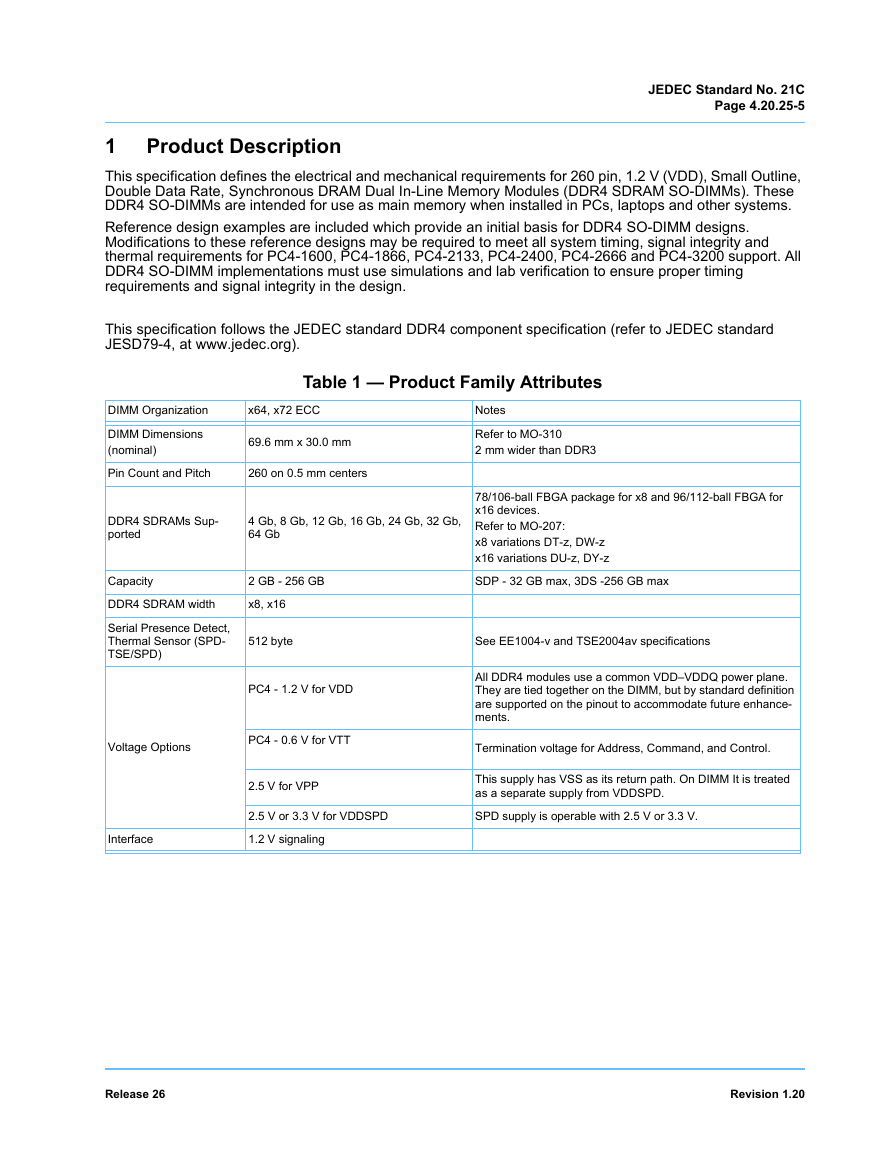

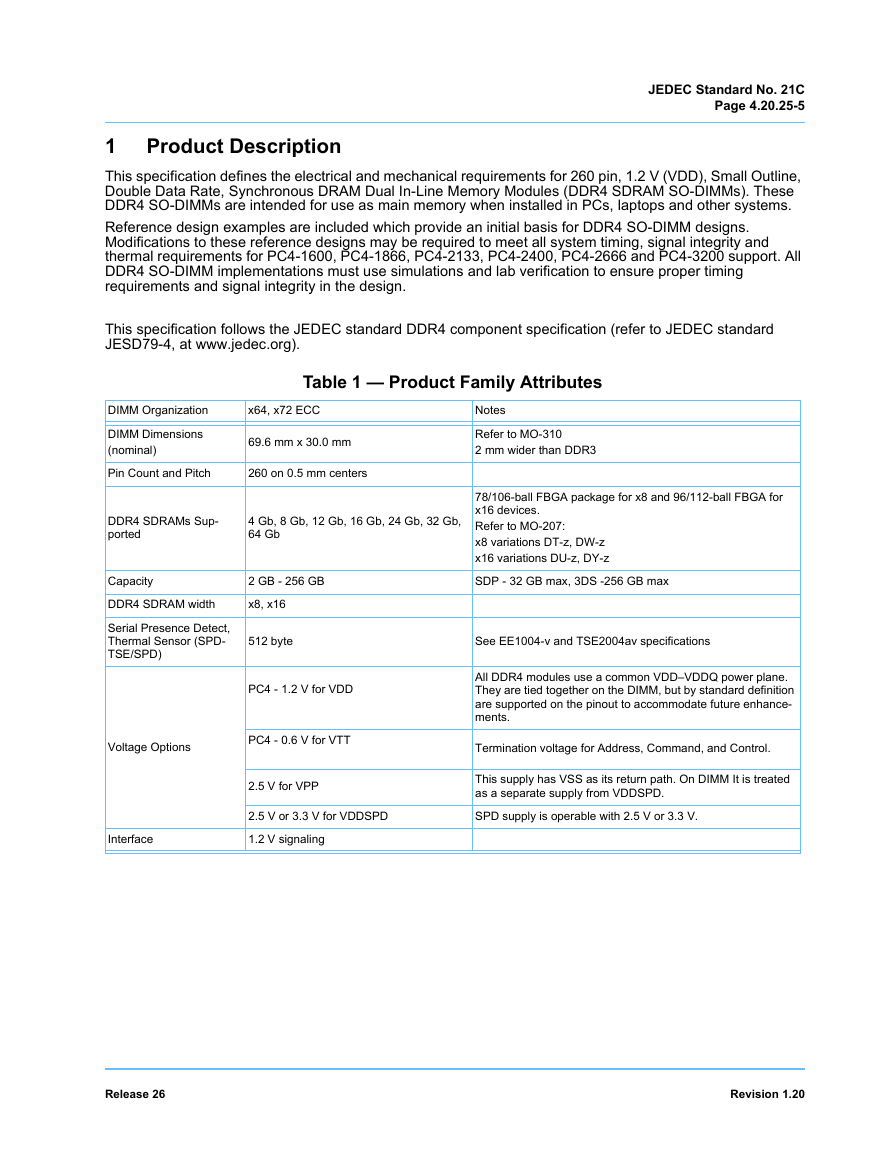

1 Product Description

Table 1 — Product Family Attributes

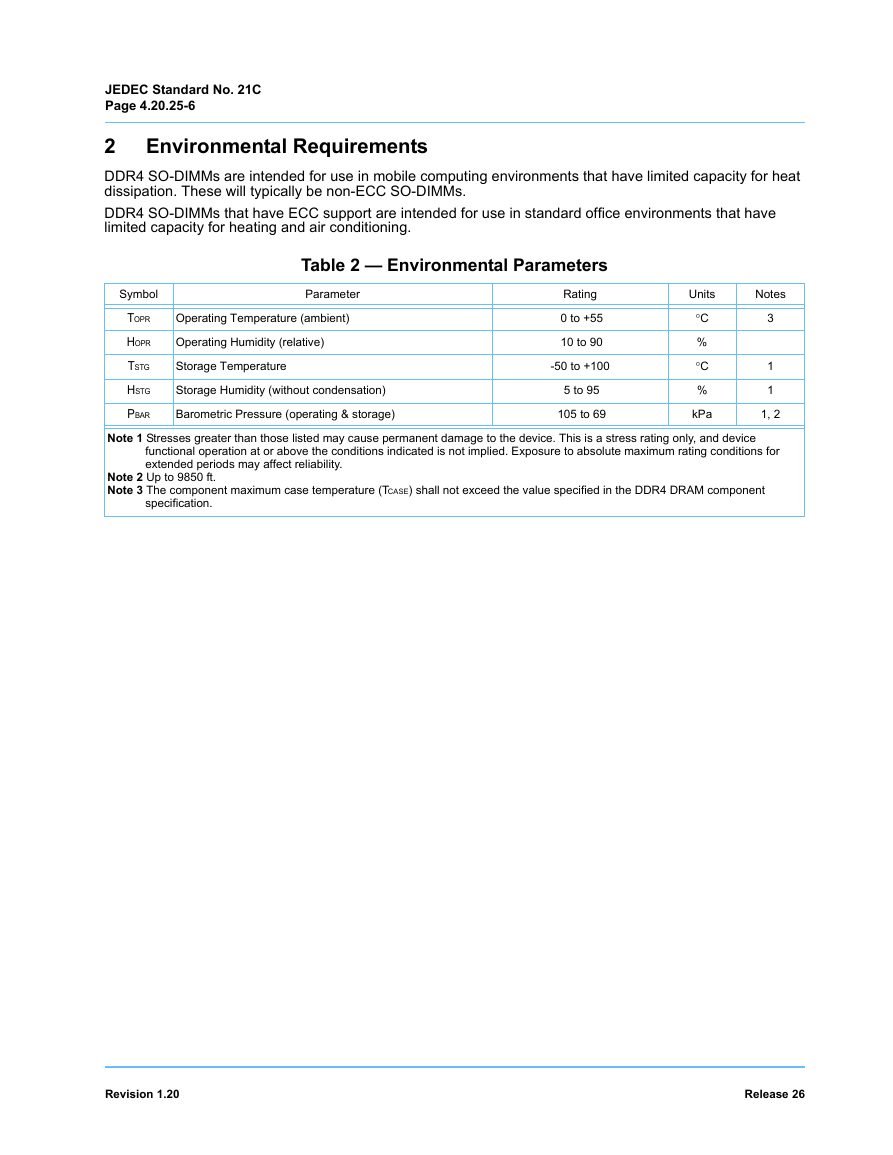

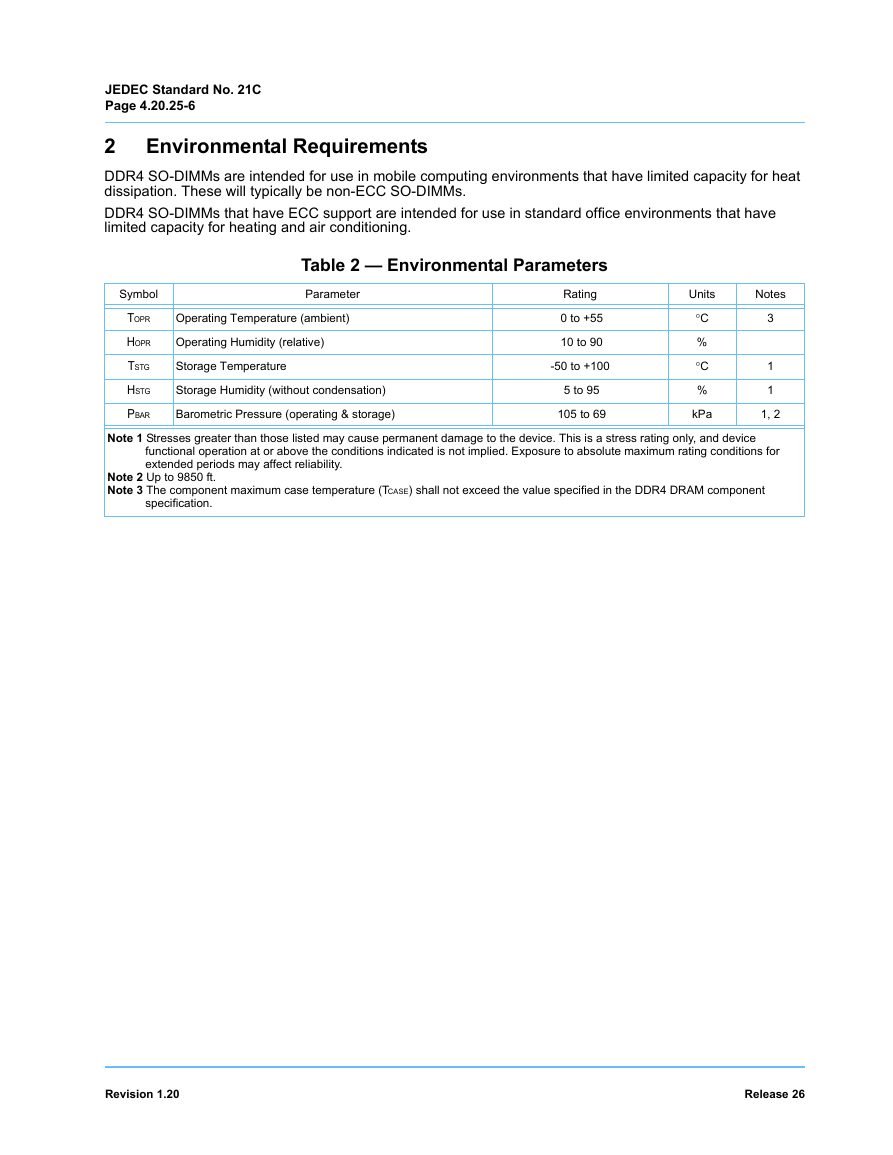

2 Environmental Requirements

Table 2 — Environmental Parameters

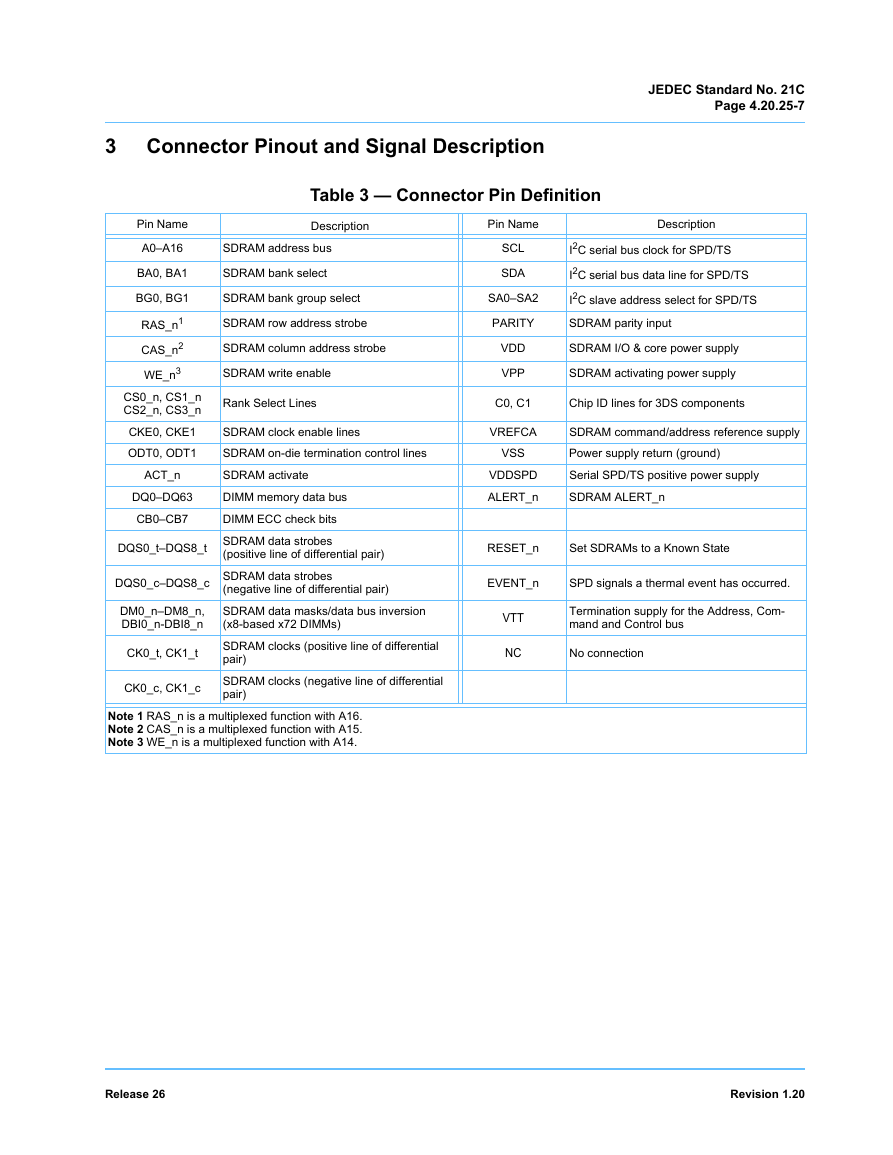

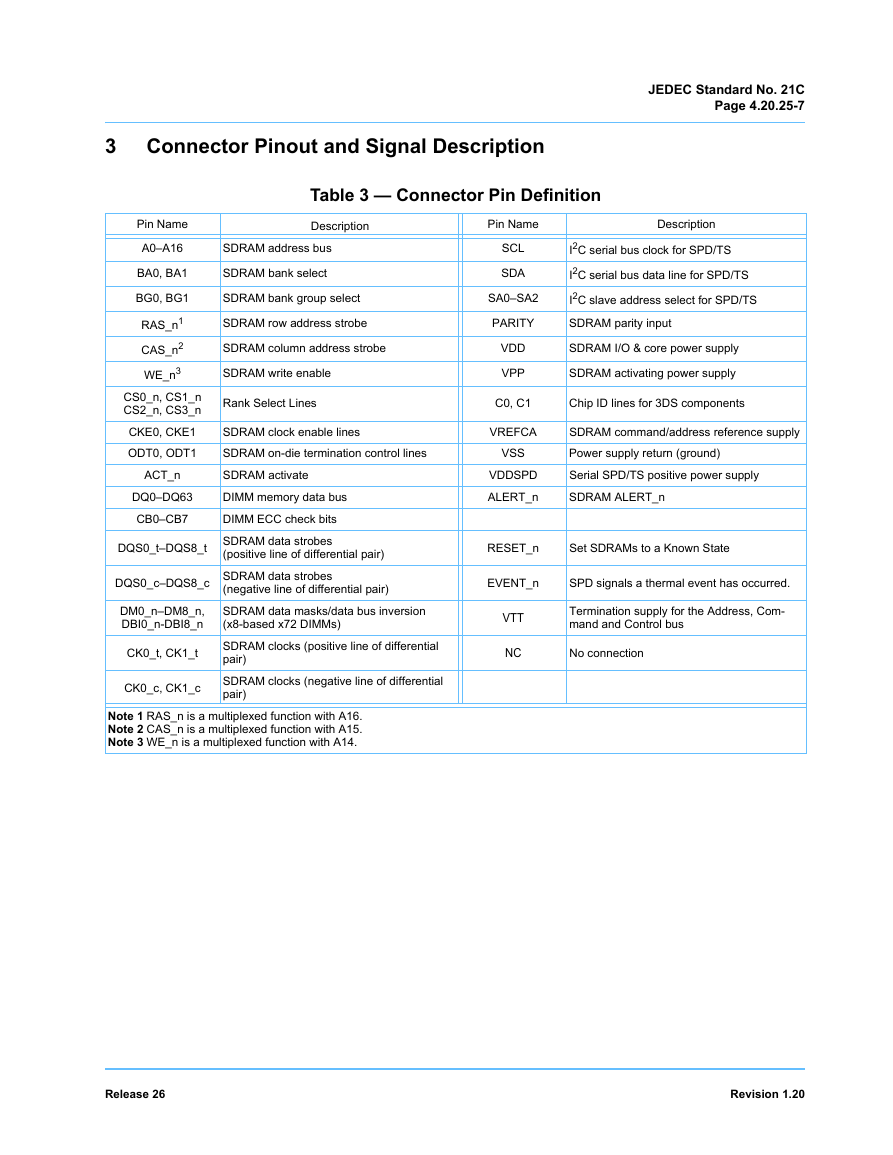

3 Connector Pinout and Signal Description

Table 3 — Connector Pin Definition

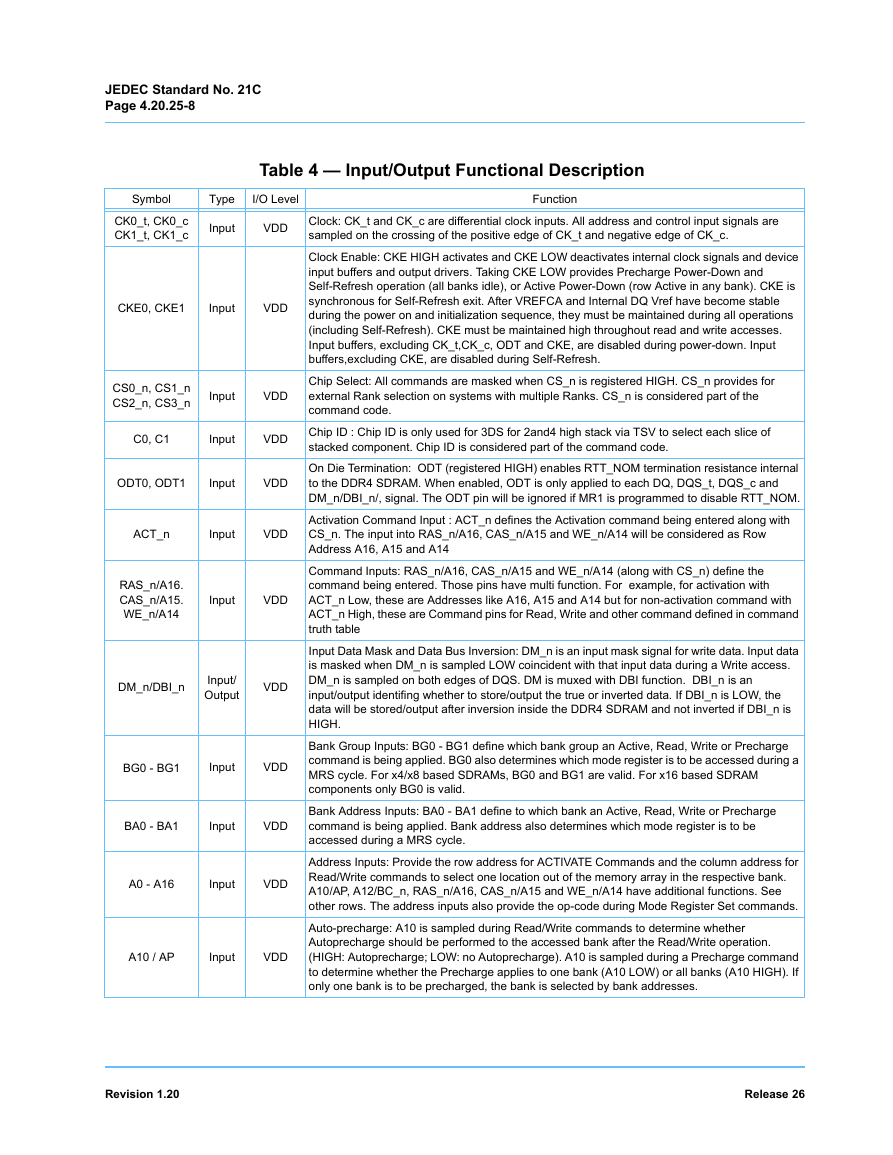

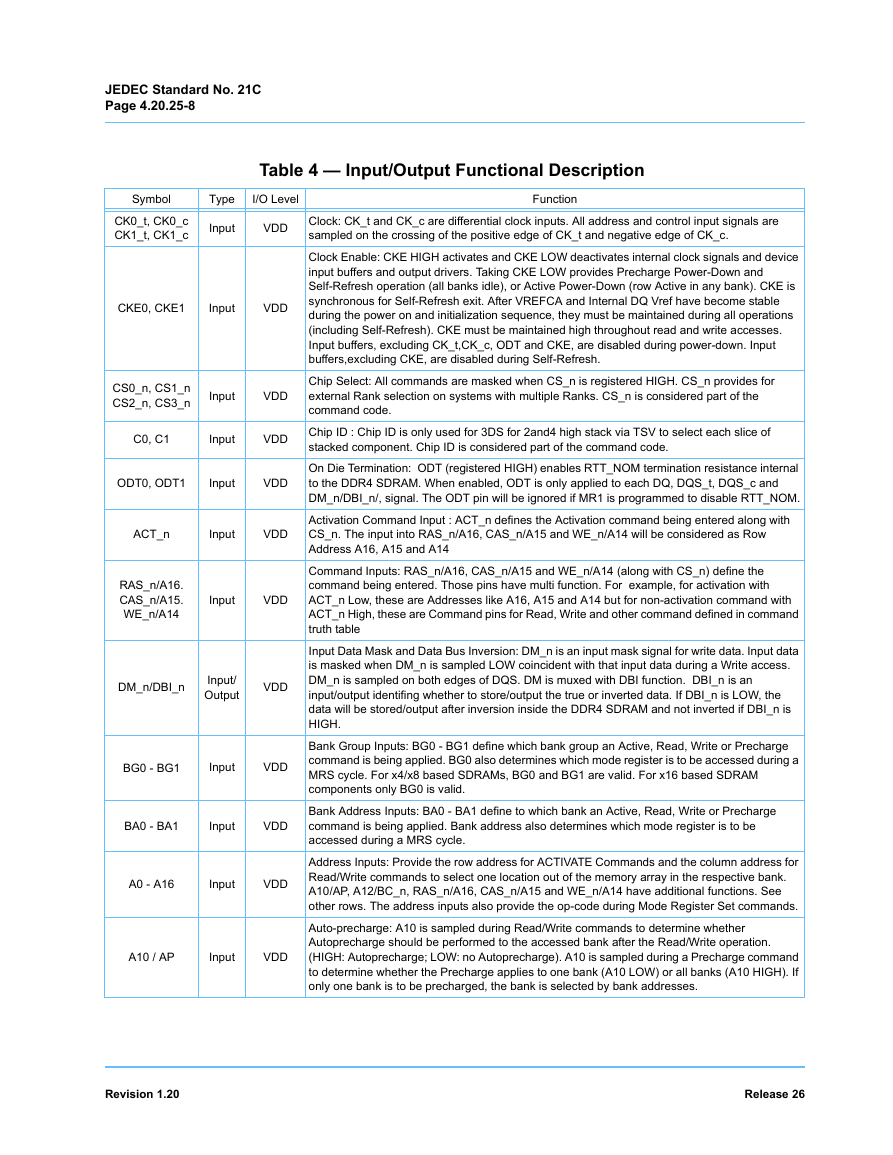

Table 4 — Input/Output Functional Description

3.1 DDR4 SO-DIMM Connector Pin Assignments

Table 5 — DDR4 SO-DIMM 260 Pin Connector Pin Wiring Assignments

4 Power Details

4.1 DIMM Voltage Requirements

Table 6 — DDR4 SO-DIMM DC Operating Voltage1,2,3 - 1.2 V operation

4.2 Rules for Power-Up Sequence

Figure 1 — Graphical View of Recommended Power Sequence

Figure 2 — Graphical View of Recommended Power Down Sequence

4.3 Feed Through Voltage (VFT)

5 Component Details

Figure 3 — DIMM Ball Patterns for DDR4 SDRAM Components

Table 7 — DDR4 x8 SDRAM DIMM Pad Array

Table 8 — DDR4 x16 SDRAM DIMM Pad Array

5.1 Component Types and Placement

5.2 Decoupling Guidelines

Table 9 — DDR4 SO-DIMM Decoupling Capacitor Guidelines

6 DIMM Design Details

6.1 Signal Groups

Figure 4 — Example SO-DIMM Fly-By Topology

6.2 Explanation of Net Structure Diagrams

Figure 5 — Net Structure Example

6.3 General Net Structure Routing Rules

Table 10 — CK, CTRL, and ADD/CMD Group Length Matching Rules

Figure 6 — Example Address routing topology

Table 11 — Data and Strobe Group Length Matching Rules

Figure 7 — ALERT_n Wiring Illustration

Figure 8 — Via Compensation Diagram

Table 12 — Plane Referencing

6.4 Address Mirroring

Table 13 — DIMM Wiring Definition for Address Mirroring

6.5 DIMM Routing Space Constraints

Table 14 — Routing Space Constraints

6.6 DIMM Physical Requirements

6.7 Reference Stackups

Table 15 — Preferred 10 Layer Stackup for SO-DIMMs

Table 16 — Preferred 8 Layer Stackup for SO-DIMMs

Table 17 — Preferred 6 Layer Stackup for SO-DIMMs

6.8 Impedance Targets

Table 18 — Impedance Assignments by Signal Type

6.9 SPD Wiring and Placement

Figure 9 — Block Diagram: SPD-TSE/ SPD

6.10 DQ Mapping to Support CRC

Table 19 — SPD DQ Nibble Map for CRC

Table 20 — Nibble/Byte DQ Map Patterns for CRC

Figure 10 — Example of DQ Wiring with Mapping for CRC

Table 21 — Example of DQ Mapping for CRC

7 Serial Presence Detect Component Specification

7.1 Serial Presence Detect Definition

Table 22 — SPD Address Map

Table 23 — Block 0: Base Configuration and DRAM Parameters

8 Product Label

8.1 DDR4 DIMM Label Format for DRAM-only module types

8.2 DDR4 DIMM Label Format for Hybrid module types

9 JEDEC Process

2023年江西萍乡中考道德与法治真题及答案.doc

2023年江西萍乡中考道德与法治真题及答案.doc 2012年重庆南川中考生物真题及答案.doc

2012年重庆南川中考生物真题及答案.doc 2013年江西师范大学地理学综合及文艺理论基础考研真题.doc

2013年江西师范大学地理学综合及文艺理论基础考研真题.doc 2020年四川甘孜小升初语文真题及答案I卷.doc

2020年四川甘孜小升初语文真题及答案I卷.doc 2020年注册岩土工程师专业基础考试真题及答案.doc

2020年注册岩土工程师专业基础考试真题及答案.doc 2023-2024学年福建省厦门市九年级上学期数学月考试题及答案.doc

2023-2024学年福建省厦门市九年级上学期数学月考试题及答案.doc 2021-2022学年辽宁省沈阳市大东区九年级上学期语文期末试题及答案.doc

2021-2022学年辽宁省沈阳市大东区九年级上学期语文期末试题及答案.doc 2022-2023学年北京东城区初三第一学期物理期末试卷及答案.doc

2022-2023学年北京东城区初三第一学期物理期末试卷及答案.doc 2018上半年江西教师资格初中地理学科知识与教学能力真题及答案.doc

2018上半年江西教师资格初中地理学科知识与教学能力真题及答案.doc 2012年河北国家公务员申论考试真题及答案-省级.doc

2012年河北国家公务员申论考试真题及答案-省级.doc 2020-2021学年江苏省扬州市江都区邵樊片九年级上学期数学第一次质量检测试题及答案.doc

2020-2021学年江苏省扬州市江都区邵樊片九年级上学期数学第一次质量检测试题及答案.doc 2022下半年黑龙江教师资格证中学综合素质真题及答案.doc

2022下半年黑龙江教师资格证中学综合素质真题及答案.doc