28.10.2009

Simulation of Composite Structures with

Abaqus Unified FEA from SIMULIA

Martin Küssner

Dassault Systemes Simulia GmbH

Martin.KUESSNER@3ds.com

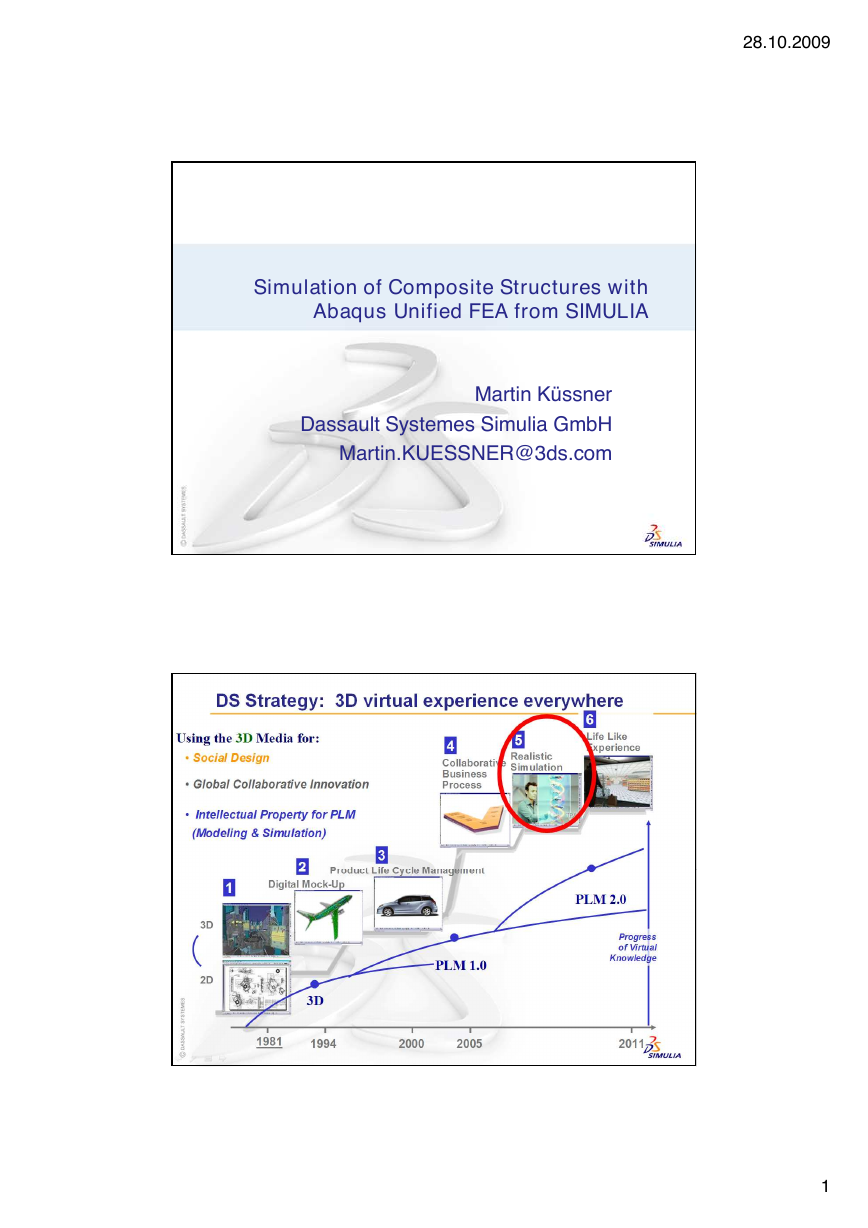

DS Strategy: 3D virtual experience everywhere

2

1

�

DS Brands

3D

MCAD

Virtual

Product

Virtual

Testing

Virtual

Production

PLM

User

Collaboration

Experience

P

h

o

o

t

c

o

u

r

t

Productive, Easy-

to-use 3D Design

Product

Excellence

Realistic

Simulation

Production

Performance

Collaborative

Intelligence

Lifelike

Experience

e

s

y

o

f

B

M

W

Abaqus Product Line

Abaqus/CAE

Interactive, parametric, finite element

modeler and results viewer

Abaqus/Standard

Linear and nonlinear statics, dynamics,

acoustics, and heat transfer

Abaqus/Explicit

Transient, very large deformation, highly

nonlinear simulations

Tightly integrated with Abaqus/Standard

Abaqus for CATIA V5

Access to Abaqus technology from within

the V5 environment

28.10.2009

2

�

Industry trends

Composite usage is increasing in all industries

Aerospace

Boeing 787 – 1st large jet with a majority of composites by weight

Airbus 350WX - Over 60% of airframe made of new materials

UAVs – primarily composite construction

Automotive

F1 race teams – composite shells

Toyota's Tundra pickup has a composite box

Nissan Concept uses carbon-fiber components

Civil

Composite-wrapped bridge structures

Dentistry

Fiber-reinforced composite dental bridges!

Industry need – customer pains

Current simulation methodology is not up to the task

Verification of composites relies on testing

Expensive, time consuming

Current methodology has not evolved since the 1980s

Typical simulation uses linear methods to estimate first failure

Current composite interfaces are not up to the task

It is very time consuming to define composites and post-process

composites in today's CAE tools

Some CAD/CAE/PLM packages do not support progressive failure,

delamination, or material damage

With linear methods, design margins for composite parts

today are often too high – the part is too expensive and heavy

as a result

This reduces the value of the use of composites and blunts the cost

advantages that composites can provide to a product

28.10.2009

3

�

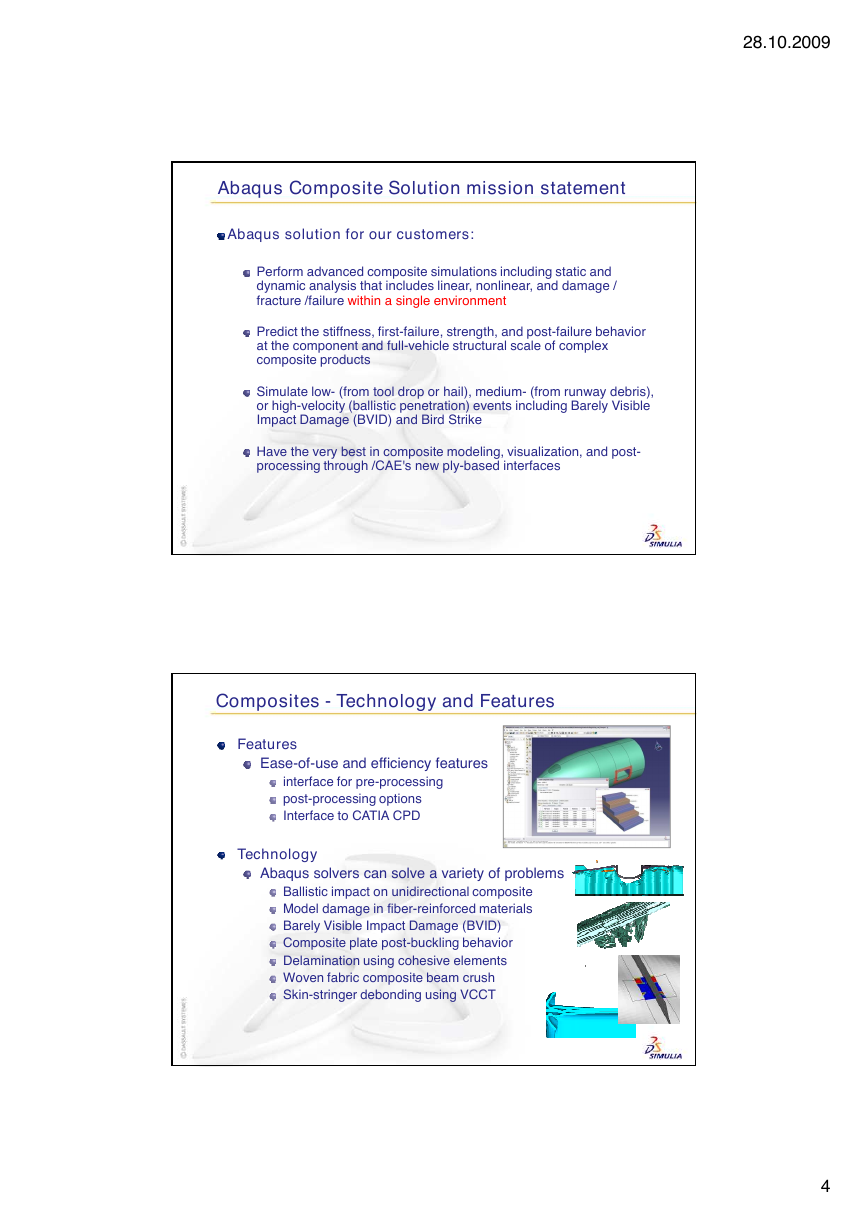

Abaqus Composite Solution mission statement

Abaqus solution for our customers:

Perform advanced composite simulations including static and

dynamic analysis that includes linear, nonlinear, and damage /

fracture /failure within a single environment

Predict the stiffness, first-failure, strength, and post-failure behavior

at the component and full-vehicle structural scale of complex

composite products

Simulate low- (from tool drop or hail), medium- (from runway debris),

or high-velocity (ballistic penetration) events including Barely Visible

Impact Damage (BVID) and Bird Strike

Have the very best in composite modeling, visualization, and post-

processing through /CAE's new ply-based interfaces

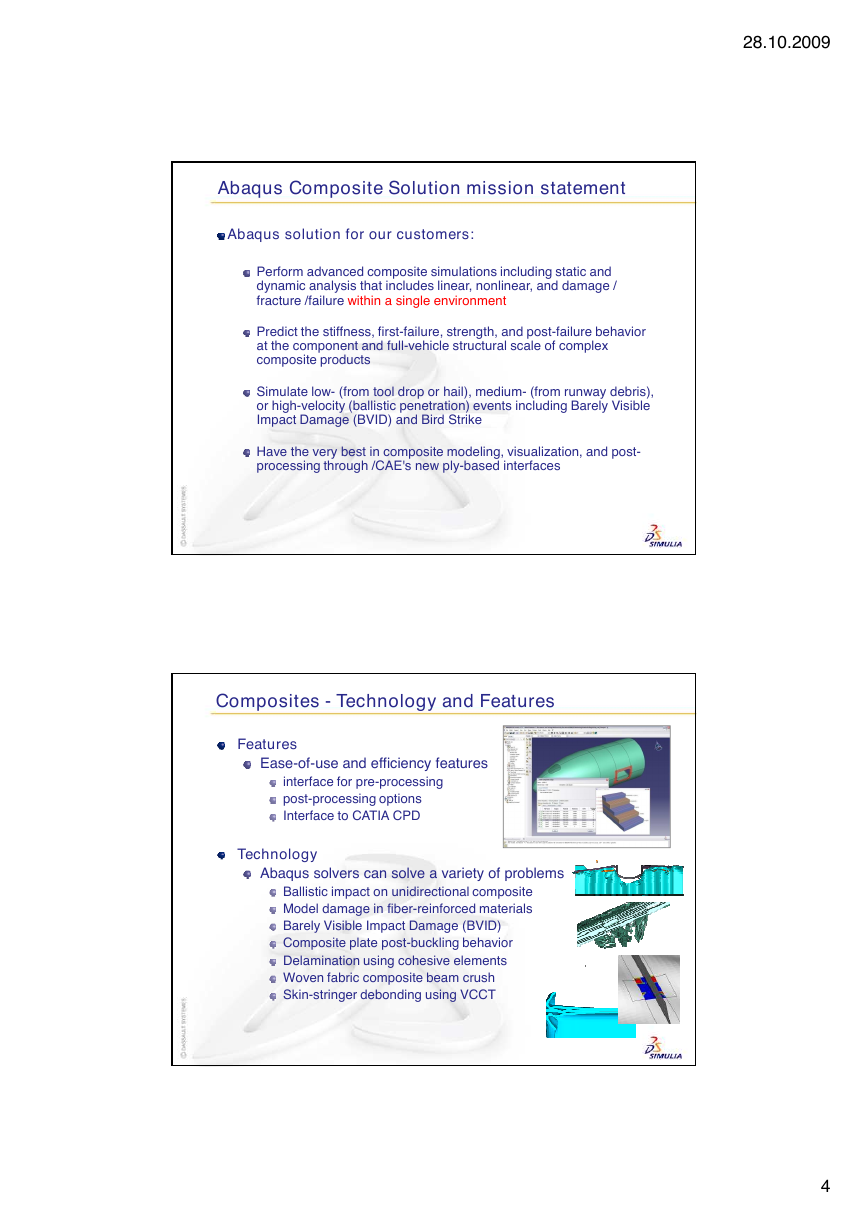

Composites - Technology and Features

Features

Ease-of-use and efficiency features

interface for pre-processing

post-processing options

Interface to CATIA CPD

Technology

Abaqus solvers can solve a variety of problems

Ballistic impact on unidirectional composite

Model damage in fiber-reinforced materials

Barely Visible Impact Damage (BVID)

Composite plate post-buckling behavior

Delamination using cohesive elements

Woven fabric composite beam crush

Skin-stringer debonding using VCCT

28.10.2009

4

�

28.10.2009

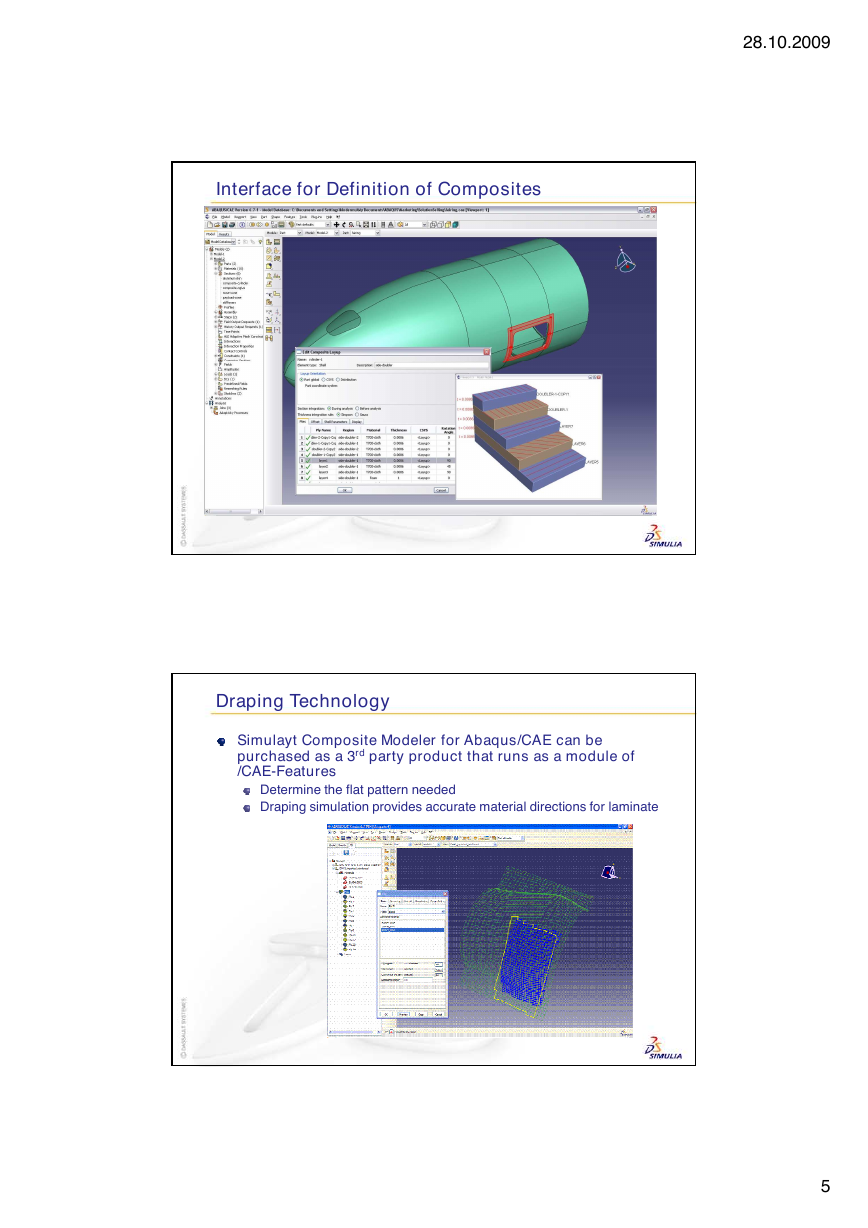

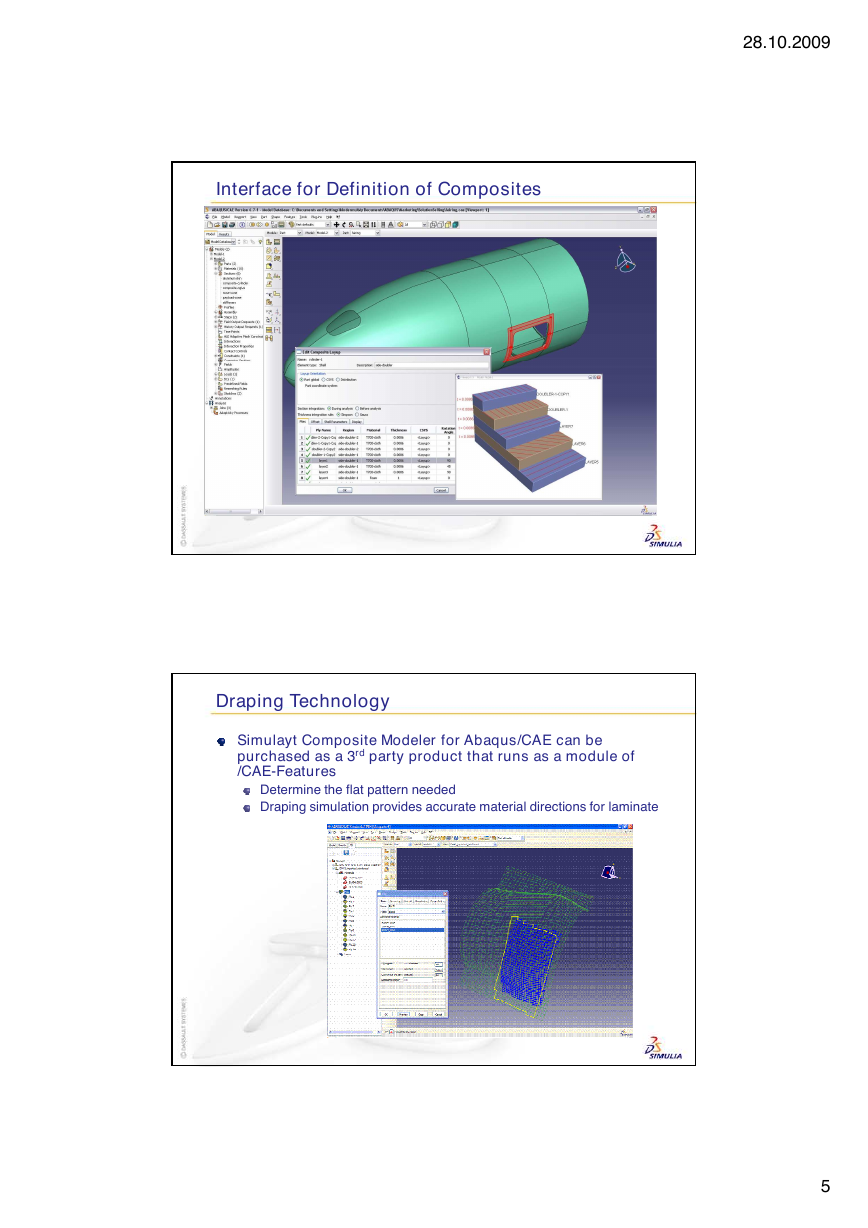

Interface for Definition of Composites

Draping Technology

Simulayt Composite Modeler for Abaqus/CAE can be

purchased as a 3rd party product that runs as a module of

/CAE-Features

Determine the flat pattern needed

Draping simulation provides accurate material directions for laminate

5

�

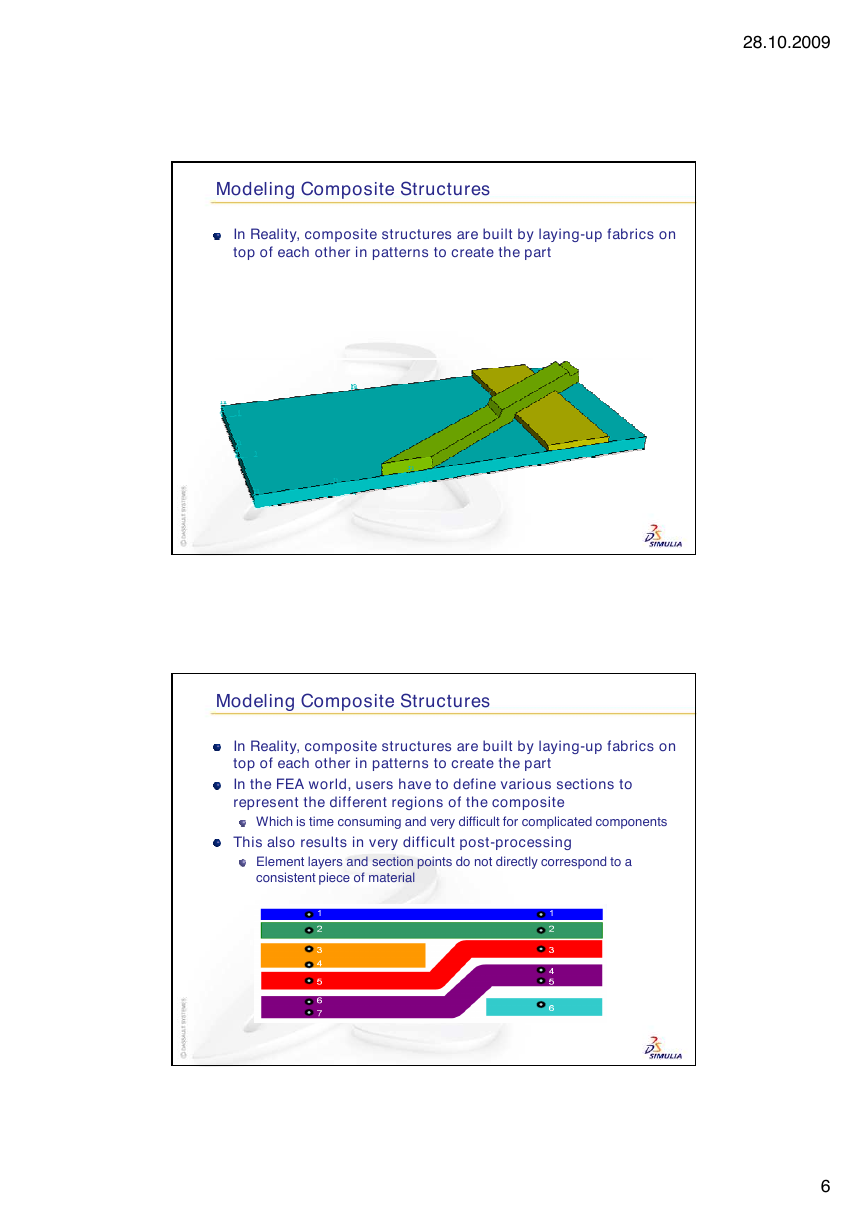

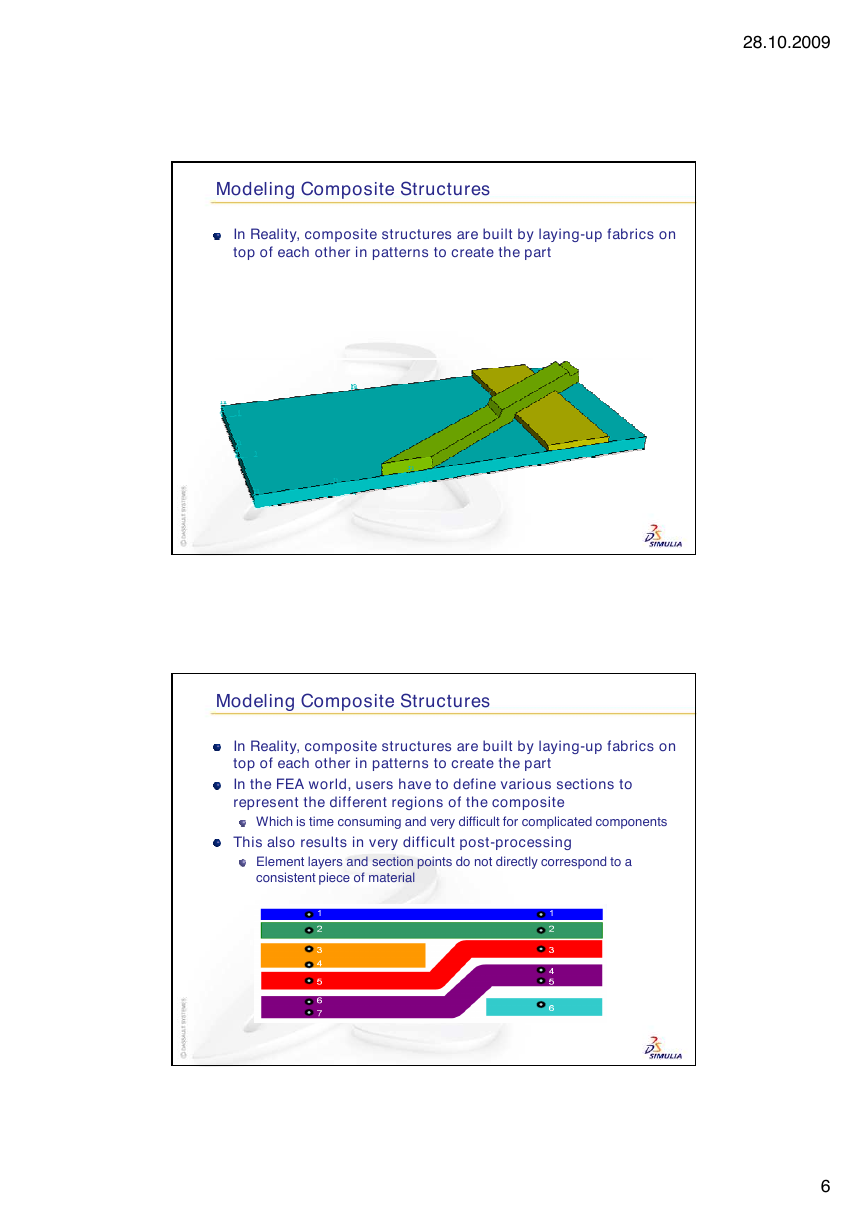

Modeling Composite Structures

In Reality, composite structures are built by laying-up fabrics on

top of each other in patterns to create the part

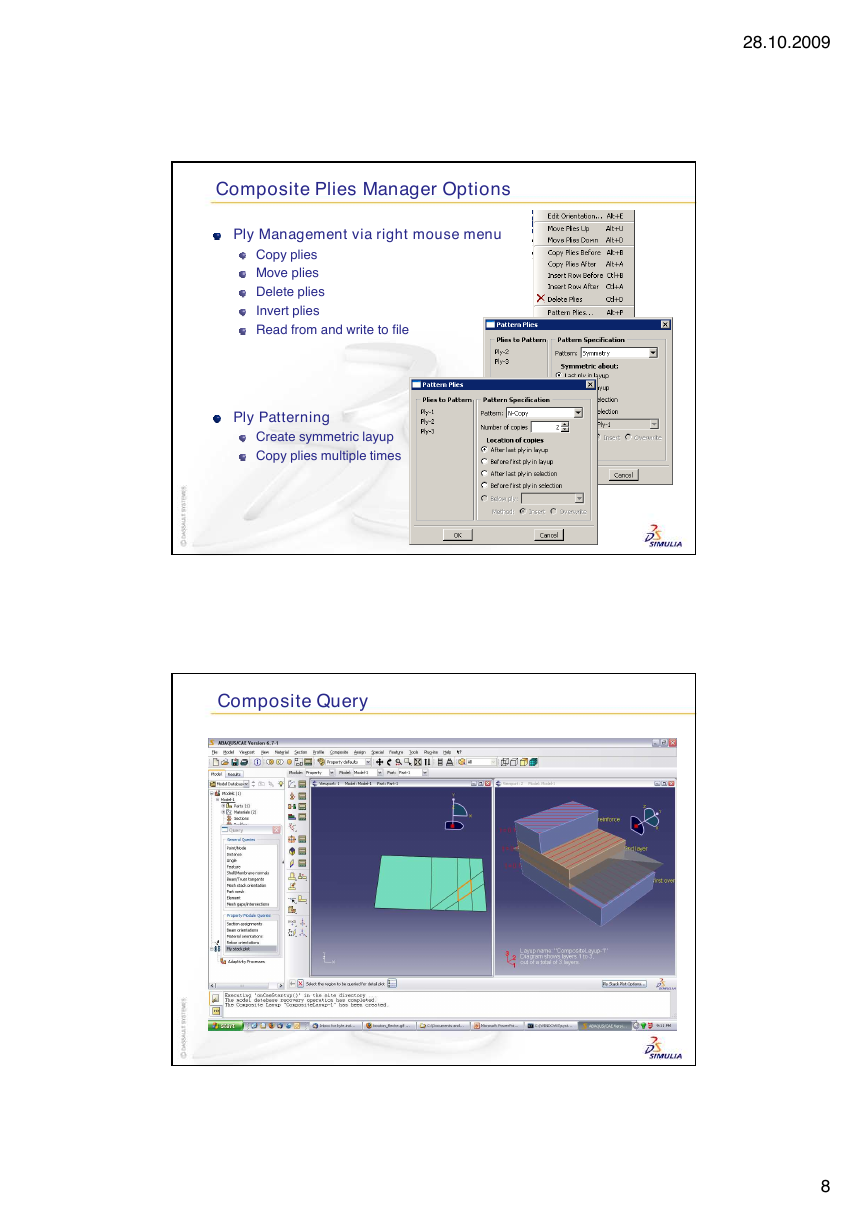

Modeling Composite Structures

In Reality, composite structures are built by laying-up fabrics on

top of each other in patterns to create the part

In the FEA world, users have to define various sections to

represent the different regions of the composite

Which is time consuming and very difficult for complicated components

This also results in very difficult post-processing

Element layers and section points do not directly correspond to a

consistent piece of material

28.10.2009

6

�

Users Can Now Model in Terms of Plies

Think in terms of “Plies”

Representation of the materials as placed in a mold

User supplied ply name is available in ODB and /Viewer for easy

tracking in post-processing operations

Plies defined on picked regions or named sets of partitioned

geometry or orphan mesh parts

Ply-1

Ply-2

Ply-3

Composite modeling in Abaqus

Composite Layup Object

Part level replacement for multiple sections, section assignments

and material orientations for layered composites - in one object

Advantages:

Ply-based

More intuitive definition of

ply regions than “artificial”

section assignments

Output requests can be

defined by composite layup

Suppressible

Supports shell, layered continuum shell and layered solid

elements

28.10.2009

7

�

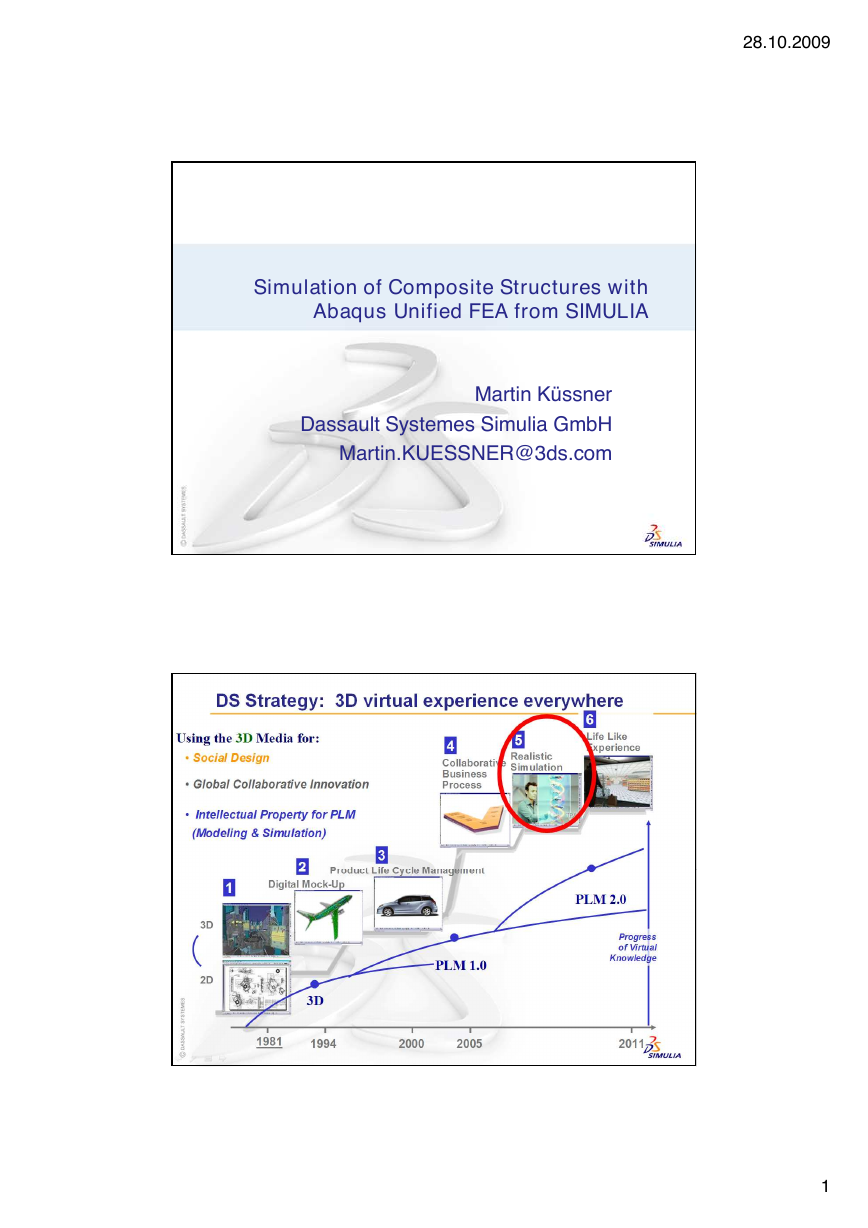

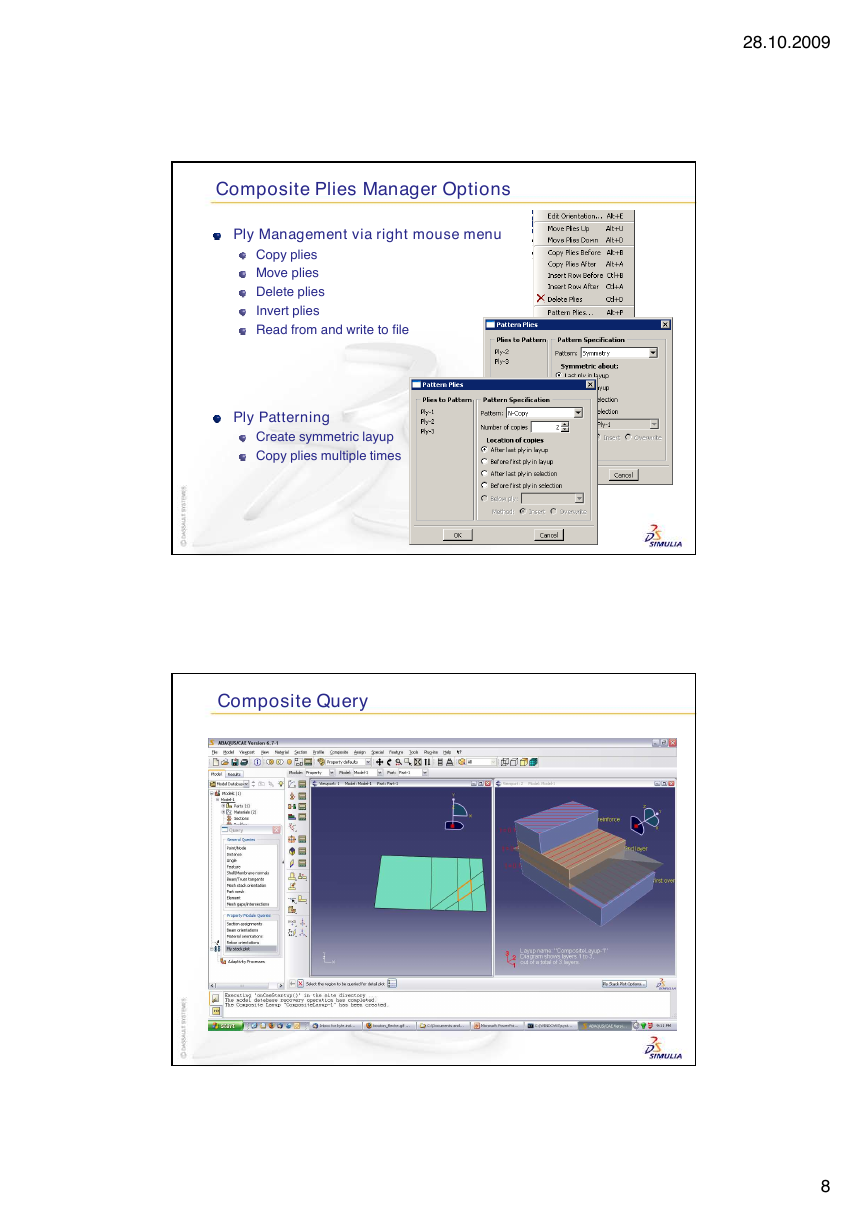

Composite Plies Manager Options

Ply Management via right mouse menu

Copy plies

Move plies

Delete plies

Invert plies

Read from and write to file

Ply Patterning

Create symmetric layup

Copy plies multiple times

Composite Query

28.10.2009

8

�

2023年江西萍乡中考道德与法治真题及答案.doc

2023年江西萍乡中考道德与法治真题及答案.doc 2012年重庆南川中考生物真题及答案.doc

2012年重庆南川中考生物真题及答案.doc 2013年江西师范大学地理学综合及文艺理论基础考研真题.doc

2013年江西师范大学地理学综合及文艺理论基础考研真题.doc 2020年四川甘孜小升初语文真题及答案I卷.doc

2020年四川甘孜小升初语文真题及答案I卷.doc 2020年注册岩土工程师专业基础考试真题及答案.doc

2020年注册岩土工程师专业基础考试真题及答案.doc 2023-2024学年福建省厦门市九年级上学期数学月考试题及答案.doc

2023-2024学年福建省厦门市九年级上学期数学月考试题及答案.doc 2021-2022学年辽宁省沈阳市大东区九年级上学期语文期末试题及答案.doc

2021-2022学年辽宁省沈阳市大东区九年级上学期语文期末试题及答案.doc 2022-2023学年北京东城区初三第一学期物理期末试卷及答案.doc

2022-2023学年北京东城区初三第一学期物理期末试卷及答案.doc 2018上半年江西教师资格初中地理学科知识与教学能力真题及答案.doc

2018上半年江西教师资格初中地理学科知识与教学能力真题及答案.doc 2012年河北国家公务员申论考试真题及答案-省级.doc

2012年河北国家公务员申论考试真题及答案-省级.doc 2020-2021学年江苏省扬州市江都区邵樊片九年级上学期数学第一次质量检测试题及答案.doc

2020-2021学年江苏省扬州市江都区邵樊片九年级上学期数学第一次质量检测试题及答案.doc 2022下半年黑龙江教师资格证中学综合素质真题及答案.doc

2022下半年黑龙江教师资格证中学综合素质真题及答案.doc