Evaluation Board for

2-Channel Software Selectable ADC

EVAL-AD7321/AD7322

FEATURES

Full featured evaluation board for the AD7321 and

AD7322 devices

Evaluation control board (EVAL-CONTROL BRD2) compatible

Standalone capability

On-board analog buffering and voltage reference

Various linking options

PC software for control and data analysis when used with

EVAL-CONTROL BRD2

GENERAL DESCRIPTION

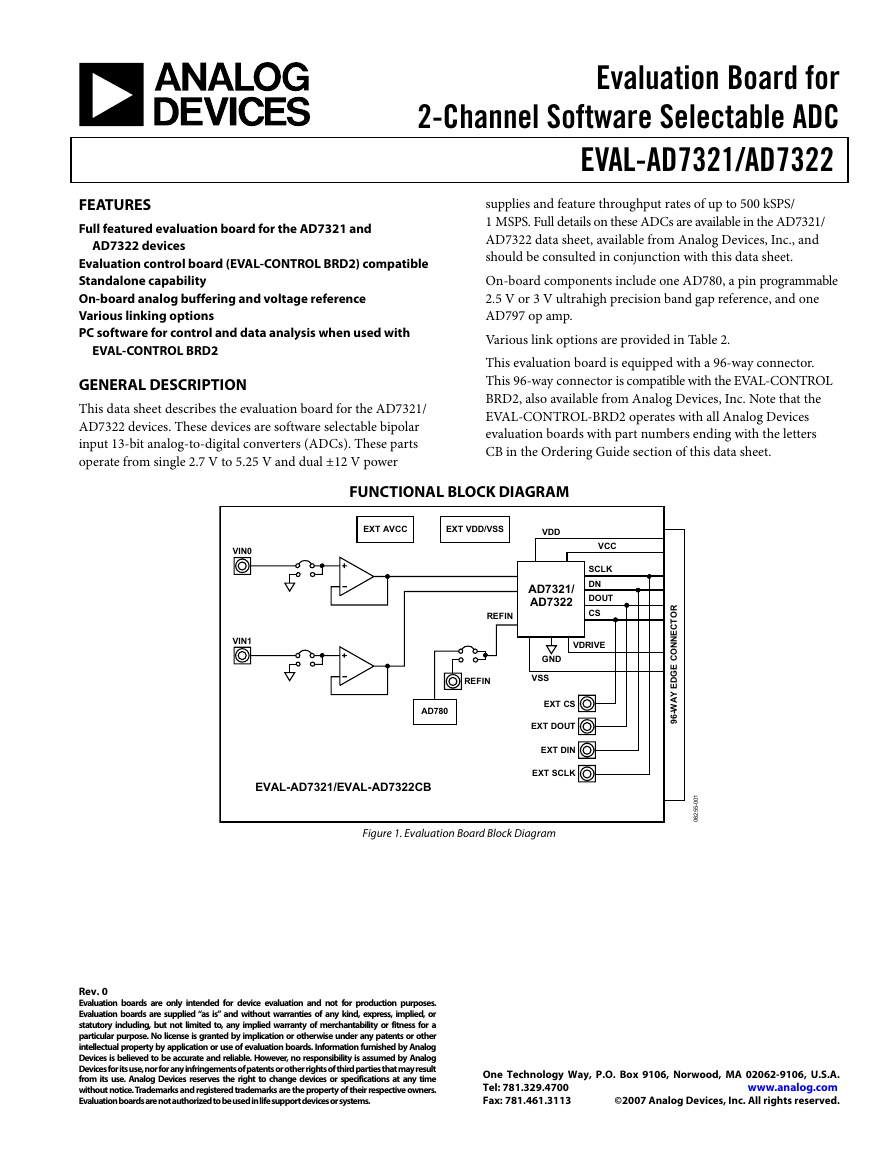

This data sheet describes the evaluation board for the AD7321/

AD7322 devices. These devices are software selectable bipolar

input 13-bit analog-to-digital converters (ADCs). These parts

operate from single 2.7 V to 5.25 V and dual ±12 V power

supplies and feature throughput rates of up to 500 kSPS/

1 MSPS. Full details on these ADCs are available in the AD7321/

AD7322 data sheet, available from Analog Devices, Inc., and

should be consulted in conjunction with this data sheet.

On-board components include one AD780, a pin programmable

2.5 V or 3 V ultrahigh precision band gap reference, and one

AD797 op amp.

Various link options are provided in Table 2.

This evaluation board is equipped with a 96-way connector.

This 96-way connector is compatible with the EVAL-CONTROL

BRD2, also available from Analog Devices, Inc. Note that the

EVAL-CONTROL-BRD2 operates with all Analog Devices

evaluation boards with part numbers ending with the letters

CB in the Ordering Guide section of this data sheet.

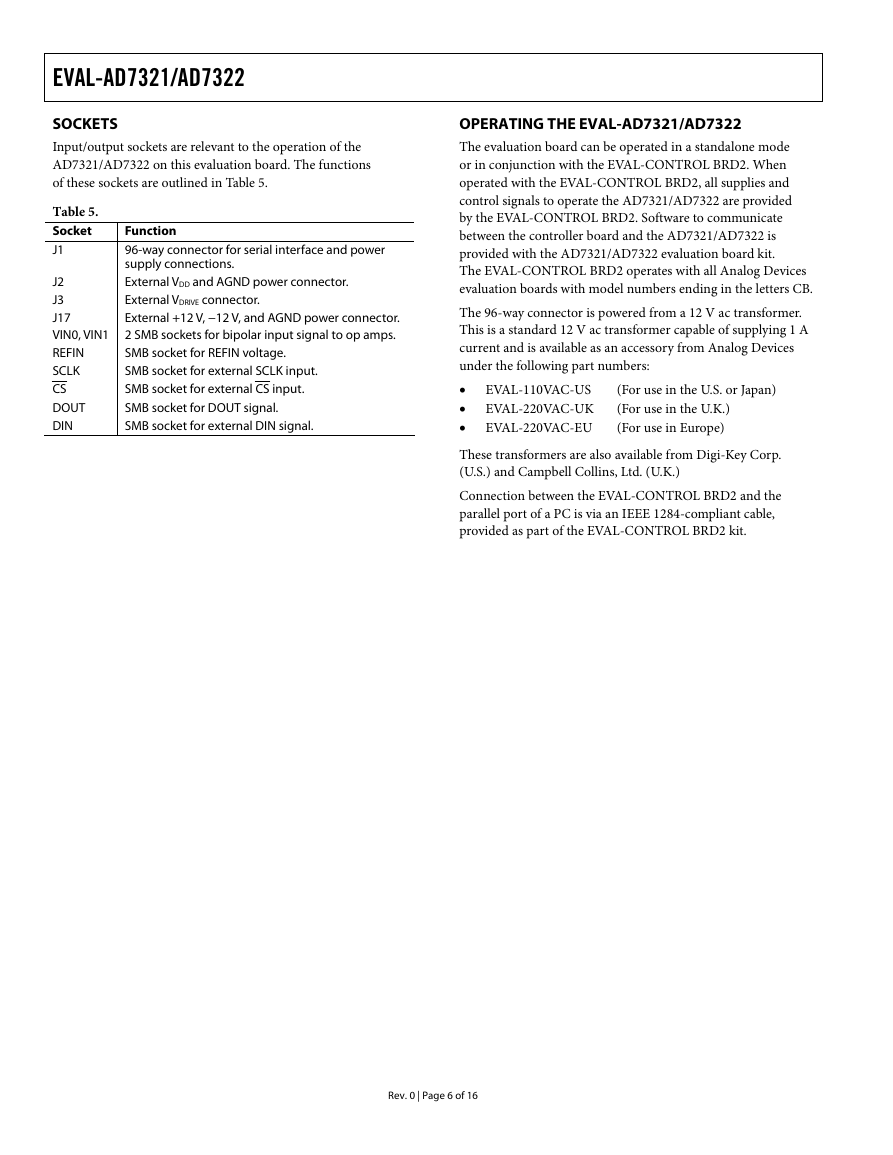

VIN0

VIN1

FUNCTIONAL BLOCK DIAGRAM

EXT AVCC

EXT VDD/VSS

VDD

VCC

SCLK

DN

DOUT

CS

AD7321/

AD7322

REFIN

REFIN

AD780

EVAL-AD7321/EVAL-AD7322CB

VDRIVE

GND

VSS

EXT CS

EXT DOUT

EXT DIN

EXT SCLK

R

O

T

C

E

N

N

O

C

E

G

D

E

Y

A

W

-

6

9

Figure 1. Evaluation Board Block Diagram

1

0

0

-

5

5

2

6

0

Rev. 0

Evaluation boards are only intended for device evaluation and not for production purposes.

Evaluation boards are supplied “as is” and without warranties of any kind, express, implied, or

statutory including, but not limited to, any implied warranty of merchantability or fitness for a

particular purpose. No license is granted by implication or otherwise under any patents or other

intellectual property by application or use of evaluation boards. Information furnished by Analog

Devices is believed to be accurate and reliable. However, no responsibility is assumed by Analog

Devices for its use, nor for any infringements of patents or other rights of third parties that may result

from its use. Analog Devices reserves the right to change devices or specifications at any time

without notice. Trademarks and registered trademarks are the property of their respective owners.

Evaluation boards are not authorized to be used in life support devices or systems.

One Technology Way, P.O. Box 9106, Norwood, MA 02062-9106, U.S.A.

www.analog.com

Tel: 781.329.4700

©2007 Analog Devices, Inc. All rights reserved.

Fax: 781.461.3113

�

EVAL-AD7321/AD7322

TABLE OF CONTENTS

Features .............................................................................................. 1

General Description......................................................................... 1

Functional Block Diagram .............................................................. 1

Revision History ............................................................................... 2

Evaluation Board Hardware............................................................ 3

Power Supplies .............................................................................. 3

Initial Setup Conditions .............................................................. 3

Link Options ................................................................................. 4

Interfacing the Evaluation Boards.............................................. 5

Sockets ........................................................................................... 6

Operating the EVAL-AD7321/AD7322 .................................... 6

Evaluation Board Software.............................................................. 7

Installing the Software ................................................................. 7

REVISION HISTORY

12/07—Revision 0: Initial Version

Checking the EVAL-CONTROL BRD2 .....................................7

The Main Screen............................................................................7

Load Configuration Screen..........................................................8

Running the Software ...................................................................9

Software Configuration Files.................................................... 10

Configuring the Analog Inputs for Single-Ended and

Differential Operation ............................................................... 10

Evaluation Board Schematics and Artwork................................ 11

Bill of Materials........................................................................... 13

Ordering Information.................................................................... 14

Ordering Guide .......................................................................... 14

ESD Caution................................................................................ 14

Rev. 0 | Page 2 of 16

�

EVAL-AD7321/AD7322

reference are also decoupled with 10 μF tantalum and 0.1 μF

ceramic capacitors as are the VDD, VSS, and VCC pins of the

AD7321/AD7322.

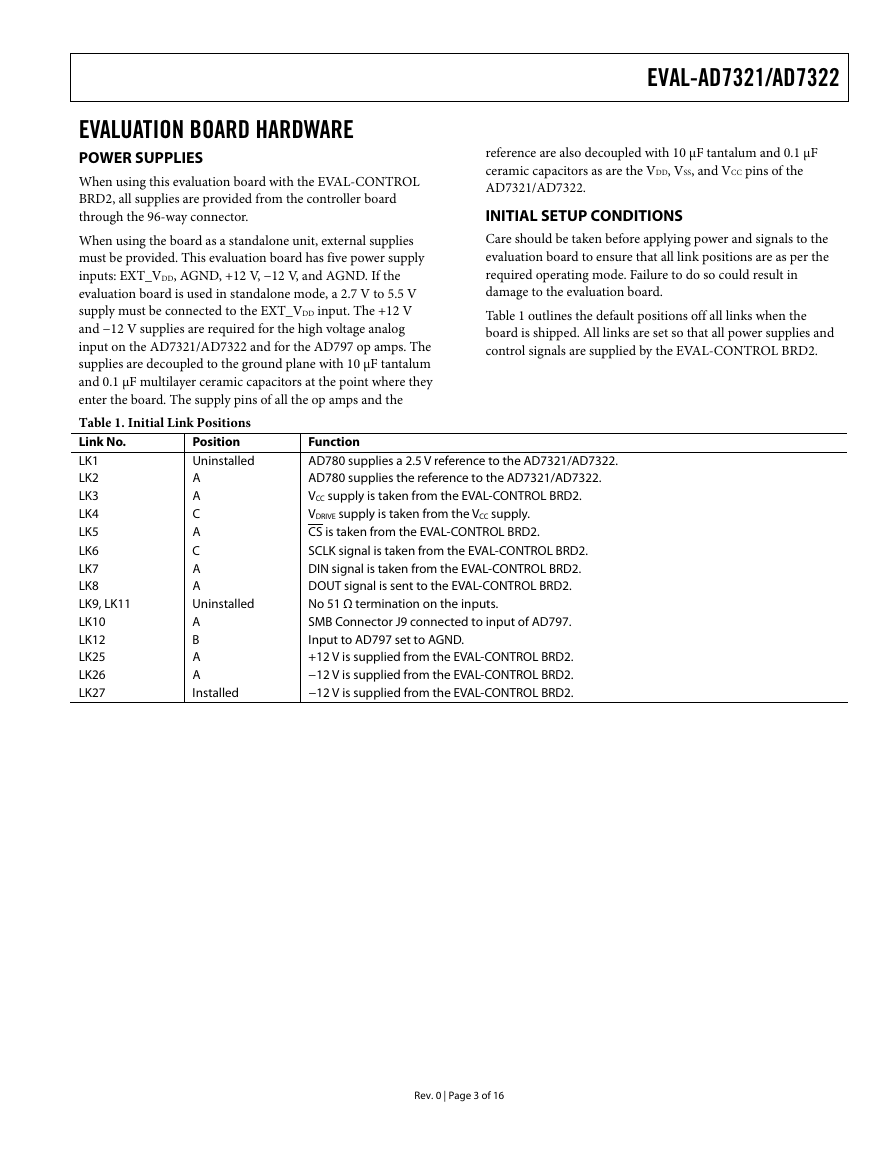

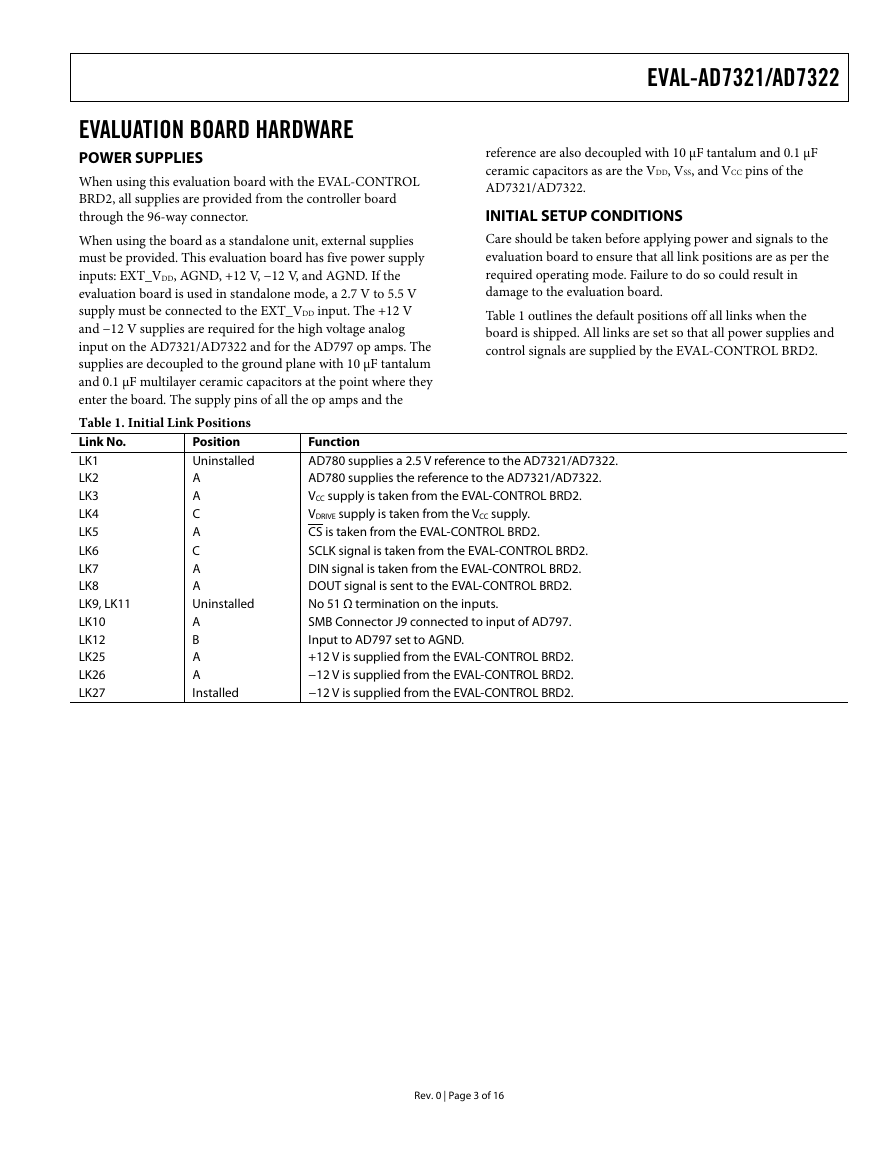

INITIAL SETUP CONDITIONS

Care should be taken before applying power and signals to the

evaluation board to ensure that all link positions are as per the

required operating mode. Failure to do so could result in

damage to the evaluation board.

Table 1 outlines the default positions off all links when the

board is shipped. All links are set so that all power supplies and

control signals are supplied by the EVAL-CONTROL BRD2.

EVALUATION BOARD HARDWARE

POWER SUPPLIES

When using this evaluation board with the EVAL-CONTROL

BRD2, all supplies are provided from the controller board

through the 96-way connector.

When using the board as a standalone unit, external supplies

must be provided. This evaluation board has five power supply

inputs: EXT_VDD, AGND, +12 V, −12 V, and AGND. If the

evaluation board is used in standalone mode, a 2.7 V to 5.5 V

supply must be connected to the EXT_VDD input. The +12 V

and −12 V supplies are required for the high voltage analog

input on the AD7321/AD7322 and for the AD797 op amps. The

supplies are decoupled to the ground plane with 10 μF tantalum

and 0.1 μF multilayer ceramic capacitors at the point where they

enter the board. The supply pins of all the op amps and the

Table 1. Initial Link Positions

Position

Link No.

Uninstalled

LK1

LK2

A

A

LK3

C

LK4

A

LK5

LK6

C

A

LK7

A

LK8

Uninstalled

LK9, LK11

LK10

A

B

LK12

A

LK25

A

LK26

LK27

Installed

Function

AD780 supplies a 2.5 V reference to the AD7321/AD7322.

AD780 supplies the reference to the AD7321/AD7322.

VCC supply is taken from the EVAL-CONTROL BRD2.

VDRIVE supply is taken from the VCC supply.

CS is taken from the EVAL-CONTROL BRD2.

SCLK signal is taken from the EVAL-CONTROL BRD2.

DIN signal is taken from the EVAL-CONTROL BRD2.

DOUT signal is sent to the EVAL-CONTROL BRD2.

No 51 Ω termination on the inputs.

SMB Connector J9 connected to input of AD797.

Input to AD797 set to AGND.

+12 V is supplied from the EVAL-CONTROL BRD2.

−12 V is supplied from the EVAL-CONTROL BRD2.

−12 V is supplied from the EVAL-CONTROL BRD2.

Rev. 0 | Page 3 of 16

�

EVAL-AD7321/AD7322

LINK OPTIONS

Link options which must be set for the required operating setup before using the evaluation board. The functions of these options are

outlined in Table 2.

Table 2.

Link No.

LK1

LK2

LK3

LK4

LK5

LK6

LK7

LK8

LK9, LK11

LK10, LK12

LK25

LK26

LK27

Function

Controls the program pin of the AD780 voltage reference.

Selects the source of the REFIN voltage to be applied to the REFIN pin of the AD7321/AD7322.

In Position A, the AD780 supplies the 2.5 V reference to the AD7321/AD7322.

In Position B, the REFIN is supplied through the J4 SMB connector.

Selects the source of the VCC supply for the AD7321/AD7322.

In Position A, the VCC supply is taken from the 96-way connector to the EVAL-CONTROL BRD2.

In Position B, the VCC supply is taken from the external J2 connector.

Selects the source of the VDRIVE voltage for the AD7321/AD7322.

In Position A, the VDRIVE voltage is taken from the external J3 V drive socket.

In Position B, the VDRIVE voltage is taken from the 96-way connector to the EVAL-CONTROL BRD2.

In Position C, the VDRIVE voltage is tied to the VCC voltage.

Selects the source of the CS signal.

In Position A, CS is taken from the 96-way connector to the EVAL-CONTROL BRD2.

In Position B, the CS signal is taken from the J5 CS SMB socket.

Selects the source of the SCLK signal for the AD7321/AD7322.

In Position A, the SCLK signal comes from J6 SMB socket.

In Position B, the SCLK signal comes from 7S04 inverter, which is an inverted SCLK signal from the 96-way connector.

In Position C, the SCLK signal is taken directly from EVAL-CONTROL-BRD2 through the 96-way connector.

Selects the source of the DIN signal to the AD7321/AD7322.

In Position A, DIN is taken from the 96-way connector to the EVAL-CONTROL BRD2.

In Position B, the DIN signal is taken from the J7 DIN SMB socket.

Selects the destination of the DOUT signal from the AD7321/AD7322.

In Position A, DOUT goes to the 96-way connector to the EVAL-CONTROL BRD2.

In Position B, the DOUT signal goes to the DOUT J8 SMB socket.

Adds a 51 Ω termination resistor to AGND at the VIN0 to VIN1 input sockets.

Selects the input to the AD797 op amps.

In Position A, the AD797 noninverting input it tied to the SMB socket.

In Position B, the AD797 noninverting input it tied to AGND.

Selects the source of the +12 V supply for the EVAL-AD7321/AD7322.

In Position A, the +12 V supply is sourced from the EVAL-CONTROL BRD2 via the 96-way connector.

In Position B, the +12 V supply is sourced externally via the J17 connector.

Selects the source of the −12 V supply for the EVAL-AD7321/AD7322.

In Position A, the −12 V supply is sourced from the EVAL-CONTROL BRD2 via the 96-way connector.

In Position B, the −12 V supply is sourced externally via the J17 connector.

Select the configuration of the noninverting input to U5. The configuration of this link depends on whether the board is

being used in single-ended or differential mode.

For single-ended mode, this link should be installed.

For true differential mode, this link should be uninstalled.

Rev. 0 | Page 4 of 16

�

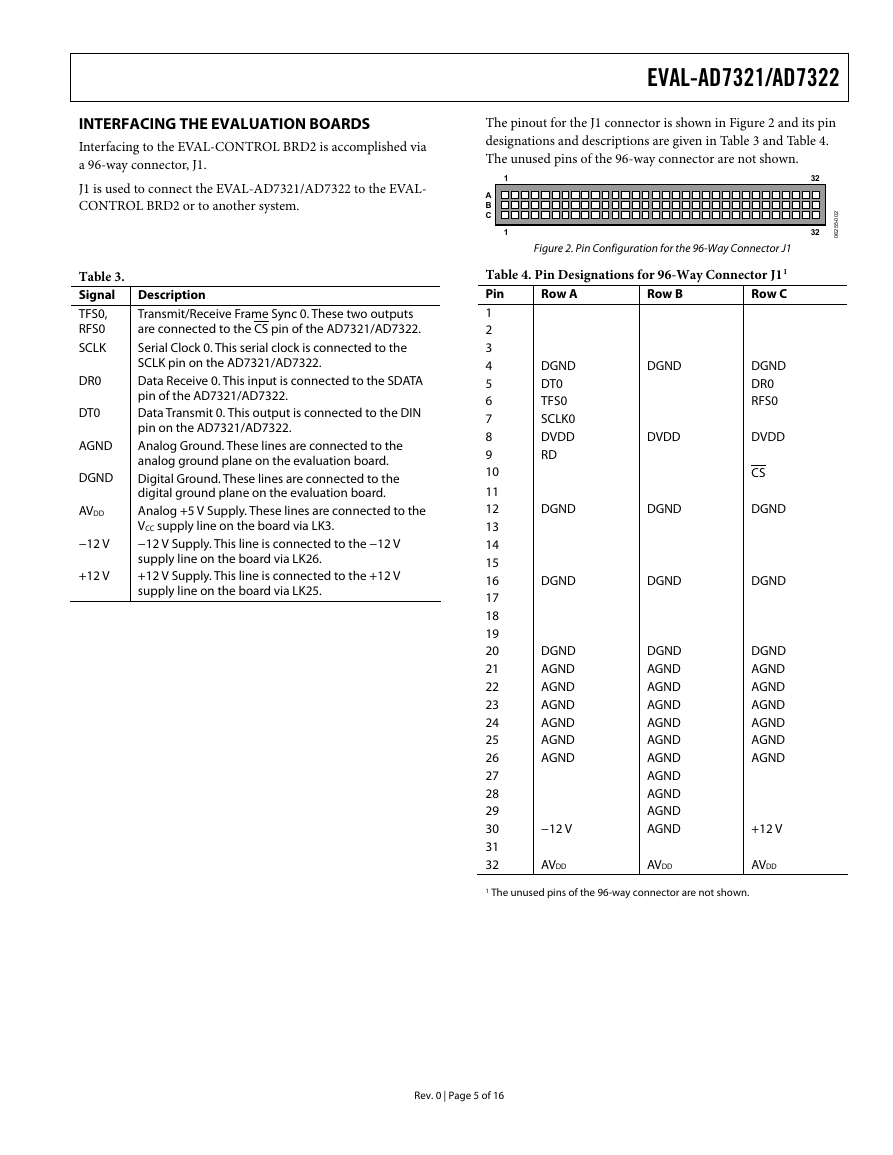

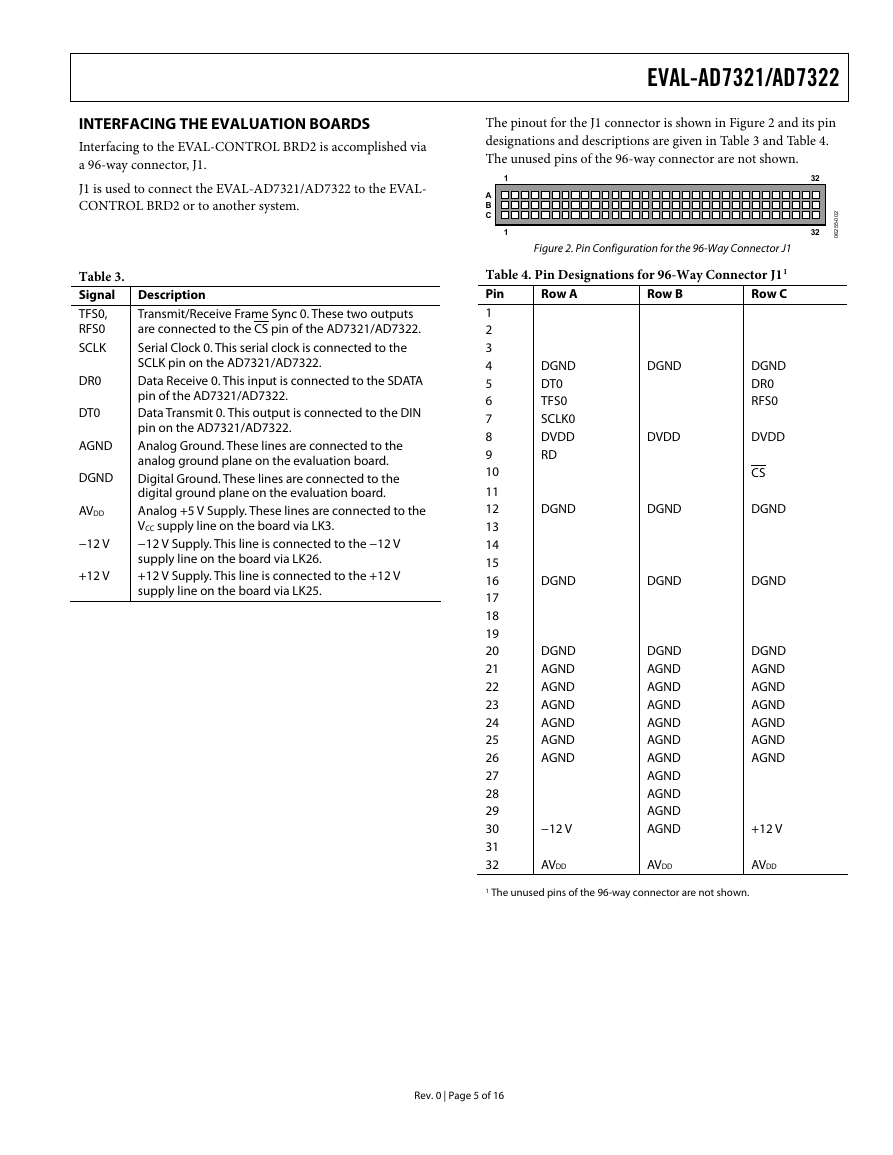

INTERFACING THE EVALUATION BOARDS

Interfacing to the EVAL-CONTROL BRD2 is accomplished via

a 96-way connector, J1.

J1 is used to connect the EVAL-AD7321/AD7322 to the EVAL-

CONTROL BRD2 or to another system.

Table 3.

Signal

TFS0,

RFS0

SCLK

DR0

DT0

AGND

DGND

AVDD

−12 V

+12 V

Description

Transmit/Receive Frame Sync 0. These two outputs

are connected to the CS pin of the AD7321/AD7322.

Serial Clock 0. This serial clock is connected to the

SCLK pin on the AD7321/AD7322.

Data Receive 0. This input is connected to the SDATA

pin of the AD7321/AD7322.

Data Transmit 0. This output is connected to the DIN

pin on the AD7321/AD7322.

Analog Ground. These lines are connected to the

analog ground plane on the evaluation board.

Digital Ground. These lines are connected to the

digital ground plane on the evaluation board.

Analog +5 V Supply. These lines are connected to the

VCC supply line on the board via LK3.

−12 V Supply. This line is connected to the −12 V

supply line on the board via LK26.

+12 V Supply. This line is connected to the +12 V

supply line on the board via LK25.

EVAL-AD7321/AD7322

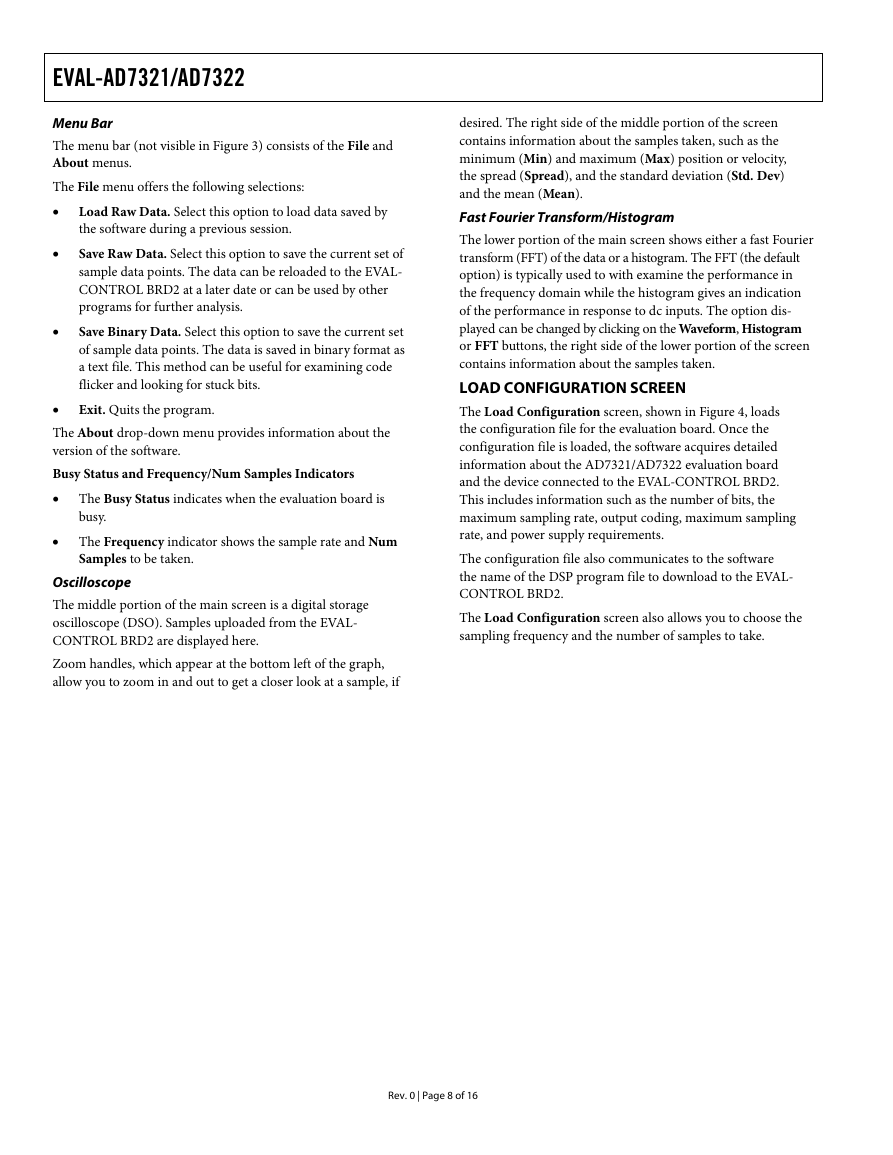

The pinout for the J1 connector is shown in Figure 2 and its pin

designations and descriptions are given in Table 3 and Table 4.

The unused pins of the 96-way connector are not shown.

A

B

C

1

1

Figure 2. Pin Configuration for the 96-Way Connector J1

32

32

2

0

0

-

5

5

2

6

0

Table 4. Pin Designations for 96-Way Connector J11

Row C

Pin

1

2

3

DGND

4

DR0

5

6

RFS0

7

DVDD

8

9

10

CS

11

DGND

12

13

14

15

DGND

16

17

18

19

DGND

20

AGND

21

AGND

22

23

AGND

AGND

24

AGND

25

AGND

26

27

28

29

+12 V

30

31

32

AVDD

1 The unused pins of the 96-way connector are not shown.

Row A

DGND

DT0

TFS0

SCLK0

DVDD

RD

DGND

DGND

DGND

AGND

AGND

AGND

AGND

AGND

AGND

−12 V

AVDD

Row B

DGND

DVDD

DGND

DGND

DGND

AGND

AGND

AGND

AGND

AGND

AGND

AGND

AGND

AGND

AGND

AVDD

Rev. 0 | Page 5 of 16

�

EVAL-AD7321/AD7322

SOCKETS

Input/output sockets are relevant to the operation of the

AD7321/AD7322 on this evaluation board. The functions

of these sockets are outlined in Table 5.

Table 5.

Socket

J1

Function

96-way connector for serial interface and power

supply connections.

External VDD and AGND power connector.

J2

External VDRIVE connector.

J3

J17

External +12 V, −12 V, and AGND power connector.

VIN0, VIN1 2 SMB sockets for bipolar input signal to op amps.

REFIN

SCLK

CS

DOUT

DIN

SMB socket for REFIN voltage.

SMB socket for external SCLK input.

SMB socket for external CS input.

SMB socket for DOUT signal.

SMB socket for external DIN signal.

OPERATING THE EVAL-AD7321/AD7322

The evaluation board can be operated in a standalone mode

or in conjunction with the EVAL-CONTROL BRD2. When

operated with the EVAL-CONTROL BRD2, all supplies and

control signals to operate the AD7321/AD7322 are provided

by the EVAL-CONTROL BRD2. Software to communicate

between the controller board and the AD7321/AD7322 is

provided with the AD7321/AD7322 evaluation board kit.

The EVAL-CONTROL BRD2 operates with all Analog Devices

evaluation boards with model numbers ending in the letters CB.

The 96-way connector is powered from a 12 V ac transformer.

This is a standard 12 V ac transformer capable of supplying 1 A

current and is available as an accessory from Analog Devices

under the following part numbers:

•

•

•

(For use in the U.S. or Japan)

(For use in the U.K.)

(For use in Europe)

EVAL-110VAC-US

EVAL-220VAC-UK

EVAL-220VAC-EU

These transformers are also available from Digi-Key Corp.

(U.S.) and Campbell Collins, Ltd. (U.K.)

Connection between the EVAL-CONTROL BRD2 and the

parallel port of a PC is via an IEEE 1284-compliant cable,

provided as part of the EVAL-CONTROL BRD2 kit.

Rev. 0 | Page 6 of 16

�

EVALUATION BOARD SOFTWARE

INSTALLING THE SOFTWARE

Included in the EVAL-AD7321/AD7322CB evaluation kit

is a CD-ROM, which contains software for controlling and

evaluating the performance of the AD7321/AD7322 when it

is operated with the EVAL-CONTROL BRD2.

When the CD is inserted into the PC, an installation program

automatically begins. This program installs the evaluation

software onto the PC as well as electronic versions of the eval-

uation board data sheets, the AD7321/AD7322 data sheet, and

EVAL-CONTROL BRD2 data sheet. All literature on the CD

is in the Adobe Systems, Inc. portable documentation format

(PDF) and requires Acrobat Reader™ to be viewed or printed.

The user interface on the PC is a dedicated program written

especially for the AD7321/AD7322 when operated with the

EVAL-CONTROL BRD2.

CHECKING THE EVAL-CONTROL BRD2

The EVAL-CONTROL BRD2 and evaluation board should

be connected together as described in the Interfacing the

Evaluation Boards section. The power is applied to the

EVAL-CONTROL BRD2 via a 12 V ac transformer.

EVAL-AD7321/AD7322

At this stage, the red LED on the EVAL-CONTROL BRD2

should be flashing. This indicates that the EVAL-CONTROL

BRD2 is functional and ready to receive instructions.

Note that the software should be installed before the printer

port cable is connected between the EVAL-CONTROL BRD2

and the PC. This ensures that the printer port has been

initialized properly.

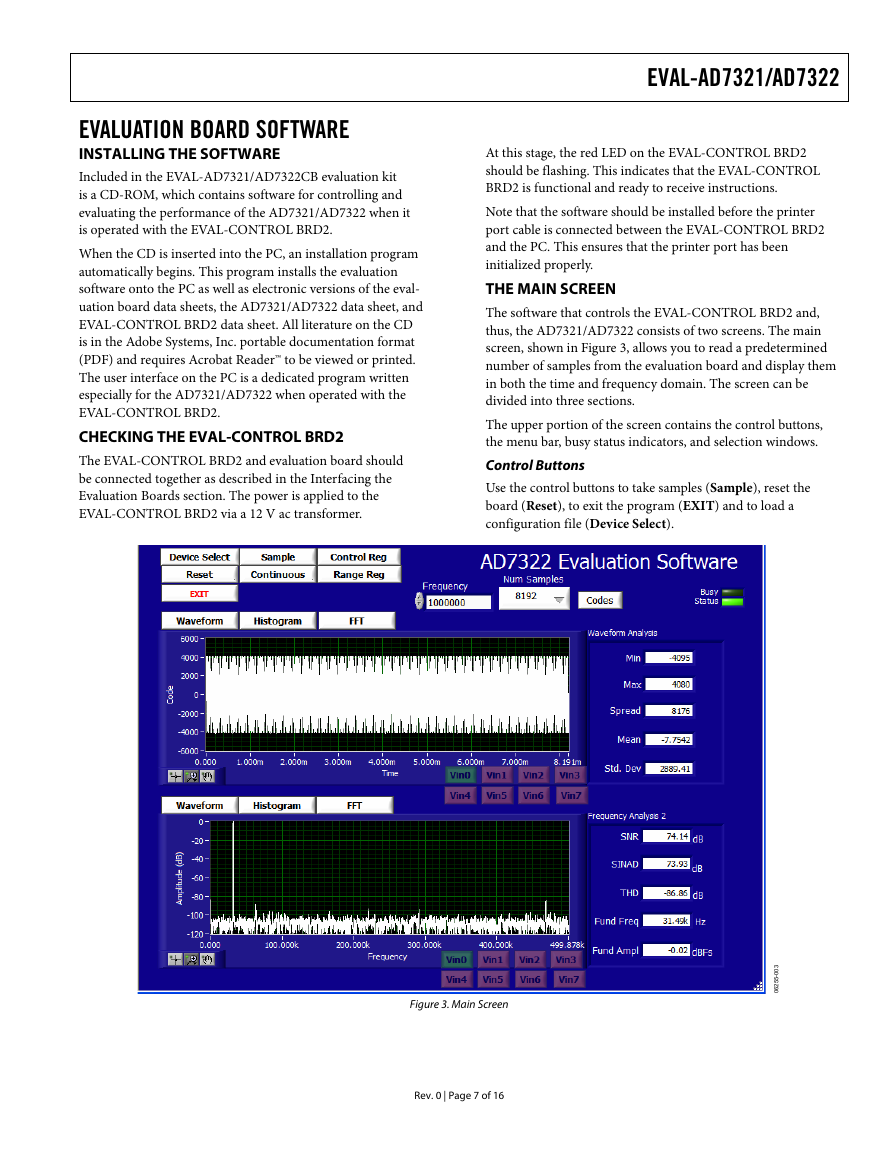

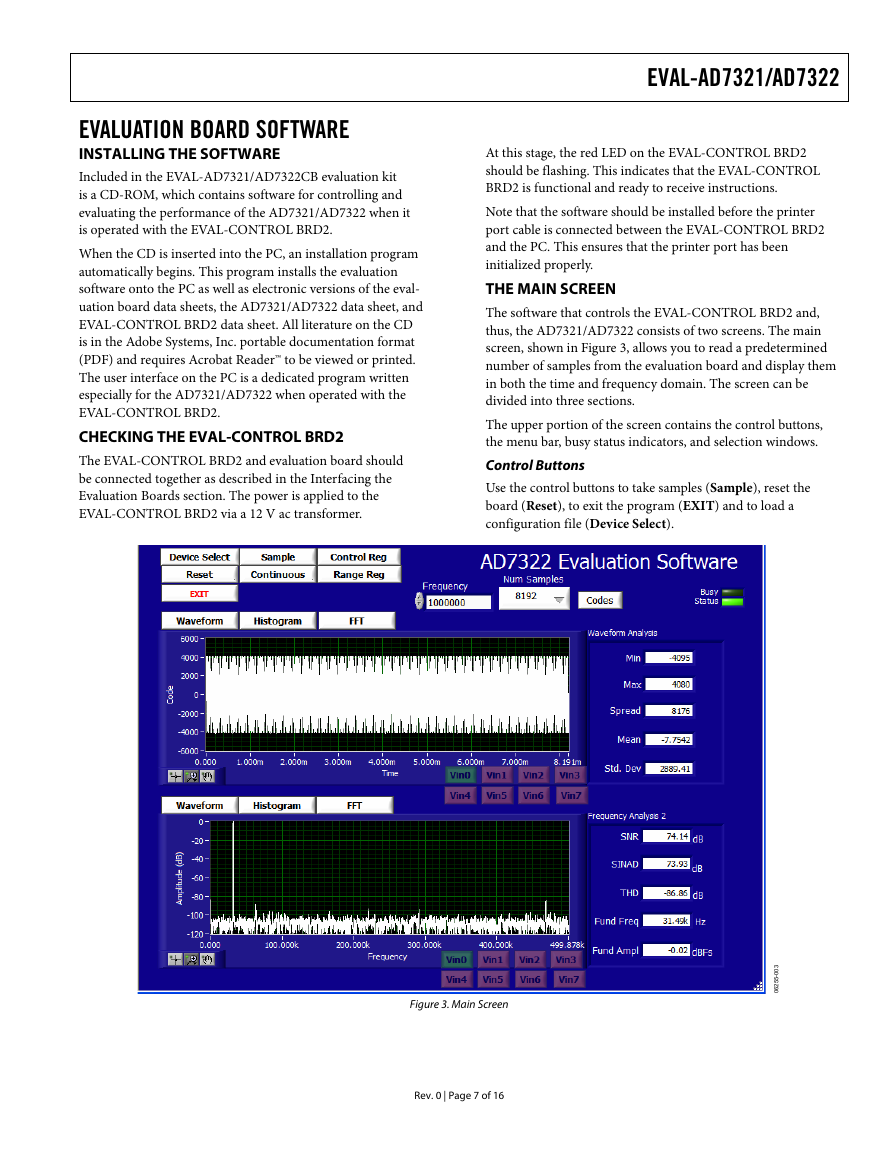

THE MAIN SCREEN

The software that controls the EVAL-CONTROL BRD2 and,

thus, the AD7321/AD7322 consists of two screens. The main

screen, shown in Figure 3, allows you to read a predetermined

number of samples from the evaluation board and display them

in both the time and frequency domain. The screen can be

divided into three sections.

The upper portion of the screen contains the control buttons,

the menu bar, busy status indicators, and selection windows.

Control Buttons

Use the control buttons to take samples (Sample), reset the

board (Reset), to exit the program (EXIT) and to load a

configuration file (Device Select).

3

0

0

-

5

5

2

6

0

Figure 3. Main Screen

Rev. 0 | Page 7 of 16

�

EVAL-AD7321/AD7322

Menu Bar

The menu bar (not visible in Figure 3) consists of the File and

About menus.

The File menu offers the following selections:

•

Load Raw Data. Select this option to load data saved by

the software during a previous session.

Save Raw Data. Select this option to save the current set of

sample data points. The data can be reloaded to the EVAL-

CONTROL BRD2 at a later date or can be used by other

programs for further analysis.

Save Binary Data. Select this option to save the current set

of sample data points. The data is saved in binary format as

a text file. This method can be useful for examining code

flicker and looking for stuck bits.

•

•

• Exit. Quits the program.

The About drop-down menu provides information about the

version of the software.

Busy Status and Frequency/Num Samples Indicators

• The Busy Status indicates when the evaluation board is

busy.

• The Frequency indicator shows the sample rate and Num

Samples to be taken.

Oscilloscope

The middle portion of the main screen is a digital storage

oscilloscope (DSO). Samples uploaded from the EVAL-

CONTROL BRD2 are displayed here.

Zoom handles, which appear at the bottom left of the graph,

allow you to zoom in and out to get a closer look at a sample, if

desired. The right side of the middle portion of the screen

contains information about the samples taken, such as the

minimum (Min) and maximum (Max) position or velocity,

the spread (Spread), and the standard deviation (Std. Dev)

and the mean (Mean).

Fast Fourier Transform/Histogram

The lower portion of the main screen shows either a fast Fourier

transform (FFT) of the data or a histogram. The FFT (the default

option) is typically used to with examine the performance in

the frequency domain while the histogram gives an indication

of the performance in response to dc inputs. The option dis-

played can be changed by clicking on the Waveform, Histogram

or FFT buttons, the right side of the lower portion of the screen

contains information about the samples taken.

LOAD CONFIGURATION SCREEN

The Load Configuration screen, shown in Figure 4, loads

the configuration file for the evaluation board. Once the

configuration file is loaded, the software acquires detailed

information about the AD7321/AD7322 evaluation board

and the device connected to the EVAL-CONTROL BRD2.

This includes information such as the number of bits, the

maximum sampling rate, output coding, maximum sampling

rate, and power supply requirements.

The configuration file also communicates to the software

the name of the DSP program file to download to the EVAL-

CONTROL BRD2.

The Load Configuration screen also allows you to choose the

sampling frequency and the number of samples to take.

Rev. 0 | Page 8 of 16

�

2023年江西萍乡中考道德与法治真题及答案.doc

2023年江西萍乡中考道德与法治真题及答案.doc 2012年重庆南川中考生物真题及答案.doc

2012年重庆南川中考生物真题及答案.doc 2013年江西师范大学地理学综合及文艺理论基础考研真题.doc

2013年江西师范大学地理学综合及文艺理论基础考研真题.doc 2020年四川甘孜小升初语文真题及答案I卷.doc

2020年四川甘孜小升初语文真题及答案I卷.doc 2020年注册岩土工程师专业基础考试真题及答案.doc

2020年注册岩土工程师专业基础考试真题及答案.doc 2023-2024学年福建省厦门市九年级上学期数学月考试题及答案.doc

2023-2024学年福建省厦门市九年级上学期数学月考试题及答案.doc 2021-2022学年辽宁省沈阳市大东区九年级上学期语文期末试题及答案.doc

2021-2022学年辽宁省沈阳市大东区九年级上学期语文期末试题及答案.doc 2022-2023学年北京东城区初三第一学期物理期末试卷及答案.doc

2022-2023学年北京东城区初三第一学期物理期末试卷及答案.doc 2018上半年江西教师资格初中地理学科知识与教学能力真题及答案.doc

2018上半年江西教师资格初中地理学科知识与教学能力真题及答案.doc 2012年河北国家公务员申论考试真题及答案-省级.doc

2012年河北国家公务员申论考试真题及答案-省级.doc 2020-2021学年江苏省扬州市江都区邵樊片九年级上学期数学第一次质量检测试题及答案.doc

2020-2021学年江苏省扬州市江都区邵樊片九年级上学期数学第一次质量检测试题及答案.doc 2022下半年黑龙江教师资格证中学综合素质真题及答案.doc

2022下半年黑龙江教师资格证中学综合素质真题及答案.doc