Table of contents

Preface

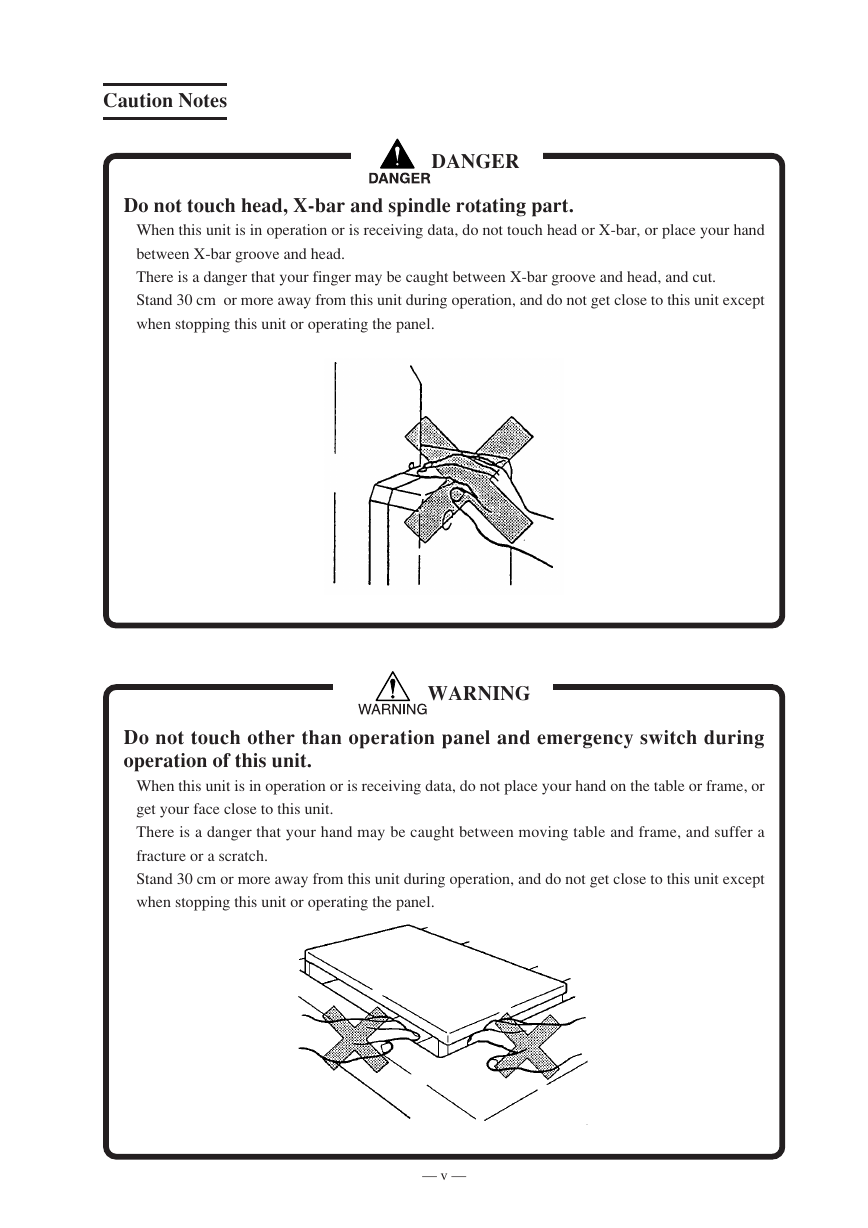

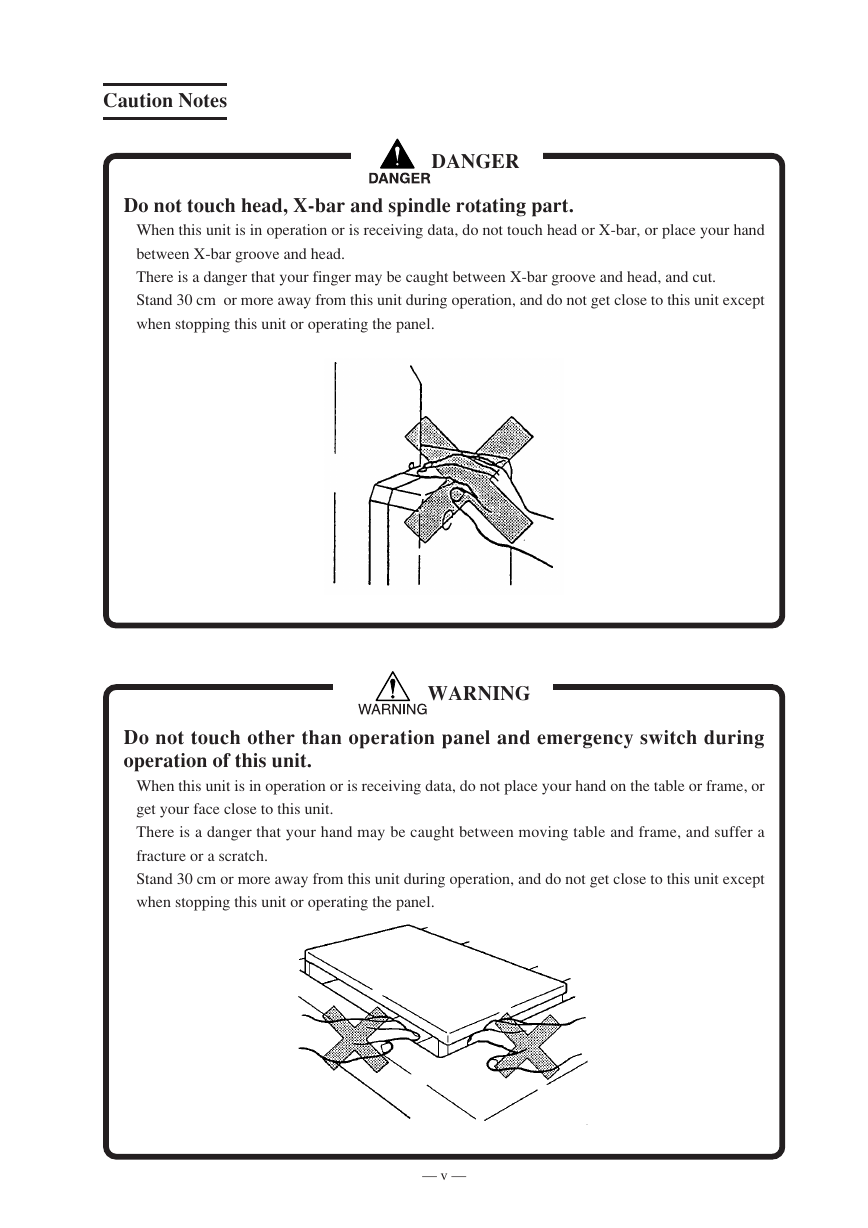

Caution Notes

Spindle Front Cover

Regarding the Safety Label

Daily Maintenance

The Purpose of Use and Features

Definition of Terminology

CHAPTER 1 PREPARATION

Check of Accessories

Names and Functions of Parts of Main unit

Electrical equipment box

Operation Panel

Selecting an Installation Location

Cable Connections

Types of cable

Connecting position of the cable

Power cable connection (to the outlet)

CHAPTER 2 PRIOR TO OPERATION

The Method of Emergency Stop/Emergency Stop Release

The method of emergency stop

Releasing an Emergency Stop

On the Modes

On STOP mode

On START mode

On the received data overwrite function

On the override function

On FUNCTION mode

On FUNCTION mode

List of Operations

CHAPTER 3 BASIC OPERATIONS

Basic operation Procedure

Attachment/Removal of Tool

Name of each part

Procedure for attaching end mill

Removal of end mill

Removing procedure

Turn the Power on/off

The method or power on

The method of power off

Attaching a Workpiece

Type of work

Installing the center vise

Using the plate jig

The method to mount T slot table

Regarding the clamp jig

Mounting of work on the T slot table

Setting of Z Axis Origin

Setting procedure

Setting the X・Y Origin

Setting procedures

Setting the Cut Area

Setting procedure

Cutting Conditions Setting

Guide for cutting conditions

Setting procedure

On Spindle Rotation

Turning spindle rotation on and off

When spindle rotation is on

When spindle rotation is off

Spindle rotation speed adjustment

Checking the rotation of the spindle

CHAPTER 4 PRACTICAL OPERATION AND ADJUSTMENT

Moving the Head

Moving the head

Type or head movement

Viewing

The method to perform VIEW

Setting to the head standby position

Moving to the X.Y Origin

Regarding the Moving Speed

Moving speed or X, Y and Z axis

Arrow keys

Jog dial

Automatic Z Origin Detection

Automatic Z origin detection

Finely Adjusting the X.Y Origin

On the Self-Tests

MIMAKI logo engraving

On Copying

How to copy

Errors that can occur during copying

Data Clear

Clearing Data

Switching the Operation Switches

Command

Communication Conditions Setting

Setting the External I/O Port

IN port (input port)

OUT port (output port)

Setting procedure

ERROR LOG

CHAPTER 5 OCCURRENCE OF ERRORS AND CORRECTIVE MEASURES

Error Messages and Corrective Measures

Error of which error no. is shown on the LCD

Breakers

What to do If There Seems to be Trouble

The unit cannot be powered up.

The cutter fails to come down.

The spindle fails to rotate.

Finished state of engraving is poor in quality.

CHAPTER 6 APPENDIX

Basic Specifications

Modeliong main dimensions

Table of Responding NC Code

Interface Specifications

Specifications for bi-directional parallel interface

2023年江西萍乡中考道德与法治真题及答案.doc

2023年江西萍乡中考道德与法治真题及答案.doc 2012年重庆南川中考生物真题及答案.doc

2012年重庆南川中考生物真题及答案.doc 2013年江西师范大学地理学综合及文艺理论基础考研真题.doc

2013年江西师范大学地理学综合及文艺理论基础考研真题.doc 2020年四川甘孜小升初语文真题及答案I卷.doc

2020年四川甘孜小升初语文真题及答案I卷.doc 2020年注册岩土工程师专业基础考试真题及答案.doc

2020年注册岩土工程师专业基础考试真题及答案.doc 2023-2024学年福建省厦门市九年级上学期数学月考试题及答案.doc

2023-2024学年福建省厦门市九年级上学期数学月考试题及答案.doc 2021-2022学年辽宁省沈阳市大东区九年级上学期语文期末试题及答案.doc

2021-2022学年辽宁省沈阳市大东区九年级上学期语文期末试题及答案.doc 2022-2023学年北京东城区初三第一学期物理期末试卷及答案.doc

2022-2023学年北京东城区初三第一学期物理期末试卷及答案.doc 2018上半年江西教师资格初中地理学科知识与教学能力真题及答案.doc

2018上半年江西教师资格初中地理学科知识与教学能力真题及答案.doc 2012年河北国家公务员申论考试真题及答案-省级.doc

2012年河北国家公务员申论考试真题及答案-省级.doc 2020-2021学年江苏省扬州市江都区邵樊片九年级上学期数学第一次质量检测试题及答案.doc

2020-2021学年江苏省扬州市江都区邵樊片九年级上学期数学第一次质量检测试题及答案.doc 2022下半年黑龙江教师资格证中学综合素质真题及答案.doc

2022下半年黑龙江教师资格证中学综合素质真题及答案.doc