10.1109/ULTSYM.2011.0481

1-3 Microfabricated Composite Acoustic Matching

Layers for High Frequency Transducers

Tung Manh, Lars Hoff

Institute of Micro and Nano Systems Technology

Vestfold University College

Horten, Norway

Tung.Manh@hive.no

Tonni Franke Johansen

Department of Circulation and Medical Imaging

Norwegian University of Science and Technology

Trondheim, Norway

Geir Uri Jensen

Department of Microsystems and Nanotechnology

SINTEF ICT

Oslo, Norway

the

paper

presents

fabrication

and

Abstract—This

characterization of a 1-3 silicon-polymer composite matching

layer made by Deep Reactive Ion Etch (DRIE) method. A well-

defined composite layer thickness of 83 µm was obtained by using

Silicon-on-Insulator (SOI) wafers as substrate. The resulting

composite has 7 µm size posts and 9 µm spacing between posts. A

slight tapering of the posts was observed after the DRIE process,

causing the posts to be narrower in the bottom than at the top.

The composite was used as acoustic matching layer in an air-

backed 15 MHz transducer and characterized by electrical

impedance measurements in air. The effective acoustic properties

of the composite, speed of sound and acoustic impedance,

deduced from measured results, were found to be lower than

those predicted from iso-strain model. This deviation can be

explained by tapering of the trench walls and the dispersion

caused by the finite dimensions of the bi-phase material, an

explanation that was verified by FEM simulations.

Keywords-1-3 composite; acoustic matching layers; silicon

micromachining; high frequency transducers.

I.

INTRODUCTION

for

high

frequency

High frequency broadband ultrasound transducers provide

high resolution images in situations where the imaging depth

is small, e.g. in intravascular ultrasound. In such transducers,

one or more acoustic matching layers are used to effectively

couple energy from the transducer to the tissue. We have

previously presented methods to fabricate such matching

layers

using

micromachining technologies from Micro-Electro-Mechanical

Systems (MEMS) industry, such as photolithography and etch

[1]. The acoustic matching

is a silicon-polymer

composite, of 2-2 or 1-3 connectivity, where the silicon

substrate is micromachined and filled with epoxy resin.

Different micromachining methods can be used to fabricate

such a layer, e.g. anisotropic wet etch of <110>-oriented

silicon wafer or Deep Reactive Ion Etch (DRIE) by the Bosch-

process. Anisotropic wet etch depends on

the crystal

orientation, and is only suitable to form 2-2 composite

transducers

layer

by

structures. This method requires a very good alignment of the

feature lines along the <111> crystal planes, which can be

demanding at the small dimensions needed for transducers

working at high frequencies.

This paper describes fabrication of 1-3 composites by DRIE

method. This technology is not sensitive to crystal orientation,

and is promising for mass production. The process uses a

Silicon-on-Insulator (SOI) wafer with a buried silicon dioxide

layer to stop the etching at a well-defined thickness, 83 µm.

The composite fabricated by this method was bonded to a

15MHz PZT disc with coaxial electrodes, forming an air-

backed ultrasound transducer. Composite properties were

calculated from electrical measurements in air, and compared

to values calculated from the iso-strain model.

II. THEORY

A. The iso-strain model

A composite behaves acoustically like a homogeneous

material if its lateral dimensions are sufficiently fine. Within

this regime, effective elastic parameters of the composite can

be calculated from the theoretical model developed by Smith

et al. [2] without piezoelectric coupling. The resulting

effective parameters for a 1-3 composite are

=

C

c

33

⎡

⎢

⎢

v c

⎢

⎢

⎢

⎣

Si

11

2

+

p

⎛

c

⎜

12

⎝

Si

⎞

c

⎟

12

⎠

−

ˆ

v

Si

c

11

ˆ

v

⎛

⎜

⎝

2

−

Si

⎞

c

⎟

12

⎠

p

+

ν

⎛

c

⎜

11

⎝

=

v

Z

Si

ˆ p

C

ρ ρ ρ

+ %

v

C

C C

c ρ

33

C

c

33

C

ρ

V

C

=

=

⎤

⎥

⎥

⎥

⎥

⎥

⎦

+

p

c

12

⎞

⎟

⎠

+

ˆ

vc

p

11

(1)

(2)

(3)

(4)

This work is funded by the Research Council of Norway under Grants

No. 176540, 191282, and 181712/I30.

978-1-4577-1252-4/11/$26.00 ©2011 IEEE

1932

2011 IEEE International Ultrasonics Symposium Proceedings

�

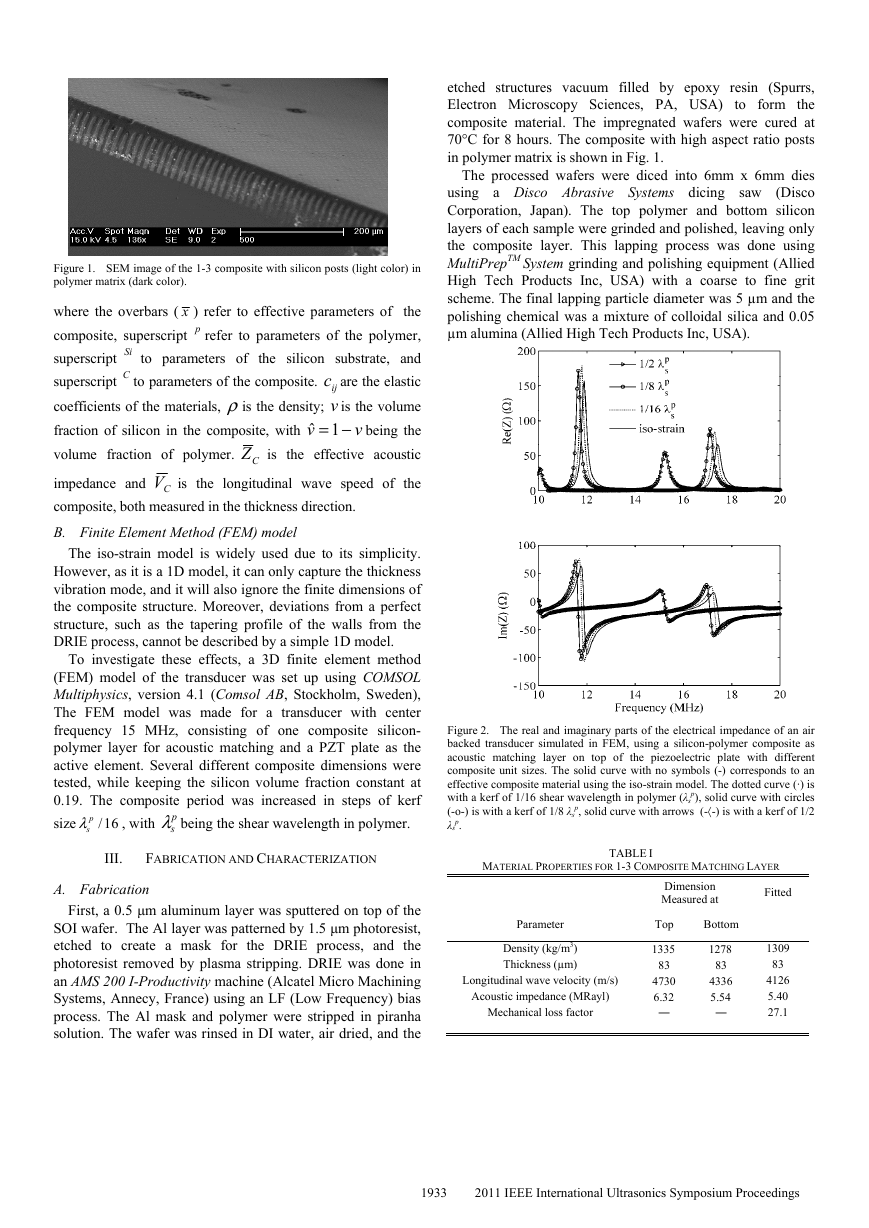

etched structures vacuum filled by epoxy resin (Spurrs,

Electron Microscopy Sciences, PA, USA) to form the

composite material. The impregnated wafers were cured at

70°C for 8 hours. The composite with high aspect ratio posts

in polymer matrix is shown in Fig. 1.

The processed wafers were diced into 6mm x 6mm dies

using a Disco Abrasive Systems dicing saw

(Disco

Corporation, Japan). The top polymer and bottom silicon

layers of each sample were grinded and polished, leaving only

the composite layer. This lapping process was done using

MultiPrepTM System grinding and polishing equipment (Allied

High Tech Products Inc, USA) with a coarse to fine grit

scheme. The final lapping particle diameter was 5 µm and the

polishing chemical was a mixture of colloidal silica and 0.05

µm alumina (Allied High Tech Products Inc, USA).

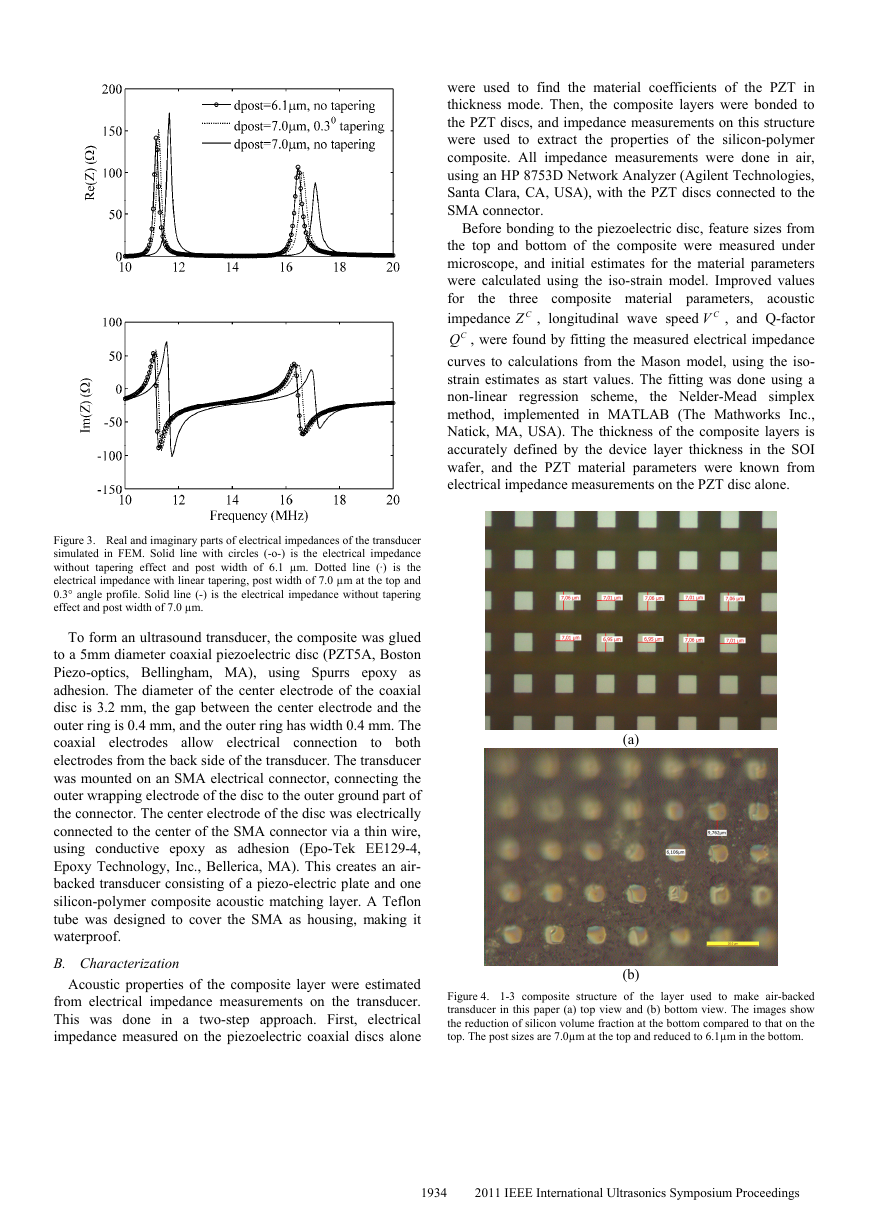

Figure 2. The real and imaginary parts of the electrical impedance of an air

backed transducer simulated in FEM, using a silicon-polymer composite as

acoustic matching layer on top of the piezoelectric plate with different

composite unit sizes. The solid curve with no symbols (-) corresponds to an

effective composite material using the iso-strain model. The dotted curve (·) is

p), solid curve with circles

with a kerf of 1/16 shear wavelength in polymer (λs

p, solid curve with arrows (-〈-) is with a kerf of 1/2

(-o-) is with a kerf of 1/8 λs

p.

λs

Figure 1. SEM image of the 1-3 composite with silicon posts (light color) in

polymer matrix (dark color).

where the overbars ( x ) refer to effective parameters of the

composite, superscript p refer to parameters of the polymer,

superscript Si

to parameters of the silicon substrate, and

ijc are the elastic

superscript C to parameters of the composite.

coefficients of the materials, ρis the density; v is the volume

fraction of silicon in the composite, with

being the

CZ is the effective acoustic

volume fraction of polymer.

CV is the longitudinal wave speed of the

impedance and

composite, both measured in the thickness direction.

B. Finite Element Method (FEM) model

−= 1ˆ

v

v

The iso-strain model is widely used due to its simplicity.

However, as it is a 1D model, it can only capture the thickness

vibration mode, and it will also ignore the finite dimensions of

the composite structure. Moreover, deviations from a perfect

structure, such as the tapering profile of the walls from the

DRIE process, cannot be described by a simple 1D model.

To investigate these effects, a 3D finite element method

(FEM) model of the transducer was set up using COMSOL

Multiphysics, version 4.1 (Comsol AB, Stockholm, Sweden),

The FEM model was made for a transducer with center

frequency 15 MHz, consisting of one composite silicon-

polymer layer for acoustic matching and a PZT plate as the

active element. Several different composite dimensions were

tested, while keeping the silicon volume fraction constant at

0.19. The composite period was increased in steps of kerf

sλ being the shear wavelength in polymer.

size

sλ , with

p

p

/16

III.

FABRICATION AND CHARACTERIZATION

MATERIAL PROPERTIES FOR 1-3 COMPOSITE MATCHING LAYER

TABLE I

A. Fabrication

First, a 0.5 μm aluminum layer was sputtered on top of the

SOI wafer. The Al layer was patterned by 1.5 μm photoresist,

etched to create a mask for the DRIE process, and the

photoresist removed by plasma stripping. DRIE was done in

an AMS 200 I-Productivity machine (Alcatel Micro Machining

Systems, Annecy, France) using an LF (Low Frequency) bias

process. The Al mask and polymer were stripped in piranha

solution. The wafer was rinsed in DI water, air dried, and the

Parameter

Density (kg/m3)

Thickness (µm)

Longitudinal wave velocity (m/s)

Acoustic impedance (MRayl)

Mechanical loss factor

Dimension

Measured at

Fitted

Top

1335

83

4730

6.32

―

Bottom

1278

83

4336

5.54

―

1309

83

4126

5.40

27.1

1933

2011 IEEE International Ultrasonics Symposium Proceedings

�

were used to find the material coefficients of the PZT in

thickness mode. Then, the composite layers were bonded to

the PZT discs, and impedance measurements on this structure

were used to extract the properties of the silicon-polymer

composite. All impedance measurements were done in air,

using an HP 8753D Network Analyzer (Agilent Technologies,

Santa Clara, CA, USA), with the PZT discs connected to the

SMA connector.

Before bonding to the piezoelectric disc, feature sizes from

the top and bottom of the composite were measured under

microscope, and initial estimates for the material parameters

were calculated using the iso-strain model. Improved values

three composite material parameters, acoustic

for

CZ , longitudinal wave speed

CV , and Q-factor

impedance

CQ , were found by fitting the measured electrical impedance

curves to calculations from the Mason model, using the iso-

strain estimates as start values. The fitting was done using a

non-linear regression scheme, the Nelder-Mead simplex

method, implemented in MATLAB (The Mathworks Inc.,

Natick, MA, USA). The thickness of the composite layers is

accurately defined by the device layer thickness in the SOI

wafer, and the PZT material parameters were known from

electrical impedance measurements on the PZT disc alone.

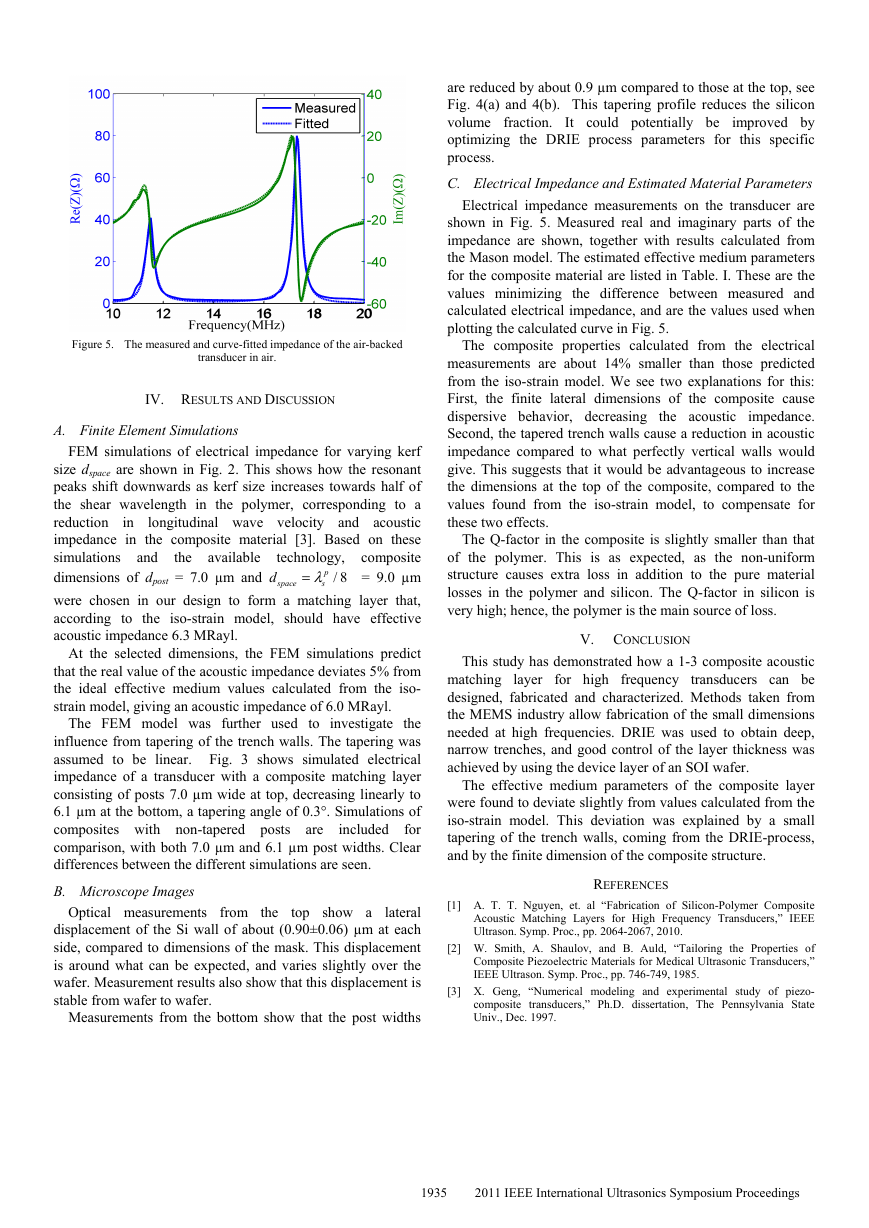

the

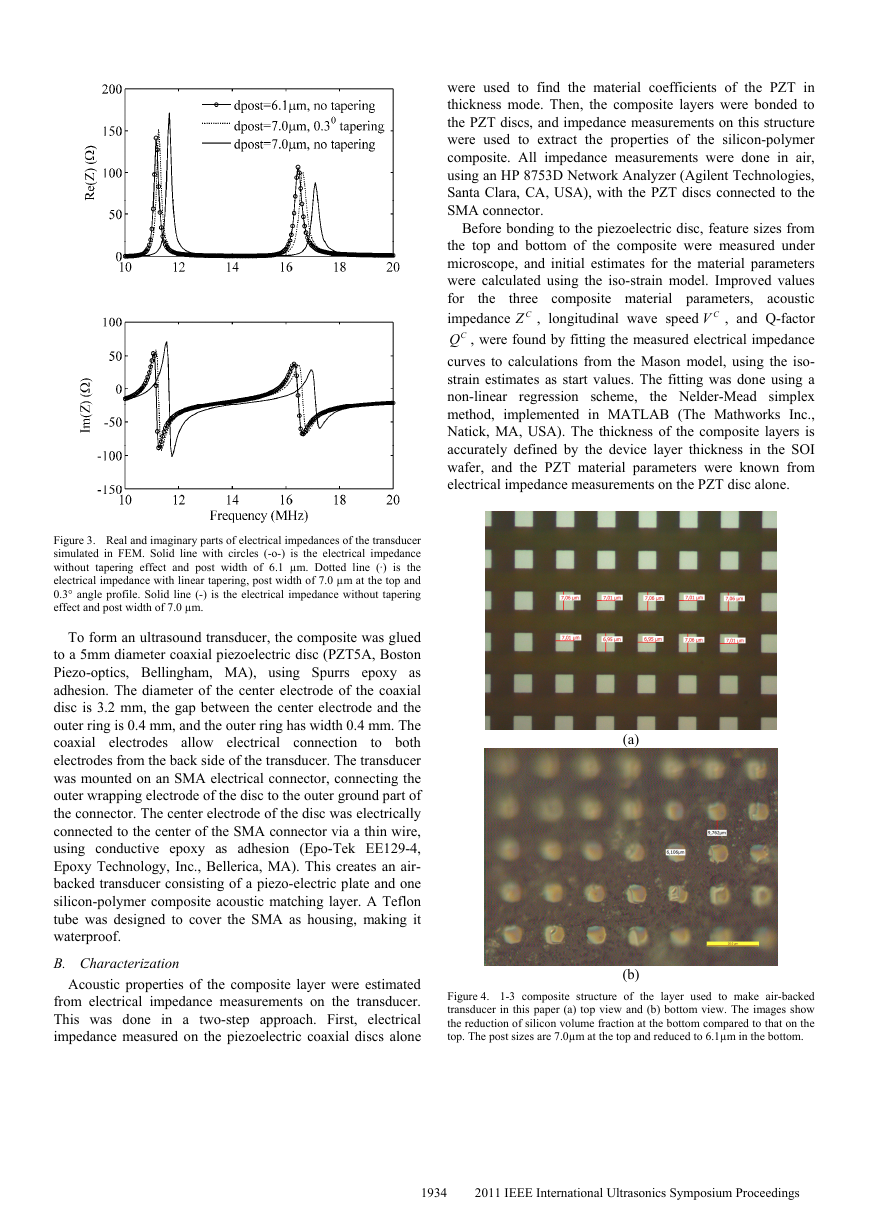

Figure 3. Real and imaginary parts of electrical impedances of the transducer

simulated in FEM. Solid line with circles (-o-) is the electrical impedance

without tapering effect and post width of 6.1 µm. Dotted line (·) is the

electrical impedance with linear tapering, post width of 7.0 µm at the top and

0.3° angle profile. Solid line (-) is the electrical impedance without tapering

effect and post width of 7.0 µm.

To form an ultrasound transducer, the composite was glued

to a 5mm diameter coaxial piezoelectric disc (PZT5A, Boston

Piezo-optics, Bellingham, MA), using Spurrs epoxy as

adhesion. The diameter of the center electrode of the coaxial

disc is 3.2 mm, the gap between the center electrode and the

outer ring is 0.4 mm, and the outer ring has width 0.4 mm. The

coaxial electrodes allow electrical connection

to both

electrodes from the back side of the transducer. The transducer

was mounted on an SMA electrical connector, connecting the

outer wrapping electrode of the disc to the outer ground part of

the connector. The center electrode of the disc was electrically

connected to the center of the SMA connector via a thin wire,

using conductive epoxy as adhesion (Epo-Tek EE129-4,

Epoxy Technology, Inc., Bellerica, MA). This creates an air-

backed transducer consisting of a piezo-electric plate and one

silicon-polymer composite acoustic matching layer. A Teflon

tube was designed to cover the SMA as housing, making it

waterproof.

B. Characterization

Acoustic properties of the composite layer were estimated

from electrical impedance measurements on the transducer.

This was done in a two-step approach. First, electrical

impedance measured on the piezoelectric coaxial discs alone

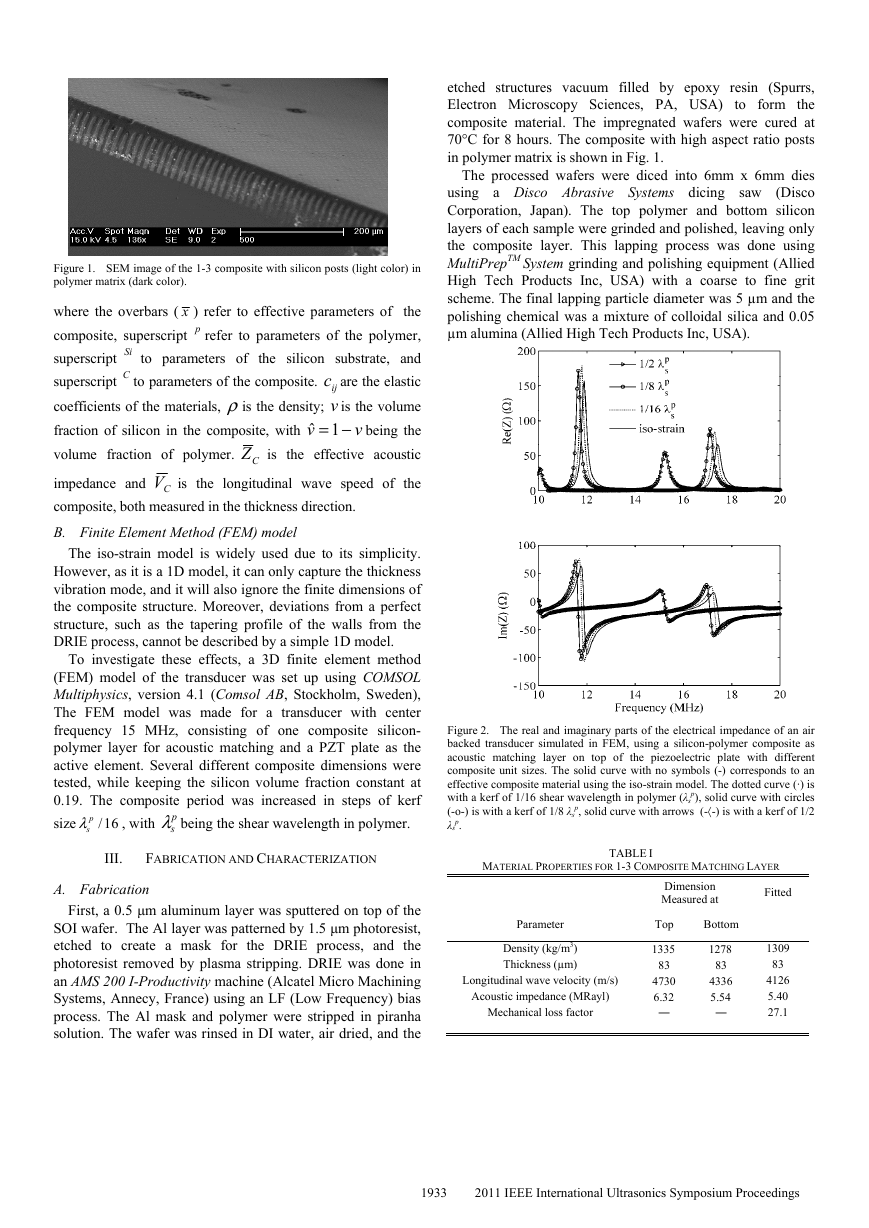

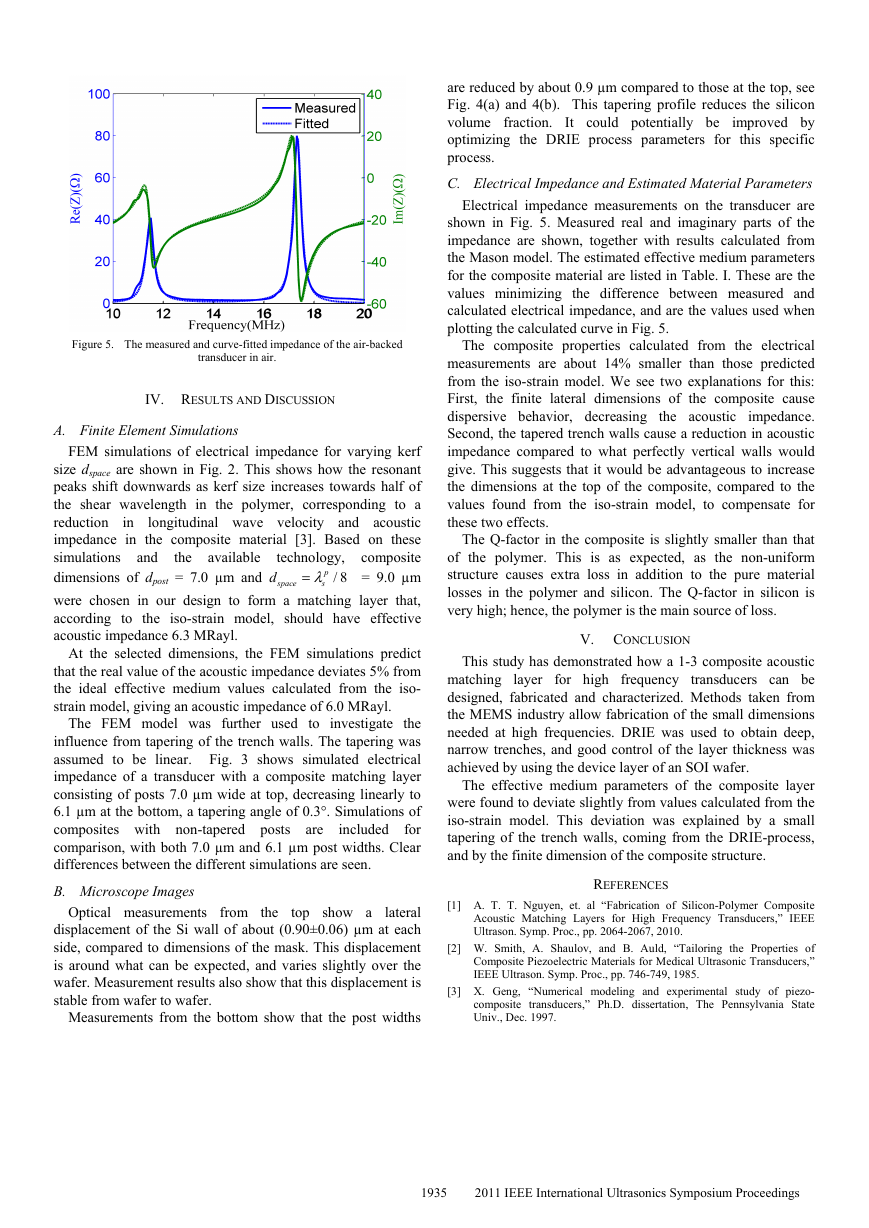

(a)

(b)

Figure 4. 1-3 composite structure of the layer used to make air-backed

transducer in this paper (a) top view and (b) bottom view. The images show

the reduction of silicon volume fraction at the bottom compared to that on the

top. The post sizes are 7.0µm at the top and reduced to 6.1µm in the bottom.

1934

2011 IEEE International Ultrasonics Symposium Proceedings

�

are reduced by about 0.9 µm compared to those at the top, see

Fig. 4(a) and 4(b). This tapering profile reduces the silicon

volume fraction. It could potentially be

improved by

optimizing the DRIE process parameters for this specific

process.

C. Electrical Impedance and Estimated Material Parameters

Electrical impedance measurements on the transducer are

shown in Fig. 5. Measured real and imaginary parts of the

impedance are shown, together with results calculated from

the Mason model. The estimated effective medium parameters

for the composite material are listed in Table. I. These are the

values minimizing the difference between measured and

calculated electrical impedance, and are the values used when

plotting the calculated curve in Fig. 5.

The composite properties calculated from the electrical

measurements are about 14% smaller than those predicted

from the iso-strain model. We see two explanations for this:

First, the finite lateral dimensions of the composite cause

dispersive behavior, decreasing

impedance.

Second, the tapered trench walls cause a reduction in acoustic

impedance compared to what perfectly vertical walls would

give. This suggests that it would be advantageous to increase

the dimensions at the top of the composite, compared to the

values found from the iso-strain model, to compensate for

these two effects.

the acoustic

The Q-factor in the composite is slightly smaller than that

of the polymer. This is as expected, as the non-uniform

structure causes extra loss in addition to the pure material

losses in the polymer and silicon. The Q-factor in silicon is

very high; hence, the polymer is the main source of loss.

V. CONCLUSION

layer for high frequency

This study has demonstrated how a 1-3 composite acoustic

matching

transducers can be

designed, fabricated and characterized. Methods taken from

the MEMS industry allow fabrication of the small dimensions

needed at high frequencies. DRIE was used to obtain deep,

narrow trenches, and good control of the layer thickness was

achieved by using the device layer of an SOI wafer.

The effective medium parameters of the composite layer

were found to deviate slightly from values calculated from the

iso-strain model. This deviation was explained by a small

tapering of the trench walls, coming from the DRIE-process,

and by the finite dimension of the composite structure.

REFERENCES

[1] A. T. T. Nguyen, et. al “Fabrication of Silicon-Polymer Composite

Acoustic Matching Layers for High Frequency Transducers,” IEEE

Ultrason. Symp. Proc., pp. 2064-2067, 2010.

[2] W. Smith, A. Shaulov, and B. Auld, “Tailoring the Properties of

Composite Piezoelectric Materials for Medical Ultrasonic Transducers,”

IEEE Ultrason. Symp. Proc., pp. 746-749, 1985.

[3] X. Geng, “Numerical modeling and experimental study of piezo-

composite transducers,” Ph.D. dissertation, The Pennsylvania State

Univ., Dec. 1997.

Figure 5. The measured and curve-fitted impedance of the air-backed

transducer in air.

IV. RESULTS AND DISCUSSION

A. Finite Element Simulations

d

space

in

FEM simulations of electrical impedance for varying kerf

size dspace are shown in Fig. 2. This shows how the resonant

peaks shift downwards as kerf size increases towards half of

the shear wavelength in the polymer, corresponding to a

reduction

longitudinal wave velocity and acoustic

impedance in the composite material [3]. Based on these

simulations and

technology, composite

the available

dimensions of dpost = 7.0 µm and

= 9.0 µm

were chosen in our design to form a matching layer that,

according to the iso-strain model, should have effective

acoustic impedance 6.3 MRayl.

λ=

/ 8p

s

At the selected dimensions, the FEM simulations predict

that the real value of the acoustic impedance deviates 5% from

the ideal effective medium values calculated from the iso-

strain model, giving an acoustic impedance of 6.0 MRayl.

The FEM model was further used to investigate the

influence from tapering of the trench walls. The tapering was

assumed to be linear. Fig. 3 shows simulated electrical

impedance of a transducer with a composite matching layer

consisting of posts 7.0 µm wide at top, decreasing linearly to

6.1 µm at the bottom, a tapering angle of 0.3°. Simulations of

composites with non-tapered posts are

for

comparison, with both 7.0 µm and 6.1 µm post widths. Clear

differences between the different simulations are seen.

B. Microscope Images

included

the

top show a

Optical measurements from

lateral

displacement of the Si wall of about (0.90±0.06) µm at each

side, compared to dimensions of the mask. This displacement

is around what can be expected, and varies slightly over the

wafer. Measurement results also show that this displacement is

stable from wafer to wafer.

Measurements from the bottom show that the post widths

1935

2011 IEEE International Ultrasonics Symposium Proceedings

�

2023年江西萍乡中考道德与法治真题及答案.doc

2023年江西萍乡中考道德与法治真题及答案.doc 2012年重庆南川中考生物真题及答案.doc

2012年重庆南川中考生物真题及答案.doc 2013年江西师范大学地理学综合及文艺理论基础考研真题.doc

2013年江西师范大学地理学综合及文艺理论基础考研真题.doc 2020年四川甘孜小升初语文真题及答案I卷.doc

2020年四川甘孜小升初语文真题及答案I卷.doc 2020年注册岩土工程师专业基础考试真题及答案.doc

2020年注册岩土工程师专业基础考试真题及答案.doc 2023-2024学年福建省厦门市九年级上学期数学月考试题及答案.doc

2023-2024学年福建省厦门市九年级上学期数学月考试题及答案.doc 2021-2022学年辽宁省沈阳市大东区九年级上学期语文期末试题及答案.doc

2021-2022学年辽宁省沈阳市大东区九年级上学期语文期末试题及答案.doc 2022-2023学年北京东城区初三第一学期物理期末试卷及答案.doc

2022-2023学年北京东城区初三第一学期物理期末试卷及答案.doc 2018上半年江西教师资格初中地理学科知识与教学能力真题及答案.doc

2018上半年江西教师资格初中地理学科知识与教学能力真题及答案.doc 2012年河北国家公务员申论考试真题及答案-省级.doc

2012年河北国家公务员申论考试真题及答案-省级.doc 2020-2021学年江苏省扬州市江都区邵樊片九年级上学期数学第一次质量检测试题及答案.doc

2020-2021学年江苏省扬州市江都区邵樊片九年级上学期数学第一次质量检测试题及答案.doc 2022下半年黑龙江教师资格证中学综合素质真题及答案.doc

2022下半年黑龙江教师资格证中学综合素质真题及答案.doc