IEEE JOURNAL OF ROBOTICS AND AUTOMATION, VOL. RA-3, NO. 4, AUGUST 1987

323

A Versatile Camera Calibration Techniaue for

High-Accuracy 3D Machine Vision Metrology

Using Off-the-shelf TV Cameras and Lenses

ROGER

Y. TSAI

Abstract-A new technique for three-dimensional (3D) camera calibra-

tion for machine vision metrology using off-the-shelf TV cameras and

lenses is described. The two-stage technique is aimed at efficient

computation of camera external position and orientation relative to

object reference coordinate system as well as the effective focal length,

radial lens distortion, and image scanning parameters. The two-stage

technique has advantage in terms of accuracy, speed, and versatility over

existing state of the art. A critical review of the state of the art is given in

the beginning. A theoretical framework is established, supported by

comprehensive proof in five appendixes, and may pave the way for future

research on 3D robotics vision. Test results using real data are described.

Both accuracy and speed are reported. The experimental results are

analyzed and compared with theoretical prediction. Recent effort indi-

cates that with slight modification, the two-stage calibration can be done

in real time.

I. INTRODUCTION

A . The Importance of Versatile Camera Calibration

dimensional (3D) machine vision is

Technique C AMERA CALIBRATION in the context of three-

the process of

determining the internal camera geometric and optical charac-

teristics (intrinsic parameters) and/or the 3D position and

orientation of the camera frame relative to a certain world

coordinate system (extrinsic parameters), for the following

purposes.

I ) Inferring 3 0 Information from Computer Image

Coordinates: There are two kinds of 3D information to be

inferred. They are different mainly because of the difference

in applications.

a) The first is 3D information concerning the location of

the object, target, or feature. For simplicity, if the object is a

point feature (e.g., a point spot on a mechanical part

illuminated by a laser beam, or the corner of an electrical

component on a printed circuit board), camera calibration

provides a way of determining a ray in 3D space that the object

point must lie on, given the computer image coordinates. With

two views either taken from two cameras ,or one camera in two

locations, the position of the object point can be determined by

intersecting the two rays. Both intrinsic and extrinsic parame-

ters need to be calibrated. The applications include mechanical

part dimensional measurement, automatic assembly of me-

chanical or electronics components, tracking, robot calibration

and trajectory analysis. In the above applications, the camera

calibration need be done only once.

b) The second kind is 3D information concerning the

position and orientation of moving camera (e.g., a camera

held by a robot) relative to the target world coordinate system.

The applications include robot calibration with camera-on-

robot configuration, and robot vehicle guidance.

2) Inferring 2 0 Computer Image Coordinates from 3 0

In formation: In model-driven inspection or assembly appli-

cations using machine vision, a hypothesis of the state of the

world can be verified or confirmed by observing if the image

coordinates of the object conform to the hypothesis. In doing

so, it is necessary to have both the intrinsic and extrinsic

camera model parameters calibrated so that the two-dimen-

sional (2D) image coordinate can be properly predicted given

the hypothetical 3D location of the object.

The above purposes can be best served if the following

criteria for the camera calibration are met.

I ) Autonomous: The calibration procedure should not

require operator intervention such as giving initial guesses for

certain parameters, or choosing certain system parameters

manually.

2) Accurate: Many applications such as mechanical part

inspection, assembly, or robot arm calibration require an

accuracy that is one part in a few thousand of the working

range. The camera calibration technique should have the

potential of meeting such accuracy requirements. This re-

quires that the theoretical modeling of the imaging process

must be accurate (should include lens distortion and perspec-

tive rather than parallel projection).

3) Reasonably Efficient: The complete camera calibra-

tion procedure should not include high dimension (more than

five) nonlinear search. Since type b) application mentioned

earlier needs repeated calibration of extrinsic parameters, the

calibration approach should allow enough potential for high-

speed implementation.

4) Versatile: The calibration technique should operate

uniformly and autonomously for a wide range of accuracy

requirements, optical setups, and applications.

5) Need Only Common Off-the-shelf Camera and

Lens: Most camera calibration techniques developed in the

photogrammetric area require special professional cameras

and processing equipment. Such requirements prohibit full

automation and are labor-intensive and time-consuming to

Manuscript received October

18, 1985; revised September

2, 1986. A

version of this paper was presented at the 1986 IEEE International Conference

on Computer Vision and Pattern Recognition and received the Best Paper

Award.

The author is with the IBM T. J . Watson Research Center, Yorktown

Heights, NY 10598.

IEEE Log Number 8613011.

0882-4967/87/0800-0323$01.00 O 1987 IEEE

�

324

implement. ’ The advantages of using off-the-shelf solid state

or vidicon camera and lens are

versatile-solid state cameras and lenses can be used for a

variety of automation applications;

availability-since off-the-shelf solid state cameras and

lenses are common in many applications, they are at hand

when you need them and need not be custom ordered;

familiarity, user-friendly-not many people have

the

experience of operating the professional metric camera

used in photogrammetry

or the tetralateral photodiode

with preamplifier and associated electronics calibration,

while solid state is easily interfaced with a computer and

easy to install.

The next section shows deficiencies of existing techniques in

one or more of these criteria.

B. Why Existing Techniques Need Improvement

In this section, existing techniques are first classified into

of each

several categories. The strength and weakness

category are analyzed.

Category I-Techniques Involving Full-Scale Nonlinear

Optimization: See [I]-[3], [7], [lo], [14], [17], [22], [30],

for example.

Advantage: It allows easy adaptation of any arbitrarily

accurate yet complex model

for imaging. The best accuracy

obtained in this category is comparable to the accuracy of the

new technique proposed in this paper.

Problems: I) It requires a good initial guess to start the

nonlinear search. This violates the principle of automation. 2)

It needs computer-intensive full-scale nonlinear search.

Classical Approach: Faig’s technique [7]

is a good

representative for these techniques. It uses a very elaborate

model for imaging, uses at least 17 unknowns for each photo,

and is very computer-intensive [7]. However, because of the

large number of unknowns, the accuracy is excellent. The rms

(root mean square or average) error can be as good as 0.1 mil.

However, this rms error is in photo scale (i.e., error of fitting

the model with

plane). When

transformed into 3D error, it is comparable to the average

error (0.5 mil) obtained using monoview multiplane

calibra-

is the typical case among the various

tion technique, which

two-stage techniques proposed in

this paper. Another reason

why such photogrammetric techniques produce very accurate

results is that large professional format photo is used rather

than solid-state image array such as CCD. The resolution for

such photos is generally three to four times better than that for

the solid-state imaging sensor array.

the observations in image

Direct linear transformation (DL T): Another example

is the direct linear transformation (DLT) developed by Abdel-

Aziz and Karara [ 11, [2]. One reason why DLT was developed

is that only linear equations need be solved. However, it was

later found that, unless lens distortion is ignored, full-scale

nonlinear search

is needed. In [14, p. 361 Karara, the co-

’ Although existing techniques such

Section I-B) can be implemented

cameras, the version NBS implemented uses high resolution analog tetra-

lateral photodiode, and the associated optoelectronics accessories need special

manual calibration (see [5] for details).

transformation (see

or vidicon

using common solid state

as direct linear

IEEE JOURNAL OF ROBOTICS

AUTOMATION,

AND

VOL. RA-3, NO. 4, AUGUST 1987

inventor of DLT, comments,

When originally presented in 1971 (Abdel-Aziz and Karara,

1971), the DLT basic equations did not involve any image

refinement parameters, and represented an actual linear

transformation between comparator coordinates

and object-

space coordinates. When the DLT mathematical model was

later expanded to encompass image refinement parameters, the

title DLT was retained unchanged.

Although Wong [30] mentioned

that there are two possible

procedures of using DLT (one entails solving linear equations

only, and the other requires nonlinear search), the procedure

using linear equation solving actually contains approximation.

One of the artificial parameters he introduced, K ~ ,

is a function

of (x, y , z ) world coordinate and

therefore not a constant.

Nevertheless, DLT bridges the gap between photogrammetry

and computer vision so that both areas can use DLT directly to

solve camera calibration problem.

(to be discussed

the same type of measure

When lens distortion is not considered, DLT falls into the

second category

later) that entails solving

linear equations only. It, too, has its pros and cons and will be

discussed later when the second category is presented. Dainis

and Juberts [5] from the Manufacturing Engineering Center of

NBS reported results using DLT for camera calibrations to do

accurate measurement of robot trajectory motion. Although

the NBS system can do 3D measurement at a rate of 40 Hz, the

camera calibration was not and need not be done in real time.

The accuracy reported uses

for

accessing or evaluating camera calibration accuracy as Type I

measure used

in this paper (see Section 111-A). The total

accuracy in 3D is one part in 2000 within the center 80 percent

of the detector field of view. This

is comparable to the

accuracy of the proposed two-stage method in measuring the x

(the proposed two-stage

and y parts of the 3D coordinates

technique yields better percentage accuracy

for the depth).

Notice, however, that the image sensing device NBS used is

not a TV camera but a tetralateral photodiode. It senses the

position of incidence light spot on the surface of detector by

means of analog and uses a 12-bit AID converter to convert the

analog positions into a digital quantity to be processed by the

computer. Therefore, the

effective 4K X 4K spatial resolution, as opposed to a 388 X

480 full-resolution Fairchild CCD area sensor. Many thought

that the low resolution characteristics of solid-state imaging

sensor could not be used

This paper reveals that wit,h proper calibration, a solid-state

sensor (such as CCD) is still a valid tool in high-accuracy 3D

machine vision metrology applications. Dainis and Juberts [5]

mentioned that the accuracy is 100 percent lower for points

outside the center 90-percent field of view. This suggests that

lens distortion is not considered when using DLT to calibrate

the camera. Therefore,

to be

solved. This actually puts the NBS work in a different category

that follows which include

all techniques that computes the

perspective transformation matrix first. Again, the pros and

cons for the latter will be discussed later.

for high-accuracy 3D metrology.

tetralateral photodiode has an

only linear equations need

Sobel, Gennery, Lowe: Sobel [23] described a system

solving.

is

for calibrating a camera using nonlinear equation

Eighteen parameters must be optimized. The approach

�

TSAI: VERSATILE CAMERA CALIBRATION TECHNIQUE

325

similar to Faig’s method described earlier. No accuracy results

were reported. Gennery [lo] described a method that finds

camera parameters iteratively by minimizing the error of

epipolar constraints without using 3D coordinates of calibra-

tion points. It is mentioned in [4, p. 2531 and [20, p. 501 that

the technique is too error-prone.

Category 11- Techniques Involving Computing Perspec-

tive Transformation Matrix First Using Linear Equation

Solving: See [ 13, [2], [9], [ 111, [ 141, [241, [251, and [3 11, for

example.

Advantage: No nonlinear optimization is needed.

Problems: 1) Lens distortion cannot be considered. 2)

The number of unknowns in linear equations is much larger

than the actual degrees of freedom (i.e., the unknowns to be

solved are not linearly independent). The disadvantage of such

redundant parameterization is that erroneous combination of

these parameters can still make a good fit between experimen-

tal observations and model prediction in real situation when

the observation is not

perfect. This means the accuracy

potential is limited in noisy situation.

Although the equations characterizing the transformation

from 3D world coordinates to 2D image coordinates are

nonlinear functions of the extrinsic and intrinsic camera model

parameters (see Section 11-C1 and -2 for definition of camera

parameters), they are linear if lens distortion is ignored and if

the coefficients of the 3 x 4 perspective transformation matrix

are regarded as unknown parameters (see Duda and Hart [6]

for a definition of perspective transformation matrix). Given

the 3D world coordinates of a number of points and

the

corresponding 2D image coordinates, the coefficients in the

perspective transformation matrix can be solved by least

square solution of an overdetermined systems of linear

equations. Given the perspective transformation matrix, the

camera model parameters can then be computed if needed.

However, many investigators have found that ignoring lens

distortion is unacceptable when doing 3D measurement (e.g.,

Itoh et al. [12], Luh and Klassen

[ 161). The error of 3D

measurement reported in this paper using two-stage camera

calibration technique would have been an order of magnitude

larger if the lens distortion were not corrected.

Sutherland: Sutherland [25] formulated very explicitly

the procedure for computing the perspective transformation

matrix given 3 0 world coordinates and 2D image coordinates

of a number of points. It was applied to graphics applications,

and no accuracy results are reported.

Yakimovsky and Cunningham: Yakimovsky and Cun-

ningham’s stereo program [31] was developed for the JPL

Robotics Research Vehicle, a testbed for a Mars rover and

remote processing systems. Due to the narrow field of view

and large object distance, they used a highly linear lens and

ignored distortion. They reported that the 3D measurement

accuracy of k 5 mm at a distance of 2 m. This is equivalent to

a depth resolution of one part in 400, which is one order of

magnitude less accurate than the test results to be described in

this paper. One reason is that Yakimovsky and Cunningham’s

system does not consider lens distortion. The other reason is

probably that

the unknown parameters computed by linear

equations are not linearly independent. Notice also that had it

not been for the fact that the field of view in Yakimovsky and

Cunningham’s system is narrow and that the object distance is

large, ignoring distortion should cause more error.

DLT: By disregarding lens distortion, DLT developed

by Abdel-Aziz and Karara [ 11, [2] described in Category I falls

into Category 11. Accuracy results on real experiments have

been reported only by Dainis and Juberts from NBS [SI. The

accuracy results and the comparison with the proposed

technique are described earlier in Category I.

Hall et al.: Hall et al. [l 11 used a straightforward linear

least square technique to solve for the elements of perspective

transformation matrix for doing 3D curved surface measure-

ment. The computer 3D coordinates were tabulated, but no

ground truth was given, and therefore the accuracy is

unknown.

Ganapathy, Strat: Ganapathy [9] derived a noniterative

technique in computing camera parameters given the perspec-

tive transformation matrix computed using any of the tech-

niques discussed in this category. He used

the perspective

transformation matrix given from Potmesil through private

communications and computed the camera parameters. It was

not applied to 3D measurement, and therefore no accuracy

results were available. Similar results are obtained by Strat

~ 4 1 .

Category 111-Two-Plane Method: See [13] and 1191 for

ple.

Advantage: No nonlinear search is needed.

Problems: 1) No lens distortion can be considered. 2)

Focal length is assumed given. 3) Uncertainty of image scale

factor is not allowed.

Fischler and Bolles [8] use a geometric construction to

derive direct solution for the camera locations and orientation.

However, none of the camera intrinsic parameters (see Section

11-C2) can be computed. No accuracy results of real 3D

measurement was reported.

example.

Advantage: Only linear equations need be solved.

Problems: 1) The number of unknowns is at least 24 (12

for each plane), much larger than the degrees of freedom. 2)

The formula used for the transformation between image and

object coordinates is empirically based only.

The two-plane method developed by Martins et ai.

[19]

theoretically can be applied in general without having any

restrictions on the extrinsic camera parameters. However, for

the experimental results reported, the relative orientation

between the camera coordinate system and the object world

coordinate system was assumed known (no relative rotation).

In such a restricted case, the average error is about 4 mil with a

distance of 25 in, which is comparable to the accuracy

obtained using the proposed technique. Since the formula for

the transformation between image and object coordinates is

empirically based, it is not clear what kind of approximation is

assumed. Nonlinear lens distortion theoretically cannot be

corrected. A general calibration using the two-plane technique

was proposed by Isaguirre et al. [13]. Full-scale nonlinear

optimization is needed. No experimental results were re-

ported.

Category IV-Geometric Technique:

See [8] for exam-

�

326

IEEE JOURNAL OF ROBOTICS AND AUTOMATION, VOL. RA-3. NO. 4, AUGUST 1987

0

)X

11. THE NEW APPROACH TO MACHINE VISION CAMERA

CALIBRATION USING A TWO-STAGE TECHNIQUE

the problem. After

In the following, an overview is first given that describes

the strategy we took in approaching

the

overview, the underlying camera model and the definition of

the parameters to be

calibrated are described. Then, the

calibration algorithm and the theoretical derivation and other

issues will be presented. For those readers who would like to

have a physical feeling of how to perform calibration in a real

setup, first read “Experimental Procedure,” Section IV-A1 .

A . Overview

Camera calibration entails solving for a large number of

calibration parameters, resulting in the classical approach

mentioned in the Introduction that requires large scale nonlin-

ear search. The conventional way of avoiding this large-scale

nonlinear search

is to use the approaches similar to DLT

described in the Introduction that solves for a set of parameters

(coefficients of homogeneous transformation matrix) with

linear equations, ignoring the dependency between the param-

eters, resulting in a situation with the number of unknowns

greater than the number of degrees of freedoms. The lens

distortion is also ignored (see the Introduction for more

detail). Our approach

is to look for a real constraint or

equation that is only a function of a subset of the calibration

parameters to reduce the dimensionality of

the unknown

parameter space. It turns out that such constraint does exist,

and we call it the radial alignment constraint (to be described

later). This constraint (or equations resulting from such

physical constraint) is only a function of the relative rotation

and translation (except for the z component) between

the

camera and the calibration points (see Section 11-B for detail).

Furthermore, although the constraint is a nonlinear function of

the abovementioned calibration parameters (called group I

parameters), there is a simple and efficient way of computing

them. The rest of the calibration parameters (called group I1

parameters) are computed with normal projective equations. A

very good initial guess of group I1 parameters can be obtained

by ignoring the lens distortion and using simple linear equation

with two unknowns. The precise values for group I1 parame-

ters can then be computed with one

or two iterations in

minimizing the perspective equation error. Be aware that when

single-plane calibration points are used, the plane must not be

exactly parallel to image plane (see (15), to follow, for detail).

for the image-to-object

transformation described

in the next section, subpixel accu-

racy interpolation for extracting image coordinates of calibra-

tion points can be used to enhance the calibration accuracy to

maximum. Note

that this is not true if a DLT-type linear

approximation technique

is used since ignoring distortion

results in image coordinate error more than a pixel unless very

narrow angle

subpixel

accuracy image feature extraction is described in Section IV-

Al.

B. The Camera Model

lens is used. One way of achieving

Due to the accurate modeling

This section describes the camera model,

defines the

calibration parameters, and presents the simple radial align-

Fig. 1. Camera geometry with perspective projection and radial lens

distortion.

or P(xw,yw,zw)

at Oi

ment principle (to be described in Section 11-E) that provides

the original motivation for the proposed technique. The

camera model itself is basically the same as that used by any of

the techniques in Category I in Section I-B.

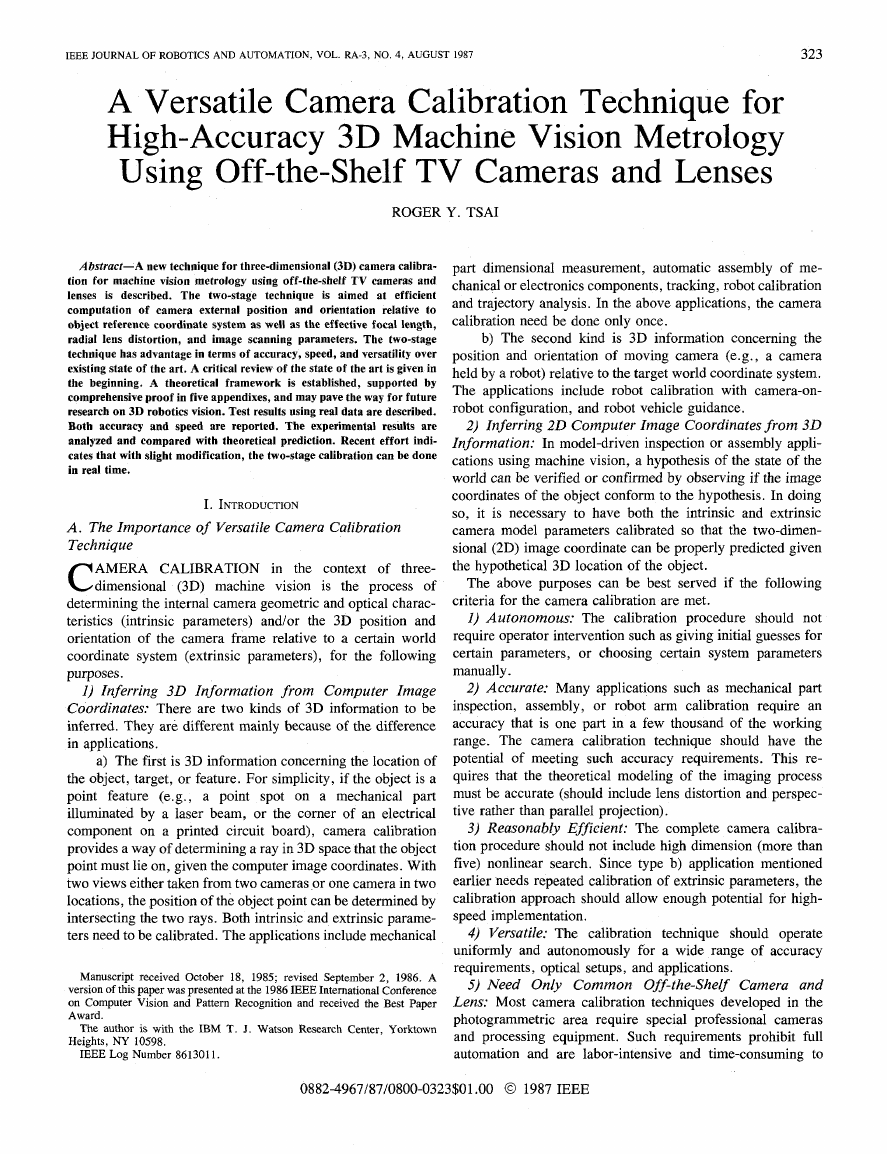

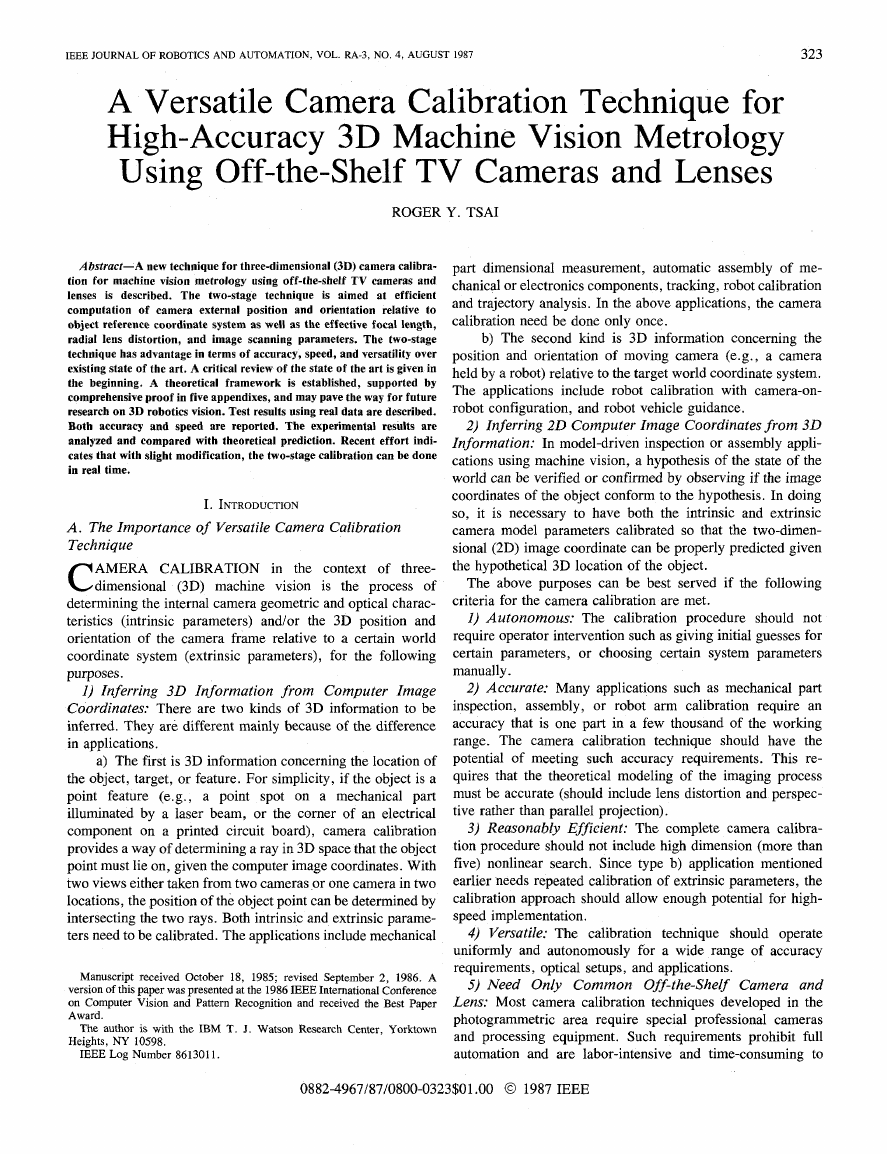

I) The Four Steps of Transformation from 3 0 World

Coordinate to Camera Coordinate: Fig. 1

illustrates the

basic geometry of the camera model. (xw, y w , z,) is the 3D

coordinate of the object point P in the 3D world coordinate

system. (x, y , z ) is the 3D coordinate of the object point P in

the 3D camera coordinate system, which

is centered at point

0, the optical center, with the z axis the same as the optical

axis. ( X , Y ) is the image coordinate system centered

(intersection of the optical axis z and the front image plane)

and parallel to x and y axes. f is the distance between front

the optical center. (X,, Y,) is the image

image plane and

coordinate of (x, y , z) if a perfect pinhole camera model

is

used. ( X d , Yd) is the actual image coordinate which differs

from (X,, Y,) due to lens distortion. However, since the unit

for ( X f , Yf), the coordinate used in

the computer, is the

number of pixels for the discrete image in the frame memory,

additional parameters need be specified (and calibrated) that

relates the image coordinate in the front image plane to the

computer image coordinatk system. The overall transforma-

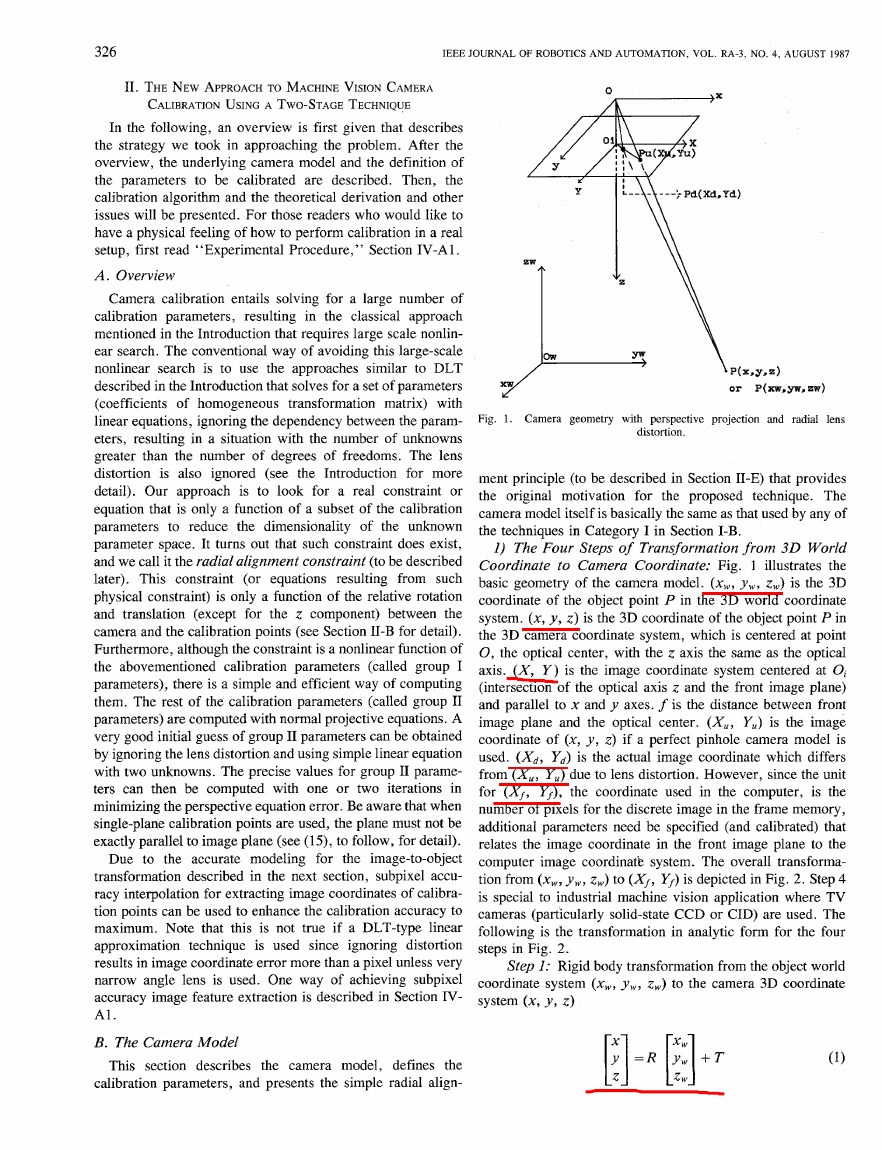

tion from (x,,,, y,, z,) to ( X f , Yf) is depicted in Fig. 2. Step 4

is special to industrial machine vision application where TV

cameras (particularly solid-state CCD or CID) are used. The

following is the transformation in analytic form for the four

steps in Fig. 2.

Step I: Rigid body transformation from the object world

coordinate system (x,,,, yw, z,,,) to the camera 3D coordinate

system (x, Y , z )

�

TSAI: VERSATILE CAMERA CALIBRATION TECHNIQUE

327

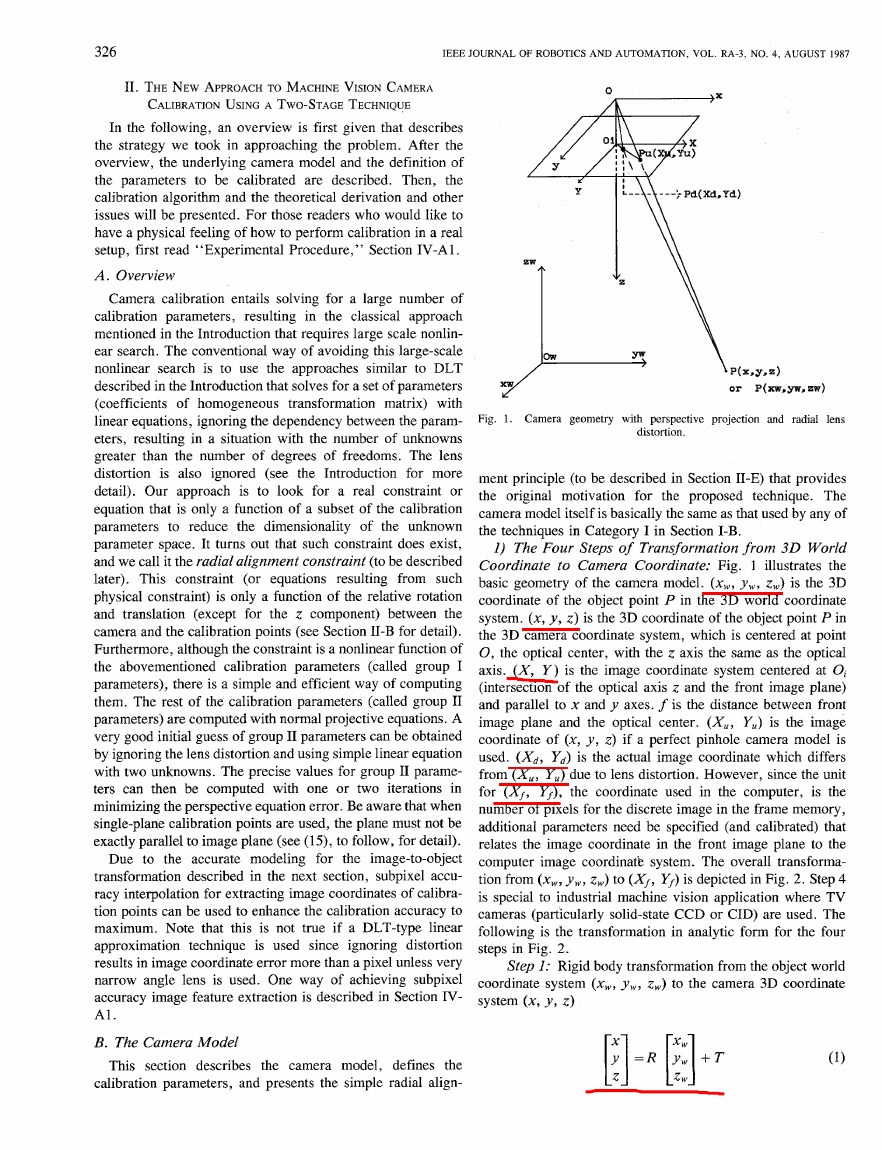

(xw, yw, zw) 3 0 world coordinate

I

v

Rigid body transformation from (xw, y,. zw) to (x, y , z )

Step 1

Parameters to be calibrated: R, T

I

v

(x, y, z ) 3 0 camera coordinate system

I

7

Step 2

Perspective projection with pin hole geometry

Parameters to be calibrated: f

I

v

(X,, Y,) Ideal undistorted image coordinate

I

v

Step 3

Radial lens distortion

Parameters to be calibrated: K , , K*

I

v

(X,, Y,) Distorted image coordinate

I

w

TV scanning, Sampling, computer acquisition

Parameter to be calibrated: uncertainty scale factor s, for image

~

~

~~

Step 4

X coordinate

I

v

(Xr. Yf) Computer image coordinate in frame medory

Fig, 2. Four steps of transformation from 3D world coordinate to computer image coordinate.

where R is the 3 X 3 rotation matrix

r3

R = r4 rs r6

r9]

f-1 r2

[ r7 r8

[;I.

T E

,

(2)

(3)

and T is the translation vector

The parameters to be calibrated are R and T.

Note that the rigid body transformation from one Cartesian

coordinate system (x,,,, yw, z,) to another (x, y , z ) is unique if

the transformation is defined as 3D rotation around the origin

(be it defined as three separate rotations-yaw, pitch, and roll-

around an axis passing through the origin) followed by the 3D

translation. Most of

the existing techniques for camera

calibration (e.g., see Section I-B) define the transformation as

translation followed by rotation. It will be seen later (see

Section 11-E) that this order (rotation followed by translation)

is crucial to the motivation and development of the new

calibration technique.

Step 2: Transformation from 3D camera coordinate (x,

y , z ) to ideal (undistorted) image coordinate (Xu, Yu) using

perspective projection with pinhole camera geometry

X

X u = f -

Z

(44

The parameter to be calibrated is the effective focal length f .

Step 3: Radial lens distortion is

x d + D x = x u

(54

(5b)

where ( X d , Yd) is the distorted or true image coordinate on the

image plane ,and

Y d + D y = Y u

DX =Xd( K , r2 + ~~r~ +

-)

Dy= Y d ( ~ I r 2 + ~ 2 r 4 +

* e -

)

r = q d .

�

328

IEEE JOURNAL OF ROBOTICS AND AUTOMATION, VOL. RA-3, NO. 4, AUGUST 1987

The parameters to be calibrated are distortion coefficients K ~ .

The modeling of lens distortion can be found in [ 181. There

are two kinds of distortion: radial and tangential. For each

kind of distortion, an infinite series is required. However, my

experience shows that for industrial machine vision applica-

tion, only radial distortion needs to be considered, and only

one term is needed. Any more elaborate modeling not only

would not help but also would cause numerical instability.

Step 4: Real image coordinate ( X d , Yd) to computer

image coordinate coordinate ( X f , Y f ) transformation

only the odd or the even field is used, then dy is twice the

center-to-center distance between adjacent CCD sensor ele-

ments in the Y direction. The situation in X is different.

Normally, in TV camera scanning, an analog waveform is

generated for each image line by zeroth-order sample and

hold. Then it is sampled by the computer into Nfx samples.

Therefore, one would easily draw the conclusion that

where

(Xf, Yf) row and column numbers of the image pixel in

(ex, Cy) row and column numbers of the center of

(6c)

computer frame memory,

computer frame memory,

dX

dY

N c x

Nfx

the

direction,

center to center distance between adjacent sensor

elements in X (scan line)

@e)

center to center distance between adjacent CCD

sensor in

(6f)

number of sensor elements in the X direc-

tion,

(6g)

number of pixels in a line as sampled by the

computer.

(6h)

Y direction,

The parameter to be calibrated is the uncertainty image scale

factor s,.

To transform between the computer image coordinate (in

the forms of rows and columns in frame buffer) and the real

image coordinate, obviously the distances between the two

adjacent pixels in both the row and column direction in the

frame buffer mapped to the real image coordinates need be

used. When a vidicon camera is used where both such

distances are not known a priori, the multiplane (rather than

single plane) calibration technique described in this paper must

be used. However, the scale in y is absorbed by the focal

length since focal length scales the image in both the x and y

directions. Therefore, dy (6b) should be set to one while the

computed focal length f will be a product of the actual focal

length and the scale factor in y . Also, Ncx and Nfx in (6d)

should be set to one since they only apply to CCD cameras.

a vidicon type camera is used, the sensor

element or pixel mentioned earlier should be regarded as each

individual resolution element in the receptor area with the

resolution being determined by the sampling rate. If a solid-

state CCD or CID discrete array sensor is used and

if full

resolution is used, since the image is scanned line by line,

obviously the distance between adjacent pixels in the y

direction is just the same as dy , center to center distance

between adjacent CCD sensor elements in Y direction.

Therefore, (6b) is the right relationship between Yd and Y. If

Note that if

Normally, manufacturers of CCD cameras supply informa-

tion of dx and dy (defined in (6e) and (6f)) to submicron

accuracy. However, an additional uncertainty parameter has to

be introduced. This is due to a variety of factors, such as slight

hardware timing mismatch between image acquisition hard-

ware and camera scanning hardware, or the imprecision of the

timing of TV scanning itself. Even a one-percent difference

can cause three- to five-pixels error for a full resolution frame.

Our experience with the Fairchild CCD 3000 camera shows

that the uncertainty is as much as five-percent. Therefore, an

unknown parameter sx in (6a) is introduced to accommodate

this uncertainty, and to include it in

the list of unknown

parameters to be calibrated, multiplane calibration technique

described in this paper should be used. However, there are a

variety of other simple techniques one can use to determine

this scale factor in advance (see Lenz and Tsai [ZS]). In this

case, the single plane calibration technique suffices. The issue

of (ex, Cy) will be discussed later (see Note at end of paper).

C. Equations Relating the 3 0 World Coordinates to the

2 0 Computer Image Coordinates

By combining the last three steps, the ( X , Y ) computer

coordinate is related to (x, y , z), the 3D coordinate of the

object point in camera coordinate system, by the following

equation:

s;'d:X+s;'d:XK1r2=

X

f -

2

dy'Y+dyYKIr2=f- Y

Z

(7b)

where

r=d(s;1d:X)2+(dyY)2.

\,

Substituting (1) into (7a) and (7b) gives

where

�

TSAI: VERSATILE CAMERA CALIBRATION TECHNIQUE

329

The parameters used in

categorized into the following two classes:

the transformation in Fig. 2 can be

1) Extrinsic Parameters: The parameters in Step 1 in Fig.

2 for the transformation from 3D object world coordinate

system to the camera 3D coordinate system centered at the

optical center are called the extrinsic parameters. There are

six extrinsic parameters: the Euler angles yaw 8, pitch +, and

tilt $ for rotation, the three components for the translation

vector T. The rotation matrix R can be expressed as function

of 8, 9, and $ as follows:

r

1

-sin$cos++cos$sin8cos+

sin$sin++cos$sin8cos+

cos $ cos 8

R =

- -

according to (4a) and (4b), z changes X , and Y, by the same

scale, so that oiP,//oiPd).

- Observation IV.‘ The constraint that OjPd is parallel to

Po,P for every point, being shown to be independent of the

radial distortion coefficients K ] and K ~ , the effective focal

length f, and the z component of 3D translation vector T, is

actually sufficient to determine the 3D rotation R , X , and Y

component of 3D translation from the world coordinate system

to the camera coordinate system, and the uncertainty scale

factor s, in X component of the image coordinate.

sin $ cos 8

cos $cosc$+sin$sinesin+ cosOsin+

-cos$sin++sin$sinOcos+

-sin 8 1

.

1

C O S ~ C O S +

(9)

2) Intrinsic Parameters: The parameters in Steps 2-4 in

Fig. 2 for the transformation from 3D object coordinate in the

camera coordinate system to the computer image coordinate

are called the intrinsic parameters. There are six intrinsic

effective focal length, or image plane to projec-

tive center distance,

lens distortion coefficient,

uncertainty scale factor for x , due to TV camera

scanning and acquisition timing error,

computer image coordinate for the origin in the

image plane.

D. Problem Definition

The problem of camera calibration is to compute the camera

intrinsic and extrinsic parameters based on a number of points

whose object coordinates in the (xw, yw, z,) coordinate system

are known and whose image coordinates ( X , Y ) are mea-

sured.

E. The New Two-Stage Camera Calibration Technique:

Motivation

The original basis of the new technique is the following four

observations.

-

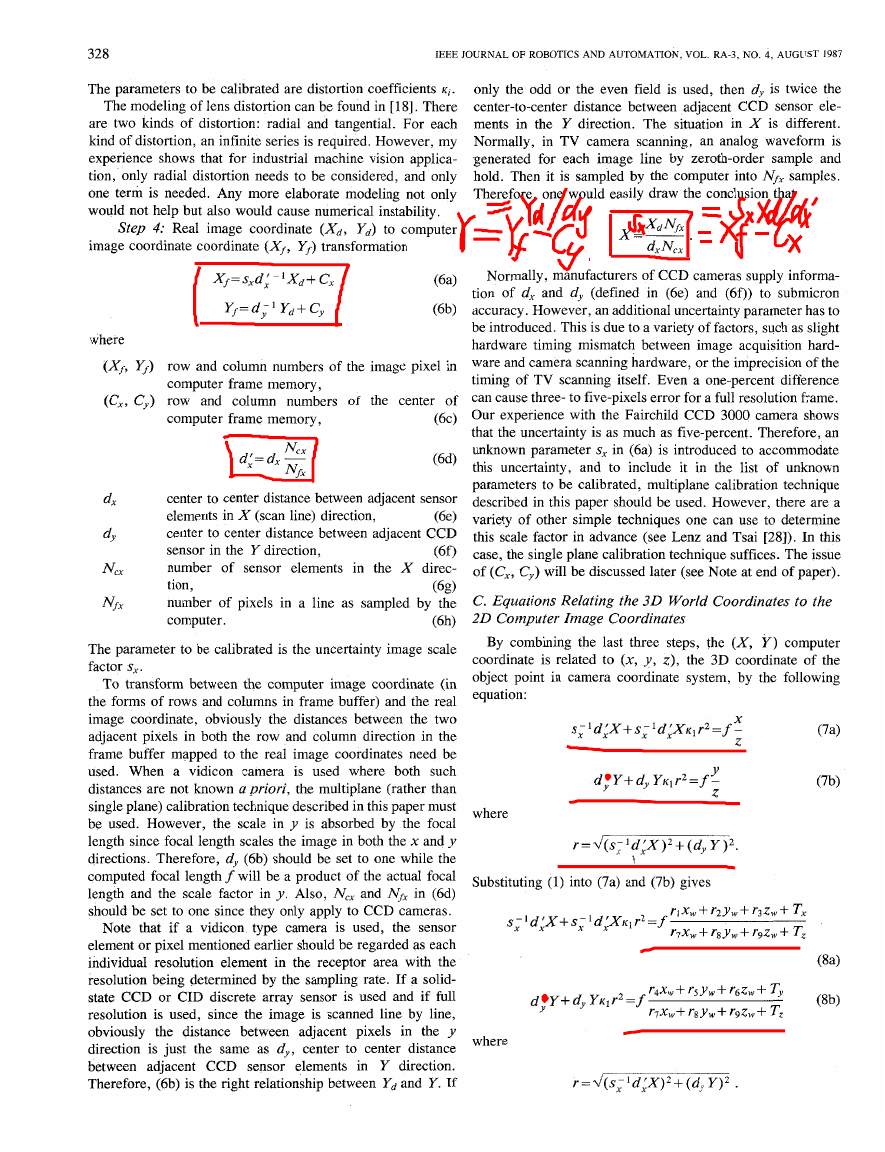

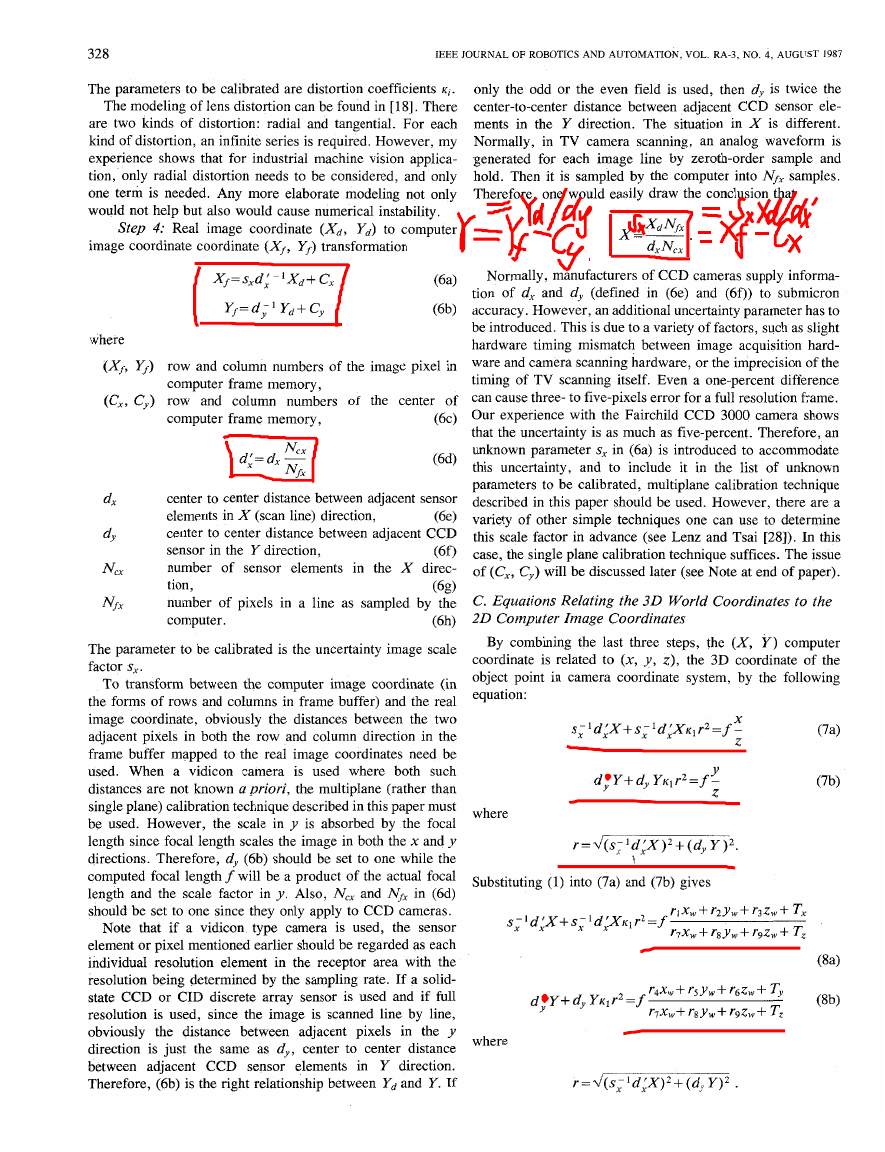

Observation Z: Since we assume that the distortion is

radial, no matter how much the distortion is, the direction of

the vector OiPd extending from the origin oi in the image

plane to the image point (Xd, Yd) - remains unchanged and is

radially aligned with the vector P,,P extending from the

optical axis (or, more precisely, the point Po, on the optical

axis whose z coordinate is the same as that for the object point

( x , y , z ) ) to the object point (x, y, z). This is illustrated in Fig.

3. See Appendix I for a geometric and an algebraic proof of

the radial alignment constraint (RAC).

Observation ZI: The effective focal length f also does not

-

influence the direction of the vector Oipd, since f scales the

image coordinate Xd and Yd by the same rate.

Observation ZIZ: Once the object world coordinate system

is rotated and translated in x and y as in step 1 such that OiPd is

parallel to PozP for every point, then translation in will not

alter the direction of OjPd (this comes from the fact that,

-

-

Among the four observations, the first three are clearly true,

while the last one requires some geometric intuition and

“imagination” to establish its validity. It is possible for the

author to go into further details on how

this intuition was

sufficient for a complete proof.

reached, but it will not be

Rather, the complete proof will be given

analytically in the

next few sections. In fact, as we will see later, not only is the

radial alignment constraint sufficient to determine uniquely the

extrinsic parameters (except for T,) and one of the intrinsic

parameters (s,), but also the computation entails only the

solution of linear equations with five to seven unknowns. This

means it can ‘be done fast and done automatically since no

initial guess, which is

normally required for nonlinear

optimization, is needed.

F. Calibrating a Camera Using a Monoview Coplanar

Set of Points

To aid those readers who intend to implement the proposed

technique in their applications, the presentation will be

algorithm-oriented. The computation procedure for each

individual step will first be given, while the derivation and

other theoretical issues will follow. Most technical details

appear in the Appendices.

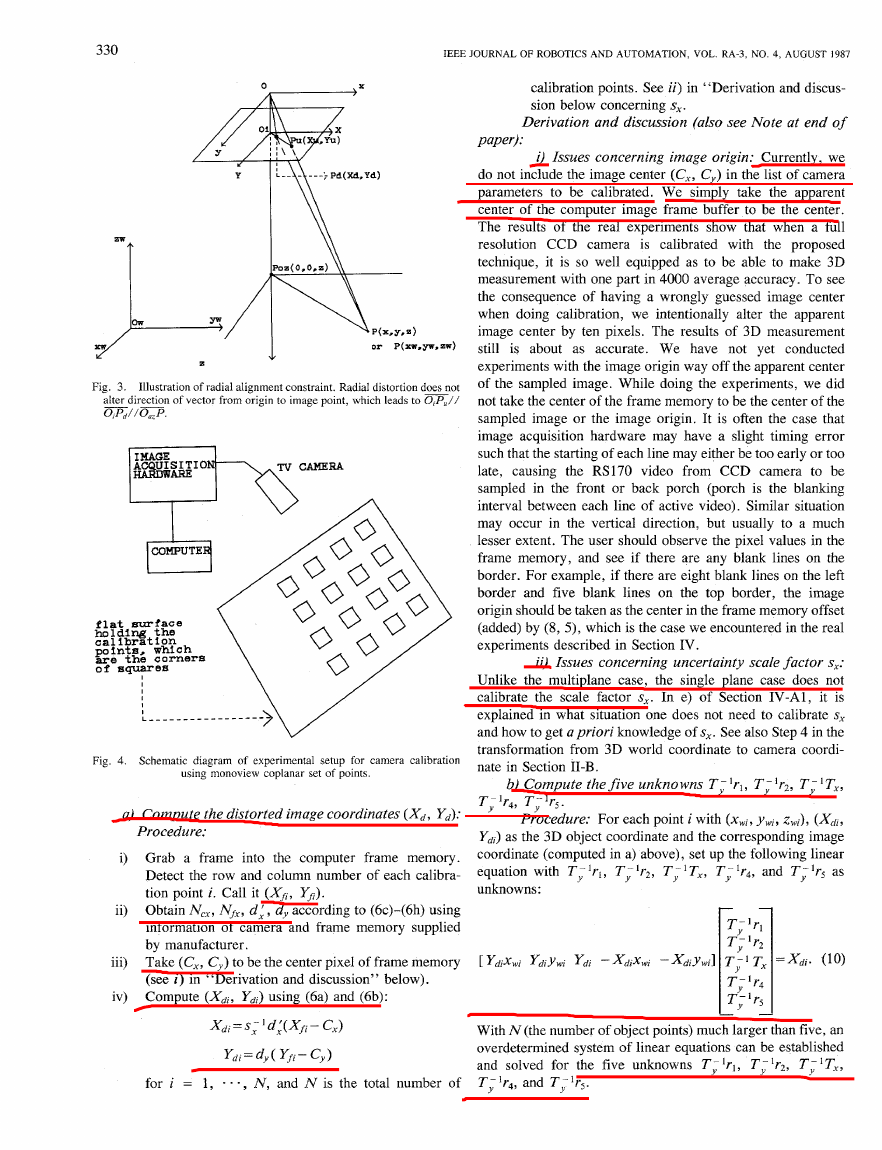

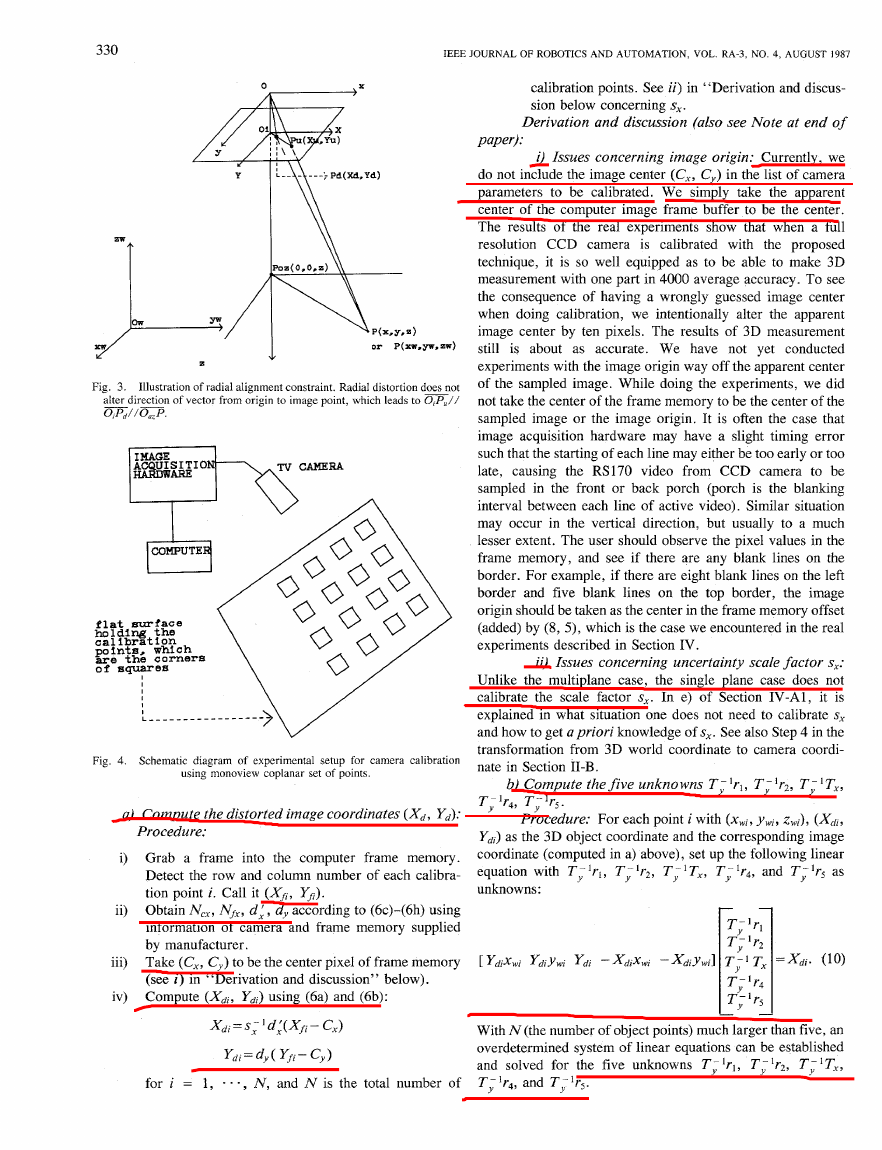

Fig. 4 illustrates the setup for calibrating a camera using a

monoview coplanar set of points. In the actual setup, the plane

illustrated in the figure is the top surface of a metal block. The

detailed description of the physical setup is given in Section

IV-A1. Since the calibration points are on a common plane,

the (xw, yw, z,) coordinate system can be chosen such that zw

= 0 and the origin is not close to the center of the view or y

axis of the camera coordinate system. Since the (xw, y w , z,) is

user-defined and the origin is arbitrary, it is no problem setting

z,) to be out of the field of view and not

the origin of (xw, yw,

close to the y axis. The purpose for the latter is to make sure

that T, is not exactly zero, so that the presentation of the

computation procedure to be described in the following can be

made more unified and simpler. (In case it is zero, it is quite

straightforward to modify the algorithm but is unnecessary

since it can be avoided.)

I ) Stage I-Compute 3D Orientation, Position (x and

Y):

�

/*

O

A

X

330

IEEE JOURNAL OF ROBOTICS AND AUTOMATION, VOL. RA-3, NO. 4, AUGUST 1987

Y

I I \ L . \

--j-\---)Pd(Xd,Yd)

Fig. 3.

Illustration of radial alignment constraint. Radial distortion doesnot

alter direction of vector from origin to image point, which leads to O,P,//

- -

O,P,//O,,P.

flat surface

holding the

calibration

po i nta, whi ch

a r e the cornera

of squares.

I

I

I

I

Fig. 4. Schematic diagram of experimental setup for camera calibration

using monoview coplanar set of points.

a) Compute the distorted image coordinates ( X d , Yd):

Procedure:

i) Grab a frame

into the computer frame memory.

Detect the row and column number of each

tion point i. Call it (Xfi, Yfi).

calibra-

ii) Obtain N,, Nf,, d i , dy according to (6c)-(6h) using

supplied

information of camera and frame memory

by manufacturer.

iii) Take (C,, Cy) to be the center pixel of frame memory

(see i ) in “Derivation and discussion” below).

iv) Compute (Xdi, Ydj) using (6a) and (6b):

X d i = S i d i (X, - c,)

Ydj=dy(Yfj-Cy)

for i = 1, . . . , N, and N is the total number of

calibration points. See ii) in “Derivation and discus-

sion below concerning s,.

Derivation and discussion (also see Note at end of

paper):

i) Issues concerning image origin: Currently, we

do not include the image center (C,, Cy) in the list of camera

parameters to be calibrated. We simply

take the apparent

center of the computer image frame buffer to be the center.

The results of the real experiments show

that when a full

resolution CCD camera is calibrated with the proposed

technique, it is so well equipped as to be able to make 3D

measurement with one part in 4000 average accuracy. To see

the consequence of having a wrongly guessed image center

when doing calibration, we intentionally alter the apparent

image center by ten pixels. The results of 3D measurement

still is about as accurate. We have not yet conducted

experiments with the image origin way off the apparent center

of the sampled image. While doing

the experiments, we did

not take the center of the frame memory to be the center of the

sampled image or the image origin. It is often the case that

image acquisition hardware may have

a slight timing error

such that the starting of each line may either be too early or too

late, causing the RS170 video from CCD camera to be

sampled in

is the blanking

interval between each line of active video). Similar situation

may occur in

to a much

lesser extent. The user should observe the pixel values in the

frame memory, and

see if there are any blank lines on the

border. For example, if there are eight blank lines on the left

border and

five blank lines on the top border, the image

origin should be taken as the center in the frame memory offset

(added) by (8, 5), which is the case we encountered in the real

experiments described in Section IV.

the vertical direction, but usually

the front or back porch (porch

ii) Issues concerning uncertainty scale factor s,:

Unlike the multiplane case, the single plane case does not

calibrate the scale factor s,.

it is

explained in what situation one does not need

to calibrate s,

and how to get apriori knowledge of s,.

See also Step 4 in the

to camera coordi-

transformation from 3D world coordinate

nate in Section 11-B.

b) Compute the five unknowns T;lrl, T;’r2, T;lT,,

In e) of Section IV-A1,

T;lr4, T;’r5.

Procedure: For each point i with (xwj, ywj, zwj), (&i,

Ydj) as the 3D object coordinate and the corresponding image

coordinate (computed in a) above), set up the following linear

equation with

as

unknowns:

T;lrl, T;lr2, T; ‘T,, T;Ir4, and

7:;1

[ Ydjxwi Ydiywj Y d i - x d i x w i

- x d i ~ w i I T; 1 T, =

(10)

With N (the number of object points) much larger than five, an

overdetermined system of linear equations can be established

for the five unknowns T; lrl, T y ‘r2, T i T,,

and solved

T;lr4, and Ty1r5.

�

2023年江西萍乡中考道德与法治真题及答案.doc

2023年江西萍乡中考道德与法治真题及答案.doc 2012年重庆南川中考生物真题及答案.doc

2012年重庆南川中考生物真题及答案.doc 2013年江西师范大学地理学综合及文艺理论基础考研真题.doc

2013年江西师范大学地理学综合及文艺理论基础考研真题.doc 2020年四川甘孜小升初语文真题及答案I卷.doc

2020年四川甘孜小升初语文真题及答案I卷.doc 2020年注册岩土工程师专业基础考试真题及答案.doc

2020年注册岩土工程师专业基础考试真题及答案.doc 2023-2024学年福建省厦门市九年级上学期数学月考试题及答案.doc

2023-2024学年福建省厦门市九年级上学期数学月考试题及答案.doc 2021-2022学年辽宁省沈阳市大东区九年级上学期语文期末试题及答案.doc

2021-2022学年辽宁省沈阳市大东区九年级上学期语文期末试题及答案.doc 2022-2023学年北京东城区初三第一学期物理期末试卷及答案.doc

2022-2023学年北京东城区初三第一学期物理期末试卷及答案.doc 2018上半年江西教师资格初中地理学科知识与教学能力真题及答案.doc

2018上半年江西教师资格初中地理学科知识与教学能力真题及答案.doc 2012年河北国家公务员申论考试真题及答案-省级.doc

2012年河北国家公务员申论考试真题及答案-省级.doc 2020-2021学年江苏省扬州市江都区邵樊片九年级上学期数学第一次质量检测试题及答案.doc

2020-2021学年江苏省扬州市江都区邵樊片九年级上学期数学第一次质量检测试题及答案.doc 2022下半年黑龙江教师资格证中学综合素质真题及答案.doc

2022下半年黑龙江教师资格证中学综合素质真题及答案.doc