Introduction

Review of a Basic Theory for RFID antenna Design

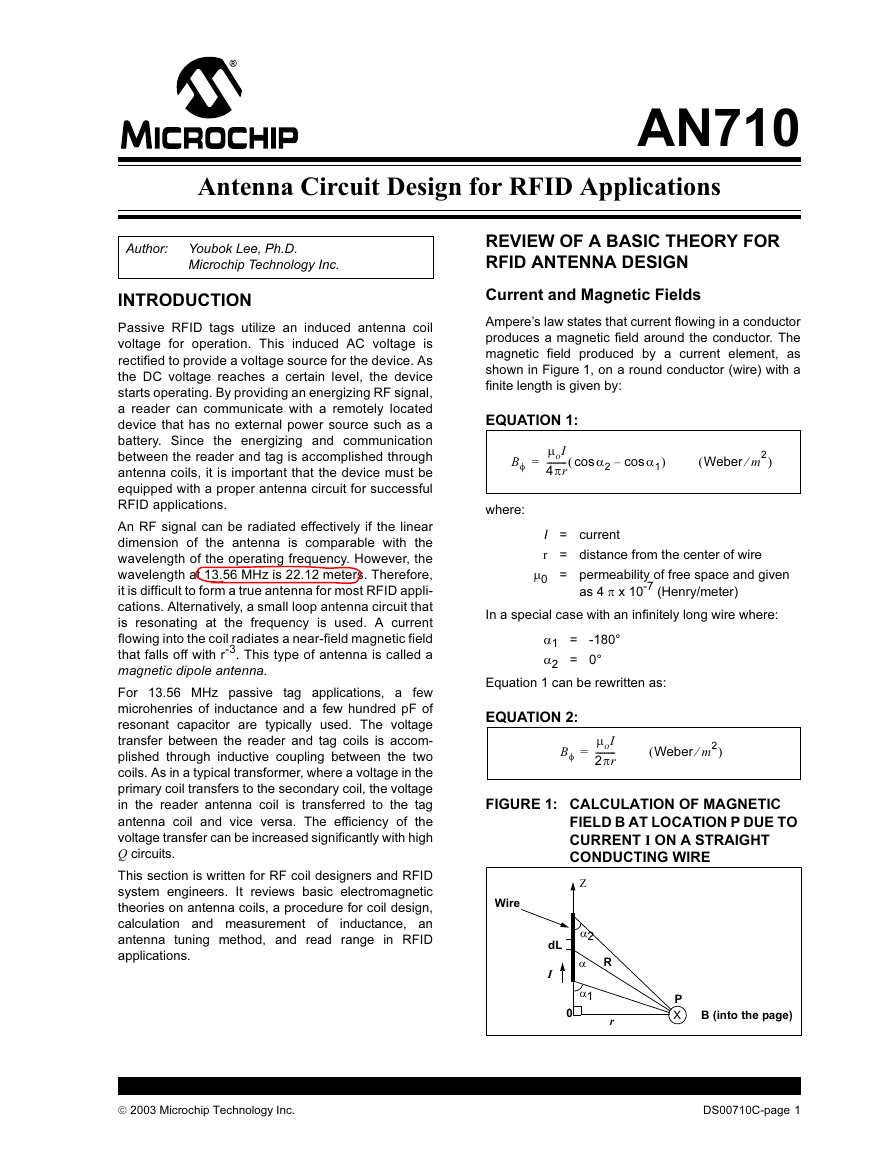

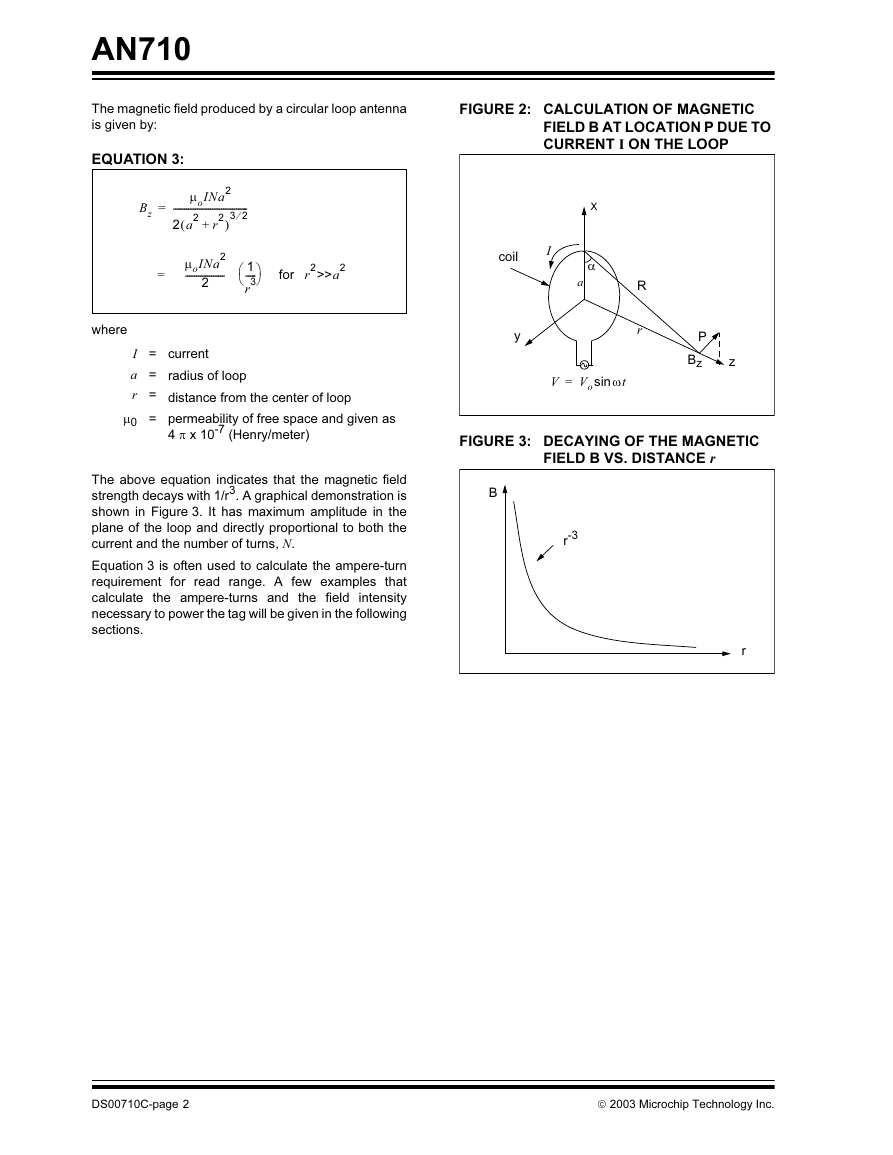

Current and Magnetic Fields

FIGURE 1: Calculation of magnetic field B at location P due to current I on a straight conducting...

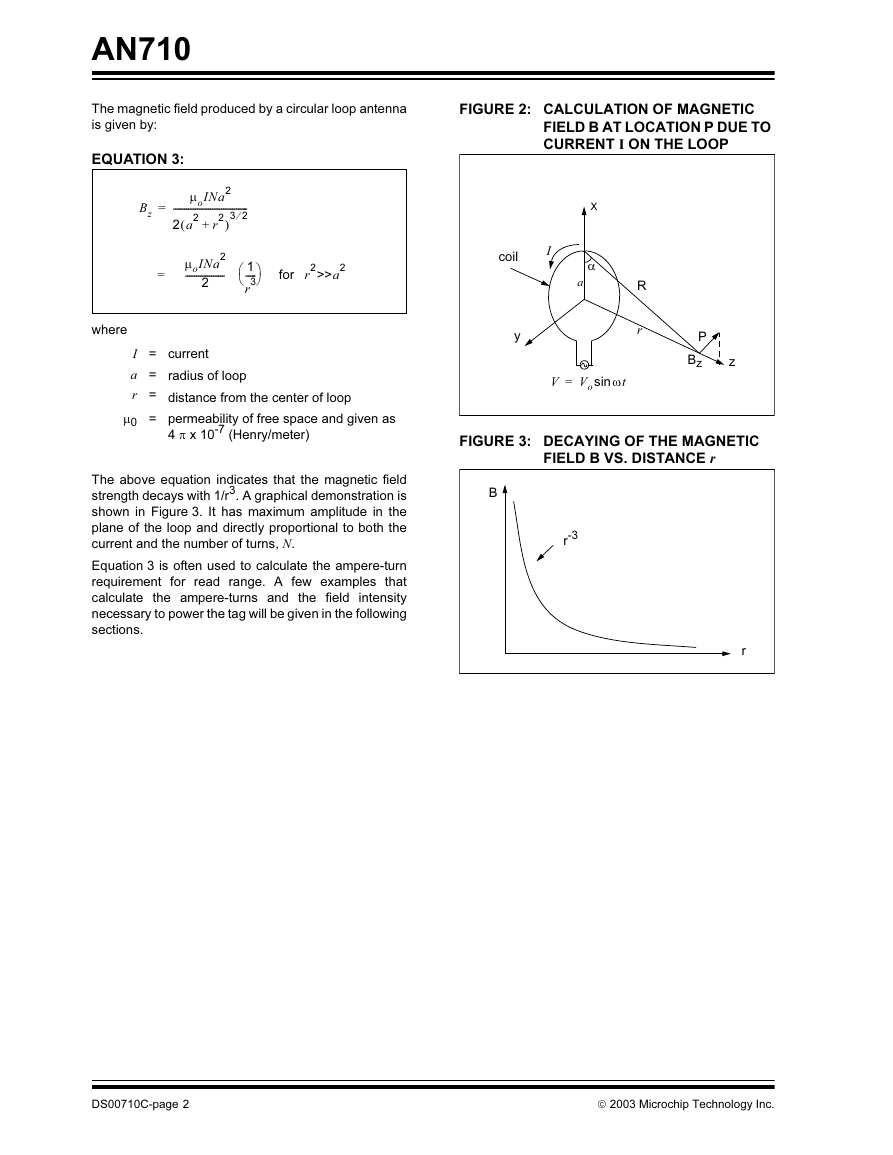

FIGURE 2: Calculation of magnetic field B at location P due to current I on the loop

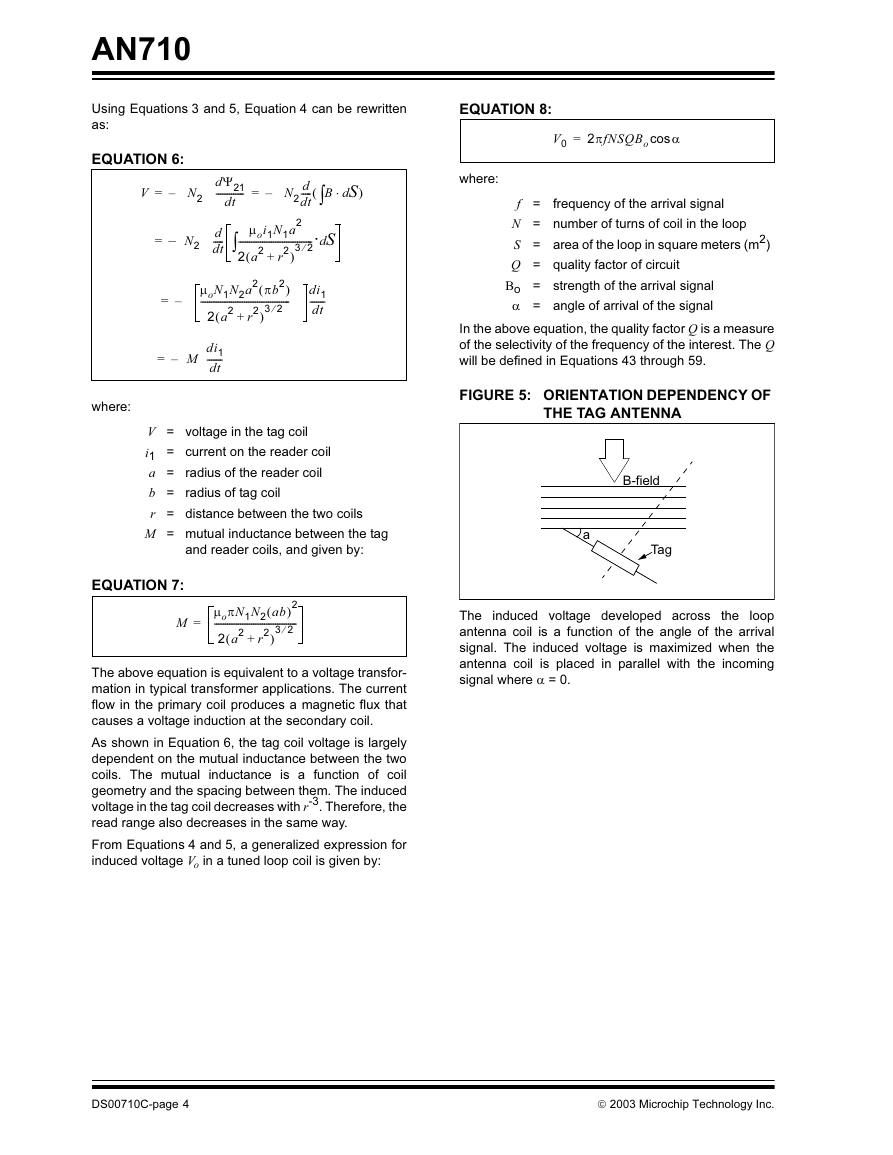

FIGURE 3: Decaying of the magnetic field B vs. distance r

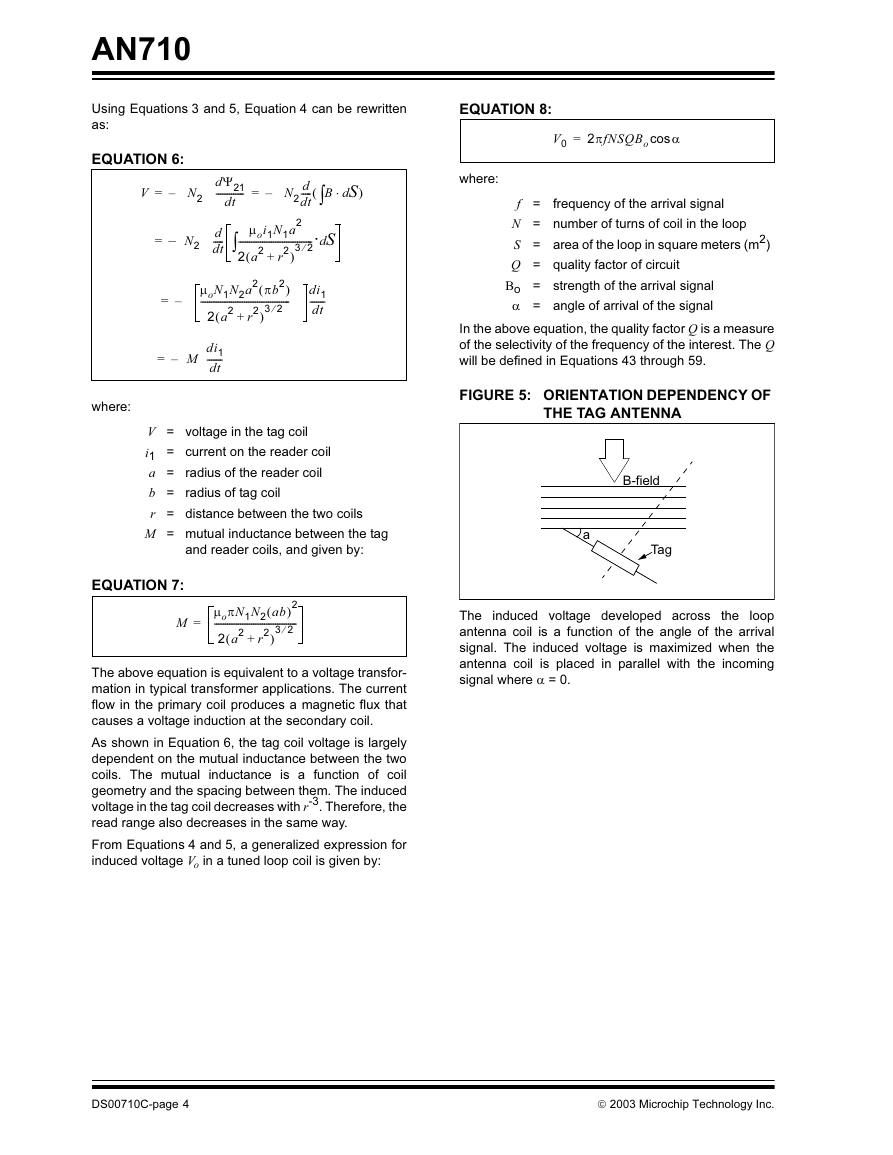

Induced Voltage in an Antenna Coil

FIGURE 4: A basic configuration of reader and tag antennas in RFID applications

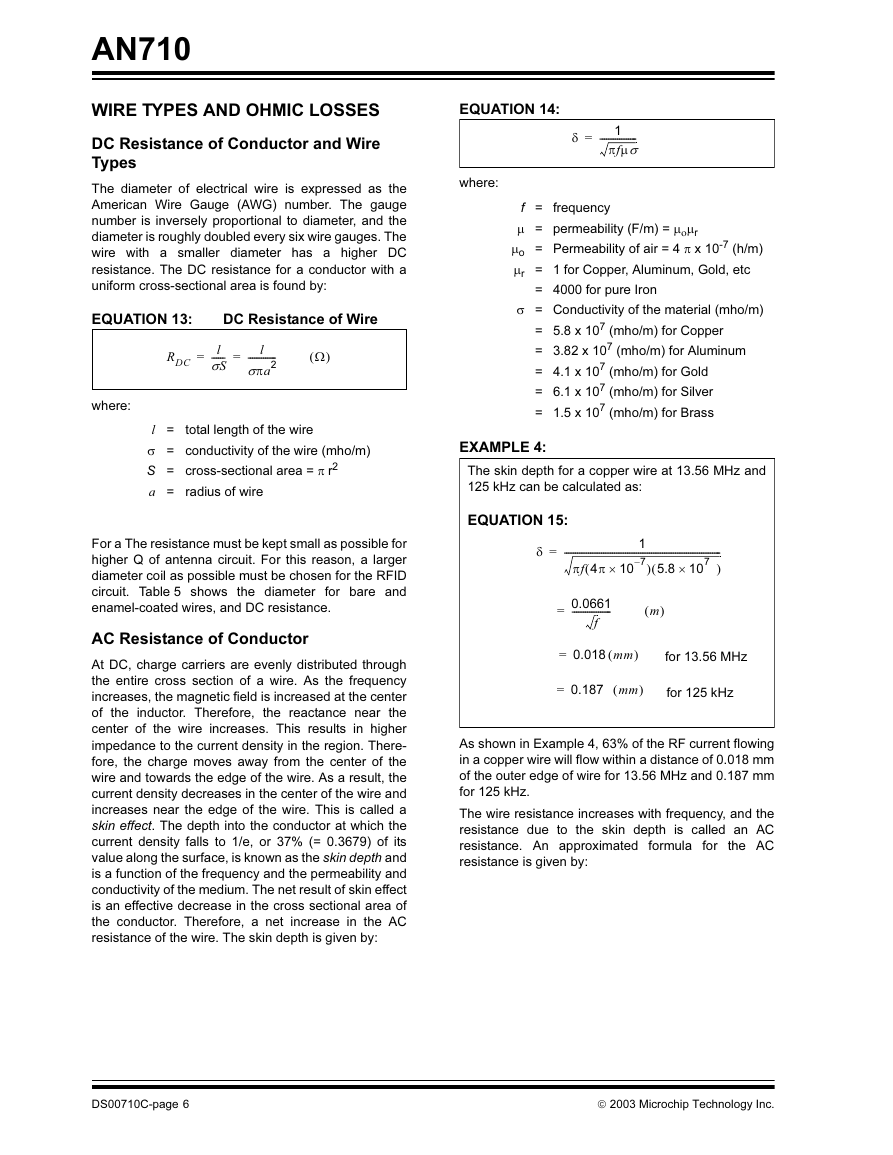

FIGURE 5: Orientation Dependency of the Tag Antenna

Wire Types and Ohmic Losses

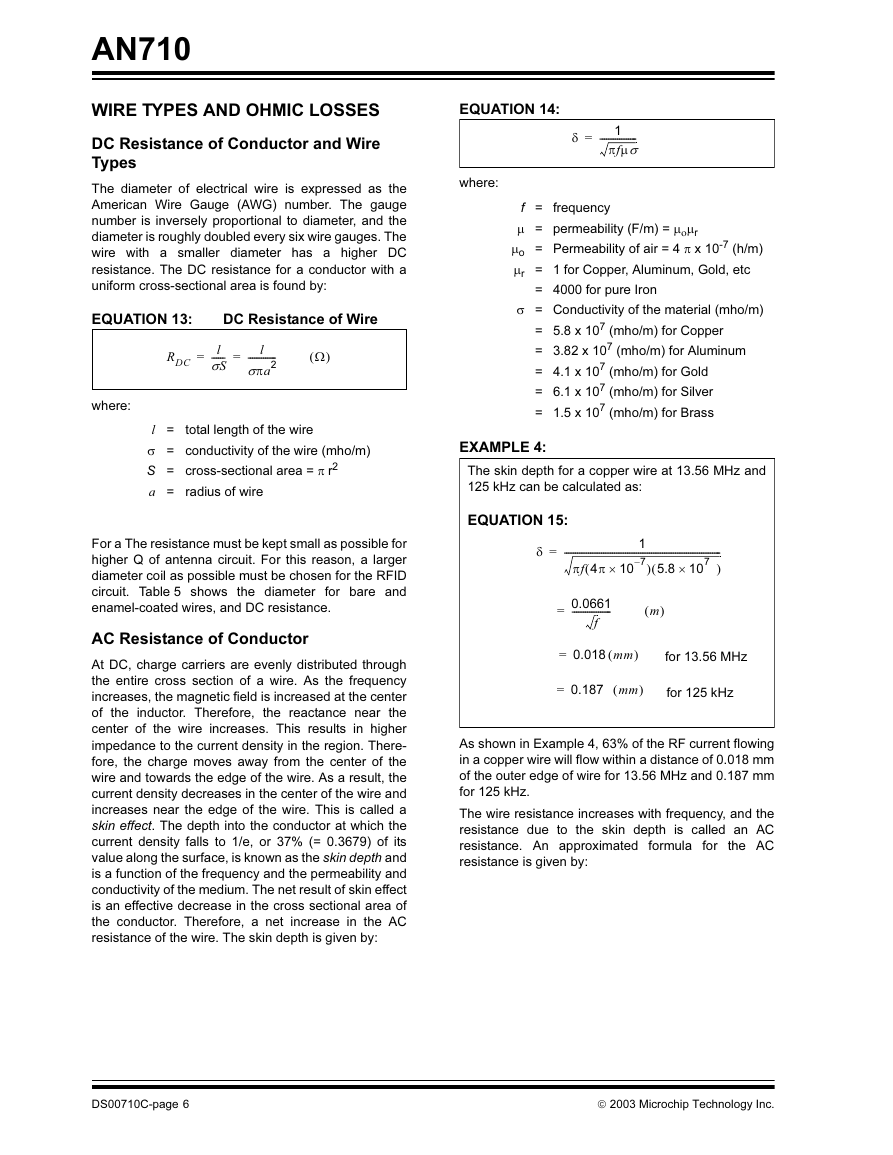

DC Resistance of Conductor and Wire Types

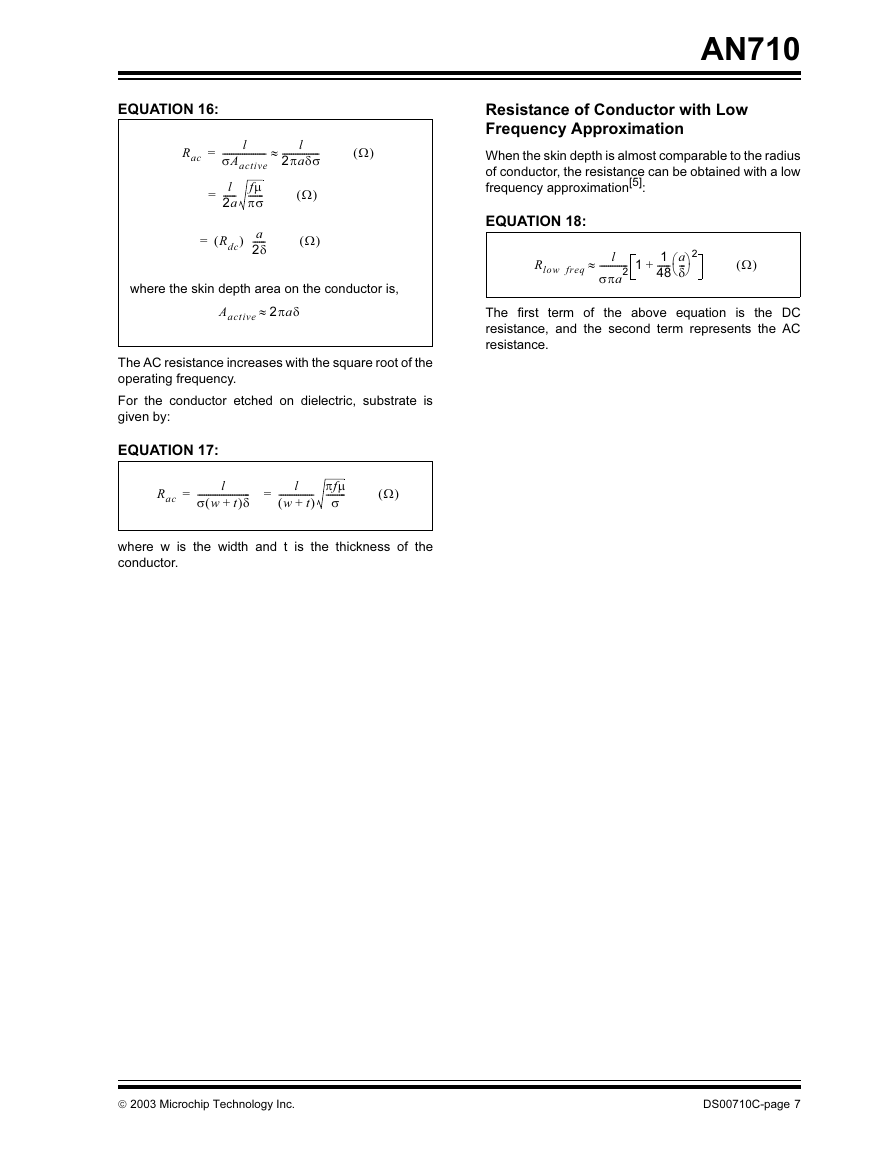

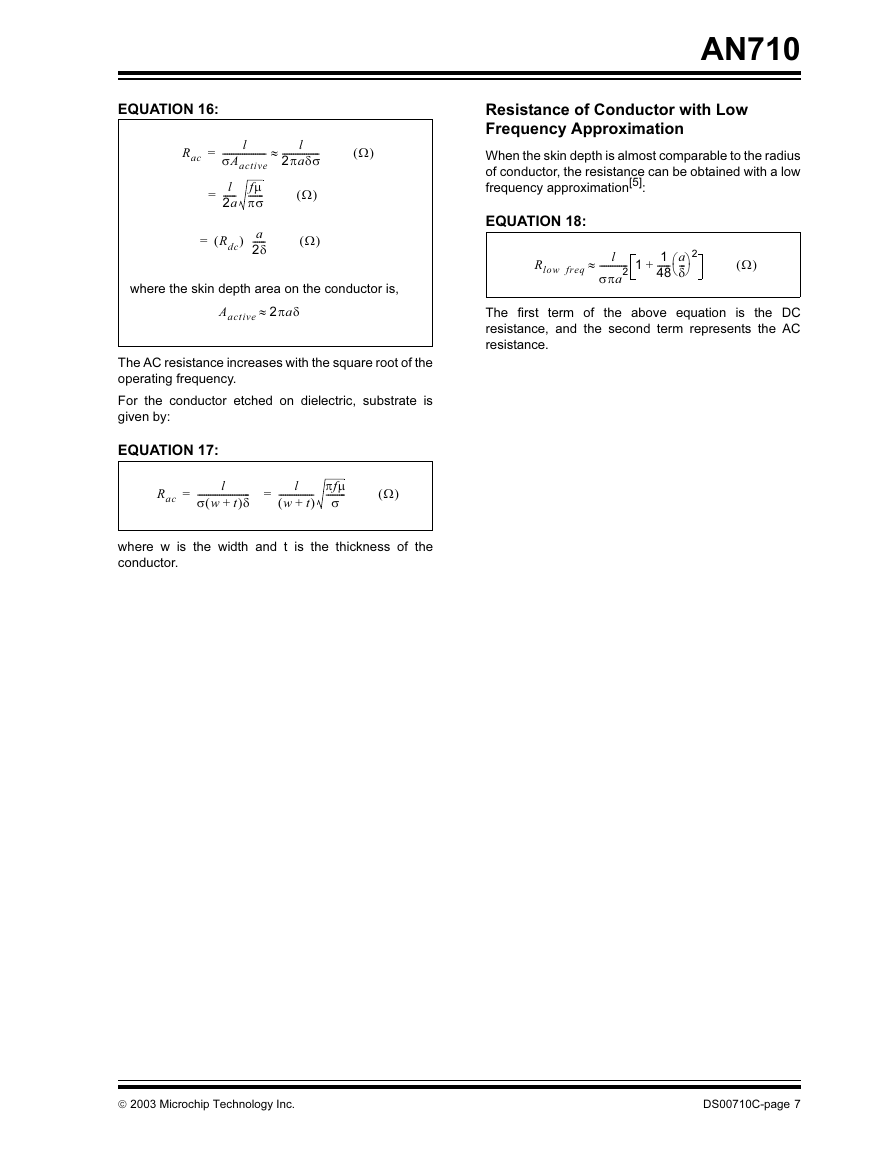

AC Resistance of Conductor

Resistance of Conductor with Low Frequency Approximation

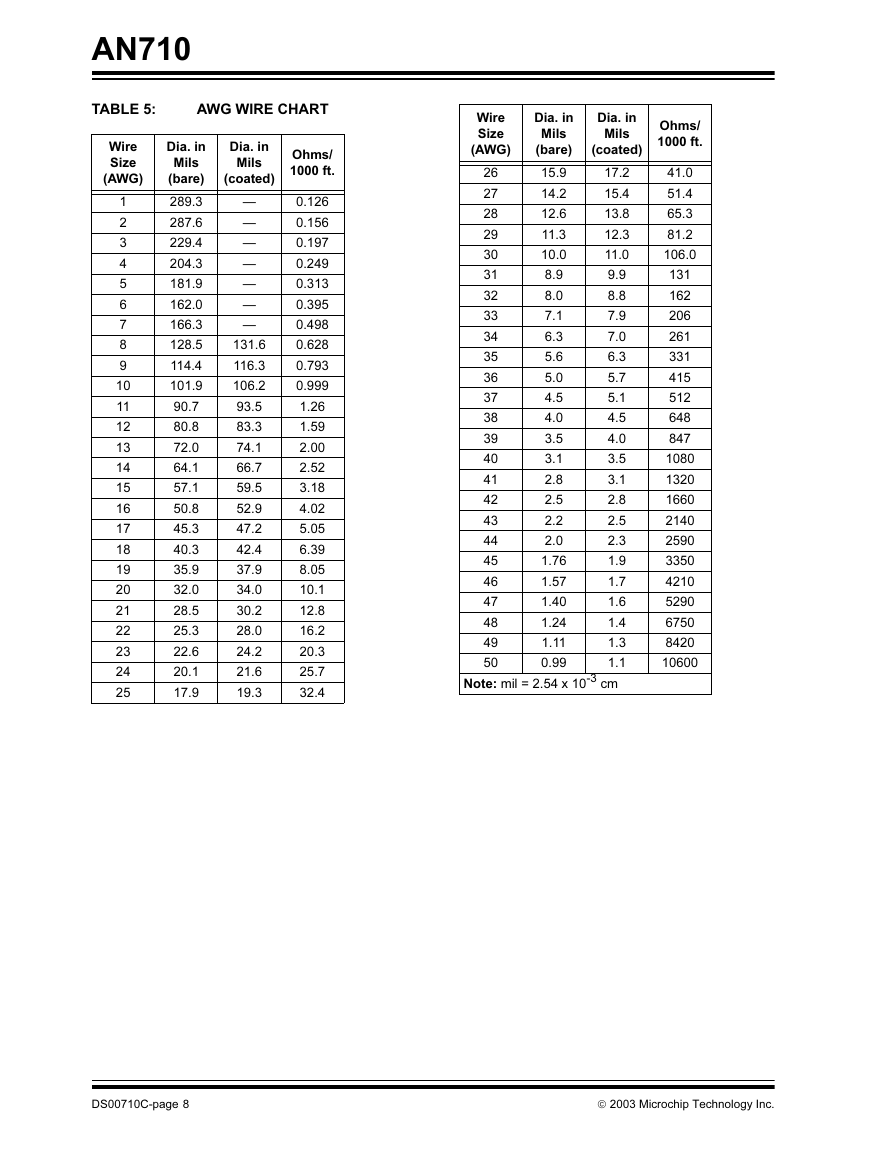

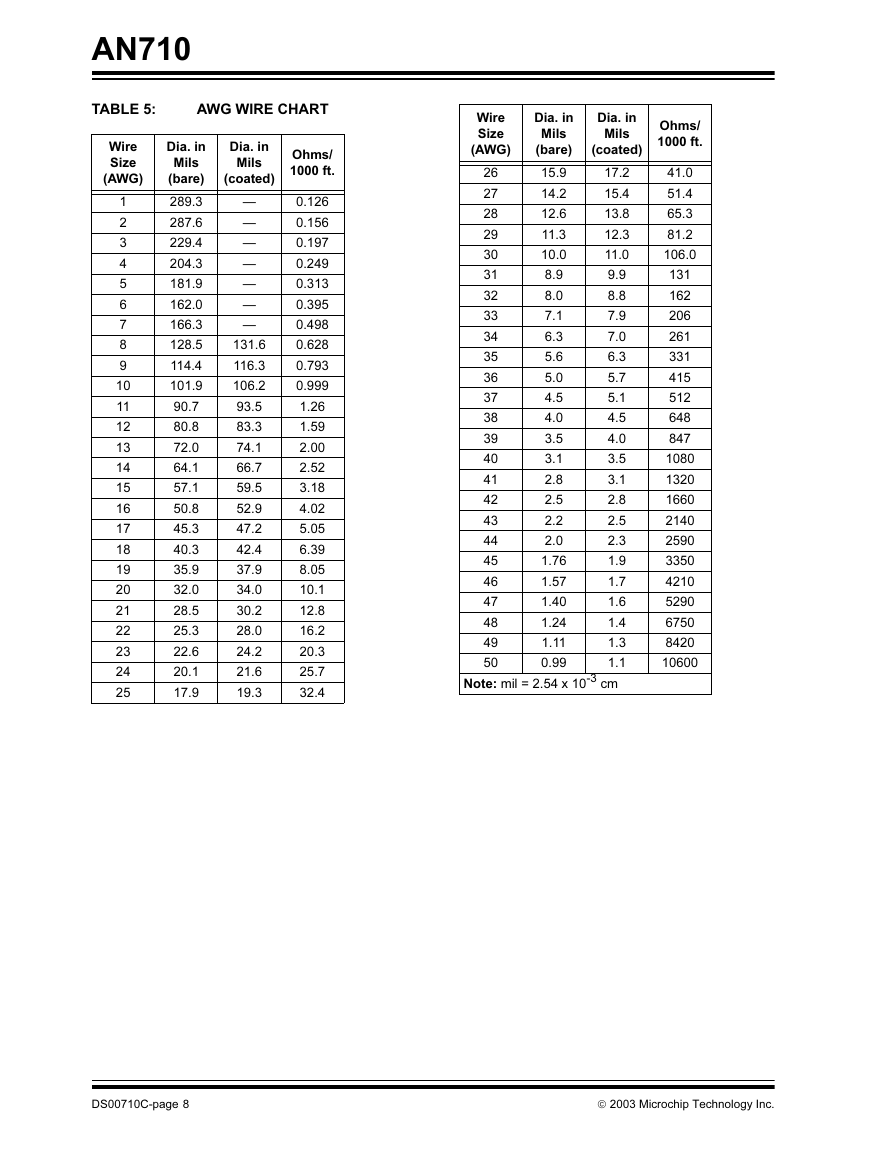

TABLE 5: AWG Wire Chart

Inductance of Various Antenna Coils

Calculation of Inductance

FIGURE 6: A circular coil with single turn

FIGURE 7: A circular coil with single turn

FIGURE 8: N-turn multilayer circular coil

FIGURE 9: A spiral coil

FIGURE 10: N-turn square loop coil with multilayer

FIGURE 11: N-turn square loop coil with multilayer

FIGURE 12: A straight thin film inductor

FIGURE 13: Square loop inductor with a rectangular cross section

FIGURE 14: One turn Reader antenna

Example with dimension:

FIGURE 15: Two conductor segments for mutual inductance calculation

Configuration of Antenna Circuits

Reader Antenna Circuits

FIGURE 16: Various Reader Antenna Circuits

Tag Antenna Circuits

Consideration on Quality Factor Q and Bandwidth of Tuning Circuit

FIGURE 17: Various External Circuit Configurations

Bandwidth requirement and limit on circuit Q for MCRF355

Resonant Circuits

Parallel Resonant Circuit

FIGURE 18: Parallel Resonant Circuit

Series Resonant Circuit

FIGURE 19: Series Resonance Circuit

Tuning Method

FIGURE 20: Voltage vs. Frequency for Resonant Circuit

FIGURE 21: Frequency Responses for Resonant Circuit

Read Range of RFID Devices

FIGURE 22: Read Range vs. Tag Size for Typical Proximity Applications*

FIGURE 23: Read Range vs. Tag Size for Typical Long Range Applications*

Appendix A: Calculation of Mutual Inductance Terms in Equations 36 and 37

Appendix B: Mathlab program example for Example 8

References

Trademarks

Worldwide Sales

2023年江西萍乡中考道德与法治真题及答案.doc

2023年江西萍乡中考道德与法治真题及答案.doc 2012年重庆南川中考生物真题及答案.doc

2012年重庆南川中考生物真题及答案.doc 2013年江西师范大学地理学综合及文艺理论基础考研真题.doc

2013年江西师范大学地理学综合及文艺理论基础考研真题.doc 2020年四川甘孜小升初语文真题及答案I卷.doc

2020年四川甘孜小升初语文真题及答案I卷.doc 2020年注册岩土工程师专业基础考试真题及答案.doc

2020年注册岩土工程师专业基础考试真题及答案.doc 2023-2024学年福建省厦门市九年级上学期数学月考试题及答案.doc

2023-2024学年福建省厦门市九年级上学期数学月考试题及答案.doc 2021-2022学年辽宁省沈阳市大东区九年级上学期语文期末试题及答案.doc

2021-2022学年辽宁省沈阳市大东区九年级上学期语文期末试题及答案.doc 2022-2023学年北京东城区初三第一学期物理期末试卷及答案.doc

2022-2023学年北京东城区初三第一学期物理期末试卷及答案.doc 2018上半年江西教师资格初中地理学科知识与教学能力真题及答案.doc

2018上半年江西教师资格初中地理学科知识与教学能力真题及答案.doc 2012年河北国家公务员申论考试真题及答案-省级.doc

2012年河北国家公务员申论考试真题及答案-省级.doc 2020-2021学年江苏省扬州市江都区邵樊片九年级上学期数学第一次质量检测试题及答案.doc

2020-2021学年江苏省扬州市江都区邵樊片九年级上学期数学第一次质量检测试题及答案.doc 2022下半年黑龙江教师资格证中学综合素质真题及答案.doc

2022下半年黑龙江教师资格证中学综合素质真题及答案.doc