ECPE Guideline

AQG 324

Release 02.1/2019

ECPE Guideline AQG 324

Qualification of Power Modules for Use in Power Electronics

Converter Units in Motor Vehicles

Release no.:

Release date:

Contact:

02.1/2019

15.05.2019

ECPE European Center for Power Electronics e.V.

Dipl.-Phys. Thomas Harder

Landgrabenstrasse 94

90443 Nuremberg, Germany

Email thomas.harder@ecpe.org

Phone (+49) 911 8102 880

Page 1 of 70

�

ECPE Guideline

AQG 324

Release 02.1/2019

Preface

This Guideline was prepared by the ECPE Working Group ´Automotive Power Module

Qualification´ comprising ECPE member companies active in the automotive market.

The original version is based on the supply specification LV 324 which has been

developed by German automotive OEMs together with representatives from the power

electronics supplier industry in a joint working group of ECPE and the German ZVEI

association.

The industrial standards referenced in this document have consciously been selected in

the specific versions or release years. This means they represent the technical state of

the art of the industry, which was not prepared for automotive applications, but has

been deemed suitable with regard to automotive applications. In particular, this avoids

automotive-relevant details being omitted during revisions with a focus on non-

automotive applications.

The official version of the Guideline released by the ECPE Working Group is a public

document available on the ECPE web site (www.ecpe.org).

Legal disclaimer

No liability shall attach to ECPE e.V. or its directors, employees, member organizations

or members of the responsible ECPE working group for any personal injury, property

damage or other damage of any nature whatsoever, whether direct or indirect, or for

costs (including legal fees) and expenses arising out of the publication of, use of, or

reliance upon, this ECPE Guideline or any other ECPE publications.

ECPE guidelines and publications are adopted without regard to whether or not their

adoption may involve patents or articles, materials, or processes. By such action ECPE

does not assume any liability to any patent owner, nor does it assume any obligation

whatever to parties adopting the ECPE guidelines or publications.

The ECPE Guideline AQG 324 is owned by ECPE European Center for Power

Electronics e.V.

This ECPE Guideline AQG 324 is licensed under a Creative Commons license

(license model CC BY ND) - with credit and sharing under the same conditions.

Page 2 of 70

�

ECPE Guideline

AQG 324

Release 02.1/2019

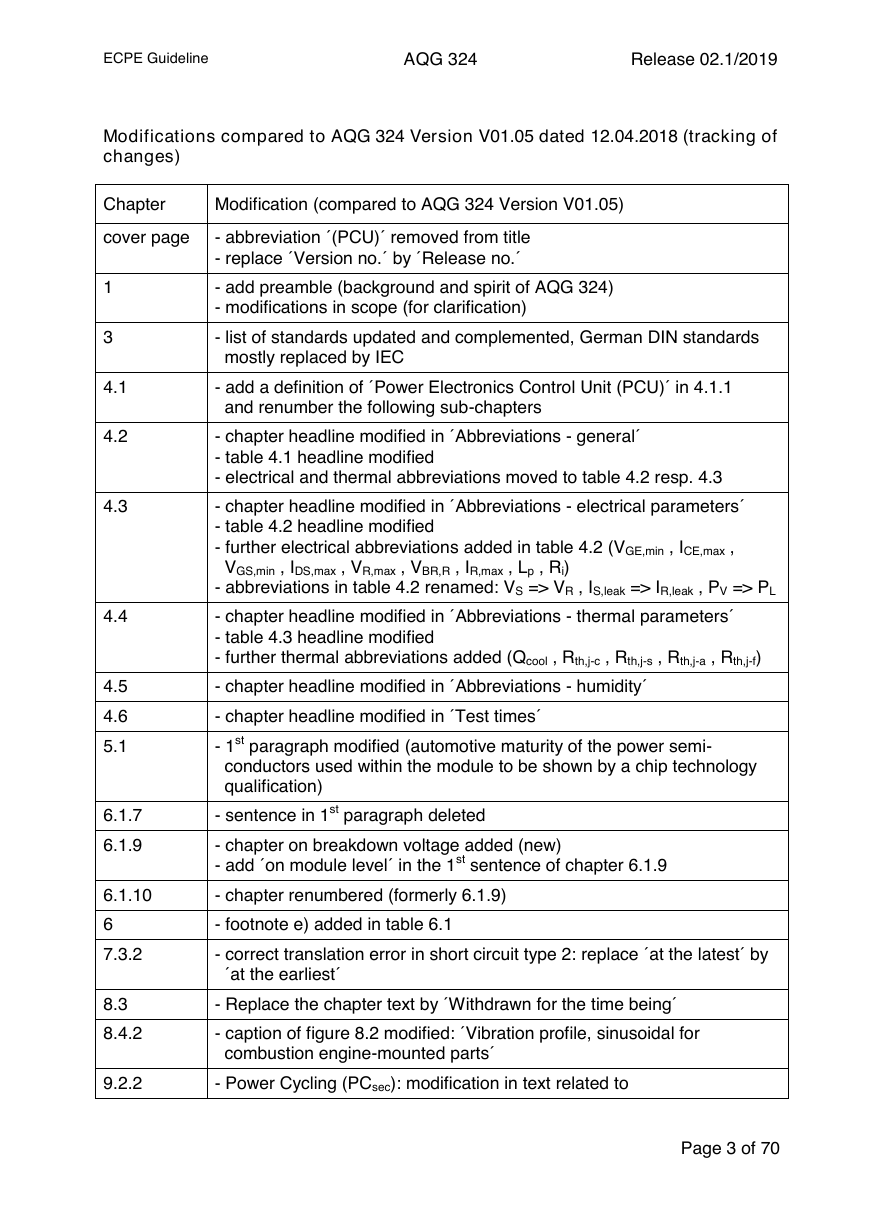

Modifications compared to AQG 324 Version V01.05 dated 12.04.2018 (tracking of

changes)

Chapter

Modification (compared to AQG 324 Version V01.05)

cover page

- abbreviation ´(PCU)´ removed from title

- replace ´Version no.´ by ´Release no.´

1

3

4.1

4.2

4.3

4.4

4.5

4.6

5.1

6.1.7

6.1.9

- add preamble (background and spirit of AQG 324)

- modifications in scope (for clarification)

- list of standards updated and complemented, German DIN standards

mostly replaced by IEC

- add a definition of ´Power Electronics Control Unit (PCU)´ in 4.1.1

and renumber the following sub-chapters

- chapter headline modified in ´Abbreviations - general´

- table 4.1 headline modified

- electrical and thermal abbreviations moved to table 4.2 resp. 4.3

- chapter headline modified in ´Abbreviations - electrical parameters´

- table 4.2 headline modified

- further electrical abbreviations added in table 4.2 (VGE,min , ICE,max ,

VGS,min , IDS,max , VR,max , VBR,R , IR,max , Lp , Ri)

- abbreviations in table 4.2 renamed: VS => VR , IS,leak => IR,leak , PV => PL

- chapter headline modified in ´Abbreviations - thermal parameters´

- table 4.3 headline modified

- further thermal abbreviations added (Qcool , Rth,j-c , Rth,j-s , Rth,j-a , Rth,j-f)

- chapter headline modified in ´Abbreviations - humidity´

- chapter headline modified in ´Test times´

- 1st paragraph modified (automotive maturity of the power semi-

conductors used within the module to be shown by a chip technology

qualification)

- sentence in 1st paragraph deleted

- chapter on breakdown voltage added (new)

- add ´on module level´ in the 1st sentence of chapter 6.1.9

6.1.10

- chapter renumbered (formerly 6.1.9)

6

7.3.2

8.3

8.4.2

- footnote e) added in table 6.1

- correct translation error in short circuit type 2: replace ´at the latest´ by

´at the earliest´

- Replace the chapter text by ´Withdrawn for the time being´

- caption of figure 8.2 modified: ´Vibration profile, sinusoidal for

combustion engine-mounted parts´

9.2.2

- Power Cycling (PCsec): modification in text related to

Page 3 of 70

�

ECPE Guideline

AQG 324

Release 02.1/2019

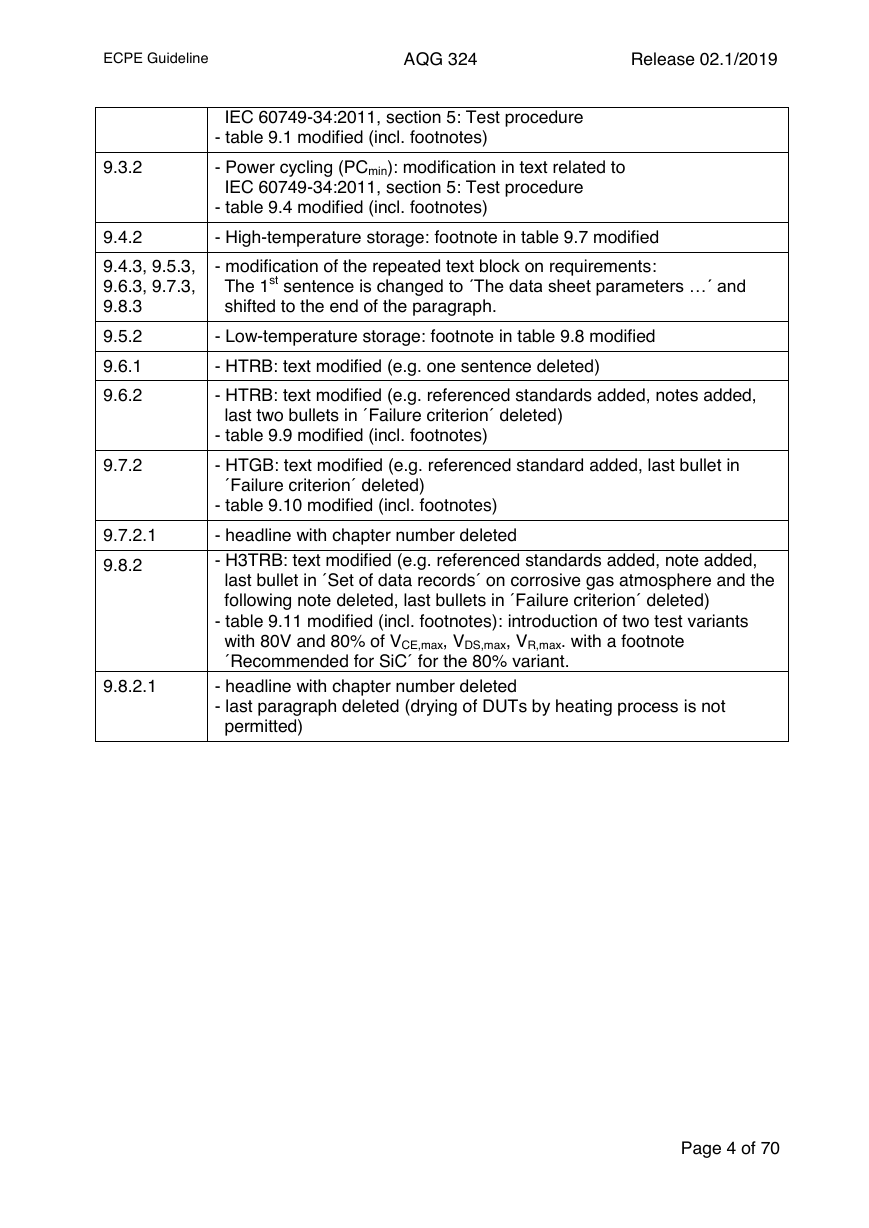

9.3.2

IEC 60749-34:2011, section 5: Test procedure

- table 9.1 modified (incl. footnotes)

- Power cycling (PCmin): modification in text related to

IEC 60749-34:2011, section 5: Test procedure

- table 9.4 modified (incl. footnotes)

9.4.2

- High-temperature storage: footnote in table 9.7 modified

9.4.3, 9.5.3,

9.6.3, 9.7.3,

9.8.3

- modification of the repeated text block on requirements:

The 1st sentence is changed to ´The data sheet parameters …´ and

shifted to the end of the paragraph.

9.5.2

9.6.1

9.6.2

9.7.2

- Low-temperature storage: footnote in table 9.8 modified

- HTRB: text modified (e.g. one sentence deleted)

- HTRB: text modified (e.g. referenced standards added, notes added,

last two bullets in ´Failure criterion´ deleted)

- table 9.9 modified (incl. footnotes)

- HTGB: text modified (e.g. referenced standard added, last bullet in

´Failure criterion´ deleted)

- table 9.10 modified (incl. footnotes)

9.7.2.1

- headline with chapter number deleted

9.8.2

- H3TRB: text modified (e.g. referenced standards added, note added,

last bullet in ´Set of data records´ on corrosive gas atmosphere and the

following note deleted, last bullets in ´Failure criterion´ deleted)

- table 9.11 modified (incl. footnotes): introduction of two test variants

with 80V and 80% of VCE,max, VDS,max, VR,max. with a footnote

´Recommended for SiC´ for the 80% variant.

9.8.2.1

- headline with chapter number deleted

- last paragraph deleted (drying of DUTs by heating process is not

permitted)

Page 4 of 70

�

ECPE Guideline

AQG 324

Release 02.1/2019

Contents

Scope

Overview

Referenced standards

Terms and definitions

Definitions

Abbreviations - general

Abbreviations - electrical parameters

Abbreviations - thermal parameters

Abbreviations - humidity

Test times

Standard tolerances

Standard values

7

9

11

12

12

14

15

16

17

17

18

18

19

General part

19

Prerequisites for chip usage in the module

Technology qualification

19

Qualification of special designs (of power el. modules) based on discrete devices 20

20

Sampling rates and measured value resolutions

20

Design of insulation properties

21

Interface description

Physical analysis

21

21

Procedure limitations

Module test

QM – 01 Module test

Characterizing module testing

QC-01 Determining parasitic stray inductance (Lp)

QC-02 Determining thermal resistance (Rth value)

QC-03 Determining short-circuit capability

QC-04 Insulation test

QC-05 Determining mechanical data

Test sequence

Environmental testing

Use of generic data

QE-01 Thermal shock test (TST)

QE-02 Contactability (CO)

QE-03 Vibration (V)

QE-04 Mechanical shock (MS)

Lifetime testing

Use of generic data

QL-01 Power cycling (PCsec)

QL-02 Power cycle (PCmin)

QL-03 High-temperature storage (HTS)

QL-04 Low-temperature storage (LTS)

QL-05 High-temperature reverse bias (HTRB)

QL-06 High-temperature gate bias (HTGB)

QL-07 High-humidity, high-temperature reverse bias (H3TRB)

22

22

26

26

26

29

32

34

35

36

36

36

38

38

44

46

46

46

51

56

57

58

60

61

Page 5 of 70

1

2

3

4

4.1

4.2

4.3

4.4

4.5

4.6

4.7

4.8

5

5.1

5.2

5.3

5.4

5.5

5.6

5.7

5.8

6

6.1

7

7.1

7.2

7.3

7.4

7.5

7.6

8

8.1

8.2

8.3

8.4

8.5

9

9.1

9.2

9.3

9.4

9.5

9.6

9.7

9.8

�

ECPE Guideline

AQG 324

Annex A Test flow chart (normative)

Annex B Delta qualification matrix (normative)

Annex C Documentation of tests (normative)

Annex D References (informative)

Annex E Typical aspects for physical analysis (informative)

Release 02.1/2019

64

66

67

70

70

Page 6 of 70

�

ECPE Guideline

AQG 324

Release 02.1/2019

1 Scope

Preamble

The AQG324 represents an industry guideline based on best practices and outstanding

requirement engineering alignment through the automotive supply chain for power

electronic converter units. It also acts as blueprint for further approaches within the

automotive transformation to overcome innovation blocking hurdles and to close gaps in

product capability or corresponding assurance processes.

With the continuously increasing complexity of automotive electronics systems it is

necessary to combine the expertise and to standardize approaches along the whole

supply chain – different to outdated approaches where the alignment primarily occurred

within a design hierarchical level, rather than from a complete system perspective.

Consequently, a core achievement has been and still is to define the same technical

language as was only possible through jointly define and tune terms, definitions and

processes.

This document defines requirements, test conditions and tests for validating properties,

including the lifetime of power electronics modules and equivalent special designs

based on discrete devices, for use in power electronics converter units (PCUs) of motor

vehicles up to 3.5 t gross vehicle weight

The described tests concern the module design as well as the qualification of devices

on module level (i.e. the assembly), but not the qualification of semiconductor chips or

manufacturing processes.

These tests do not replace the qualification tests for complete vehicle PCUs.

The qualification requirements shall be extended or adapted, as necessary, on use of

technologically novel designs.

The requirements, test conditions and tests listed in this document essentially refer to

power modules based on Si power semiconductors while wide bandgap power

semiconductors (e.g. SiC or GaN) are not yet fully covered. Future releases of this

guideline will address these alternative semiconductor technologies, as well as novel

assembly and interconnection technologies where other failure mechanisms become

important compared to the todays technologies.

The tests listed in this document also apply for validating power module properties when

using a thermal interface between the power module and the cooling system on PCU-

level, if this interface is not a part of the module structure as a result of the design.

Corresponding tests must be conducted on a reference test setup recommended and

documented by the module manufacturer, and any equivalent/generic test setups must

be specified and documented.

Note:

If the thermal interface to the cooling system is implemented in the PCU and not in the

power module, the module manufacturer cannot validate this interface. However, the

module manufacturer must demonstrate

the module

qualification in case of a connection as per the specification (recommended reference

that his module passes

Page 7 of 70

�

ECPE Guideline

AQG 324

Release 02.1/2019

test setups). The PCU manufacturer must ensure that the thermal interface selected by

it complies with the specifications from the module manufacturer.

Example:

Validation of the thermal interface of power electronics modules, which are applied to a

heat sink using a thermal interface material (TIM), is considered through specified

reference test setups (including materials) in this document.

Validation of the thermal interface of power electronics modules with a pin-fin base plate

located directly in the cooling medium is considered in this document.

Page 8 of 70

�

2023年江西萍乡中考道德与法治真题及答案.doc

2023年江西萍乡中考道德与法治真题及答案.doc 2012年重庆南川中考生物真题及答案.doc

2012年重庆南川中考生物真题及答案.doc 2013年江西师范大学地理学综合及文艺理论基础考研真题.doc

2013年江西师范大学地理学综合及文艺理论基础考研真题.doc 2020年四川甘孜小升初语文真题及答案I卷.doc

2020年四川甘孜小升初语文真题及答案I卷.doc 2020年注册岩土工程师专业基础考试真题及答案.doc

2020年注册岩土工程师专业基础考试真题及答案.doc 2023-2024学年福建省厦门市九年级上学期数学月考试题及答案.doc

2023-2024学年福建省厦门市九年级上学期数学月考试题及答案.doc 2021-2022学年辽宁省沈阳市大东区九年级上学期语文期末试题及答案.doc

2021-2022学年辽宁省沈阳市大东区九年级上学期语文期末试题及答案.doc 2022-2023学年北京东城区初三第一学期物理期末试卷及答案.doc

2022-2023学年北京东城区初三第一学期物理期末试卷及答案.doc 2018上半年江西教师资格初中地理学科知识与教学能力真题及答案.doc

2018上半年江西教师资格初中地理学科知识与教学能力真题及答案.doc 2012年河北国家公务员申论考试真题及答案-省级.doc

2012年河北国家公务员申论考试真题及答案-省级.doc 2020-2021学年江苏省扬州市江都区邵樊片九年级上学期数学第一次质量检测试题及答案.doc

2020-2021学年江苏省扬州市江都区邵樊片九年级上学期数学第一次质量检测试题及答案.doc 2022下半年黑龙江教师资格证中学综合素质真题及答案.doc

2022下半年黑龙江教师资格证中学综合素质真题及答案.doc