www.altairhyperworks.com | HyperWorks is a division of

�

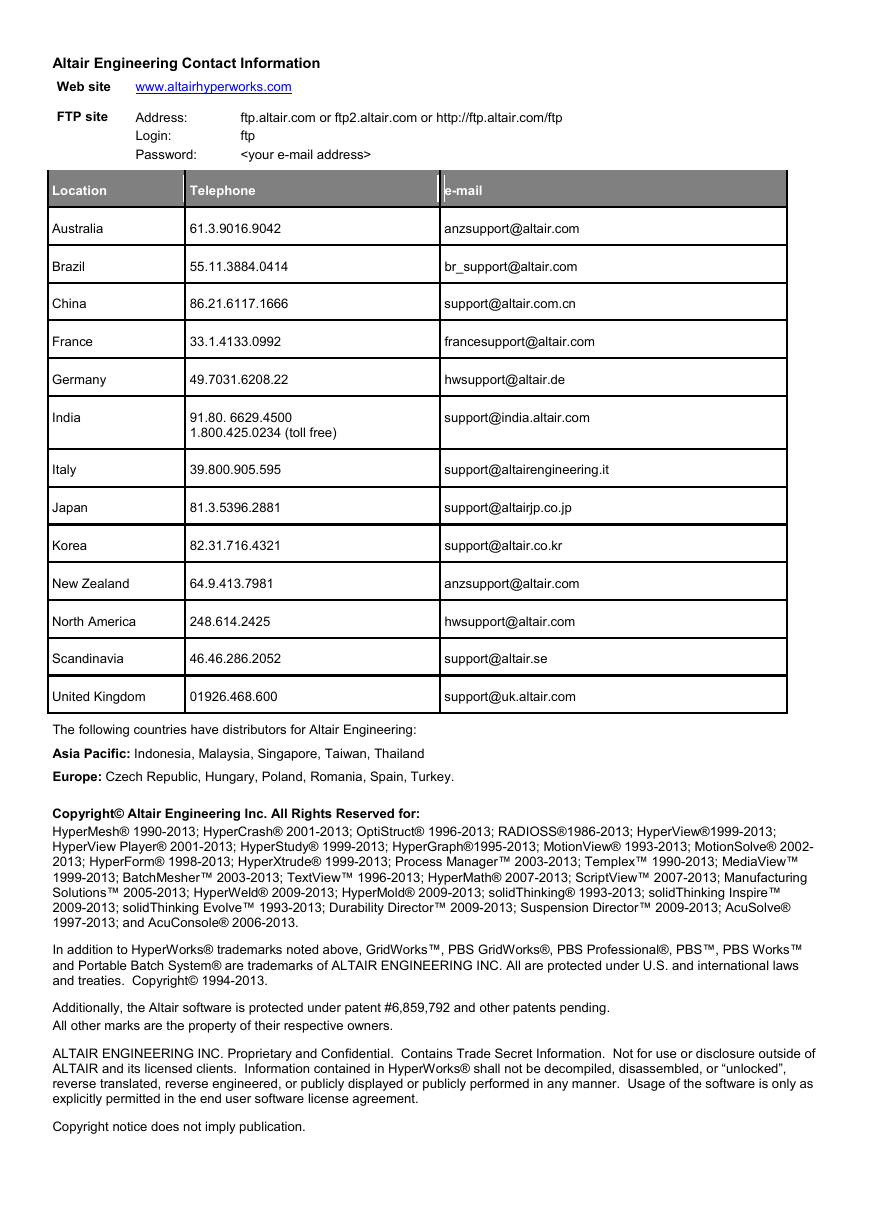

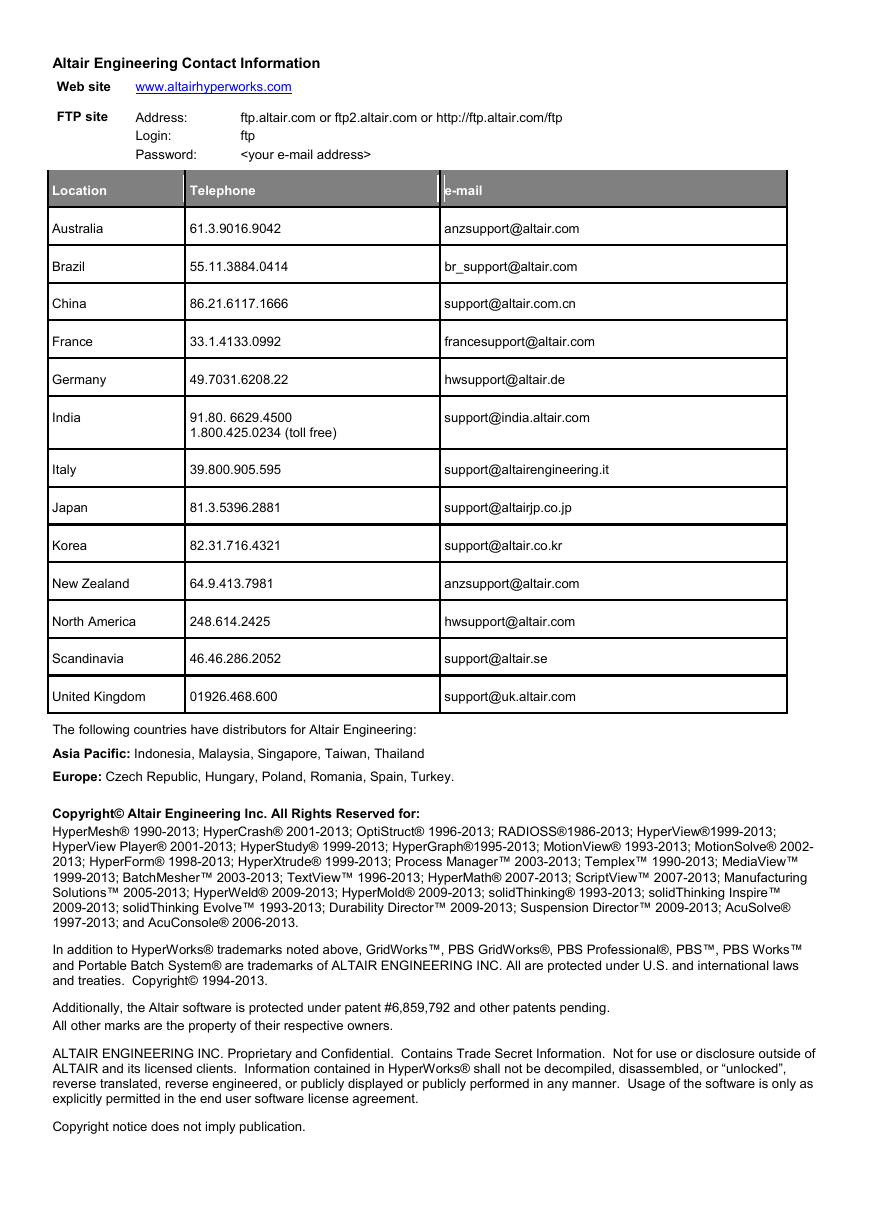

Altair Engineering Contact Information

Web site

www.altairhyperworks.com

FTP site

Location

Australia

Brazil

China

France

Address:

Login:

Password:

ftp.altair.com or ftp2.altair.com or http://ftp.altair.com/ftp

ftp

Telephone

61.3.9016.9042

55.11.3884.0414

86.21.6117.1666

33.1.4133.0992

e-mail

anzsupport@altair.com

br_support@altair.com

support@altair.com.cn

francesupport@altair.com

Germany

49.7031.6208.22

hwsupport@altair.de

91.80. 6629.4500

1.800.425.0234 (toll free)

support@india.altair.com

support@altairengineering.it

support@altairjp.co.jp

support@altair.co.kr

anzsupport@altair.com

hwsupport@altair.com

India

Italy

Japan

Korea

39.800.905.595

81.3.5396.2881

82.31.716.4321

New Zealand

64.9.413.7981

North America

248.614.2425

Scandinavia

46.46.286.2052

support@altair.se

United Kingdom

01926.468.600

support@uk.altair.com

The following countries have distributors for Altair Engineering:

Asia Pacific: Indonesia, Malaysia, Singapore, Taiwan, Thailand

Europe: Czech Republic, Hungary, Poland, Romania, Spain, Turkey.

Copyright© Altair Engineering Inc. All Rights Reserved for:

HyperMesh® 1990-2013; HyperCrash® 2001-2013; OptiStruct® 1996-2013; RADIOSS®1986-2013; HyperView®1999-2013;

HyperView Player® 2001-2013; HyperStudy® 1999-2013; HyperGraph®1995-2013; MotionView® 1993-2013; MotionSolve® 2002-

2013; HyperForm® 1998-2013; HyperXtrude® 1999-2013; Process Manager™ 2003-2013; Templex™ 1990-2013; MediaView™

1999-2013; BatchMesher™ 2003-2013; TextView™ 1996-2013; HyperMath® 2007-2013; ScriptView™ 2007-2013; Manufacturing

Solutions™ 2005-2013; HyperWeld® 2009-2013; HyperMold® 2009-2013; solidThinking® 1993-2013; solidThinking Inspire™

2009-2013; solidThinking Evolve™ 1993-2013; Durability Director™ 2009-2013; Suspension Director™ 2009-2013; AcuSolve®

1997-2013; and AcuConsole® 2006-2013.

In addition to HyperWorks® trademarks noted above, GridWorks™, PBS GridWorks®, PBS Professional®, PBS™, PBS Works™

and Portable Batch System® are trademarks of ALTAIR ENGINEERING INC. All are protected under U.S. and international laws

and treaties. Copyright© 1994-2013.

Additionally, the Altair software is protected under patent #6,859,792 and other patents pending.

All other marks are the property of their respective owners.

ALTAIR ENGINEERING INC. Proprietary and Confidential. Contains Trade Secret Information. Not for use or disclosure outside of

ALTAIR and its licensed clients. Information contained in HyperWorks® shall not be decompiled, disassembled, or “unlocked”,

reverse translated, reverse engineered, or publicly displayed or publicly performed in any manner. Usage of the software is only as

explicitly permitted in the end user software license agreement.

Copyright notice does not imply publication.

�

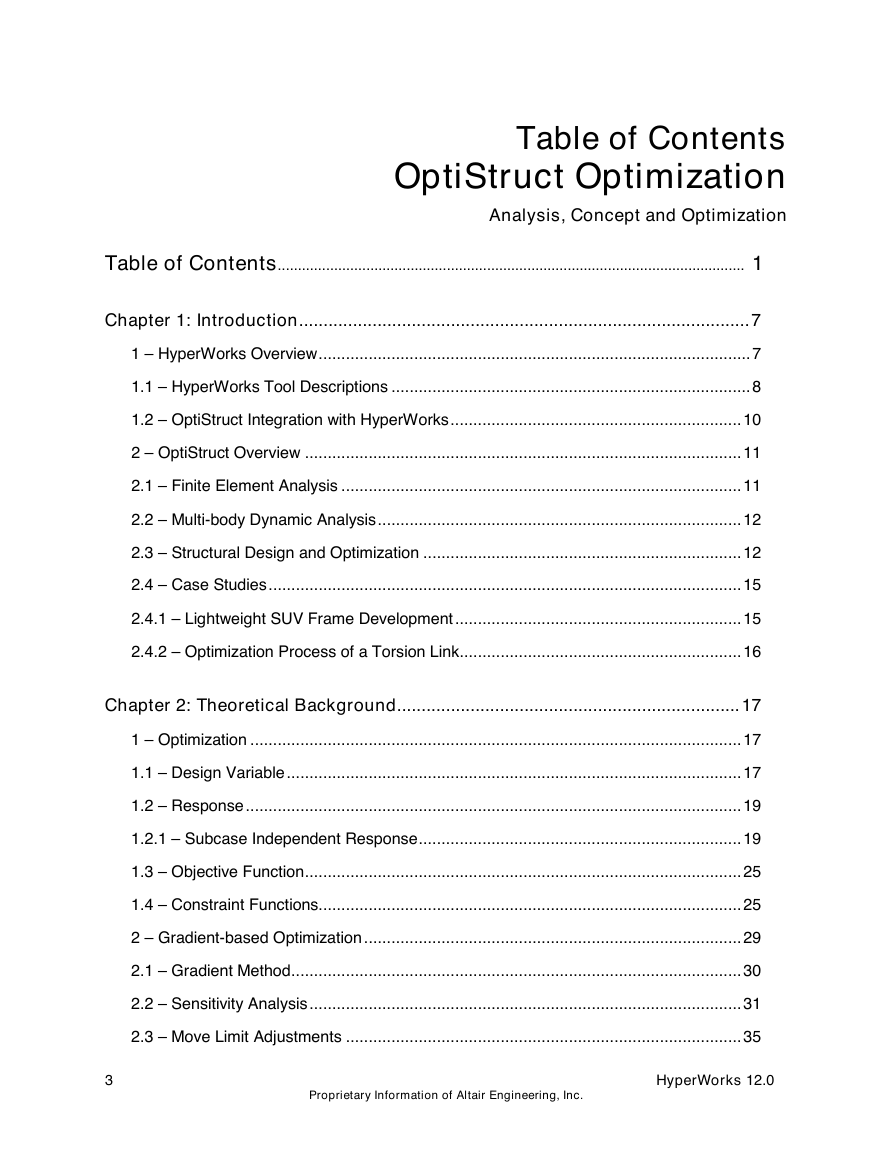

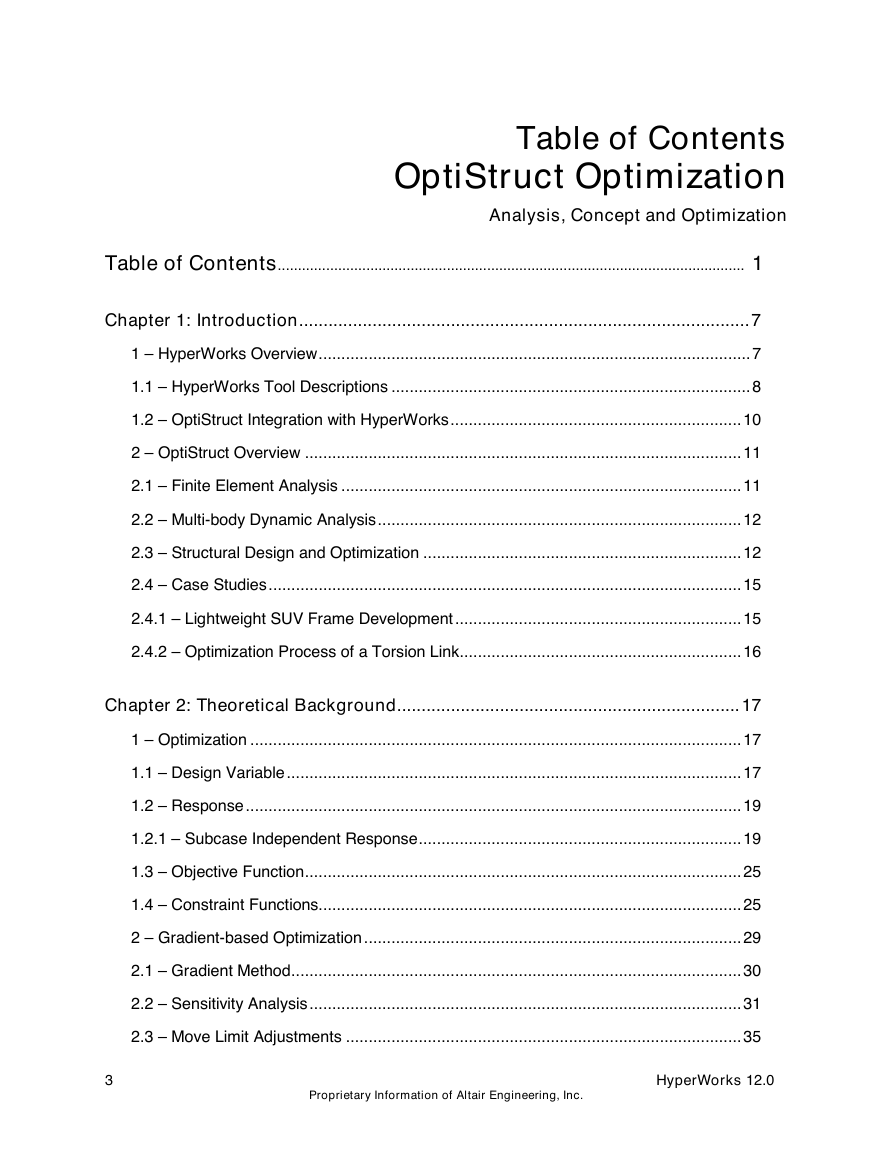

Table of Contents

OptiStruct Optimization

Analysis, Concept and Optimization

Table of Contents .................................................................................................................... 1

Chapter 1: Introduction ............................................................................................ 7

1 – HyperWorks Overview ............................................................................................... 7

1.1 – HyperWorks Tool Descriptions ............................................................................... 8

1.2 – OptiStruct Integration with HyperWorks ................................................................ 10

2 – OptiStruct Overview ................................................................................................ 11

2.1 – Finite Element Analysis ........................................................................................ 11

2.2 – Multi-body Dynamic Analysis ................................................................................ 12

2.3 – Structural Design and Optimization ...................................................................... 12

2.4 – Case Studies ........................................................................................................ 15

2.4.1 – Lightweight SUV Frame Development ............................................................... 15

2.4.2 – Optimization Process of a Torsion Link .............................................................. 16

Chapter 2: Theoretical Background ...................................................................... 17

1 – Optimization ............................................................................................................ 17

1.1 – Design Variable .................................................................................................... 17

1.2 – Response ............................................................................................................. 19

1.2.1 – Subcase Independent Response ....................................................................... 19

1.3 – Objective Function ................................................................................................ 25

1.4 – Constraint Functions............................................................................................. 25

2 – Gradient-based Optimization ................................................................................... 29

2.1 – Gradient Method ................................................................................................... 30

2.2 – Sensitivity Analysis ............................................................................................... 31

2.3 – Move Limit Adjustments ....................................................................................... 35

3

Proprietary Information of Altair Engineering, Inc.

HyperWorks 12.0

�

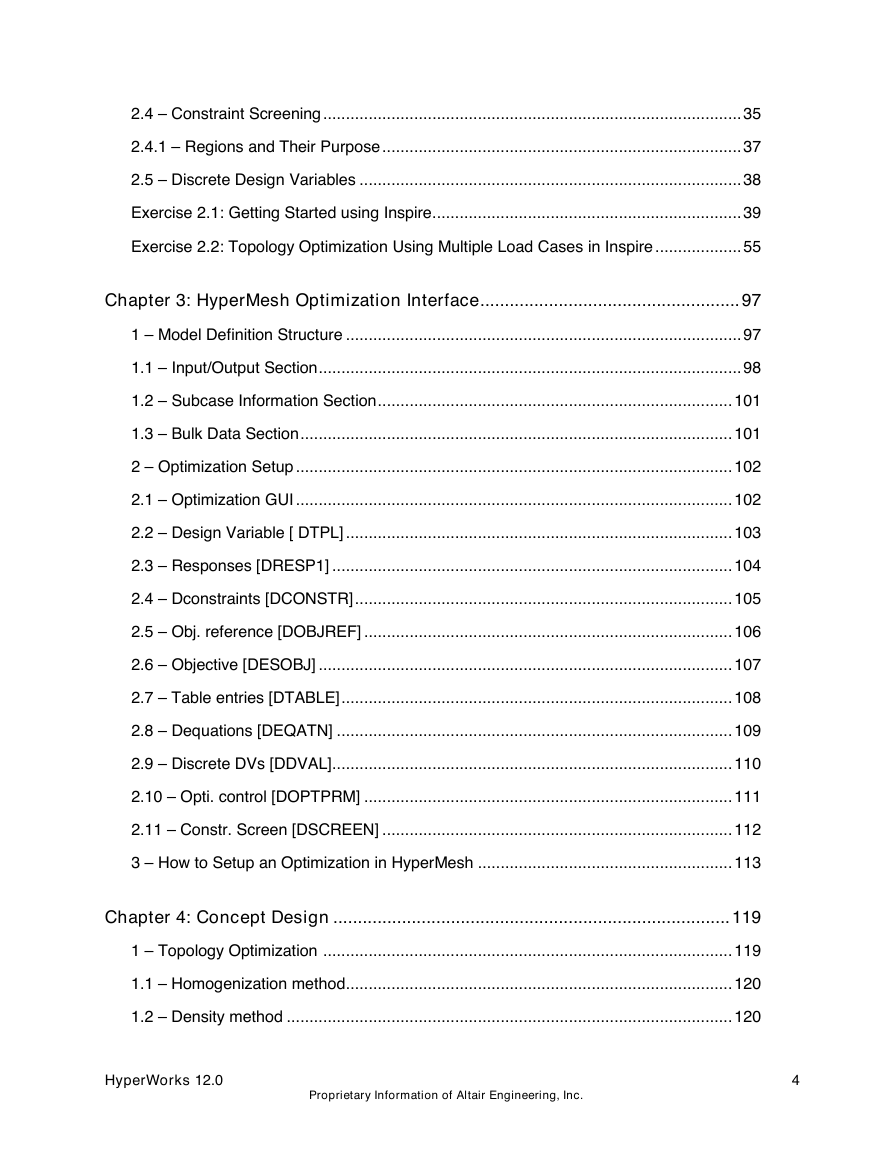

2.4 – Constraint Screening ............................................................................................ 35

2.4.1 – Regions and Their Purpose ............................................................................... 37

2.5 – Discrete Design Variables .................................................................................... 38

Exercise 2.1: Getting Started using Inspire .................................................................... 39

Exercise 2.2: Topology Optimization Using Multiple Load Cases in Inspire ................... 55

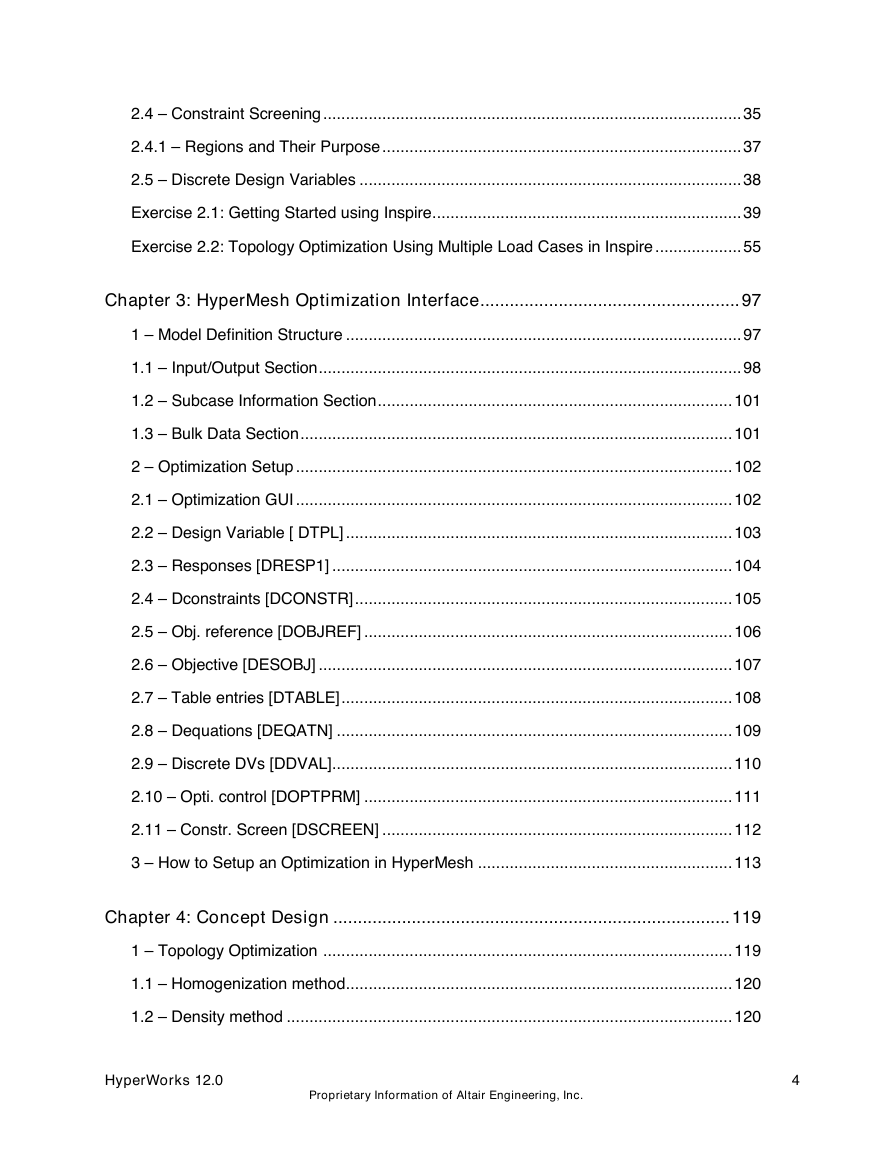

Chapter 3: HyperMesh Optimization Interface ..................................................... 97

1 – Model Definition Structure ....................................................................................... 97

1.1 – Input/Output Section ............................................................................................. 98

1.2 – Subcase Information Section .............................................................................. 101

1.3 – Bulk Data Section ............................................................................................... 101

2 – Optimization Setup ................................................................................................ 102

2.1 – Optimization GUI ................................................................................................ 102

2.2 – Design Variable [ DTPL] ..................................................................................... 103

2.3 – Responses [DRESP1] ........................................................................................ 104

2.4 – Dconstraints [DCONSTR] ................................................................................... 105

2.5 – Obj. reference [DOBJREF] ................................................................................. 106

2.6 – Objective [DESOBJ] ........................................................................................... 107

2.7 – Table entries [DTABLE] ...................................................................................... 108

2.8 – Dequations [DEQATN] ....................................................................................... 109

2.9 – Discrete DVs [DDVAL] ........................................................................................ 110

2.10 – Opti. control [DOPTPRM] ................................................................................. 111

2.11 – Constr. Screen [DSCREEN] ............................................................................. 112

3 – How to Setup an Optimization in HyperMesh ........................................................ 113

Chapter 4: Concept Design ................................................................................. 119

1 – Topology Optimization .......................................................................................... 119

1.1 – Homogenization method ..................................................................................... 120

1.2 – Density method .................................................................................................. 120

HyperWorks 12.0

Proprietary Information of Altair Engineering, Inc.

4

�

Exercise 4.1 – Topology Optimization of a Hook with Stress Constraints .................... 121

Exercise 4.2 – Topology Optimization of a Control Arm ............................................... 129

Exercise 4.3: Pattern Repetition using Topology Optimization ..................................... 135

2 – Topography Optimization ...................................................................................... 141

2.1 – Design Variables for Topography Optimization ................................................... 141

2.1.1 – Variable Generation ......................................................................................... 142

2.1.2 – Multiple Topography Design Regions .............................................................. 143

Exercise 4.4 – Topography Optimization of an L-Bracket Including Autobead

Reinterpretation ........................................................................................................... 147

3 – Free-size Optimization........................................................................................... 155

Exercise 4.5 – Free-size optimization of Finite Plate with hole .................................... 161

4 – Design Interpretation - OSSmooth ......................................................................... 169

4.1 – OSSmooth Input Data ........................................................................................ 171

4.2 – Running OSSmooth ........................................................................................... 173

4.3 – Interpretation of Topography Optimization Results ............................................. 174

4.4 – Shape Optimization Results, Surface Reduction and Surface Smoothing ........... 175

Exercise 4.6 – OSSmooth surfaces from a topology optimization ................................ 177

Chapter 5: Fine-Tuning ........................................................................................ 181

1 – Size Optimization .................................................................................................. 181

1.1 – Design Variables for Size Optimization ............................................................... 182

Exercise 5.1 – Size Optimization of a Rail Joint ........................................................... 183

Exercise 5.2 – Discrete Size Optimization of a Welded Bracket .................................. 191

2 – Shape Optimization ............................................................................................... 199

2.1 – Design Variables for Shape Optimization ........................................................... 200

2.2 – HyperMorph ....................................................................................................... 201

2.2.1 – The Three Basic Approaches to Morphing ....................................................... 201

Exercise 5.3 – Cantilever L-beam Shape Optimization ................................................ 203

Exercise 5.4 – Shape Optimization of a Rail Joint ....................................................... 229

5

Proprietary Information of Altair Engineering, Inc.

HyperWorks 12.0

�

3 – Free-shape Optimization ....................................................................................... 229

3.1 – Defining Free-shape Design Regions ................................................................. 229

3.2 – Free-shape Parameters ...................................................................................... 231

3.2.1 – Direction type .................................................................................................. 231

3.2.2 – Move factor ..................................................................................................... 232

3.2.3 – Number of layers for mesh smoothing ............................................................. 232

3.2.4 – Maximum shrinkage and growth ...................................................................... 233

3.2.5 – Constraints on Grids in the Design Region ...................................................... 234

Exercise 5.5 – Free-shape Optimization of a Compressor Bracket .............................. 237

Exercise 5.6 - Shape Optimization of a 3-D Bracket using the Free-shape Method .... 245

Appendix A ........................................................................................................... 255

HyperWorks 12.0

Proprietary Information of Altair Engineering, Inc.

6

�

Chapter 1: Introduction

Chapter 1

Introduction

1- HyperWorks Overview

HyperWorks®, A Platform for Innovation™, is an enterprise simulation solution for rapid

design exploration and decision-making. As one of the most comprehensive CAE solutions

in the industry, HyperWorks provides a tightly integrated suite of best-in-class tools for:

o Modeling

o Analysis

o Optimization

o Visualization

o Reporting

o Performance data management.

Based on a revolutionary “pay-for-use” token-based business model, HyperWorks delivers

increased value and flexibility over other software licensing models.

Below we list the applications that are part of HyperWorks, for extra information about them

go to www.altairhyperworks.com web page or go to HyperWorks online documentation.

HyperWorks 12.0

Proprietary Information of Altair Engineering, Inc.

OptiStruct Optimization 7

�

Chapter 1: Introduction

1.1 – HyperWorks Tool Descriptions

Finite Element Meshing and Modeling

HyperMesh

HyperCrash

BatchMesher

Multi-body Dynamics Modeling

MotionView

Solvers

RADIOSS

MotionSolve

OptiStruct

Post-processing and Data Analysis

HyperView

HyperGraph

HyperGraph 3D

HyperView Player

Study and Optimization

HyperStudy

Data Management and Process Automation

Altair Data Manager

Process Manager

Assembler

Universal finite element pre- and post-processor

Finite element pre-processor for automotive crash and

safety analysis

Geometry cleanup and auto-meshing in batch mode for

given CAD files

Multi-body dynamics pre- and post-processor

Finite element solver for linear and non-linear problems

Multi-body dynamics solver

Design and optimization software using finite elements

and multi-body dynamics

High performance finite element and mechanical

system post-processor, engineering plotter, and data

analysis tool

Engineering plotter and data analysis tool

Engineering 3-D plotter and data analysis tool

Viewer for visualizing 3-D CAE results via the Internet

or desktop

Integrated optimization, DOE, and robustness engine

A solution that organizes, manages, and stores CAE

and test data throughout the product design cycle

Process automation tool for HyperWorks and third

party software; Processes can be created with the help

of Process Studio.

A tool that enables CAE analysts to manage, organize,

and control their CAE mesh data

OptiStruct Optimization 8

Proprietary Information of Altair Engineering, Inc.

HyperWorks 12.0

�

2023年江西萍乡中考道德与法治真题及答案.doc

2023年江西萍乡中考道德与法治真题及答案.doc 2012年重庆南川中考生物真题及答案.doc

2012年重庆南川中考生物真题及答案.doc 2013年江西师范大学地理学综合及文艺理论基础考研真题.doc

2013年江西师范大学地理学综合及文艺理论基础考研真题.doc 2020年四川甘孜小升初语文真题及答案I卷.doc

2020年四川甘孜小升初语文真题及答案I卷.doc 2020年注册岩土工程师专业基础考试真题及答案.doc

2020年注册岩土工程师专业基础考试真题及答案.doc 2023-2024学年福建省厦门市九年级上学期数学月考试题及答案.doc

2023-2024学年福建省厦门市九年级上学期数学月考试题及答案.doc 2021-2022学年辽宁省沈阳市大东区九年级上学期语文期末试题及答案.doc

2021-2022学年辽宁省沈阳市大东区九年级上学期语文期末试题及答案.doc 2022-2023学年北京东城区初三第一学期物理期末试卷及答案.doc

2022-2023学年北京东城区初三第一学期物理期末试卷及答案.doc 2018上半年江西教师资格初中地理学科知识与教学能力真题及答案.doc

2018上半年江西教师资格初中地理学科知识与教学能力真题及答案.doc 2012年河北国家公务员申论考试真题及答案-省级.doc

2012年河北国家公务员申论考试真题及答案-省级.doc 2020-2021学年江苏省扬州市江都区邵樊片九年级上学期数学第一次质量检测试题及答案.doc

2020-2021学年江苏省扬州市江都区邵樊片九年级上学期数学第一次质量检测试题及答案.doc 2022下半年黑龙江教师资格证中学综合素质真题及答案.doc

2022下半年黑龙江教师资格证中学综合素质真题及答案.doc