doc 2020年四川甘孜小升初语文真题及答案I卷.doc

2020年四川甘孜小升初语文真题及答案I卷.doc 2020年注册岩土工程师专业基础考试真题及答案.doc

2020年注册岩土工程师专业基础考试真题及答案.doc 2023-2024学年福建省厦门市九年级上学期数学月考试题及答案.doc

2023-2024学年福建省厦门市九年级上学期数学月考试题及答案.doc 2021-2022学年辽宁省沈阳市大东区九年级上学期语文期末试题及答案.doc

2021-2022学年辽宁省沈阳市大东区九年级上学期语文期末试题及答案.doc 2022-2023学年北京东城区初三第一学期物理期末试卷及答案.doc

2022-2023学年北京东城区初三第一学期物理期末试卷及答案.doc 2018上半年江西教师资格初中地理学科知识与教学能力真题及答案.doc

2018上半年江西教师资格初中地理学科知识与教学能力真题及答案.doc 2012年河北国家公务员申论考试真题及答案-省级.doc

2012年河北国家公务员申论考试真题及答案-省级.doc 2020-2021学年江苏省扬州市江都区邵樊片九年级上学期数学第一次质量检测试题及答案.doc

2020-2021学年江苏省扬州市江都区邵樊片九年级上学期数学第一次质量检测试题及答案.doc 2022下半年黑龙江教师资格证中学综合素质真题及答案.doc

2022下半年黑龙江教师资格证中学综合素质真题及答案.doc