AN1211

Maximum Power Solar Converter

Author:

John Charais

Microchip Technology Inc.

the development of

INTRODUCTION

As the need for remote operation of electronic devices

continues to increase, power for these devices becomes

more of a concern. Remote applications are powered

mostly by batteries that are either recharged or changed

on a regular basis. The more remote the location is, the

bigger the challenge becomes of replacing these

batteries. Since

the modern

photovoltaic cell in 1954, remotely powered applications

that do not have to be serviced became possible.

The focus of this application note is to identify how to

get the maximum power out of a solar panel to power a

remote application. The Maximum Power Point

Converter is essentially a DC-to-DC converter, where

the DC input voltage is a solar panel and the output

voltage is 28 volts. The intent of the converter is to

show how to take the solar panel and generate a

voltage capable of recharging a 24-volt battery.

Although the chemistry of the battery and how to

charge the battery properly are extremely important to

the actual design, these details will not be covered in

this application note. Also associated with

this

application note is a zip file with source code and Excel

spreadsheet.

SOLAR PANELS

Solar Panels are an array of solar cells. The

characteristics of the solar panel are essentially the

same as those of the solar cells, only scaled up in

voltage or current based on the number of solar cells

used and the arrangement of the array. Solar panels

come in a variety of shapes, sizes and efficiencies, but

all have similar characteristics.

A solar panel will generate its maximum voltage when

the panel is in full sunlight with no load. This voltage is

commonly referred to as the open circuit voltage (VOC)

of the panel. As the load of the solar panel increases,

the output voltage of the solar panel will decrease in a

nonlinear fashion until the maximum output current, the

short circuit current (JSC) of the panel, is reached.

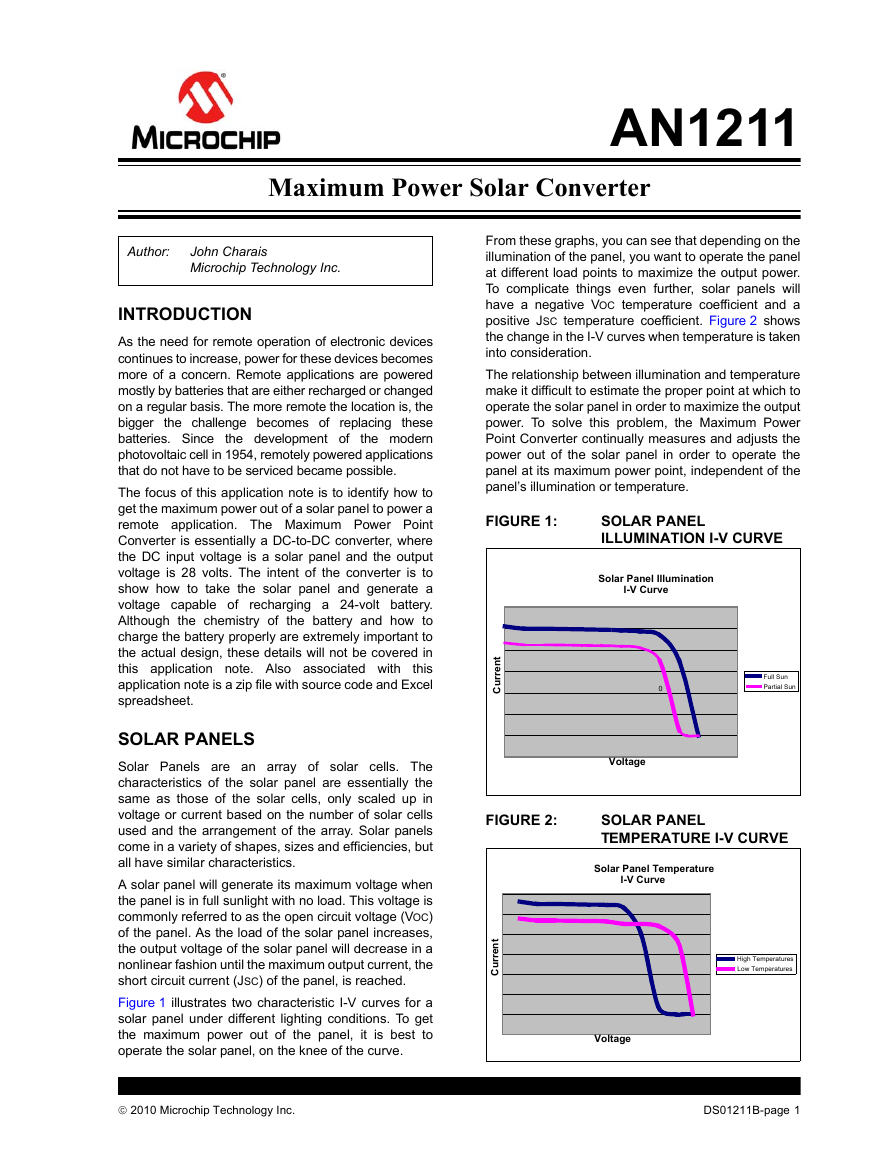

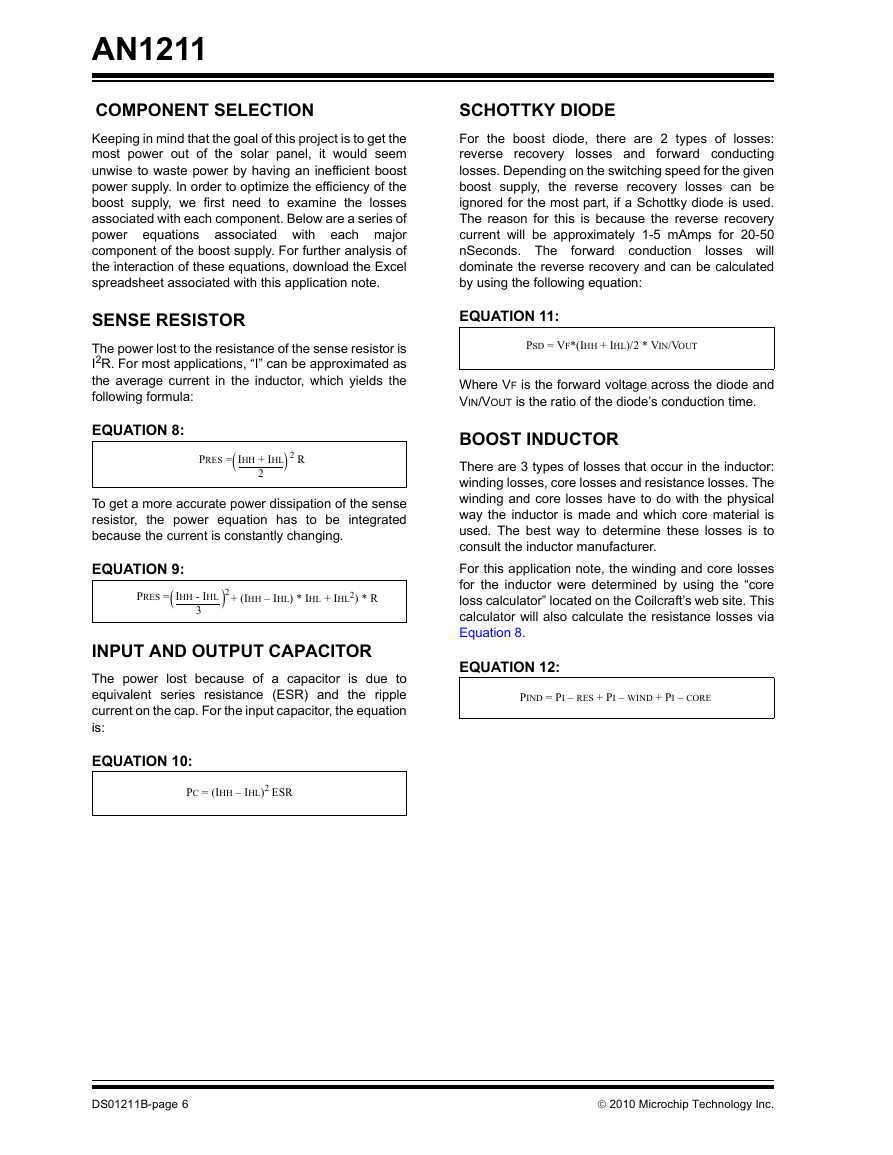

Figure 1 illustrates two characteristic I-V curves for a

solar panel under different lighting conditions. To get

the maximum power out of the panel, it is best to

operate the solar panel, on the knee of the curve.

From these graphs, you can see that depending on the

illumination of the panel, you want to operate the panel

at different load points to maximize the output power.

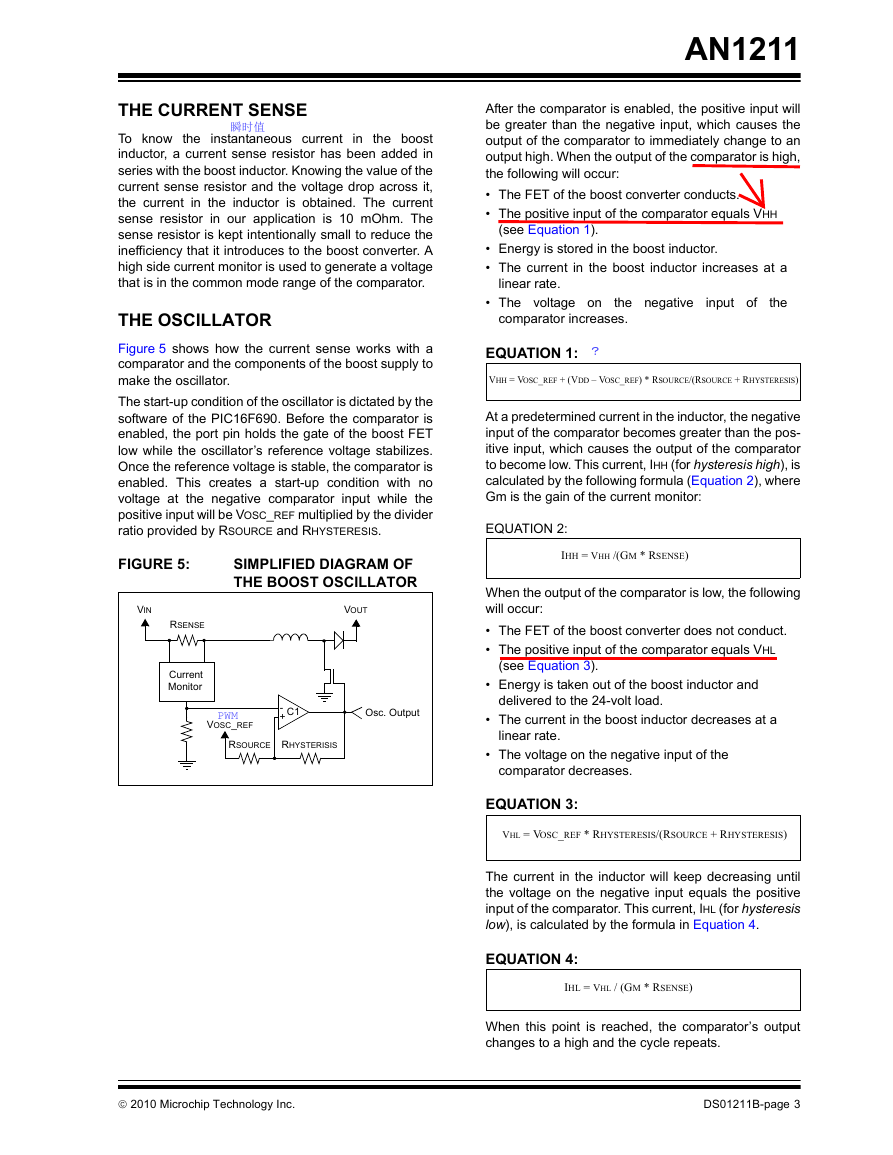

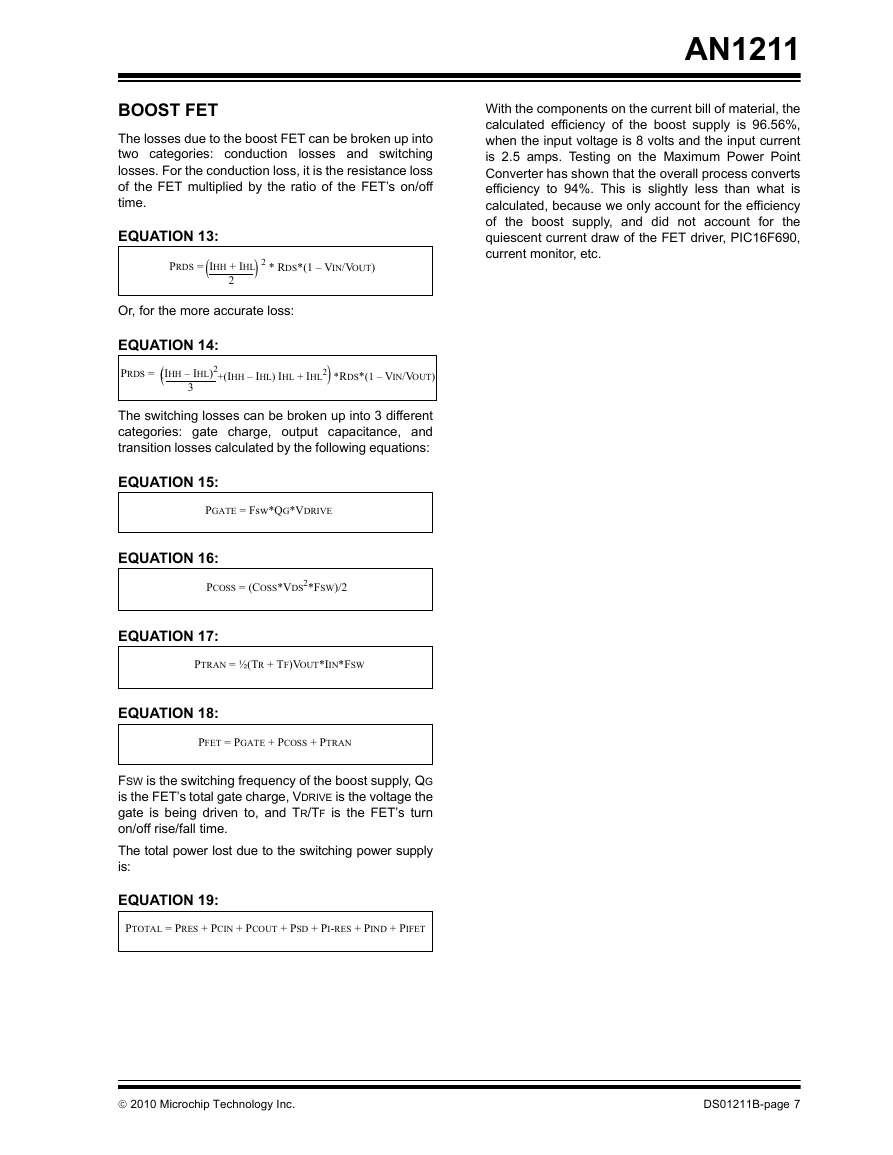

To complicate things even further, solar panels will

have a negative VOC temperature coefficient and a

positive JSC temperature coefficient. Figure 2 shows

the change in the I-V curves when temperature is taken

into consideration.

The relationship between illumination and temperature

make it difficult to estimate the proper point at which to

operate the solar panel in order to maximize the output

power. To solve this problem, the Maximum Power

Point Converter continually measures and adjusts the

power out of the solar panel in order to operate the

panel at its maximum power point, independent of the

panel’s illumination or temperature.

FIGURE 1:

SOLAR PANEL

ILLUMINATION I-V CURVE

Solar Panel Illumination

Voltage

t

n

e

r

r

u

C

Full Sun

0.51

0.5

0.5

0.497

0.495

0.492

0.487

0.47

0.35

0.3

0

0

5

10

20

25

30

35

40

45

47

50

I-V Curve

Partial Sun High Tem Low Temp

0.47685

0.4675

0.4675

0.5467 0.464695

0.5445 0.462825

0.4505

0.45

0.44

0.38

0.28

0

0.4335

0.425

0.425

0.42245

0.42075

0.4182

0.41

0.35

0.025

0

0

0.561

0.55

0.55

0.53

0.4

0.035

0

0

0

Full Sun

Partial Sun

Voltage

FIGURE 2:

SOLAR PANEL

TEMPERATURE I-V CURVE

Solar Panel Temperature

I-V Curve

t

n

e

r

r

u

C

High Temperatures

Low Temperatures

Voltage

2010 Microchip Technology Inc.

DS01211B-page 1

�

AN1211

OVERVIEW

For this project we will be using a 10-volt open circuit

solar panel with a short circuit current of 2.5 amps. With

an open circuit voltage of 10 volts, a boost converter is

needed to charge the 24-volt battery. See Figure 3.

FIGURE 3:

BOOST CONVERTER

Solar

Panel

Battery

To get the solar panel to operate at its maximum power

point, there are a few items needed. First, in order to

know the output power of the solar panel, both the

current and voltage of the solar panel have to be

monitored. This will be accomplished by a high side

current monitor and simple resistor divider on the solar

panel’s output voltage. There also needs to be a way to

control the output power of the solar panel. This is done

by manipulating the panel’s output current. And lastly,

a software algorithm is needed to know which way to

manipulate the current (e.g., whether the current out of

the solar panel should be increased or decreased).

To make the Maximum Power Point Converter work,

the functions of the boost converter need to be merged

with the solar panel’s output load. The boost converter

is either storing current in the boost inductor (switch

closed) or it is delivering current from the boost inductor

to the load (switch opened). When the boost inductor is

storing current, the current comes from the solar panel.

In essence, the boost inductor is the solar panel’s load.

By making the current stored in the boost inductor

programmable, the load of the solar panel becomes

programmable. This is the principal on how the

Maximum Power Point Converter works. The Maximum

Power Point Converter combines a boost converter, a

programmable current oscillator and a software

algorithm to maximize the power out of a solar panel.

HARDWARE OVERVIEW

Figure 4 shows the block diagram of the Maximum

Power Point Converter.

FIGURE 4:

MAXIMUM POWER POINT CONVERTER

Solar Panel

Current Sense

Boost Supply

Output

Voltage Sense

Oscillator

Max Power

Algorithm

Programmable

Voltage Reference

Over-Voltage

Protection

PIC16F690

DS01211B-page 2

2010 Microchip Technology Inc.

�

THE CURRENT SENSE

To know the instantaneous current in the boost

inductor, a current sense resistor has been added in

series with the boost inductor. Knowing the value of the

current sense resistor and the voltage drop across it,

the current in the inductor is obtained. The current

sense resistor in our application is 10 mOhm. The

sense resistor is kept intentionally small to reduce the

inefficiency that it introduces to the boost converter. A

high side current monitor is used to generate a voltage

that is in the common mode range of the comparator.

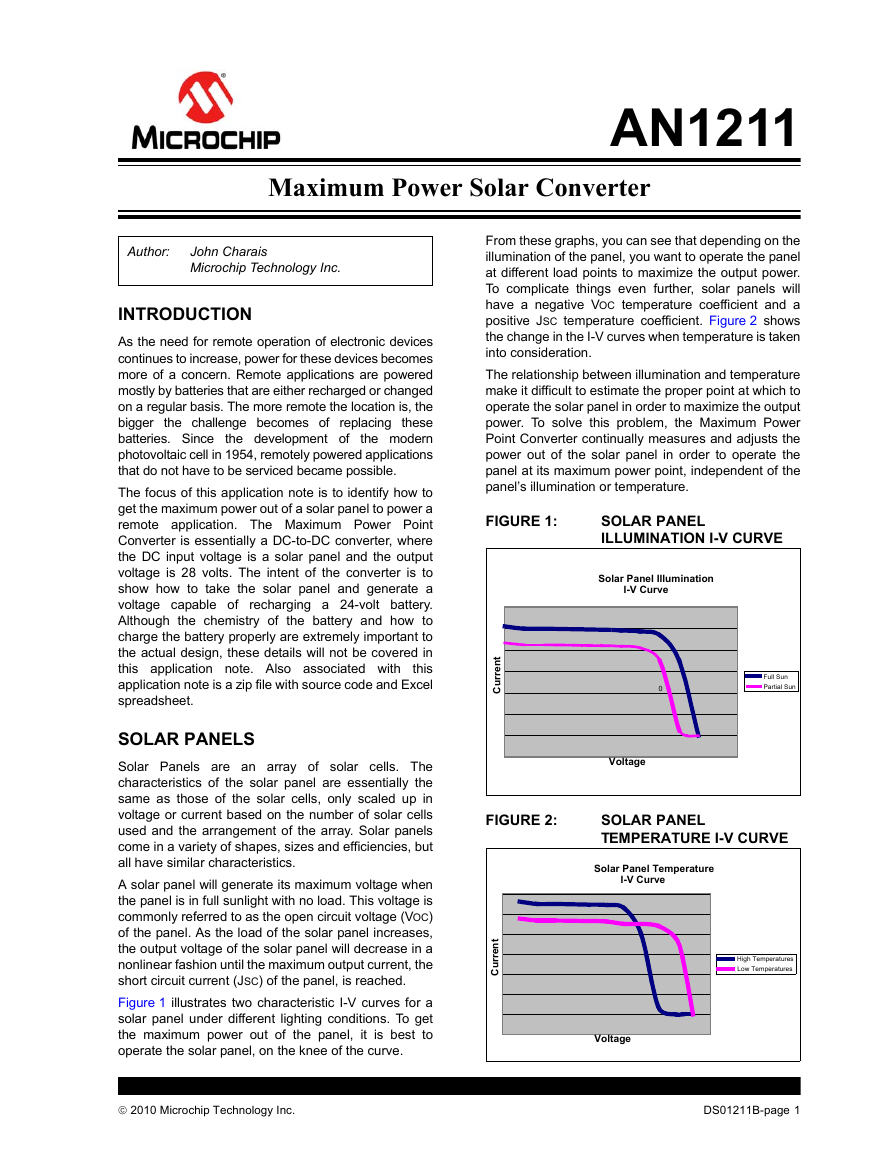

THE OSCILLATOR

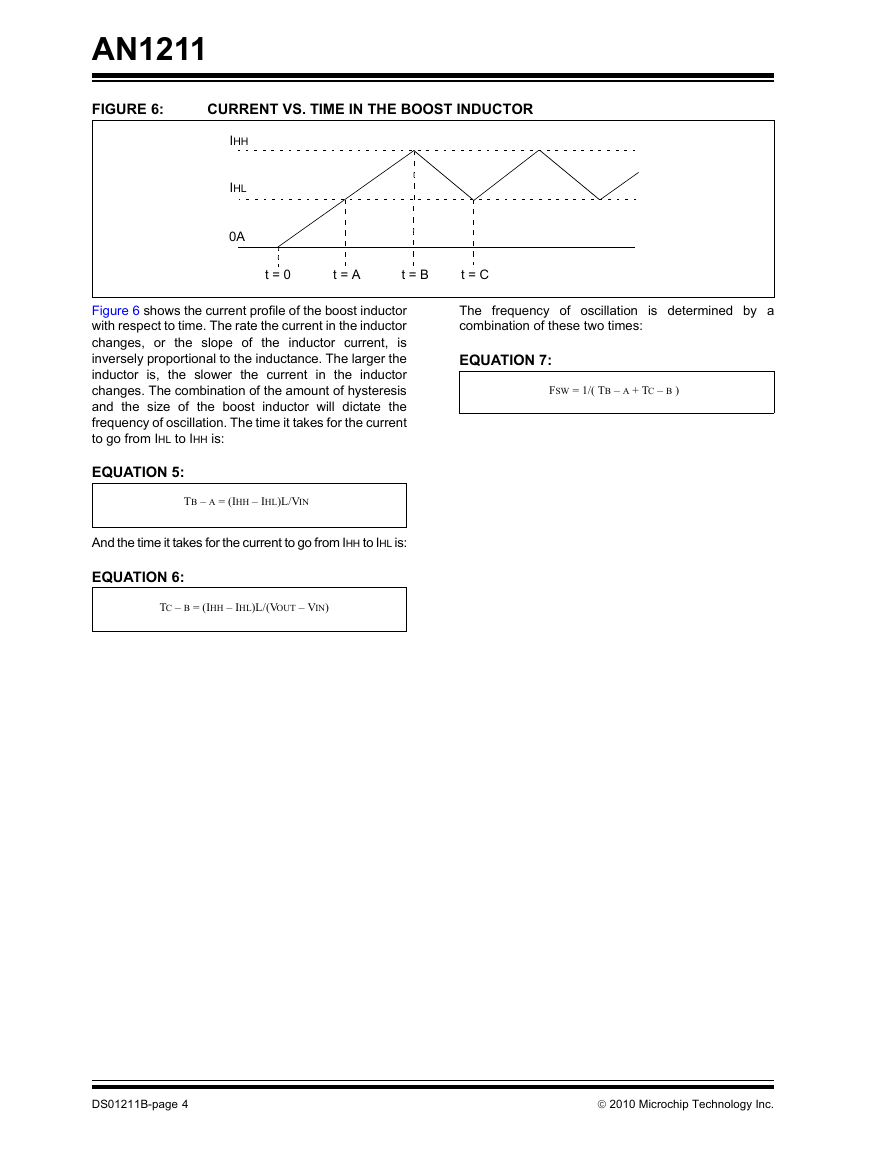

Figure 5 shows how the current sense works with a

comparator and the components of the boost supply to

make the oscillator.

The start-up condition of the oscillator is dictated by the

software of the PIC16F690. Before the comparator is

enabled, the port pin holds the gate of the boost FET

low while the oscillator’s reference voltage stabilizes.

Once the reference voltage is stable, the comparator is

enabled. This creates a start-up condition with no

voltage at the negative comparator input while the

positive input will be VOSC_REF multiplied by the divider

ratio provided by RSOURCE and RHYSTERESIS.

FIGURE 5:

SIMPLIFIED DIAGRAM OF

THE BOOST OSCILLATOR

VOUT

VIN

RSENSE

Current

Monitor

C1-

+

VOSC_REF

RSOURCE

RHYSTERISIS

Osc. Output

AN1211

After the comparator is enabled, the positive input will

be greater than the negative input, which causes the

output of the comparator to immediately change to an

output high. When the output of the comparator is high,

the following will occur:

• The FET of the boost converter conducts.

• The positive input of the comparator equals VHH

(see Equation 1).

• Energy is stored in the boost inductor.

• The current in the boost inductor increases at a

linear rate.

• The voltage on

comparator increases.

the negative

input of

the

EQUATION 1:

VHH = VOSC_REF + (VDD – VOSC_REF) * RSOURCE/(RSOURCE + RHYSTERESIS)

At a predetermined current in the inductor, the negative

input of the comparator becomes greater than the pos-

itive input, which causes the output of the comparator

to become low. This current, IHH (for hysteresis high), is

calculated by the following formula (Equation 2), where

Gm is the gain of the current monitor:

EQUATION 2:

IHH = VHH /(GM * RSENSE)

When the output of the comparator is low, the following

will occur:

• The FET of the boost converter does not conduct.

• The positive input of the comparator equals VHL

(see Equation 3).

• Energy is taken out of the boost inductor and

delivered to the 24-volt load.

• The current in the boost inductor decreases at a

linear rate.

• The voltage on the negative input of the

comparator decreases.

EQUATION 3:

VHL = VOSC_REF * RHYSTERESIS/(RSOURCE + RHYSTERESIS)

The current in the inductor will keep decreasing until

the voltage on the negative input equals the positive

input of the comparator. This current, IHL (for hysteresis

low), is calculated by the formula in Equation 4.

EQUATION 4:

IHL = VHL / (GM * RSENSE)

When this point is reached, the comparator’s output

changes to a high and the cycle repeats.

2010 Microchip Technology Inc.

DS01211B-page 3

�

AN1211

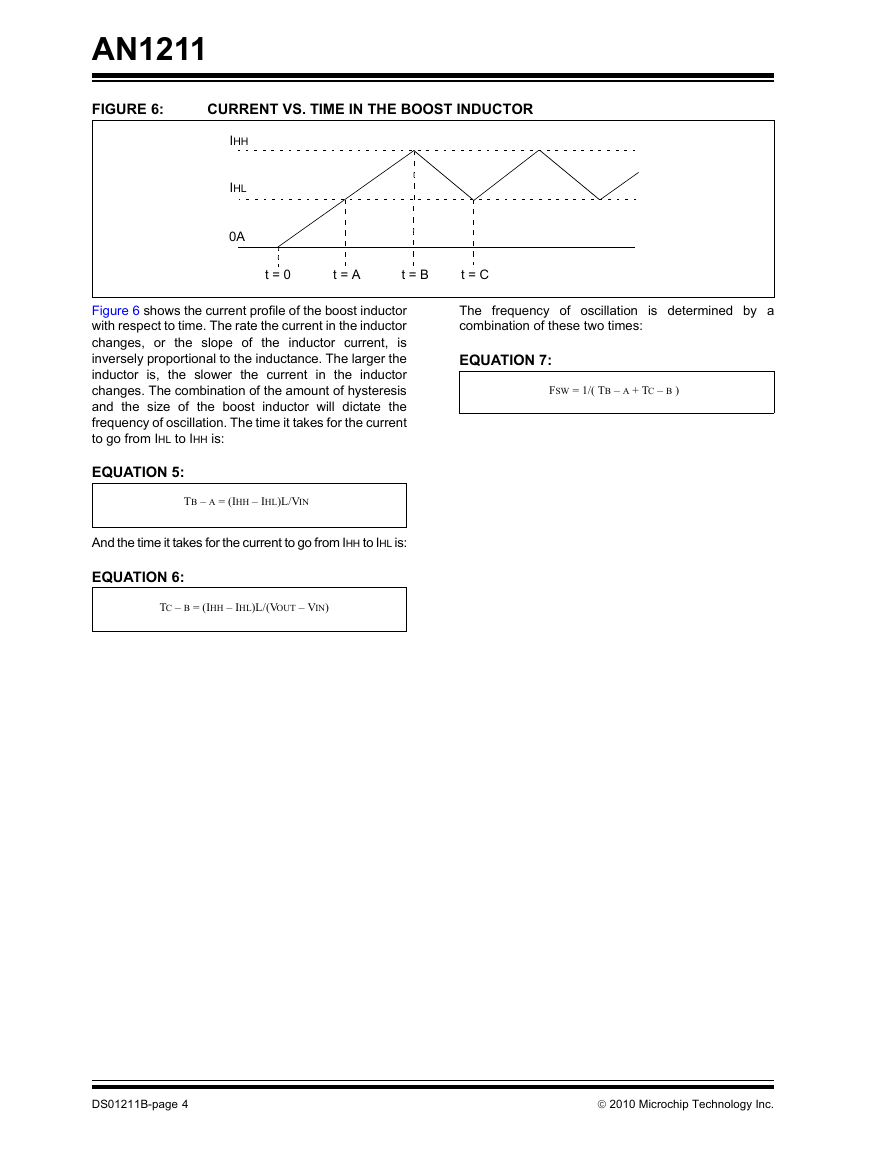

FIGURE 6:

CURRENT VS. TIME IN THE BOOST INDUCTOR

IHH

IHL

0A

t = 0

t = A

t = B

t = C

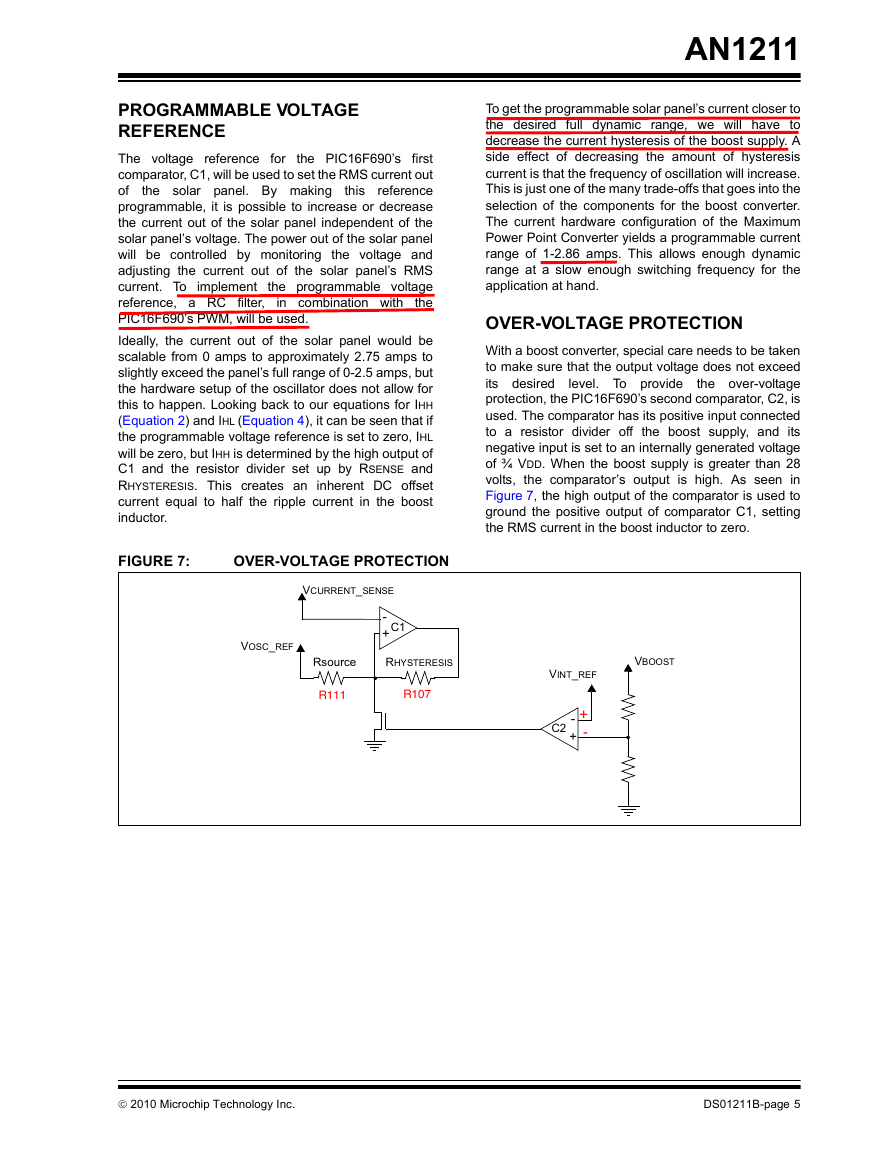

The frequency of oscillation is determined by a

combination of these two times:

EQUATION 7:

FSW = 1/( TB – A + TC – B )

Figure 6 shows the current profile of the boost inductor

with respect to time. The rate the current in the inductor

changes, or the slope of the inductor current, is

inversely proportional to the inductance. The larger the

inductor is, the slower the current in the inductor

changes. The combination of the amount of hysteresis

and the size of the boost inductor will dictate the

frequency of oscillation. The time it takes for the current

to go from IHL to IHH is:

EQUATION 5:

TB – A = (IHH – IHL)L/VIN

And the time it takes for the current to go from IHH to IHL is:

EQUATION 6:

TC – B = (IHH – IHL)L/(VOUT – VIN)

DS01211B-page 4

2010 Microchip Technology Inc.

�

this

the solar panel. By making

PROGRAMMABLE VOLTAGE

REFERENCE

The voltage reference for the PIC16F690’s first

comparator, C1, will be used to set the RMS current out

of

reference

programmable, it is possible to increase or decrease

the current out of the solar panel independent of the

solar panel’s voltage. The power out of the solar panel

will be controlled by monitoring the voltage and

adjusting the current out of the solar panel’s RMS

current. To implement the programmable voltage

reference, a RC

the

PIC16F690’s PWM, will be used.

Ideally, the current out of the solar panel would be

scalable from 0 amps to approximately 2.75 amps to

slightly exceed the panel’s full range of 0-2.5 amps, but

the hardware setup of the oscillator does not allow for

this to happen. Looking back to our equations for IHH

(Equation 2) and IHL (Equation 4), it can be seen that if

the programmable voltage reference is set to zero, IHL

will be zero, but IHH is determined by the high output of

C1 and the resistor divider set up by RSENSE and

RHYSTERESIS. This creates an inherent DC offset

current equal to half the ripple current in the boost

inductor.

filter,

in combination with

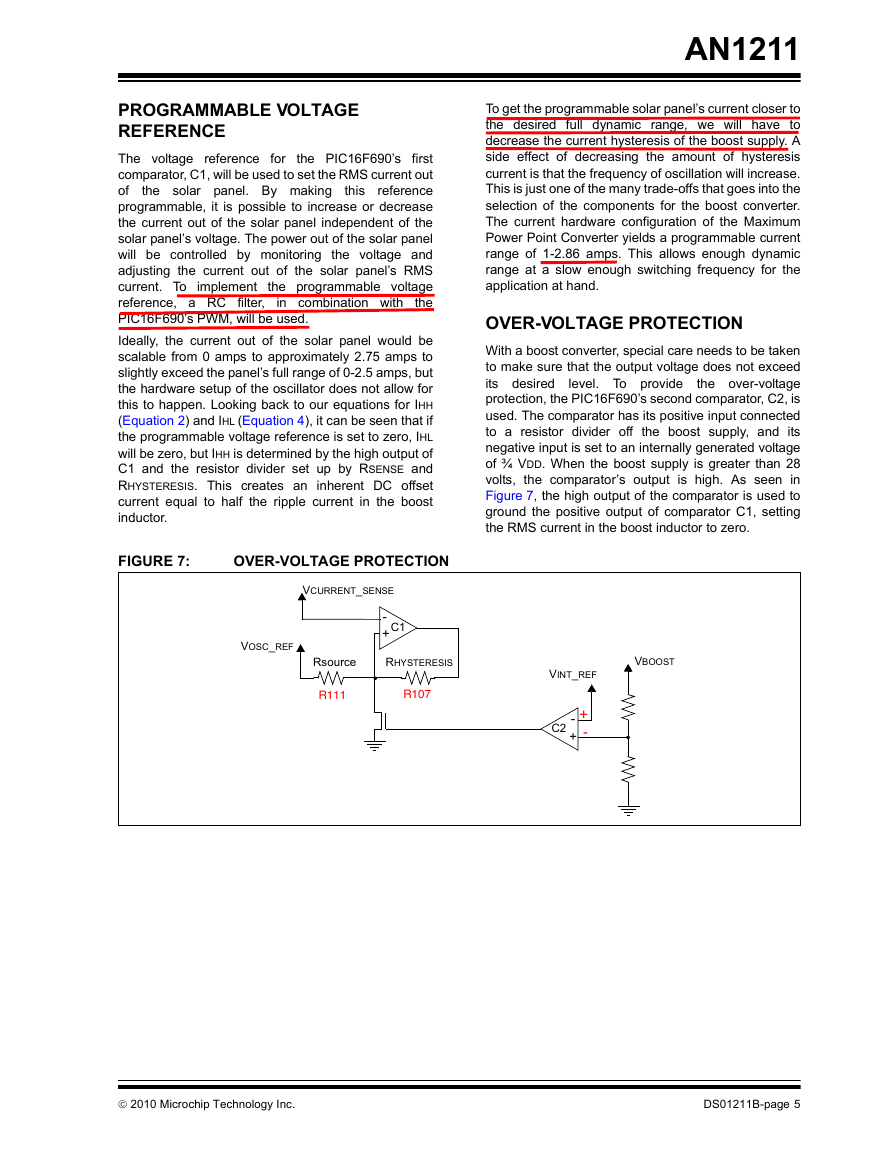

FIGURE 7:

OVER-VOLTAGE PROTECTION

VCURRENT_SENSE

-

+

C1

Rsource

RHYSTERESIS

VOSC_REF

AN1211

To get the programmable solar panel’s current closer to

the desired full dynamic range, we will have to

decrease the current hysteresis of the boost supply. A

side effect of decreasing the amount of hysteresis

current is that the frequency of oscillation will increase.

This is just one of the many trade-offs that goes into the

selection of the components for the boost converter.

The current hardware configuration of the Maximum

Power Point Converter yields a programmable current

range of 1-2.86 amps. This allows enough dynamic

range at a slow enough switching frequency for the

application at hand.

level. To provide

OVER-VOLTAGE PROTECTION

With a boost converter, special care needs to be taken

to make sure that the output voltage does not exceed

its desired

the over-voltage

protection, the PIC16F690’s second comparator, C2, is

used. The comparator has its positive input connected

to a resistor divider off the boost supply, and its

negative input is set to an internally generated voltage

of ¾ VDD. When the boost supply is greater than 28

volts, the comparator’s output is high. As seen in

Figure 7, the high output of the comparator is used to

ground the positive output of comparator C1, setting

the RMS current in the boost inductor to zero.

VBOOST

VINT_REF

-

C2 +

2010 Microchip Technology Inc.

DS01211B-page 5

�

AN1211

COMPONENT SELECTION

Keeping in mind that the goal of this project is to get the

most power out of the solar panel, it would seem

unwise to waste power by having an inefficient boost

power supply. In order to optimize the efficiency of the

boost supply, we first need to examine the losses

associated with each component. Below are a series of

power equations associated with each major

component of the boost supply. For further analysis of

the interaction of these equations, download the Excel

spreadsheet associated with this application note.

SENSE RESISTOR

The power lost to the resistance of the sense resistor is

I2R. For most applications, “I” can be approximated as

the average current in the inductor, which yields the

following formula:

EQUATION 8:

PRES = IHH + IHL 2 R

(

)

2

To get a more accurate power dissipation of the sense

resistor, the power equation has to be integrated

because the current is constantly changing.

EQUATION 9:

(

3

PRES = IHH - IHL 2

) + (IHH – IHL) * IHL + IHL2) * R

INPUT AND OUTPUT CAPACITOR

The power lost because of a capacitor is due to

equivalent series resistance (ESR) and the ripple

current on the cap. For the input capacitor, the equation

is:

EQUATION 10:

PC = (IHH – IHL)2 ESR

SCHOTTKY DIODE

For the boost diode, there are 2 types of losses:

reverse recovery losses and

forward conducting

losses. Depending on the switching speed for the given

boost supply, the reverse recovery losses can be

ignored for the most part, if a Schottky diode is used.

The reason for this is because the reverse recovery

current will be approximately 1-5 mAmps for 20-50

nSeconds. The

losses will

dominate the reverse recovery and can be calculated

by using the following equation:

forward conduction

EQUATION 11:

PSD = VF*(IHH + IHL)/2 * VIN/VOUT

Where VF is the forward voltage across the diode and

VIN/VOUT is the ratio of the diode’s conduction time.

BOOST INDUCTOR

There are 3 types of losses that occur in the inductor:

winding losses, core losses and resistance losses. The

winding and core losses have to do with the physical

way the inductor is made and which core material is

used. The best way to determine these losses is to

consult the inductor manufacturer.

For this application note, the winding and core losses

for the inductor were determined by using the “core

loss calculator” located on the Coilcraft’s web site. This

calculator will also calculate the resistance losses via

Equation 8.

EQUATION 12:

PIND = PI – RES + PI – WIND + PI – CORE

DS01211B-page 6

2010 Microchip Technology Inc.

�

AN1211

With the components on the current bill of material, the

calculated efficiency of the boost supply is 96.56%,

when the input voltage is 8 volts and the input current

is 2.5 amps. Testing on the Maximum Power Point

Converter has shown that the overall process converts

efficiency to 94%. This is slightly less than what is

calculated, because we only account for the efficiency

of the boost supply, and did not account for the

quiescent current draw of the FET driver, PIC16F690,

current monitor, etc.

BOOST FET

The losses due to the boost FET can be broken up into

two categories: conduction losses and switching

losses. For the conduction loss, it is the resistance loss

of the FET multiplied by the ratio of the FET’s on/off

time.

EQUATION 13:

(

)

PRDS = IHH + IHL 2

2

* RDS*(1 – VIN/VOUT)

Or, for the more accurate loss:

EQUATION 14:

PRDS = (IHH – IHL)2

(

3

+(IHH – IHL) IHL + IHL2) *RDS*(1 – VIN/VOUT)

The switching losses can be broken up into 3 different

categories: gate charge, output capacitance, and

transition losses calculated by the following equations:

EQUATION 15:

PGATE = Fsw*QG*VDRIVE

EQUATION 16:

PCOSS = (COSS*VDS2*FSW)/2

EQUATION 17:

PTRAN = ½(TR + TF)VOUT*IIN*FSW

EQUATION 18:

PFET = PGATE + PCOSS + PTRAN

FSW is the switching frequency of the boost supply, QG

is the FET’s total gate charge, VDRIVE is the voltage the

gate is being driven to, and TR/TF is the FET’s turn

on/off rise/fall time.

The total power lost due to the switching power supply

is:

EQUATION 19:

PTOTAL = PRES + PCIN + PCOUT + PSD + PI-RES + PIND + PIFET

2010 Microchip Technology Inc.

DS01211B-page 7

�

AN1211

SOFTWARE

The software to control the Maximum Power Point

Converter can be broken into two algorithms: Current

Reduction and the dither routine, which are controlled

via the Interrupt Service Routine (ISR). Both algorithms

manipulate the current of the solar panel via the

Programmable Voltage reference generated by the

PIC16F690’s 10-bit PWM.

By modifying the duty cycle of the PWM, the current out

of the solar panel will scale linearly with respect to the

duty cycle of PWM. To simplify the math for both

algorithms, only the 8 MSBs of the PWM’s duty cycle

will be used, yielding 256 discrete current settings for

the solar panel.

DITHER ROUTINE

The dither routine is used to optimize the power out of

the solar panel. The algorithm does not use the exact

power out of the solar panel, but rather, a difference in

the proportional power. For the dither routine, only the

relative difference between two successive power

calculations is important. Did the power increase or did

the power decrease? The amount the power changed

has no effect on the algorithm. For this reason, the

exact power out of the solar panel is not required,

which allows us to use the linear relationship of the

PWM’s duty cycle and the solar panels current. The

proportional power out of the solar panel is calculated

by multiplying the voltage of the solar panel by the duty

cycle of the PWM. For simplicity, the 8 Most Significant

Bytes (MSBs) of PWM’s duty cycle is multiplied by the

8 MSBs of the A/D reading on the solar panels voltage.

FIGURE 8:

DITHER ROUTINE

)

s

p

m

A

(

t

n

e

r

r

u

C

0

3

5

10

20

2.5

25

30

2

35

40

45

1.5

50

1

0.5

0

0

Solar Panel I-V Curve

50 Cells in a 5x10 array

0

1

2

4

5

6

7

8

9

10

0.51

0.5

0.5

0.497

0.495

0.492

0.487

0.47

0.35

0

2.55

2.5

2.5

2.485

2.475

2.46

2.435

2.35

1.75

0

0.25

0.25

0.25

0.245

0.244

0.24

0.238

0.2

0.08

0

0

2.5

5

9.94

12.375

14.76

17.045

18.8

15.75

0

0

2.5

5

9.94

12.375

14.76

17.045

18.8

15.75

0

0

1.25

2.5

4.9

6.1

7.2

8.33

8

3.6

0

Full Sun

2

4

6

8

10

12

Voltage (Volts)

Using the PWM duty cycle for the solar panel’s current

has two benefits. The first benefit is that it eliminates

the need for additional hardware. To get the exact

current out of the solar panel, an analog buffer on ROUT

is needed, as well as an additional RC filter located on

the buffer’s output. The second benefit is that the

PWM’s duty cycle is already in a digital format

speeding up the control loop, because there is no need

to perform a second A/D conversion.

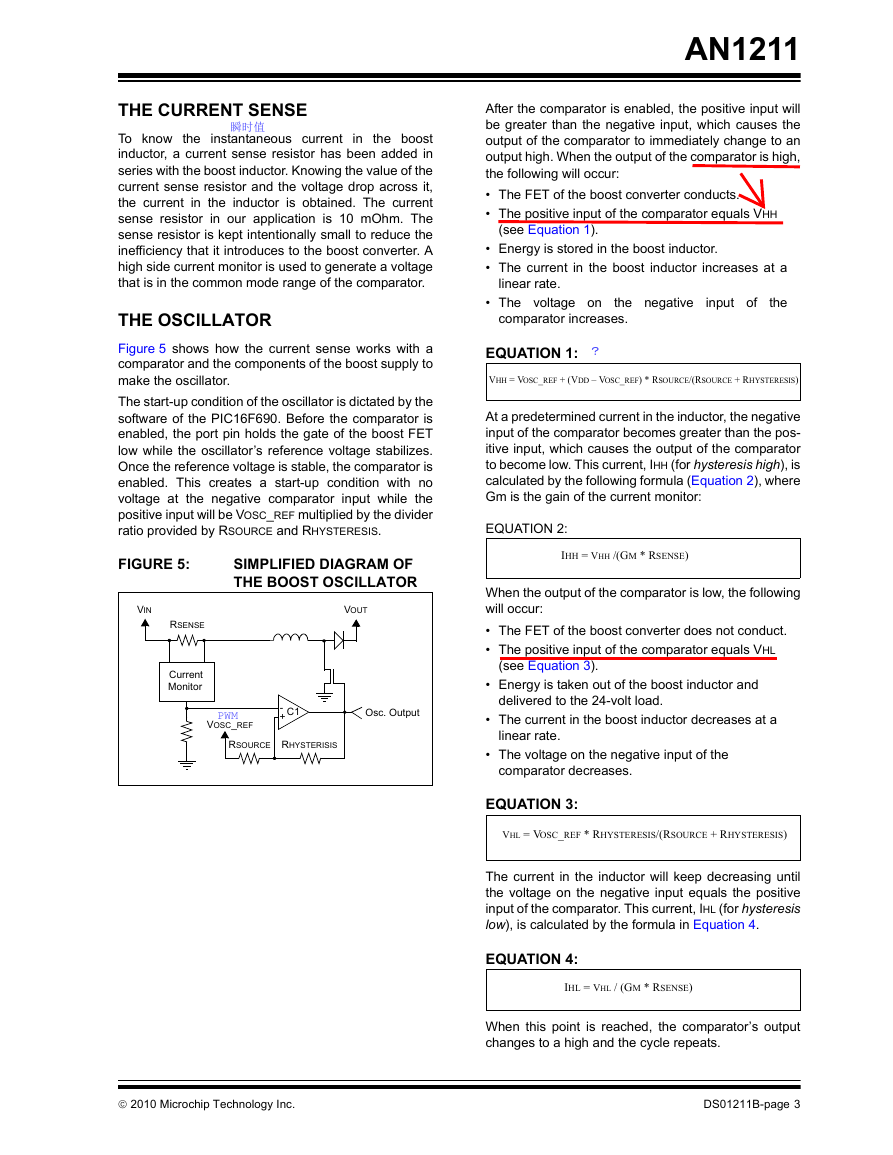

Figure 8 shows the I-V curve and the maximum power

curve of the solar panel the Maximum Power Point

Converter was designed for. Starting with no load on

the output, we have an open-circuit voltage of 10 volts.

When the panel is operating at this voltage, the panel

produces no power. By increasing the current taken out

of the panel, we begin to collapse the solar panels

voltage, but gain power. If the current out of the panel

is increased beyond a certain point, the supply voltage

will quickly collapse and the power out of the solar

panel will decrease.

The

the

proportional power of the solar panel is calculated by

multiplying the voltage of the solar panel by the

minimum duty cycle of the PWM. After the power has

been calculated, the PWM’s duty cycle is increased

and the direction flag is set to indicate that the current

out of the panel was increased (if the current out of the

panel was decreased, the direction flag would be

cleared). The second time through the dither routine,

the power is again calculated and compared to the

previous power calculation. If the power increases, the

current will be adjusted in the same manner as

indicated by the direction flag; in this case, the current

would be increased. This will continue to happen until

the power decreases. When the power decreases, the

current is adjusted in the opposite manner as indicated

by the direction flag (decreased), and then the direction

flag is cleared.

the dither

routine,

first

time

through

Solar Panel Power Curve

50 cells in a 5x10 array

Full Sun

0

2

4

6

8

Voltage (Volts)

10

12

)

s

t

t

a

W

(

r

e

w

o

P

20

15

10

5

0

DS01211B-page 8

2010 Microchip Technology Inc.

�

2023年江西萍乡中考道德与法治真题及答案.doc

2023年江西萍乡中考道德与法治真题及答案.doc 2012年重庆南川中考生物真题及答案.doc

2012年重庆南川中考生物真题及答案.doc 2013年江西师范大学地理学综合及文艺理论基础考研真题.doc

2013年江西师范大学地理学综合及文艺理论基础考研真题.doc 2020年四川甘孜小升初语文真题及答案I卷.doc

2020年四川甘孜小升初语文真题及答案I卷.doc 2020年注册岩土工程师专业基础考试真题及答案.doc

2020年注册岩土工程师专业基础考试真题及答案.doc 2023-2024学年福建省厦门市九年级上学期数学月考试题及答案.doc

2023-2024学年福建省厦门市九年级上学期数学月考试题及答案.doc 2021-2022学年辽宁省沈阳市大东区九年级上学期语文期末试题及答案.doc

2021-2022学年辽宁省沈阳市大东区九年级上学期语文期末试题及答案.doc 2022-2023学年北京东城区初三第一学期物理期末试卷及答案.doc

2022-2023学年北京东城区初三第一学期物理期末试卷及答案.doc 2018上半年江西教师资格初中地理学科知识与教学能力真题及答案.doc

2018上半年江西教师资格初中地理学科知识与教学能力真题及答案.doc 2012年河北国家公务员申论考试真题及答案-省级.doc

2012年河北国家公务员申论考试真题及答案-省级.doc 2020-2021学年江苏省扬州市江都区邵樊片九年级上学期数学第一次质量检测试题及答案.doc

2020-2021学年江苏省扬州市江都区邵樊片九年级上学期数学第一次质量检测试题及答案.doc 2022下半年黑龙江教师资格证中学综合素质真题及答案.doc

2022下半年黑龙江教师资格证中学综合素质真题及答案.doc