M AN687

Precision Temperature-Sensing With RTD Circuits

Author:

Bonnie C. Baker

Microchip Technology Inc.

INTRODUCTION

The most widely measured phenomena in the process

control environment is temperature. Common ele-

ments, such as Resistance Temperature Detectors

(RTDs), thermistors, thermocouples or diodes are used

to sense absolute temperatures, as well as changes in

temperature. For an overview and comparison of these

sensors, refer to Microchip’s AN679, “Temperature-

Sensing Technologies”, DS00679.

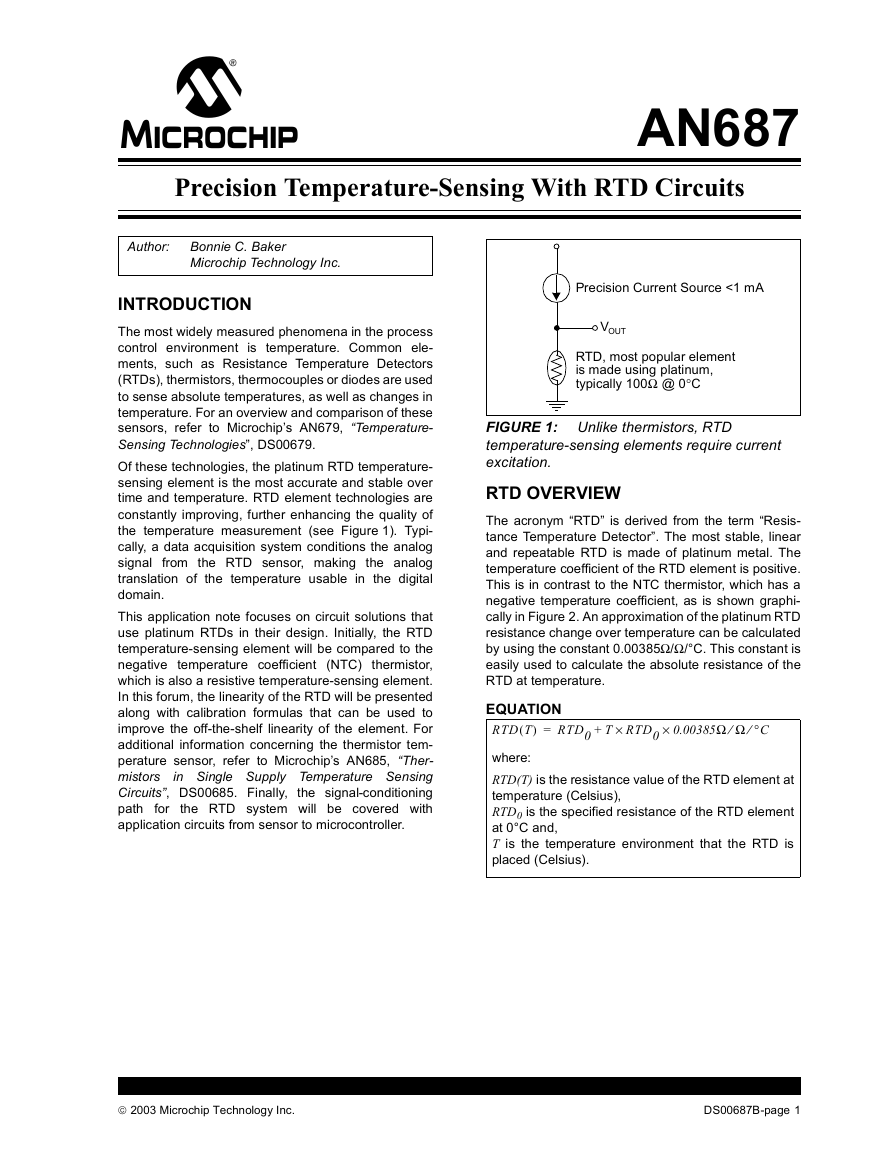

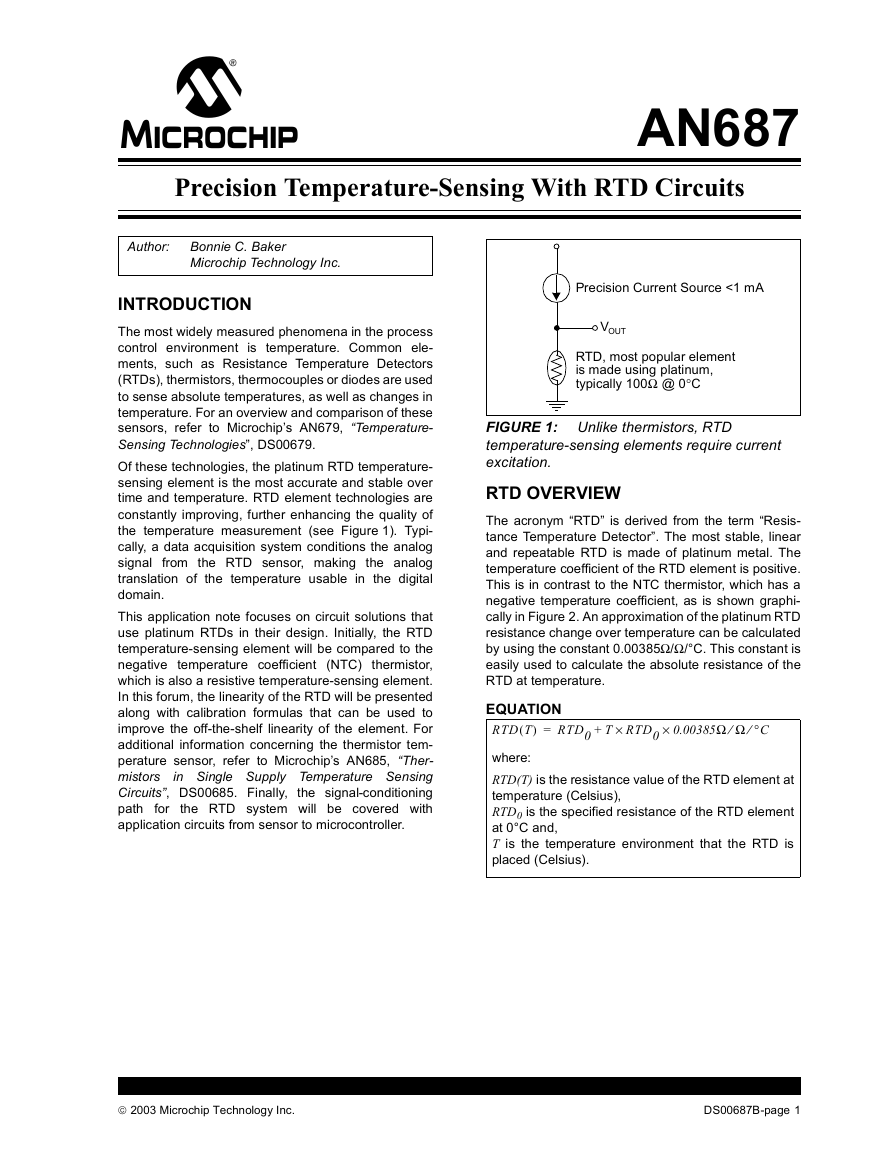

Of these technologies, the platinum RTD temperature-

sensing element is the most accurate and stable over

time and temperature. RTD element technologies are

constantly improving, further enhancing the quality of

the temperature measurement (see Figure 1). Typi-

cally, a data acquisition system conditions the analog

signal from the RTD sensor, making the analog

translation of the temperature usable in the digital

domain.

This application note focuses on circuit solutions that

use platinum RTDs in their design. Initially, the RTD

temperature-sensing element will be compared to the

negative temperature coefficient (NTC) thermistor,

which is also a resistive temperature-sensing element.

In this forum, the linearity of the RTD will be presented

along with calibration formulas that can be used to

improve the off-the-shelf linearity of the element. For

additional information concerning the thermistor tem-

perature sensor, refer to Microchip’s AN685, “Ther-

mistors

in Single Supply Temperature Sensing

Circuits”, DS00685. Finally, the signal-conditioning

path

the RTD system will be covered with

application circuits from sensor to microcontroller.

for

Precision Current Source <1 mA

VOUT

RTD, most popular element

is made using platinum,

typically 100Ω @ 0°C

FIGURE 1: Unlike thermistors, RTD

temperature-sensing elements require current

excitation.

RTD OVERVIEW

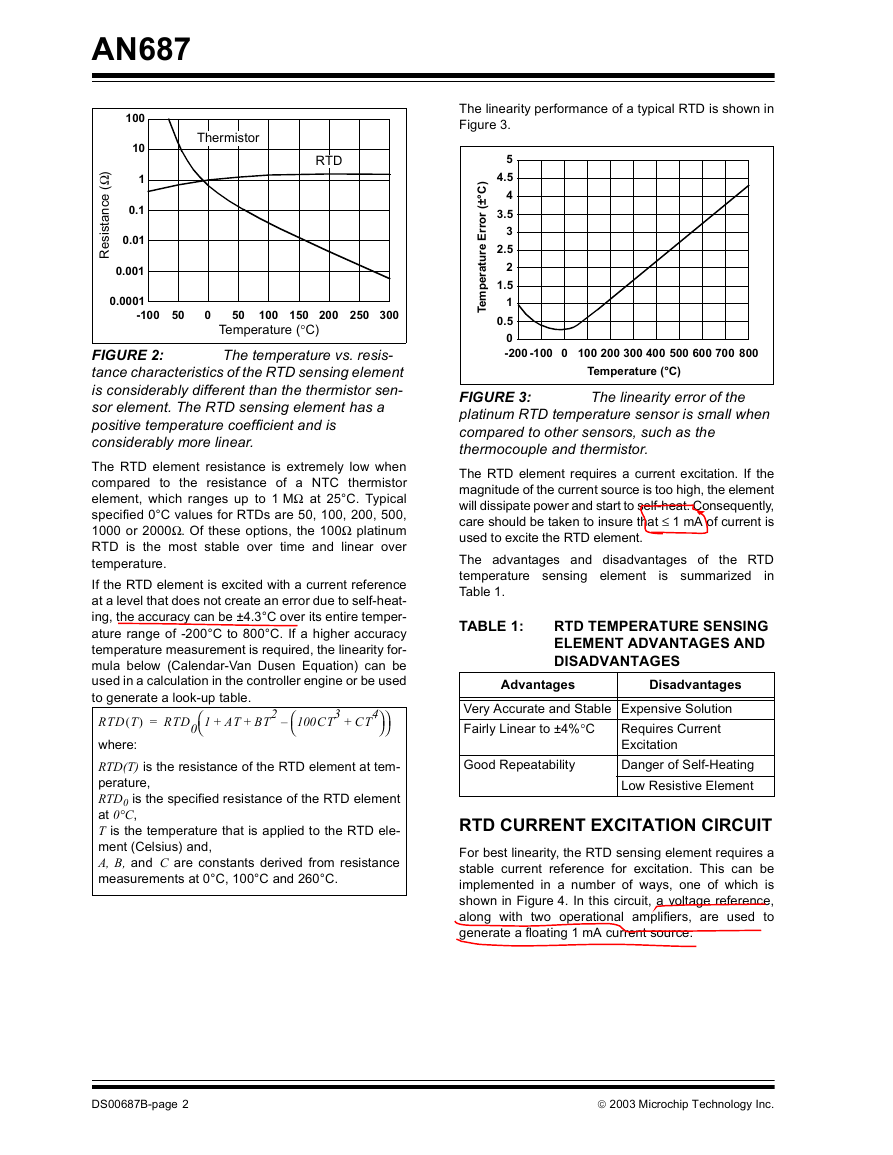

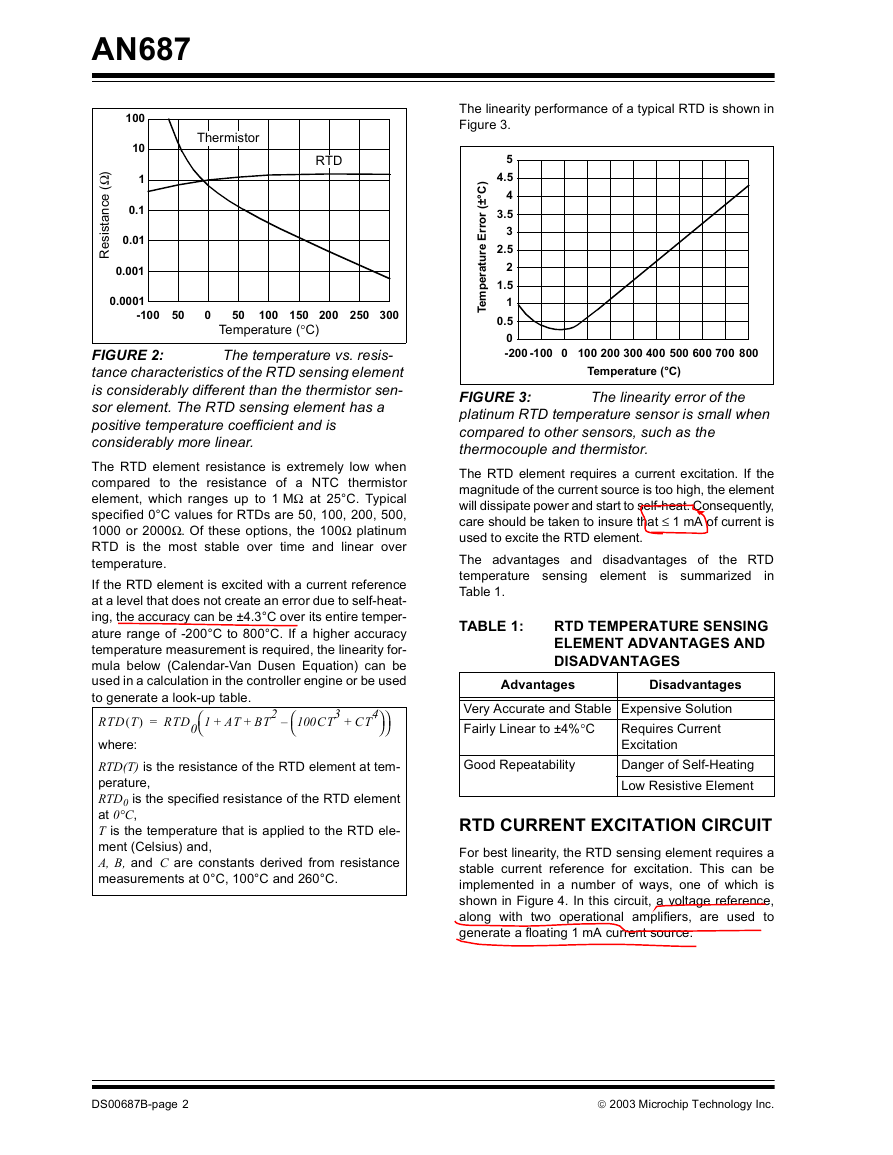

The acronym “RTD” is derived from the term “Resis-

tance Temperature Detector”. The most stable, linear

and repeatable RTD is made of platinum metal. The

temperature coefficient of the RTD element is positive.

This is in contrast to the NTC thermistor, which has a

negative temperature coefficient, as is shown graphi-

cally in Figure 2. An approximation of the platinum RTD

resistance change over temperature can be calculated

by using the constant 0.00385Ω/Ω/°C. This constant is

easily used to calculate the absolute resistance of the

RTD at temperature.

EQUATION

RTD T(

0.00385Ω Ω⁄

°C⁄

=

)

RTD0 T RTD0

+

×

×

where:

RTD(T) is the resistance value of the RTD element at

temperature (Celsius),

RTD0 is the specified resistance of the RTD element

at 0°C and,

T is the temperature environment that the RTD is

placed (Celsius).

2003 Microchip Technology Inc.

DS00687B-page 1

�

AN687

100

10

1

0.1

0.01

0.001

)

Ω

(

e

c

n

a

t

s

s

e

R

i

Thermistor

RTD

0.0001

-100 50

0

50

100 150 200 250 300

Temperature (°C)

The temperature vs. resis-

FIGURE 2:

tance characteristics of the RTD sensing element

is considerably different than the thermistor sen-

sor element. The RTD sensing element has a

positive temperature coefficient and is

considerably more linear.

The RTD element resistance is extremely low when

compared to the resistance of a NTC thermistor

element, which ranges up to 1 MΩ at 25°C. Typical

specified 0°C values for RTDs are 50, 100, 200, 500,

1000 or 2000Ω. Of these options, the 100Ω platinum

RTD is the most stable over time and linear over

temperature.

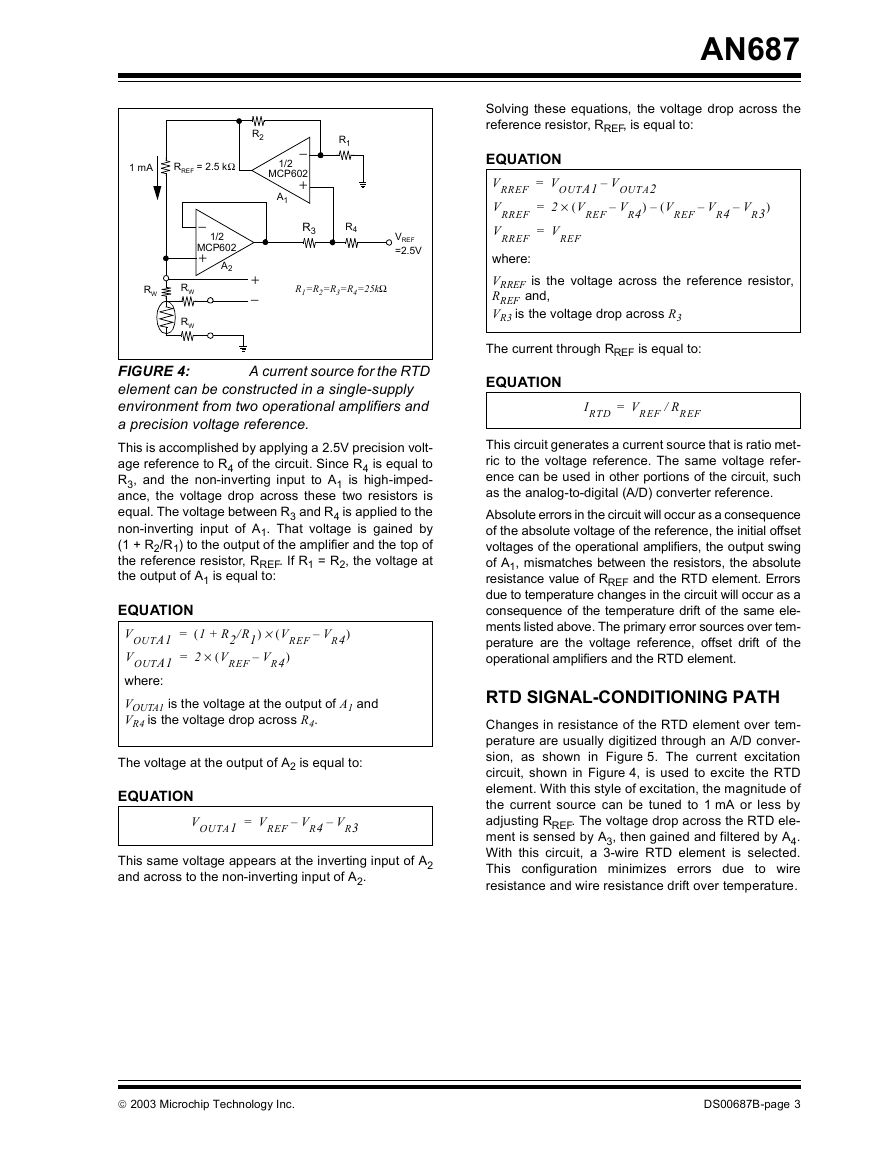

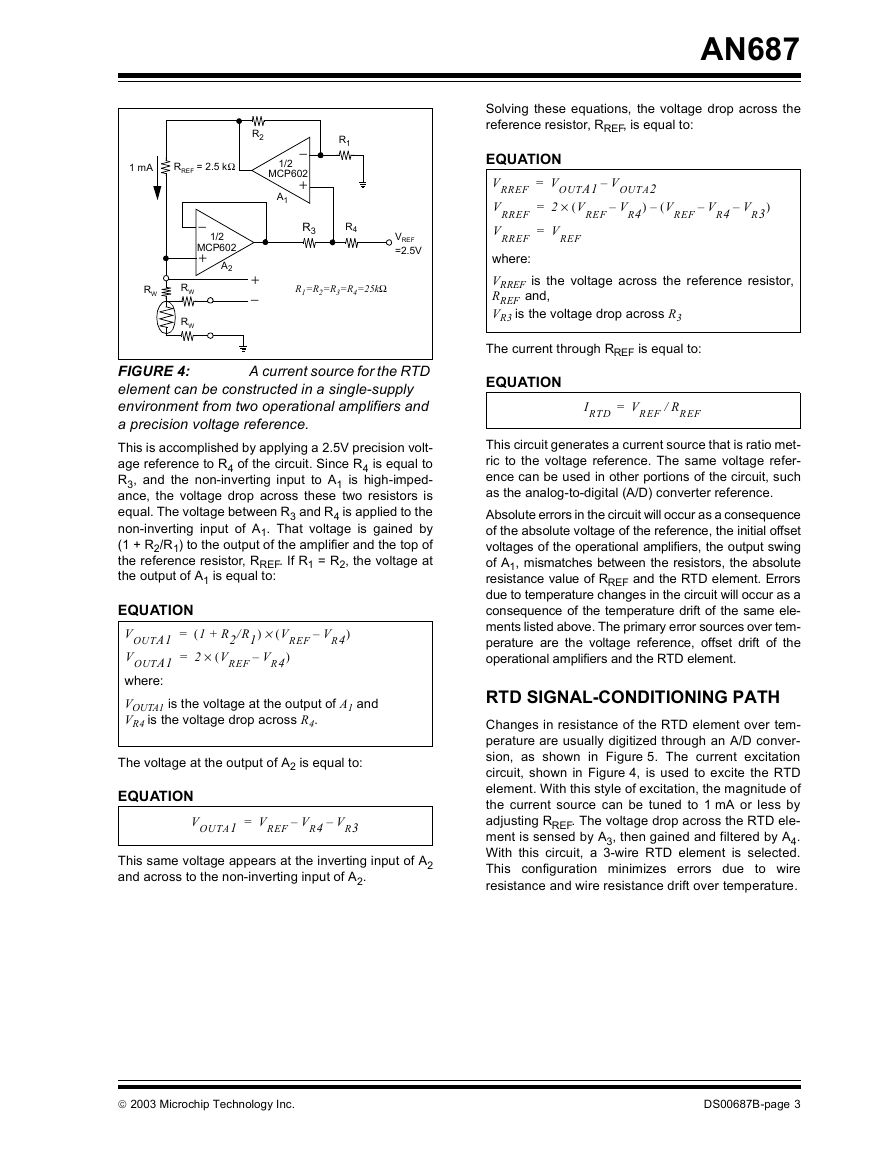

If the RTD element is excited with a current reference

at a level that does not create an error due to self-heat-

ing, the accuracy can be ±4.3°C over its entire temper-

ature range of -200°C to 800°C. If a higher accuracy

temperature measurement is required, the linearity for-

mula below (Calendar-Van Dusen Equation) can be

used in a calculation in the controller engine or be used

to generate a look-up table.

RTD T(

+

where:

RTD(T) is the resistance of the RTD element at tem-

perature,

RTD0 is the specified resistance of the RTD element

at 0°C,

T is the temperature that is applied to the RTD ele-

ment (Celsius) and,

A, B, and C are constants derived from resistance

measurements at 0°C, 100°C and 260°C.

RTD0 1 AT BT2

100CT3 CT4

)

=

+

–

+

The linearity performance of a typical RTD is shown in

Figure 3.

)

C

°

±

(

r

o

r

r

E

e

r

u

t

a

r

e

p

m

e

T

5

4.5

4

3.5

3

2.5

2

1.5

1

0.5

0

-200-100 0 100 200 300 400 500 600 700 800

Temperature (°C)

The linearity error of the

FIGURE 3:

platinum RTD temperature sensor is small when

compared to other sensors, such as the

thermocouple and thermistor.

The RTD element requires a current excitation. If the

magnitude of the current source is too high, the element

will dissipate power and start to self-heat. Consequently,

care should be taken to insure that ≤ 1 mA of current is

used to excite the RTD element.

The advantages and disadvantages of the RTD

temperature sensing element

in

Table 1.

is summarized

TABLE 1:

RTD TEMPERATURE SENSING

ELEMENT ADVANTAGES AND

DISADVANTAGES

Advantages

Disadvantages

Very Accurate and Stable Expensive Solution

Fairly Linear to ±4%°C

Requires Current

Excitation

Danger of Self-Heating

Low Resistive Element

Good Repeatability

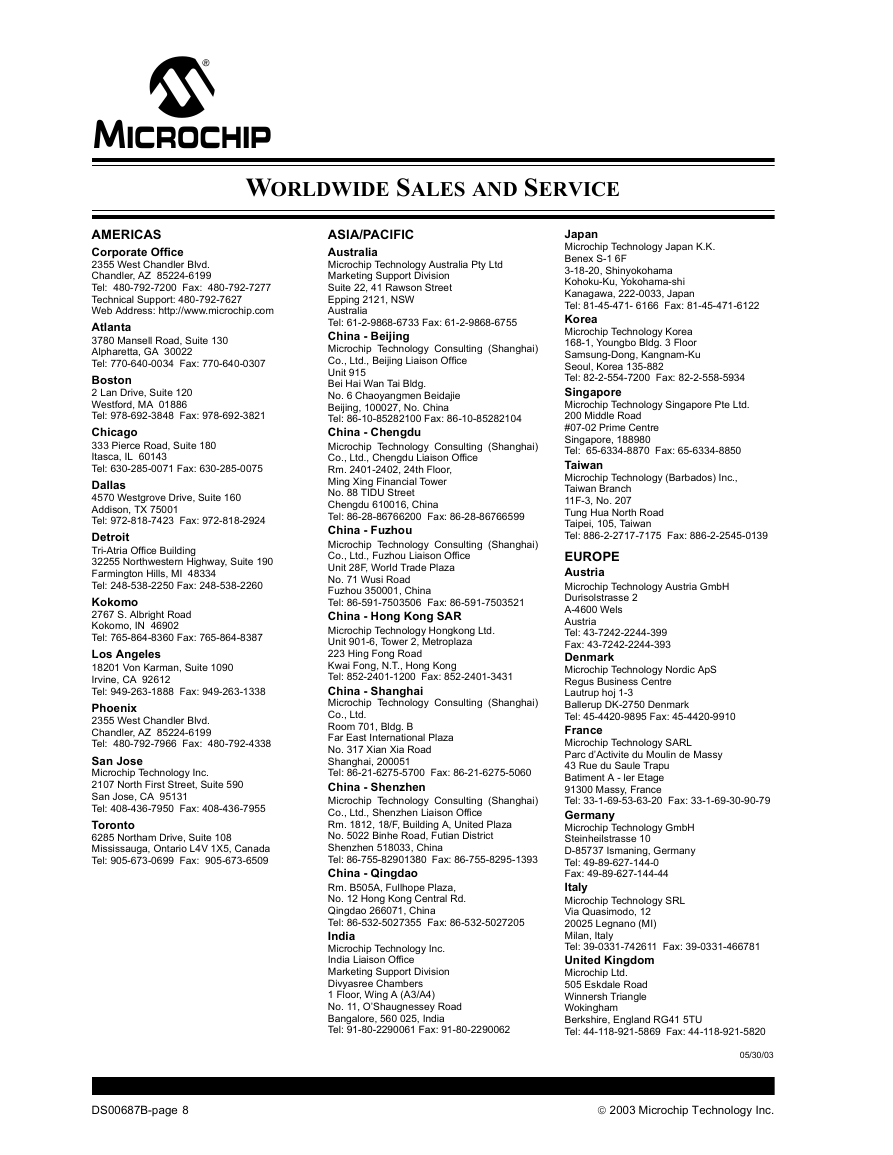

RTD CURRENT EXCITATION CIRCUIT

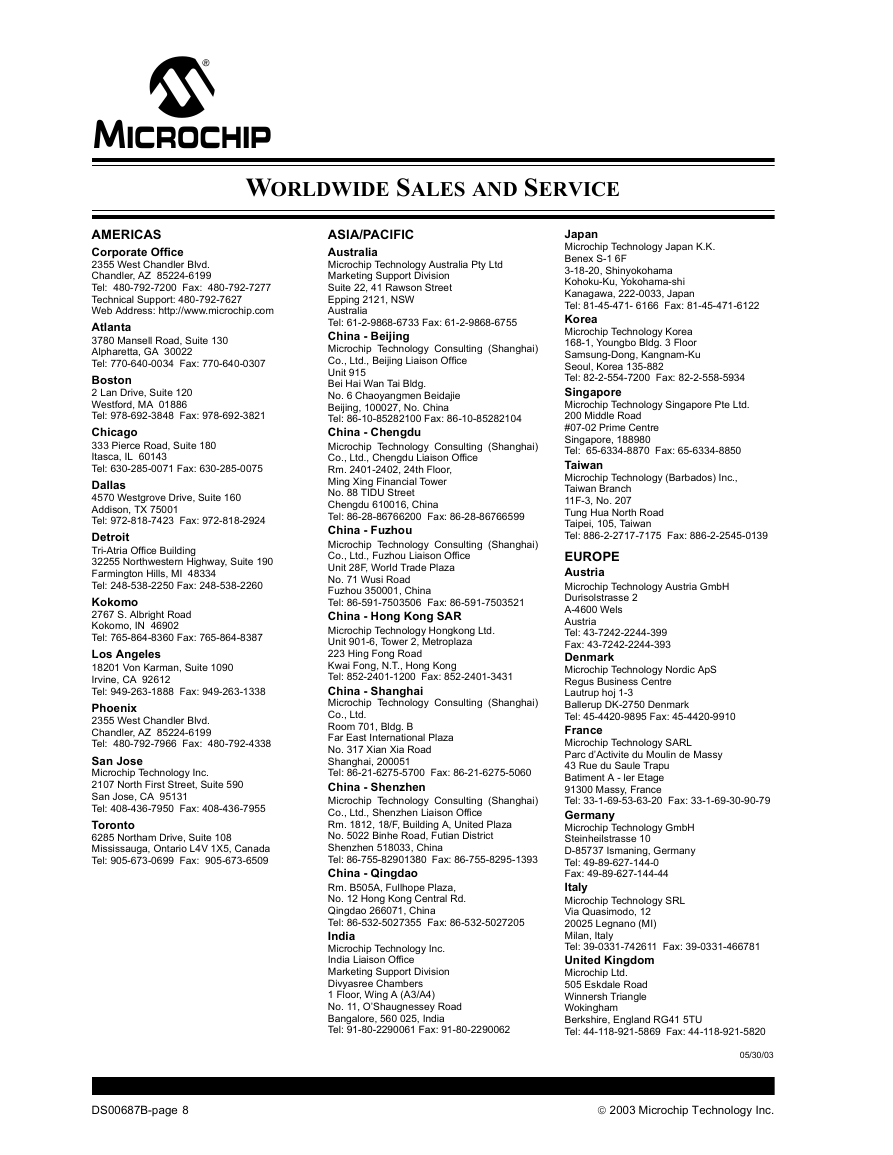

For best linearity, the RTD sensing element requires a

stable current reference for excitation. This can be

implemented in a number of ways, one of which is

shown in Figure 4. In this circuit, a voltage reference,

along with two operational amplifiers, are used to

generate a floating 1 mA current source.

DS00687B-page 2

2003 Microchip Technology Inc.

�

R2

+

−

1 mA

RREF = 2.5 kΩ

1/2

−

MCP602

+

A2

RW

RW

RW

R1

1/2

−

MCP602

+

A1

R3

R4

VREF

=2.5V

R1=R2=R3=R4=25kΩ

A current source for the RTD

FIGURE 4:

element can be constructed in a single-supply

environment from two operational amplifiers and

a precision voltage reference.

This is accomplished by applying a 2.5V precision volt-

age reference to R4 of the circuit. Since R4 is equal to

R3, and the non-inverting input to A1 is high-imped-

ance, the voltage drop across these two resistors is

equal. The voltage between R3 and R4 is applied to the

non-inverting input of A1. That voltage is gained by

(1 + R2/R1) to the output of the amplifier and the top of

the reference resistor, RREF. If R1 = R2, the voltage at

the output of A1 is equal to:

)

+(

1 R2/R1

(

×

2

–

(

×

VREF VR4

EQUATION

=

VOUTA1

=

VOUTA1

where:

VOUTA1 is the voltage at the output of A1 and

VR4 is the voltage drop across R4.

VREF VR4

)

–

)

The voltage at the output of A2 is equal to:

EQUATION

VOUTA1

=

VREF VR4

–

–

VR3

This same voltage appears at the inverting input of A2

and across to the non-inverting input of A2.

AN687

Solving these equations, the voltage drop across the

reference resistor, RREF, is equal to:

(

–

–

=

=

=

VREF VR4

VOUTA1 VOUTA2

×

)

(

2

–

VREF

EQUATION

VRREF

VRREF

VRREF

where:

VRREF is the voltage across the reference resistor,

RREF and,

VR3 is the voltage drop across R3

VREF VR4

VR3

–

–

)

The current through RREF is equal to:

EQUATION

IRTD

=

VREF / RREF

This circuit generates a current source that is ratio met-

ric to the voltage reference. The same voltage refer-

ence can be used in other portions of the circuit, such

as the analog-to-digital (A/D) converter reference.

Absolute errors in the circuit will occur as a consequence

of the absolute voltage of the reference, the initial offset

voltages of the operational amplifiers, the output swing

of A1, mismatches between the resistors, the absolute

resistance value of RREF and the RTD element. Errors

due to temperature changes in the circuit will occur as a

consequence of the temperature drift of the same ele-

ments listed above. The primary error sources over tem-

perature are the voltage reference, offset drift of the

operational amplifiers and the RTD element.

RTD SIGNAL-CONDITIONING PATH

Changes in resistance of the RTD element over tem-

perature are usually digitized through an A/D conver-

sion, as shown in Figure 5. The current excitation

circuit, shown in Figure 4, is used to excite the RTD

element. With this style of excitation, the magnitude of

the current source can be tuned to 1 mA or less by

adjusting RREF. The voltage drop across the RTD ele-

ment is sensed by A3, then gained and filtered by A4.

With this circuit, a 3-wire RTD element is selected.

This configuration minimizes errors due to wire

resistance and wire resistance drift over temperature.

2003 Microchip Technology Inc.

DS00687B-page 3

�

AN687

R

A1

1/4

−

MCP602

+

R

Current

Generator

Circuit

1 mA

RREF = 2.5 kΩ

VREF = 2.5V

1/4

A2

−

MCP602

+

R1=100 kΩ

R

R

R2 = 100 kΩ

1/4

A3

−

MCP604

+

R3

R4

C4

R5

C3

1/4

A4

+

MCP604

−

R6

RW1

RW2

RW2

VIN

,

)

D

T

R

0

0

1

T

P

C

°

0

@

Ω

0

0

1

(

8

0

5

C

2

1

C

P

I

VREF

+IN

–IN

VSS

MCP3201

FIGURE 5:

This circuit uses a RTD temperature-sensitive element to measure temperatures from

-200°C to 600°C. The current generator circuit from Figure 4 excites the sensor. An operational amplifier

(A3) is used to zero wire resistance error. A fourth amplifier (A4) is used to gain the signal and filter possible

alias interference. A 12-bit converter (MCP3201) converts the voltage across the RTD to digital code for the

8-pin controller (PIC12C508).

DS00687B-page 4

2003 Microchip Technology Inc.

�

AN687

Technologies”,

“Temperature Sensing

REFERENCES

AN679,

DS00679, Baker, Bonnie, Microchip Technology Inc.

“Practical Temperature Measurements”, OMEGA

CATALOG, pg Z-11

AN684, “Single-Supply Temperature Sensing with

Thermocouples”, DS00684, Baker, Bonnie, Microchip

Technology Inc.

AN682, “Using Operational Amplifiers for Analog Gain

in Embedded System Design”, DS00682, Baker, Bon-

nie, Microchip Technology Inc.

AN685, “Thermistors in Single-Supply Temperature-

Sensing Circuits”, DS00685, Baker, Bonnie, Microchip

Technology Inc.

“Evaluating Thin Film RTD Stability”, SENSORS, Hyde,

Darrell, OCT. 1997, pg 79

“Refresher on Resistance Temperature Devices”,

Madden, J.R., SENSORS, Sept., 1997, pg 66

“Producing Higher Accuracy From SPRTs (Standard

Platinum Resistance Thermometer)”, MEASUREMENT

& CONTROL, Li, Xumo, June, 1996, pg118

In this circuit, the RTD element equals 100Ω at 0°C. If

the RTD is used to sense temperature over its entire

range of -200°C to 600°C, the range of resistance pro-

duced by the RTD would be nominally 23Ω to 331Ω.

Since the resistance range is relatively low, wire resis-

tance and wire resistance change over temperature can

skew the measurement of the RTD element. Conse-

quently, a 3-wire RTD device is used to reduce these

errors.

The errors contributed by the wire resistances, RW1

and RW3, are subtracted from the circuit with A3, the

operational amplifier circuit. In this configuration, R1

and R2 are equal and are relatively high. The value of

R3 is selected to ensure that the leakage currents

through the resistor do not introduce errors to the cur-

rent in the RTD element. The transfer function of this

portion of the circuit is:

(

)

VIN Vw1

–

) 1 R2/ R1

+(

) VIN R2/R1

–

EQUATION

(

VOUTA3

=

where:

VIN = VW1+VRTD+VW3,

VWx is the voltage drop across the wires to and from

the RTD and

VOUTA3 is the voltage at the output of A3.

If it is assumed that

R1 = R2 and RW1 = RW3

the transfer function above reduces to:

VOUTA3 = VRTD

The voltage signal at the output of A3 is filtered with a

2nd order, low pass filter created with A4, R3, C3, R4 and

C4. This same signal is also gained by the resistors R5

and R6.

CONCLUSION

Although the RTD requires more circuitry in the signal-

conditioning path than the thermistor or the silicon tem-

perature sensor, it ultimately provides a high-precision,

relatively linear result over a wider temperature range.

If further linearization is performed in the controller, the

RTD circuit can achieve ±0.01°C accuracy.

2003 Microchip Technology Inc.

DS00687B-page 5

�

AN687

NOTES:

DS00687B-page 6

2003 Microchip Technology Inc.

�

Note the following details of the code protection feature on Microchip devices:

•

Microchip products meet the specification contained in their particular Microchip Data Sheet.

•

•

•

•

Microchip believes that its family of products is one of the most secure families of its kind on the market today, when used in the

intended manner and under normal conditions.

There are dishonest and possibly illegal methods used to breach the code protection feature. All of these methods, to our

knowledge, require using the Microchip products in a manner outside the operating specifications contained in Microchip's Data

Sheets. Most likely, the person doing so is engaged in theft of intellectual property.

Microchip is willing to work with the customer who is concerned about the integrity of their code.

Neither Microchip nor any other semiconductor manufacturer can guarantee the security of their code. Code protection does not

mean that we are guaranteeing the product as “unbreakable.”

Code protection is constantly evolving. We at Microchip are committed to continuously improving the code protection features of our

products. Attempts to break microchip’s code protection feature may be a violation of the Digital Millennium Copyright Act. If such acts

allow unauthorized access to your software or other copyrighted work, you may have a right to sue for relief under that Act.

Information contained in this publication regarding device

applications and the like is intended through suggestion only

and may be superseded by updates. It is your responsibility to

ensure that your application meets with your specifications.

No representation or warranty is given and no liability is

assumed by Microchip Technology Incorporated with respect

to the accuracy or use of such information, or infringement of

patents or other intellectual property rights arising from such

use or otherwise. Use of Microchip’s products as critical

components in life support systems is not authorized except

with express written approval by Microchip. No licenses are

conveyed, implicitly or otherwise, under any intellectual

property rights.

Trademarks

The Microchip name and logo, the Microchip logo, dsPIC,

KEELOQ, MPLAB, PIC, PICmicro, PICSTART, PRO MATE and

PowerSmart are registered trademarks of Microchip

Technology Incorporated in the U.S.A. and other countries.

FilterLab, microID, MXDEV, MXLAB, PICMASTER, SEEVAL

and The Embedded Control Solutions Company are

registered trademarks of Microchip Technology Incorporated

in the U.S.A.

Accuron, Application Maestro, dsPICDEM, dsPICDEM.net,

ECONOMONITOR, FanSense, FlexROM, fuzzyLAB, In-

Circuit Serial Programming, ICSP, ICEPIC, microPort,

Migratable Memory, MPASM, MPLIB, MPLINK, MPSIM,

PICC, PICkit, PICDEM, PICDEM.net, PowerCal, PowerInfo,

PowerMate, PowerTool, rfLAB, rfPIC, Select Mode,

SmartSensor, SmartShunt, SmartTel and Total Endurance are

trademarks of Microchip Technology Incorporated in the

U.S.A. and other countries.

Serialized Quick Turn Programming (SQTP) is a service mark

of Microchip Technology Incorporated in the U.S.A.

All other trademarks mentioned herein are property of their

respective companies.

© 2003, Microchip Technology Incorporated, Printed in the

U.S.A., All Rights Reserved.

Printed on recycled paper.

Microchip received QS-9000 quality system

certification for its worldwide headquarters,

design and wafer fabrication facilities in

Chandler and Tempe, Arizona in July 1999

and Mountain View, California in March 2002.

The Company’s quality system processes and

procedures are QS-9000 compliant for its

PICmicro® 8-bit MCUs, KEELOQ® code hopping

devices, Serial EEPROMs, microperipherals,

non-volatile memory and analog products. In

addition, Microchip’s quality system for the

design and manufacture of development

systems is ISO 9001 certified.

2003 Microchip Technology Inc.

DS00687B-page 7

�

M

WORLDWIDE SALES AND SERVICE

AMERICAS

Corporate Office

2355 West Chandler Blvd.

Chandler, AZ 85224-6199

Tel: 480-792-7200 Fax: 480-792-7277

Technical Support: 480-792-7627

Web Address: http://www.microchip.com

Atlanta

3780 Mansell Road, Suite 130

Alpharetta, GA 30022

Tel: 770-640-0034 Fax: 770-640-0307

Boston

2 Lan Drive, Suite 120

Westford, MA 01886

Tel: 978-692-3848 Fax: 978-692-3821

Chicago

333 Pierce Road, Suite 180

Itasca, IL 60143

Tel: 630-285-0071 Fax: 630-285-0075

Dallas

4570 Westgrove Drive, Suite 160

Addison, TX 75001

Tel: 972-818-7423 Fax: 972-818-2924

Detroit

Tri-Atria Office Building

32255 Northwestern Highway, Suite 190

Farmington Hills, MI 48334

Tel: 248-538-2250 Fax: 248-538-2260

Kokomo

2767 S. Albright Road

Kokomo, IN 46902

Tel: 765-864-8360 Fax: 765-864-8387

Los Angeles

18201 Von Karman, Suite 1090

Irvine, CA 92612

Tel: 949-263-1888 Fax: 949-263-1338

Phoenix

2355 West Chandler Blvd.

Chandler, AZ 85224-6199

Tel: 480-792-7966 Fax: 480-792-4338

San Jose

Microchip Technology Inc.

2107 North First Street, Suite 590

San Jose, CA 95131

Tel: 408-436-7950 Fax: 408-436-7955

Toronto

6285 Northam Drive, Suite 108

Mississauga, Ontario L4V 1X5, Canada

Tel: 905-673-0699 Fax: 905-673-6509

ASIA/PACIFIC

Australia

Microchip Technology Australia Pty Ltd

Marketing Support Division

Suite 22, 41 Rawson Street

Epping 2121, NSW

Australia

Tel: 61-2-9868-6733 Fax: 61-2-9868-6755

China - Beijing

Microchip Technology Consulting (Shanghai)

Co., Ltd., Beijing Liaison Office

Unit 915

Bei Hai Wan Tai Bldg.

No. 6 Chaoyangmen Beidajie

Beijing, 100027, No. China

Tel: 86-10-85282100 Fax: 86-10-85282104

China - Chengdu

Microchip Technology Consulting (Shanghai)

Co., Ltd., Chengdu Liaison Office

Rm. 2401-2402, 24th Floor,

Ming Xing Financial Tower

No. 88 TIDU Street

Chengdu 610016, China

Tel: 86-28-86766200 Fax: 86-28-86766599

China - Fuzhou

Microchip Technology Consulting (Shanghai)

Co., Ltd., Fuzhou Liaison Office

Unit 28F, World Trade Plaza

No. 71 Wusi Road

Fuzhou 350001, China

Tel: 86-591-7503506 Fax: 86-591-7503521

China - Hong Kong SAR

Microchip Technology Hongkong Ltd.

Unit 901-6, Tower 2, Metroplaza

223 Hing Fong Road

Kwai Fong, N.T., Hong Kong

Tel: 852-2401-1200 Fax: 852-2401-3431

China - Shanghai

Microchip Technology Consulting (Shanghai)

Co., Ltd.

Room 701, Bldg. B

Far East International Plaza

No. 317 Xian Xia Road

Shanghai, 200051

Tel: 86-21-6275-5700 Fax: 86-21-6275-5060

China - Shenzhen

Microchip Technology Consulting (Shanghai)

Co., Ltd., Shenzhen Liaison Office

Rm. 1812, 18/F, Building A, United Plaza

No. 5022 Binhe Road, Futian District

Shenzhen 518033, China

Tel: 86-755-82901380 Fax: 86-755-8295-1393

China - Qingdao

Rm. B505A, Fullhope Plaza,

No. 12 Hong Kong Central Rd.

Qingdao 266071, China

Tel: 86-532-5027355 Fax: 86-532-5027205

India

Microchip Technology Inc.

India Liaison Office

Marketing Support Division

Divyasree Chambers

1 Floor, Wing A (A3/A4)

No. 11, O’Shaugnessey Road

Bangalore, 560 025, India

Tel: 91-80-2290061 Fax: 91-80-2290062

Japan

Microchip Technology Japan K.K.

Benex S-1 6F

3-18-20, Shinyokohama

Kohoku-Ku, Yokohama-shi

Kanagawa, 222-0033, Japan

Tel: 81-45-471- 6166 Fax: 81-45-471-6122

Korea

Microchip Technology Korea

168-1, Youngbo Bldg. 3 Floor

Samsung-Dong, Kangnam-Ku

Seoul, Korea 135-882

Tel: 82-2-554-7200 Fax: 82-2-558-5934

Singapore

Microchip Technology Singapore Pte Ltd.

200 Middle Road

#07-02 Prime Centre

Singapore, 188980

Tel: 65-6334-8870 Fax: 65-6334-8850

Taiwan

Microchip Technology (Barbados) Inc.,

Taiwan Branch

11F-3, No. 207

Tung Hua North Road

Taipei, 105, Taiwan

Tel: 886-2-2717-7175 Fax: 886-2-2545-0139

EUROPE

Austria

Microchip Technology Austria GmbH

Durisolstrasse 2

A-4600 Wels

Austria

Tel: 43-7242-2244-399

Fax: 43-7242-2244-393

Denmark

Microchip Technology Nordic ApS

Regus Business Centre

Lautrup hoj 1-3

Ballerup DK-2750 Denmark

Tel: 45-4420-9895 Fax: 45-4420-9910

France

Microchip Technology SARL

Parc d’Activite du Moulin de Massy

43 Rue du Saule Trapu

Batiment A - ler Etage

91300 Massy, France

Tel: 33-1-69-53-63-20 Fax: 33-1-69-30-90-79

Germany

Microchip Technology GmbH

Steinheilstrasse 10

D-85737 Ismaning, Germany

Tel: 49-89-627-144-0

Fax: 49-89-627-144-44

Italy

Microchip Technology SRL

Via Quasimodo, 12

20025 Legnano (MI)

Milan, Italy

Tel: 39-0331-742611 Fax: 39-0331-466781

United Kingdom

Microchip Ltd.

505 Eskdale Road

Winnersh Triangle

Wokingham

Berkshire, England RG41 5TU

Tel: 44-118-921-5869 Fax: 44-118-921-5820

05/30/03

DS00687B-page 8

2003 Microchip Technology Inc.

�

2023年江西萍乡中考道德与法治真题及答案.doc

2023年江西萍乡中考道德与法治真题及答案.doc 2012年重庆南川中考生物真题及答案.doc

2012年重庆南川中考生物真题及答案.doc 2013年江西师范大学地理学综合及文艺理论基础考研真题.doc

2013年江西师范大学地理学综合及文艺理论基础考研真题.doc 2020年四川甘孜小升初语文真题及答案I卷.doc

2020年四川甘孜小升初语文真题及答案I卷.doc 2020年注册岩土工程师专业基础考试真题及答案.doc

2020年注册岩土工程师专业基础考试真题及答案.doc 2023-2024学年福建省厦门市九年级上学期数学月考试题及答案.doc

2023-2024学年福建省厦门市九年级上学期数学月考试题及答案.doc 2021-2022学年辽宁省沈阳市大东区九年级上学期语文期末试题及答案.doc

2021-2022学年辽宁省沈阳市大东区九年级上学期语文期末试题及答案.doc 2022-2023学年北京东城区初三第一学期物理期末试卷及答案.doc

2022-2023学年北京东城区初三第一学期物理期末试卷及答案.doc 2018上半年江西教师资格初中地理学科知识与教学能力真题及答案.doc

2018上半年江西教师资格初中地理学科知识与教学能力真题及答案.doc 2012年河北国家公务员申论考试真题及答案-省级.doc

2012年河北国家公务员申论考试真题及答案-省级.doc 2020-2021学年江苏省扬州市江都区邵樊片九年级上学期数学第一次质量检测试题及答案.doc

2020-2021学年江苏省扬州市江都区邵樊片九年级上学期数学第一次质量检测试题及答案.doc 2022下半年黑龙江教师资格证中学综合素质真题及答案.doc

2022下半年黑龙江教师资格证中学综合素质真题及答案.doc