English

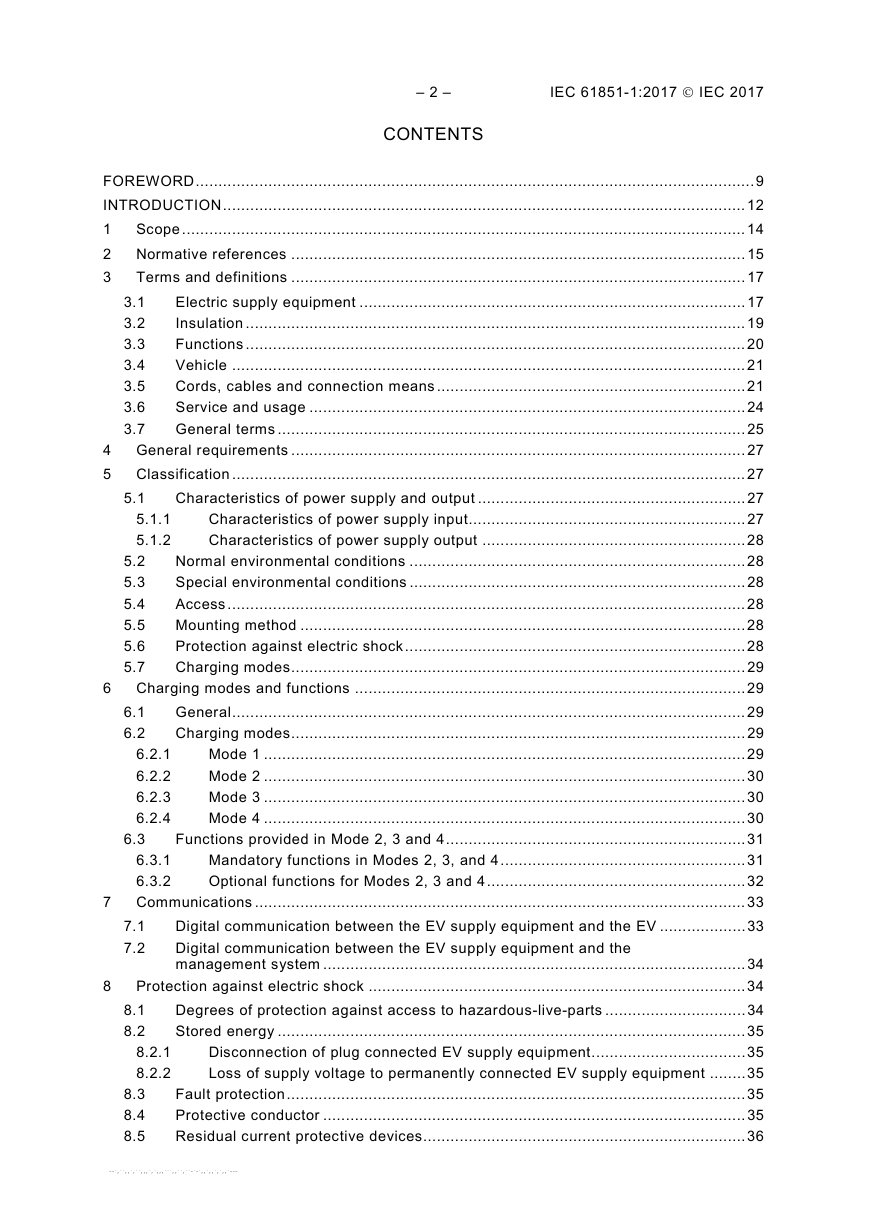

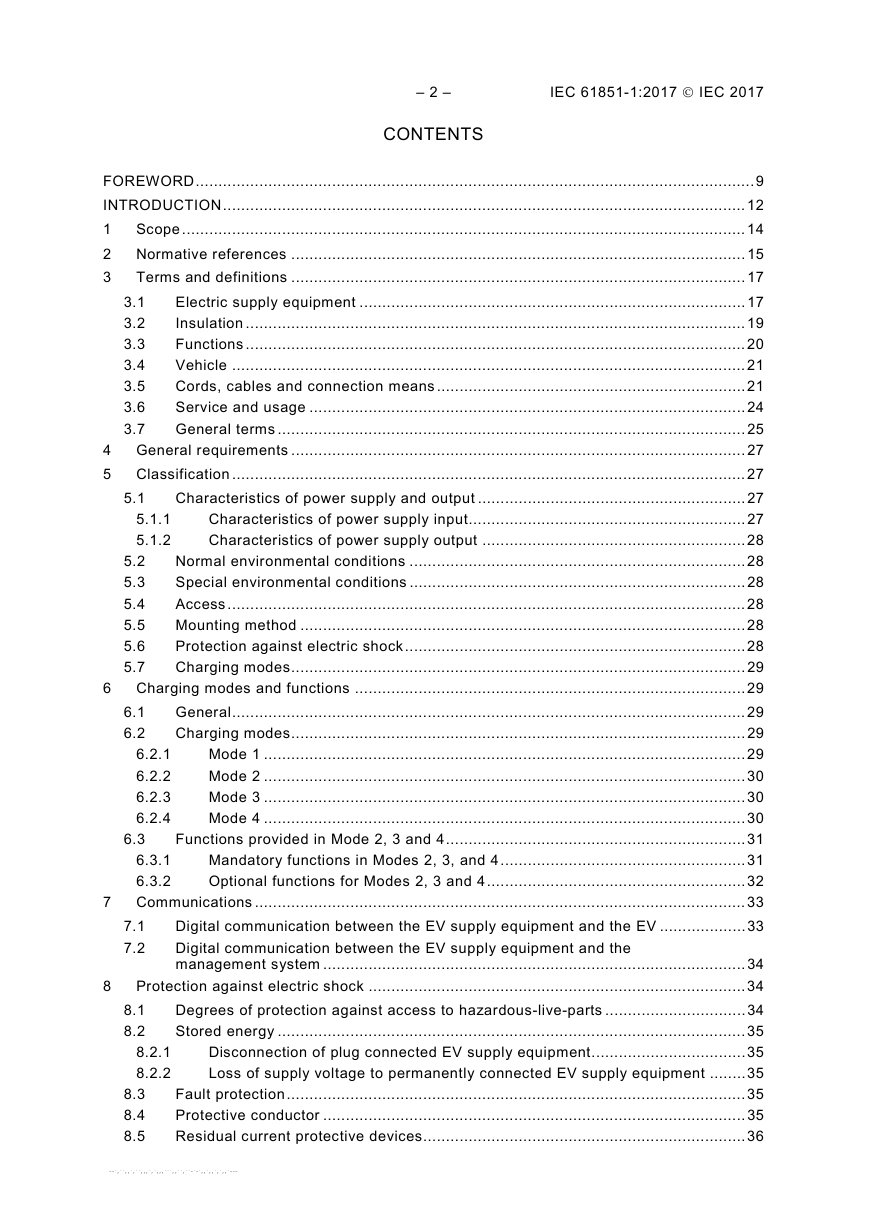

CONTENTS

FOREWORD

INTRODUCTION

1 Scope

2 Normative references

3 Terms and definitions

3.1 Electric supply equipment

3.2 Insulation

3.3 Functions

3.4 Vehicle

3.5 Cords, cables and connection means

3.6 Service and usage

3.7 General terms

4 General requirements

5 Classification

5.1 Characteristics of power supply and output

5.1.1 Characteristics of power supply input

5.1.2 Characteristics of power supply output

5.2 Normal environmental conditions

5.3 Special environmental conditions

5.4 Access

5.5 Mounting method

5.6 Protection against electric shock

5.7 Charging modes

6 Charging modes and functions

6.1 General

6.2 Charging modes

6.2.1 Mode 1

6.2.2 Mode 2

6.2.3 Mode 3

6.2.4 Mode 4

6.3 Functions provided in Mode 2, 3 and 4

6.3.1 Mandatory functions in Modes 2, 3, and 4

6.3.2 Optional functions for Modes 2, 3 and 4

7 Communications

7.1 Digital communication between the EV supply equipment and the EV

7.2 Digital communication between the EV supply equipment and the management system

8 Protection against electric shock

8.1 Degrees of protection against access to hazardous-live-parts

8.2 Stored energy

8.2.1 Disconnection of plug connected EV supply equipment

8.2.2 Loss of supply voltage to permanently connected EV supply equipment

8.3 Fault protection

8.4 Protective conductor

8.5 Residual current protective devices

8.6 Safety requirements for signalling circuits between the EV supply equipment and the EV

8.7 Isolating transformers

9 Conductive electrical interface requirements

9.1 General

9.2 Functional description of standard accessories

9.3 Functional description of the basic interface

9.4 Functional description of the universal interface

9.5 Functional description of the DC interface

9.6 Functional description of the combined interface

9.7 Wiring of the neutral conductor

10 Requirements for adaptors

11 Cable assembly requirements

11.1 General

11.2 Electrical rating

11.3 Dielectric withstand characteristics

11.4 Construction requirements

11.5 Cable dimensions

11.6 Strain relief

11.7 Cable management and storage means for cables assemblies

12 EV supply equipment constructional requirements and tests

12.1 General

12.2 Characteristics of mechanical switching devices

12.2.1 General

12.2.2 Switch and switch-disconnector

12.2.3 Contactor

12.2.4 Circuit-breaker

12.2.5 Relays

12.2.6 Inrush current

12.2.7 Residual direct current monitoring device (RDC MD)

12.3 Clearances and creepage distances

12.4 IP degrees

12.4.1 Degrees of protection against solid foreign objects and water for the enclosures

12.4.2 Degrees of protection against solid foreign objects and water for basic, universal and combined and DC interfaces

12.5 Insulation resistance

12.6 Touch current

12.7 Dielectric withstand voltage

12.7.1 AC withstand voltage

12.7.2 Impulse dielectric withstand (1,2 μs/50 μs)

12.8 Temperature rise

12.9 Damp heat functional test

12.10 Minimum temperature functional test

12.11 Mechanical strength

13 Overload and short-circuit protection

13.1 General

13.2 Overload protection of the cable assembly

13.3 Short-circuit protection of the charging cable

14 Automatic reclosing of protective devices

15 Emergency switching or disconnect (optional)

16 Marking and instructions

16.1 Installation manual of EV charging stations

16.2 User manual for EV supply equipment

16.3 Marking of EV supply equipment

16.4 Marking of charging cable assemblies case B

16.5 Durability test for marking

Annexes

Annex A (normative) Control pilot function through a control pilot circuit using a PWM signal and a control pilot wire

A.1 General

A.2 Control pilot circuit

A.2.1 General

A.2.2 Typical control pilot circuit

A.2.3 Simplified control pilot circuit

A.2.4 Additional components and high frequency signals

A.3 Requirements for parameters and system behaviour

A.4 Test procedures

A.4.1 General

A.4.2 Constructional requirements of the EV simulator

A.4.3 Test procedure

A.4.4 Oscillator frequency and generator voltage test

A.4.5 Duty cycle test

A.4.6 Pulse wave shape test

A.4.7 Sequences test

A.4.8 Test of interruption of the protective conductor

A.4.9 Test of short-circuit values of the voltage

A.4.10 Example of a test simulator of the vehicle (informative)

A.4.11 Optional hysteresis test

A.5 Implementation hints

A.5.1 Retaining a valid authentication until reaching CP State B

A.5.2 Load control using transitions between state x1 and x2

A.5.3 Information on difficulties encountered with some legacy EVs for wake-up after a long period of inactivity (informative)

Annex B (normative) Proximity detection and cable current coding circuits for the basic interface

B.1 Circuit diagram for vehicle couplers using an auxiliary switch associated with the proximity detection contact

B.2 Circuit for simultaneous proximity detection and current coding

Annex C (informative) Examples of circuit diagrams for a basic and universal vehicle couplers

C.1 General

C.2 Circuits diagrams for Mode 1, Mode 2 and Mode 3, using a basic single phase vehicle coupler

C.3 Circuits diagrams for Mode 3, using a basic single phase or three-phase accessory without proximity switch

C.4 Example of circuit diagram for Mode 4 connection using universal coupler

Annex D (informative) Control pilot function that provides LIN communicationusing the control pilot circuit

D.1 Overview

D.1.1 General

D.1.2 LIN-CP features

D.1.3 Normative references

D.1.4 Terms and abbreviations

D.2 Scope and context

D.3 Overview of control pilot functions

D.4 Control pilot circuit

D.4.1 General

D.4.2 Control pilot circuit

D.4.3 Charging station control pilot circuit interface

D.4.4 EV control pilot circuit interface

D.4.5 LIN communication transceiver

D.4.6 Optional cable assembly node

D.5 Control pilot circuit interaction

D.5.1 General

D.5.2 Control pilot circuit states and transitions

D.6 System requirements

D.6.1 General

D.6.2 Control of LIN signals

D.6.3 Control of the S2 switch and the vehicle load current

D.6.4 Control of the switching device in the charging station

D.6.5 Control of latching and unlatching of IEC€62196-2 type 2 socket-outlets and vehicle inlets

D.7 Charging sequences

D.7.1 General

D.7.2 Start-up of normal AC charging sequence

D.7.3 Normal EV-triggered stop of charging

D.7.4 Normal stop of charging triggered by charging station

D.8 LIN Communication

D.8.1 General

D.8.2 Schedules

D.8.3 Frames

D.8.4 Signals

D.9 Requirements for charging stations and EVs that implement both LIN-CP and PWM-CP

D.9.1 General

D.9.2 Interoperability between charging stations and EVs

D.9.3 Control pilot circuit hardware

D.9.4 Control pilot circuit functionality

D.9.5 Sequence to select LIN-CP or PWM-CP after plug-in

D.10 Procedures for test of charging stations

D.10.1 General

D.10.2 Test of normal use

D.10.3 Test of disconnection under load

D.10.4 Overcurrent test

D.10.5 Test of interruption of LIN communication

D.10.6 Test of short circuit between the control pilot conductor and the protective conductor

D.10.7 Test of options

Annex E (informative) Charging station designed with a standard socket-outlet – Minimum gap for connection of Modes 1 and 2 cable assembly

E.1 Overview

E.2 General

E.3 Minimum gap for connection of Mode 2 cables with type E/F plug and socket-outlet systems

E.4 Minimum gap for connection of Mode 2 cables with type BS1363 plug and socket-outlet systems

E.5 Minimum gap for connection of Mode 2 cables with IEC€60309-2 straight plug and socket-outlet systems

Bibliography

Figures

Figure 1 – Case A connection

Figure 2 – Case B connection

Figure 3 – Case C connection

Figure A.1 – Typical control pilot circuit (equivalent circuit)

Figure A.2 – Simplified control pilot circuit (equivalent circuit)

Figure A.3 – State diagram for typical control pilot (informative)

Figure A.4 – State diagram for simplified control pilot (informative)

Figure A.5 – Test sequence using a typical control pilot circuit

Figure A.6 – Test sequence using the simplified control pilot circuit

Figure A.7 – Optional test sequence with interruption by EV supply equipment

Figure A.8 – Example of a test circuit (EV simulator)

Figure B.1 – Equivalent circuit diagram for proximity function using an auxiliary switch and no current coding

Figure B.2 – Equivalent circuit diagram for simultaneous proximity detection and current coding

Figure C.1 – Example of Mode 1 case B using the proximity circuit as in B.1

Figure C.2 – Example of Mode 2 case B using proximity detection as in B.1

Figure C.3 – Example of Mode 3 case B using proximity detection as in B.1

Figure C.4 – Example of Mode 3 case C using proximity detection as in B.1

Figure C.5 – Example of Mode 3 case B using proximity detection as in B.2 (without proximity push button switch S3)

Figure C.6 – Example of Mode 4 case C using the universal vehicle coupler

Figure D.1 – Example of an EV charging system with a typical configuration of functions, information flow and power flow

Figure D.2 – Electrical equivalent circuit for connection of LIN nodes to the control pilot circuit

Figure D.3 – Control pilot circuit state diagram for LIN-CP (key list in Table D.5)

Figure D.4 – Example of timing diagram for start-up of normal AC charging sequence

Figure D.5 – Timing diagram for normal EV-triggered stop of charging

Figure D.6 – Example of timing diagram for normal stopof charging triggered by charging station

Figure D.7 – State diagram of the LIN node in the charging station

Figure D.8 – Energy transfer between different charging stations and EVs that are equipped with accessories according to IEC 62196-2

Figure D.9 – Control pilot circuit state diagram for LIN-CP and PWM-CP (See key list in Table D.5)

Figure E.1 – Examples of standard plugs that are considered for this Annex E

Figure E.2 – Packaging configurations allowing the use of a large part of the common products for standard plugs and socket-outlets

Tables

Table 1 – Touch current limits

Table A.1 – Maximum allowable high frequency signal voltageson control pilot conductor and the protective conductor

Table A.2 – Control pilot circuit parameters and values for the EV supply equipment

Table A.3 – EV control pilot circuit values and parameters and values for the EV

Table A.4 – System states detected by the EV supply equipment

Table A.5 – State behaviour

Table A.6 – List of sequences

Table A.7 – PWM duty cycle provided by EV supply equipment

Table A.8 – Maximum current to be drawn by vehicle

Table A.9 – Test resistance values

Table A.10 – Parameters of control pilot voltages

Table A.11 – Test parameters of control pilot signals

Table A.12 – Parameters for sequence tests

Table A.13 – Position of switches

Table A.14 – Initial settings of the potentiometer at the beginning of each test

Table B.1 – Component values proximity circuit without current coding

Table B.2 – Current coding resistor for EV plug and vehicle connector

Table C.1 – Component description for Figure C.6 Mode 4 case C

Table D.1 – Control pilot functions in LIN-CP and PWM-CP

Table D.2 – Additional LIN-CP control pilot functions

Table D.3 – Generation and detection of CP voltage levels

Table D.4 – Generation and detection of LIN communication levels

Table D.5 – Key list for Figure D.3 and Figure D.9

Table D.6 – Control of LIN signals

Table D.7 – Control of the S2 switch and the vehicle load

Table D.8 – Control of the switching device

Table D.9 – Control of latching and unlatching

Table D.10 – Timing for start-up of normal charging sequence

Table D.11 – Timing for normal EV-triggered stop of charging

Table D.12 – Timing for normal stop of charging triggered by charging station

Table D.13 – States of the LIN node in the charging station and frame schedule description

Table D.14 – Transitions of the LIN node in the charging station

Table D.15 – Frames for AC charging

Table D.16 – General signals

Table D.17 – Signals for version negotiation

Table D.18 – Signals for system initialization

Table D.19 – Signals for EV status information

Table D.20 – Signals for charging station status information

Table D.21 – Codes for the frame StNotReadyList

Table D.22 – Codes for frame EvS2openList

Table D.23 – Codes for frame StErrorList

Table D.24 – Codes for frame EvErrorList

Table D.25 – Normal charge cycle test

2023年江西萍乡中考道德与法治真题及答案.doc

2023年江西萍乡中考道德与法治真题及答案.doc 2012年重庆南川中考生物真题及答案.doc

2012年重庆南川中考生物真题及答案.doc 2013年江西师范大学地理学综合及文艺理论基础考研真题.doc

2013年江西师范大学地理学综合及文艺理论基础考研真题.doc 2020年四川甘孜小升初语文真题及答案I卷.doc

2020年四川甘孜小升初语文真题及答案I卷.doc 2020年注册岩土工程师专业基础考试真题及答案.doc

2020年注册岩土工程师专业基础考试真题及答案.doc 2023-2024学年福建省厦门市九年级上学期数学月考试题及答案.doc

2023-2024学年福建省厦门市九年级上学期数学月考试题及答案.doc 2021-2022学年辽宁省沈阳市大东区九年级上学期语文期末试题及答案.doc

2021-2022学年辽宁省沈阳市大东区九年级上学期语文期末试题及答案.doc 2022-2023学年北京东城区初三第一学期物理期末试卷及答案.doc

2022-2023学年北京东城区初三第一学期物理期末试卷及答案.doc 2018上半年江西教师资格初中地理学科知识与教学能力真题及答案.doc

2018上半年江西教师资格初中地理学科知识与教学能力真题及答案.doc 2012年河北国家公务员申论考试真题及答案-省级.doc

2012年河北国家公务员申论考试真题及答案-省级.doc 2020-2021学年江苏省扬州市江都区邵樊片九年级上学期数学第一次质量检测试题及答案.doc

2020-2021学年江苏省扬州市江都区邵樊片九年级上学期数学第一次质量检测试题及答案.doc 2022下半年黑龙江教师资格证中学综合素质真题及答案.doc

2022下半年黑龙江教师资格证中学综合素质真题及答案.doc