Automatic Defect Inspection for LCDs Using Singular Value Decomposition

Chi-Jie Lu Du-Ming Tsai* and Hsu-Nan Yen

Department of Industrial Engineering and Management

Yuan-Ze University

Taoyuan, Taiwan, R.O.C.

the

scheme using

Abstract - The purpose of this study aims at the use of

machine vision for automatic surface inspection, in

which defects are embedded in homogenously LCDs

textured surfaces. The proposed method does not rely on

local features of textures. It is based on a global image

reconstruction

singular value

decomposition (SVD). The singular values on the

decomposed diagonal matrix represent different degrees

of detail in the textured surface. By selecting proper

singular values on the diagonal matrix and reconstructing

the matrix with the selected singular values, we can

eliminate regular, periodical patterns of the textured

image, and preserve the anomalies in the restored image.

Experimental results have shown that the proposed

method is effective for detecting micro-defects in LCDs

surfaces.

1. INTRODUCTION

A

few

Since Liquid Crystal Displays (LCDs) have many

advantages in its full-color display capabilities, low

power consumption, and small size, LCDs are becoming

increasingly important in recently years. In order to

guarantee the display quality of LCD flat panels, human

operators visually inspect the TFT- array plate against

prescribed standards. However, the manual activity of

inspection could be subjective and highly dependent on

the experience of human inspectors. In this paper, we

propose an automatic visual system for LCD defect

inspection.

systems

automatic

inspection

or

methodologies have been proposed in recent years for

LCD manufacturing. Kido

[7] presented a non-

destructive, in-process inspection technique for partially

completed active-matrix LCD panel and used surface

reflection to sense optical changes and to generate maps

showing the type and location of defects. Lin et al. [1]

proposed a vision system to detect the degree of

uniformity of light reflection using a light guide plate

before the diffuser has been attached. They designed a

bright spot search and statistical software for adjusting

the parameters of the LCD light guide plate before

manufacture. Kido et al. [8] proposed an optical

charge-sensing method for testing and characterizing

Thin Film Transistor (TFT) arrays. They used interface

reflection to generate maps that show the type and

location of line and point defects. Most of the existing

methods of automatic optical inspection systems for

TFT-array were based on conventional electrical methods

and electro-optic modulator

the surface

to detect

potential of a TFT-array [8]. But those methods can not

be applied to detect the small defects on the surface

directly.

In the TFT-array plate, defects could roughly

classified into two parts [4]. One is called macro-defects

including “MURA”, “SIMI” and “ZURE”. Macro-

defects are large in size and, therefore, can be easily

detected by human inspection. Another type of defects is

called micro-defects including pinholes, fingerprints,

particle and scrapes. Because the size of the micro

defects are very small and can not be easily found by

human eyesight, electrical methods and electro-optic

modulator.

A TFT-array plate generally consists of TFT-array

and Polimide film (PI film). It involves many horizontal

gate lines and vertical data lines, and lines intersect to

form right angles. The TFT-array plate surface can be

treated as a structural texture in an image. Since the

composition of TFT- array plate surface comprise

horizontal and vertical elements, it can be classified as a

structural texture in the image.

The textural feature of TFT-array plate surface is a

homogeneous texture that consists of an arrangement

primarily of horizontal and vertical elements appearing

periodically on the surface. Few studies have utilized the

structure characteristics of TFT-array plate to inspect the

defects. Since singular value decomposition (SVD)

involves horizontal and vertical basis functions, we use

SVD-based image reconstruction technique to detect the

micro-defects on the TFT-array plate surface.

The method of SVD was first proposed in 1970 and

has been applied in a wide range of computer vision

applications such as data compression, image restoration,

and feature extraction [5,6]. A few studies have been

done on using SVD for texture analysis in computer

vision. Luo and Chen [3] utilized SVD strategy for

texture discrimination. They used the proportion of

dominant singular value of an image matrix as textures

for texture discrimination and employed SVD-based

algorithm for discriminating synthesized textures and

natural textures. Xia et al. [2] proposed a method that

combines SVD and gray-level co-occurrence matrix

(GLCM) to extract textural features embedded in forest

image. The aforementioned methods for texture analysis

generally use singular values or singular vectors that

derived from the textured images to characterize the

textural features, and use those features to segment or

classify textures. Different textures may need different

singular values and singular vectors to describe the

textural features. The feature extraction process for a best

set of textural features is generally carried out by

try-and-error, and may highly rely on human expertise.

SVD can be used to decompose an image and obtain

*Corresponding author: iedmtsai@saturn.yzu.edu.tw

1

�

a diagonal matrix. The ordered entries of the diagonal

matrix are singular values. The main information of an

image can be represented by the larger singular values.

The other singular values with small magnitude provide

detailed information of the image. For the application of

image restoration, we can preserve only the larger

singular values to reconstruct an image. In application of

defect inspection, we can set the larger singular values to

zero and preserve

to

reconstruct an image. The background information will

be eliminated and can be distinctly retained the defects in

the restored image.

the smaller singular values

In this paper, we propose a global approach based

on an image reconstruction scheme using singular value

decomposition for inspecting micro- defects including

pinholes, scrapes and fingerprints on the surface of

TFT-array plates. A simple thresholding can then be used

to discriminate between defective region and regular

regions in the reconstructed image.

2. SVD IMAGE RECONSTRUCTION

2.1 TFT-Array Plate

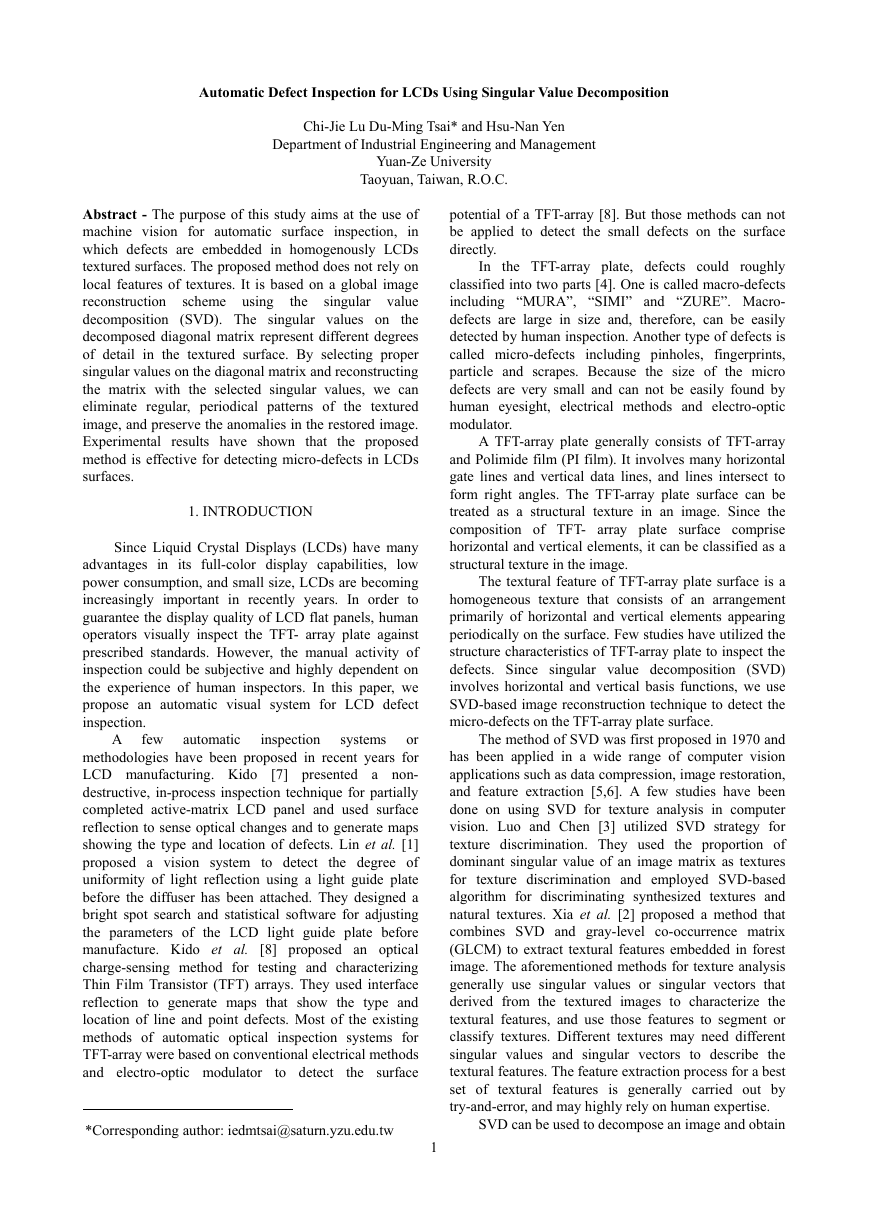

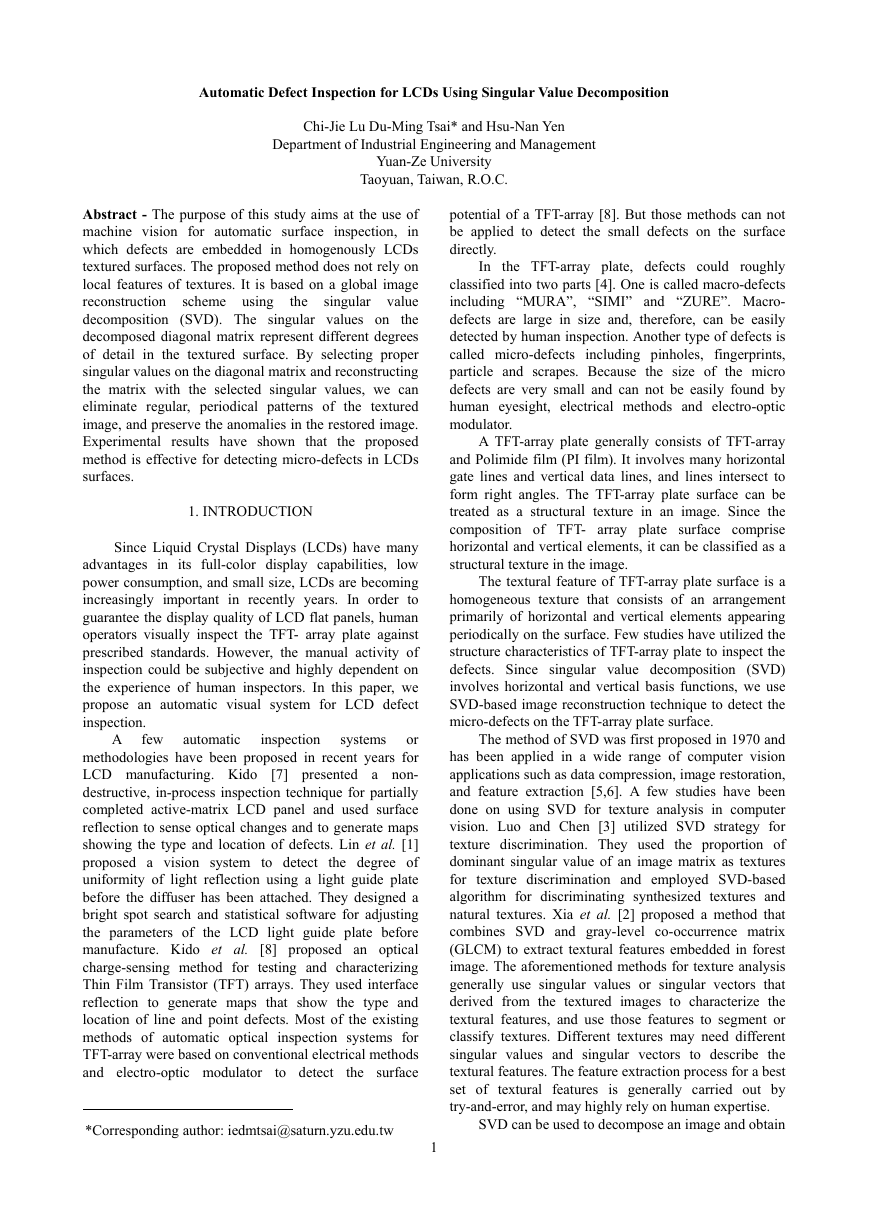

A TFT-array plate generally consists of TFT-array

and Polimide film (PI film). A TFT-array has horizontal

gate lines on one plane and vertical data line on other

plane. At each pixel, the gate of the TFT is connected to

the gate line and the source is connected to the data line

[8]. Fig. 1 shows a schematic of a typical single pixel.

Since the TFT-array involves many horizontal gate lines

and vertical data lines. The features of TFT- array surface

will have horizontal and vertical structures. Since the PI

film is coated in TFT-array and the color is nearly limpid,

it does not change the texture on the TFT-array surface.

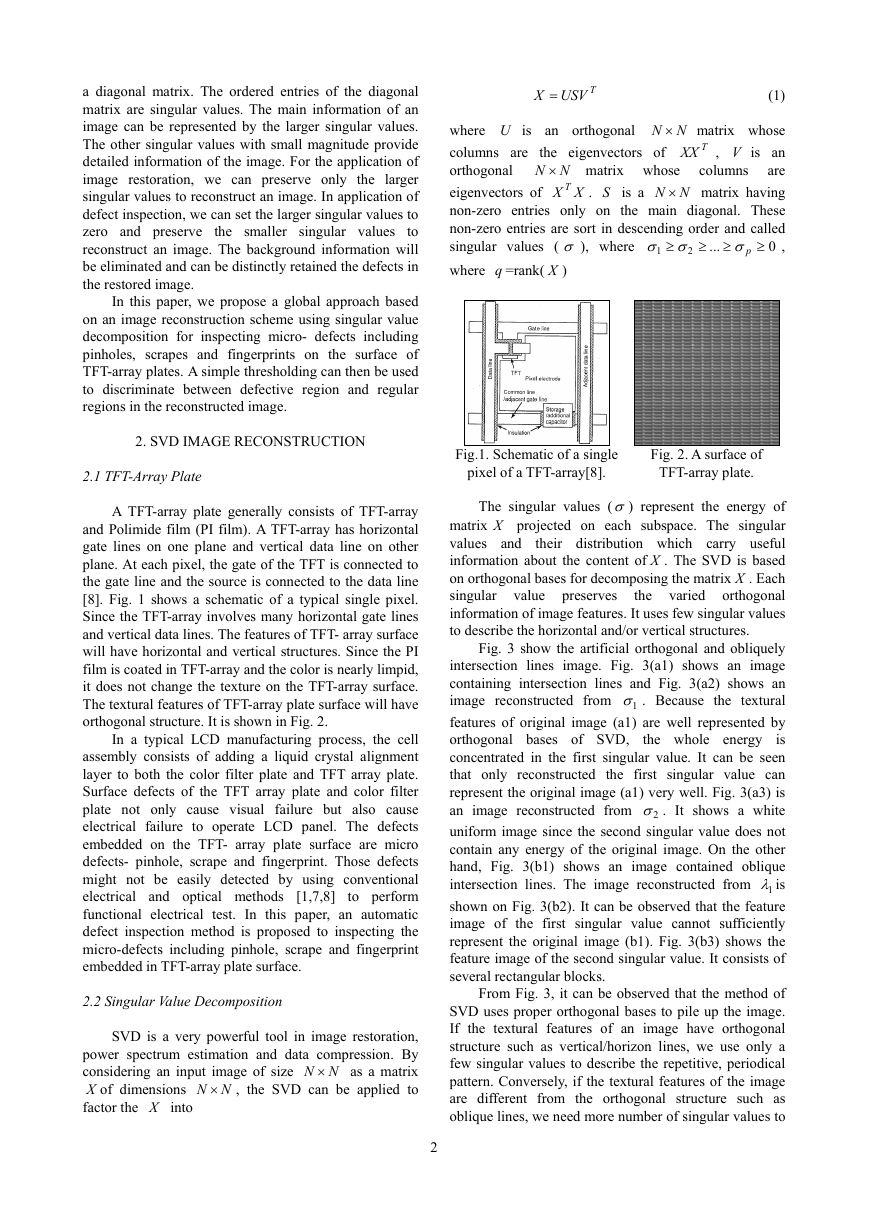

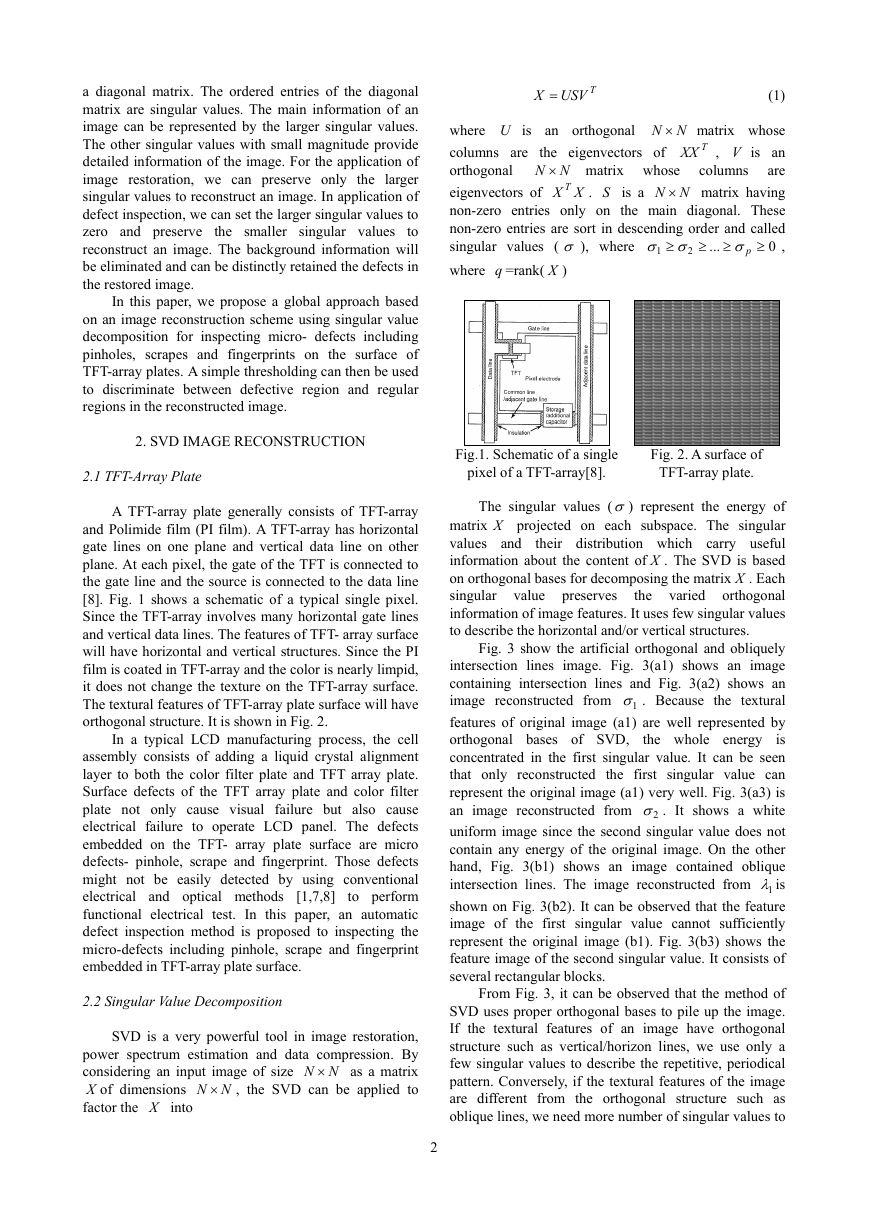

The textural features of TFT-array plate surface will have

orthogonal structure. It is shown in Fig. 2.

In a typical LCD manufacturing process, the cell

assembly consists of adding a liquid crystal alignment

layer to both the color filter plate and TFT array plate.

Surface defects of the TFT array plate and color filter

plate not only cause visual failure but also cause

electrical failure to operate LCD panel. The defects

embedded on the TFT- array plate surface are micro

defects- pinhole, scrape and fingerprint. Those defects

might not be easily detected by using conventional

electrical and optical methods [1,7,8]

to perform

functional electrical test. In this paper, an automatic

defect inspection method is proposed to inspecting the

micro-defects including pinhole, scrape and fingerprint

embedded in TFT-array plate surface.

2.2 Singular Value Decomposition

SVD is a very powerful tool in image restoration,

power spectrum estimation and data compression. By

considering an input image of size

as a matrix

X of dimensions

, the SVD can be applied to

factor the X into

NN ×

NN ×

2

X =

TUSV

(1)

NN ×

NN ×

where U is an orthogonal

matrix whose

TXX , V is an

columns are the eigenvectors of

orthogonal

columns

are

eigenvectors of

matrix having

non-zero entries only on the main diagonal. These

non-zero entries are sort in descending order and called

singular values ( σ ), where

,

where q =rank( X )

matrix whose

. S is a

NN ×

σσ

2

XX T

pσ

≥

...

≥

≥

0

≥

1

Fig.1. Schematic of a single

pixel of a TFT-array[8].

Fig. 2. A surface of

TFT-array plate.

The singular values (σ) represent the energy of

matrix X projected on each subspace. The singular

values and

their distribution which carry useful

information about the content of X . The SVD is based

on orthogonal bases for decomposing the matrix X . Each

singular value preserves

the varied orthogonal

information of image features. It uses few singular values

to describe the horizontal and/or vertical structures.

the whole energy

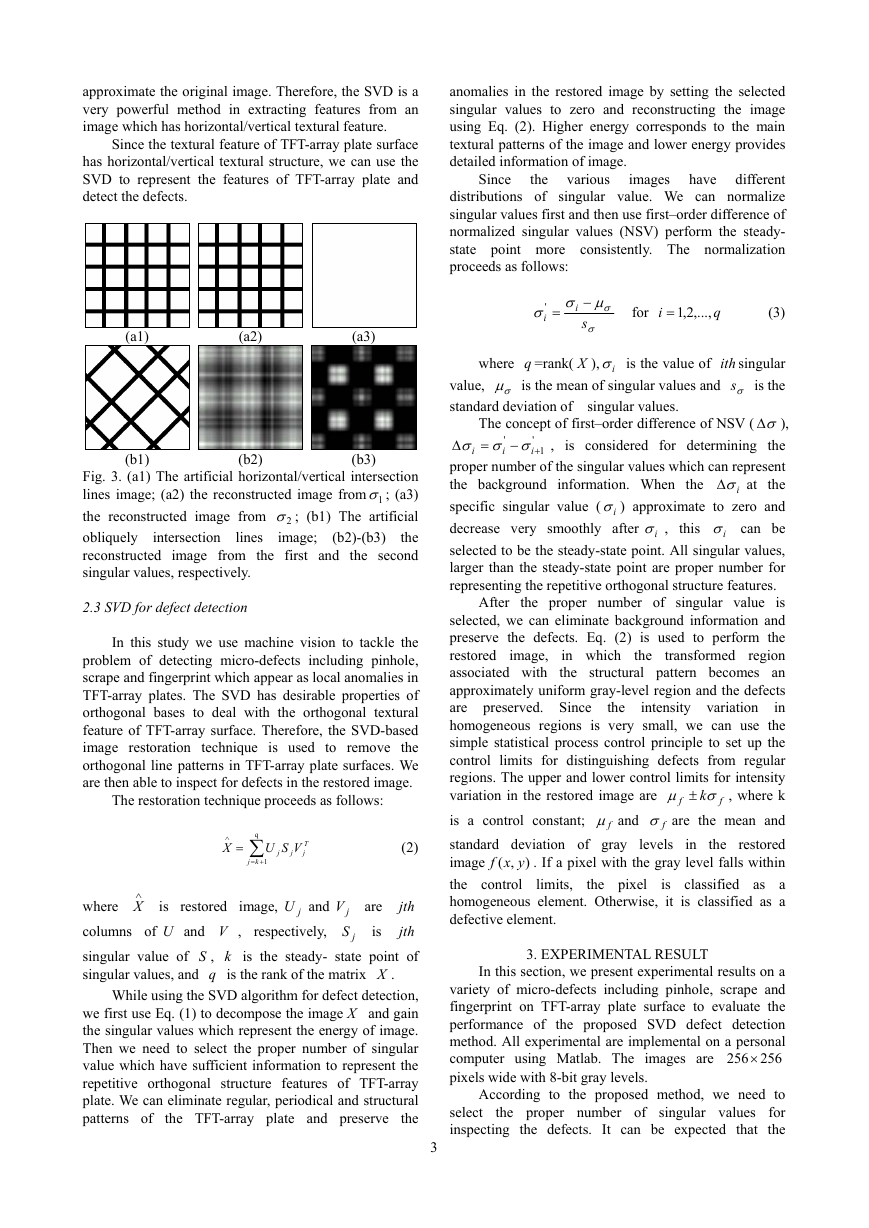

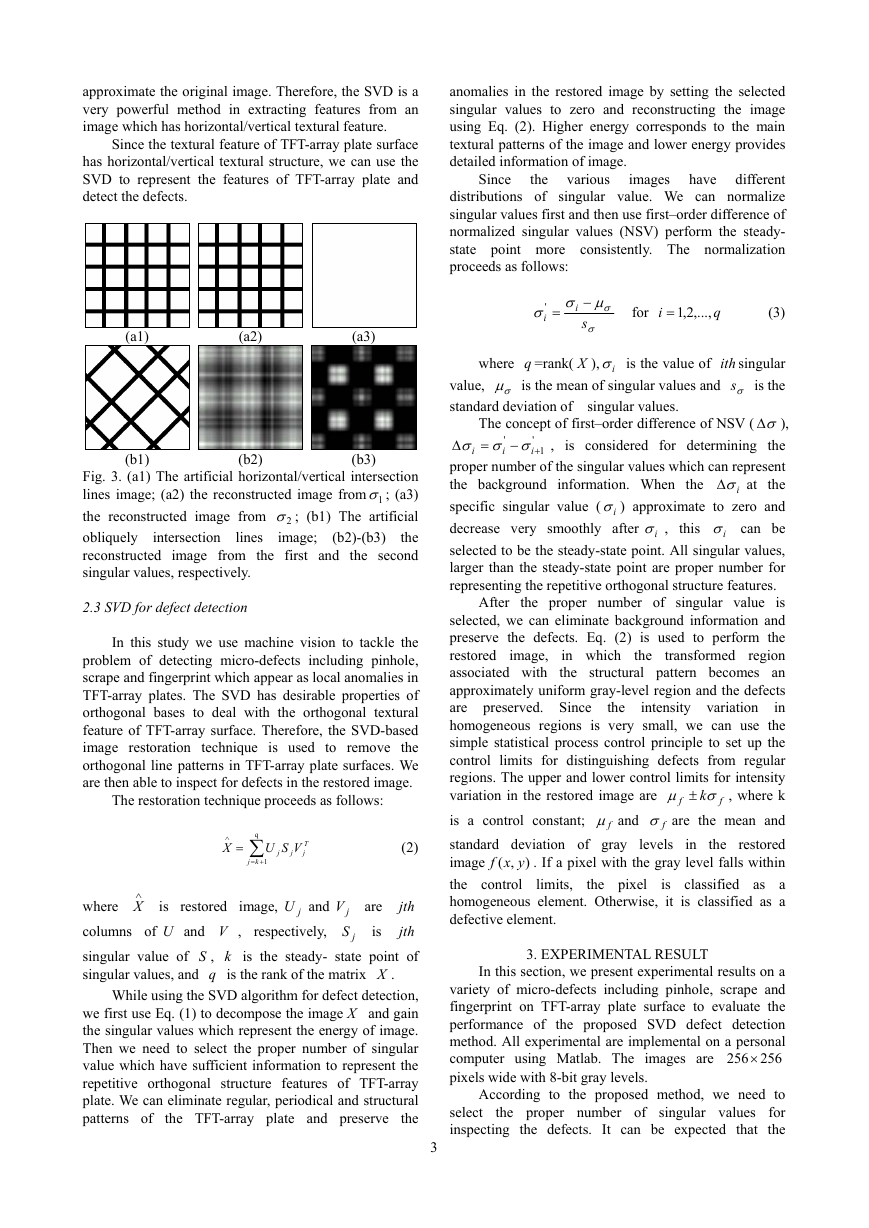

Fig. 3 show the artificial orthogonal and obliquely

intersection lines image. Fig. 3(a1) shows an image

containing intersection lines and Fig. 3(a2) shows an

image reconstructed from

1σ . Because the textural

features of original image (a1) are well represented by

orthogonal bases of SVD,

is

concentrated in the first singular value. It can be seen

that only reconstructed the first singular value can

represent the original image (a1) very well. Fig. 3(a3) is

an image reconstructed from

2σ . It shows a white

uniform image since the second singular value does not

contain any energy of the original image. On the other

hand, Fig. 3(b1) shows an image contained oblique

intersection lines. The image reconstructed from

1λ is

shown on Fig. 3(b2). It can be observed that the feature

image of the first singular value cannot sufficiently

represent the original image (b1). Fig. 3(b3) shows the

feature image of the second singular value. It consists of

several rectangular blocks.

From Fig. 3, it can be observed that the method of

SVD uses proper orthogonal bases to pile up the image.

If the textural features of an image have orthogonal

structure such as vertical/horizon lines, we use only a

few singular values to describe the repetitive, periodical

pattern. Conversely, if the textural features of the image

are different from the orthogonal structure such as

oblique lines, we need more number of singular values to

�

approximate the original image. Therefore, the SVD is a

very powerful method in extracting features from an

image which has horizontal/vertical textural feature.

Since the textural feature of TFT-array plate surface

has horizontal/vertical textural structure, we can use the

SVD to represent the features of TFT-array plate and

detect the defects.

(a1)

(a2)

(a3)

(b1)

(b2)

(b3)

Fig. 3. (a1) The artificial horizontal/vertical intersection

lines image; (a2) the reconstructed image from 1σ ; (a3)

the reconstructed image from

2σ ; (b1) The artificial

obliquely

lines

image;

the

reconstructed image from the first and the second

singular values, respectively.

intersection

(b2)-(b3)

2.3 SVD for defect detection

In this study we use machine vision to tackle the

problem of detecting micro-defects including pinhole,

scrape and fingerprint which appear as local anomalies in

TFT-array plates. The SVD has desirable properties of

orthogonal bases to deal with the orthogonal textural

feature of TFT-array surface. Therefore, the SVD-based

image restoration technique is used to remove the

orthogonal line patterns in TFT-array plate surfaces. We

are then able to inspect for defects in the restored image.

The restoration technique proceeds as follows:

(2)

∧

X

=

q

∑

1kj

+=

j VSU

j

T

j

∧

X is restored image,

jth

jU and

where

columns of U and V , respectively,

jth

singular value of S , k is the steady- state point of

singular values, and q is the rank of the matrix X .

jV are

jS

is

While using the SVD algorithm for defect detection,

we first use Eq. (1) to decompose the image X and gain

the singular values which represent the energy of image.

Then we need to select the proper number of singular

value which have sufficient information to represent the

repetitive orthogonal structure features of TFT-array

plate. We can eliminate regular, periodical and structural

patterns of

the

the TFT-array plate and preserve

3

anomalies in the restored image by setting the selected

singular values to zero and reconstructing the image

using Eq. (2). Higher energy corresponds to the main

textural patterns of the image and lower energy provides

detailed information of image.

have

Since

images

various

different

distributions of singular value. We can normalize

singular values first and then use first–order difference of

normalized singular values (NSV) perform the steady-

state point more consistently. The normalization

proceeds as follows:

the

='

σ

i

σμσ

i

−

s

σ

for

i

,...,2,1=

q

(3)

where q =rank( X ),

i

'

i

1

+

−

iσΔ

iσ is the value of ith singular

value, σμ is the mean of singular values and σs is the

standard deviation of singular values.

iσ , this

The concept of first–order difference of NSV ( σΔ ),

'

, is considered for determining the

Δ

=

σσσ

i

proper number of the singular values which can represent

the background information. When the

at the

specific singular value (

iσ ) approximate to zero and

decrease very smoothly after

iσ can be

selected to be the steady-state point. All singular values,

larger than the steady-state point are proper number for

representing the repetitive orthogonal structure features.

After the proper number of singular value is

selected, we can eliminate background information and

preserve the defects. Eq. (2) is used to perform the

in which

restored

image,

transformed region

associated with

the structural pattern becomes an

approximately uniform gray-level region and the defects

are preserved. Since

in

homogeneous regions is very small, we can use the

simple statistical process control principle to set up the

control limits for distinguishing defects from regular

regions. The upper and lower control limits for intensity

, where k

variation in the restored image are

fσ are the mean and

is a control constant;

standard deviation of gray

levels

the restored

yxf

image

. If a pixel with the gray level falls within

,(

)

the control

limits,

is classified as a

homogeneous element. Otherwise, it is classified as a

defective element.

intensity variation

kσμ ±

f

the pixel

fμ and

the

the

in

f

3. EXPERIMENTAL RESULT

In this section, we present experimental results on a

variety of micro-defects including pinhole, scrape and

fingerprint on TFT-array plate surface to evaluate the

performance of the proposed SVD defect detection

method. All experimental are implemental on a personal

computer using Matlab. The images are

256

pixels wide with 8-bit gray levels.

256×

According to the proposed method, we need to

select

the proper number of singular values for

inspecting the defects. It can be expected that the

�

'

normalized singular value (NSV) of the first singular

1σ ) dominate all other singular values, and the

value (

NSV of remaining singular values drop dramatically. It

reaches a steady-state point that approximates to zero

after a few number of NSVs. The steady-state point with

can be used to distinguish the repetitive

05.0<Δσ

background and defects in the image. We can use the

first-order difference of consecutive NSV (

iσΔ ) to find

the location of the steady-state singular value.

1 σσ −

5

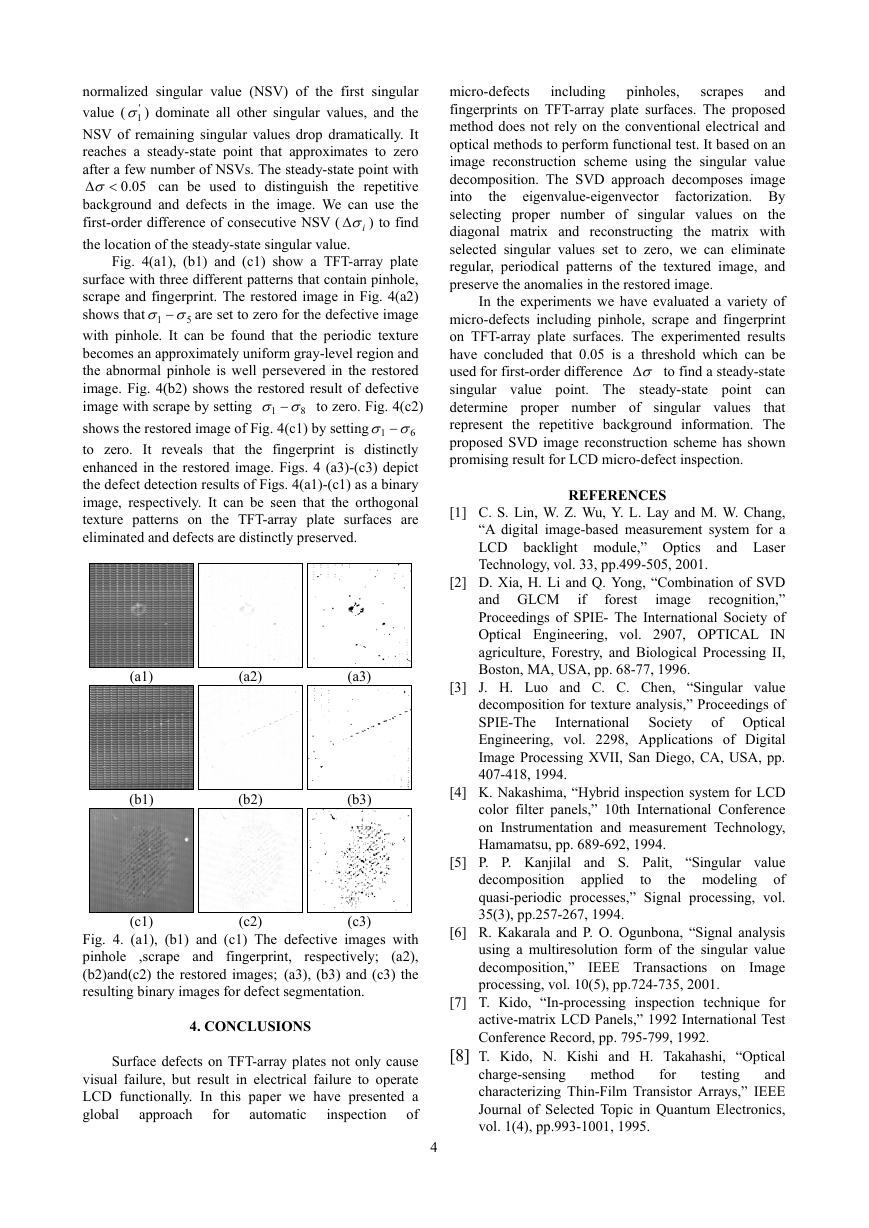

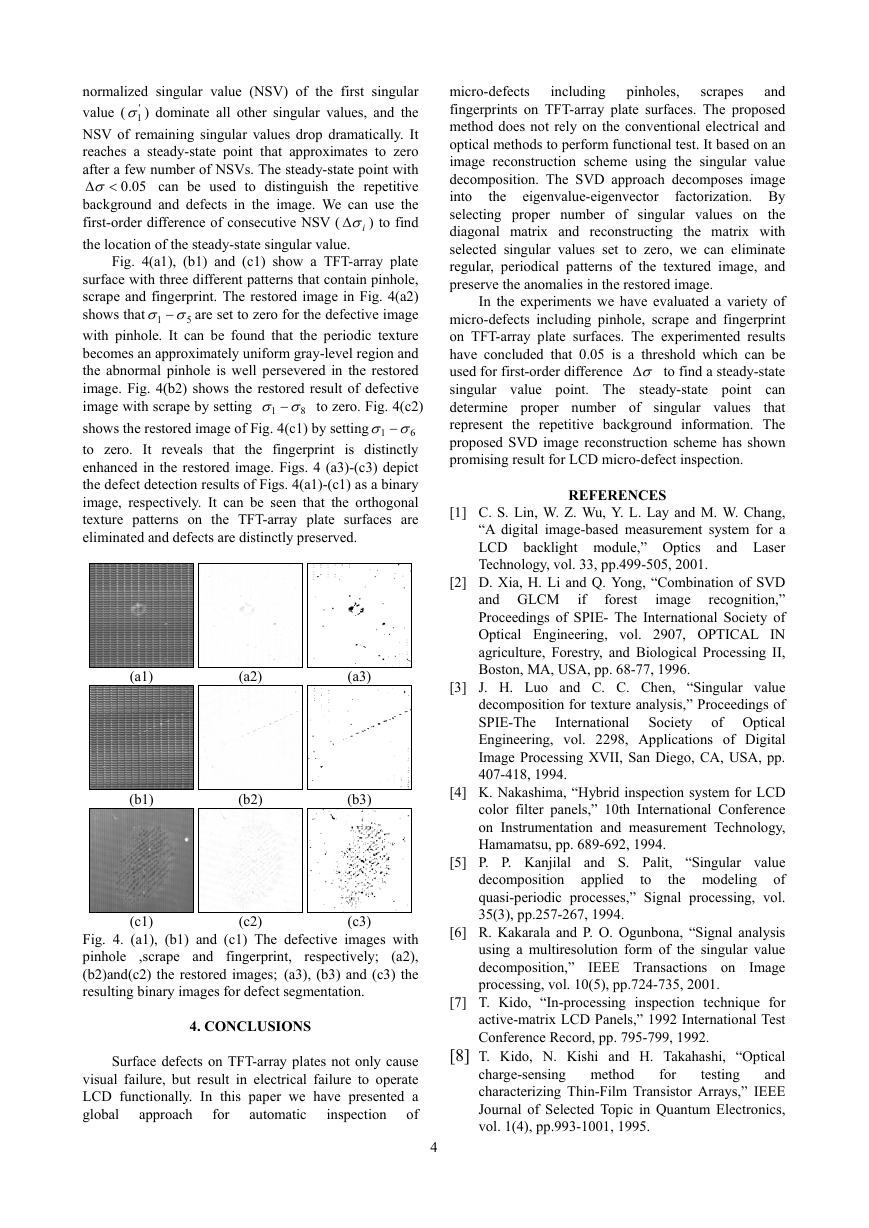

Fig. 4(a1), (b1) and (c1) show a TFT-array plate

surface with three different patterns that contain pinhole,

scrape and fingerprint. The restored image in Fig. 4(a2)

shows that

are set to zero for the defective image

with pinhole. It can be found that the periodic texture

becomes an approximately uniform gray-level region and

the abnormal pinhole is well persevered in the restored

image. Fig. 4(b2) shows the restored result of defective

to zero. Fig. 4(c2)

image with scrape by setting

shows the restored image of Fig. 4(c1) by setting

1 σσ −

6

to zero. It reveals that the fingerprint is distinctly

enhanced in the restored image. Figs. 4 (a3)-(c3) depict

the defect detection results of Figs. 4(a1)-(c1) as a binary

image, respectively. It can be seen that the orthogonal

texture patterns on the TFT-array plate surfaces are

eliminated and defects are distinctly preserved.

1 σσ −

8

(a1)

(b1)

(a2)

(b2)

(a3)

(b3)

(c3)

(c1)

(c2)

Fig. 4. (a1), (b1) and (c1) The defective images with

pinhole

,scrape and fingerprint, respectively; (a2),

(b2)and(c2) the restored images; (a3), (b3) and (c3) the

resulting binary images for defect segmentation.

4. CONCLUSIONS

Surface defects on TFT-array plates not only cause

visual failure, but result in electrical failure to operate

LCD functionally. In this paper we have presented a

global

of

inspection

automatic

approach

for

4

scrapes

pinholes,

including

micro-defects

and

fingerprints on TFT-array plate surfaces. The proposed

method does not rely on the conventional electrical and

optical methods to perform functional test. It based on an

image reconstruction scheme using the singular value

decomposition. The SVD approach decomposes image

into

factorization. By

selecting proper number of singular values on the

diagonal matrix and reconstructing the matrix with

selected singular values set to zero, we can eliminate

regular, periodical patterns of the textured image, and

preserve the anomalies in the restored image.

the eigenvalue-eigenvector

In the experiments we have evaluated a variety of

micro-defects including pinhole, scrape and fingerprint

on TFT-array plate surfaces. The experimented results

have concluded that 0.05 is a threshold which can be

used for first-order difference σΔ to find a steady-state

singular value point. The steady-state point can

determine proper number of singular values

that

represent the repetitive background information. The

proposed SVD image reconstruction scheme has shown

promising result for LCD micro-defect inspection.

REFERENCES

if

[1] C. S. Lin, W. Z. Wu, Y. L. Lay and M. W. Chang,

“A digital image-based measurement system for a

LCD backlight module,” Optics and Laser

Technology, vol. 33, pp.499-505, 2001.

forest

[2] D. Xia, H. Li and Q. Yong, “Combination of SVD

and GLCM

recognition,”

Proceedings of SPIE- The International Society of

Optical Engineering, vol. 2907, OPTICAL IN

agriculture, Forestry, and Biological Processing II,

Boston, MA, USA, pp. 68-77, 1996.

image

[3] J. H. Luo and C. C. Chen, “Singular value

decomposition for texture analysis,” Proceedings of

SPIE-The

of Optical

Engineering, vol. 2298, Applications of Digital

Image Processing XVII, San Diego, CA, USA, pp.

407-418, 1994.

International Society

[4] K. Nakashima, “Hybrid inspection system for LCD

color filter panels,” 10th International Conference

on Instrumentation and measurement Technology,

Hamamatsu, pp. 689-692, 1994.

[5] P. P. Kanjilal and S. Palit, “Singular value

decomposition applied

the modeling of

quasi-periodic processes,” Signal processing, vol.

35(3), pp.257-267, 1994.

[6] R. Kakarala and P. O. Ogunbona, “Signal analysis

using a multiresolution form of the singular value

decomposition,”

Image

processing, vol. 10(5), pp.724-735, 2001.

IEEE Transactions on

[7] T. Kido, “In-processing inspection technique for

active-matrix LCD Panels,” 1992 International Test

Conference Record, pp. 795-799, 1992.

[8] T. Kido, N. Kishi and H. Takahashi, “Optical

charge-sensing method

and

characterizing Thin-Film Transistor Arrays,” IEEE

Journal of Selected Topic in Quantum Electronics,

vol. 1(4), pp.993-1001, 1995.

testing

for

to

�

2023年江西萍乡中考道德与法治真题及答案.doc

2023年江西萍乡中考道德与法治真题及答案.doc 2012年重庆南川中考生物真题及答案.doc

2012年重庆南川中考生物真题及答案.doc 2013年江西师范大学地理学综合及文艺理论基础考研真题.doc

2013年江西师范大学地理学综合及文艺理论基础考研真题.doc 2020年四川甘孜小升初语文真题及答案I卷.doc

2020年四川甘孜小升初语文真题及答案I卷.doc 2020年注册岩土工程师专业基础考试真题及答案.doc

2020年注册岩土工程师专业基础考试真题及答案.doc 2023-2024学年福建省厦门市九年级上学期数学月考试题及答案.doc

2023-2024学年福建省厦门市九年级上学期数学月考试题及答案.doc 2021-2022学年辽宁省沈阳市大东区九年级上学期语文期末试题及答案.doc

2021-2022学年辽宁省沈阳市大东区九年级上学期语文期末试题及答案.doc 2022-2023学年北京东城区初三第一学期物理期末试卷及答案.doc

2022-2023学年北京东城区初三第一学期物理期末试卷及答案.doc 2018上半年江西教师资格初中地理学科知识与教学能力真题及答案.doc

2018上半年江西教师资格初中地理学科知识与教学能力真题及答案.doc 2012年河北国家公务员申论考试真题及答案-省级.doc

2012年河北国家公务员申论考试真题及答案-省级.doc 2020-2021学年江苏省扬州市江都区邵樊片九年级上学期数学第一次质量检测试题及答案.doc

2020-2021学年江苏省扬州市江都区邵樊片九年级上学期数学第一次质量检测试题及答案.doc 2022下半年黑龙江教师资格证中学综合素质真题及答案.doc

2022下半年黑龙江教师资格证中学综合素质真题及答案.doc