1

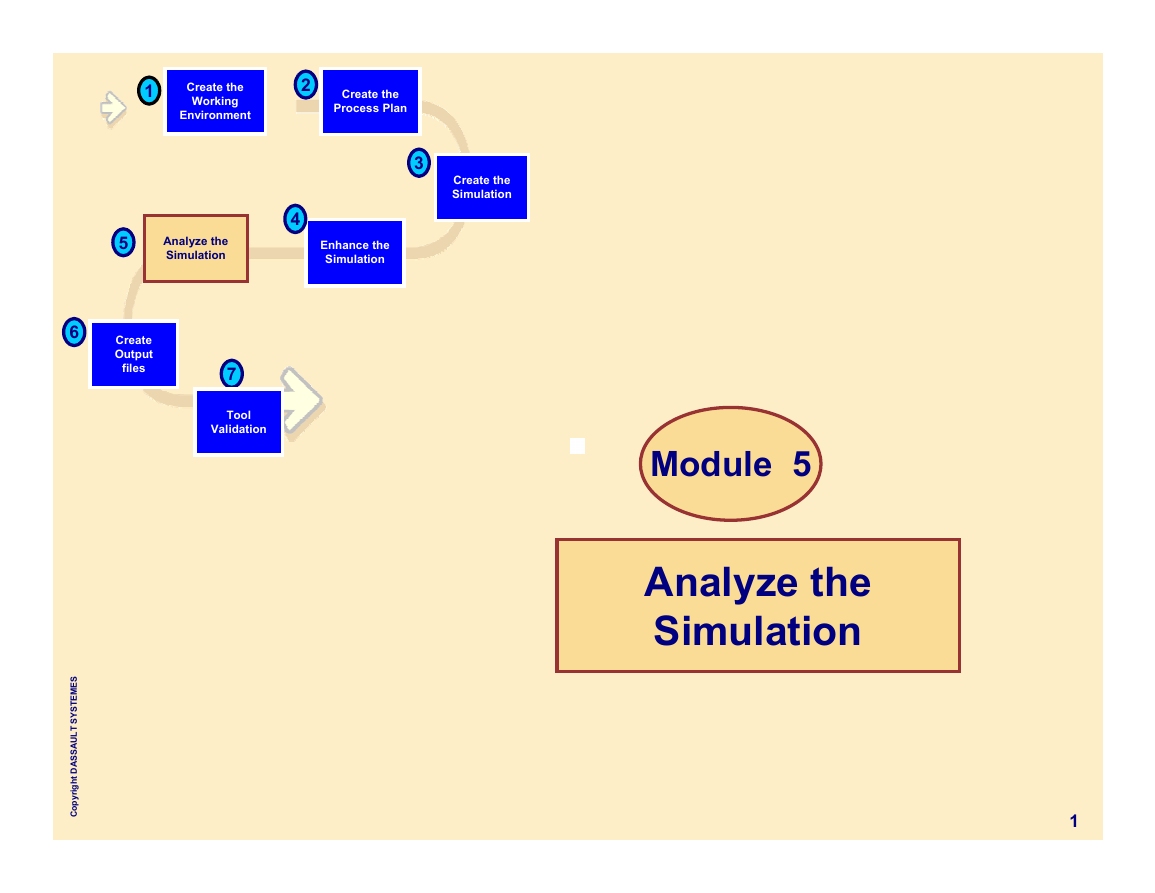

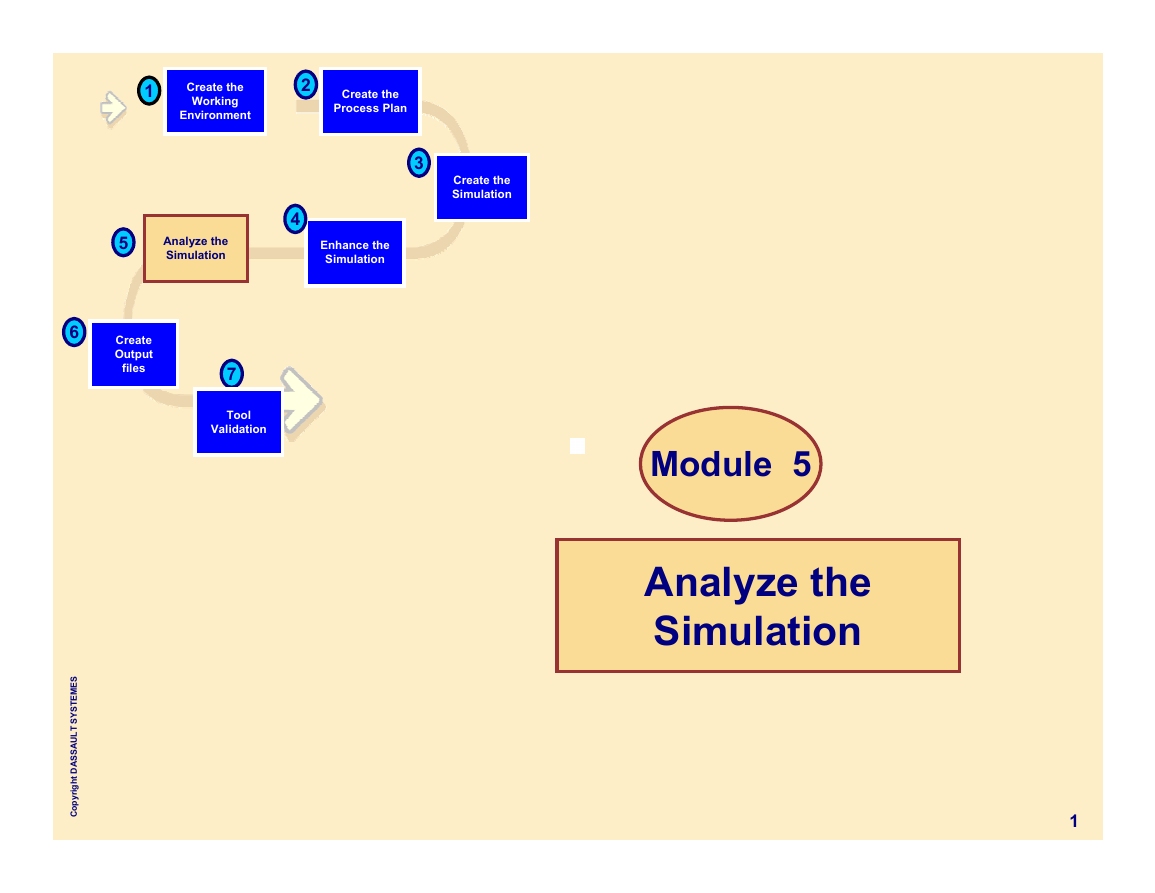

Create the

Working

Environment

2

Create the

Process Plan

3

Create the

Simulation

5

Analyze the

Simulation

4

Enhance the

Simulation

6

Create

Output

files

7

Tool

Validation

S

E

M

E

T

S

Y

S

T

L

U

A

S

S

A

D

t

h

g

i

r

y

p

o

C

Module 5

Analyze the

Simulation

1

�

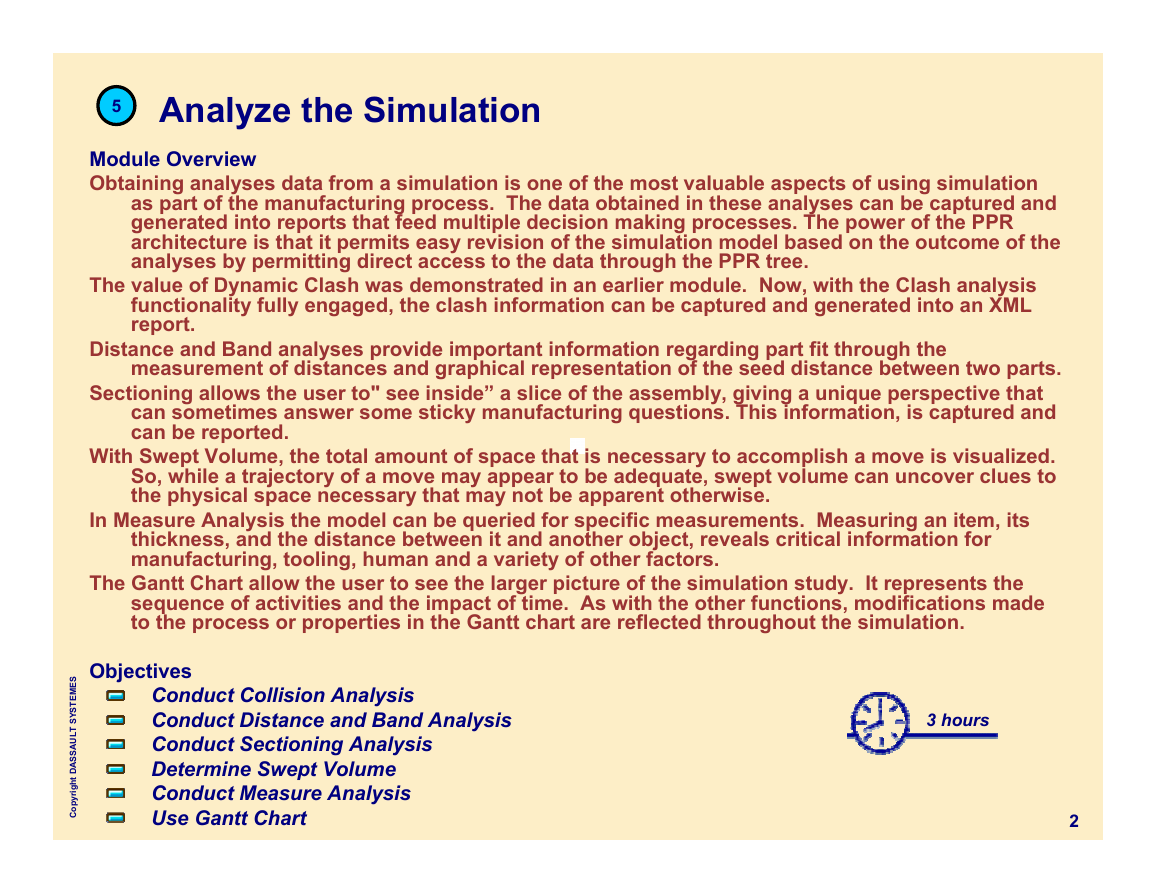

5 Analyze the Simulation

Module Overview

Obtaining analyses data from a simulation is one of the most valuable aspects of using simulation

as part of the manufacturing process. The data obtained in these analyses can be captured and

generated into reports that feed multiple decision making processes. The power of the PPR

architecture is that it permits easy revision of the simulation model based on the outcome of the

analyses by permitting direct access to the data through the PPR tree.

The value of Dynamic Clash was demonstrated in an earlier module. Now, with the Clash analysis

functionality fully engaged, the clash information can be captured and generated into an XML

report.

Distance and Band analyses provide important information regarding part fit through the

measurement of distances and graphical representation of the seed distance between two parts.

Sectioning allows the user to" see inside” a slice of the assembly, giving a unique perspective that

can sometimes answer some sticky manufacturing questions. This information, is captured and

can be reported.

With Swept Volume, the total amount of space that is necessary to accomplish a move is visualized.

So, while a trajectory of a move may appear to be adequate, swept volume can uncover clues to

the physical space necessary that may not be apparent otherwise.

In Measure Analysis the model can be queried for specific measurements. Measuring an item, its

thickness, and the distance between it and another object, reveals critical information for

manufacturing, tooling, human and a variety of other factors.

The Gantt Chart allow the user to see the larger picture of the simulation study. It represents the

sequence of activities and the impact of time. As with the other functions, modifications made

to the process or properties in the Gantt chart are reflected throughout the simulation.

Objectives

Conduct Collision Analysis

Conduct Distance and Band Analysis

Conduct Sectioning Analysis

Determine Swept Volume

Conduct Measure Analysis

Use Gantt Chart

S

E

M

E

T

S

Y

S

T

L

U

A

S

S

A

D

t

h

g

i

r

y

p

o

C

3 hours

2

�

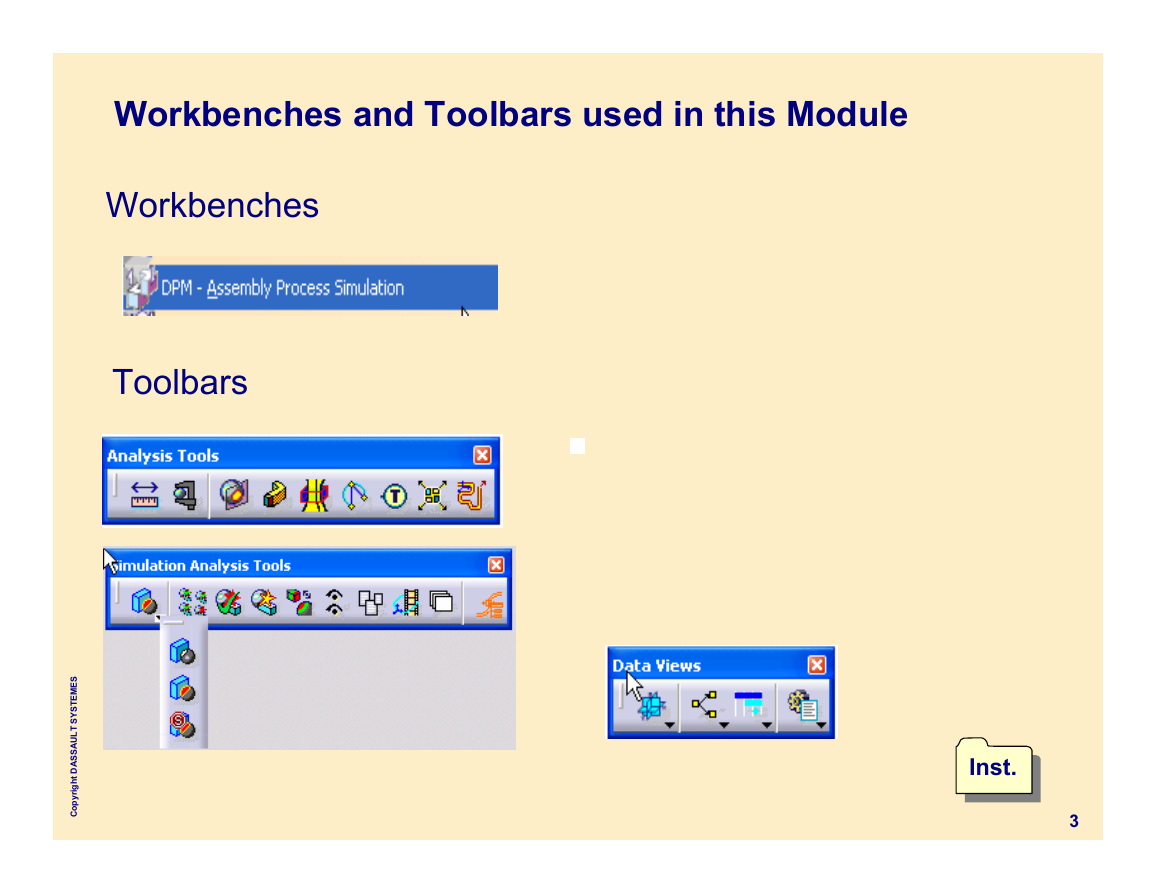

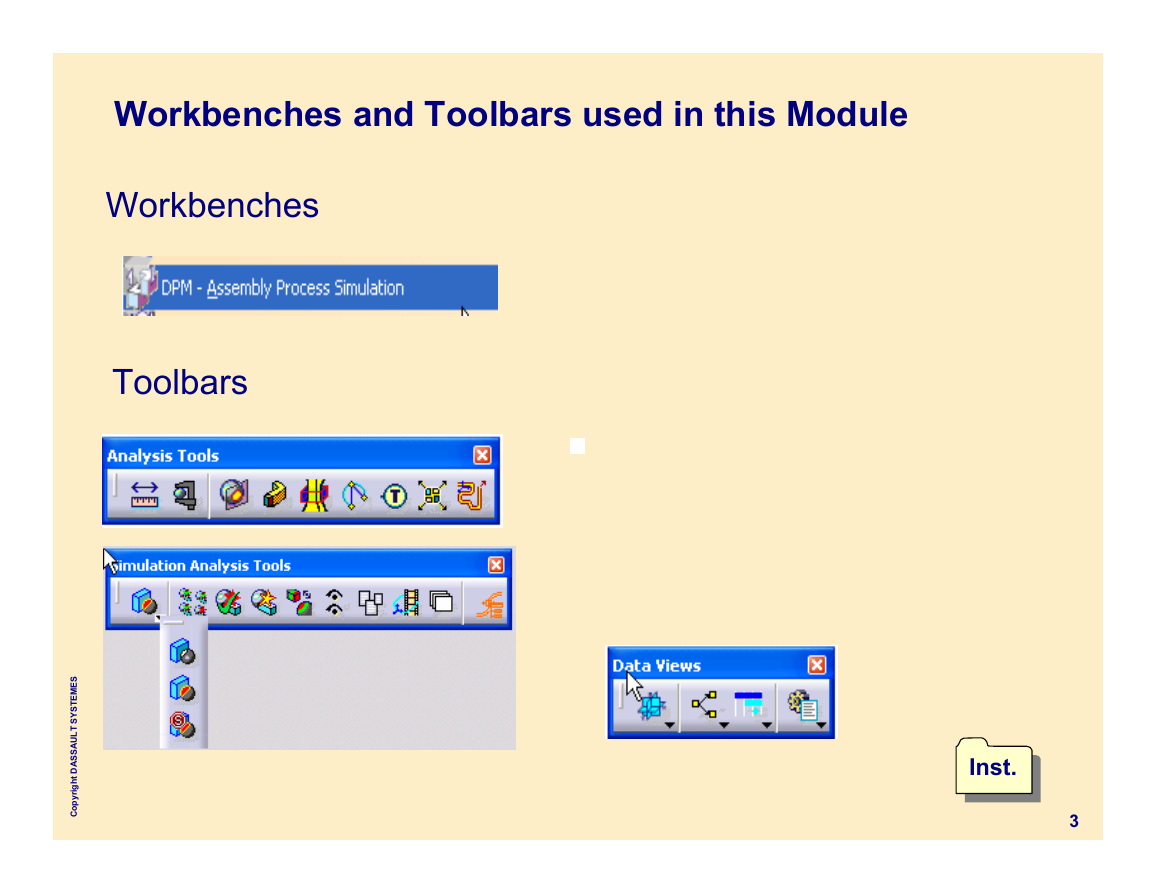

Workbenches and Toolbars used in this Module

Workbenches

Toolbars

S

E

M

E

T

S

Y

S

T

L

U

A

S

S

A

D

t

h

g

i

r

y

p

o

C

Inst.

Inst.

3

�

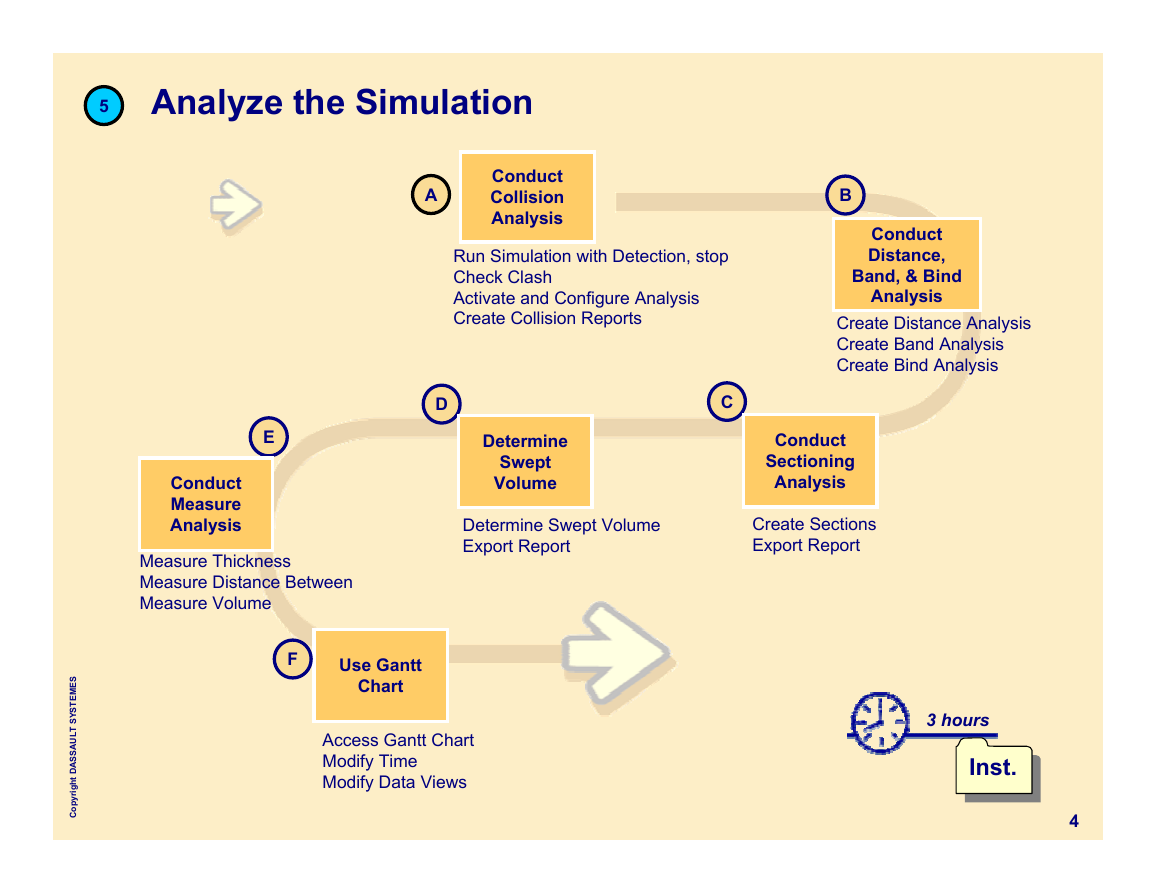

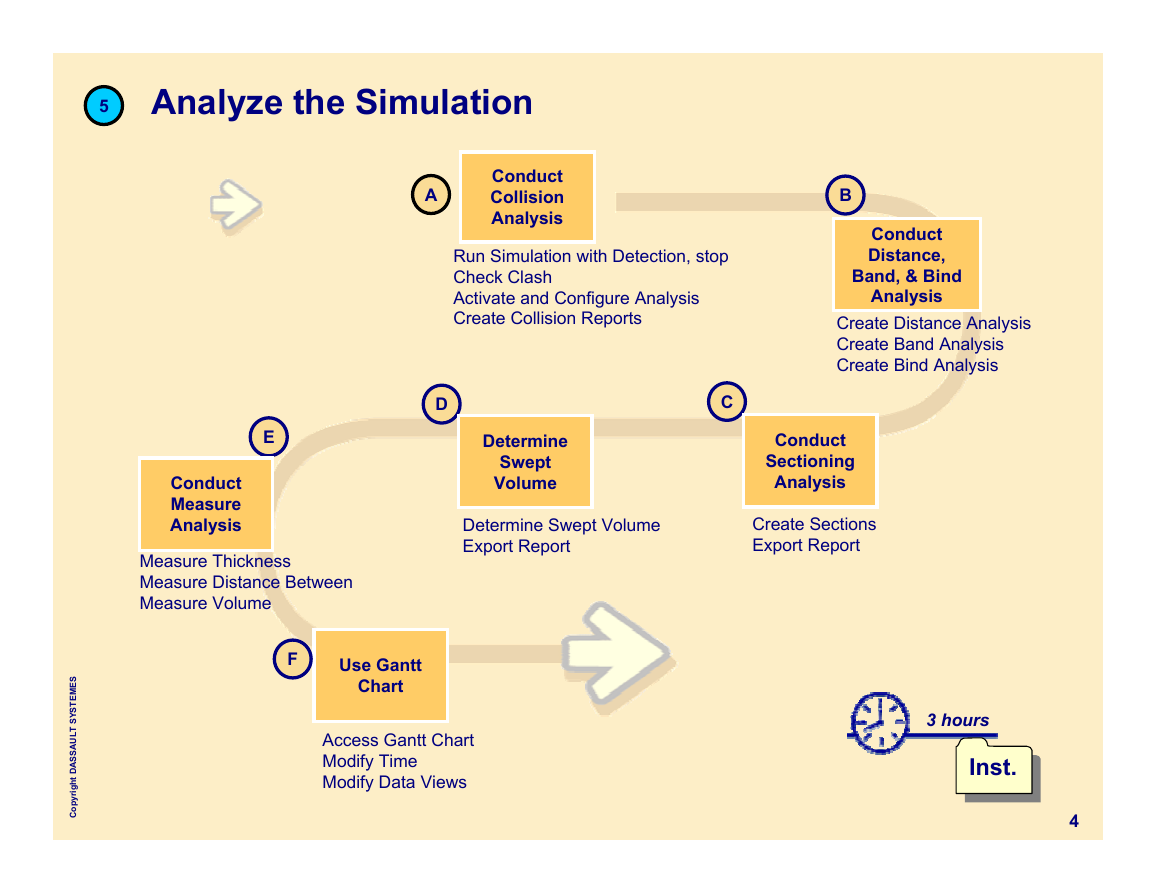

5

Analyze the Simulation

A

Conduct

Collision

Analysis

Run Simulation with Detection, stop

Check Clash

Activate and Configure Analysis

Create Collision Reports

B

Conduct

Distance,

Band, & Bind

Analysis

Create Distance Analysis

Create Band Analysis

Create Bind Analysis

E

Conduct

Measure

Analysis

Measure Thickness

Measure Distance Between

Measure Volume

D

C

Determine

Swept

Volume

Determine Swept Volume

Export Report

Conduct

Sectioning

Analysis

Create Sections

Export Report

S

E

M

E

T

S

Y

S

T

L

U

A

S

S

A

D

t

h

g

i

r

y

p

o

C

F

Use Gantt

Chart

Access Gantt Chart

Modify Time

Modify Data Views

3 hours

Inst.

Inst.

4

�

Conduct

Collision

Analysis

A

Run Simulation with Detection

Check Clash

Activate and Configure Analysis

Create Collision Reports

S

E

M

E

T

S

Y

S

T

L

U

A

S

S

A

D

t

h

g

i

r

y

p

o

C

Inst.

Inst.

5

�

5

Analyze the Simulation

About Collision Analysis

Conduct

Collision

Analysis

Earlier, Dynamic clash detection was used to get a general idea of the intended moves when

creating a simulation. This topic describes how to use Clash Detection when bodies are static

and when a move activity is executed. This clash methodology is capable of analyzing the

clash situation, capturing the data, and producing reports that assist with project

communication.

Running the simulation in assembly or disassembly

sequence with the stop mode activated will cause the

simulation to stop at every occurrence of a clash.

This offers an overview of existing conditions.

When Clash Checking is activated its parameters can be

set to examine interference in a variety of ways. The

analysis can be configured as the clash is examined

or, a queue can be established ahead of time that

forms a list of specific items to be analyzed. When

the analysis is configured, the ability to conduct a

Bind analysis is activated.

Producing XML reports of clash conditions

captures the information for discussion

and is easily shared in many media forms.

More about Clash Detection can be found in

the On-Line documentation

6

S

E

M

E

T

S

Y

S

T

L

U

A

S

S

A

D

t

h

g

i

r

y

p

o

C

�

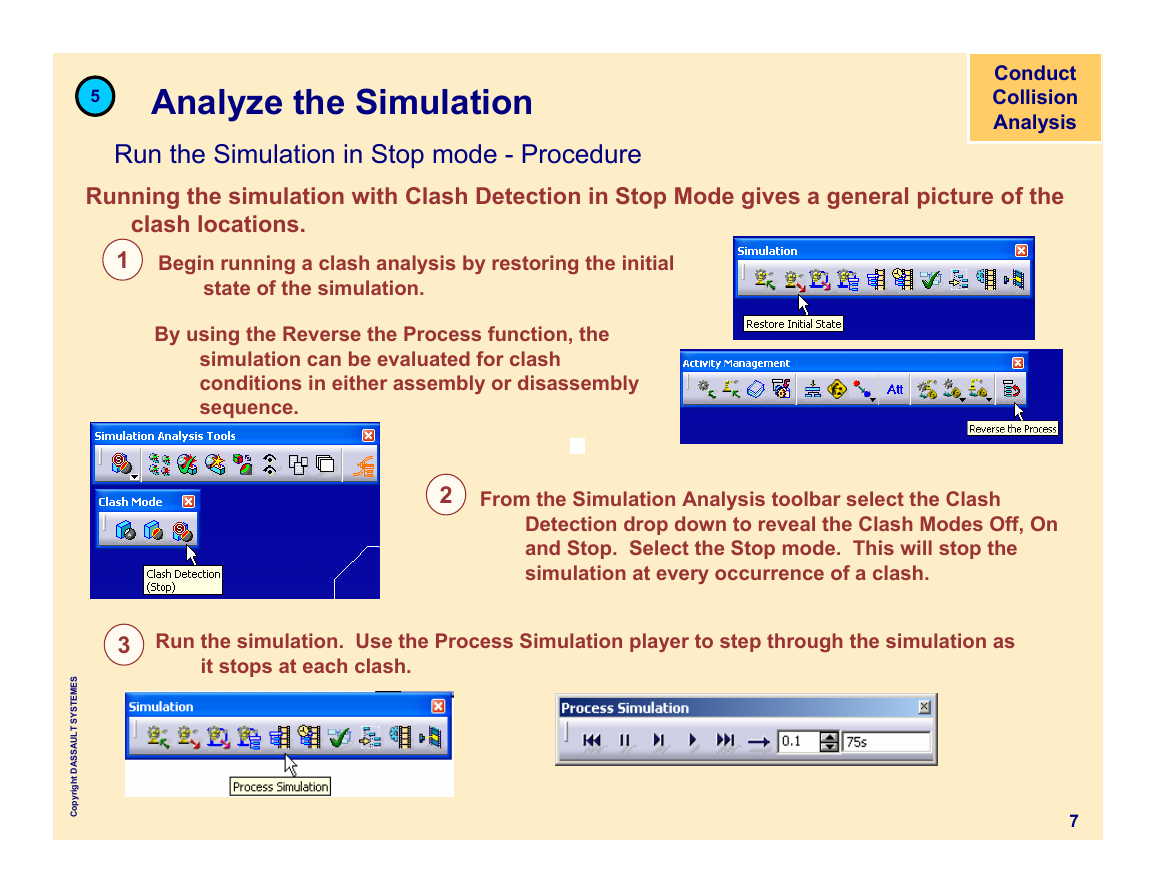

5

Analyze the Simulation

Run the Simulation in Stop mode - Procedure

Conduct

Collision

Analysis

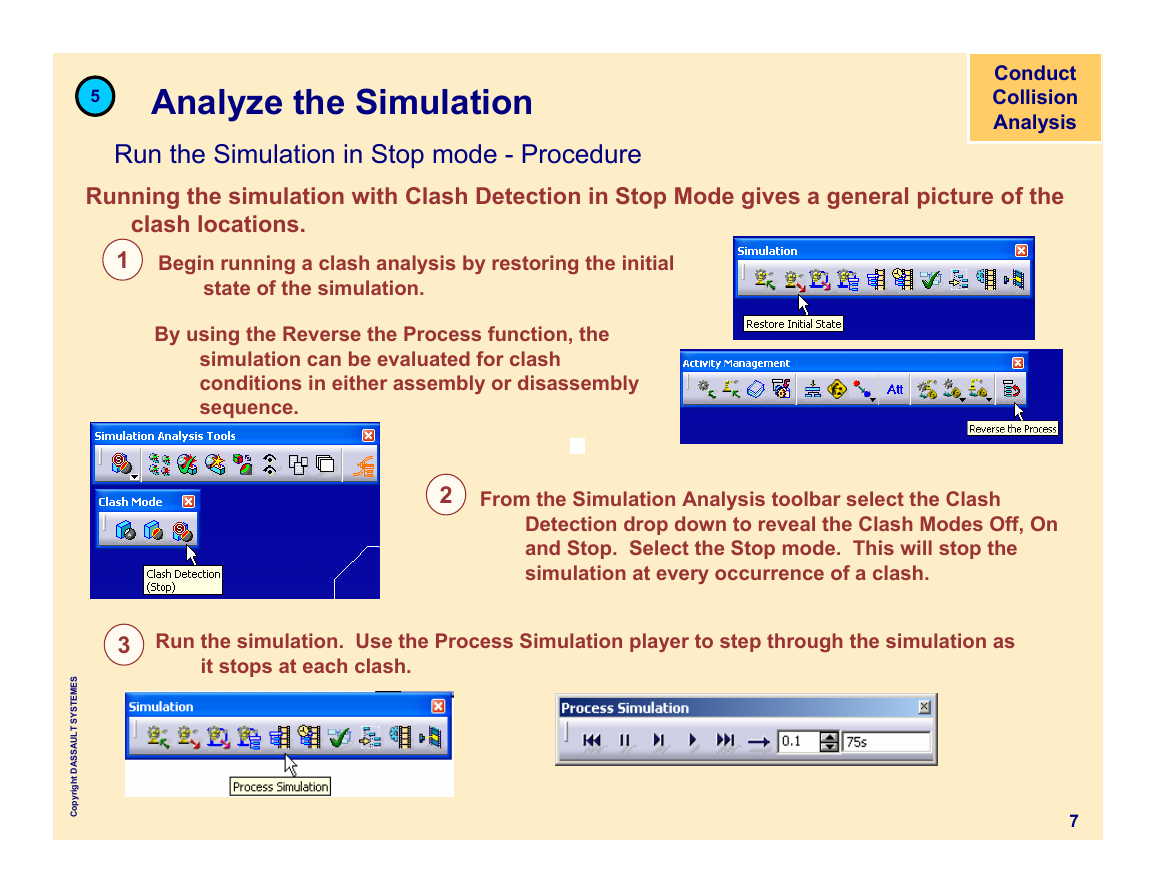

Running the simulation with Clash Detection in Stop Mode gives a general picture of the

clash locations.

1 Begin running a clash analysis by restoring the initial

state of the simulation.

By using the Reverse the Process function, the

simulation can be evaluated for clash

conditions in either assembly or disassembly

sequence.

2

From the Simulation Analysis toolbar select the Clash

Detection drop down to reveal the Clash Modes Off, On

and Stop. Select the Stop mode. This will stop the

simulation at every occurrence of a clash.

3 Run the simulation. Use the Process Simulation player to step through the simulation as

it stops at each clash.

7

S

E

M

E

T

S

Y

S

T

L

U

A

S

S

A

D

t

h

g

i

r

y

p

o

C

�

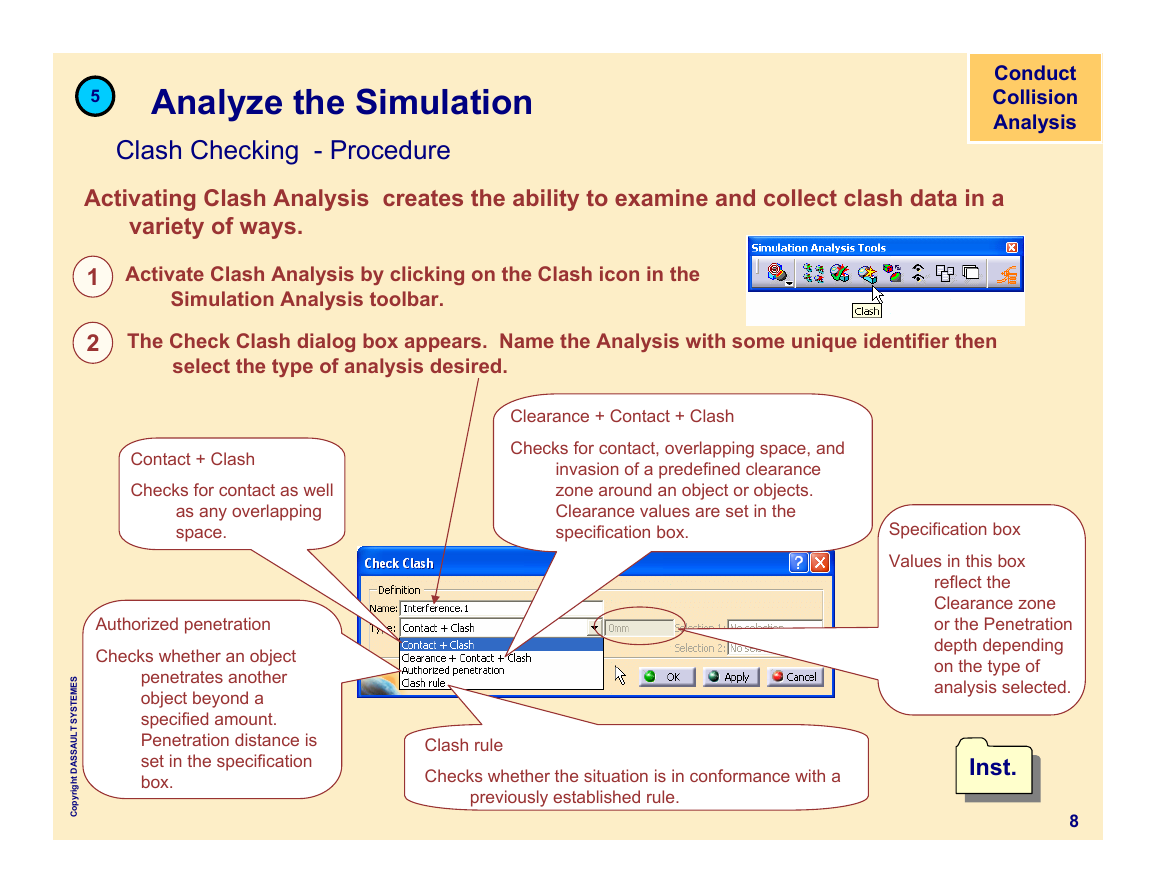

5

Analyze the Simulation

Clash Checking - Procedure

Conduct

Collision

Analysis

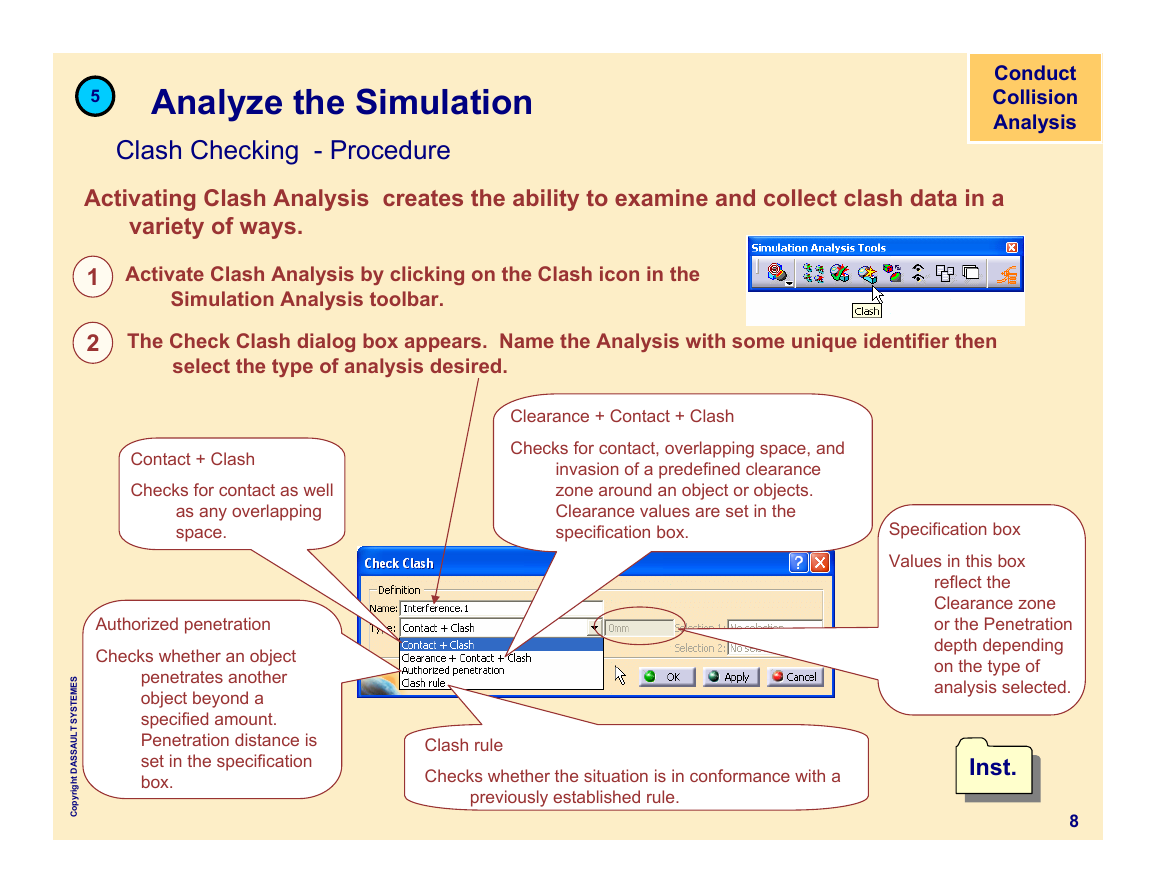

Activating Clash Analysis creates the ability to examine and collect clash data in a

variety of ways.

1 Activate Clash Analysis by clicking on the Clash icon in the

Simulation Analysis toolbar.

2

The Check Clash dialog box appears. Name the Analysis with some unique identifier then

select the type of analysis desired.

Contact + Clash

Checks for contact as well

as any overlapping

space.

Authorized penetration

Checks whether an object

penetrates another

object beyond a

specified amount.

Penetration distance is

set in the specification

box.

S

E

M

E

T

S

Y

S

T

L

U

A

S

S

A

D

t

h

g

i

r

y

p

o

C

Clearance + Contact + Clash

Checks for contact, overlapping space, and

invasion of a predefined clearance

zone around an object or objects.

Clearance values are set in the

specification box.

Clash rule

Checks whether the situation is in conformance with a

previously established rule.

Specification box

Values in this box

reflect the

Clearance zone

or the Penetration

depth depending

on the type of

analysis selected.

Inst.

Inst.

8

�

2023年江西萍乡中考道德与法治真题及答案.doc

2023年江西萍乡中考道德与法治真题及答案.doc 2012年重庆南川中考生物真题及答案.doc

2012年重庆南川中考生物真题及答案.doc 2013年江西师范大学地理学综合及文艺理论基础考研真题.doc

2013年江西师范大学地理学综合及文艺理论基础考研真题.doc 2020年四川甘孜小升初语文真题及答案I卷.doc

2020年四川甘孜小升初语文真题及答案I卷.doc 2020年注册岩土工程师专业基础考试真题及答案.doc

2020年注册岩土工程师专业基础考试真题及答案.doc 2023-2024学年福建省厦门市九年级上学期数学月考试题及答案.doc

2023-2024学年福建省厦门市九年级上学期数学月考试题及答案.doc 2021-2022学年辽宁省沈阳市大东区九年级上学期语文期末试题及答案.doc

2021-2022学年辽宁省沈阳市大东区九年级上学期语文期末试题及答案.doc 2022-2023学年北京东城区初三第一学期物理期末试卷及答案.doc

2022-2023学年北京东城区初三第一学期物理期末试卷及答案.doc 2018上半年江西教师资格初中地理学科知识与教学能力真题及答案.doc

2018上半年江西教师资格初中地理学科知识与教学能力真题及答案.doc 2012年河北国家公务员申论考试真题及答案-省级.doc

2012年河北国家公务员申论考试真题及答案-省级.doc 2020-2021学年江苏省扬州市江都区邵樊片九年级上学期数学第一次质量检测试题及答案.doc

2020-2021学年江苏省扬州市江都区邵樊片九年级上学期数学第一次质量检测试题及答案.doc 2022下半年黑龙江教师资格证中学综合素质真题及答案.doc

2022下半年黑龙江教师资格证中学综合素质真题及答案.doc