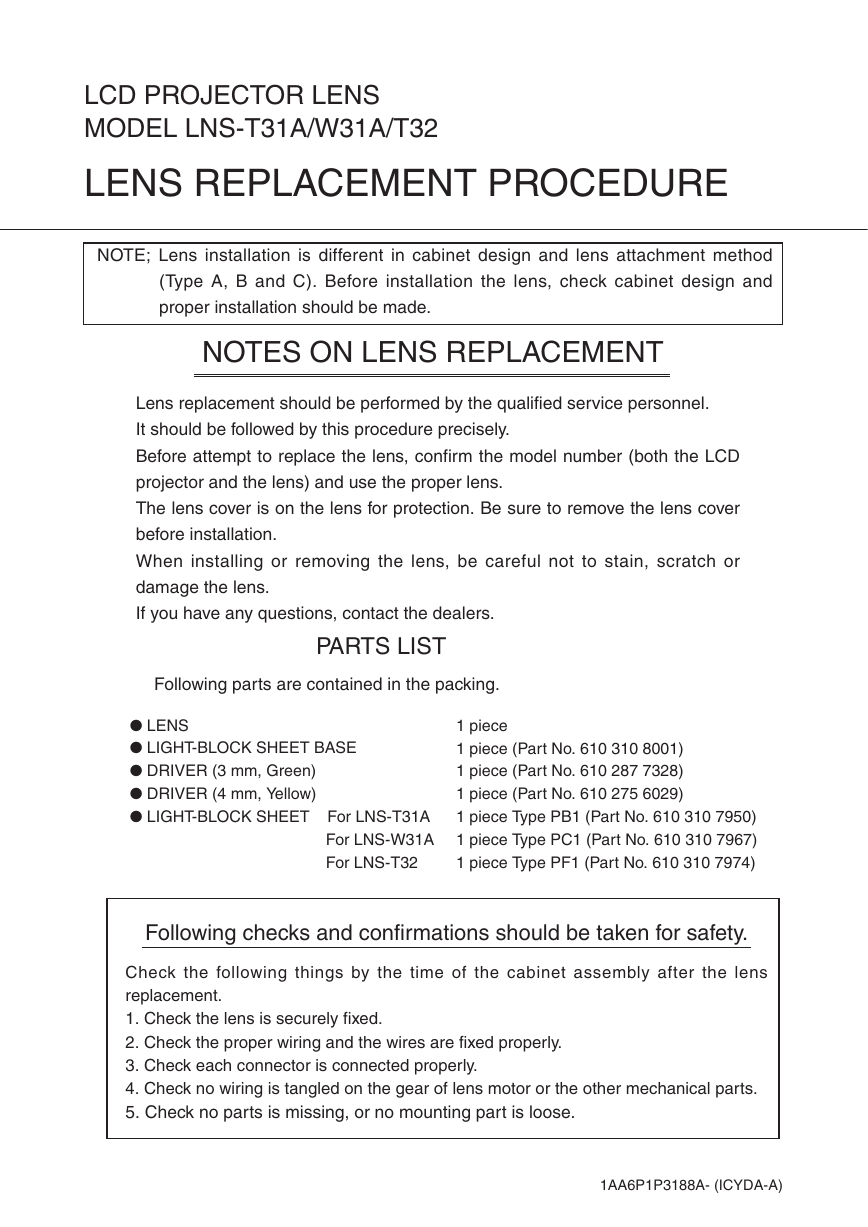

LCD PROJECTOR LENS

MODEL LNS-T31A/W31A/T32

LENS REPLACEMENT PROCEDURE

NOTE; Lens installation is different in cabinet design and lens attachment method

(Type A, B and C). Before installation the lens, check cabinet design and

proper installation should be made.

NOTES ON LENS REPLACEMENT

Lens replacement should be performed by the qualified service personnel.

It should be followed by this procedure precisely.

Before attempt to replace the lens, confirm the model number (both the LCD

projector and the lens) and use the proper lens.

The lens cover is on the lens for protection. Be sure to remove the lens cover

before installation.

When installing or removing the lens, be careful not to stain, scratch or

damage the lens.

If you have any questions, contact the dealers.

PARTS LIST

Following parts are contained in the packing.

G LENS

G LIGHT-BLOCK SHEET BASE

G DRIVER (3 mm, Green)

G DRIVER (4 mm, Yellow)

G LIGHT-BLOCK SHEET For LNS-T31A

For LNS-W31A

For LNS-T32

1 piece

1 piece (Part No. 610 310 8001)

1 piece (Part No. 610 287 7328)

1 piece (Part No. 610 275 6029)

1 piece Type PB1 (Part No. 610 310 7950)

1 piece Type PC1 (Part No. 610 310 7967)

1 piece Type PF1 (Part No. 610 310 7974)

Following checks and confirmations should be taken for safety.

Check the following things by the time of the cabinet assembly after the lens

replacement.

1. Check the lens is securely fixed.

2. Check the proper wiring and the wires are fixed properly.

3. Check each connector is connected properly.

4. Check no wiring is tangled on the gear of lens motor or the other mechanical parts.

5. Check no parts is missing, or no mounting part is loose.

1AA6P1P3188A- (ICYDA-A)

�

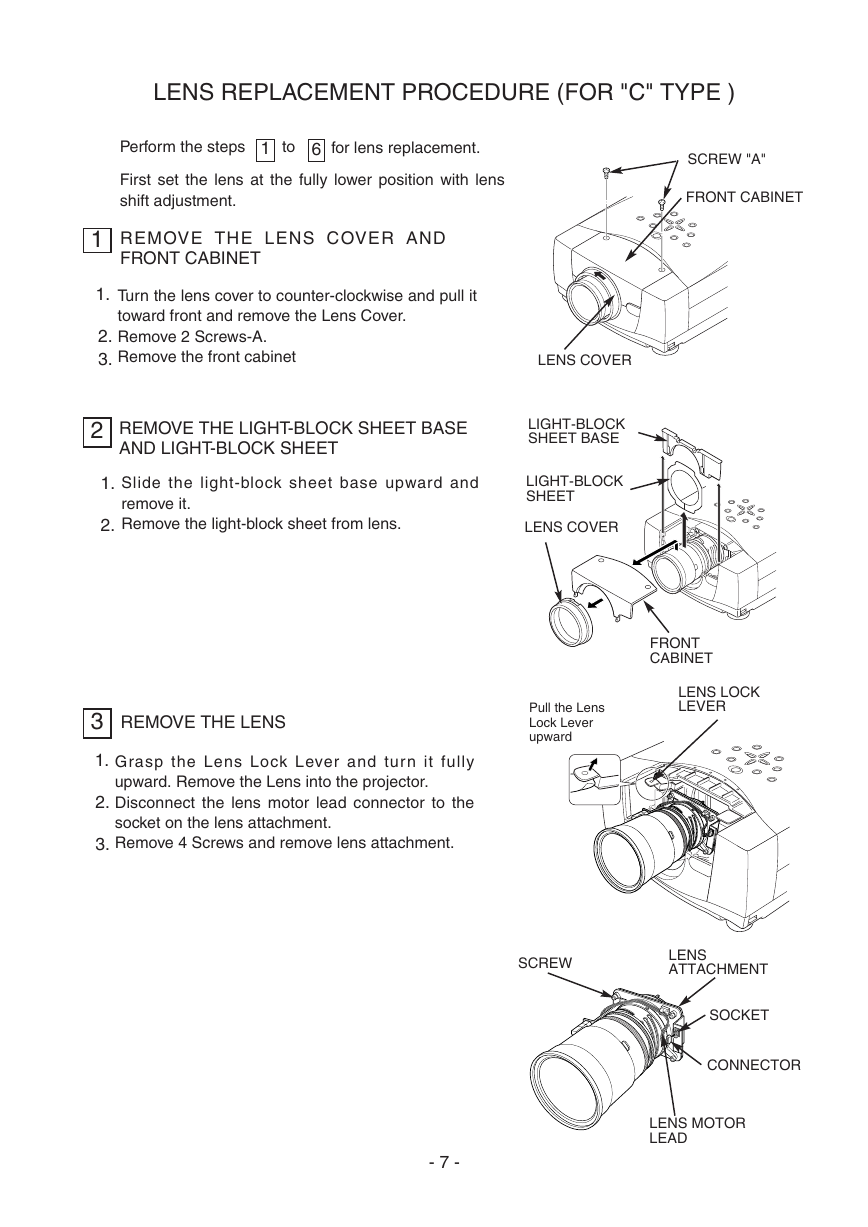

LENS REPLACEMENT PROCEDURE (FOR "A" TYPE )

Perform the steps

1

to

6

for lens replacement.

SCREW "A"

First set the lens at the center position with lens

shift adjustment.

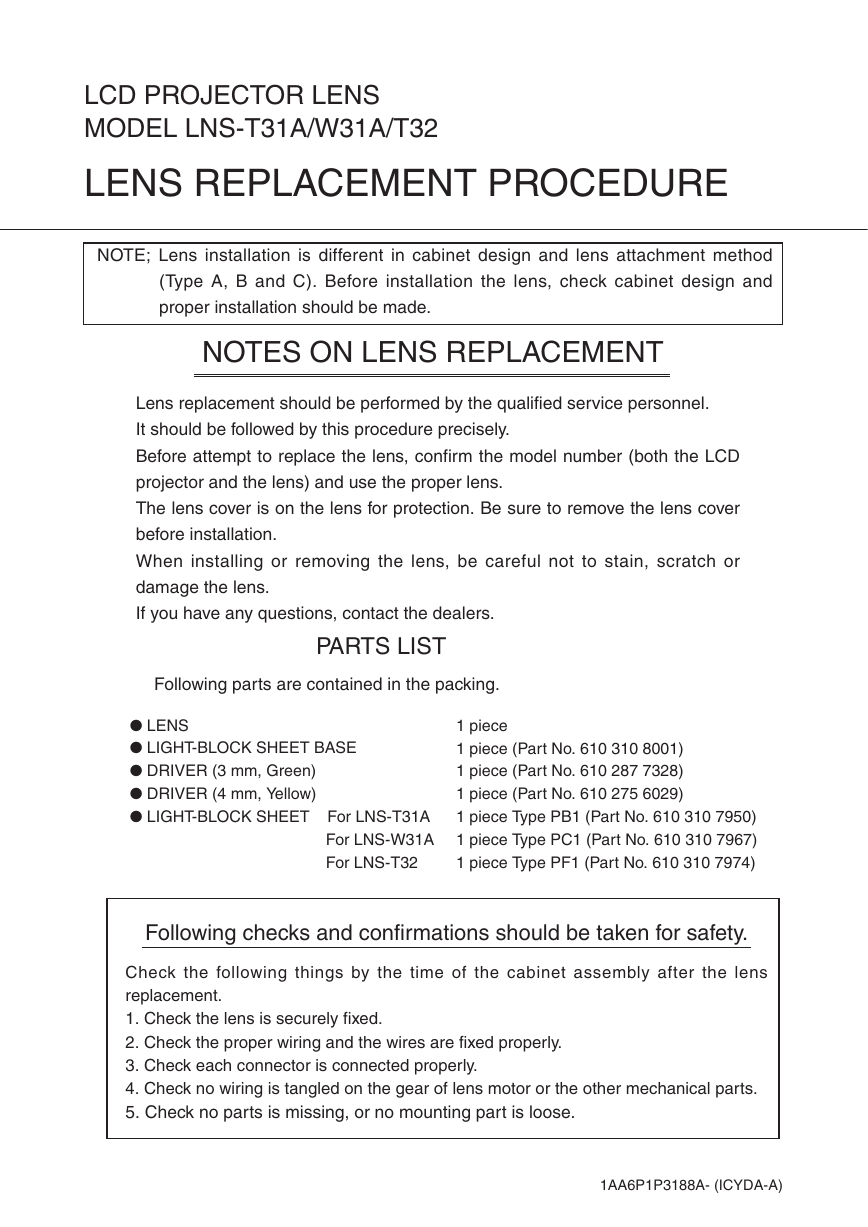

1

REMOVE THE LENS COVER AND LIGHT-

BLOCK SHEET (See Figure-1 and 2)

1.

2.

3.

Remove 2 screws-A.

Press the button (or remove 2 screws-B) on

the lower of the lens cover and remove the

lens cover.

Remove the light-block sheet from the light-

block sheet base.

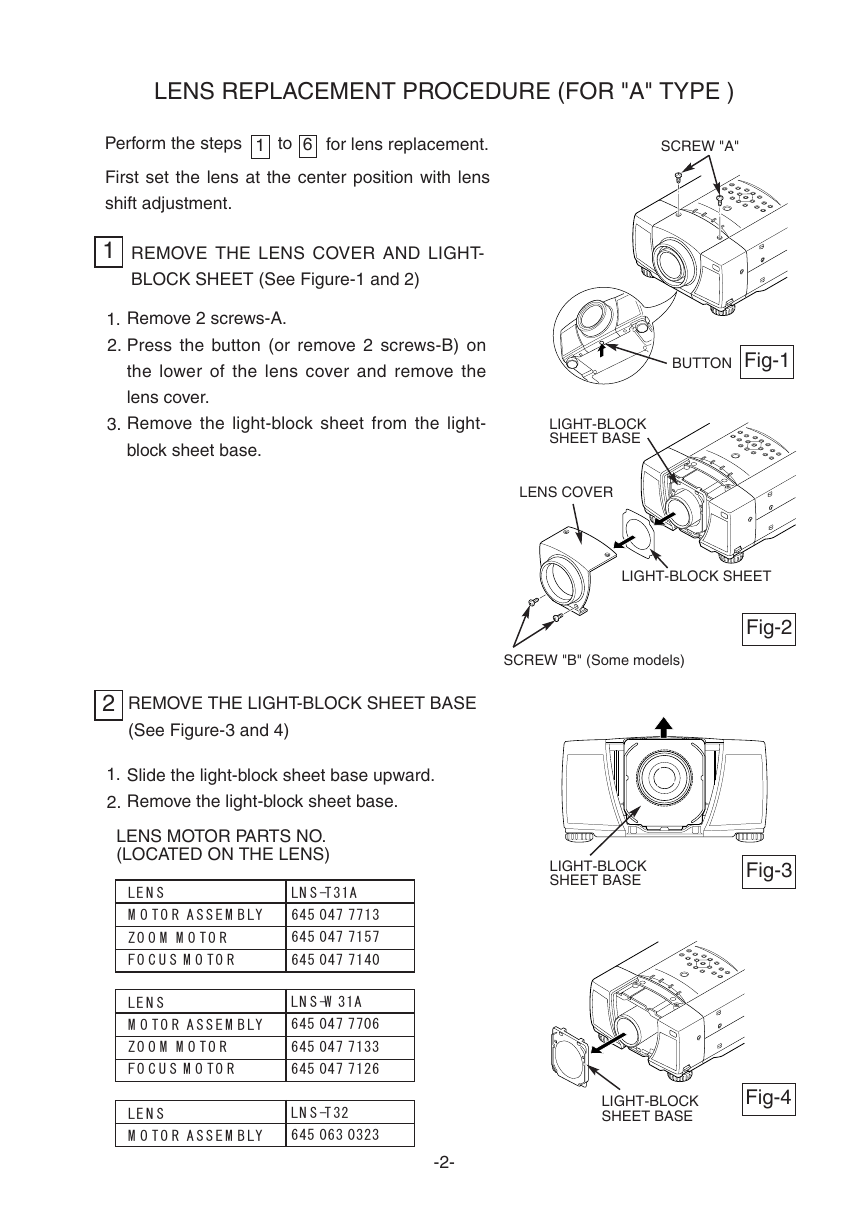

2 REMOVE THE LIGHT-BLOCK SHEET BASE

(See Figure-3 and 4)

1.

2.

Slide the light-block sheet base upward.

Remove the light-block sheet base.

LENS MOTOR PARTS NO.

(LOCATED ON THE LENS)

LENS

MOTOR ASSEMBLY

ZOOM MOTOR

FOCUS MOTOR

LENS

MOTOR ASSEMBLY

ZOOM MOTOR

FOCUS MOTOR

LNS-T31A

645 047 7713

645 047 7157

645 047 7140

LNS-W31A

645 047 7706

645 047 7133

645 047 7126

LENS

MOTOR ASSEMBLY

LNS-T32

645 063 0323

BUTTON

Fig-1

LIGHT-BLOCK

SHEET BASE

LENS COVER

LIGHT-BLOCK SHEET

Fig-2

SCREW "B" (Some models)

LIGHT-BLOCK

SHEET BASE

Fig-3

LIGHT-BLOCK

SHEET BASE

Fig-4

-2-

�

3 REMOVE THE LENS (See Figure-5 and 6)

1.

2.

Remove the connector "K16J" of the circuit board.

Remove the lens motor lead from lead holder.

Remove screws-C (4 screws) which fastens the

lens and remove the lens. Use the driver (3 mm,

Green) included with the lens to remove the

screws.

Be careful not to drop the lens when removing the

screws.

After using, save the driver for latter use.

4 MOUNT THE LENS (See Figure-5 and 6)

1.

2.

Remove protective caps (front and back) on the

lens.

Mount the lens on lens mounting bracket with 4

screws. (locate motor on left side).

Use the driver (4 mm, Yellow) included with the

lens to fasten the screws.

After using, save the driver for latter use.

3.

4.

Connect the lens motor lead to the connector

"K16J" of the circuit board.

Connect the lens motor lead to the lead holder.

LENS

MOTOR

LEAD

HOLDER

SCREW "C"

(Part No. 412 062 3705)

LENS MOTOR LEAD

CONNECTOR "K16J"

Fig-5

DRIVER

IN THE LENS

LENS MOUNTING

BRACKET

Fig-6

5 MOUNT THE LIGHT-BLOCK SHEET BASE

(See Figure-7)

LIGHT-BLOCK

SHEET BASE

1.

Mount the light-block sheet base to the projector.

6 MOUNT THE LIGHT-BLOCK SHEET AND

LENS COVER (See Figure-8)

1.

2.

3.

Mount the light-block sheet to the light-block sheet

base as shown in the Figure-8. (In the same

position as the removed sheet has been placed).

Use the sheet included with the lens.

Make sure the part no. and mark (TOP and BACK)

on Light-Block Sheet and set them properly.

Mount the lens cover with the screws.

-3-

Fig-7

LIGHT-BLOCK

SHEET

LENS COVER

Fig-8

�

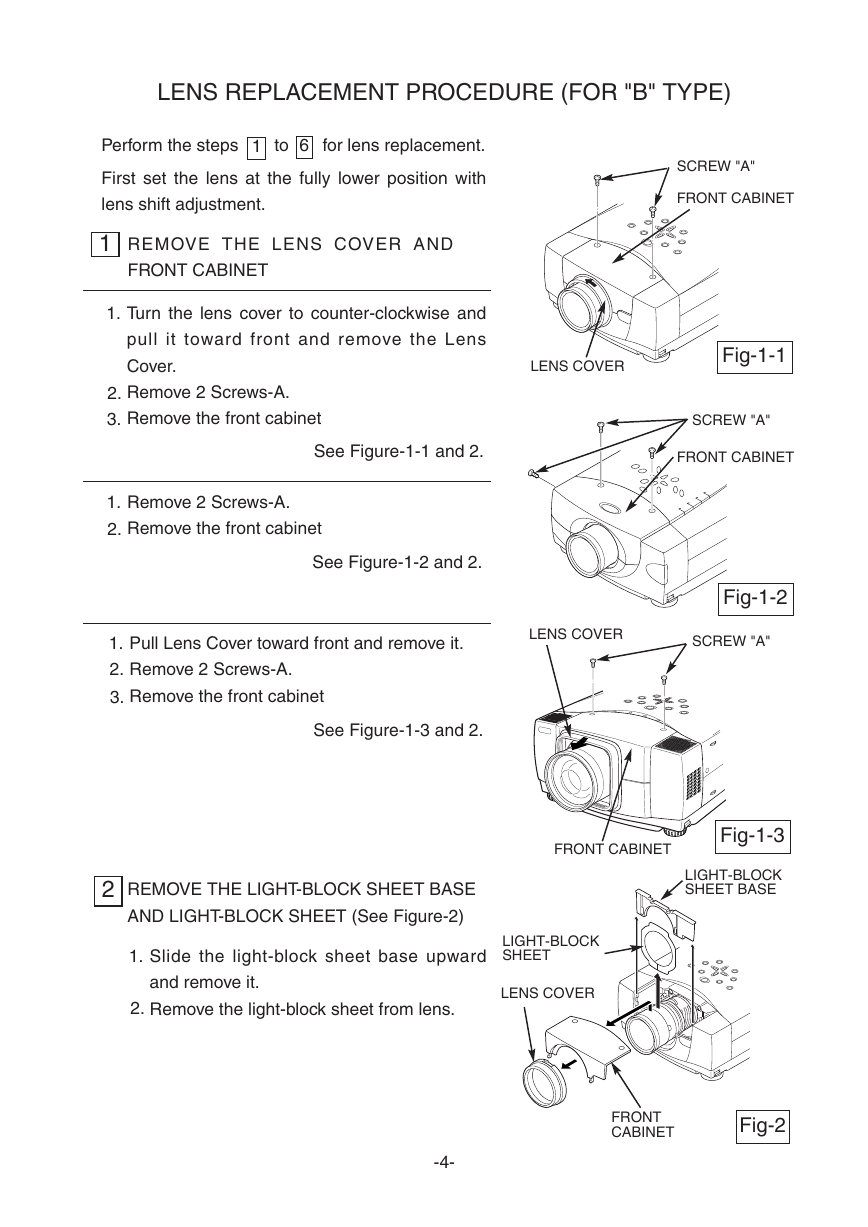

LENS REPLACEMENT PROCEDURE (FOR "B" TYPE)

Perform the steps

1

to

6

for lens replacement.

First set the lens at the fully lower position with

lens shift adjustment.

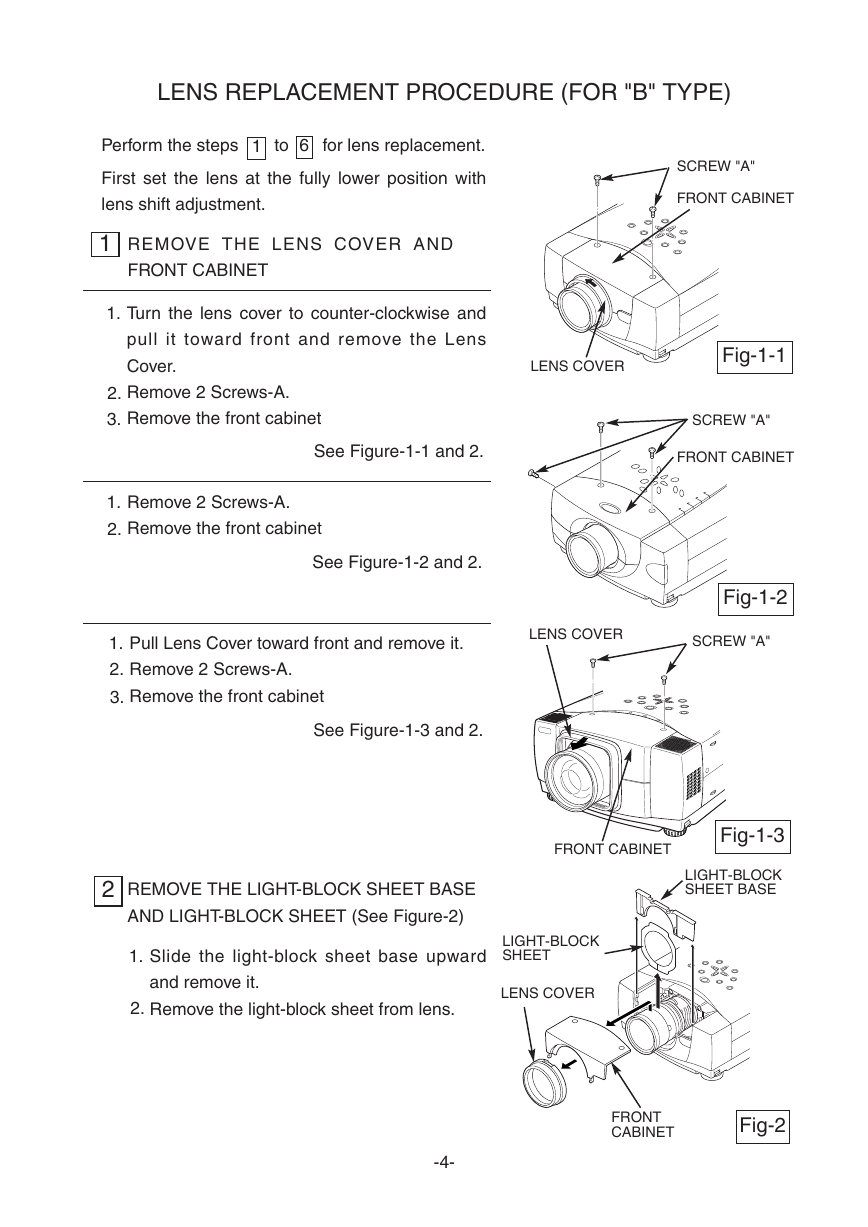

1

REMOVE THE LENS COVER AND

FRONT CABINET

1.

2.

3.

Turn the lens cover to counter-clockwise and

pull it toward front and remove the Lens

Cover.

Remove 2 Screws-A.

Remove the front cabinet

See Figure-1-1 and 2.

1.

2.

Remove 2 Screws-A.

Remove the front cabinet

See Figure-1-2 and 2.

1.

2.

3.

Pull Lens Cover toward front and remove it.

Remove 2 Screws-A.

Remove the front cabinet

See Figure-1-3 and 2.

SCREW "A"

FRONT CABINET

LENS COVER

Fig-1-1

SCREW "A"

FRONT CABINET

Fig-1-2

LENS COVER

SCREW "A"

2 REMOVE THE LIGHT-BLOCK SHEET BASE

AND LIGHT-BLOCK SHEET (See Figure-2)

FRONT CABINET

Fig-1-3

LIGHT-BLOCK

SHEET BASE

1.

2.

Slide the light-block sheet base upward

and remove it.

Remove the light-block sheet from lens.

LIGHT-BLOCK

SHEET

LENS COVER

FRONT

CABINET

Fig-2

-4-

�

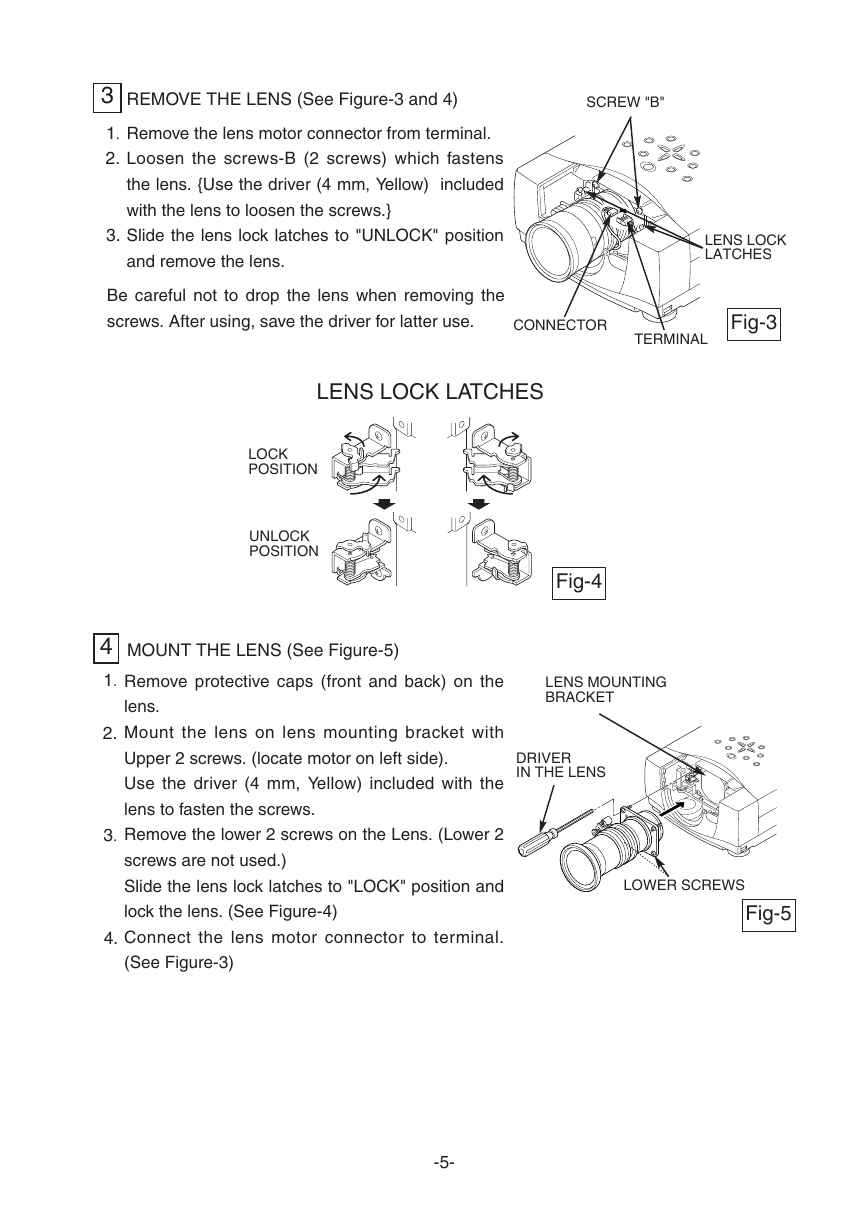

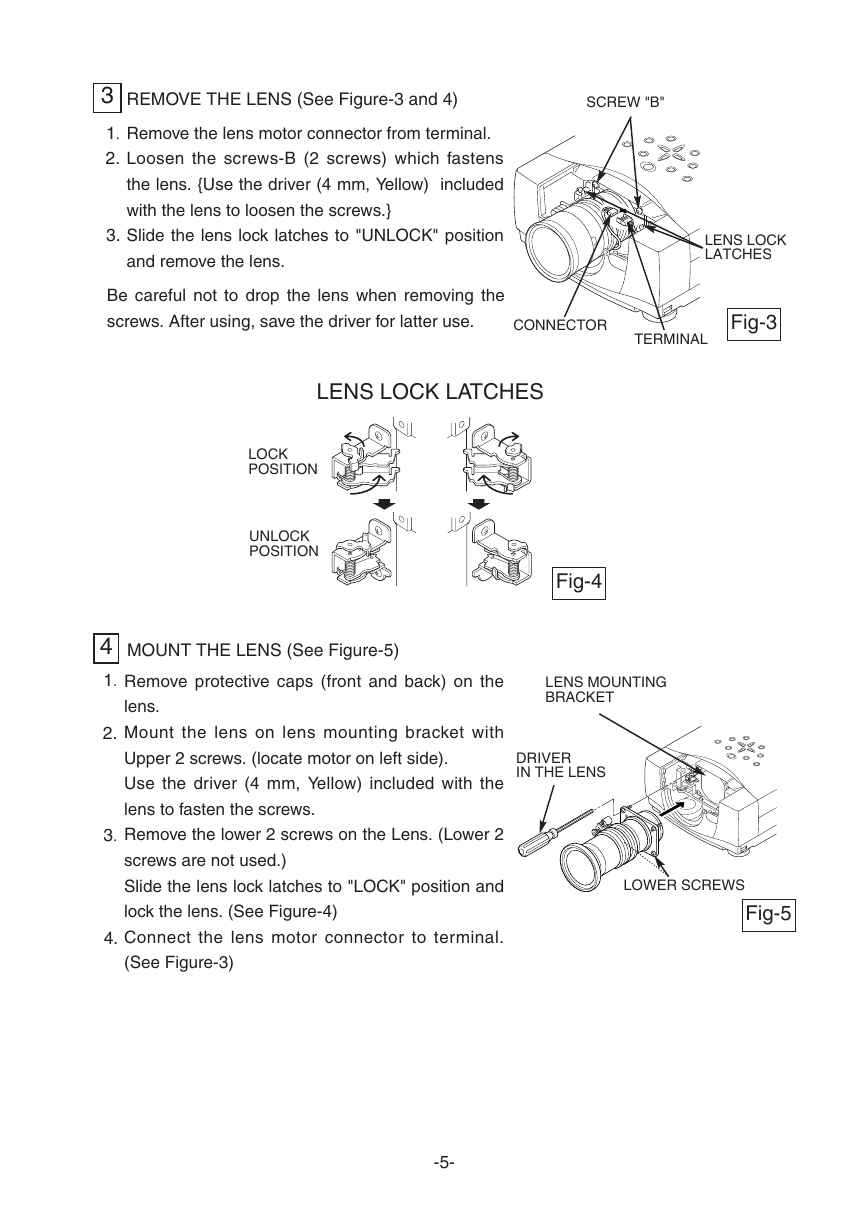

3 REMOVE THE LENS (See Figure-3 and 4)

1.

2.

Remove the lens motor connector from terminal.

Loosen the screws-B (2 screws) which fastens

the lens. {Use the driver (4 mm, Yellow) included

with the lens to loosen the screws.}

Slide the lens lock latches to "UNLOCK" position

and remove the lens.

3.

SCREW "B"

LENS LOCK

LATCHES

Be careful not to drop the lens when removing the

screws. After using, save the driver for latter use.

CONNECTOR

Fig-3

TERMINAL

LENS LOCK LATCHES

LOCK

POSITION

UNLOCK

POSITION

4 MOUNT THE LENS (See Figure-5)

1.

Remove protective caps (front and back) on the

lens.

Mount the lens on lens mounting bracket with

Upper 2 screws. (locate motor on left side).

Use the driver (4 mm, Yellow) included with the

lens to fasten the screws.

Remove the lower 2 screws on the Lens. (Lower 2

screws are not used.)

Slide the lens lock latches to "LOCK" position and

lock the lens. (See Figure-4)

Connect the lens motor connector to terminal.

(See Figure-3)

2.

3.

4.

Fig-4

LENS MOUNTING

BRACKET

DRIVER

IN THE LENS

LOWER SCREWS

Fig-5

-5-

�

5 MOUNT THE LIGHT-BLOCK SHEET AND

LIGHT-BLOCK SHEET BASE (See Figure-6)

1.

2.

3.

Mount the light-block sheet on the lens as shown

in the Figure-6. (In the same position as the

removed sheet has been placed). Use the sheet

included with the lens.

Make sure the part no. and mark (TOP and BACK)

on Light-Block Sheet and set them properly.

Mount the light-block sheet base included with the

lens.

LIGHT-BLOCK

SHEET

P

U

LIGHT-BLOCK

SHEET BASE

FRONT

CABINET

LENS COVER

Fig-6

6 MOUNT THE FRONT CABINET AND LENS

COVER (See Figure-6 and 7)

1.

2.

Mount the front cabinet with 2 screws.

Mount the lens cover.

For the cabinet Fig. 1-1, position the marked UP of

Lens Cover on top and push in to the front cabinet

and turn the Lens Cover fully clockwise until it is

properly locked.

For the cabinet Fig. 1-3, push the Lens Cover onto

the cabinet

Fig-7

-6-

�

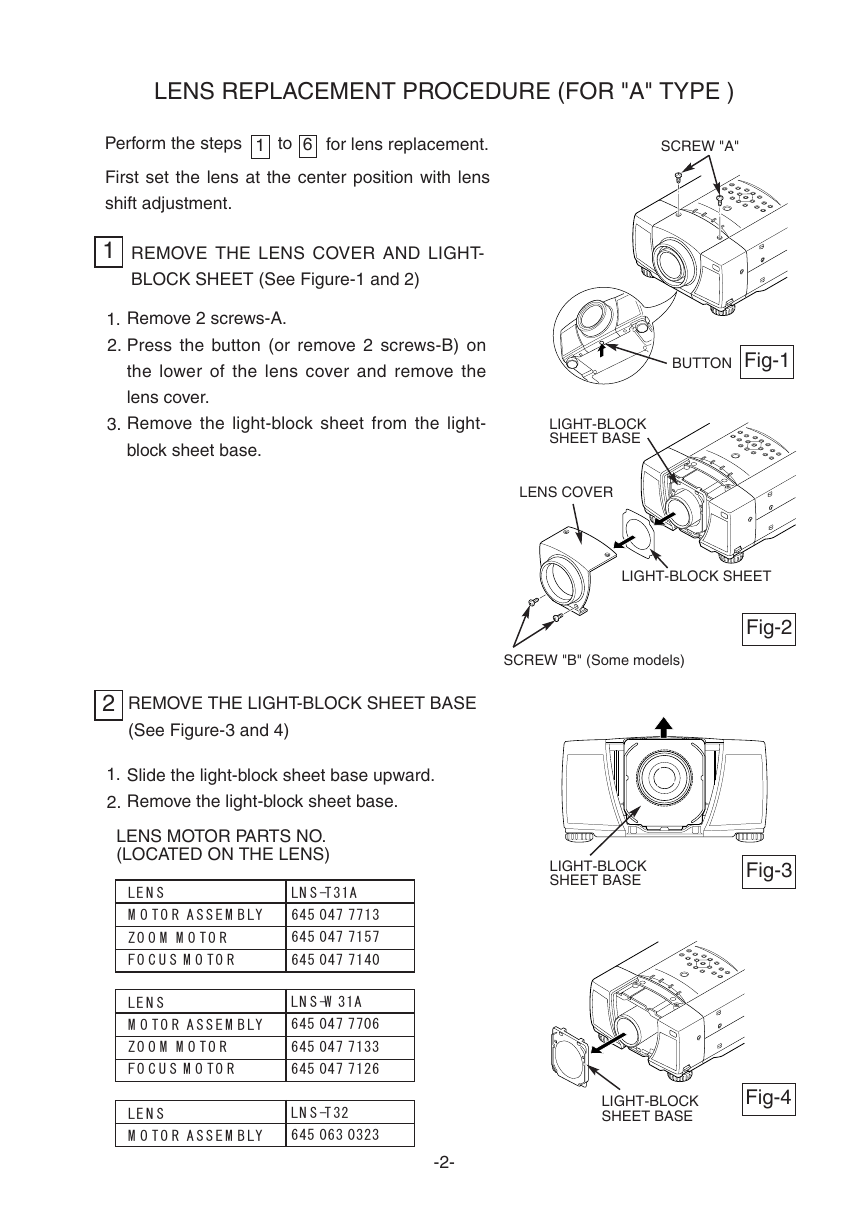

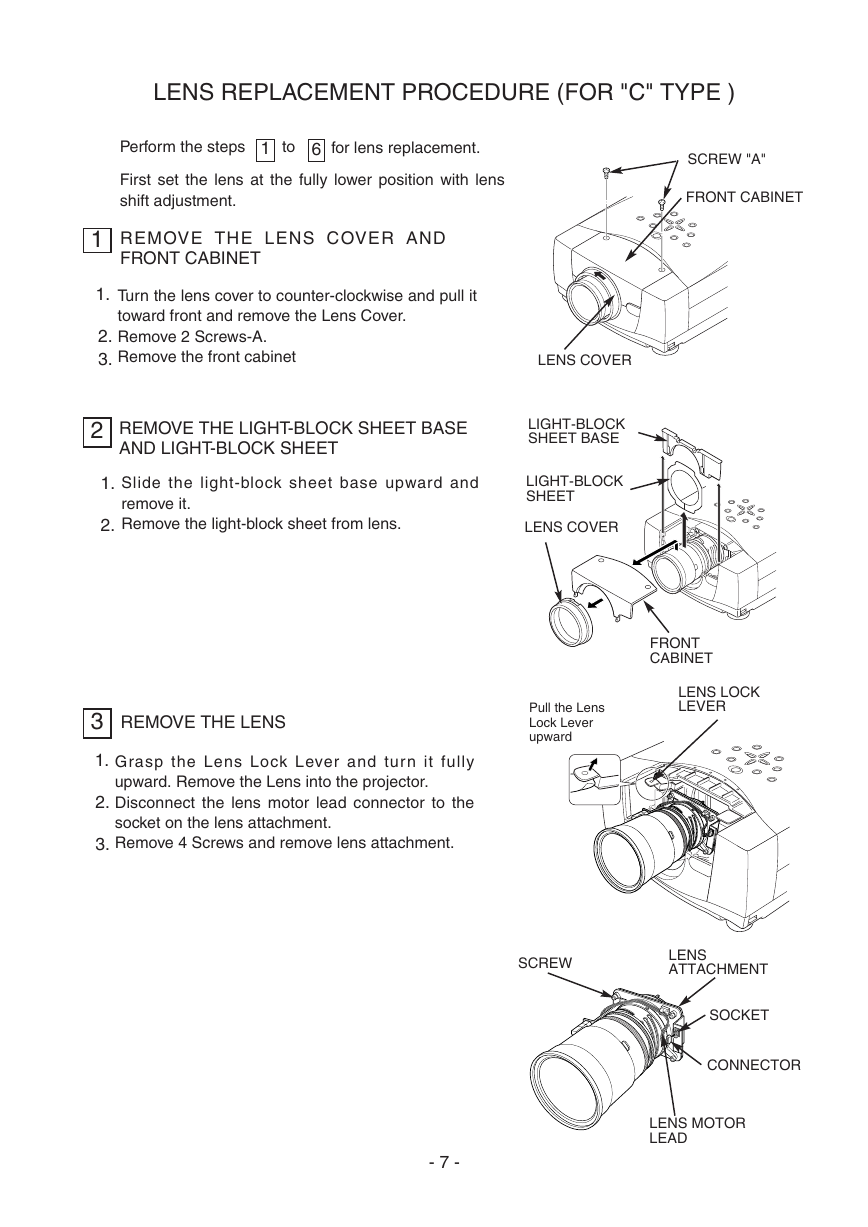

LENS REPLACEMENT PROCEDURE (FOR "C" TYPE )

SCREW "A"

FRONT CABINET

Perform the steps

1

to

6

for lens replacement.

First set the lens at the fully lower position with lens

shift adjustment.

1

1.

2.

3.

REMOVE THE LENS COVER AND

FRONT CABINET

Turn the lens cover to counter-clockwise and pull it

toward front and remove the Lens Cover.

Remove 2 Screws-A.

Remove the front cabinet

2 REMOVE THE LIGHT-BLOCK SHEET BASE

AND LIGHT-BLOCK SHEET

1.

2.

Slide the light-block sheet base upward and

remove it.

Remove the light-block sheet from lens.

LENS COVER

LIGHT-BLOCK

SHEET BASE

LIGHT-BLOCK

SHEET

LENS COVER

FRONT

CABINET

LENS LOCK

LEVER

Pull the Lens

Lock Lever

upward

3 REMOVE THE LENS

1.

2.

3.

Grasp the Lens Lock Lever and turn it fully

upward. Remove the Lens into the projector.

Disconnect the lens motor lead connector to the

socket on the lens attachment.

Remove 4 Screws and remove lens attachment.

SCREW

LENS

ATTACHMENT

SOCKET

CONNECTOR

LENS MOTOR

LEAD

- 7 -

�

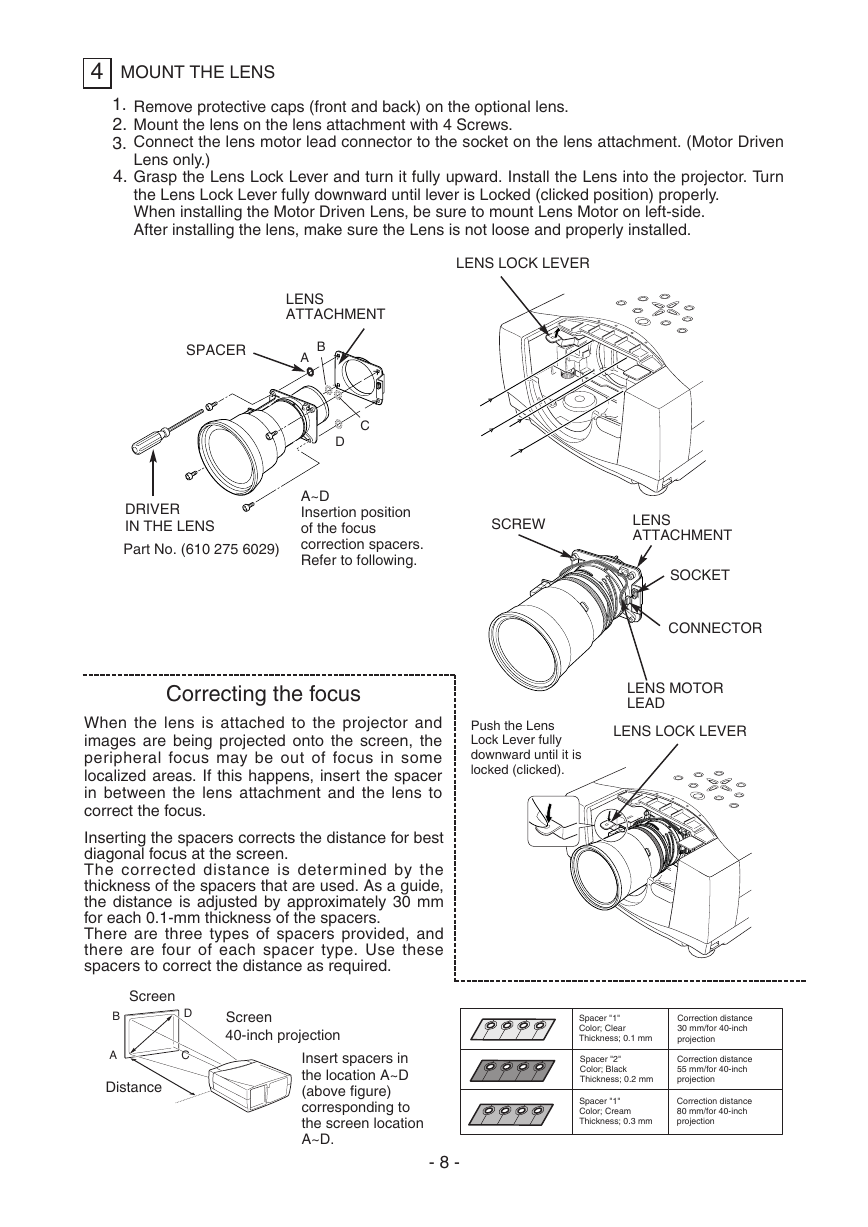

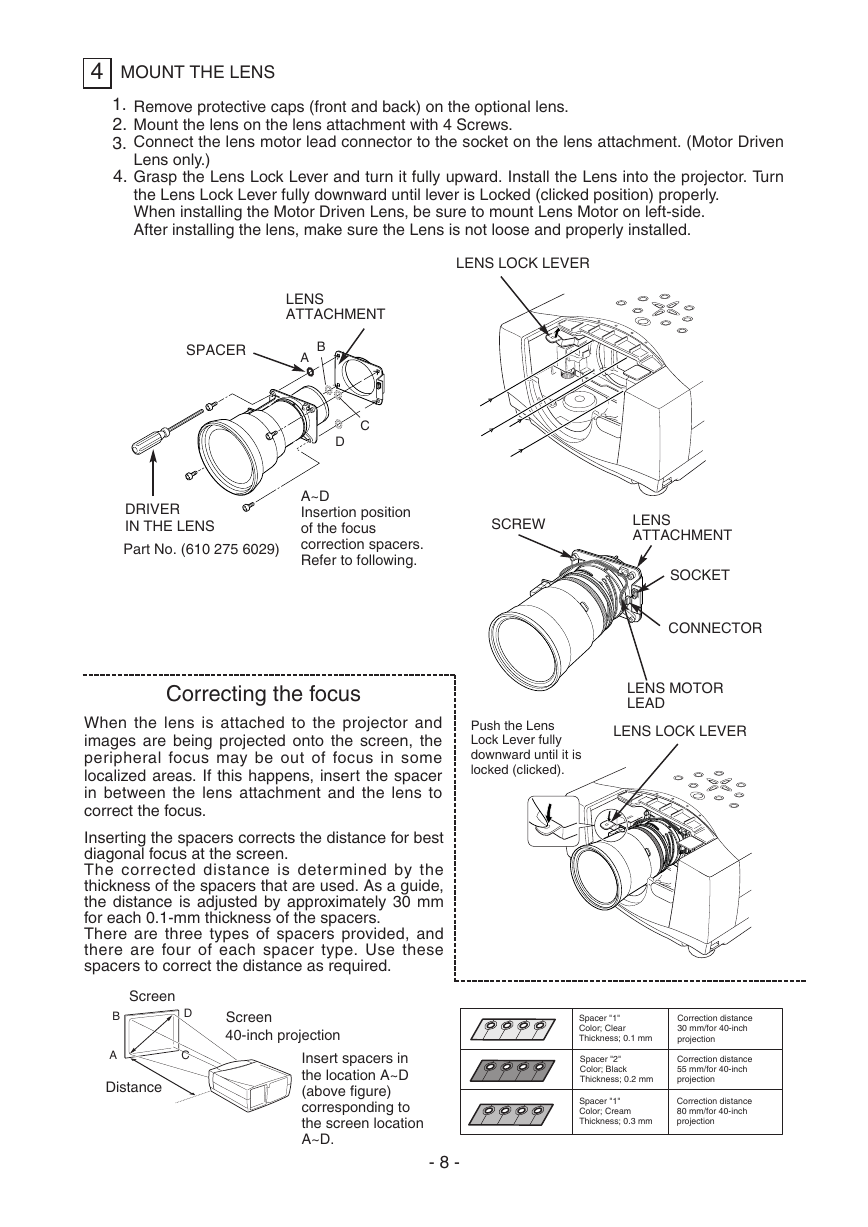

4 MOUNT THE LENS

1.

2.

3.

4.

Remove protective caps (front and back) on the optional lens.

Mount the lens on the lens attachment with 4 Screws.

Connect the lens motor lead connector to the socket on the lens attachment. (Motor Driven

Lens only.)

Grasp the Lens Lock Lever and turn it fully upward. Install the Lens into the projector. Turn

the Lens Lock Lever fully downward until lever is Locked (clicked position) properly.

When installing the Motor Driven Lens, be sure to mount Lens Motor on left-side.

After installing the lens, make sure the Lens is not loose and properly installed.

LENS LOCK LEVER

LENS

ATTACHMENT

SPACER

B

A

C

D

DRIVER

IN THE LENS

Part No. (610 275 6029)

A~D

Insertion position

of the focus

correction spacers.

Refer to following.

SCREW

Correcting the focus

When the lens is attached to the projector and

images are being projected onto the screen, the

peripheral focus may be out of focus in some

localized areas. If this happens, insert the spacer

in between the lens attachment and the lens to

correct the focus.

Inserting the spacers corrects the distance for best

diagonal focus at the screen.

The corrected distance is determined by the

thickness of the spacers that are used. As a guide,

the distance is adjusted by approximately 30 mm

for each 0.1-mm thickness of the spacers.

There are three types of spacers provided, and

there are four of each spacer type. Use these

spacers to correct the distance as required.

Screen

D

C

B

A

Distance

Screen

40-inch projection

Insert spacers in

the location A~D

(above figure)

corresponding to

the screen location

A~D.

- 8 -

LENS

ATTACHMENT

SOCKET

CONNECTOR

LENS MOTOR

LEAD

LENS LOCK LEVER

Push the Lens

Lock Lever fully

downward until it is

locked (clicked).

Spacer "1"

Color; Clear

Thickness; 0.1 mm

Correction distance

30 mm/for 40-inch

projection

Spacer "2"

Color; Black

Thickness; 0.2 mm

Correction distance

55 mm/for 40-inch

projection

Spacer "1"

Color; Cream

Thickness; 0.3 mm

Correction distance

80 mm/for 40-inch

projection

�

2023年江西萍乡中考道德与法治真题及答案.doc

2023年江西萍乡中考道德与法治真题及答案.doc 2012年重庆南川中考生物真题及答案.doc

2012年重庆南川中考生物真题及答案.doc 2013年江西师范大学地理学综合及文艺理论基础考研真题.doc

2013年江西师范大学地理学综合及文艺理论基础考研真题.doc 2020年四川甘孜小升初语文真题及答案I卷.doc

2020年四川甘孜小升初语文真题及答案I卷.doc 2020年注册岩土工程师专业基础考试真题及答案.doc

2020年注册岩土工程师专业基础考试真题及答案.doc 2023-2024学年福建省厦门市九年级上学期数学月考试题及答案.doc

2023-2024学年福建省厦门市九年级上学期数学月考试题及答案.doc 2021-2022学年辽宁省沈阳市大东区九年级上学期语文期末试题及答案.doc

2021-2022学年辽宁省沈阳市大东区九年级上学期语文期末试题及答案.doc 2022-2023学年北京东城区初三第一学期物理期末试卷及答案.doc

2022-2023学年北京东城区初三第一学期物理期末试卷及答案.doc 2018上半年江西教师资格初中地理学科知识与教学能力真题及答案.doc

2018上半年江西教师资格初中地理学科知识与教学能力真题及答案.doc 2012年河北国家公务员申论考试真题及答案-省级.doc

2012年河北国家公务员申论考试真题及答案-省级.doc 2020-2021学年江苏省扬州市江都区邵樊片九年级上学期数学第一次质量检测试题及答案.doc

2020-2021学年江苏省扬州市江都区邵樊片九年级上学期数学第一次质量检测试题及答案.doc 2022下半年黑龙江教师资格证中学综合素质真题及答案.doc

2022下半年黑龙江教师资格证中学综合素质真题及答案.doc