Essential Electronic Design Automation

(EDA)

By Mark D. Birnbaum

of

Publisher

Pub Date

ISBN

Pages

Slots

: Prentice Hall PTR

: October 01, 2003

: 0-13-182829-0

: 256

:

1.0

• Table

Contents

• Index

Essential Electronic Design Automation (EDA) demystifies this highly technical industry for

anyone with a "need-to-know" about EDA. A friendly, informal introduction to EDA business

and technology, clear enough for laypeople yet detailed enough for technical readers. The

book also makes an excellent complementary text for cross-disciplinary engineering,

business and marketing courses on VLSI Design.

Simply and clearly, veteran industry leader Mark Birnbaum introduces the design problems

EDA is intended to solve, the tools that exist to solve them, the designers who use them,

and what makes EDA crucial to electronic product and chip design.

•

• Explains how EDA fits into the electronic product and semiconductor industries

• Examines the EDA industry from both the tool user and EDA software vendor

perspectives, including business models, return on investment, and tool evaluation

Includes electronic system-level tools for defining what ICs will do, front -end

functional chip-level tools for design how the IC will behave, and back-end design

tools for implementing the IC physical layout

• Discusses EDA industry trends and IC design issues, including deep submicron

challenges, intellectual property (IP), and system-on-chip (SoC)

Includes EDA standards organizations and publications

•

Industry newcomers will appreciate the book's extensive set of appendices, including

primers on electricity, semiconductor manufacturing, computing, and common dimensions,

reference sources and a complete glossary with acronym pronunciation.

1

�

Preface

Purpose of This Book

Purpose of This Book

The tremendous increase in the use of tiny electronic devices is common knowledge. We find

them everywhere today, in cars, household appliances, telephones, music, and business

equipment. The typical car or house uses dozens of them.

These devices are called microchips or integrated circuits (ICs). Today a single IC can do

more than an entire roomful of equipment just a decade ago. Integrated circuits are small

enough to hold in your hand, yet contain millions of tiny electronic components.

Engineers create detailed design plans to make ICs, similar to an architect's building plans.

Architects use computer tools to design a building and predict the structure's response to

storms or earthquakes. Similarly, IC designers use computer program tools to design an IC,

test its performance, and verify its behavior. We refer to the tools as electronic design

automation (EDA) .

An entire industry has evolved to provide these tools to aid the IC designers. This book

introduces readers to the EDA industry. It discusses both the technical and business aspects

of EDA in clear non-technical language without equations. The text briefly describes the

related semiconductor industry issues and evolving chip design problems addressed by the

EDA tools. A unique, dialog format presents the technical material in an easy-to-read

manner.

The book focuses solely on EDA for IC design, intentionally excluding other design

automation areas (e.g., printed circuit boards and mechanical design). The text gives

generic tool descriptions since company and product names change rapidly.

Intended Audience

The electronic product industry consists of electronic system manufacturers, semiconductor

companies, and chip design houses. Semiconductor equipment providers, test equipment

manufacturers, and EDA companies are also part of the industry.

In most of these firms, over half the employees are non-technical or "semi-technical."

These semi-technical people are involved in the EDA or related industries. Experienced

e mployees will have picked up some jargon and knowledge, but both they and most new

employees lack an overall introduction to this highly technical field.

Sales and marketing, communications, legal, or finance personnel will find the book useful.

Others in financial analysis, public relations, or publications firms also need to know about

the EDA industry. Some readers will be interested only in the overview, business, or industry

sections, while others will focus on particular technical EDA chapters.

2

�

Along with the semi-technical people, many people with technical backgrounds will find

the book very beneficial. The technical backgrounds include computer engineering,

programming, electronic testing, mechanical engineering, packaging, or academic fields.

These readers may not have EDA backgrounds and so seek a simple introduction to EDA.

The book is thus helpful to new employees, both technical and non-technical. Some readers

may be familiar with a portion of EDA and want to see "the big picture." Others may focus

on technical areas relevant to their own work.

Faculty and students in universities, colleges, community colleges, and technical institutes

can use the book as an introduction to the IC and EDA industries. The book will fit well in

cross-discipline business/engineering courses. Technical students will find the full coverage

useful and complementary to an academic course on ICs or EDA.

Non-technical readers include:

Within the organization:

Marketing communications, sales, and marketing personnel

Human relations, administrative personnel, and new hires

Manufacturing, purchasing, and operations personnel

Finance, accounting, and legal personnel

Outside the organization:

Financial analysts, law firms

Public relations, publications, or media representatives

Manufacturing representatives, personnel recruiters, or technical writers

Technical readers include:

Electrical engineers new to EDA

Mechanical, packaging, and quality assurance engineers

Programmers (software engineers)

Technical marketing and support personnel

Academic fields include:

Electrical, Mechanical, Systems, and Computer Engineering

Physics

Computer Science and Programming

3

�

Business, Marketing, and Management

Organization

The book's successive chapters build on each other, forming a logical sequence. However,

most chapters can be read independently. The book may also serve as a reference source,

using the several appendixes.

Chapter 1 gives an overview of EDA tools, the people who use them, and the design tasks

they support. (EDA tools address specific design issues, so one has to understand those

problems.)

Chapter 2 describes the EDA business itself. Chapter 3 provides a user perspective on EDA

technical and business issues. Chapter 4 discusses the range of EDA tools and introduces

some essential concepts.

Chapters 5, 6, and 7 focus on the three major EDA design tool areas: electronic system-level,

functional chip-level, and physical. System-level tools help decide what the IC will do and

how it will be made. Chip-level tools help design how the IC will operate (function). Physical

design tools help implement the actual IC physical layout.

Chapter 8 discusses EDA industry trends and related IC design issues.

Since readers have a wide range of backgrounds, several appendixes fill in the technology

basics. Appendixes A, B, and C introduce (in simple English) elementary electricity,

semiconductor manufacture, and computer basics.

Many technical EDA and semiconductor terms are confusing. Most terms are metrics—each

with different units of measure (such as inches, mils, or microns). Some are in English units,

some are in metric units, and some are in both, depending on the context. Appendix D

describes and compares these metrics.

Appendix E has pointers to other EDA reference sourc es for the reader to explore further.

These include organizations, conferences, magazines, the Internet, and universities.

Appendix F provides more depth in several areas that affect the EDA business. These include

deep submicron issues, intellectual property, and system-on-chip.

Every human enterprise (such as medicine, law, or academia) has its own jargon. EDA is no

exception. There is a myriad of strange terms. Many come fro m the semiconductor world

addressed by the EDA tools. In addition, there are all sorts of abbreviations and acronyms.

The text defines many terms in context, and Appendix G provides an extensive

glossary/acronym list with acronym pronunciation.

In summary, readers will be introduced to both the business and technical aspects of the

EDA industry. They will learn about EDA tools, the designers who use them, and their design

problems. In addition, they will gain insight into the current and future role of EDA in the

electronics industries.

4

�

Chapter 1. Introduction to EDA

In this chapter...

Introduction

•

• EDA Party—Users and Tools

• EDA Benefits

• Summary

Introduction

Electronic Products

Engineers use Electronic Design Automation (EDA) tools to design electronic products.

Electronic products include just about anything that plugs into the wall or uses a battery for

electric power, such as computers, cell phones, digital cameras, and communications

equipment. Electronics are used in houses, automobiles, aerospace products, and all kinds of

industrial products.

To understand EDA we have to look more closely at electronic products. Like any technical

area, electronics and EDA use lots of jargon. Let us begin with a little vocabulary so

everyone can start with the same basic terms.

Printed Circuit (PC) Boards

Look inside a stereo, personal computer, or cellular phone, and you will see thin plastic

(often green) printed circuit boards (PC boards).

Did You Know?

Printed Circuit (PC) boards are NOT the same as Personal Computers (PCs), and

are NOT Politically Correct (PC). Unfo rtunately, the same abbreviation is used (PC).

However, Personal Computers do contain PC boards.

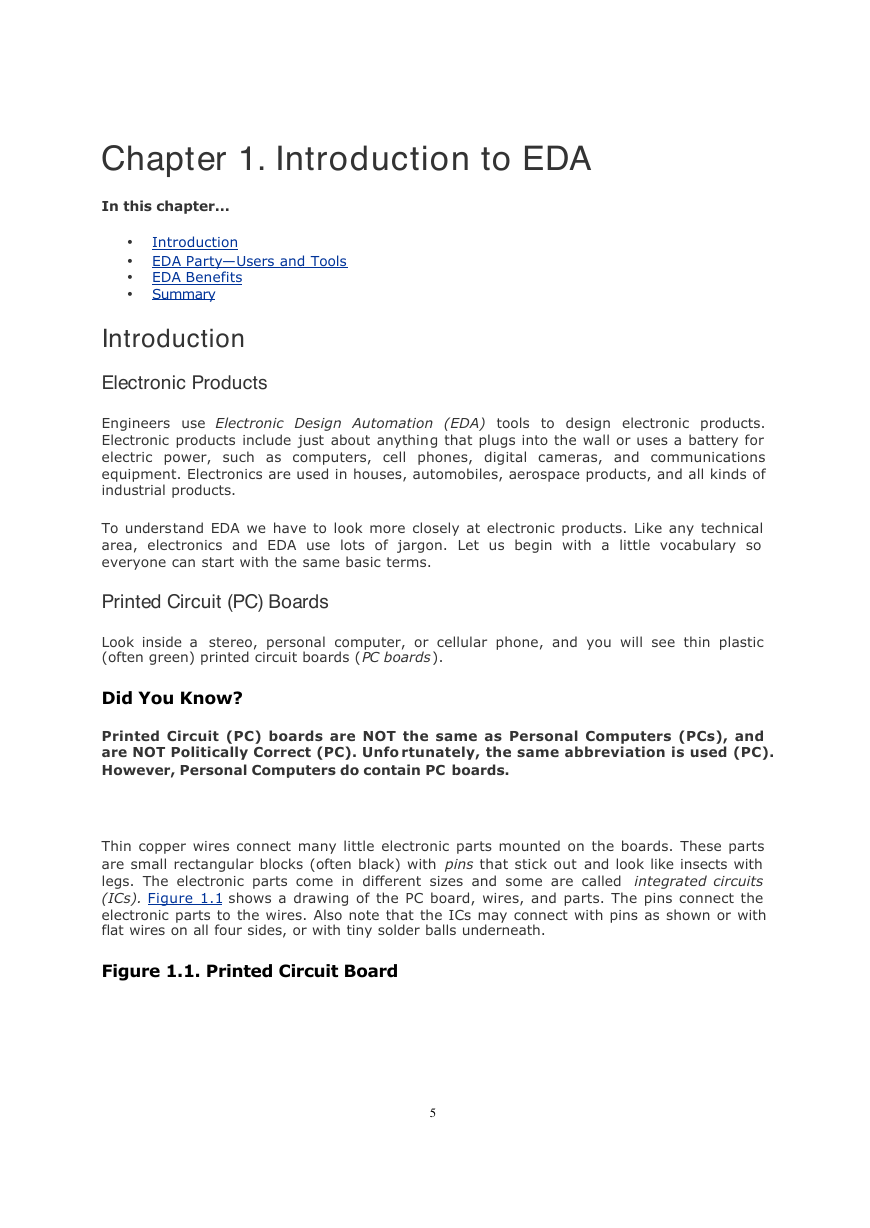

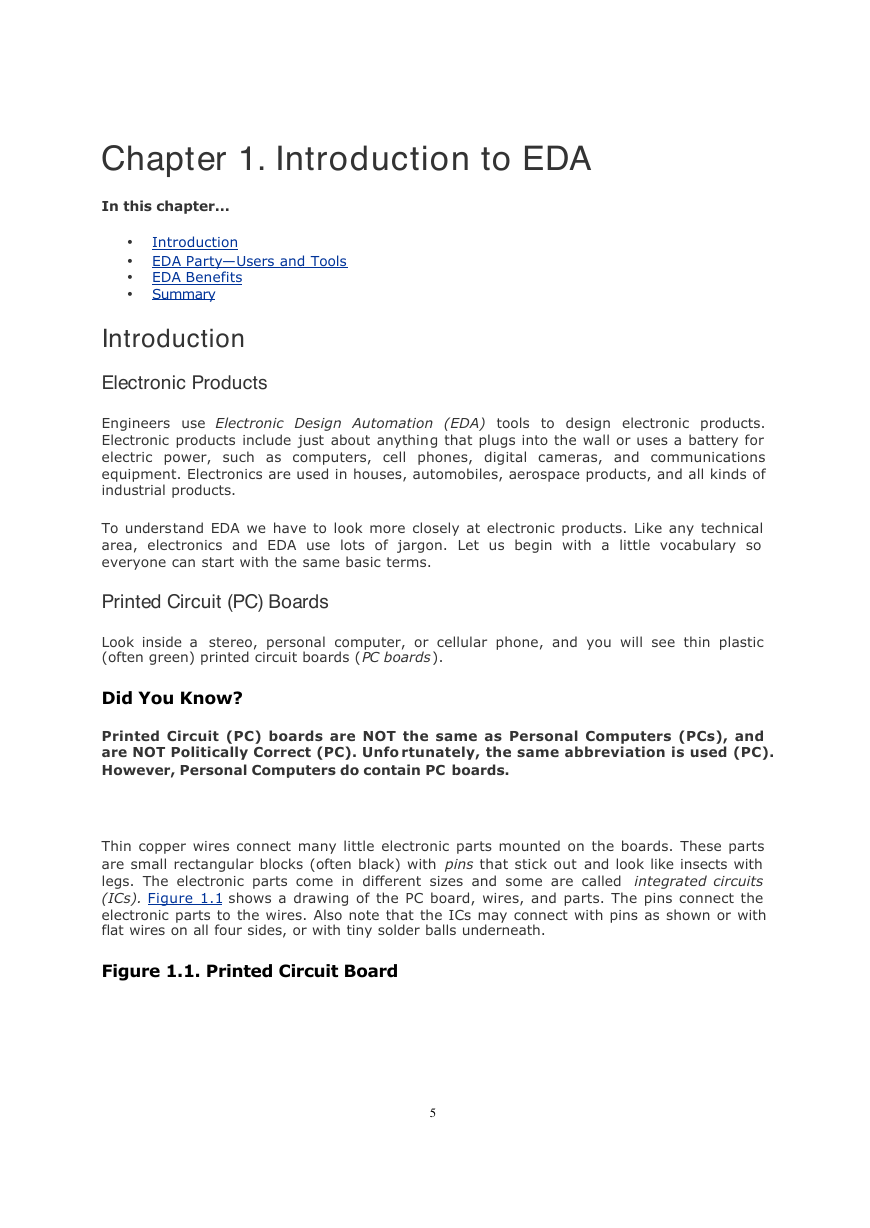

Thin copper wires connect many little electronic parts mounted on the boards. These parts

are small rectangular blocks (often black) with pins that stick out and look like insects with

legs. The electronic parts come in different sizes and some are called integrated circuits

(ICs). Figure 1.1 shows a drawing of the PC board, wires, and parts. The pins connect the

electronic parts to the wires. Also note that the ICs may connect with pins as shown or with

flat wires on all four sides, or with tiny solder balls underneath.

Figure 1.1. Printed Circuit Board

5

�

Note that the PC board wires are printed or deposited, and so are flat, not round. The PC

board also has printed copper fingers or connectors at the edge for electrical connections off

the board.

Integrated Circuits

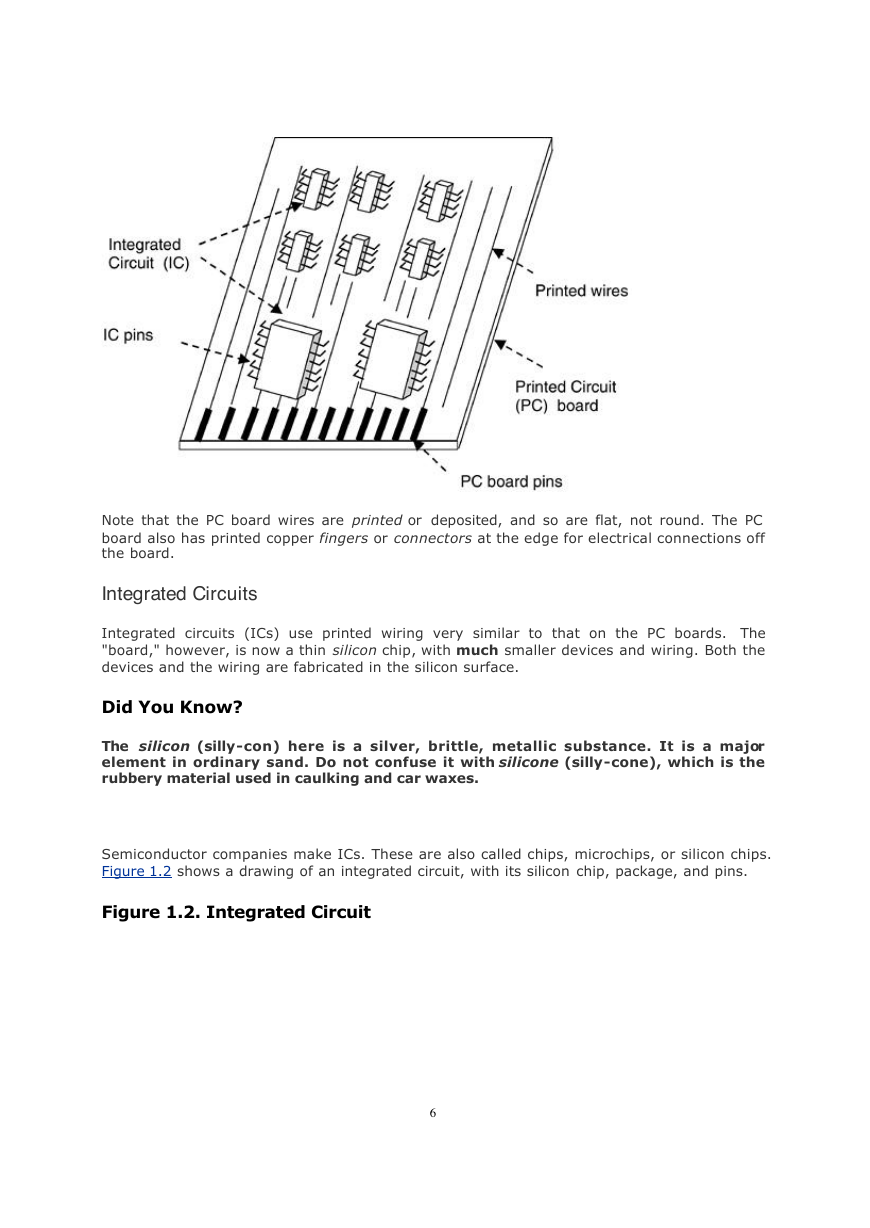

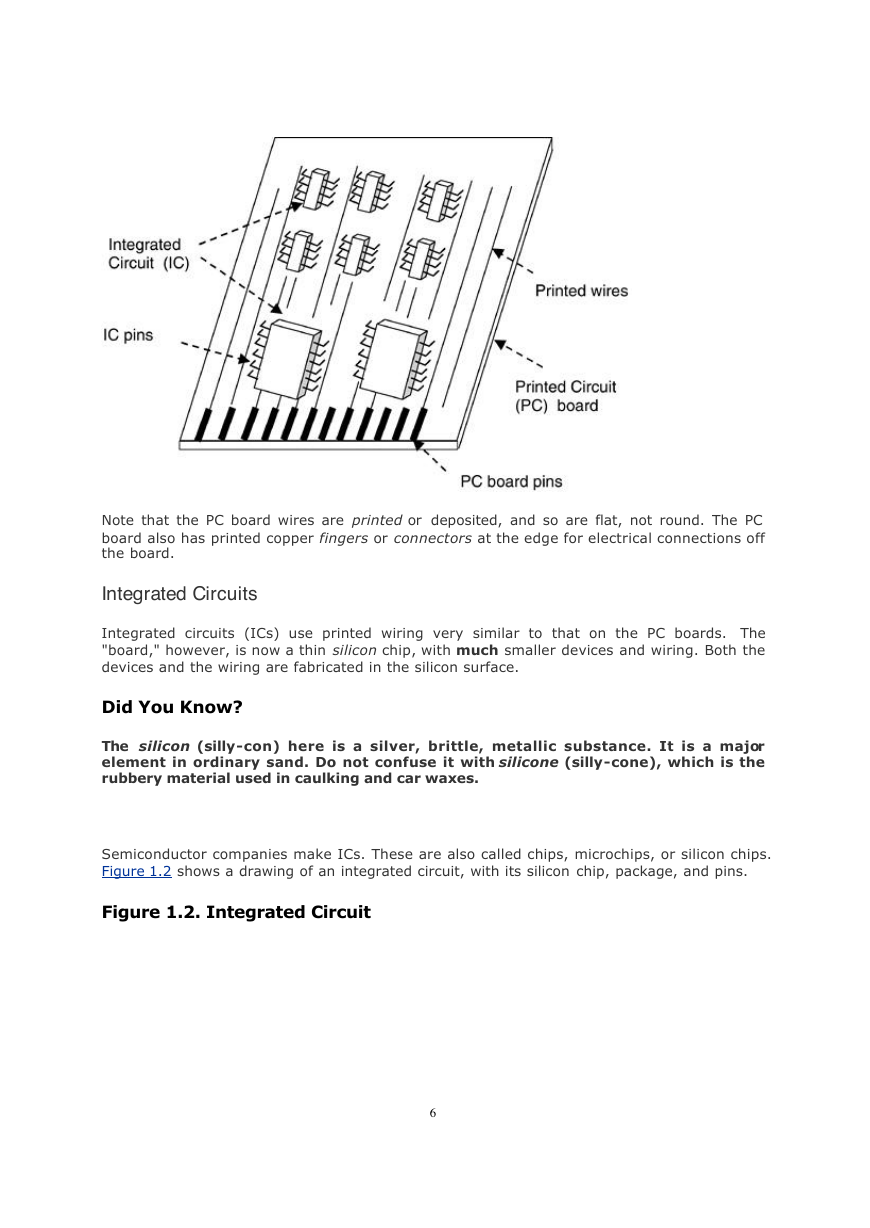

Integrated circuits (ICs) use printed wiring very similar to that on the PC boards. The

"board," however, is now a thin silicon chip, with much smaller devices and wiring. Both the

devices and the wiring are fabricated in the silicon surface.

Did You Know?

The silicon (silly-con) here is a silver, brittle, metallic substance. It is a major

element in ordinary sand. Do not confuse it with silicone (silly-cone), which is the

rubbery material used in caulking and car waxes.

Semiconductor companies make ICs. These are also called chips, microchips, or silicon chips.

Figure 1.2 shows a drawing of an integrated circuit, with its silicon chip, package, and pins.

Figure 1.2. Integrated Circuit

6

�

The figure shows the fine gold bonding wires which connect the chip pads to the package

pins. The wires are thinner than a human hair. The IC package takes up much more room

than the tiny chip. There are many other styles of IC packages besides the example shown.

Some chips are encased in smaller chip scale packages. Some ICs (called flip chips) can

connect directly to PC boards, without package, wires, or pins. This allows those boards to

hold more chips.

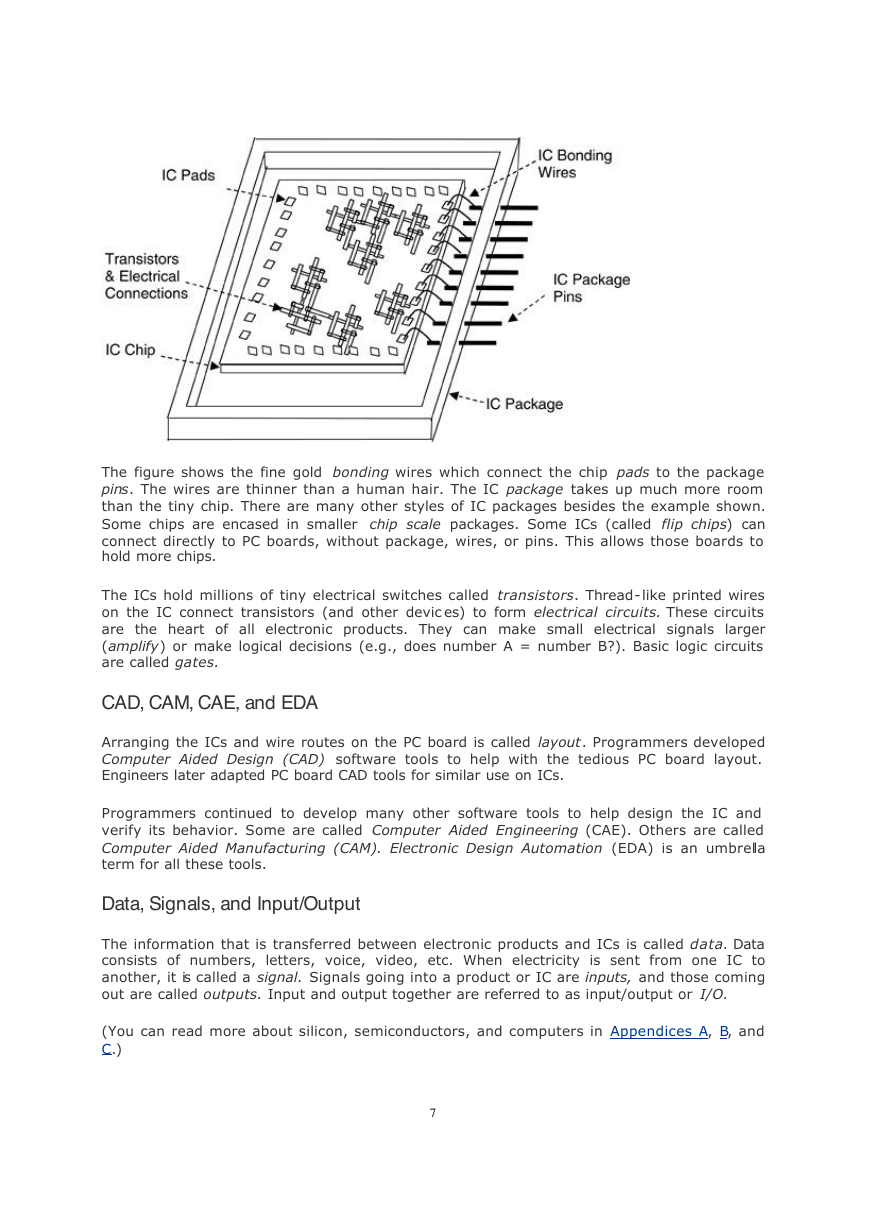

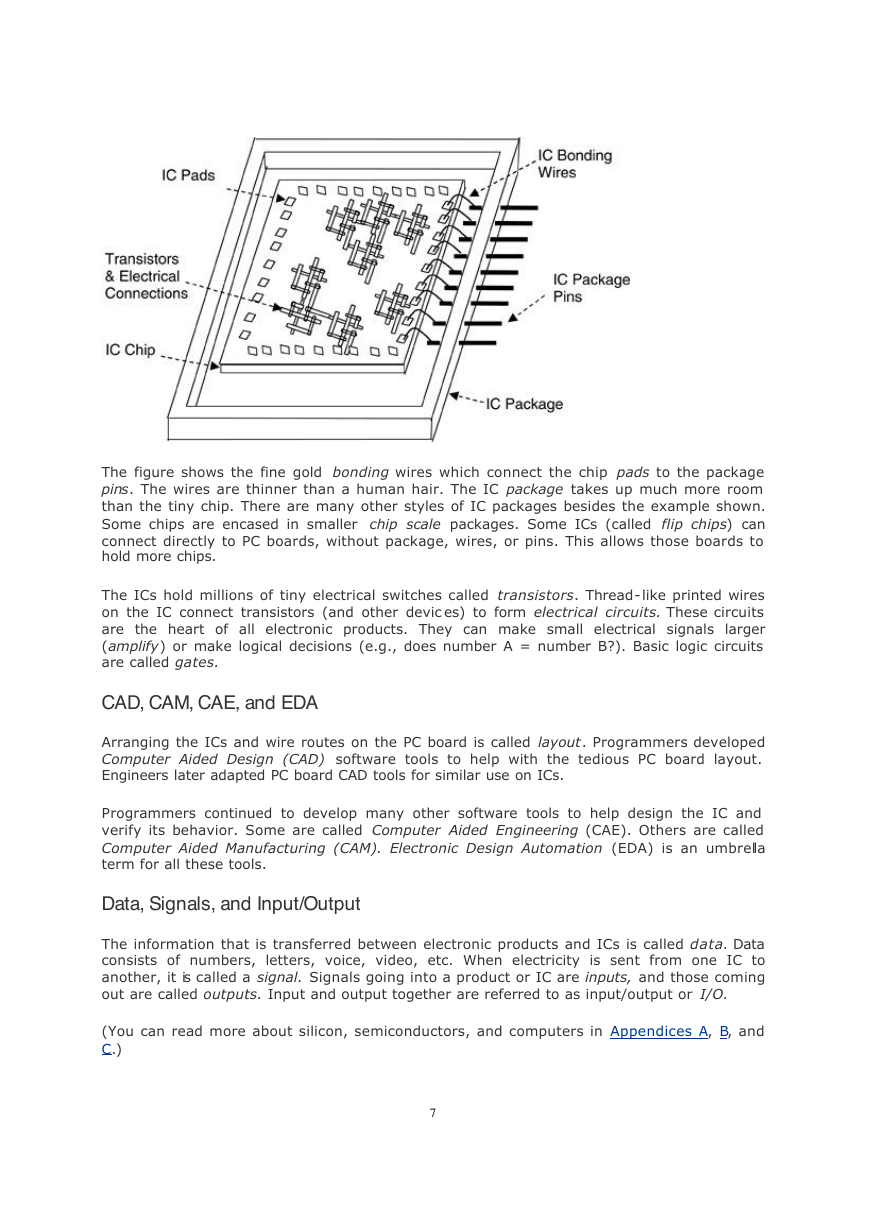

The ICs hold millions of tiny electrical switches called transistors. Thread-like printed wires

on the IC connect transistors (and other devic es) to form electrical circuits. These circuits

are the heart of all electronic products. They can make small electrical signals larger

(amplify) or make logical decisions (e.g., does number A = number B?). Basic logic circuits

are called gates.

CAD, CAM, CAE, and EDA

Arranging the ICs and wire routes on the PC board is called layout. Programmers developed

Computer Aided Design (CAD) software tools to help with the tedious PC board layout.

Engineers later adapted PC board CAD tools for similar use on ICs.

Programmers continued to develop many other software tools to help design the IC and

verify its behavior. Some are called Computer Aided Engineering (CAE). Others are called

Computer Aided Manufacturing (CAM). Electronic Design Automation (EDA) is an umbrella

term for all these tools.

Data, Signals, and Input/Output

The information that is transferred between electronic products and ICs is called data. Data

consists of numbers, letters, voice, video, etc. When electricity is sent from one IC to

another, it is called a signal. Signals going into a product or IC are inputs, and those coming

out are called outputs. Input and output together are referred to as input/output or I/O.

(You can read more about silicon, semiconductors, and computers in Appendices A, B, and

C.)

7

�

Electronic Product Development

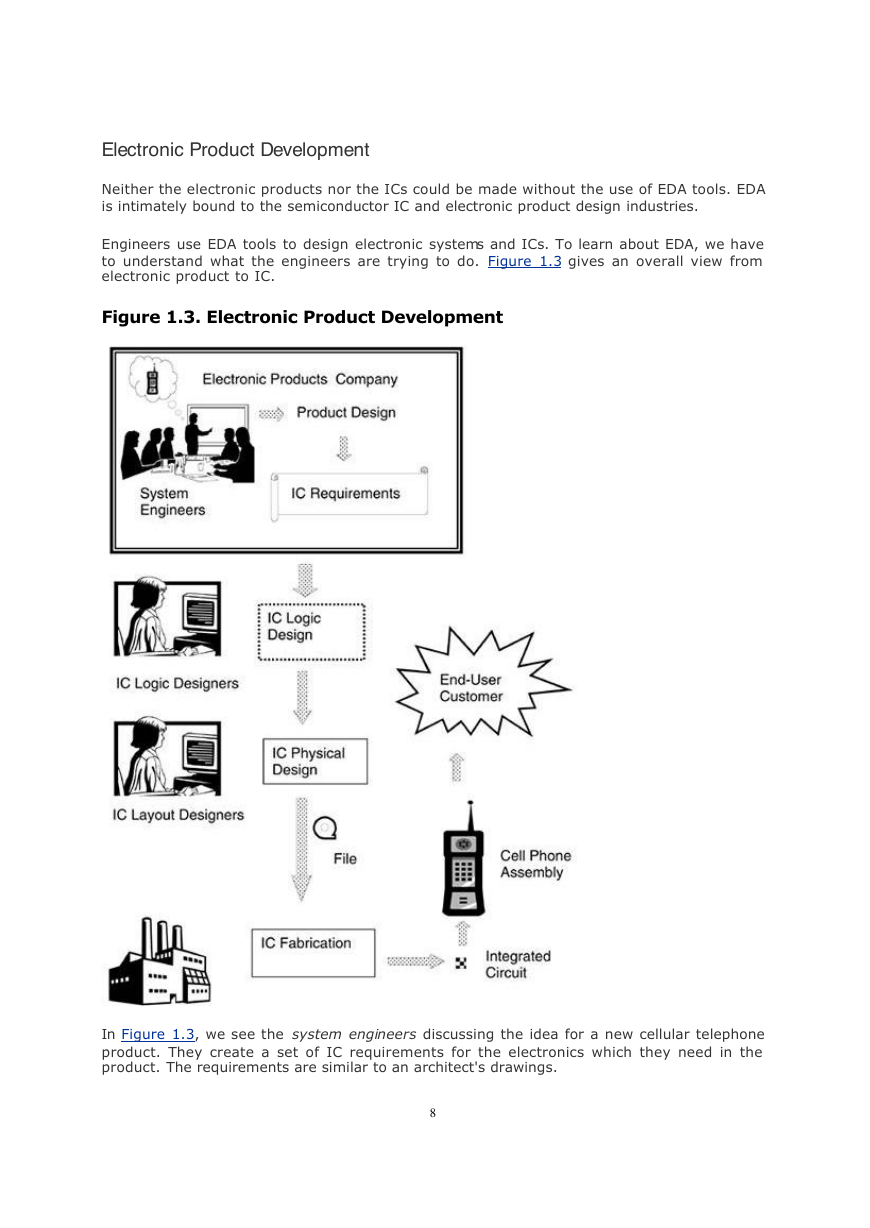

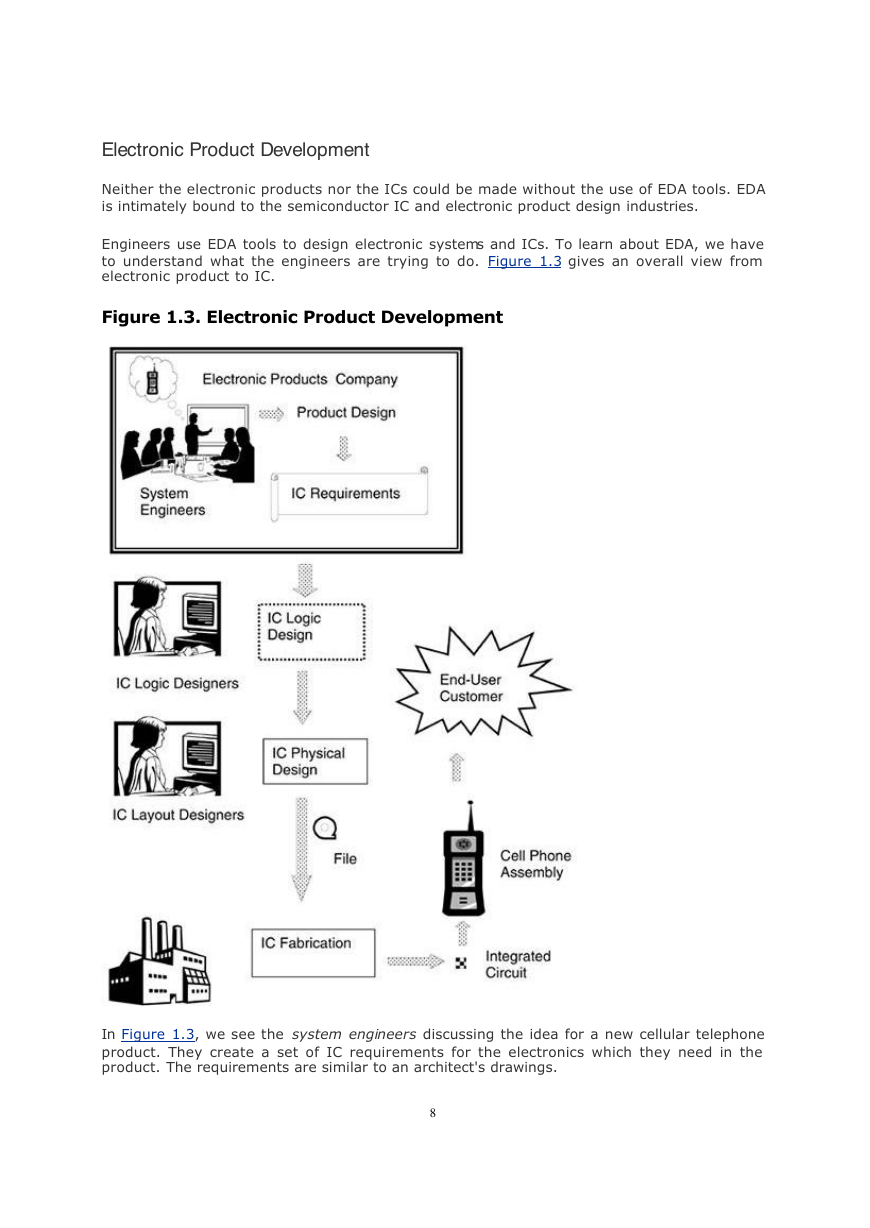

Neither the electronic products nor the ICs could be made without the use of EDA tools. EDA

is intimately bound to the semiconductor IC and electronic product design industries.

Engineers use EDA tools to design electronic systems and ICs. To learn about EDA, we have

to understand what the engineers are trying to do. Figure 1.3 gives an overall view from

electronic product to IC.

Figure 1.3. Electronic Product Development

In Figure 1.3, we see the system engineers discussing the idea for a new cellular telephone

product. They create a set of IC requirements for the electronics which they need in the

product. The requirements are similar to an architect's drawings.

8

�

2023年江西萍乡中考道德与法治真题及答案.doc

2023年江西萍乡中考道德与法治真题及答案.doc 2012年重庆南川中考生物真题及答案.doc

2012年重庆南川中考生物真题及答案.doc 2013年江西师范大学地理学综合及文艺理论基础考研真题.doc

2013年江西师范大学地理学综合及文艺理论基础考研真题.doc 2020年四川甘孜小升初语文真题及答案I卷.doc

2020年四川甘孜小升初语文真题及答案I卷.doc 2020年注册岩土工程师专业基础考试真题及答案.doc

2020年注册岩土工程师专业基础考试真题及答案.doc 2023-2024学年福建省厦门市九年级上学期数学月考试题及答案.doc

2023-2024学年福建省厦门市九年级上学期数学月考试题及答案.doc 2021-2022学年辽宁省沈阳市大东区九年级上学期语文期末试题及答案.doc

2021-2022学年辽宁省沈阳市大东区九年级上学期语文期末试题及答案.doc 2022-2023学年北京东城区初三第一学期物理期末试卷及答案.doc

2022-2023学年北京东城区初三第一学期物理期末试卷及答案.doc 2018上半年江西教师资格初中地理学科知识与教学能力真题及答案.doc

2018上半年江西教师资格初中地理学科知识与教学能力真题及答案.doc 2012年河北国家公务员申论考试真题及答案-省级.doc

2012年河北国家公务员申论考试真题及答案-省级.doc 2020-2021学年江苏省扬州市江都区邵樊片九年级上学期数学第一次质量检测试题及答案.doc

2020-2021学年江苏省扬州市江都区邵樊片九年级上学期数学第一次质量检测试题及答案.doc 2022下半年黑龙江教师资格证中学综合素质真题及答案.doc

2022下半年黑龙江教师资格证中学综合素质真题及答案.doc