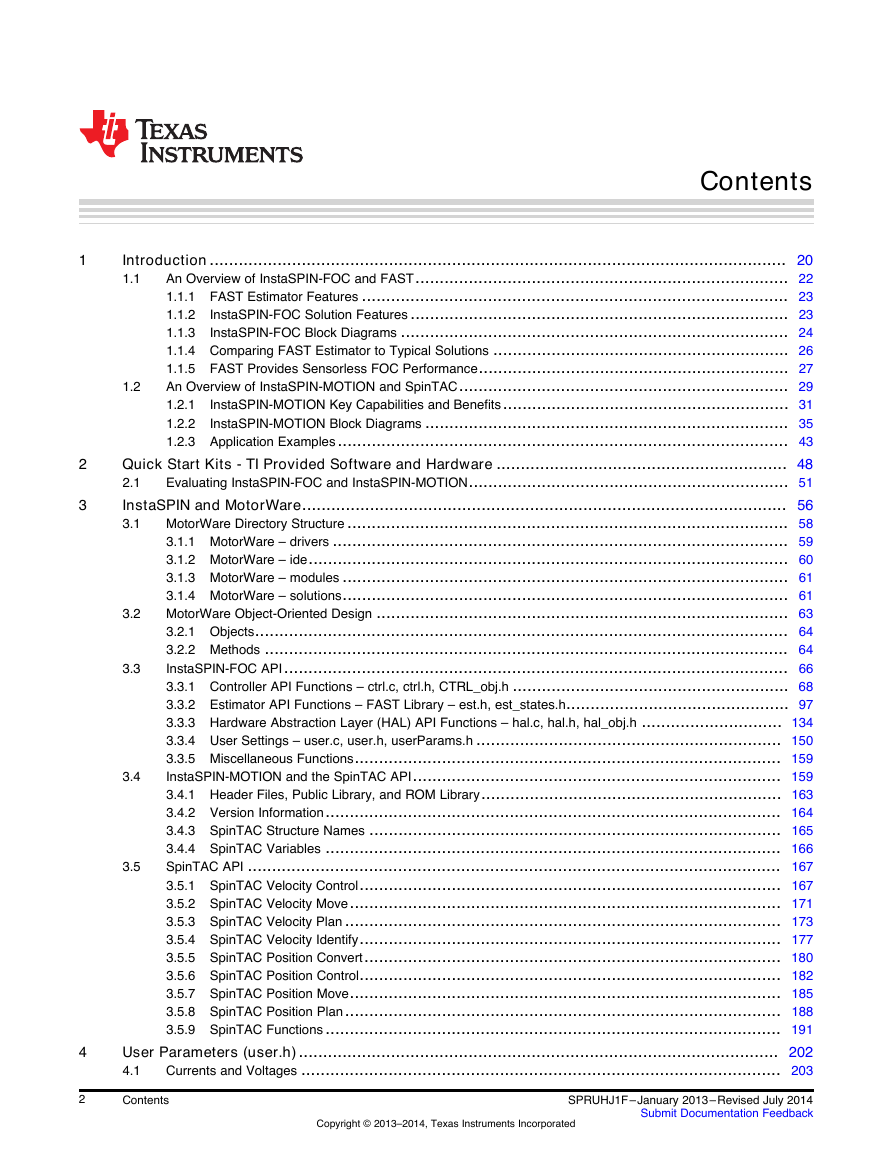

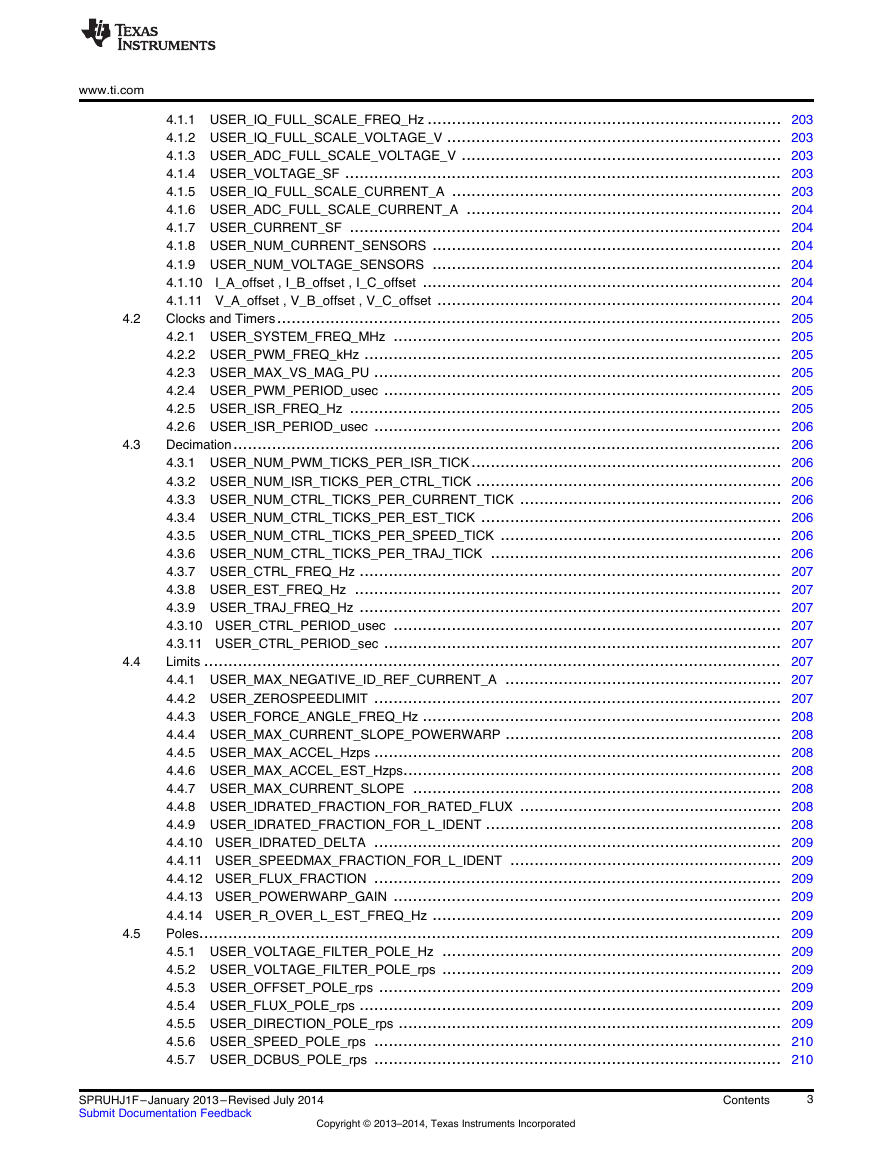

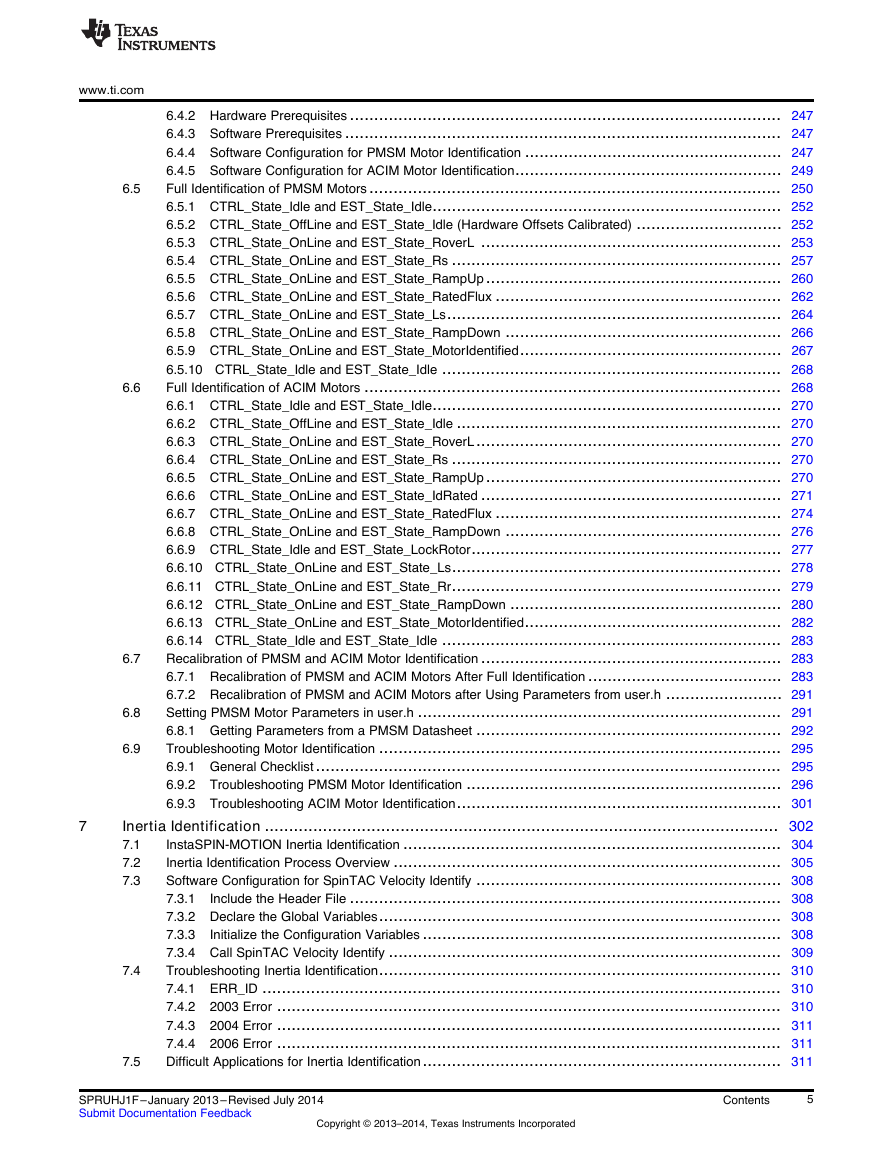

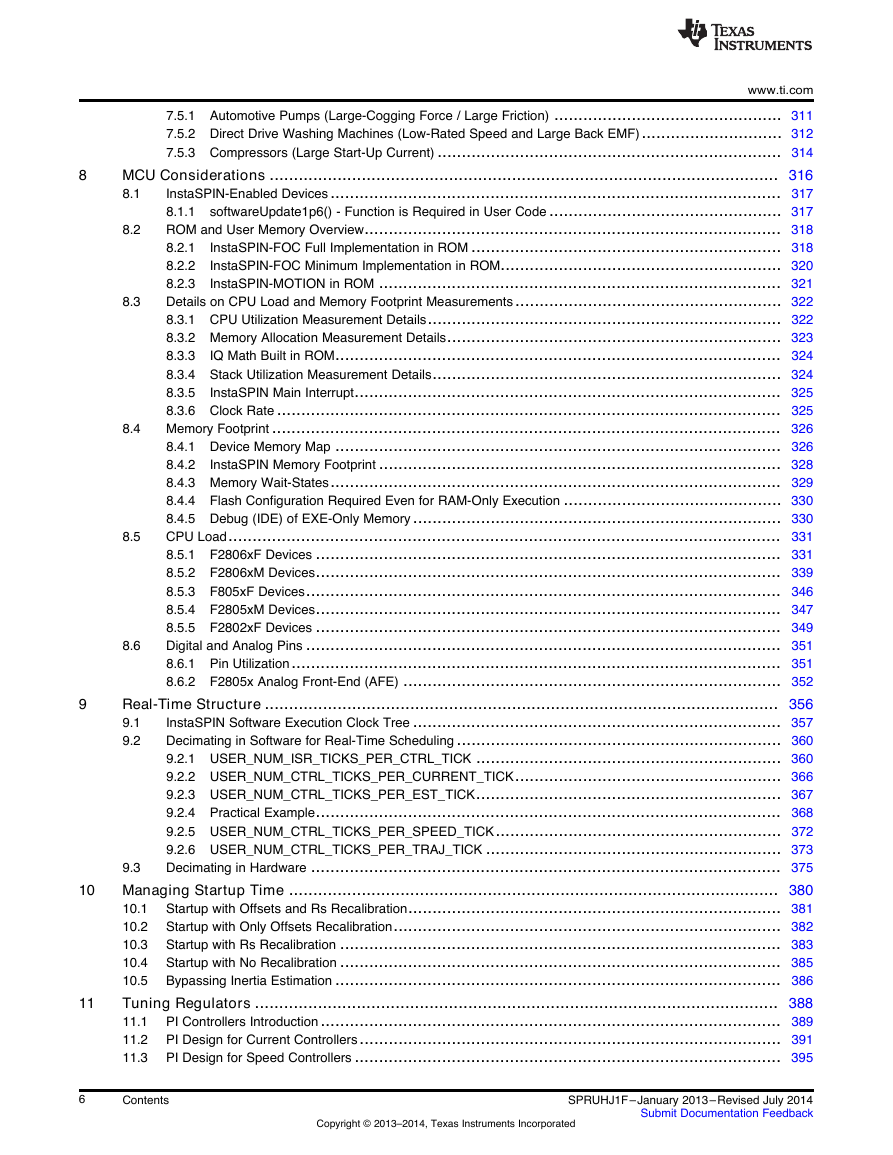

Table of Contents

1 Introduction

1.1 An Overview of InstaSPIN-FOC and FAST

1.1.1 FAST Estimator Features

1.1.2 InstaSPIN-FOC Solution Features

1.1.3 InstaSPIN-FOC Block Diagrams

1.1.4 Comparing FAST Estimator to Typical Solutions

1.1.5 FAST Provides Sensorless FOC Performance

1.1.5.1 FAST Estimator Replaces Mechanical Sensor

1.1.5.2 Rotor Angle Accuracy Critical for Performance

1.2 An Overview of InstaSPIN-MOTION and SpinTAC

1.2.1 InstaSPIN-MOTION Key Capabilities and Benefits

1.2.1.1 The FAST Unified Software Observer

1.2.1.2 The SpinTAC Motion Control Suite

1.2.1.2.1 IDENTIFY

1.2.1.2.2 CONTROL

1.2.1.2.3 MOVE

1.2.1.2.4 PLAN

1.2.1.3 Additional InstaSPIN-MOTION Features

1.2.2 InstaSPIN-MOTION Block Diagrams

1.2.3 Application Examples

1.2.3.1 Treadmill Conveyor: Smooth Motion Across Varying Speeds and Loads

1.2.3.2 Video Camera: Smooth Motion and Position Accuracy at Low Speeds

1.2.3.3 Washing Machine: Smooth Motion and Position Accuracy at Low Speeds

1.2.3.3.1 Agitation Cycle

1.2.3.3.2 Spin Cycles

1.2.3.3.3 InstaSPIN-MOTION Works Over the Entire Operating Range

2 Quick Start Kits - TI Provided Software and Hardware

2.1 Evaluating InstaSPIN-FOC and InstaSPIN-MOTION

3 InstaSPIN and MotorWare

3.1 MotorWare Directory Structure

3.1.1 MotorWare – drivers

3.1.2 MotorWare – ide

3.1.3 MotorWare – modules

3.1.4 MotorWare – solutions

3.2 MotorWare Object-Oriented Design

3.2.1 Objects

3.2.2 Methods

3.2.2.1 Init method

3.2.2.2 Set method

3.2.2.3 Get method

3.2.2.4 Run method

3.3 InstaSPIN-FOC API

3.3.1 Controller API Functions – ctrl.c, ctrl.h, CTRL_obj.h

3.3.1.1 CTRL Enumerations and Structures

3.3.1.2 CTRL State Control and Error Handling

3.3.1.3 CTRL Get Functions

3.3.1.4 CTRL Counter Functions

3.3.1.5 CTRL Set Functions

3.3.1.6 CTRL Run and Compute Functions

3.3.2 Estimator API Functions – FAST Library – est.h, est_states.h

3.3.2.1 EST Enumerations and Structures

3.3.2.2 EST Set Functions

3.3.2.3 EST Get Functions

3.3.2.4 EST Run and Compute Functions

3.3.2.5 EST Counter Functions

3.3.2.6 EST State Control and Error Handling Functions

3.3.3 Hardware Abstraction Layer (HAL) API Functions – hal.c, hal.h, hal_obj.h

3.3.3.1 HAL Enumerations and Structures

3.3.3.2 HAL – ADC and AFE

3.3.3.3 HAL – PWM and PWM-DAC

3.3.3.4 HAL – CPU Timers

3.3.3.5 HAL – GPIO and LED

3.3.3.6 HAL – Miscellaneous

3.3.4 User Settings – user.c, user.h, userParams.h

3.3.4.1 USER Enumerations and Structures

3.3.4.2 USER Set and Compute Functions

3.3.4.3 USER Error Handling Functions

3.3.5 Miscellaneous Functions

3.4 InstaSPIN-MOTION and the SpinTAC API

3.4.1 Header Files, Public Library, and ROM Library

3.4.2 Version Information

3.4.2.1 Code Example for returning SpinTAC Version Information

3.4.2.1.1 Include the Header File

3.4.2.1.2 Declare the Global Structure

3.4.2.1.3 Initialize the Configuration Variables

3.4.2.1.4 Return the Version Information

3.4.3 SpinTAC Structure Names

3.4.4 SpinTAC Variables

3.5 SpinTAC API

3.5.1 SpinTAC Velocity Control

3.5.1.1 SpinTAC Velocity Control Interface

3.5.1.2 SpinTAC Velocity Control Run Function

3.5.2 SpinTAC Velocity Move

3.5.2.1 SpinTAC Velocity Move Interface

3.5.2.2 SpinTAC Velocity Move Run Function

3.5.3 SpinTAC Velocity Plan

3.5.3.1 SpinTAC Velocity Plan Interface

3.5.3.2 SpinTAC Velocity Plan Primary Functions

3.5.4 SpinTAC Velocity Identify

3.5.4.1 SpinTAC Velocity Identify Interface

3.5.4.2 SpinTAC Velocity Identify Run Function

3.5.5 SpinTAC Position Convert

3.5.5.1 SpinTAC Position Convert Interfaces

3.5.5.2 SpinTAC Position Convert Run Function

3.5.6 SpinTAC Position Control

3.5.6.1 SpinTAC Position Control Interface

3.5.6.2 SpinTAC Position Control Run Function

3.5.7 SpinTAC Position Move

3.5.7.1 Position Move Interface

3.5.7.2 SpinTAC Position Move Run Function

3.5.8 SpinTAC Position Plan

3.5.8.1 Position Plan Interface

3.5.8.2 SpinTAC Position Plan Primary Functions

3.5.9 SpinTAC Functions

4 User Parameters (user.h)

4.1 Currents and Voltages

4.1.1 USER_IQ_FULL_SCALE_FREQ_Hz

4.1.2 USER_IQ_FULL_SCALE_VOLTAGE_V

4.1.3 USER_ADC_FULL_SCALE_VOLTAGE_V

4.1.4 USER_VOLTAGE_SF

4.1.5 USER_IQ_FULL_SCALE_CURRENT_A

4.1.6 USER_ADC_FULL_SCALE_CURRENT_A

4.1.7 USER_CURRENT_SF

4.1.8 USER_NUM_CURRENT_SENSORS

4.1.9 USER_NUM_VOLTAGE_SENSORS

4.1.10 I_A_offset , I_B_offset , I_C_offset

4.1.11 V_A_offset , V_B_offset , V_C_offset

4.2 Clocks and Timers

4.2.1 USER_SYSTEM_FREQ_MHz

4.2.2 USER_PWM_FREQ_kHz

4.2.3 USER_MAX_VS_MAG_PU

4.2.4 USER_PWM_PERIOD_usec

4.2.5 USER_ISR_FREQ_Hz

4.2.6 USER_ISR_PERIOD_usec

4.3 Decimation

4.3.1 USER_NUM_PWM_TICKS_PER_ISR_TICK

4.3.2 USER_NUM_ISR_TICKS_PER_CTRL_TICK

4.3.3 USER_NUM_CTRL_TICKS_PER_CURRENT_TICK

4.3.4 USER_NUM_CTRL_TICKS_PER_EST_TICK

4.3.5 USER_NUM_CTRL_TICKS_PER_SPEED_TICK

4.3.6 USER_NUM_CTRL_TICKS_PER_TRAJ_TICK

4.3.7 USER_CTRL_FREQ_Hz

4.3.8 USER_EST_FREQ_Hz

4.3.9 USER_TRAJ_FREQ_Hz

4.3.10 USER_CTRL_PERIOD_usec

4.3.11 USER_CTRL_PERIOD_sec

4.4 Limits

4.4.1 USER_MAX_NEGATIVE_ID_REF_CURRENT_A

4.4.2 USER_ZEROSPEEDLIMIT

4.4.3 USER_FORCE_ANGLE_FREQ_Hz

4.4.4 USER_MAX_CURRENT_SLOPE_POWERWARP

4.4.5 USER_MAX_ACCEL_Hzps

4.4.6 USER_MAX_ACCEL_EST_Hzps

4.4.7 USER_MAX_CURRENT_SLOPE

4.4.8 USER_IDRATED_FRACTION_FOR_RATED_FLUX

4.4.9 USER_IDRATED_FRACTION_FOR_L_IDENT

4.4.10 USER_IDRATED_DELTA

4.4.11 USER_SPEEDMAX_FRACTION_FOR_L_IDENT

4.4.12 USER_FLUX_FRACTION

4.4.13 USER_POWERWARP_GAIN

4.4.14 USER_R_OVER_L_EST_FREQ_Hz

4.5 Poles

4.5.1 USER_VOLTAGE_FILTER_POLE_Hz

4.5.2 USER_VOLTAGE_FILTER_POLE_rps

4.5.3 USER_OFFSET_POLE_rps

4.5.4 USER_FLUX_POLE_rps

4.5.5 USER_DIRECTION_POLE_rps

4.5.6 USER_SPEED_POLE_rps

4.5.7 USER_DCBUS_POLE_rps

4.5.8 USER_EST_KAPPAQ

4.6 User Motor and ID Settings

4.6.1 USER_MOTOR_TYPE

4.6.2 USER_MOTOR_NUM_POLE_PAIRS

4.6.3 USER_MOTOR_Rr

4.6.4 USER_MOTOR_Rs

4.6.5 USER_MOTOR_Ls_d

4.6.6 USER_MOTOR_Ls_q

4.6.7 USER_MOTOR_RATED_FLUX

4.6.8 USER_VOLTAGE_FILTER_POLE_Hz

4.6.9 USER_MOTOR_RES_EST_CURRENT

4.6.10 USER_MOTOR_IND_EST_CURRENT

4.6.11 USER_MOTOR_MAX_CURRENT

4.6.12 USER_MOTOR_FLUX_EST_FREQ_Hz

4.6.13 USER_MOTOR_ENCODER_LINES (InstaSPIN-MOTION Only)

4.6.14 USER_MOTOR_MAX_SPEED_KRPM (InstaSPIN-MOTION Only)

4.6.15 USER_SYSTEM_INERTIA (InstaSPIN-MOTION Only)

4.6.16 USER_SYSTEM_FRICTION (InstaSPIN-MOTION Only)

4.6.17 USER_SYSTEM_BANDWIDTH_SCALE (InstaSPIN-MOTION Only)

4.7 SpinTAC Parameters (spintac_velocity.h and spintac_position.h)

4.7.1 Macro Definitions

4.7.1.1 ST_MREV_ROLLOVER (spintac_position.h only)

4.7.1.2 ST_EREV_MAXIMUM (spintac_position.h only)

4.7.1.3 ST_POS_ERROR_MAXIMUM_MREV (spintac_position.h only)

4.7.1.4 ST_ISR_TICKS_PER_SPINTAC_TICK

4.7.1.5 ST_SPEED_SAMPLE_TIME

4.7.1.6 ST_SPEED_PU_PER_KRPM

4.7.1.7 ST_SPEED_KRPM_PER_PU

4.7.1.8 ST_MOTOR_INERTIA_PU

4.7.1.9 ST_MOTOR_FRICTION_PU

4.7.1.10 ST_MIN_ID_SPEED_RPM

4.7.1.11 ST_MIN_ID_SPEED_PU

4.7.1.12 ST_ID_INCOMPLETE_ERROR

4.7.1.13 ST_VARS_DEFAULTS

4.7.2 Type Definitions

4.7.2.1 VEL_Params_t / POS_Params_t

4.7.2.2 ST_Obj

4.7.2.3 ST_Handle

4.7.2.4 ST_PlanButton_e

4.7.2.5 ST_Vars_t

4.7.3 Functions

4.7.3.1 ST_init

4.7.3.2 ST_setupPosConv

4.7.3.3 ST_setupVelCtl (Velocity Control Only)

4.7.3.4 ST_setupPosCtl (Position Control Only)

4.7.3.5 ST_setupVelMove (Velocity Control Only)

4.7.3.6 ST_setupPosMove (Position Control Only)

4.7.3.7 ST_setupVelPlan (Velocity Control Only)

4.7.3.8 ST_setupPosPlan (Position Control Only)

4.7.3.9 ST_setupVelId (Velocity Control Only)

4.7.3.10 ST_runPosConv

4.7.3.11 ST_runVelCtl (Velocity Control Only)

4.7.3.12 ST_runPosCtl (Position Control Only)

4.7.3.13 ST_runVelMove (Velocity Control Only)

4.7.3.14 ST_runPosMove (Position Control Only)

4.7.3.15 ST_runVelPlan (Velocity Control Only)

4.7.3.16 ST_runVelPlanTick (Velocity Control Only)

4.7.3.17 ST_runPosPlan (Position Control Only)

4.7.3.18 ST_runPosPlanTick (Position Control Only)

4.7.3.19 ST_runVelId (Velocity Control Only)

4.8 Setting ACIM Motor Parameters in user.h

4.8.1 Getting Parameters From an ACIM Datasheet

4.8.1.1 Number of Pole Pairs

4.8.1.2 Entering ACIM Motor Parameters From a Datasheet to user.h

4.8.1.3 Getting the Rated Magnetizing Current of an ACIM

4.8.1.4 Getting the Rated Flux of an ACIM

5 Managing Motor Signals

5.1 Software Prerequisites

5.1.1 IQ Full-Scale Frequency

5.1.2 IQ Full-Scale Voltage

5.1.3 IQ Full-Scale Current

5.1.4 Max Current

5.1.5 Decimation Rates

5.1.6 System Frequency

5.1.7 PWM Frequency

5.1.8 Max Voltage Vector

5.2 Hardware Prerequisites

5.2.1 Current Feedback Gain

5.2.2 Current Feedback Polarity

5.2.2.1 Positive Feedback

5.2.2.2 Negative Feedback

5.2.3 Voltage Feedback

5.2.4 Voltage Filter Pole

5.2.5 Number of Shunt Resistors

5.2.6 Deadtime Configuration

5.2.7 Analog Inputs Configuration

5.2.8 PWM Outputs Configuration

6 Motor Identification and State Diagrams

6.1 InstaSPIN Motor Identification

6.2 Motor Identification Process Overview

6.2.1 Controller (CTRL) State Machine

6.2.2 Estimator (EST) State Machine

6.2.3 Controller (CTRL) and Estimator (EST) State Machine Dependencies

6.3 Differences between PMSM and ACIM Identification Process

6.4 Prerequisites

6.4.1 Mechanical Prerequisites

6.4.1.1 Motor Connection

6.4.1.2 Order of the Phases

6.4.1.3 Minimum Mechanical Load

6.4.2 Hardware Prerequisites

6.4.3 Software Prerequisites

6.4.4 Software Configuration for PMSM Motor Identification

6.4.4.1 Motor Type

6.4.4.2 Number of Pole Pairs

6.4.4.3 Frequency for Rhf and Lhf

6.4.4.4 Current for Rs

6.4.4.5 Current for Ls

6.4.4.6 Frequency for Ls and Flux

6.4.5 Software Configuration for ACIM Motor Identification

6.4.5.1 Motor Type

6.4.5.2 Number of Pole Pairs

6.4.5.3 Frequency for Rhf and Lhf

6.4.5.4 Rated Flux

6.4.5.5 Current for Rs

6.4.5.6 Frequency for IdRated, Ls and Rr

6.5 Full Identification of PMSM Motors

6.5.1 CTRL_State_Idle and EST_State_Idle

6.5.2 CTRL_State_OffLine and EST_State_Idle (Hardware Offsets Calibrated)

6.5.3 CTRL_State_OnLine and EST_State_RoverL

6.5.3.1 Amplitude of Injected Current for RoverL

6.5.3.2 Frequency of Injected Current for RoverL

6.5.3.3 Measurement Time for RoverL

6.5.3.4 Troubleshooting Current Controller Stability During RoverL Identification

6.5.3.5 Adjusting Resulting Current Controller Gains for High-Speeds

6.5.4 CTRL_State_OnLine and EST_State_Rs

6.5.4.1 Troubleshooting Current Controller Stability During Rs Identification

6.5.5 CTRL_State_OnLine and EST_State_RampUp

6.5.5.1 Ramp-Up Current Amplitude

6.5.5.1.1 Troubleshooting Motor Shaft Stopping During Ramp-Up

6.5.5.2 Ramp-Up Time and Acceleration

6.5.5.2.1 Troubleshooting Motor Shaft for Smoother Ramp

6.5.5.3 Ramp-Up Final Speed for PMSM

6.5.6 CTRL_State_OnLine and EST_State_RatedFlux

6.5.6.1 Current Ramp-Down

6.5.6.2 Total Measurement Time

6.5.6.3 Troubleshooting Flux Measurement

6.5.7 CTRL_State_OnLine and EST_State_Ls

6.5.7.1 Ramp-Up Current

6.5.7.2 Troubleshooting Ls Identification

6.5.7.3 Ls_d and Ls_q, Direct and Quadrature Stator Inductance

6.5.8 CTRL_State_OnLine and EST_State_RampDown

6.5.9 CTRL_State_OnLine and EST_State_MotorIdentified

6.5.10 CTRL_State_Idle and EST_State_Idle

6.6 Full Identification of ACIM Motors

6.6.1 CTRL_State_Idle and EST_State_Idle

6.6.2 CTRL_State_OffLine and EST_State_Idle

6.6.3 CTRL_State_OnLine and EST_State_RoverL

6.6.4 CTRL_State_OnLine and EST_State_Rs

6.6.5 CTRL_State_OnLine and EST_State_RampUp

6.6.5.1 Ramp-Up Final Speed for ACIM

6.6.6 CTRL_State_OnLine and EST_State_IdRated

6.6.6.1 Reducing Oscillation to Improve Id Rated Measurement

6.6.6.2 Reading Id Rated Final Value

6.6.7 CTRL_State_OnLine and EST_State_RatedFlux

6.6.7.1 Troubleshooting Flux Measurement

6.6.8 CTRL_State_OnLine and EST_State_RampDown

6.6.9 CTRL_State_Idle and EST_State_LockRotor

6.6.9.1 Troubleshooting Locked Rotor Test

6.6.10 CTRL_State_OnLine and EST_State_Ls

6.6.11 CTRL_State_OnLine and EST_State_Rr

6.6.12 CTRL_State_OnLine and EST_State_RampDown

6.6.13 CTRL_State_OnLine and EST_State_MotorIdentified

6.6.14 CTRL_State_Idle and EST_State_Idle

6.7 Recalibration of PMSM and ACIM Motor Identification

6.7.1 Recalibration of PMSM and ACIM Motors After Full Identification

6.7.1.1 Start-Up Time Consideration

6.7.1.2 CTRL_State_Idle and EST_State_Idle

6.7.1.3 CTRL_State_OffLine and EST_State_Idle

6.7.1.4 CTRL_State_OnLine and EST_State_Rs

6.7.1.4.1 Managing Time Required for Rs Recalibration

6.7.1.4.2 Software configuration for Rs recalibration

6.7.1.5 CTRL_State_OnLine and EST_State_OnLine

6.7.1.5.1 Transitioning to Online State from CTRL Online and EST Rs

6.7.1.5.2 Transitioning to Online state from (CTRL Idle or CTRL Offline) and EST Idle

6.7.1.6 CTRL_State_Idle and EST_State_Idle

6.7.2 Recalibration of PMSM and ACIM Motors after Using Parameters from user.h

6.8 Setting PMSM Motor Parameters in user.h

6.8.1 Getting Parameters from a PMSM Datasheet

6.8.1.1 Number of Pole Pairs

6.8.1.2 Stator Resistance (Rs)

6.8.1.3 Stator Inductance (Ls_d and Ls_q)

6.8.1.4 Rated Flux (ψ)

6.9 Troubleshooting Motor Identification

6.9.1 General Checklist

6.9.2 Troubleshooting PMSM Motor Identification

6.9.2.1 Identifying PMSM Motors When Load Cannot be Detached

6.9.2.2 Can Motor Rotate with the Attached Load?

6.9.2.3 Run First Three Steps of Identification

6.9.2.4 Run Using Motor Parameters from user.h

6.9.2.5 Troubleshooting Current Controller Stability during RoverL Identification

6.9.2.6 Troubleshooting Motor Shaft Stopping During Ramp-Up

6.9.2.7 Troubleshooting Motor Shaft for Smoother Ramp

6.9.2.8 Troubleshooting Flux Measurement

6.9.2.9 Troubleshooting Ls Identification

6.9.2.9.1 Identifying Low Inductance PMSM Motors

6.9.2.9.2 Identifying Inductance of Salient PMSM Motors

6.9.2.9.3 Identifying Inductance of Salient PMSM Motors

6.9.2.10 Identifying High-Speed PMSM Motors

6.9.2.11 Identifying High-Cogging Torque PMSM Motors

6.9.3 Troubleshooting ACIM Motor Identification

6.9.3.1 Identifying Low-Voltage and High-Current ACIM Motors

6.9.3.2 Identifying Low-Inductance ACIM Motors

6.9.3.3 Troubleshooting Flux Measurement

6.9.3.4 Troubleshooting Locked Rotor Test

7 Inertia Identification

7.1 InstaSPIN-MOTION Inertia Identification

7.2 Inertia Identification Process Overview

7.3 Software Configuration for SpinTAC Velocity Identify

7.3.1 Include the Header File

7.3.2 Declare the Global Variables

7.3.3 Initialize the Configuration Variables

7.3.4 Call SpinTAC Velocity Identify

7.4 Troubleshooting Inertia Identification

7.4.1 ERR_ID

7.4.2 2003 Error

7.4.3 2004 Error

7.4.3.1 Motor Spins Continuously

7.4.3.2 Motor Does Not Spin Initially

7.4.4 2006 Error

7.5 Difficult Applications for Inertia Identification

7.5.1 Automotive Pumps (Large-Cogging Force / Large Friction)

7.5.2 Direct Drive Washing Machines (Low-Rated Speed and Large Back EMF)

7.5.3 Compressors (Large Start-Up Current)

8 MCU Considerations

8.1 InstaSPIN-Enabled Devices

8.1.1 softwareUpdate1p6() - Function is Required in User Code

8.2 ROM and User Memory Overview

8.2.1 InstaSPIN-FOC Full Implementation in ROM

8.2.1.1 Executing from ROM and RAM

8.2.1.2 Executing from ROM and FLASH

8.2.2 InstaSPIN-FOC Minimum Implementation in ROM

8.2.2.1 Executing from ROM and RAM

8.2.2.2 Executing from ROM and FLASH

8.2.3 InstaSPIN-MOTION in ROM

8.2.3.1 Executing InstaSPIN-MOTION in the Main Interrupt

8.2.3.2 Executing Library from RAM

8.2.3.3 Executing Library from Flash

8.3 Details on CPU Load and Memory Footprint Measurements

8.3.1 CPU Utilization Measurement Details

8.3.2 Memory Allocation Measurement Details

8.3.3 IQ Math Built in ROM

8.3.4 Stack Utilization Measurement Details

8.3.5 InstaSPIN Main Interrupt

8.3.6 Clock Rate

8.4 Memory Footprint

8.4.1 Device Memory Map

8.4.1.1 F2806xF and F2806xM Devices

8.4.1.2 F2805xF and F2805xM Devices

8.4.1.3 F2802xF Devices

8.4.2 InstaSPIN Memory Footprint

8.4.2.1 F2806xF and F2805xF Devices

8.4.2.2 F2802xF Devices

8.4.2.3 F2806xM and F2805xM Devices

8.4.3 Memory Wait-States

8.4.3.1 F2806xF/M Devices

8.4.3.2 F2805xF/M Devices

8.4.3.3 F2802xF Devices

8.4.4 Flash Configuration Required Even for RAM-Only Execution

8.4.5 Debug (IDE) of EXE-Only Memory

8.5 CPU Load

8.5.1 F2806xF Devices

8.5.1.1 CPU Cycles

8.5.1.1.1 User Code in RAM

8.5.1.1.2 User Code in FLASH

8.5.1.2 CPU Load with PWM = 10 kHz

8.5.1.3 CPU Load with PWM = 20 kHz

8.5.1.4 CPU Load Examples

8.5.1.4.1 Example 1

8.5.1.4.2 Example 2

8.5.2 F2806xM Devices

8.5.2.1 CPU Cycles

8.5.2.1.1 RAM Execution - SpinTAC Library and User Code

8.5.2.1.2 FLASH Execution - SpinTAC Library and User Code

8.5.2.2 CPU Load Examples

8.5.2.2.1 Example 1

8.5.2.2.2 Example 2

8.5.2.2.3 Example 3

8.5.2.2.4 Example 4 (SpinTAC Position)

8.5.3 F805xF Devices

8.5.3.1 CPU Cycles

8.5.3.2 CPU Load with PWM = 10 kHz

8.5.3.3 CPU Load with PWM = 20 kHz

8.5.4 F2805xM Devices

8.5.4.1 CPU Cycles

8.5.4.1.1 FLASH Execution - SpinTAC Library and User Code

8.5.5 F2802xF Devices

8.5.5.1 CPU Cycles

8.5.5.2 CPU Load with PWM = 10 kHz

8.5.5.3 CPU Load with PWM = 20 kHz

8.6 Digital and Analog Pins

8.6.1 Pin Utilization

8.6.2 F2805x Analog Front-End (AFE)

8.6.2.1 Consideration of AFE Module

8.6.2.2 Routing Current Signals

8.6.2.3 Voltage Reference Connection

8.6.2.4 Routing Voltage Signals

9 Real-Time Structure

9.1 InstaSPIN Software Execution Clock Tree

9.2 Decimating in Software for Real-Time Scheduling

9.2.1 USER_NUM_ISR_TICKS_PER_CTRL_TICK

9.2.2 USER_NUM_CTRL_TICKS_PER_CURRENT_TICK

9.2.3 USER_NUM_CTRL_TICKS_PER_EST_TICK

9.2.4 Practical Example

9.2.5 USER_NUM_CTRL_TICKS_PER_SPEED_TICK

9.2.6 USER_NUM_CTRL_TICKS_PER_TRAJ_TICK

9.3 Decimating in Hardware

10 Managing Startup Time

10.1 Startup with Offsets and Rs Recalibration

10.2 Startup with Only Offsets Recalibration

10.3 Startup with Rs Recalibration

10.4 Startup with No Recalibration

10.5 Bypassing Inertia Estimation

11 Tuning Regulators

11.1 PI Controllers Introduction

11.2 PI Design for Current Controllers

11.3 PI Design for Speed Controllers

11.4 Calculating PI Gains Based On Stability and Bandwidth

11.5 Calculating Speed and Current PI Gains Based on Damping Factor

11.6 Considerations When Adding Poles to the Speed Loop

11.7 Speed PI Controller Considerations: Current Limits, Clamping and Inertia

11.8 Considerations When Designing PI Controllers for FOC Systems

11.8.1 FOC Differences Between Motor Types

11.8.2 Coupling Between Q-Axis and D-Axis

11.9 Sampling and Digital Systems Considerations

11.9.1 Sampling Period Considerations in the Integral Gain

11.9.2 Number Format Considerations

11.9.3 PI Coefficients Scaling Considerations

12 InstaSPIN-MOTION Controllers

12.1 Stability

12.1.1 Quantifying Stability

12.1.1.1 SpinTAC Velocity Control Stability

12.1.1.2 SpinTAC Position Control Stability

12.1.2 Performance

12.1.2.1 Frequency Domain Analysis

12.1.2.2 Time Domain Analysis

12.1.3 Trade-Off Between Stability and Performance

12.1.4 Tuning the SpinTAC Controller

12.1.4.1 Considerations

12.1.4.2 Tuning the InstaSPIN-MOTION Controller

12.2 Software Configuration for the SpinTAC Velocity Control

12.2.1 Include the Header File

12.2.2 Declare the Global Structure

12.2.3 Initialize the Configuration Variables

12.2.4 Call SpinTAC Velocity Control

12.2.5 Troubleshooting SpinTAC Velocity Control

12.2.5.1 ERR_ID

12.3 Optimal Performance in Speed Control

12.3.1 Introduction

12.3.2 Comparing Speed Controllers

12.3.3 Disturbance Rejection

12.3.4 Profile Tracking

12.3.5 InstaSPIN-MOTION Velocity Control Advantage

12.3.5.1 Single Parameter Tuning

12.3.5.2 Disturbance Rejection Test

12.3.5.3 Feedforward

12.3.5.4 No Integrator Windup

12.3.5.5 Minimum Startup Overshoot

12.3.5.6 Conclusions

12.4 Software Configuration for SpinTAC Position Control

12.4.1 Include the Header File

12.4.2 Declare the Global Structure

12.4.3 Initialize the Configuration Variables

12.4.4 Call SpinTAC Position Control

12.4.5 Troubleshooting SpinTAC Position Control

12.4.5.1 ERR_ID

12.5 Optimal Performance in Position Control

12.5.1 Introduction

12.5.2 Comparing Position Controllers

12.5.3 Disturbance Rejection

12.5.4 Profile Tracking

12.5.5 InstaSPIN-MOTION Position Control Advantage

12.5.5.1 Single Parameter Tuning

12.5.5.2 Disturbance Rejection

12.5.5.3 Feedforward

12.5.5.4 Low-Speed Operation and Smooth Startup

12.5.5.5 Minimum Step Response Settling Time

12.5.5.6 Conclusions

13 Trajectory Planning

13.1 InstaSPIN-MOTION Profile Generation

13.1.1 Jerk Impact on System Performance

13.2 Software Configuration for SpinTAC Velocity Move

13.2.1 Include the Header File

13.2.2 Declare the Global Structure

13.2.3 Initialize the Configuration Variables

13.2.4 Call SpinTAC Velocity Move

13.2.5 Troubleshooting SpinTAC Velocity Move

13.2.5.1 ERR_ID

13.3 Software Configuration for SpinTAC Position Move

13.3.1 Include the Header File

13.3.2 Declare the Global Structure

13.3.3 Initialize the Configuration Variables

13.3.4 Call SpinTAC Position Move

13.3.5 Troubleshooting SpinTAC Position Move

13.3.5.1 Position Profile Limits

13.3.5.2 ERR_ID

13.4 InstaSPIN-MOTION Sequence Planning

13.4.1 SpinTAC Velocity Plan Elements

13.4.1.1 States

13.4.1.2 Transitions

13.4.1.3 Conditions

13.4.1.4 Variables

13.4.1.5 Actions

13.4.2 SpinTAC Velocity Plan Element Limits

13.4.2.1 Example of Sizing SpinTAC Velocity Plan Configuration Array

13.4.3 SpinTAC Velocity Plan Example: Washing Machine Agitation

13.4.4 SpinTAC Velocity Plan Example: Garage Door

13.4.5 SpinTAC Velocity Plan Example: Washing Machine

13.4.6 SpinTAC Position Plan Example: Vending Machine

13.5 Software Configuration for SpinTAC Velocity Plan

13.5.1 Include the Header File

13.5.2 Define the Size of the Configuration Array

13.5.3 Declare the Global Structure

13.5.4 Initialize the Configuration Variables

13.5.5 Call SpinTAC Velocity Plan

13.5.6 Call SpinTAC Velocity Plan Tick

13.5.7 Update SpinTAC Velocity Plan with SpinTAC Velocity Move Status

13.6 Troubleshooting SpinTAC Velocity Plan

13.6.1 ERR_ID

13.6.2 Configuration Errors

13.7 Software Configuration for SpinTAC Position Plan

13.7.1 Include the Header File

13.7.2 Define the Size of the Configuration Array

13.7.3 Declare the Global Structure

13.7.4 Initialize the Configuration Variables

13.7.5 Call SpinTAC Position Plan

13.7.6 Call SpinTAC Position Plan Tick

13.7.7 Update SpinTAC Position Plan with SpinTAC Position Move Status

13.8 Troubleshooting SpinTAC Position Plan

13.8.1 ERR_ID

13.8.2 Configuration Errors

13.9 Conclusion

14 Managing Full Load at Startup, Low-Speed and Speed Reversal

14.1 Low-Speed Operation with Full Load

14.1.1 Low Speed with Full Load Considerations

14.1.1.1 Enable Offsets Recalibration

14.1.1.2 Enable Stator Rs Recalibration

14.1.1.3 Disable Forced Angle

14.1.1.4 Tune Speed Controller to Avoid Motor Stall

14.1.1.5 Tune Voltage Feedback Circuit

14.1.2 Low Speed With Full Load Transient Examples

14.1.2.1 4-Hz, No-Load to Full-Load Transient

14.1.2.2 2-Hz, No-Load to Full-Load Transient

14.2 Speed Reversal with Full Load

14.2.1 Low Speed with Full Load Speed Reversal Considerations

14.2.2 Low Speed with Full Load Speed Reversal Examples

14.2.2.1 From -4 to +4 Hz with Full Load

14.2.2.2 From -2 to +2 Hz with Full Load

14.3 Motor Startup with Full Load

14.3.1 Motor Startup with Full Load Considerations

14.3.1.1 Enable Forced Angle

14.3.2 Motor Startup with Full Load Examples

14.3.2.1 From Standstill to 4 Hz with Full Load

14.3.2.2 From Standstill to 2 Hz with Full Load

14.4 Rapid Acceleration from Standstill With Full Load

14.4.1 Fastest Motor Startup with Full Load without Motor Alignment Considerations

14.4.1.1 Load Valid Offsets and Disable Offset Recalibration

14.4.1.2 Load Valid Rs and Disable Rs Recalibration

14.4.1.3 Fastest Motor Startup with Full Load without Motor Alignment Example

14.4.2 Fastest Motor Startup with Full Load with Motor Alignment Considerations

14.4.2.1 Maximize Current Slope

14.4.2.2 Fastest Motor Startup with Full Load with Motor Alignment Example

14.5 Overloading and Motor Overheating

14.5.1 Overloading and Motor Overheating Considerations

14.5.2 Overloading and Motor Overheating Example

14.6 InstaSPIN-MOTION and Low-Speed Considerations

15 Rs Online Recalibration

15.1 Overview

15.2 Resistance vs. Temperature

15.3 Accurate Rs Knowledge Needed at Low Speeds Including Startup

15.4 Introduction to Rs Online Recalibration

16 PowerWarp™

16.1 Overview

16.2 Enabling PowerWarp

16.3 PowerWarp Current Slopes

16.4 Practical Example

16.5 Case Study

17 Shunt Current Measurements

17.1 Introduction

17.2 Signals

17.3 1-Shunt

17.4 2-Shunt

17.5 3-Shunt

17.6 Development Kits

17.6.1 DRV8312

17.6.2 DRV8301

17.7 Conclusion

18 Sensored Systems

18.1 Hardware Configuration for Quadrature Encoder

18.1.1 Pin Usage

18.2 Software Configuration for Quadrature Encoder

18.2.1 Configure Motor for EQEP Operation

18.2.2 Initialize EQEP Handle

18.2.3 Set Digital IO to connect to QEP Peripheral

18.2.4 Enable Clock to eQEP

18.2.5 Initialize ENC Module

18.2.6 Set Up ENC Module

18.2.7 Call eQEP Function

18.2.8 Provide eQEP Angle to FOC

18.3 InstaSPIN-MOTION Position Convert

18.3.1 Software Configuration for SpinTAC Position Convert

18.3.1.1 Include the Header File

18.3.1.2 Declare the Global Structure

18.3.1.3 Initialize the Configuration Variables

18.3.1.4 Call SpinTAC Position Convert

18.3.2 Troubleshooting SpinTAC Position Convert

18.3.2.1 ERR_ID

19 Difficult Motors

20 Adding System Functions

21 Building Your InstaSPIN-FOC and InstaSPIN-MOTION Board

A Definition of Terms and Acronyms

Revision History (E to F)

Revision History (D to E)

Important Notice

2023年江西萍乡中考道德与法治真题及答案.doc

2023年江西萍乡中考道德与法治真题及答案.doc 2012年重庆南川中考生物真题及答案.doc

2012年重庆南川中考生物真题及答案.doc 2013年江西师范大学地理学综合及文艺理论基础考研真题.doc

2013年江西师范大学地理学综合及文艺理论基础考研真题.doc 2020年四川甘孜小升初语文真题及答案I卷.doc

2020年四川甘孜小升初语文真题及答案I卷.doc 2020年注册岩土工程师专业基础考试真题及答案.doc

2020年注册岩土工程师专业基础考试真题及答案.doc 2023-2024学年福建省厦门市九年级上学期数学月考试题及答案.doc

2023-2024学年福建省厦门市九年级上学期数学月考试题及答案.doc 2021-2022学年辽宁省沈阳市大东区九年级上学期语文期末试题及答案.doc

2021-2022学年辽宁省沈阳市大东区九年级上学期语文期末试题及答案.doc 2022-2023学年北京东城区初三第一学期物理期末试卷及答案.doc

2022-2023学年北京东城区初三第一学期物理期末试卷及答案.doc 2018上半年江西教师资格初中地理学科知识与教学能力真题及答案.doc

2018上半年江西教师资格初中地理学科知识与教学能力真题及答案.doc 2012年河北国家公务员申论考试真题及答案-省级.doc

2012年河北国家公务员申论考试真题及答案-省级.doc 2020-2021学年江苏省扬州市江都区邵樊片九年级上学期数学第一次质量检测试题及答案.doc

2020-2021学年江苏省扬州市江都区邵樊片九年级上学期数学第一次质量检测试题及答案.doc 2022下半年黑龙江教师资格证中学综合素质真题及答案.doc

2022下半年黑龙江教师资格证中学综合素质真题及答案.doc