COMSOL

Multiphysics ™

M

E

M

S

M

o

d

u

l

e

M

n

i

i

c

o

u

r

s

e

V E R S I O N 3 . 3

�

How to contact COMSOL:

Benelux

COMSOL BV

Röntgenlaan 19

2719 DX Zoetermeer

The Netherlands

Phone: +31 (0) 79 363 4230

Fax: +31 (0) 79 361 4212

info@femlab.nl

www.femlab.nl

Denmark

COMSOL A/S

Diplomvej 376

2800 Kgs. Lyngby

Phone: +45 88 70 82 00

Fax: +45 88 70 80 90

info@comsol.dk

www.comsol.dk

Finland

COMSOL OY

Lauttasaarentie 52

FIN-00200 Helsinki

Phone: +358 9 2510 400

Fax: +358 9 2510 4010

info@comsol.fi

www.comsol.fi

France

COMSOL France

WTC, 5 pl. Robert Schuman

F-38000 Grenoble

Phone: +33 (0)4 76 46 49 01

Fax: +33 (0)4 76 46 07 42

info@comsol.fr

www.comsol.fr

Germany

FEMLAB GmbH

Berliner Str. 4

D-37073 Göttingen

Phone: +49-551-99721-0

Fax: +49-551-99721-29

info@femlab.de

www.femlab.de

Italy

COMSOL S.r.l.

Via Vittorio Emanuele II, 22

25122 Brescia

Phone: +39-030-3793800

Fax: +39-030-3793899

info.it@comsol.com

www.it.comsol.com

Norway

COMSOL AS

Søndre gate 7

NO-7485 Trondheim

Phone: +47 73 84 24 00

Fax: +47 73 84 24 01

info@comsol.no

www.comsol.no

Sweden

COMSOL AB

Tegnérgatan 23

SE-111 40 Stockholm

Phone: +46 8 412 95 00

Fax: +46 8 412 95 10

info@comsol.se

www.comsol.se

Switzerland

FEMLAB GmbH

Technoparkstrasse 1

CH-8005 Zürich

Phone: +41 (0)44 445 2140

Fax: +41 (0)44 445 2141

info@femlab.ch

www.femlab.ch

United Kingdom

COMSOL Ltd.

Studio G8 Shepherds Building

Rockley Road

London W14 0DA

Phone:+44-(0)-20 7348 9000

Fax: +44-(0)-20 7348 9020

info.uk@comsol.com

www.uk.comsol.com

United States

COMSOL, Inc.

1 New England Executive Park

Suite 350

Burlington, MA 01803

Phone: +1-781-273-3322

Fax: +1-781-273-6603

COMSOL, Inc.

1100 Glendon Avenue, 17th Floor

Los Angeles, CA 90024

Phone: +1-310-689-7250

Fax: +1-310-689-7527

COMSOL, Inc.

744 Cowper Street

Palo Alto, CA 94301

Phone: +1-650-324-9935

Fax: +1-650-324-9936

info@comsol.com

www.comsol.com

For a complete list of international

representatives, visit

www.comsol.com/contact

Company home page

www.comsol.com

COMSOL user forums

www.comsol.com/support/forums

COMSOL Multiphysics MEMS Module Minicourse

© COPYRIGHT 1994–2006 by COMSOL AB. All rights reserved

Patent pending

The software described in this document is furnished under a license agreement. The software may be used

or copied only under the terms of the license agreement. No part of this manual may be photocopied or

reproduced in any form without prior written consent from COMSOL AB.

COMSOL, COMSOL Multiphysics, and COMSOL Script are trademarks of COMSOL AB.

Other product or brand names are trademarks or registered trademarks of their respective holders.

Version:

September 2006

COMSOL 3.3

�

C O N T E N T S

Preface

Solving Electro-Thermo-Mechanical Problems

2

3

Microresistor Beam

4

Introduction . . . . . . . . . . . . . . . . . . . . . . . . 4

Model Definition . . . . . . . . . . . . . . . . . . . . . . . 4

Results and Discussion. . . . . . . . . . . . . . . . . . . . . 5

Modeling in COMSOL Multiphysics . . . . . . . . . . . . . . . . 6

Modeling Using the Graphical User Interface . . . . . . . . . . . . 7

Solving Piezoelectric Problems

22

A Piezoelectric Shear Actuated Beam

23

Introduction . . . . . . . . . . . . . . . . . . . . . . . . 23

Model Definition . . . . . . . . . . . . . . . . . . . . . . . 23

Results. . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Modeling in COMSOL Multiphysics . . . . . . . . . . . . . . . . 26

References . . . . . . . . . . . . . . . . . . . . . . . . . 27

Modeling Using the Graphical User Interface . . . . . . . . . . . . 27

Eigenfrequency Analysis . . . . . . . . . . . . . . . . . . . . 32

Frequency-Response Analysis . . . . . . . . . . . . . . . . . . 33

Appendix: Geometry Modeling . . . . . . . . . . . . . . . . . 35

Low-Voltage Electroosmotic Micropump

38

Introduction . . . . . . . . . . . . . . . . . . . . . . . . 38

Model Definition . . . . . . . . . . . . . . . . . . . . . . . 41

Results and Discussion. . . . . . . . . . . . . . . . . . . . . 42

Modeling in COMSOL Multiphysics . . . . . . . . . . . . . . . . 45

References . . . . . . . . . . . . . . . . . . . . . . . . . 46

Modeling Using the Graphical User Interface . . . . . . . . . . . . 46

Appendix—Geometry Modeling . . . . . . . . . . . . . . . . . 54

C O N T E N T S | i

�

ii | C O N T E N T S

�

M E M S M o d u l e M i n i c o u r s e

| 1

�

Preface

Mathematical modeling has become a very important part of the research and

development work in engineering and science. Retaining a competitive edge requires

a fast path between ideas and prototypes, and in this regard mathematical modeling

and simulation provide a valuable shortcut for understanding both qualitative and

quantitative aspects of scientific and engineering design.

This minicourse gives you an introduction into the modeling of microscale systems

using COMSOL Multiphysics and the MEMS Module. It takes you though several

fields of science commonly encountered when modeling MEMS: electrical and

structural problems, piezoelectricity, and microfluidics. You do not require any prior

expertise in mathematical modeling or COMSOL Multiphysics in order to find it

rewarding.

Enjoy your modeling!

The COMSOL team

2 | M E M S M O D U L E M I N I C O U R S E

�

Solving Electro-Thermo-Mechanical

Problems

Electro-mechanical actuators and sensors constitute the backbone of the whole MEMS

area. The mechanical movement they provide differentiate MEMS devices from

conventional microelectronics where the mechanics is designed to be fixed and only

electric (wanted) and heat currents (side effect) are observed.

The MEMS Module contains several example models of MEMS actuators and sensors

such as cantilever beams, comb drives, micromirrors, resonators, thermomechanical

microvalves, pressure sensors, and accelerometers. You can make a quick 3D analysis

of the electrostatic field and calculate capacitance values based on that using

Electrostatic application mode alone. Or you can model pure continuum mechanics,

like how residual stresses affect on the resonant frequencies, by using Structural

Mechanics application modes. Using Moving Mesh application mode you can

accurately combine movements and geometry changes in your own models. Lastly you

can create fully electro-thermo-structural couplings, like in the following example of a

microresistor beam. The application in this example is to move the structure by

conducting a current through conductive layers and generate a temperature increase

that leads to a displacement through thermal expansion.

M E M S M O D U L E M I N I C O U R S E | 3

�

Microresistor Beam

Introduction

This example illustrates the ability to couple thermal, electrical, and structural analysis

in one model. This particular application moves a beam by passing a current through

it; the current generates heat, and the temperature increase leads to displacement

through thermal expansion. The model estimates how much current and increase in

temperature are necessary to displace the beam.

Although the model involves rather simple 3D geometry and straightforward physics,

it provides a good example of multiphysics modeling because it contains several appli-

cation modes added incrementally to the model. Note that this model of a microresis-

tor beam also appears in the companion MEMS Module Model Library in the

Actuators Models folder under the name micro_beam3d.

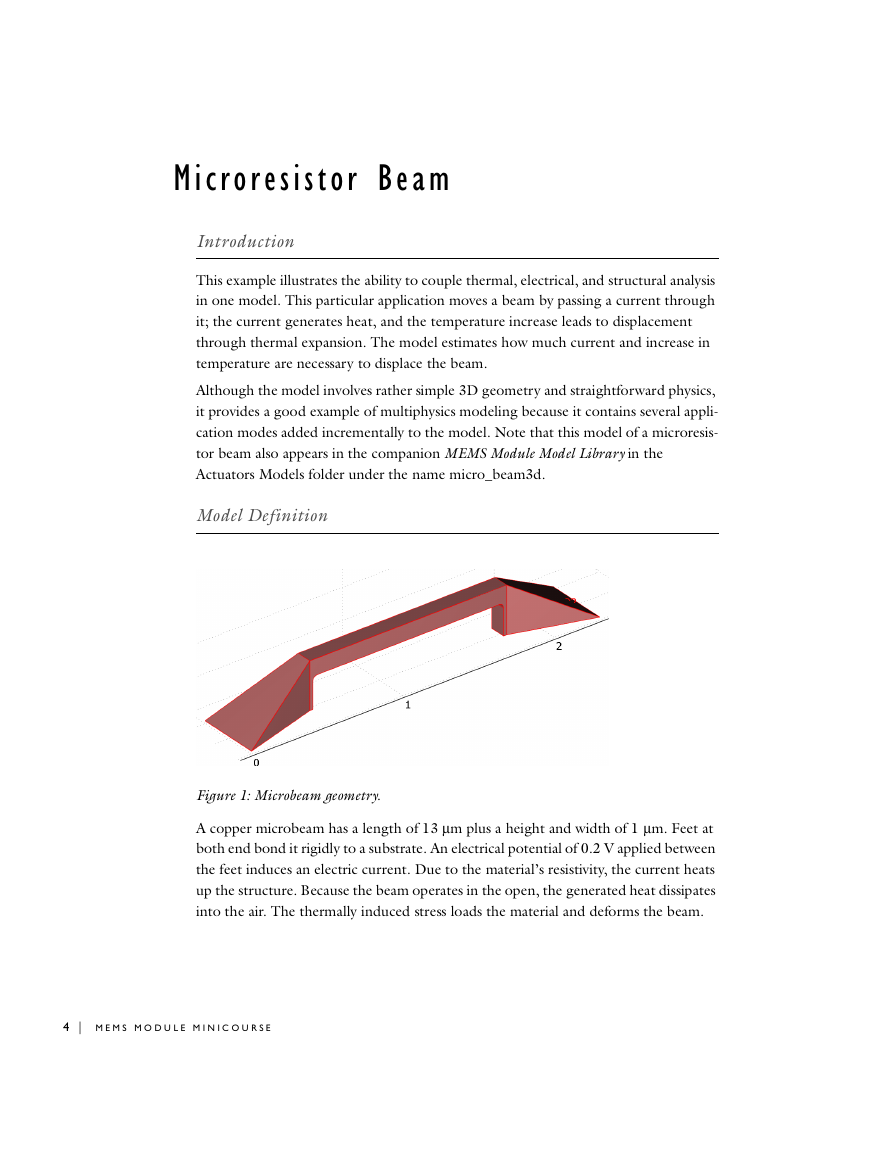

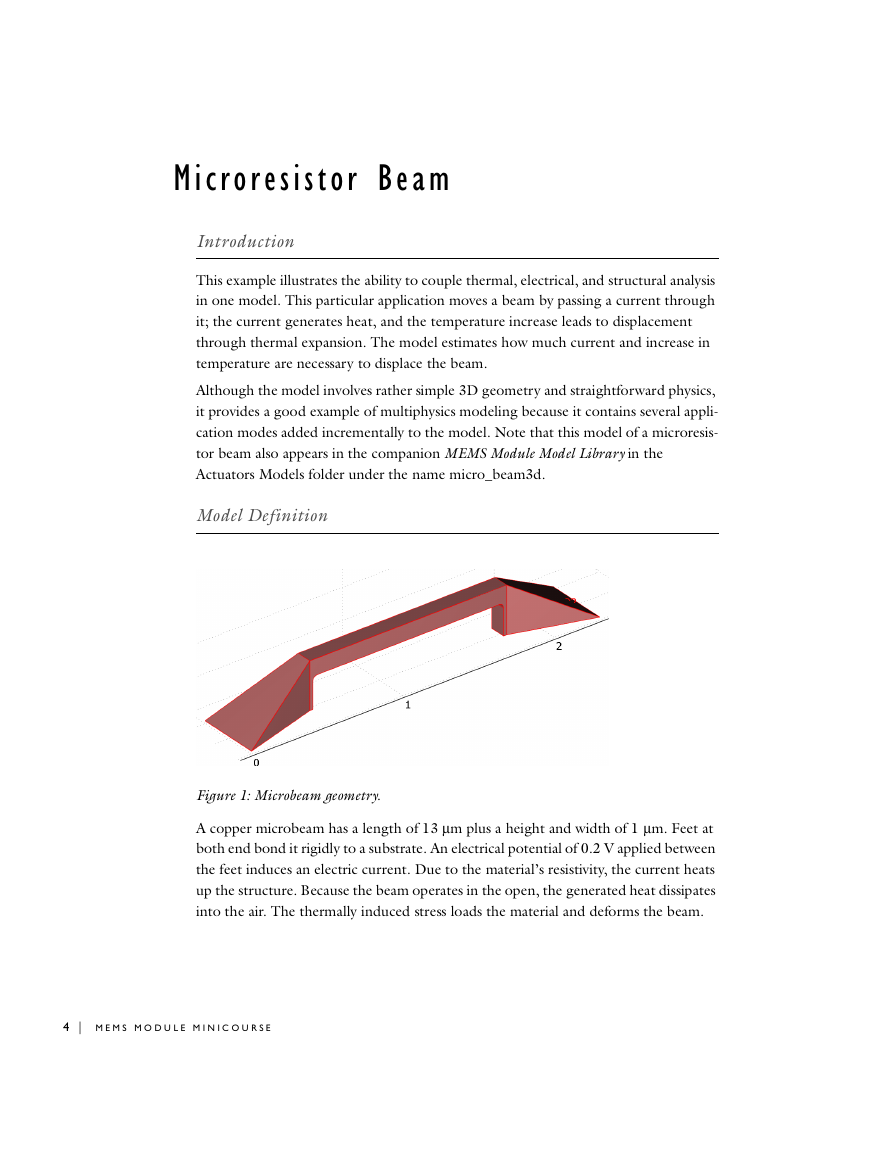

Model Definition

Figure 1: Microbeam geometry.

A copper microbeam has a length of 13 µm plus a height and width of 1 µm. Feet at

both end bond it rigidly to a substrate. An electrical potential of 0.2 V applied between

the feet induces an electric current. Due to the material’s resistivity, the current heats

up the structure. Because the beam operates in the open, the generated heat dissipates

into the air. The thermally induced stress loads the material and deforms the beam.

4 | M E M S M O D U L E M I N I C O U R S E

�

2023年江西萍乡中考道德与法治真题及答案.doc

2023年江西萍乡中考道德与法治真题及答案.doc 2012年重庆南川中考生物真题及答案.doc

2012年重庆南川中考生物真题及答案.doc 2013年江西师范大学地理学综合及文艺理论基础考研真题.doc

2013年江西师范大学地理学综合及文艺理论基础考研真题.doc 2020年四川甘孜小升初语文真题及答案I卷.doc

2020年四川甘孜小升初语文真题及答案I卷.doc 2020年注册岩土工程师专业基础考试真题及答案.doc

2020年注册岩土工程师专业基础考试真题及答案.doc 2023-2024学年福建省厦门市九年级上学期数学月考试题及答案.doc

2023-2024学年福建省厦门市九年级上学期数学月考试题及答案.doc 2021-2022学年辽宁省沈阳市大东区九年级上学期语文期末试题及答案.doc

2021-2022学年辽宁省沈阳市大东区九年级上学期语文期末试题及答案.doc 2022-2023学年北京东城区初三第一学期物理期末试卷及答案.doc

2022-2023学年北京东城区初三第一学期物理期末试卷及答案.doc 2018上半年江西教师资格初中地理学科知识与教学能力真题及答案.doc

2018上半年江西教师资格初中地理学科知识与教学能力真题及答案.doc 2012年河北国家公务员申论考试真题及答案-省级.doc

2012年河北国家公务员申论考试真题及答案-省级.doc 2020-2021学年江苏省扬州市江都区邵樊片九年级上学期数学第一次质量检测试题及答案.doc

2020-2021学年江苏省扬州市江都区邵樊片九年级上学期数学第一次质量检测试题及答案.doc 2022下半年黑龙江教师资格证中学综合素质真题及答案.doc

2022下半年黑龙江教师资格证中学综合素质真题及答案.doc