www.ti.com

5-A, WIDE INPUT RANGE, STEP-DOWN SWIFT™ CONVERTER

TPS5450

SLVS757–MARCH 2007

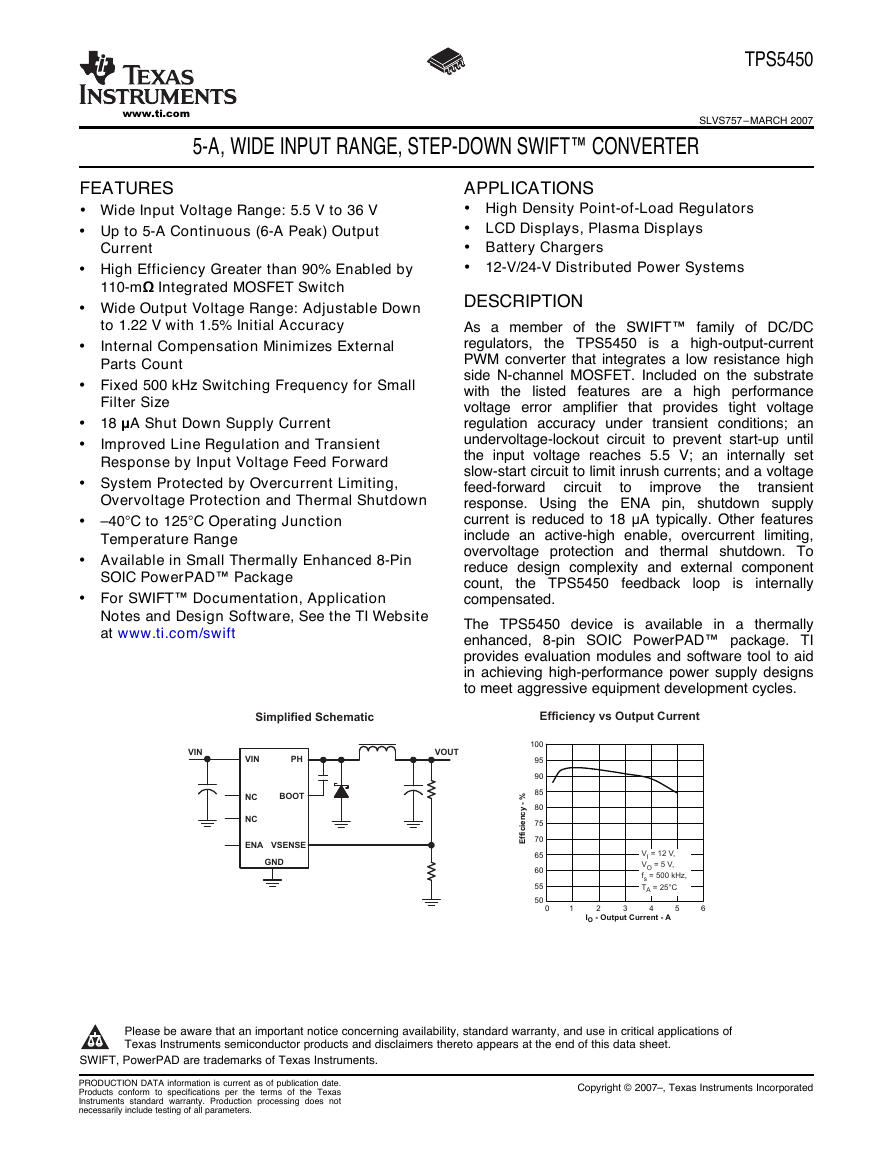

1FEATURES

2• Wide Input Voltage Range: 5.5 V to 36 V

• Up to 5-A Continuous (6-A Peak) Output

Current

• High Efficiency Greater than 90% Enabled by

110-mΩ Integrated MOSFET Switch

• Wide Output Voltage Range: Adjustable Down

•

to 1.22 V with 1.5% Initial Accuracy

Internal Compensation Minimizes External

Parts Count

• Fixed 500 kHz Switching Frequency for Small

Filter Size

• 18 μA Shut Down Supply Current

•

Improved Line Regulation and Transient

Response by Input Voltage Feed Forward

• System Protected by Overcurrent Limiting,

Overvoltage Protection and Thermal Shutdown

• –40 C to 125 C Operating Junction

Temperature Range

• Available in Small Thermally Enhanced 8-Pin

SOIC PowerPAD™ Package

• For SWIFT™ Documentation, Application

Notes and Design Software, See the TI Website

at www.ti.com/swift

APPLICATIONS

• High Density Point-of-Load Regulators

• LCD Displays, Plasma Displays

• Battery Chargers

• 12-V/24-V Distributed Power Systems

DESCRIPTION

As a member of

the SWIFT™ family of DC/DC

regulators,

the TPS5450 is a high-output-current

PWM converter that integrates a low resistance high

side N-channel MOSFET. Included on the substrate

with the listed features are a high performance

voltage error amplifier

that provides tight voltage

regulation accuracy under transient conditions; an

undervoltage-lockout circuit to prevent start-up until

the input voltage reaches 5.5 V; an internally set

slow-start circuit to limit inrush currents; and a voltage

feed-forward

transient

response. Using the ENA pin, shutdown supply

current is reduced to 18 μA typically. Other features

include an active-high enable, overcurrent

limiting,

overvoltage protection and thermal shutdown. To

reduce design complexity and external component

count,

the TPS5450 feedback loop is internally

compensated.

The TPS5450 device is available in a thermally

enhanced, 8-pin SOIC PowerPAD™ package. TI

provides evaluation modules and software tool to aid

in achieving high-performance power supply designs

to meet aggressive equipment development cycles.

improve

the

circuit

to

1

Please be aware that an important notice concerning availability, standard warranty, and use in critical applications of

Texas Instruments semiconductor products and disclaimers thereto appears at the end of this data sheet.

2SWIFT, PowerPAD are trademarks of Texas Instruments.

PRODUCTION DATA information is current as of publication date.

Products conform to specifications per the terms of

the Texas

Instruments standard warranty. Production processing does not

necessarily include testing of all parameters.

Copyright © 2007–, Texas Instruments Incorporated

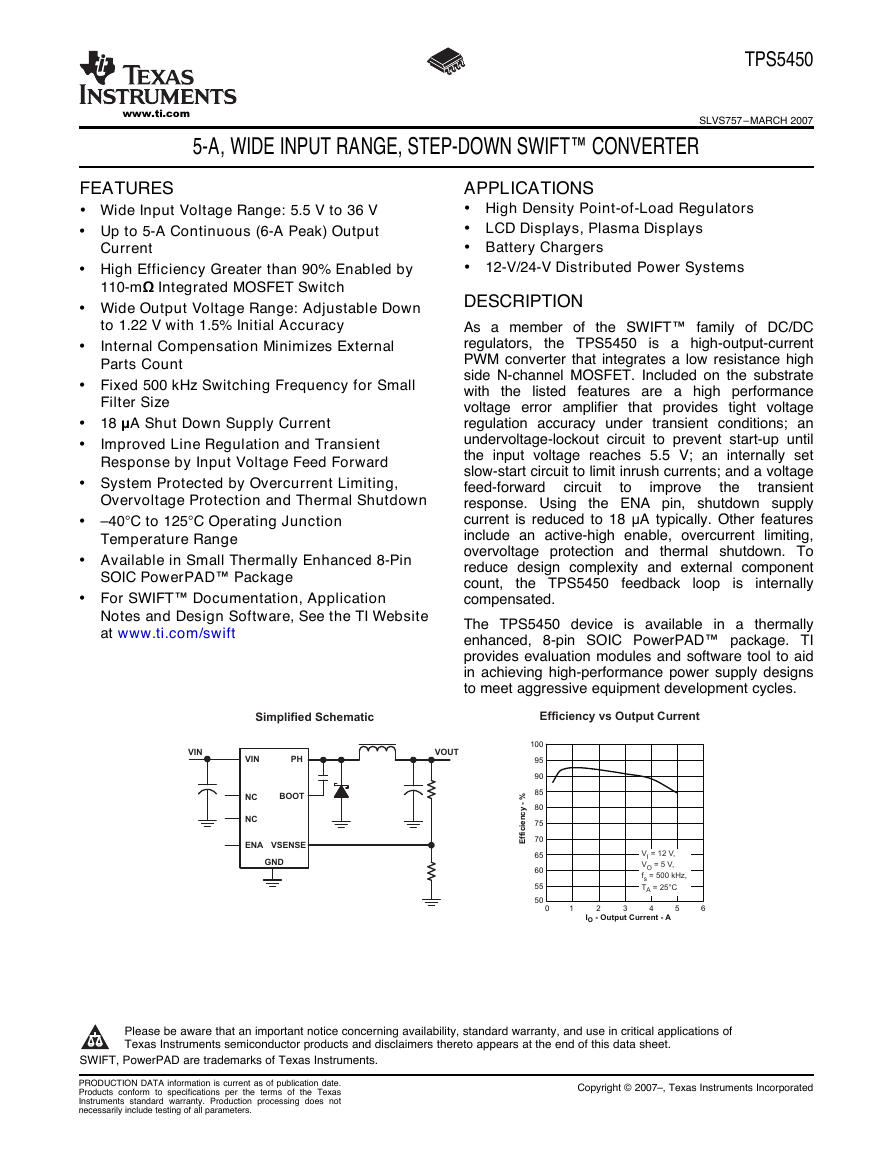

VINNCNCENAGNDVSENSEBOOTPHVINVOUTSimplified SchematicEfficiency vs Output Current50556065707580859095100I-OutputCurrent-AOEfficiency - %0123456V= 12 V,V= 5 V,f= 500 kHz,T= 25°CIOsA�

TPS5450

SLVS757–MARCH 2007

These devices have limited built-in ESD protection. The leads should be shorted together or the device placed in conductive foam

during storage or handling to prevent electrostatic damage to the MOS gates.

TJ

–40 C to 125 C

INPUT VOLTAGE

5.5 V to 36 V

OUTPUT VOLTAGE

Adjustable to 1.22 V

PACKAGE(1)

Thermally Enhanced SOIC (DDA)(2)

PART NUMBER

TPS5450DDA

ORDERING INFORMATION

(1) For the most current package and ordering information, see the Package Option Addendum at the end of this document, or see the TI

website at www.ti.com.

(2) The DDA package is also available taped and reeled. Add an R suffix to the device type (i.e., TPS5450DDAR). See applications section

of data sheet for PowerPAD™ drawing and layout information.

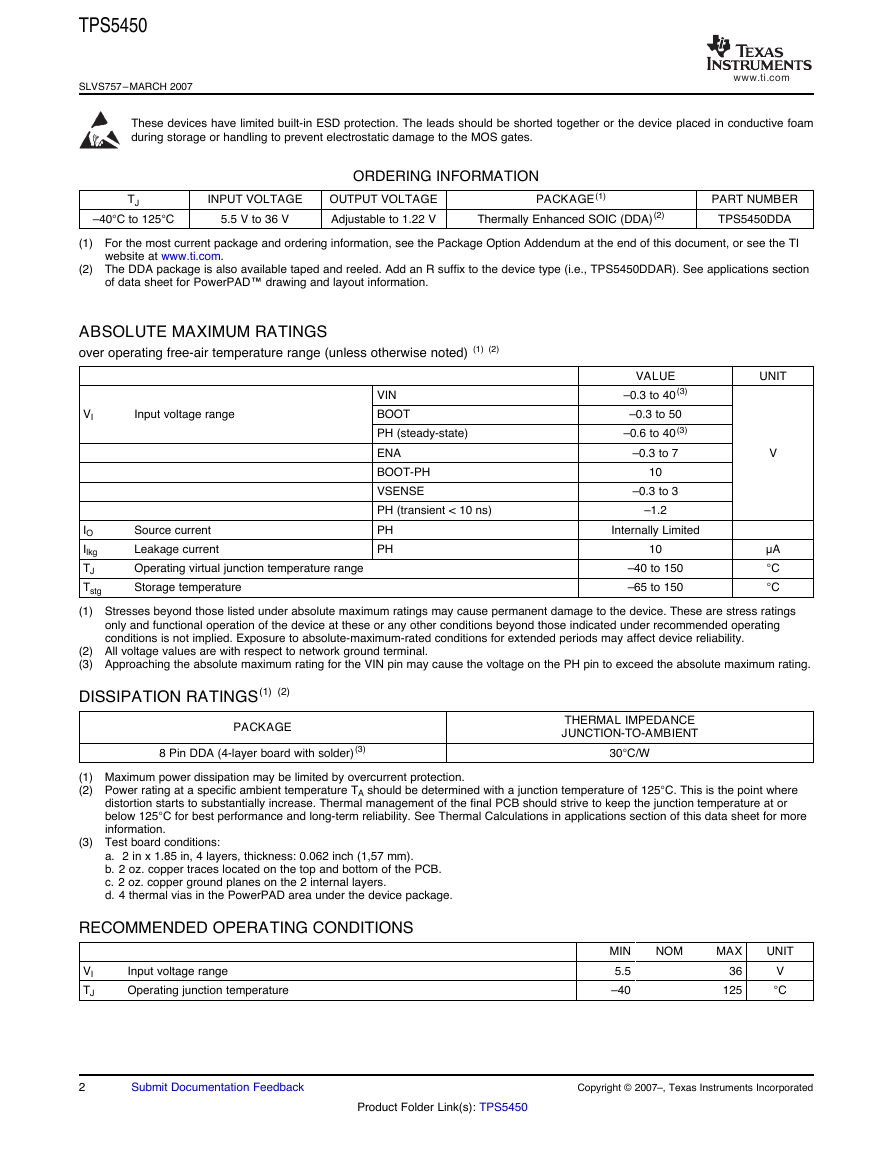

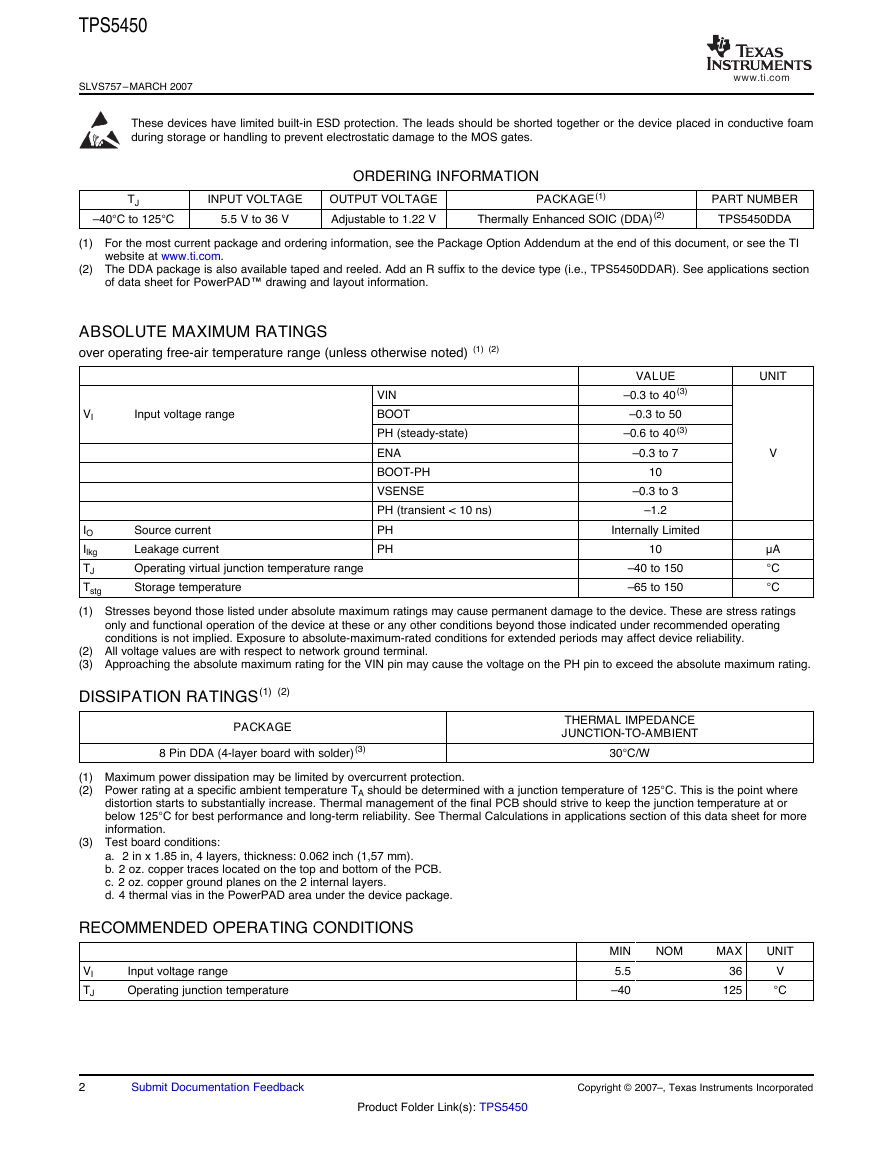

ABSOLUTE MAXIMUM RATINGS

over operating free-air temperature range (unless otherwise noted) (1) (2)

VI

Input voltage range

VIN

BOOT

PH (steady-state)

ENA

BOOT-PH

VSENSE

PH (transient < 10 ns)

PH

PH

UNIT

V

VALUE

–0.3 to 40(3)

–0.3 to 50

–0.6 to 40(3)

–0.3 to 7

10

–0.3 to 3

–1.2

Source current

Leakage current

Operating virtual junction temperature range

Storage temperature

IO

Ilkg

TJ

Tstg

(1) Stresses beyond those listed under absolute maximum ratings may cause permanent damage to the device. These are stress ratings

–40 to 150

–65 to 150

μA

C

C

Internally Limited

10

only and functional operation of the device at these or any other conditions beyond those indicated under recommended operating

conditions is not implied. Exposure to absolute-maximum-rated conditions for extended periods may affect device reliability.

(2) All voltage values are with respect to network ground terminal.

(3) Approaching the absolute maximum rating for the VIN pin may cause the voltage on the PH pin to exceed the absolute maximum rating.

DISSIPATION RATINGS(1) (2)

PACKAGE

8 Pin DDA (4-layer board with solder)(3)

THERMAL IMPEDANCE

JUNCTION-TO-AMBIENT

30 C/W

(1) Maximum power dissipation may be limited by overcurrent protection.

(2) Power rating at a specific ambient temperature TA should be determined with a junction temperature of 125 C. This is the point where

distortion starts to substantially increase. Thermal management of the final PCB should strive to keep the junction temperature at or

below 125 C for best performance and long-term reliability. See Thermal Calculations in applications section of this data sheet for more

information.

(3) Test board conditions:

a. 2 in x 1.85 in, 4 layers, thickness: 0.062 inch (1,57 mm).

b. 2 oz. copper traces located on the top and bottom of the PCB.

c. 2 oz. copper ground planes on the 2 internal layers.

d. 4 thermal vias in the PowerPAD area under the device package.

RECOMMENDED OPERATING CONDITIONS

VI

TJ

Input voltage range

Operating junction temperature

NOM

MIN

5.5

–40

MAX

36

125

UNIT

V

C

2

Submit Documentation Feedback

Copyright © 2007–, Texas Instruments Incorporated

Product Folder Link(s): TPS5450

www.ti.com�

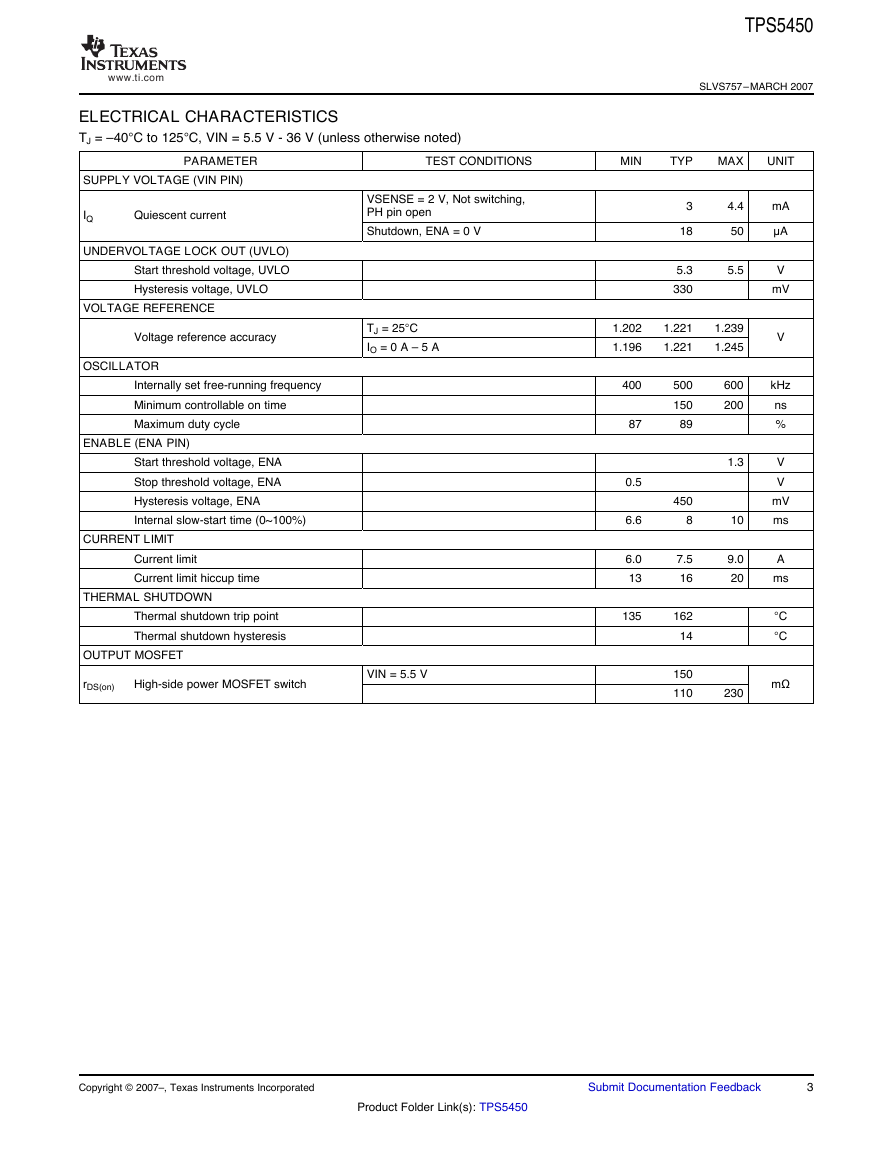

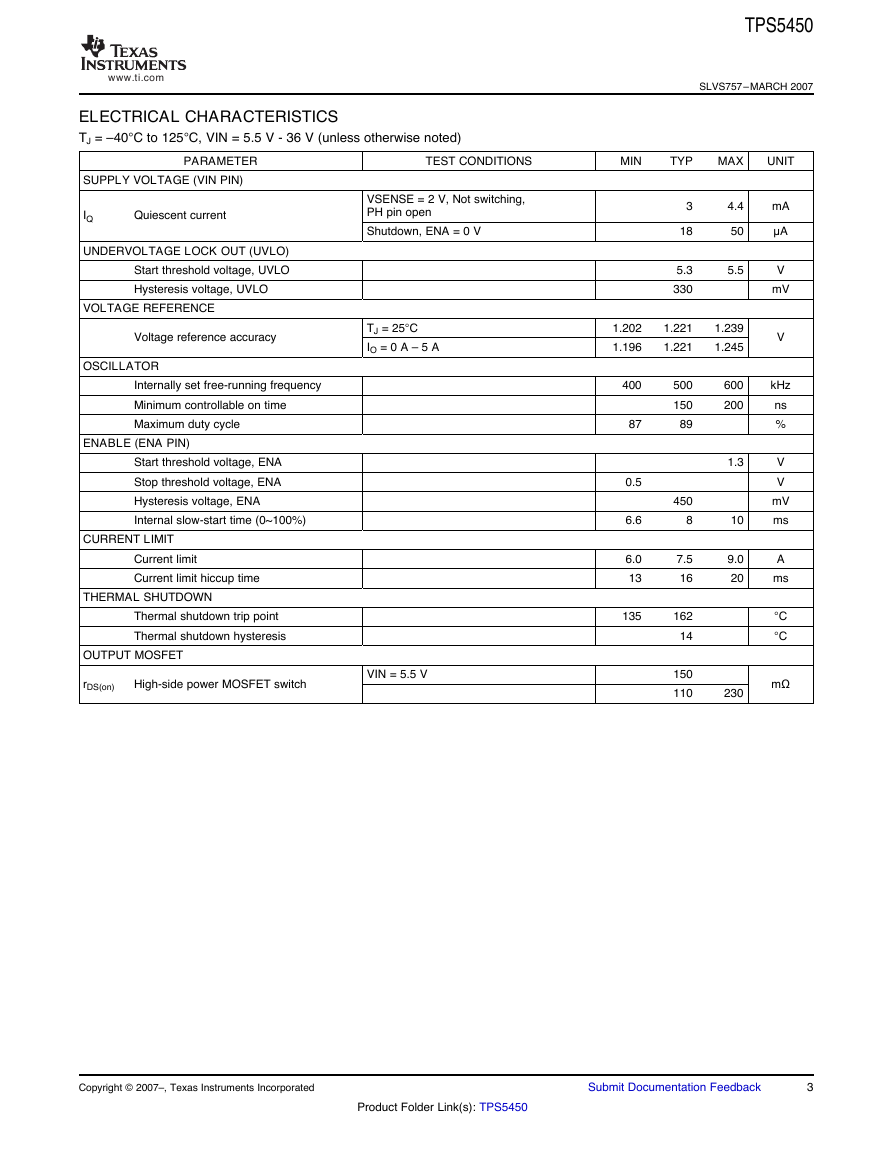

ELECTRICAL CHARACTERISTICS

TJ = –40 C to 125 C, VIN = 5.5 V - 36 V (unless otherwise noted)

TPS5450

SLVS757–MARCH 2007

PARAMETER

SUPPLY VOLTAGE (VIN PIN)

IQ

Quiescent current

UNDERVOLTAGE LOCK OUT (UVLO)

Start threshold voltage, UVLO

Hysteresis voltage, UVLO

VOLTAGE REFERENCE

Voltage reference accuracy

OSCILLATOR

Internally set free-running frequency

Minimum controllable on time

Maximum duty cycle

ENABLE (ENA PIN)

Start threshold voltage, ENA

Stop threshold voltage, ENA

Hysteresis voltage, ENA

Internal slow-start time (0~100%)

CURRENT LIMIT

Current limit

Current limit hiccup time

THERMAL SHUTDOWN

Thermal shutdown trip point

Thermal shutdown hysteresis

OUTPUT MOSFET

rDS(on)

High-side power MOSFET switch

VIN = 5.5 V

TEST CONDITIONS

MIN

TYP

MAX

UNIT

VSENSE = 2 V, Not switching,

PH pin open

Shutdown, ENA = 0 V

4.4

50

5.5

3

18

5.3

330

TJ = 25 C

IO = 0 A – 5 A

1.202

1.196

1.221

1.221

1.239

1.245

mA

μA

V

mV

V

kHz

ns

%

V

V

mV

ms

A

ms

C

C

mΩ

400

87

0.5

6.6

6.0

13

135

500

150

89

450

8

7.5

16

162

14

150

110

600

200

1.3

10

9.0

20

230

Copyright © 2007–, Texas Instruments Incorporated

Submit Documentation Feedback

3

Product Folder Link(s): TPS5450

www.ti.com�

TPS5450

SLVS757–MARCH 2007

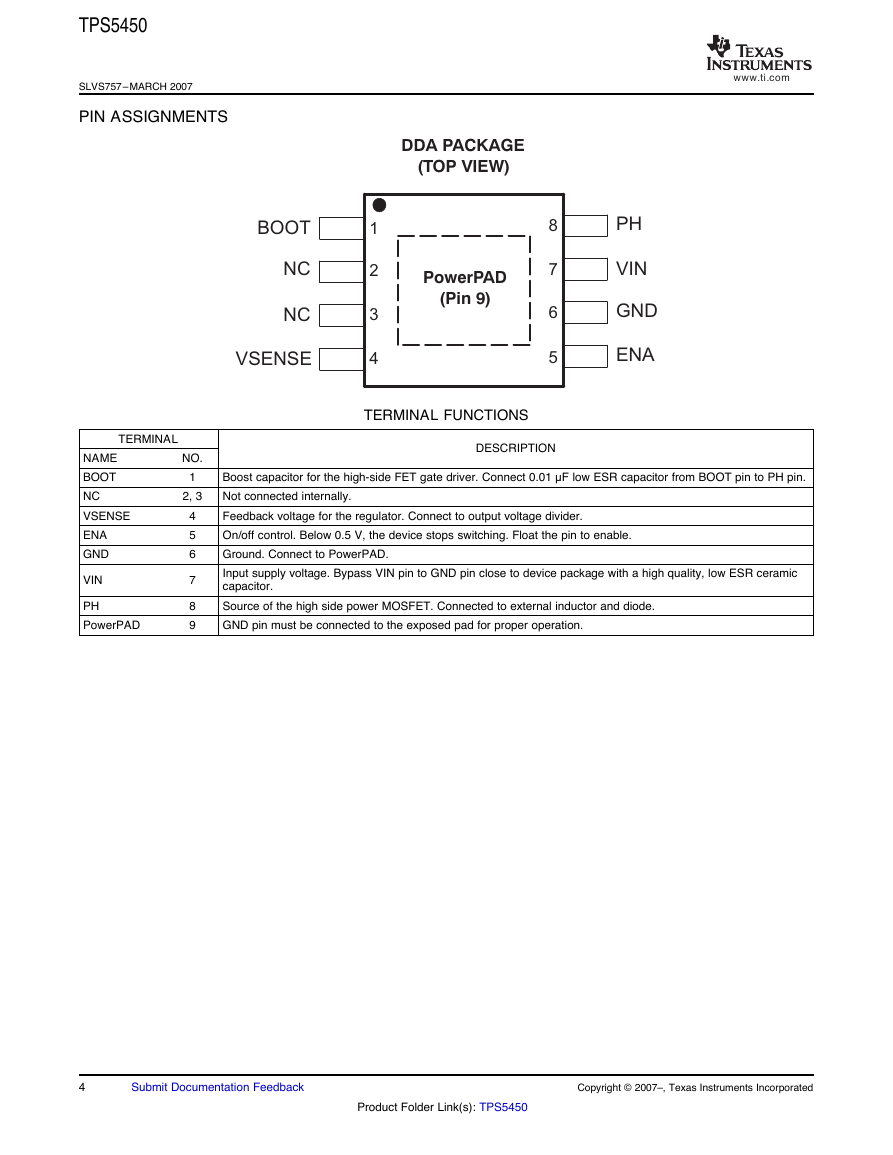

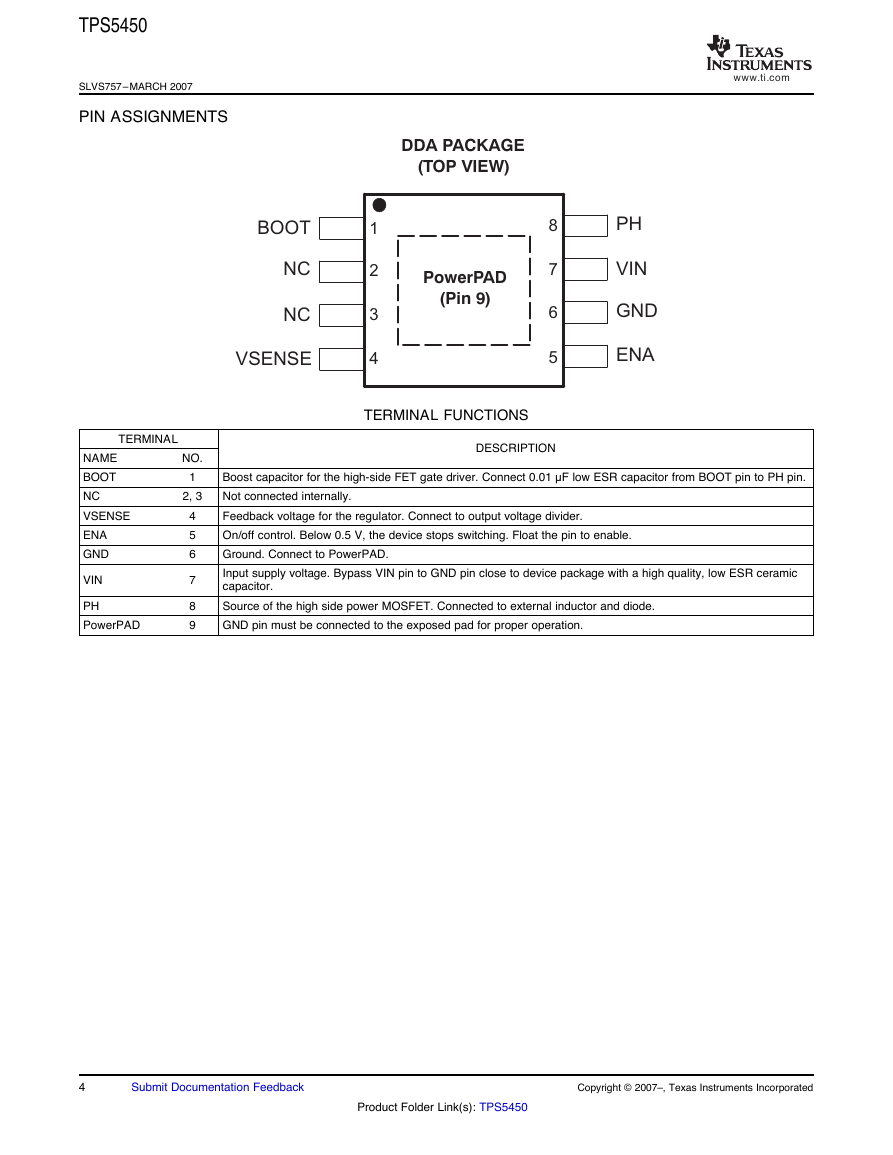

PIN ASSIGNMENTS

TERMINAL

NAME

BOOT

NC

VSENSE

ENA

GND

VIN

PH

PowerPAD

NO.

1

2, 3

4

5

6

7

8

9

TERMINAL FUNCTIONS

DESCRIPTION

Boost capacitor for the high-side FET gate driver. Connect 0.01 μF low ESR capacitor from BOOT pin to PH pin.

Not connected internally.

Feedback voltage for the regulator. Connect to output voltage divider.

On/off control. Below 0.5 V, the device stops switching. Float the pin to enable.

Ground. Connect to PowerPAD.

Input supply voltage. Bypass VIN pin to GND pin close to device package with a high quality, low ESR ceramic

capacitor.

Source of the high side power MOSFET. Connected to external inductor and diode.

GND pin must be connected to the exposed pad for proper operation.

4

Submit Documentation Feedback

Copyright © 2007–, Texas Instruments Incorporated

Product Folder Link(s): TPS5450

www.ti.com12348765PowerPAD(Pin 9)BOOTNCNCVSENSEPHVINGNDENADDA PACKAGE(TOP VIEW)�

TPS5450

SLVS757–MARCH 2007

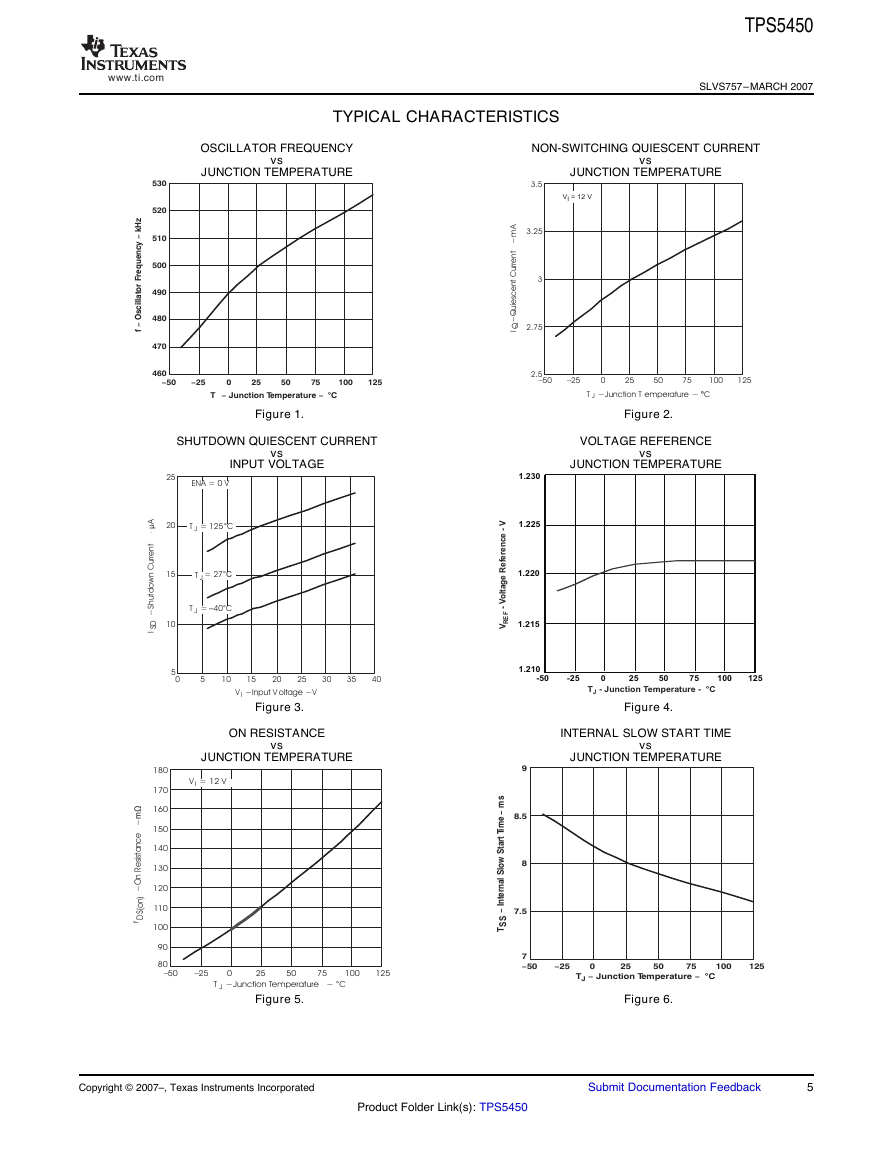

TYPICAL CHARACTERISTICS

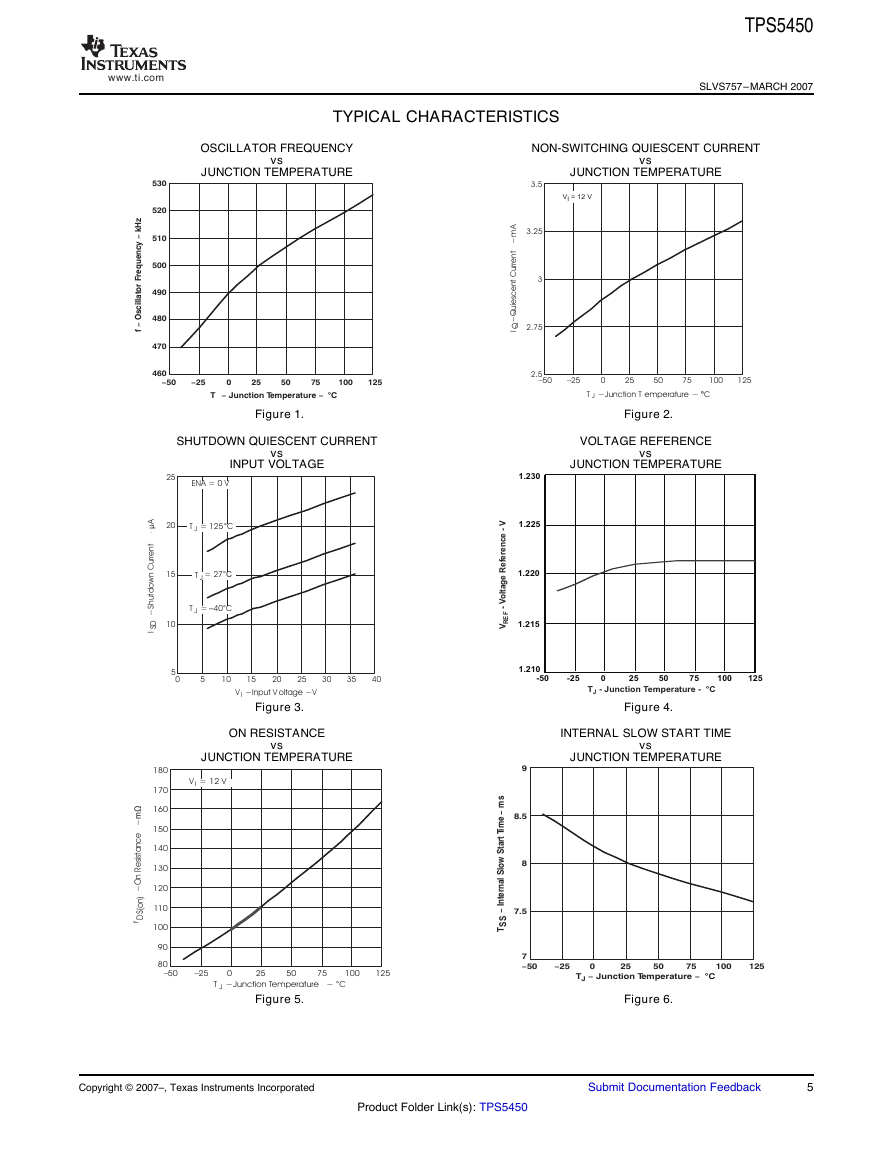

OSCILLATOR FREQUENCY

JUNCTION TEMPERATURE

vs

NON-SWITCHING QUIESCENT CURRENT

vs

JUNCTION TEMPERATURE

Figure 1.

Figure 2.

SHUTDOWN QUIESCENT CURRENT

vs

INPUT VOLTAGE

VOLTAGE REFERENCE

vs

JUNCTION TEMPERATURE

Figure 3.

Figure 4.

ON RESISTANCE

vs

JUNCTION TEMPERATURE

INTERNAL SLOW START TIME

JUNCTION TEMPERATURE

vs

Figure 5.

Figure 6.

Copyright © 2007–, Texas Instruments Incorporated

Submit Documentation Feedback

5

Product Folder Link(s): TPS5450

www.ti.com2.52.7533.253.5−50−250255075100125TJ−Junction Temperature−°CIQ−Quiescent Current−mAV= 12 VI460470480490500510520530−50−250255075100125f−Oscillator Frequency−kHzT−Junction Temperature−°C1.2101.2151.2201.2251.230-50-250255075100125T- Junction Temperature - °CJV- Voltage Reference - VREF5101520250510152025303540TJ= 125°CTJ= 27°CTJ=–°40CENA = 0 VVI−Input Voltage−VISD−Shutdown Current−Aµ77.588.59−50−250255075100125TJ−Junction Temperature−°CTSS−Internal Slow Start Time−ms8090100110120130140150160170180−50−250255075100125mΩ−On Resistance−rDS(on)TJ−Junction Temperature−°CVI= 12 V�

TPS5450

SLVS757–MARCH 2007

TYPICAL CHARACTERISTICS (continued)

MINIMUM CONTROLLABLE ON TIME

vs

JUNCTION TEMPERATURE

MINIMUM CONTROLLABLE DUTY RATIO

vs

JUNCTION TEMPERATURE

Figure 7.

Figure 8.

6

Submit Documentation Feedback

Copyright © 2007–, Texas Instruments Incorporated

Product Folder Link(s): TPS5450

www.ti.com77.257.507.758-50-250255075100125T- Junction Temperature - °CJMinimum Duty Ratio - %120130140150160170180−50−250255075100125TJ−Junction Temperature−°CMinimum Controllable On Time−ns�

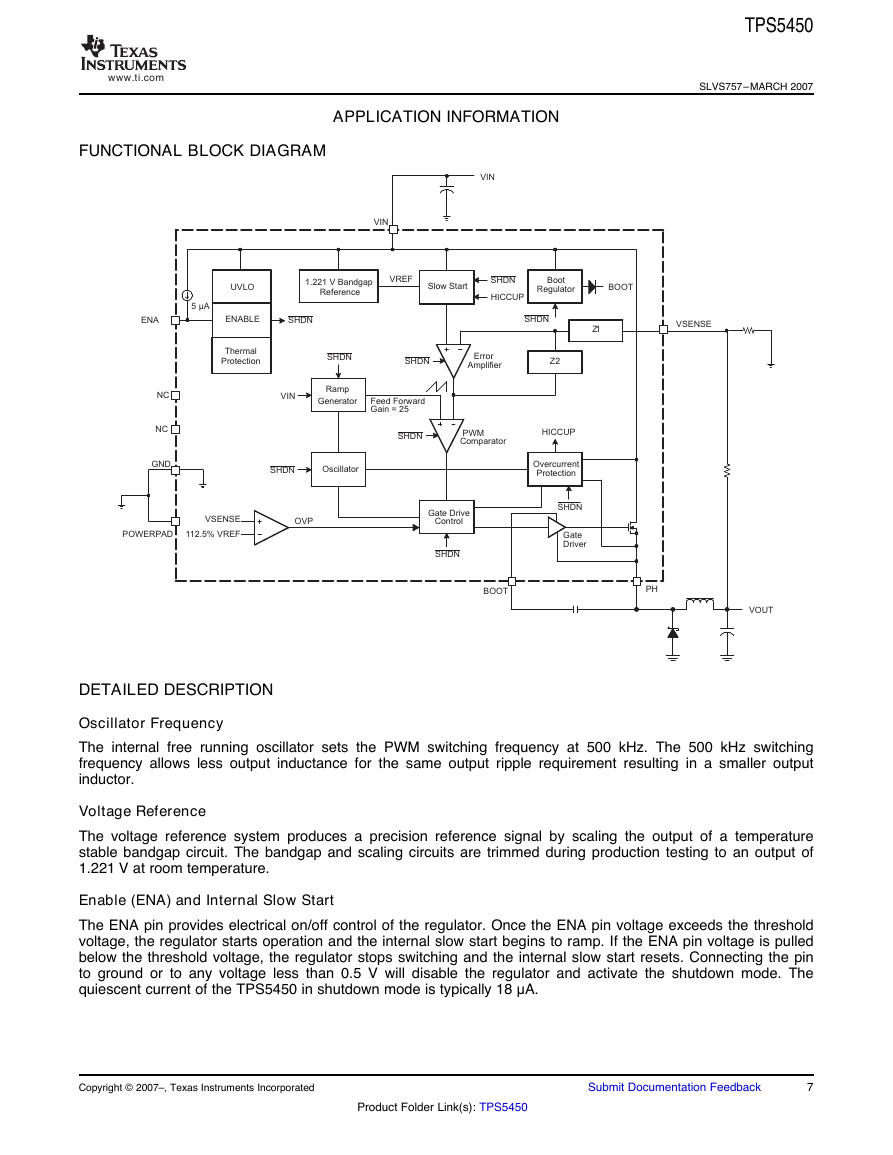

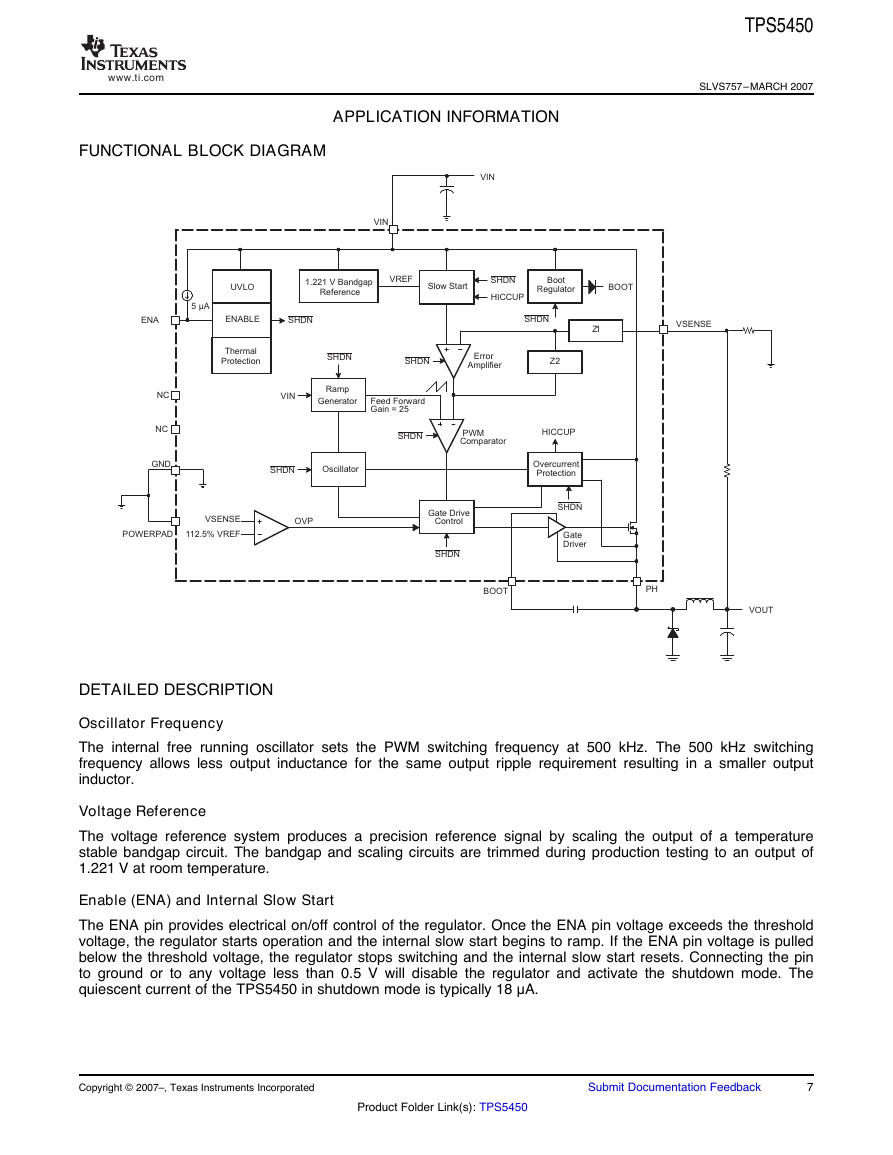

FUNCTIONAL BLOCK DIAGRAM

APPLICATION INFORMATION

TPS5450

SLVS757–MARCH 2007

DETAILED DESCRIPTION

Oscillator Frequency

The internal free running oscillator sets the PWM switching frequency at 500 kHz. The 500 kHz switching

frequency allows less output inductance for the same output ripple requirement resulting in a smaller output

inductor.

Voltage Reference

The voltage reference system produces a precision reference signal by scaling the output of a temperature

stable bandgap circuit. The bandgap and scaling circuits are trimmed during production testing to an output of

1.221 V at room temperature.

Enable (ENA) and Internal Slow Start

The ENA pin provides electrical on/off control of the regulator. Once the ENA pin voltage exceeds the threshold

voltage, the regulator starts operation and the internal slow start begins to ramp. If the ENA pin voltage is pulled

below the threshold voltage, the regulator stops switching and the internal slow start resets. Connecting the pin

to ground or to any voltage less than 0.5 V will disable the regulator and activate the shutdown mode. The

quiescent current of the TPS5450 in shutdown mode is typically 18 μA.

Copyright © 2007–, Texas Instruments Incorporated

Submit Documentation Feedback

7

Product Folder Link(s): TPS5450

www.ti.comVINUVLOENABLEThermalProtectionReferenceOvercurrentGate DriveOscillatorRampGeneratorVREFPHENAGNDBOOTZ1Z2SHDNSHDNSHDNSHDNSHDNSHDNSHDNSHDNVIN112.5% VREFVSENSEOVPHICCUPHICCUPSHDNNCFeed ForwardBOOTNCPOWERPADVINVOUT5µA1.221 V BandgapSlow StartBootRegulatorErrorAmplifierGain = 25PWMComparatorProtectionGateDriverControlVSENSE�

TPS5450

SLVS757–MARCH 2007

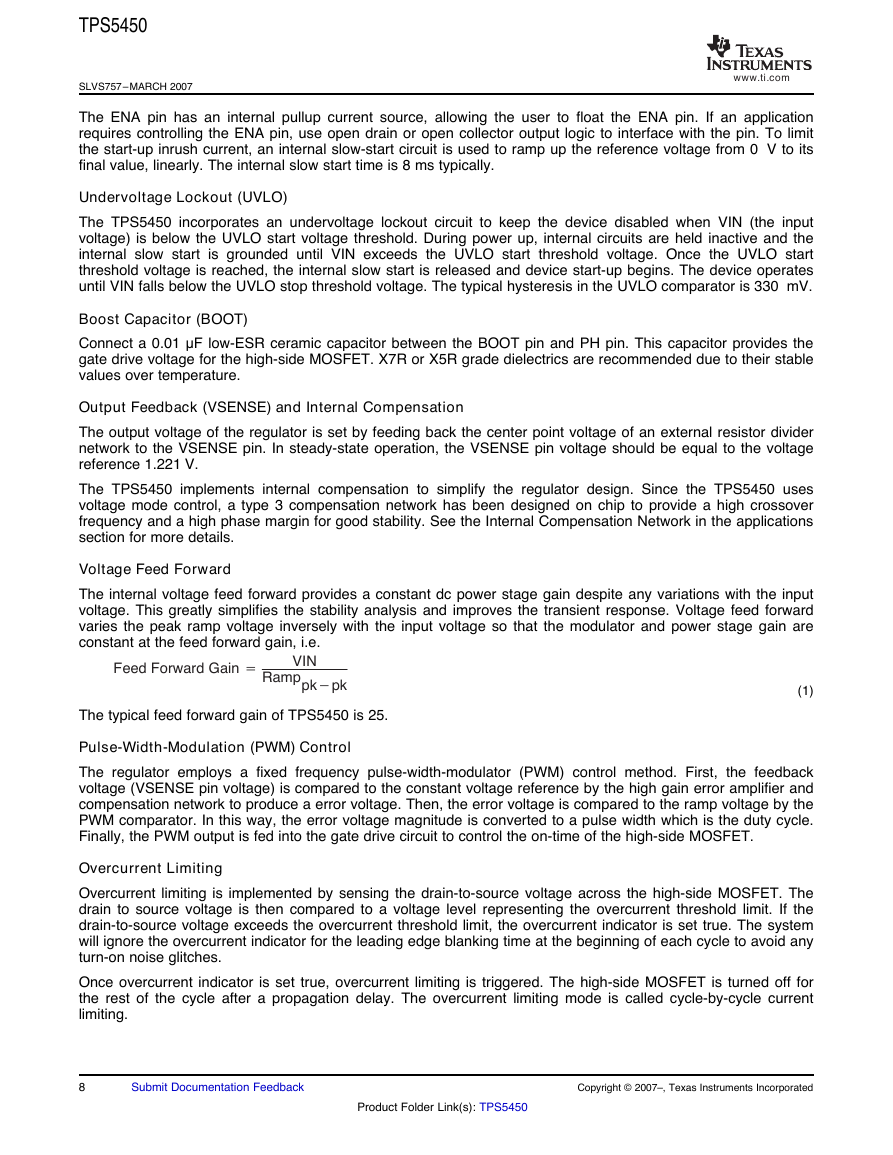

The ENA pin has an internal pullup current source, allowing the user to float the ENA pin. If an application

requires controlling the ENA pin, use open drain or open collector output logic to interface with the pin. To limit

the start-up inrush current, an internal slow-start circuit is used to ramp up the reference voltage from 0 V to its

final value, linearly. The internal slow start time is 8 ms typically.

Undervoltage Lockout (UVLO)

The TPS5450 incorporates an undervoltage lockout circuit to keep the device disabled when VIN (the input

voltage) is below the UVLO start voltage threshold. During power up, internal circuits are held inactive and the

internal slow start is grounded until VIN exceeds the UVLO start

threshold voltage. Once the UVLO start

threshold voltage is reached, the internal slow start is released and device start-up begins. The device operates

until VIN falls below the UVLO stop threshold voltage. The typical hysteresis in the UVLO comparator is 330 mV.

Boost Capacitor (BOOT)

Connect a 0.01 μF low-ESR ceramic capacitor between the BOOT pin and PH pin. This capacitor provides the

gate drive voltage for the high-side MOSFET. X7R or X5R grade dielectrics are recommended due to their stable

values over temperature.

Output Feedback (VSENSE) and Internal Compensation

The output voltage of the regulator is set by feeding back the center point voltage of an external resistor divider

network to the VSENSE pin. In steady-state operation, the VSENSE pin voltage should be equal to the voltage

reference 1.221 V.

The TPS5450 implements internal compensation to simplify the regulator design. Since the TPS5450 uses

voltage mode control, a type 3 compensation network has been designed on chip to provide a high crossover

frequency and a high phase margin for good stability. See the Internal Compensation Network in the applications

section for more details.

Voltage Feed Forward

The internal voltage feed forward provides a constant dc power stage gain despite any variations with the input

voltage. This greatly simplifies the stability analysis and improves the transient response. Voltage feed forward

varies the peak ramp voltage inversely with the input voltage so that the modulator and power stage gain are

constant at the feed forward gain, i.e.

(1)

The typical feed forward gain of TPS5450 is 25.

Pulse-Width-Modulation (PWM) Control

the feedback

The regulator employs a fixed frequency pulse-width-modulator (PWM) control method. First,

voltage (VSENSE pin voltage) is compared to the constant voltage reference by the high gain error amplifier and

compensation network to produce a error voltage. Then, the error voltage is compared to the ramp voltage by the

PWM comparator. In this way, the error voltage magnitude is converted to a pulse width which is the duty cycle.

Finally, the PWM output is fed into the gate drive circuit to control the on-time of the high-side MOSFET.

Overcurrent Limiting

Overcurrent limiting is implemented by sensing the drain-to-source voltage across the high-side MOSFET. The

drain to source voltage is then compared to a voltage level representing the overcurrent threshold limit. If the

drain-to-source voltage exceeds the overcurrent threshold limit, the overcurrent indicator is set true. The system

will ignore the overcurrent indicator for the leading edge blanking time at the beginning of each cycle to avoid any

turn-on noise glitches.

Once overcurrent indicator is set true, overcurrent limiting is triggered. The high-side MOSFET is turned off for

the rest of the cycle after a propagation delay. The overcurrent limiting mode is called cycle-by-cycle current

limiting.

8

Submit Documentation Feedback

Copyright © 2007–, Texas Instruments Incorporated

Product Folder Link(s): TPS5450

www.ti.comFeedForwardGain+VINRamppk*pk�

2023年江西萍乡中考道德与法治真题及答案.doc

2023年江西萍乡中考道德与法治真题及答案.doc 2012年重庆南川中考生物真题及答案.doc

2012年重庆南川中考生物真题及答案.doc 2013年江西师范大学地理学综合及文艺理论基础考研真题.doc

2013年江西师范大学地理学综合及文艺理论基础考研真题.doc 2020年四川甘孜小升初语文真题及答案I卷.doc

2020年四川甘孜小升初语文真题及答案I卷.doc 2020年注册岩土工程师专业基础考试真题及答案.doc

2020年注册岩土工程师专业基础考试真题及答案.doc 2023-2024学年福建省厦门市九年级上学期数学月考试题及答案.doc

2023-2024学年福建省厦门市九年级上学期数学月考试题及答案.doc 2021-2022学年辽宁省沈阳市大东区九年级上学期语文期末试题及答案.doc

2021-2022学年辽宁省沈阳市大东区九年级上学期语文期末试题及答案.doc 2022-2023学年北京东城区初三第一学期物理期末试卷及答案.doc

2022-2023学年北京东城区初三第一学期物理期末试卷及答案.doc 2018上半年江西教师资格初中地理学科知识与教学能力真题及答案.doc

2018上半年江西教师资格初中地理学科知识与教学能力真题及答案.doc 2012年河北国家公务员申论考试真题及答案-省级.doc

2012年河北国家公务员申论考试真题及答案-省级.doc 2020-2021学年江苏省扬州市江都区邵樊片九年级上学期数学第一次质量检测试题及答案.doc

2020-2021学年江苏省扬州市江都区邵樊片九年级上学期数学第一次质量检测试题及答案.doc 2022下半年黑龙江教师资格证中学综合素质真题及答案.doc

2022下半年黑龙江教师资格证中学综合素质真题及答案.doc