OpenSYMORO: An open-source software package for

Symbolic Modelling of Robots

Wisama Khalil, Aravindkumar Vijayalingam, Bogdan Khomutenko, Izzatbek Mukhanov,

Philippe Lemoine, Ga¨el Ecorchard

´Ecole Centrale de Nantes, IRCCyN UMR CNRS 6597

1 rue de la No¨e, BP 92101, 44321 Nantes Cedex 3, France

Abstract— This paper presents OpenSYMORO, an open-

source software package for symbolic modelling of robots. This

software package is based on previous work detailed in [1].

However, the package in [1] was developed using Wolfram

Mathematica and hence required Mathematica license for

use. OpenSYMORO is mainly developed using the Python

programming language and the source code will be publicly

available. The new version provides support to model robots

with flexible joints, floating base and wheeled mobile robots.

This is in addition to supporting serial, tree structure and

closed-loop robots. A visualisation tool to view the structure

of the robot is also included.

the robot and the output of inverse geometric models can be

obtained in a format that is compatible with Matlab and

Python such that the generated equations can be directly

used by these systems.

In the next section of this paper, the architecture and the

different components of the software package are discussed.

A short presentation on how to define a robot in SYMORO

follows. Thereafter, the algorithms used to model robots with

flexible joints, floating base and wheeled mobile robots are

detailed.

I. INTRODUCTION

II. SOFTWARE PACKAGE DESCRIPTION

Symbolic modelling of robots is essential for analysis and

design of robots and their controllers. Also symbolic mod-

elling results in lower execution time and is more convenient

for analysis. For instance, solution to the inverse geometric

problem can be obtained by the use of differential model to

compute an iterative numerical solution [2]. However, this

results in long execution time and may not be practical. On

the other hand the solution for the same inverse geometric

problem can be obtained using closed-form symbolic models

that can deliver all the possible solutions with a lower and

predictable computation time.

The purpose of OpenSYMORO (henceforth referred to as

SYMORO) software package is to compute the symbolic

models of a robot that are needed for design, identification,

control and simulation. Previously, such a package was

presented in [1]. However, the package in [1] was developed

using Wolfram Mathematica1 and hence required Mathe-

matica license for use. The new version of the package is

developed using Python programming language and other

third-party libraries – SymPy2 and NumPy3 that are available

for use without any licensing requirements. As a result, the

SYMORO package is available as an open-source project and

the source code will be publicly available. Consequently the

robotics community over the world can use this package and

can take part in the development of new modules.

Additionally, the new version of SYMORO software pack-

age provides support to model robots with flexible joints,

floating base and wheeled mobile robots. The new version

also provides a visualisation tool to view the structure of

1http://www.wolfram.com/mathematica/

2http://www.sympy.org/

3http://www.numpy.org/

The SYMORO software package is made up of five

different sub-packages. These sub-packages are –

symoroutils, pysymoro, symoroui, symoroviz

and symorooptim. These sub-packages may depend on

another sub-package/s.

A. symoroutils

The symoroutils package contains the utility modules

for mathematical functions and file handling. The file han-

dling modules include the functions to perform parsing of

files that are used to load robot data into the environment.

B. pysymoro

The algorithms that are used to generate the different

models that can be obtained using SYMORO are contained

in this package. The data structures that are used to store

the robot data and models are also present in this package.

This package in turn makes use of SymPy and NumPy to

perform the symbolic and numeric computations.

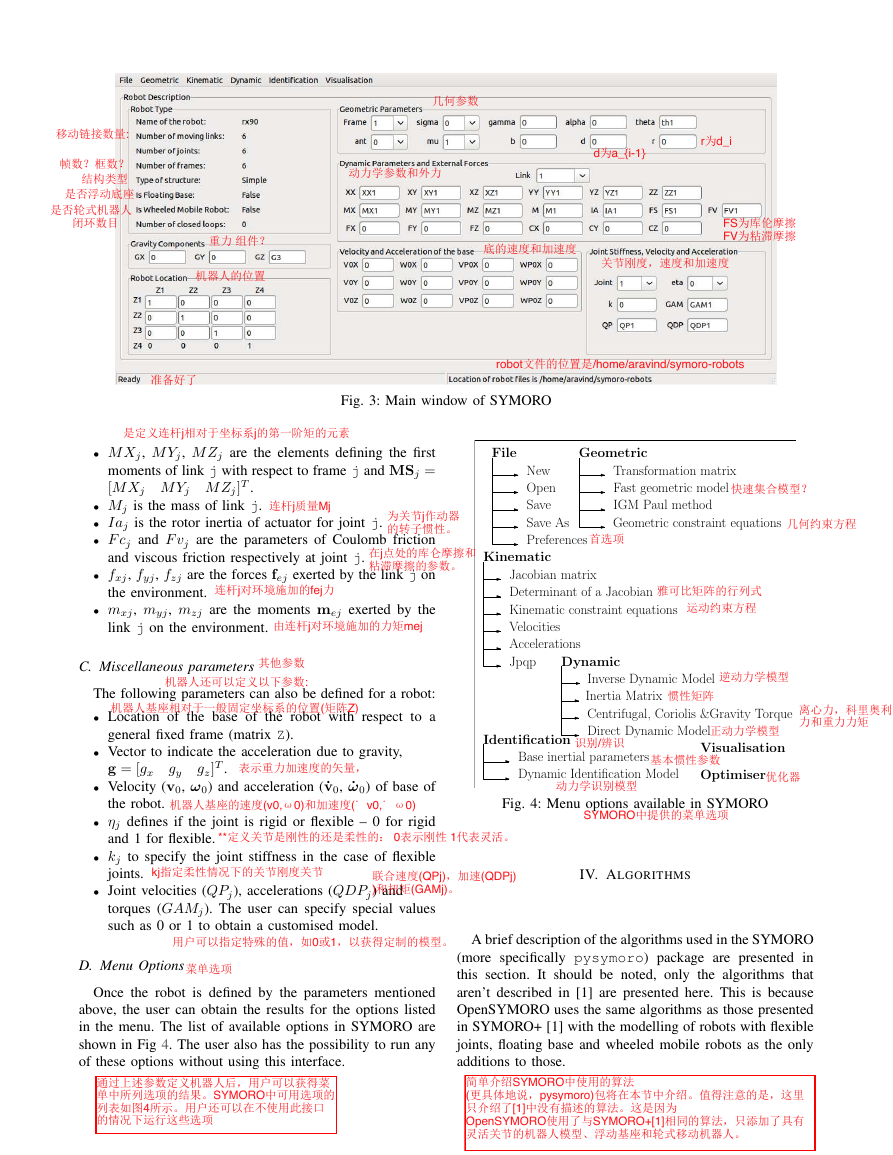

C. symoroui

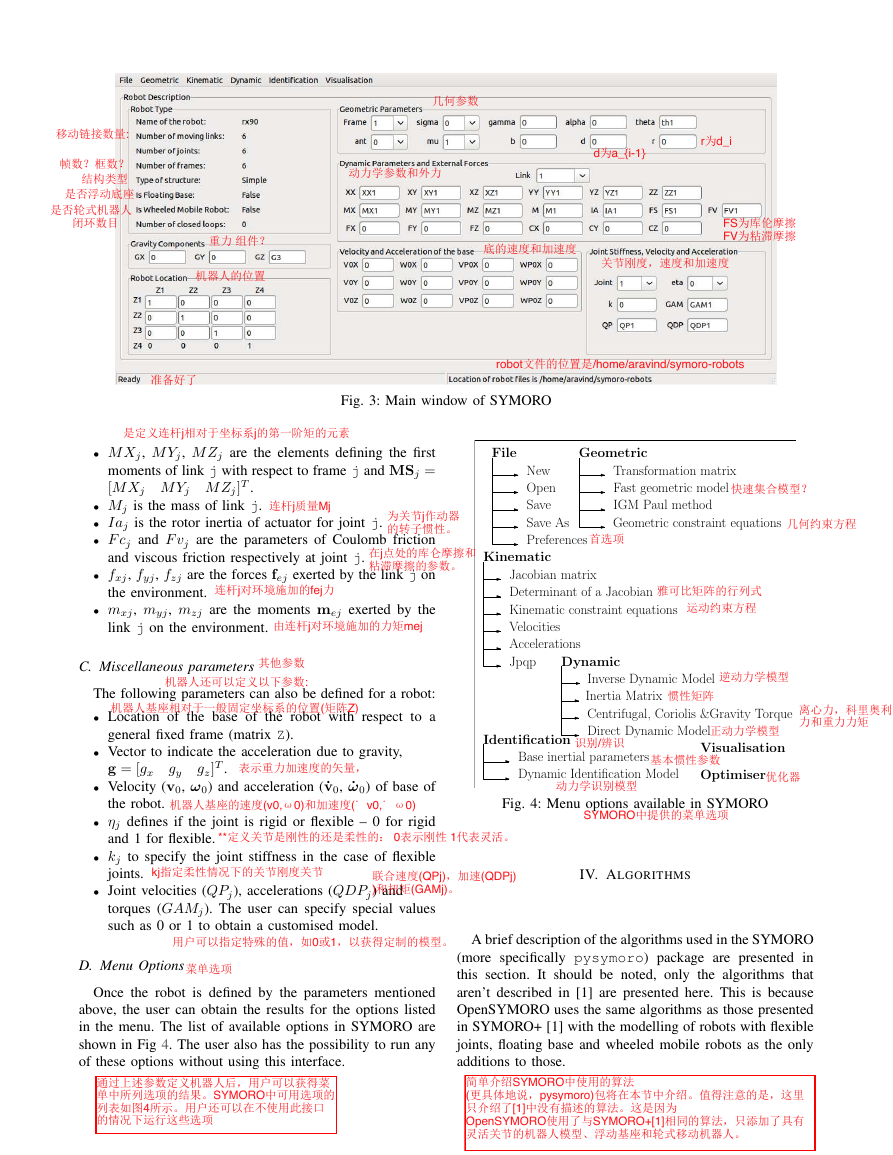

The symoroui package provides the graphical user inter-

face for the SYMORO software. The user interface created

using wxPython4 is shown in Fig 3. This package permits

to define the parameters that are needed in the calculation of

different models. This interface is also used to execute any

desired model.

4http://www.wxpython.org/

�

D. symorooptim

The purpose of this package is to generate optimised

models in symbolic form. These optimised models reduce

the total number of operations (addition and multiplication)

required to compute the respective models by the use of

intermediate variables. The output of the optimised models

can be obtained in a format

is compatible with C,

Python, Matlab, such that the generated model can be

directly used by these systems.

that

• γj , bj , αj , dj , θj and rj to define a frame j with respect

to its antecedent frame a(j). The terms γj and bj are

zero in a serial robot. The joint variable qj is either θj

or rj depending on the joint type.

• σj defines the joint type – 0 for revolute, 1 for prismatic

and 2 for a frame that has a constant relationship with

it’s antecedent. For revolute and prismatic joints, ¯σj =

1 − σj .

• µj indicates if a joint is active (actuated) or passive

(non-actuated) – 1 for active and 0 for passive. For open-

loop robots – serial and tree structure all the joints are

supposed actuated.

• a(j) to indicate the antecedent frame. Here “0” indicates

the base.

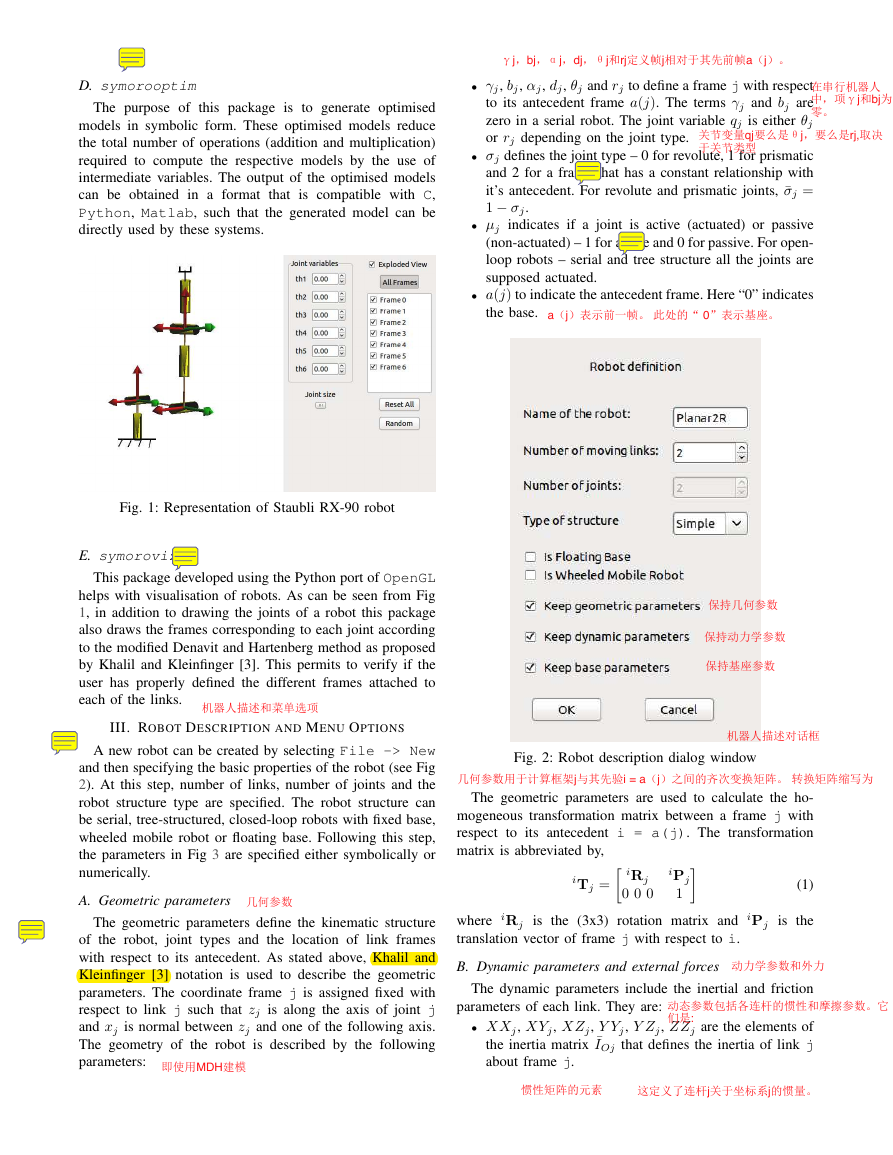

Fig. 1: Representation of Staubli RX-90 robot

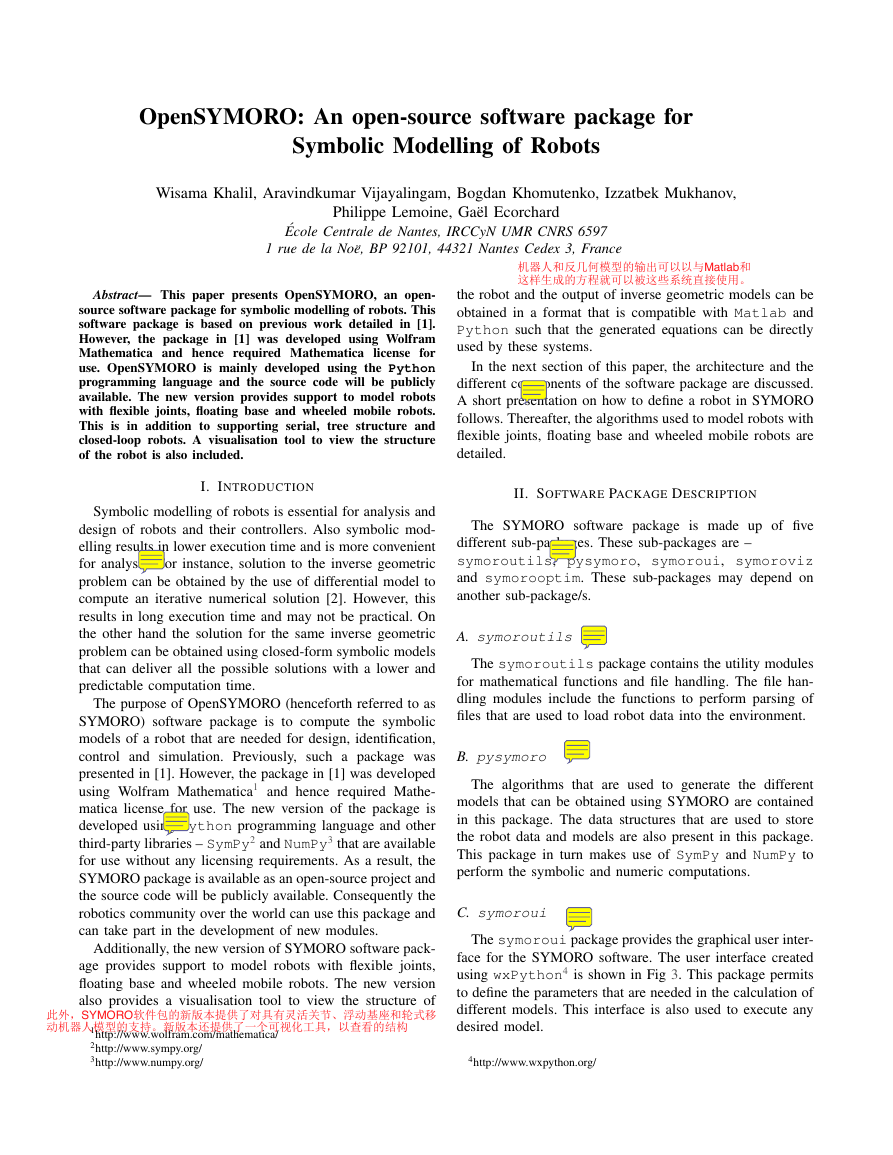

E. symoroviz

This package developed using the Python port of OpenGL

helps with visualisation of robots. As can be seen from Fig

1, in addition to drawing the joints of a robot this package

also draws the frames corresponding to each joint according

to the modified Denavit and Hartenberg method as proposed

by Khalil and Kleinfinger [3]. This permits to verify if the

user has properly defined the different frames attached to

each of the links.

III. ROBOT DESCRIPTION AND MENU OPTIONS

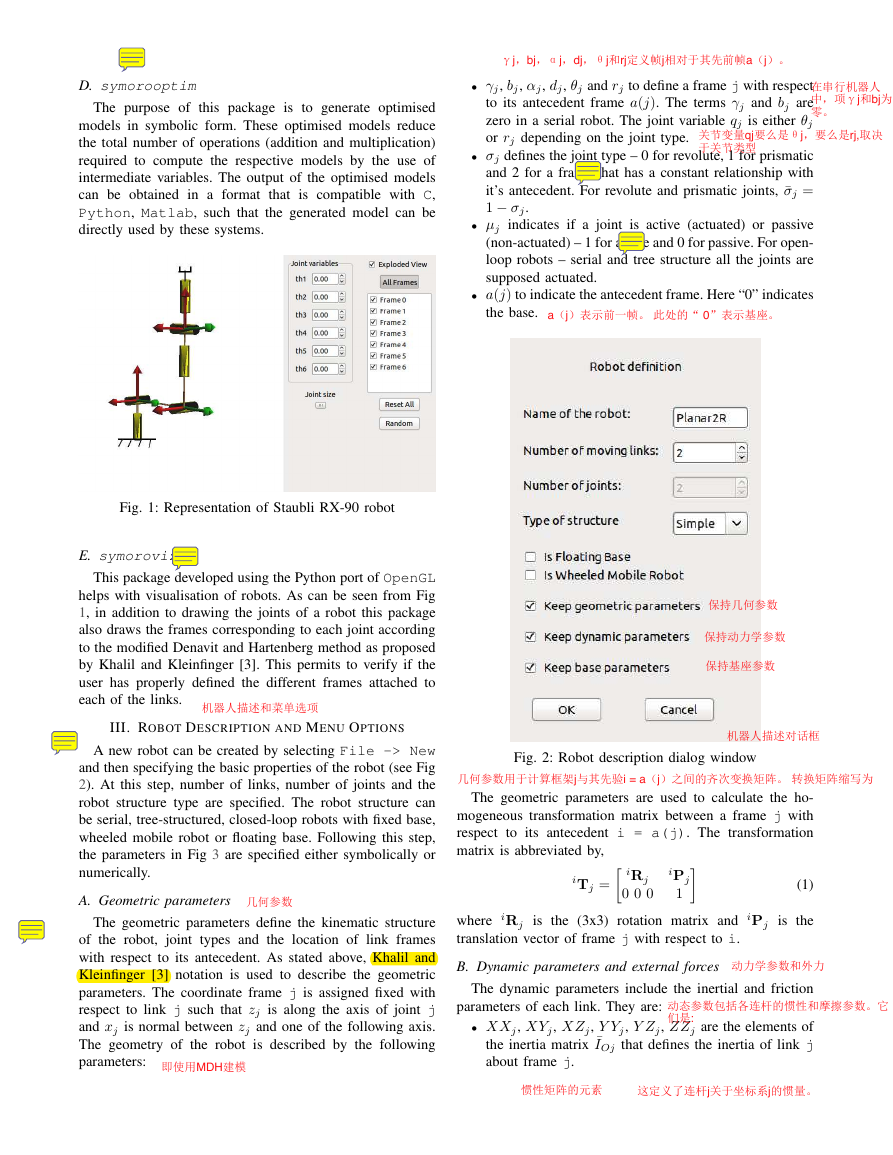

A new robot can be created by selecting File -> New

and then specifying the basic properties of the robot (see Fig

2). At this step, number of links, number of joints and the

robot structure type are specified. The robot structure can

be serial, tree-structured, closed-loop robots with fixed base,

wheeled mobile robot or floating base. Following this step,

the parameters in Fig 3 are specified either symbolically or

numerically.

A. Geometric parameters

Fig. 2: Robot description dialog window

The geometric parameters are used to calculate the ho-

mogeneous transformation matrix between a frame j with

respect to its antecedent i = a(j). The transformation

matrix is abbreviated by,

iTj = iRj

0 0 0

(1)

iPj

1

The geometric parameters define the kinematic structure

of the robot, joint types and the location of link frames

with respect to its antecedent. As stated above, Khalil and

Kleinfinger [3] notation is used to describe the geometric

parameters. The coordinate frame j is assigned fixed with

respect to link j such that zj is along the axis of joint j

and xj is normal between zj and one of the following axis.

The geometry of the robot is described by the following

parameters:

where iRj

translation vector of frame j with respect to i.

is the (3x3) rotation matrix and iPj

is the

B. Dynamic parameters and external forces

The dynamic parameters include the inertial and friction

parameters of each link. They are:

• XXj , XYj , XZj , Y Yj , Y Zj , ZZj are the elements of

the inertia matrix ¯IOj that defines the inertia of link j

about frame j.

�

Fig. 3: Main window of SYMORO

• M Xj , M Yj , M Zj are the elements defining the first

moments of link j with respect to frame j and MSj =

[M Xj M Yj M Zj]T .

• Mj is the mass of link j.

• Iaj is the rotor inertia of actuator for joint j.

• F cj and F vj are the parameters of Coulomb friction

File

Geometric

New

Open

Save

Save As

Preferences

Transformation matrix

Fast geometric model

IGM Paul method

Geometric constraint equations

and viscous friction respectively at joint j.

Kinematic

• fxj , fyj , fzj are the forces fej exerted by the link j on

the environment.

• mxj , myj , mzj are the moments mej exerted by the

link j on the environment.

C. Miscellaneous parameters

The following parameters can also be defined for a robot:

• Location of the base of the robot with respect to a

general fixed frame (matrix Z).

• Vector to indicate the acceleration due to gravity,

g = [gx

gy

gz]T .

• Velocity (v0, ω0) and acceleration ( ˙v0, ˙ω0) of base of

Jacobian matrix

Determinant of a Jacobian

Kinematic constraint equations

Velocities

Accelerations

Jpqp

Dynamic

Inverse Dynamic Model

Inertia Matrix

Centrifugal, Coriolis &Gravity Torque

Direct Dynamic Model

Identification

Base inertial parameters

Dynamic Identification Model

Visualisation

Optimiser

the robot.

Fig. 4: Menu options available in SYMORO

• ηj defines if the joint is rigid or flexible – 0 for rigid

and 1 for flexible.

• kj to specify the joint stiffness in the case of flexible

joints.

• Joint velocities (QPj ), accelerations (QDPj ) and

torques (GAMj ). The user can specify special values

such as 0 or 1 to obtain a customised model.

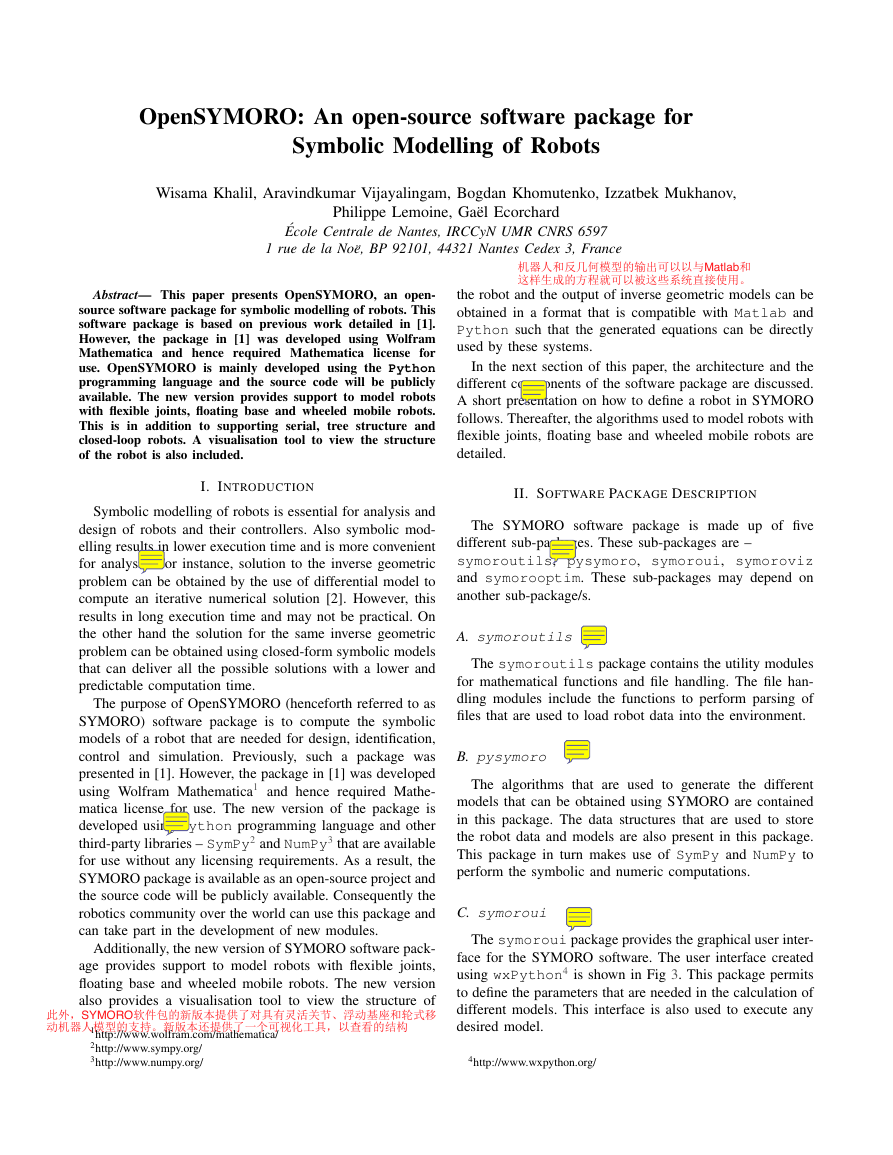

D. Menu Options

Once the robot is defined by the parameters mentioned

above, the user can obtain the results for the options listed

in the menu. The list of available options in SYMORO are

shown in Fig 4. The user also has the possibility to run any

of these options without using this interface.

IV. ALGORITHMS

A brief description of the algorithms used in the SYMORO

(more specifically pysymoro) package are presented in

this section. It should be noted, only the algorithms that

aren’t described in [1] are presented here. This is because

OpenSYMORO uses the same algorithms as those presented

in SYMORO+ [1] with the modelling of robots with flexible

joints, floating base and wheeled mobile robots as the only

additions to those.

�

A. Dynamic modelling of robots

The general form of the dynamic model of robots obtained

using Lagrange method [2], [4], [5] is,

Γ = A(q)¨q + H(q, ˙q)

(2)

where, A is the inertia matrix as a function of joint positions,

q and H is the Coriolis, centrifugal and gravity torques as

a function of joint velocities, ˙q and joint positions, q. The

joint acceleration vector is indicated by ¨q. This is known

as the inverse dynamic model as torque, Γ is obtained as a

function of (q, ˙q, ¨q). Solving to obtain ¨q as a function of

(q, ˙q, Γ) is the direct dynamic model and is given by,

¨q = A−1 [Γ − H(q, ˙q)]

(3)

For rigid robots with fixed base,

the inverse dynamic

model is obtained efficiently using the recursive Newton-

Euler algorithm. Recursive method is also developed for

the direct dynamic models which do not need to calculate

the inertia matrix [6]. For closed-loop robots and wheeled

mobile robots the inertia matrix must be calculated and this

is developed by the algorithm proposed in [7].

B. Recursive Newton-Euler method for tree-structure robots

with fixed base

This algorithm which is based on [8] constitutes the

cornerstone on which all the other algorithms are built upon.

The main characteristic of this algorithm is the recursivity

leading to reduced number of operations.

This algorithm involves a forward recursion and a back-

ward recursion. During the forward recursion link velocities,

link accelerations and dynamic wrench on each link are

computed from link 1 to link n. The backward recursion

process computes the reaction wrenches on the links and the

joint torques from link n to link 0 (base). This algorithm can

be denoted by,

Γ = NE(q, ˙q, ¨q, fe, me)

(4)

where, j¯aj = [0 0 1]T is the unit vector along zj axis which

is the axis of joint j. (ˆ∗) is the skew-symmetric matrix of

the (∗) (3x1) vector. Here j aj = [0 0 σj 0 0 ¯σj]T , j Si is the

screw transformation matrix, j IOj =" MjI3

j ¯IOj #

jdMS

jdMSj

jiT

is the spatial (6x6) inertia matrix and j ˙Vj =hj ˙vT

.

The above equations (from (5) to (8)) are initialised with

0ω0 = 0, 0 ˙ω0 = 0 and 0 ˙v0 = −0g where, g is the gravity

vector.

j ˙ωT

T

j

j

Fig. 5: Forces and moments acting on link j.

Likewise,

the backward recursive equations for j =

n, . . . , 1 with i = a(j) are:

j Fj = j fj

jmj = j Ftj + j Fej

iFei = iFei + j ST

i

j Fj

Γj = j FT

j

j aj + Fcj sign( ˙qj) + Fvj ˙qj + Iaj ¨qj

(9)

(10)

(11)

Here j Fej =j f T

ej

jmT

ejT

definitions on some of the symbols used in (5) – (11).

. Please see Section III for the

where, fe and me are the forces and moments respectively

exerted by the links on the environment.

C. Dynamic modelling of robots with flexible joints

For a robot with flexible joints the general form of the

According to [2], the forward recursive equations for j =

1, . . . , n with i = a(j) are:

jωj = j Ri

iωi

+¯σj ˙qj

j¯aj

| {z }

jωi

j Si = j Ri − j Ri

03×3

j Ri

i ˆPj

(5)

(6)

j ˙Vj = j Si

i ˙Vi + ¨qj

j aj

j¯aj

+j Riiωi ×iωi × iPj + 2σjjωi × ˙qj

j¯aj

¯σjjωi × ˙qj

j ˙Vj +jωj ×jωj × jMSj

jmtj = j IOj

jωj

jωj ×j ¯IOj

j Ftj = j ftj

(7)

(8)

dynamic model [9] is,

Γf

Γr

|{z}Γ

AT

12 A22

=A11 A12

|

}

{z

A

¨qr

¨qf

|{z}¨q

+Hr

Hf

|{z}H

(12)

where, Γr is the vector of rigid joint torques and Γf is the

vector of flexible joint torques. If a joint, j is flexible then,

Γf j = −kj (qj − qrj)

(13)

|

∆qj

{z

}

where, kj is the stiffness of the flexible joint and qrj is the

reference joint position corresponding to zero elasticity force.

From (12) for the inverse dynamic model we get,

¨qf = A−1

22 Γf − Hf − AT

12 ¨qr

¨qf + Hr

Γr =A11 A12¨qr

(14)

(15)

�

As stated in [9], [10], a three step recursive algorithm can

be used for the calculation of the inverse dynamic model to

calculate ¨qf and Γr as a function of q, ˙q, ¨qr or the direct

dynamic model to calculate ¨qf and ¨qr in terms of Γr, q,

˙q. In this paper we present only the inverse dynamic model

but both algorithms are developed in SYMORO.

(i) first forward recursion for j = 1, . . . , n computes the

screw transformation matrices j Si, the link velocities j Vj ,

the gyroscopic accelerations jγ j and the wrench jβj which

is a combination of the external forces, Coriolis forces and

centrifugal forces.

(16)

j Vj = j Si

iVi + ˙qj

j aj

j¯aj

jγ j =j Riiωi ×iωi × iPj + 2σjjωi × ˙qj

j¯aj

jβj = − j Fej −jωj ×jωj × jMSj

jωj

with j Vj =j vT

¯σjjωi × ˙qj

jωj ×j ¯IOj

jT

(ii) backward recursion for j = n, . . . , 1 calculates the

matrices giving the elastic accelerations ¨qj and j Fj as a

function of i ˙Vi. When joint j is flexible,

jωT

(17)

(18)

.

j

Hj = j aj

j Kj = j I∗

jαj = j Kj

T j I∗

j

j − j I∗

j

j aj

j aj H −1

j

j aj

T j I∗

j

jγ j + j Ij

∗ j aj H −1

j

(19)

(20)

j − jβ∗

j

(21)

T jβ∗

Γf j + j aj

When joint j is rigid (¨qj is known),

j Kj = j I∗

j

jαj = j Kj

jγ j + j Ij

∗ j aj ¨qj − jβ∗

j

If a(j) 6= 0, compute:

iI∗

iβ∗

i = iI∗

i = iβ∗

i + j Si

i − j Si

T j Kj

T jαj

j Si

(22)

(23)

(24)

(25)

The equations (19) – (25) are initialised by j I∗

jβ∗

j = jβj .

(iii) second forward recursion for j = 1, . . . , n computes

¨qj for the flexible joints and the joint torques for the rigid

joints. This recursion is initialised by 0 ˙V0 = [0gT 0T

3×1]T

to take gravity into account.

j = j IOj and

D. Dynamic modelling of robots with floating base

This category includes a large variety of systems such

as: humanoid robots, walking robots, eel-like robots [11],

snake-like robots [11], spatial vehicles, offshore structures

and flying robots. The difference between all of these systems

will be in the calculation of the interaction forces. For these

robots there is neither geometric nor kinematic relationships

between the Cartesian motion of the base and the joint

variables and the dynamic model must be used to simulate

these systems. In this case, the acceleration of the base has

to be determined while computing the inverse and direct

dynamic models.

The base frame 0 is defined with respect

to a fixed

reference frame W and the relationship between these two

frames are known at time t = 0. The transformation matrix

W T0 indicated by Z, is updated over time by integrating the

base acceleration W ˙Vb. The base velocity is indicated by

Vb.

The general form of the dynamic model of a robot with

floating base [9] is,

12 A22

Γ =A11 A12

06×1

}

{z

|

AT

A

H2

¨q +H1

0 ˙V0

|{z}H

(30)

where,

• A11 is the (6x6) inertia matrix of the composite link 0,

which is composed of the inertia of all links referred to

frame 0 (the base).

• A22 is the (nxn) inertia matrix of the other links when

the head is fixed.

• A12 is the (6xn) coupled inertia matrix of the joints and

the base. It reflects the effect of joint accelerations of the

base motion, and the dual effect of base accelerations

on the joint motions.

• H1 is the Coriolis, centrifugal, gravity and external

forces on the base.

• H2 is the Coriolis, centrifugal, gravity and external

forces on the links 1, . . . , n.

Similar to Section IV-C, a three step recursion - a forward,

a backward and then a forward again can be used for the

computation of 0 ˙V0 and Γ.

(i) first forward recursion for j = 1, . . . , n computes j Si,

j Vj , jγ j and jβj (see (16) – (18)). Additionally, relative

accelerations jζj is calculated as,

j Fj = j Kj

j Si

i ˙Vi + jαj

(26)

jζj = jγ j + ¨qj

j aj

(31)

When joint j is flexible,

¨qj = H −1

j

hΓf j − j aT

j

j I∗

jj Si

i ˙Vi + jγ j + j aj

T jβ∗

ji(27)

j ˙Vj = j Si

i ˙Vi + j aj ¨qj + jγ j

(28)

When joint j is rigid,

Γj = j FT

j

j aj + Fcj sign( ˙qj) + Fvj ˙qj + Iaj ¨qj

(29)

(ii) backward recursion for j = n, . . . , 0 computes the

base acceleration using the inertial parameters of the com-

posite link 0, where the composite link j consists of the

links articulated on it.

j Fj = j Ic

j

j ˙Vj − jβc

j

with, inertial matrix of the composite link j,

iIc

i = iIc

i + j ST

i

j Ic

j

j Si

(32)

(33)

�

and

iβc

i = iβc

i + j ST

i

jβc

j − j ST

i

j Ic

j

jζj

(34)

Since 0F0 = 0, for j = 0 from (32) we get,

0 ˙V0 = 0 ˙v0

0 ˙ω0 =0Ic

0−1 0βc

0

This backward recursion step is initialised by j Ic

j = j IOj

j = jβj . When j = 0, 0β0 is first computed using

and jβc

(18).

(iii) second forward recursion for j = 1, . . . , n calculates

the wrench j Fj and the joint torques for j = 1, . . . , n.

j ˙Vj = j Si

i ˙Vi + jζj

j Fj = j fj

jmj = j Ic

j

j ˙Vj − jβc

j

Γj = j FT

j

j aj + Fcj sign( ˙qj) + Fvj ˙qj + Iaj ¨qj

To simulate the Cartesian motion of the base, the base

acceleration needs to be computed. From (35), taking gravity

into account we get,

0 ˙Vb = 0 ˙V0 + 0g

03×1

Here it should be noted that the base acceleration got from

(39), 0 ˙Vb 6=

0V0. Thus to integrate the acceleration, the

base acceleration with respect to fixed frame W must be

calculated.

d

dt

By integrating (40) we get W Vb. Now the base velocity, 0Vb

is,

03×3

W R0 0 ˙Vb

W ˙Vb =W R0 03×3

0V0 = 0Vb =0RW 03×3

0RW W Vb

03×3

E. Dynamic modelling of wheeled mobile robots

This category of robots consist of a tree-structure robot

on a mobile base representing link 0 and classical wheels. It

can be described as shown in Section IV-D. However, in this

case the system is characterised by having kinematic non-

holonomic relationship between the Cartesian variables of

link 0 and the joint variables. Hence to study the Cartesian

evolution of these robots the computation of the dynamic

model is not a must. Whereas in (Section IV-D) the dynamic

model is essential to obtain the Cartesian motion of the

system.

The classical wheels are fixed, steering and castor. These

wheels have the rotational variable ϕj . The steering and

castor wheels also have βj the orientation variable. Hence,

the vector of configuration variables is composed of ϕj , βj

and ξ - the posture of cart position and orientation. For

the sake of simplicity, the motion of the mobile base is

θ]T . Detailed

considered as planar and thus ξ = [x y

discussion on wheeled mobile robots is presented in [12].

These wheeled mobile robots contains non-holonomic

constraints between the configuration variables. The con-

straint equations are,

W ˙q = 0 & ˙q = G ˙qa

(42)

(40)

REFERENCES

(35)

(36)

(37)

(38)

(39)

(41)

where, q =hξT βT ϕTiT

q.

, qa is the actuated variables of

The difference between floating and wheeled mobile

robots is that the coupling between the configuration vari-

ables is kinematically defined using the non-slipping and

non-sliding constraints of the wheels with respect to the

ground. The inverse dynamic model is obtained at first using

the equations of tree-structure to obtain Γ. Then (43) is

applied to project Γ on the actuated joints.

Γa = ∂ ˙q

∂ ˙qaT

Γ = GT Γ

(43)

where, Γ is the joint torques calculated by the method in

Section IV-B or Section IV-C and Γa is the actuator torques.

V. CONCLUSION

This paper presents OpenSYMORO, an open-source soft-

ware package for symbolic modelling of robots. The features

of the software package allow the generation of robot models

that are required for simulation, identification, control and

design. An overview of the algorithms that are used to model

the robots with flexible joints, floating base and wheeled

mobile robots are also presented. Further development of

the package concerns the support for modelling robots with

flexible links [13]. The capability of accessing the features

of the package through a web interface is also considered

for future versions.

[1] W. Khalil and D. Creusot, “Symoro+: a system for the symbolic

modelling of robots,” Robotica, vol. 15, pp. 153–161, 1997.

[2] W. Khalil and E. Dombre, Modeling, identification and control of

robots. Butterworth-Heinemann, 2004.

[3] W. Khalil and J. Kleinfinger, “A new geometric notation for open and

closed-loop robots,” in Robotics and Automation. Proceedings. 1986

IEEE International Conference on, vol. 3.

IEEE, 1986, pp. 1174–

1179.

[4] J. J. Craig, Introduction to robotics: mechanics and control. Addison-

Wesley, 1986.

[5] J. Angeles, Fundamentals of Robotic Mechanical Systems: Theory,

Methods, and Algorithms. Springer, 2007.

[6] R. Featherstone, “The calculation of robot dynamics using articulated-

body inertias,” The International Journal of Robotics Research, vol. 2,

no. 1, pp. 13–30, 1983.

[7] M. W. Walker and D. E. Orin, “Efficient dynamic computer simulation

of robotic mechanisms,” Journal of Dynamic Systems, Measurement,

and Control, vol. 104, no. 3, pp. 205–211, 1982.

[8] J. Y. Luh, M. W. Walker, and R. P. Paul, “On-line computational

scheme for mechanical manipulators,” Journal of Dynamic Systems,

Measurement, and Control, vol. 102, no. 2, pp. 69–76, 1980.

[9] W. Khalil, “Dynamic modeling of robots using recursive newton-euler

techniques,” ICINCO2010, 2010.

[10] W. Khalil and M. Gautier, “Modeling of mechanical systems with

lumped elasticity,” in Robotics and Automation, 2000. Proceedings.

ICRA’00. IEEE International Conference on, vol. 4.

IEEE, 2000, pp.

3964–3969.

[11] F. Boyer, M. Porez, and W. Khalil, “Macro-continuous computed

torque algorithm for a three-dimensional eel-like robot,” IEEE Trans-

actions on Robotics, pp. 563–775, 2006.

[12] G. Campion and W. Chung, “Wheeled robots,” in Springer Handbook

of Robotics, B. Siciliano and O. Khatib, Eds. Springer, 2008, ch. 17,

pp. 391–410.

[13] F. Boyer and W. Khalil, “An efficient calculation of flexible manipula-

tor inverse dynamics,” The International Journal of Robotics Research,

vol. 17, no. 3, pp. 282–293, 1998.

�

2023年江西萍乡中考道德与法治真题及答案.doc

2023年江西萍乡中考道德与法治真题及答案.doc 2012年重庆南川中考生物真题及答案.doc

2012年重庆南川中考生物真题及答案.doc 2013年江西师范大学地理学综合及文艺理论基础考研真题.doc

2013年江西师范大学地理学综合及文艺理论基础考研真题.doc 2020年四川甘孜小升初语文真题及答案I卷.doc

2020年四川甘孜小升初语文真题及答案I卷.doc 2020年注册岩土工程师专业基础考试真题及答案.doc

2020年注册岩土工程师专业基础考试真题及答案.doc 2023-2024学年福建省厦门市九年级上学期数学月考试题及答案.doc

2023-2024学年福建省厦门市九年级上学期数学月考试题及答案.doc 2021-2022学年辽宁省沈阳市大东区九年级上学期语文期末试题及答案.doc

2021-2022学年辽宁省沈阳市大东区九年级上学期语文期末试题及答案.doc 2022-2023学年北京东城区初三第一学期物理期末试卷及答案.doc

2022-2023学年北京东城区初三第一学期物理期末试卷及答案.doc 2018上半年江西教师资格初中地理学科知识与教学能力真题及答案.doc

2018上半年江西教师资格初中地理学科知识与教学能力真题及答案.doc 2012年河北国家公务员申论考试真题及答案-省级.doc

2012年河北国家公务员申论考试真题及答案-省级.doc 2020-2021学年江苏省扬州市江都区邵樊片九年级上学期数学第一次质量检测试题及答案.doc

2020-2021学年江苏省扬州市江都区邵樊片九年级上学期数学第一次质量检测试题及答案.doc 2022下半年黑龙江教师资格证中学综合素质真题及答案.doc

2022下半年黑龙江教师资格证中学综合素质真题及答案.doc