Design and Development of a Knowledge Discovery System in Inventory

Management

C. A. Mitrea, C. K. M. Lee

Division of Systems and Engineering Management, School of Mechanical and Aerospace Engineering

Nanyang Technological University, Singapore

ckmlee@ntu.edu.sg

mitr0002@ntu.edu.sg

Abstract - To manage the inventory efficiently, it is

necessary to have accurate forecasting. To extract and

deploy the knowledge associated with forecasting

attracts

the attention of both academic and

practitioners. Knowledge is regarded as a valuable

asset for enterprises and it can be manipulated

through intelligence techniques like Artificial Neural

Networks (ANN). ANN has the special ability to learn

facts about one knowledge domain by inputting data

obtained from observations. This study focuses on

exploring how ANN learns and analyzes different

types of ANN and ANN architectures used in the

demand forecasting. The feasibility of the proposed

approach

is

demonstrated with numeric data. The significance of

this study is to adopt ANN as a knowledge discovery

system thereby enhancing the inventory management.

the demand

forecasting

Keywords – Forecasting, Inventory Management,

Knowledge Discovery Process, Neural Networks, Rule

Extraction, Weights

issue

to

1. INTRODUCTION

is

efficiency

Inventory management

intelligent systems. This has been already

affected

considerably by the forecasting accuracy which can be

enhanced if knowledge about its variables is available. A

form of knowledge which is easy to understand by

humans is rules. Whether the system is efficient depends

on the quality of rules in the system. However, knowledge

acquisition is not easy. In the inventory management

field, some knowledge cannot be described easily by

knowledge engineers, some cannot be understandable

easily by managers, and some cannot be identified easily

by

the

bottleneck of knowledge management. Considered as a

tool of machine learning, an artificial neural network has

the capability to self learning hence acquiring rules by

itself through the process of inductive machine learning.

However, rules obtained by neural networks are hidden in

the architecture and weights of networks, and are not easy

to understand by human being or to be applied to improve

inventory management [1].

Two crucial criteria for NN learning are based on

comprehensibility of

learned models and predictive

accuracy. While NN attains high predictive accuracy, the

incomprehensibility of its predictive behavior prevents its

application in solving in inventory management problems.

2. LITERATURE REVIEW

For this reason, this research is exploring the techniques

and methods to extract rules, embedded in the weights of

a neural network which was trained to forecast demand

and lead time in inventory management.

This section provides a comprehensive study of three

topics which are inventory management, knowledge

discovery process and ANN. Inventory Management

requires detail planning, controlling and monitoring the

flow of and storage of goods and service. To achieve

satisfactory level of service, implicit and tacit knowledge

is required so as to enhance inventory management.

Knowledge Discovery Process

the

to knowledge are

processes of

examined. Among

(AI)

techniques, Artificial Neural Networks is identified in this

research as the engine to acquire the knowledge.

2.1 Inventory Management is the art of managing

inventory which is defined as a physical resource that a

firm/company holds in stock with the intent of selling it or

transforming it into a more valuable state [2]. Over the

past fifteen years, inventory management has become an

important focus of competitive advantage for firms and

organizations.

transforming data

is studied and

the Artificial

Intelligence

the enterprise because

According to Sprague [3], inventory management

plays a crucial role

its

performance improvement can enhance overall supply

chain activities. Liberman [4] identifies five inventory

management performance factors and the challenge faced

by the companies (1) Technical factors- Companies lack

the availability, reliability and knowledge of efficient

technology; (2) Organizational factors- Companies may

not have right technical input and financial support; (3)

Financial factors- Companies may not have explicit

financial mechanisms;

-

Companies do not have sufficient training and proper

management, and (5) Informational factors – Companies

lack appropriate

information

sharing problems.

inventory

Another

management performance conducted by Vries [5] has

as

grouped

followings

(3)

Organizational categories. Similarly, in the research of

Rajeev [6], he identifies factors such as: (1) Safety stock,

Purchasing

(2) Capacity

inventory management

(1) Economic,

performance

(2) Behavioral and

information and have

(4) Managerial

influencing

study on

utilization

factors

factors

to

level,

(3)

1449

978-1-4244-4870-8/09/$26.00 ©2009 IEEE�

effectiveness, (4) Demand forecasting accuracy, (5)

Practices of inventory management, (6) Management

attitude, (7) Employees training, (8) Interaction with

suppliers, (9) Interaction with customers and, (10)

Supplier empowerment.

Other researchers narrowed the number of inventory

management performance factors to technical aspect, and

studied only the influential factors in forecasting. Safety

Stock which is the extra units of inventory carried as

protection against possible stock-outs [7]. While making

the order quotation and calculating production plan, the

safety stock must be used to guard against the uncertainty

of the manufacturing processes, demand and lead time

[8]. Some factors such as lead time, number of customers,

customer

supply

reliability can affect the safety stock [9]. Dongxu [10]

identified the factors such as use frequency, quality grade

and actual safety stock, while Jia [11] suggested forward

factors such as stock-out cost, sales situation. Figure 1 is

an integration of all influential factors that determine

safety stock.

Not all the factors that are influencing safety stock

performance have the same relevance weighting. Factors

like lead time could have a bigger magnitude on the

determination of safety stock. To determine

the

significance of each factor into a causal NN forecasting

model is one of the objectives of this research.

satisfaction, delivery

reliability,

1.2 Knowledge Discovery Process (KDP) is a non-

trivial process of identifying valid, novel, potentially

in data [12]

useful and understandable knowledge

Researchers have proposed a seven – step approach is

described in Figure 2 [12]. A brief description of each

step is shown as following:

1) Goal identification. Goal identification has the purpose

to clearly define what should be accomplished. Goal

identification is the most difficult task, as decisions about

resource allocations as well as measures of success need

to be determined. A clear problem statement is enlisted as

set of criteria to measure success and failure.

2) Data selection - Data selection step restricts subsets of

data from larger databases and different kinds of data

sources. This phase involves sampling techniques, and

database queries.

3) Data Preprocessing – data preprocessing represents

data coding, enrichment and clearing [13] which involves

accounting

for noise and dealing with missing

information. Usually the majority of data preprocessing

takes place before data is permanently stored in a

structure such as data warehouse.

Figure 2 Knowledge Discovery Process steps

1450

Figure 1 Influential factors of safety stock

that can be solved

4) Data transformation- has the purpose to change data

into a form, from which useful knowledge can be

extracted. Data transformation methods also reduce the

dimensionality of data and eliminate statistical properties

that are harmful to data mining techniques.

5) Data mining step is made of three tasks: specification,

selection of an appropriate method, and problem solving.

The data mining task is an abstract description about the

problem

through classification,

clustering, association and prediction.

6) Evaluation and conclusion making is a user-oriented

step where the analyst interprets the model; verifies its

stability and validity, and evaluates the interestingness of

the result. The model can be evaluated quantitatively with

respect to data and formalized assumptions.

7)Use of knowledge- This is the final objective of

Knowledge Discovery Process which

involves user

action, such as minimizing Safety Stock but maintaining

the same customer service level or even improving it

according to the factors that are relevant to inventory

management performance.

is an

information processing

certain

performance characteristics in common with biological

neuron networks.

1.3 Artificial Neural Networks (ANN)

that has

system

Neural Network with hidden layers is universal

approximators, which means that, in theory they are

capable of learning an arbitrarily accurate approximation

to any unknown function, provided that they increase in

complexity at a rate approximately proportional to the

size of the training data. Neural networks can be applied

to time series modeling without assuming a priori

function forms of models. A variety of neural network

techniques have been proposed,

investigated, and

successfully applied to time series prediction and causal

prediction shown in Figure 3.

Proceedings of the 2009 IEEE IEEM�

(a)

(b) (b)

(a) (b)

(c) (d)

Figure 3 NN used in forecasting

Multilayer Feedforward NN (MFFN) (a) [14] is the most

common NN used in causal forecasting, the flow of

information is from the input layer to the output layer,

Recurrent NN (b) [17, 18] is basically a Feedforward NN

with a recurrent loop, therefore the output signals are fed

back to the input, Time delay NN (c) [15,16] integrates

time delay

and Nonlinear Autoregressive

eXogenous NN (NARX) (d) [19,20] is a combination of

all above NN, and is applied successfully in time series

forecasting and also causal forecasting. It will show in

Chapter 3.

lines,

The use of NN in forecasting can be described

intuitively as follows. Given a certain amount of historical

data which can be used to analyze the behavior of a

particular system, such data can be used to train a NN to

correlate the system with respect to time or other system

parameters. Even

this seems a simplistic

description, experiences shows that NN approach is able

to provide a more accurate prediction than expert systems

or statistical counterpart [21].

though

3. METHODOLOGY

This section proposes a knowledge discovery model

shown in Figure 4 and a computational example using a

given set of data [22]. Table 1 is the extract of first 9

values from 48 total values.

Period (month)

Season factor

Level

Trend

Demand

Random

Demand

1

0.47

18439

524

8000

21234

2

0.68

19015.4

524

13251.16

34345

3

1.17

19644.2

524

24087.26

4

1.67

20325.4

524

36306.13

9643

44321

Figure 4 Knowledge Discovery Model

Knowledge Discovery Model used is composed from nine

steps. This paper focuses only on first seven steps. Rule

extraction step will be analyzed in depth in future work.

Decompositional approach is based on an extraction

algorithm in which each component of the network is

examined. The knowledge extracted at this level is

combined afterward. As this method concentrates on the

individual components, this is considered an open-box

approach.

Pedagogical (input/output) approach concentrates on

the analysis of the input /output behavior of the network.

In essence, the method pertains to of the black box

approaches.

The purpose of this experiment is to demonstrate that

a neural network learns facts about relationships between

the input variables and output ones, if the relation exists.

Therefore after testing different NN architectures a

NARX network is selected, with 17 neurons in the hidden

layer and having four variables as inputs: Period, Season

factor, Level, Trend and Demand as output (Table 1). In

the hypothesis, it is assumed that there is a relation

between input variable and output safety stock (S)

[22]:

equation Winter

described

t+ , where F nt+ is the forecasted

F l

demand for period l, L t is the level, T t is the trend, and

t+ =(L t +lT t )S l

equation

by

5

0.47

21059

524

t+ is the seasonal factor at the time period l . According

S l

10784.34

to Winter’s model the equations that govern L, T and S

12321

are described below:

6

0.68

21845

524

16458.04

7

1.17

22683.4

524

29850.21

8

1.67

23574.2

524

44881.92

9

0.47

24517.4

524

13296.39

53423

16897

33873

43212

Table 1 Tahoe Salt data

1451

Proceedings of the 2009 IEEE IEEM�

+

1

+

1

+

1

+

1

+

1

+

/

−

=

=

L

t

T

t

S

α

D

(

t

β

L

(

t

γ

=

(

To simplify the model we assume that T and S are

constant, and the periodicity of demand is 4.

−+

α

L

)

1(

)(

t

β

−+

T

)

1(

t

γ

−+

S

)

)

1(

S

+

t

1

L

)

t

L

/

t

+

1

D

t

++

pt

1

T

t

+

1

t

)

For example the forecasted demand at period 2 is

1

2

calculated as:

F =2

ST+

)2

(L

1

Therefore in training the network, the input layer is

fed with 4 variables: L1, T1, l(time period) and S2, while

the output is F2.

=(18439+2*524)0.68=13251.16

The network uses the default Levenberg-Marquardt

algorithm for training. The application randomly divides

input vectors and target vectors into three sets: 60% are

used for training, 20% are used to validate that the

network is generalizing and to stop training before

overfitting; the last 20% are used as a completely

independent test of network generalization.

4. RESULTS

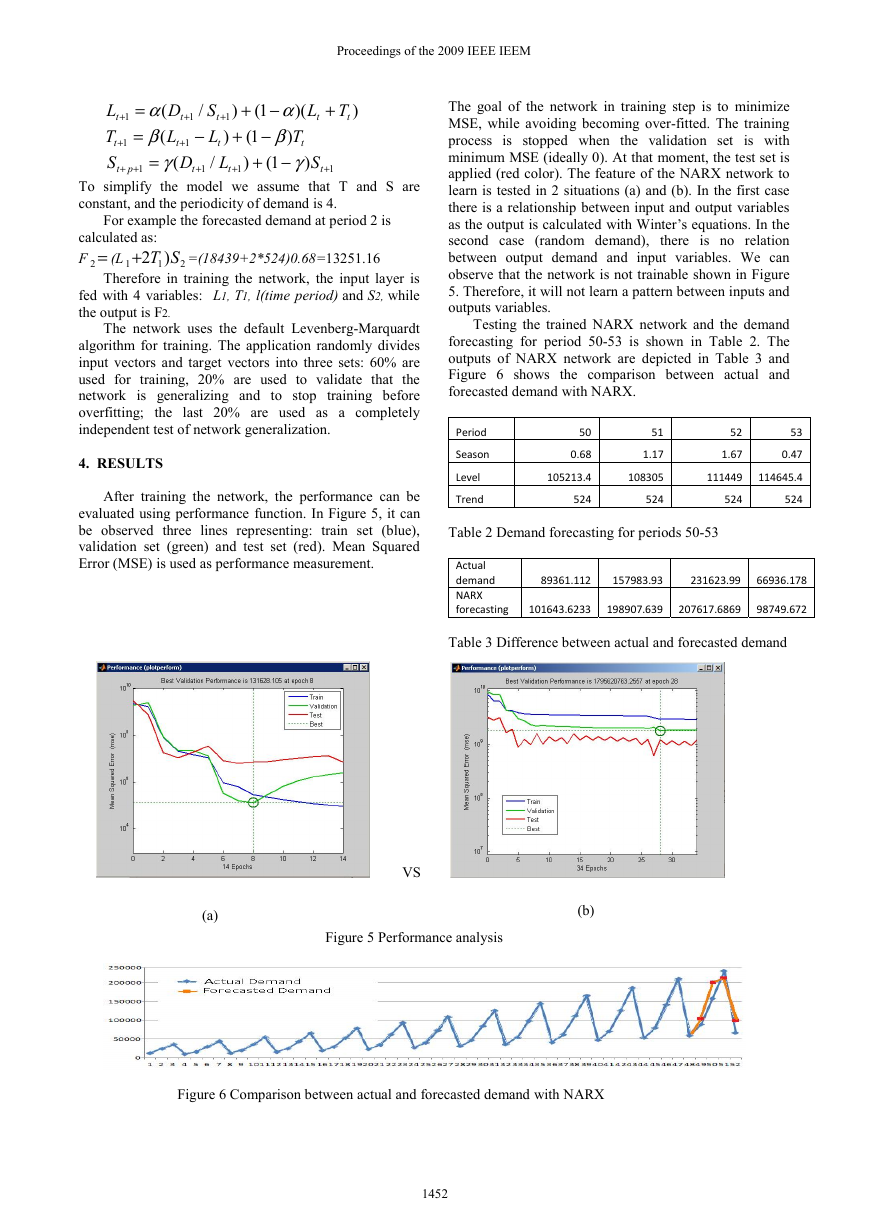

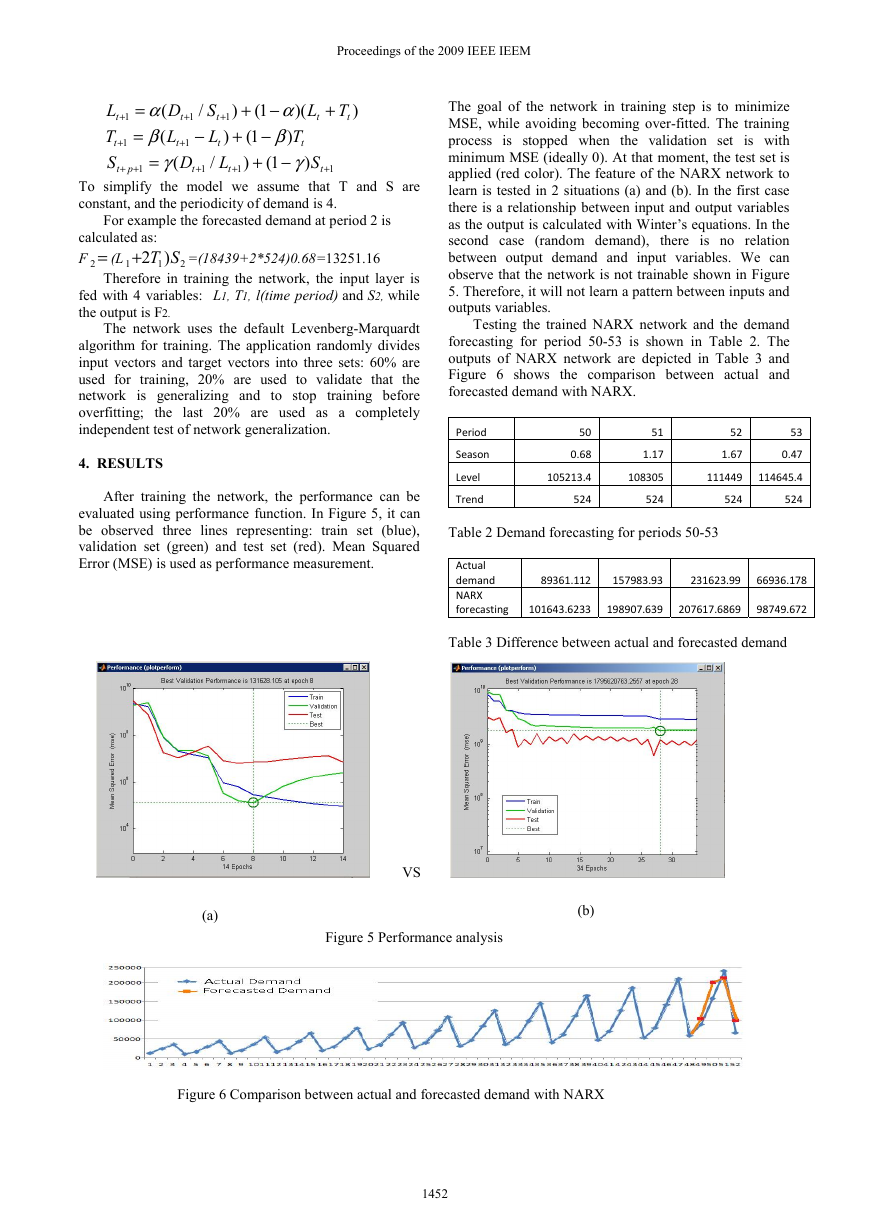

After training the network, the performance can be

evaluated using performance function. In Figure 5, it can

be observed three lines representing: train set (blue),

validation set (green) and test set (red). Mean Squared

Error (MSE) is used as performance measurement.

The goal of the network in training step is to minimize

MSE, while avoiding becoming over-fitted. The training

process is stopped when the validation set is with

minimum MSE (ideally 0). At that moment, the test set is

applied (red color). The feature of the NARX network to

learn is tested in 2 situations (a) and (b). In the first case

there is a relationship between input and output variables

as the output is calculated with Winter’s equations. In the

second case (random demand), there is no relation

between output demand and input variables. We can

observe that the network is not trainable shown in Figure

5. Therefore, it will not learn a pattern between inputs and

outputs variables.

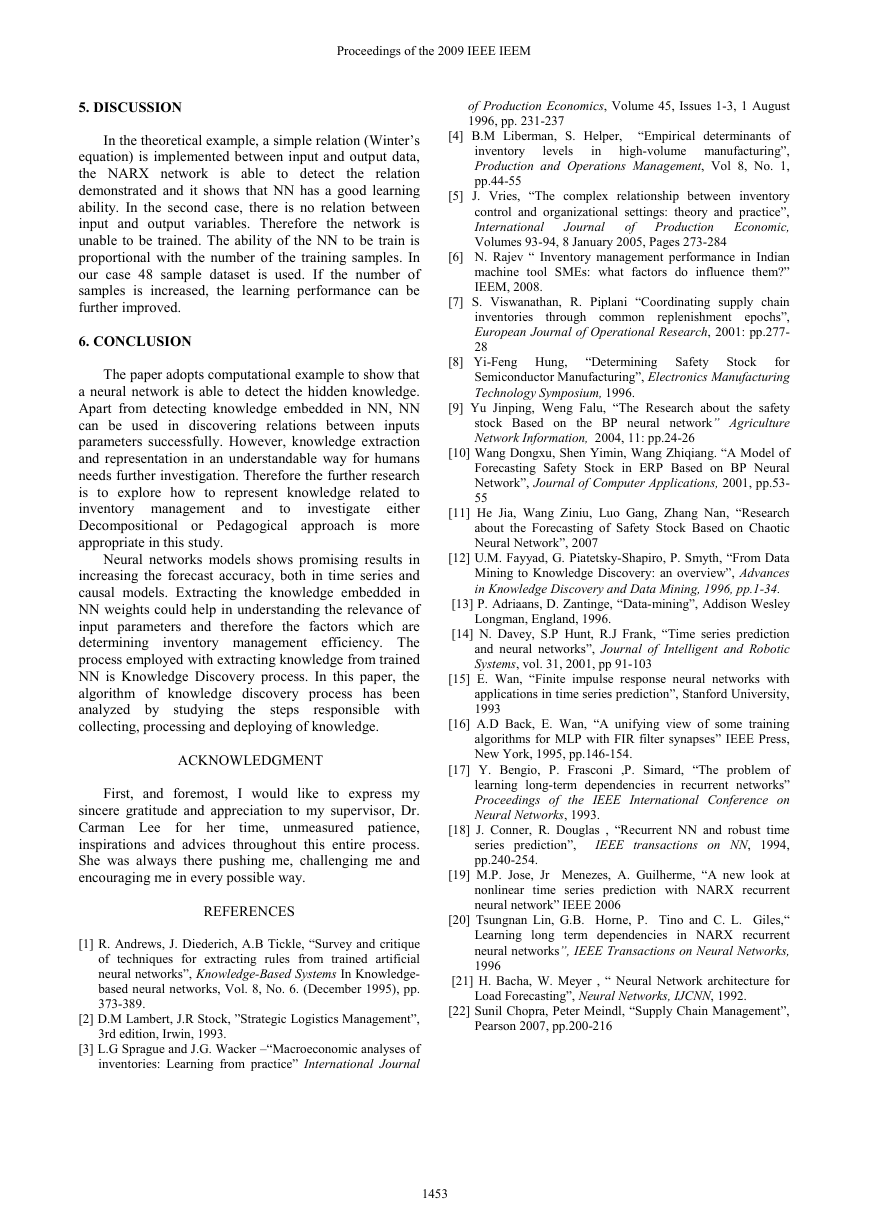

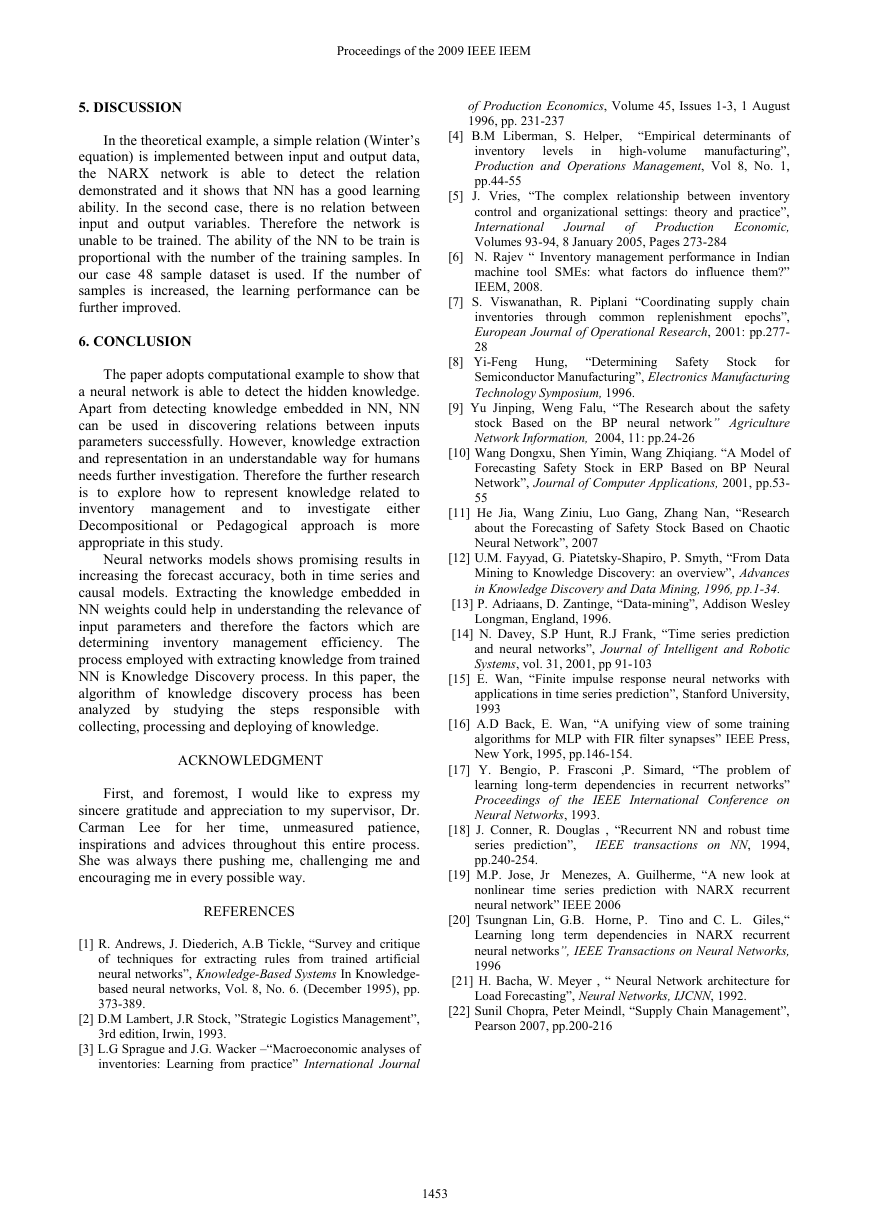

Testing the trained NARX network and the demand

forecasting for period 50-53 is shown in Table 2. The

outputs of NARX network are depicted in Table 3 and

Figure 6 shows the comparison between actual and

forecasted demand with NARX.

Period

Season

Level

50

0.68

51

1.17

52

1.67

53

0.47

105213.4

108305

111449

114645.4

Trend

524

524

524

524

Table 2 Demand forecasting for periods 50-53

Actual

demand

NARX

forecasting

89361.112

157983.93

231623.99

66936.178

101643.6233

198907.639

207617.6869

98749.672

Table 3 Difference between actual and forecasted demand

VS

Figure 5 Comparison between actual demand

(b)

(a)

Figure 5 Performance analysis

Figure 6 Comparison between actual and forecasted demand with NARX

1452

Proceedings of the 2009 IEEE IEEM�

5. DISCUSSION

In the theoretical example, a simple relation (Winter’s

equation) is implemented between input and output data,

the NARX network is able to detect the relation

demonstrated and it shows that NN has a good learning

ability. In the second case, there is no relation between

input and output variables. Therefore the network is

unable to be trained. The ability of the NN to be train is

proportional with the number of the training samples. In

our case 48 sample dataset is used. If the number of

samples is increased, the learning performance can be

further improved.

6. CONCLUSION

The paper adopts computational example to show that

a neural network is able to detect the hidden knowledge.

Apart from detecting knowledge embedded in NN, NN

can be used in discovering relations between inputs

parameters successfully. However, knowledge extraction

and representation in an understandable way for humans

needs further investigation. Therefore the further research

is to explore how to represent knowledge related to

investigate either

inventory management and

Decompositional or Pedagogical approach

is more

appropriate in this study.

Neural networks models shows promising results in

increasing the forecast accuracy, both in time series and

causal models. Extracting the knowledge embedded in

NN weights could help in understanding the relevance of

input parameters and therefore the factors which are

determining

inventory management efficiency. The

process employed with extracting knowledge from trained

NN is Knowledge Discovery process. In this paper, the

algorithm of knowledge discovery process has been

analyzed by studying

responsible with

collecting, processing and deploying of knowledge.

First, and foremost, I would like to express my

sincere gratitude and appreciation to my supervisor, Dr.

Carman Lee

time, unmeasured patience,

inspirations and advices throughout this entire process.

She was always there pushing me, challenging me and

encouraging me in every possible way.

ACKNOWLEDGMENT

the steps

for her

to

REFERENCES

[1] R. Andrews, J. Diederich, A.B Tickle, “Survey and critique

of techniques for extracting rules from trained artificial

neural networks”, Knowledge-Based Systems In Knowledge-

based neural networks, Vol. 8, No. 6. (December 1995), pp.

373-389.

[2] D.M Lambert, J.R Stock, ”Strategic Logistics Management”,

3rd edition, Irwin, 1993.

[3] L.G Sprague and J.G. Wacker –“Macroeconomic analyses of

inventories: Learning from practice” International Journal

of Production Economics, Volume 45, Issues 1-3, 1 August

1996, pp. 231-237

of

in

levels

[4] B.M Liberman, S. Helper, “Empirical determinants of

inventory

high-volume manufacturing”,

Production and Operations Management, Vol 8, No. 1,

pp.44-55

[5] J. Vries, “The complex relationship between inventory

control and organizational settings: theory and practice”,

International

Economic,

Volumes 93-94, 8 January 2005, Pages 273-284

Production

Journal

[6] N. Rajev “ Inventory management performance in Indian

machine tool SMEs: what factors do influence them?”

IEEM, 2008.

[7] S. Viswanathan, R. Piplani “Coordinating supply chain

inventories

replenishment epochs”,

European Journal of Operational Research, 2001: pp.277-

28

through common

[8] Yi-Feng Hung,

for

Semiconductor Manufacturing”, Electronics Manufacturing

Technology Symposium, 1996.

“Determining Safety Stock

[9] Yu Jinping, Weng Falu, “The Research about the safety

stock Based on the BP neural network” Agriculture

Network Information, 2004, 11: pp.24-26

[10] Wang Dongxu, Shen Yimin, Wang Zhiqiang. “A Model of

Forecasting Safety Stock in ERP Based on BP Neural

Network”, Journal of Computer Applications, 2001, pp.53-

55

[11] He Jia, Wang Ziniu, Luo Gang, Zhang Nan, “Research

about the Forecasting of Safety Stock Based on Chaotic

Neural Network”, 2007

[12] U.M. Fayyad, G. Piatetsky-Shapiro, P. Smyth, “From Data

Mining to Knowledge Discovery: an overview”, Advances

in Knowledge Discovery and Data Mining, 1996, pp.1-34.

[13] P. Adriaans, D. Zantinge, “Data-mining”, Addison Wesley

Longman, England, 1996.

[14] N. Davey, S.P Hunt, R.J Frank, “Time series prediction

and neural networks”, Journal of Intelligent and Robotic

Systems, vol. 31, 2001, pp 91-103

[15] E. Wan, “Finite impulse response neural networks with

applications in time series prediction”, Stanford University,

1993

[16] A.D Back, E. Wan, “A unifying view of some training

algorithms for MLP with FIR filter synapses” IEEE Press,

New York, 1995, pp.146-154.

[17] Y. Bengio, P. Frasconi ,P. Simard, “The problem of

learning long-term dependencies in recurrent networks”

Proceedings of the IEEE International Conference on

Neural Networks, 1993.

[18] J. Conner, R. Douglas , “Recurrent NN and robust time

series prediction”, IEEE transactions on NN, 1994,

pp.240-254.

[19] M.P. Jose, Jr Menezes, A. Guilherme, “A new look at

nonlinear time series prediction with NARX recurrent

neural network” IEEE 2006

[20] Tsungnan Lin, G.B. Horne, P. Tino and C. L. Giles,“

Learning long term dependencies in NARX recurrent

neural networks”, IEEE Transactions on Neural Networks,

1996

[21] H. Bacha, W. Meyer , “ Neural Network architecture for

Load Forecasting”, Neural Networks, IJCNN, 1992.

[22] Sunil Chopra, Peter Meindl, “Supply Chain Management”,

Pearson 2007, pp.200-216

1453

Proceedings of the 2009 IEEE IEEM�

2023年江西萍乡中考道德与法治真题及答案.doc

2023年江西萍乡中考道德与法治真题及答案.doc 2012年重庆南川中考生物真题及答案.doc

2012年重庆南川中考生物真题及答案.doc 2013年江西师范大学地理学综合及文艺理论基础考研真题.doc

2013年江西师范大学地理学综合及文艺理论基础考研真题.doc 2020年四川甘孜小升初语文真题及答案I卷.doc

2020年四川甘孜小升初语文真题及答案I卷.doc 2020年注册岩土工程师专业基础考试真题及答案.doc

2020年注册岩土工程师专业基础考试真题及答案.doc 2023-2024学年福建省厦门市九年级上学期数学月考试题及答案.doc

2023-2024学年福建省厦门市九年级上学期数学月考试题及答案.doc 2021-2022学年辽宁省沈阳市大东区九年级上学期语文期末试题及答案.doc

2021-2022学年辽宁省沈阳市大东区九年级上学期语文期末试题及答案.doc 2022-2023学年北京东城区初三第一学期物理期末试卷及答案.doc

2022-2023学年北京东城区初三第一学期物理期末试卷及答案.doc 2018上半年江西教师资格初中地理学科知识与教学能力真题及答案.doc

2018上半年江西教师资格初中地理学科知识与教学能力真题及答案.doc 2012年河北国家公务员申论考试真题及答案-省级.doc

2012年河北国家公务员申论考试真题及答案-省级.doc 2020-2021学年江苏省扬州市江都区邵樊片九年级上学期数学第一次质量检测试题及答案.doc

2020-2021学年江苏省扬州市江都区邵樊片九年级上学期数学第一次质量检测试题及答案.doc 2022下半年黑龙江教师资格证中学综合素质真题及答案.doc

2022下半年黑龙江教师资格证中学综合素质真题及答案.doc